Page 1

Technical Datasheet

Technical Datasheet

IFC 100

IFC 100

IFC 100IFC 100

Technical DatasheetTechnical Datasheet

Signal converter for electromagnetic flowmeters

•

Extended accuracy option

•

Diagnostics of device and application

•

Certified for use in hazardous areas

The documentation is only complete when used in combination with the relevant

documentation for the flow sensor.

© KROHNE 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 2

CONTENTS

IFC 100

1 Product features 3

1.1 The all-round solution...................................................................................................... 3

1.2 Options and variants......................................................................................................... 5

1.3 Signal converter/flow sensor combination possibilities ................................................. 7

1.4 Measuring principle.......................................................................................................... 7

2 Technical data 8

2.1 Technical data................................................................................................................... 8

2.2 Dimensions and weight .................................................................................................. 15

2.2.1 Housing ................................................................................................................................. 15

2.2.2 Mounting plate of wall-mounted version, aluminium housing............................................ 19

2.2.3 Mounting plate of wall-mounted version, stainless steel housing...................................... 20

2.3 Flow tables ..................................................................................................................... 21

2.4 Measuring accuracy ....................................................................................................... 23

3 Installation 24

3.1 Intended use ................................................................................................................... 24

3.2 Installation specifications .............................................................................................. 24

3.3 Mounting of the compact version................................................................................... 24

3.4 Mounting the wall-mounted housing, remote version .................................................. 25

3.4.1 Wall mounting....................................................................................................................... 25

4 Electrical connections 28

4.1 Important notes on electrical connection...................................................................... 28

4.2 Preparing the signal and field current cables ............................................................... 28

4.2.1 Signal cable A (type DS 300), construction........................................................................... 28

4.2.2 Length of signal cable A........................................................................................................ 29

4.2.3 Connection diagram for signal and field current cable ....................................................... 30

4.3 Connecting the power supply......................................................................................... 31

4.4 Overview of outputs ........................................................................................................33

4.4.1 Description of the CG number .............................................................................................. 33

4.4.2 Fixed, non-alterable output versions ................................................................................... 33

4.5 Laying electrical cables correctly .................................................................................. 34

5 Notes 35

2

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 3

IFC 100

1.1 The all-round solution

The IFC 100

IFC 100 electromagnetic signal converter combines an attractive price with a wide range of

IFC 100IFC 100

features and benefits including an excellent measuring accuracy.

The signal converter is compatible with almost any flow sensor in the OPTIFLUX and

WATERFLUX range.

The signal converter supplies the current required by two field coils to generate a magnetic field.

It converts the flow proportional signal voltage into digital values and filters out electrical noise

and interference signals. From the filtered signal, the flow velocity, the volume flow and the

mass flow are calculated.

The IFC 100

IFC 100 signal converter provides a large variety of flowmeter and process diagnostic

IFC 100IFC 100

functions guaranteeing reliable measurements. Detection of deposits or coating on the

electrodes, temperature and conductivity changes in the medium, gas bubbles or solids, and an

empty pipe are good examples of process diagnostics functions.

The flow velocity and volume can be read from the display or in analogue form via the current

output (4...20 mA) as well as by frequency, pulse and status outputs. Measuring values and

diagnostic information can be transmitted via the HART

PRODUCT FEATURES

®

interface.

1

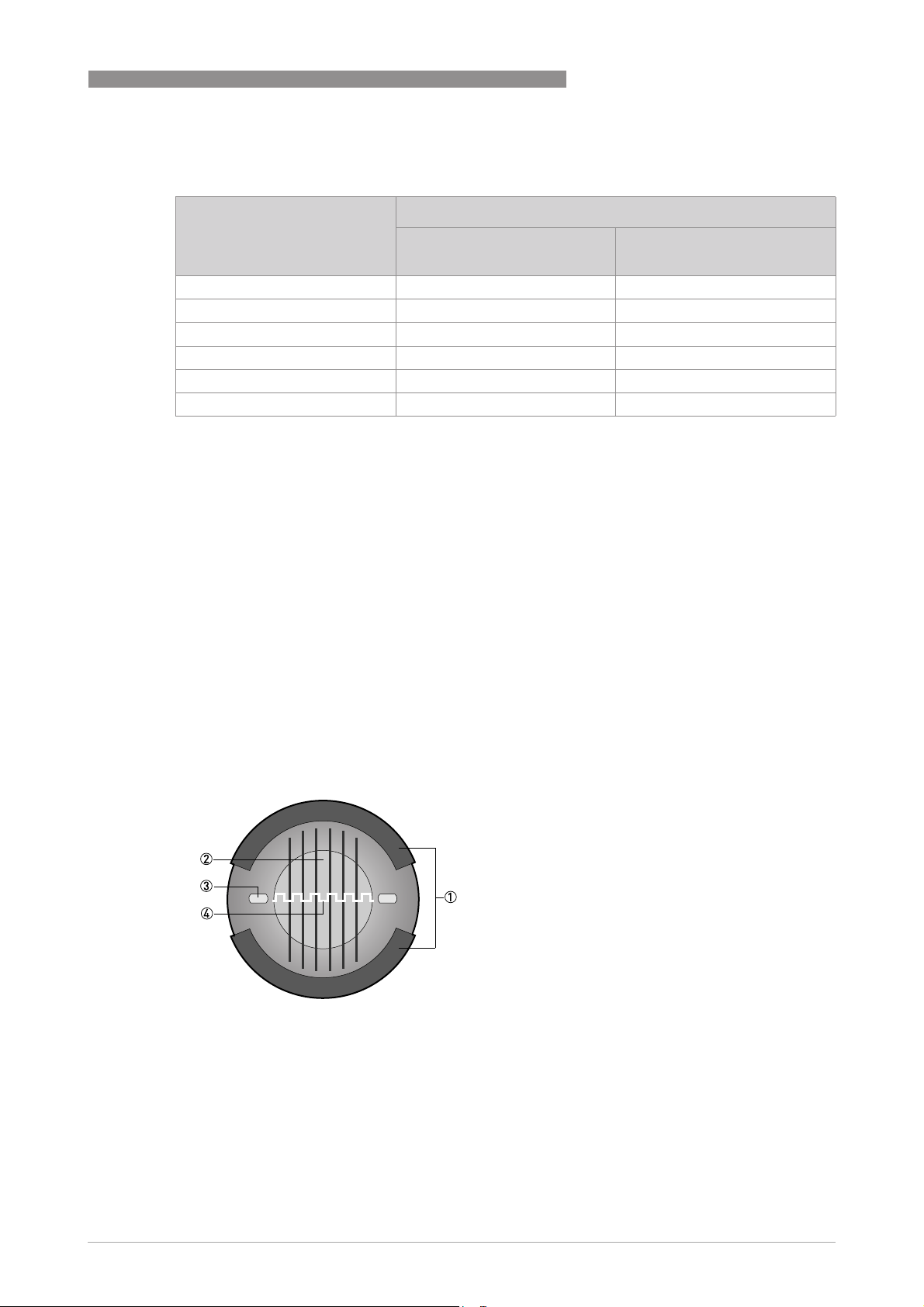

(signal converter in wall-mounted aluminium housing)

1 Large graphic display with backlit

2 Push buttons (4) for operator control without opening the housing

3 Intuitive navigation and quick menu setup

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

3

Page 4

1

PRODUCT FEATURES

Highlights

• For operation with a wide range of OPTIFLUX and WATERFLUX flow sensors

• For flow sensors over a diameter range from DN2.5 up to DN1200

• Housing in aluminium with a polyester topcoat or in stainless steel (option)

• Tropicalized electronics to protect it from humidity (option)

• Available outputs: 4...20 mA current output, pulse/frequency output and status output/limit

switch

®

• HART

• Power supply via 100…230 VAC (standard) or 24 VDC or 24 VAC/DC (optional)

• Clearly readable values due to angle of the signal converter housing which prevents dirt and

dust on the display

• Extended calibration option for higher measuring accuracy down to 0.2% of the measuring

value

• Excellent price/performance ratio

as standard

Industries

• Machinery

• Water & Wastewater

• HVAC, energy management

• Chemical

• Food and Beverages

• Metals and Mining

IFC 100

Applications

• Flow in electrically conductive mediums with a minimum conductivity of 5 µS/cm

• Water flow measurements in a wide range of industries

• Water based chemicals

• Sludge and slurries

• Sanitary applications and (HoCIP, SIP) liquid food & beverages

4

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 5

IFC 100

1.2 Options and variants

Compact or remote wall-mounted housing

(signal converter in wall-mounted

aluminium housing)

PRODUCT FEATURES

For an optimal reading of the display, the compact

variant comes in a 0° and a 45° version.

The signal converter can be rotated in 90°

increments to suit different installation positions.

The compact 0° version is designed for flowmeters

in vertical pipelines, the compact 45° version for

horizontal installations.

The wall mounted signal converter can be installed

remotely for locations where the sensor is difficult to

access, or ambient temperature conditions or

vibrations prevent a compact variant.

1

Variant for use in hazardous areas

(Compact version as 0° version)

The IFC 100 signal converter is available in a variant

suitable for hazardous areas with approvals to ATEX,

IECEx, FM, CSA and NEPSI.

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

5

Page 6

1

PRODUCT FEATURES

Stainless steel housing (option)

(signal converter in wall-mounted

stainless steel housing)

IFC 100

Whereas the standard housing material is

aluminium with a polyester topcoat, the IFC 100

optionally be ordered in a stainless steel housing.

The robust housing is suitable for many applications

in the food and beverage industry.

It is designed for environments where extreme

chemicals or aggressive cleaning are used.

The housing is dual rated to IP67/69 protection

category to resist wash down cleaning and no glass

is used for the display window.

The mounting angle for the compact housing and the

rounded edges in the wall-mount position prevent

dirt and water from building up on the surface.

IFC 100 can

IFC 100IFC 100

Diagnostics of device and application

OPTICHECK tool for on-site verification

The primary focus of a user for a flowmeter is that it

delivers reliable measurements. To achieve this all

our electromagnetic flowmeters are calibrated

before leaving the factory.

In addition, the IFC 100

functions on the flow sensor, signal converter and

process, integrated in the signal converter.

Potential problems including gas bubbles, solids,

electrode corrosion, deposits on electrodes,

conductivity changes, empty pipe can be detected by

the diagnostics features.

The OPTICHECK provides an inline health check of the

device under test by an external tool.

When the tool is connected on site, it gathers measuring

data to ensure that the flowmeter performs within 1% of its

factory calibration.

IFC 100 provides a range diagnostic

IFC 100IFC 100

(Suitcase with OPTICHECK and all cables and

accesssories)

6

The baseline can be historic repair data from the factory or

on-site test results after performing a full verification.

A hard copy of the verification report can be printed for

every flowmeter. The verification data are digitally stored.

Contact us for more information or for an on-site service

visit.

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 7

IFC 100

PRODUCT FEATURES

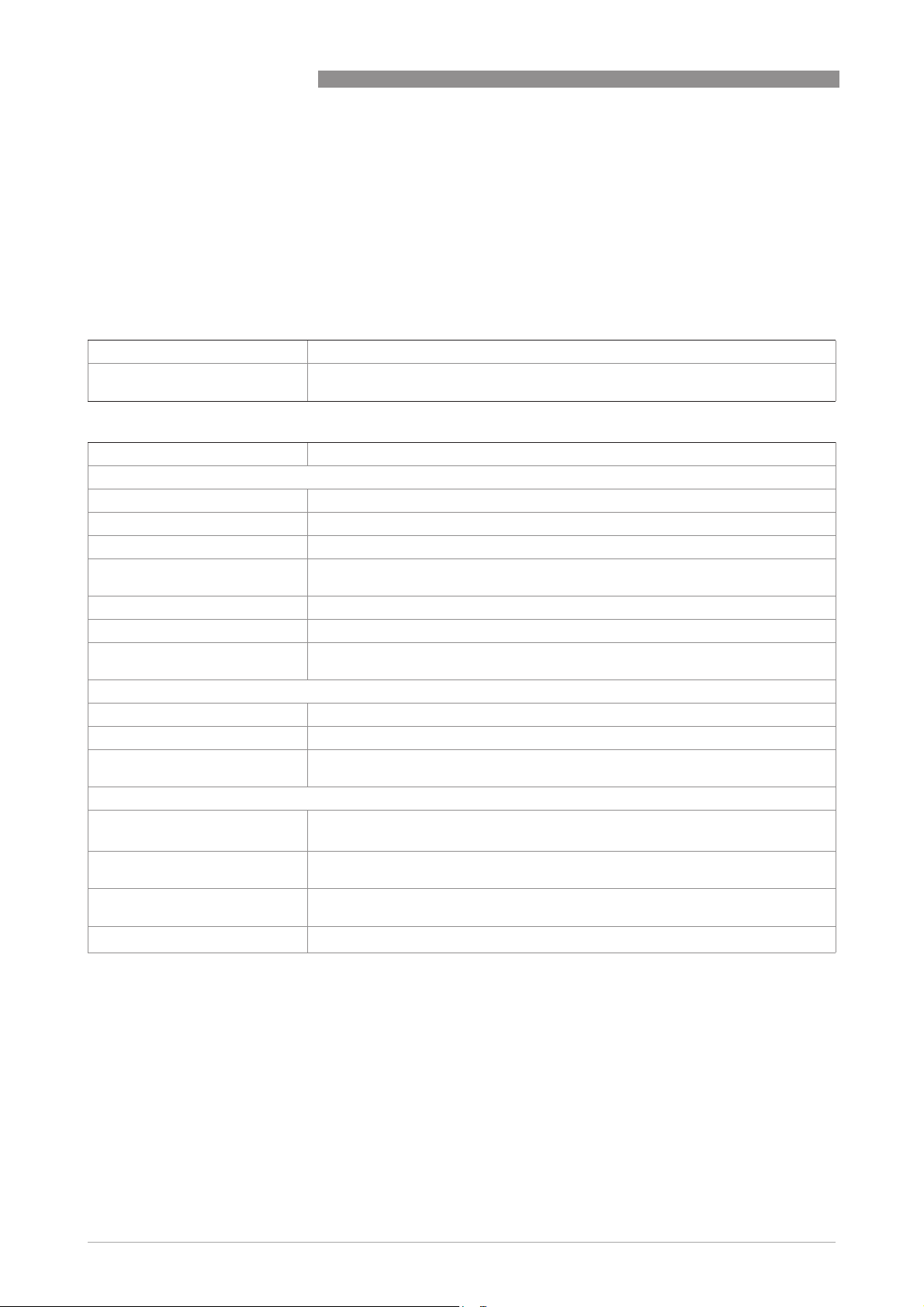

1.3 Signal converter/flow sensor combination possibilities

Flow sensor Flow sensor + signal converter IFC 100

Compact (0°/45° version) Remote wall-mounted

housing

OPTIFLUX 1000 OPTIFLUX 1100 C OPTIFLUX 1100 W

OPTIFLUX 2000 OPTIFLUX 2100 C OPTIFLUX 2100 W

OPTIFLUX 4000 OPTIFLUX 4100 C OPTIFLUX 4100 W

OPTIFLUX 5000 OPTIFLUX 5100 C OPTIFLUX 5100 W

OPTIFLUX 6000 OPTIFLUX 6100 C OPTIFLUX 6100 W

WATERFLUX 3000 WATERFLUX 3100 C WATERFLUX 3100 W

1.4 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils.

Inside of the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

1

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flowmeter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate Q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalizing, recording and output processing.

Figure 1-1: Measuring principle

1 Field coils

2 Magnetic field

3 Electrodes

4 Induced voltage (proportional to flow velocity)

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

7

Page 8

2

TECHNICAL DATA

IFC 100

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Downloadcenter).

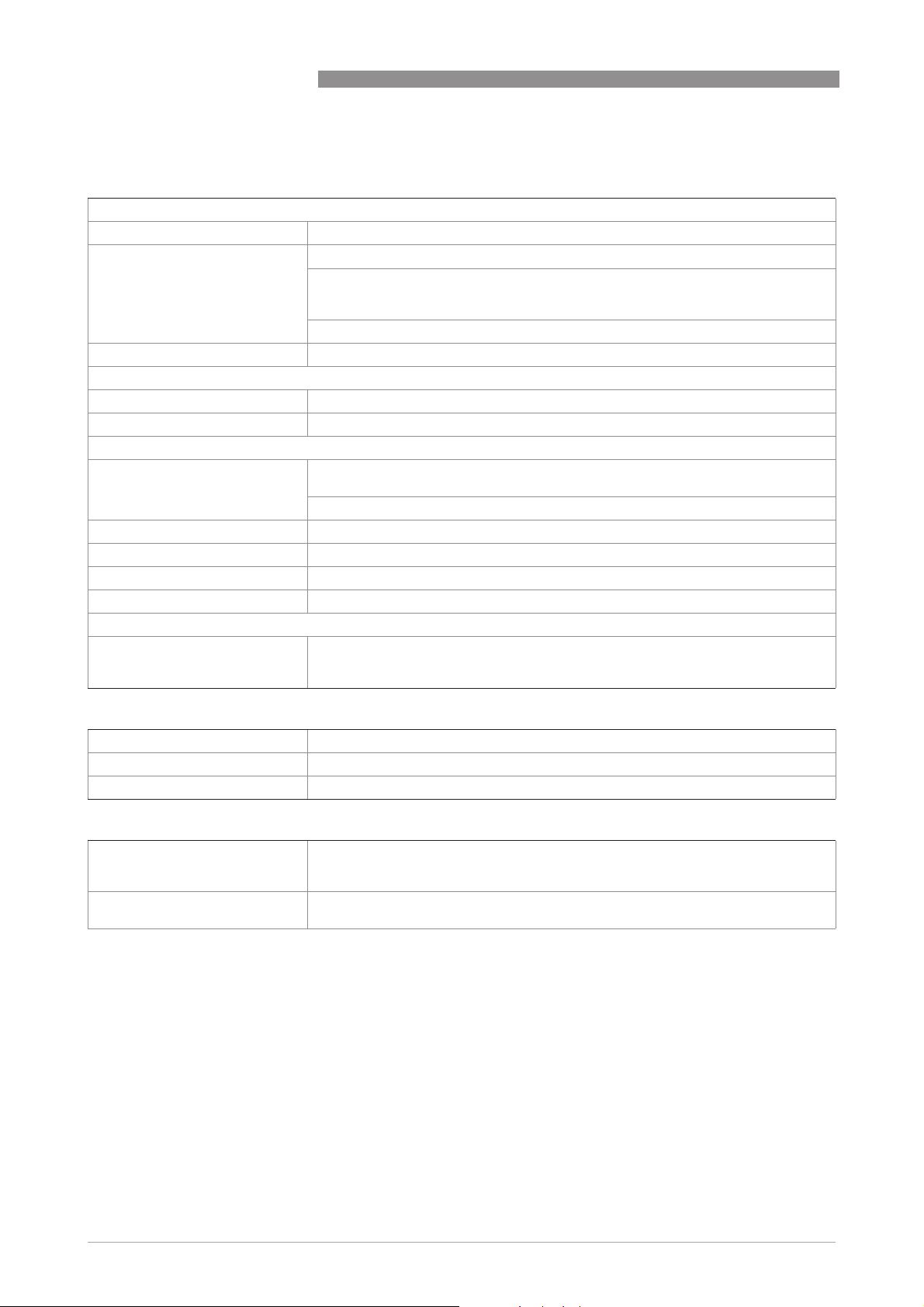

Measuring system

Measuring principle Faraday's law of induction

Application range Continuous measurement of current volume flow, flow velocity, conductivity, mass

Design

Modular construction The measuring system consists of a flow sensor and a signal converter.

Flow sensor

Flow sensor

Flow sensorFlow sensor

OPTIFLUX 1000 DN10...150 / 3/8…6"

OPTIFLUX 2000 DN25...1200 / 1…48"

OPTIFLUX 4000 DN2.5...1200 / 1/10…48"

OPTIFLUX 5000 Flange: DN15...300 / 1/2...12"

OPTIFLUX 6000 DN2.5...150 / 1/10…6"

WATERFLUX 3000 DN25...600 / 1...24"

Signal converter

Signal converter

Signal converterSignal converter

Compact version (C) IFC 100 C (0° & 45° version)

Remote version (W) IFC 100 W

Options

Options

OptionsOptions

Outputs

Counter 2 internal counters with a max. of 10 counter places (e.g. for counting volume

Verification Integrated verification, diagnostic functions: measuring device, empty pipe

Communication interface

flow (at constant density), coil temperature of the flow sensor

Sandwich: DN2.5...100 / 1/10…4"

With the exception of the OPTIFLUX 1000 and WATERFLUX 3000 all flow sensors are

also available in an Ex version.

With the exception of the OPTIFLUX 1000 and WATERFLUX 3000 all flow sensors are

also available in an Ex version.

Current output (including HART®), pulse output, frequency output, status output

and/or limit switch

and/or mass units)

detection, stabilisation

HART® as standard

8

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 9

IFC 100

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Graphic display LC display, backlit white.

Size: 128 x 64 pixels, corresponds to 59 x 31 mm = 2.32" x 1.22"

Ambient temperatures below -25°C/ -13°F may affect the readability of the display.

Operating elements 4 push buttons for operator control of the signal converter without opening the

Remote control

Display functions

Display functions

Display functionsDisplay functions

Operating menu Setting the parameters using 2 measuring pages, 1 status page, 1 graphic page

Language of display texts (as

language package)

Units Metric, British and US units selectable as required from lists for volume/mass flow

housing.

PACTwareTM (including Device Type Manager (DTM))

HART® Hand Held Communicator from Emerson Process

AMS® from Emerson Process

PDM® from Siemens

All DTMs and drivers are available free of charge from the manufacturer's website.

(measured values and graphics are freely adjustable)

Standard: English, French, German, Dutch, Portuguese, Swedish, Spanish, Italian

Eastern Europe: English, Slovenian, Czech, Hungarian

Northern Europe: English, Danish, Polish, Finnish, Norwegian

Southern Europe: English, Turkish

China: English, German, Chinese

Russia: English, German, Russian

and counting, flow velocity, electrical conductivity, temperature

TECHNICAL DATA

2

Measuring accuracy

Max. measuring accuracy Standard:

Repeatability ±0.1%

Standard:

Standard:Standard:

±0.3% of the measured value ± 1 mm/s; depending on the flow sensor

Option (optimised accuracy with extended calibration):

Option (optimised accuracy with extended calibration):

Option (optimised accuracy with extended calibration):Option (optimised accuracy with extended calibration):

±0.2% of the measured value ± 1.5 mm/s; depending on the flow sensor

For detailed information and accuracy curves refer to

23.

Special calibrations are available on request.

Current output electronics: ±10 µA; ±100 ppm/°C (typically: ±30 ppm/°C)

Measuring accuracy

on page

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

9

Page 10

2

TECHNICAL DATA

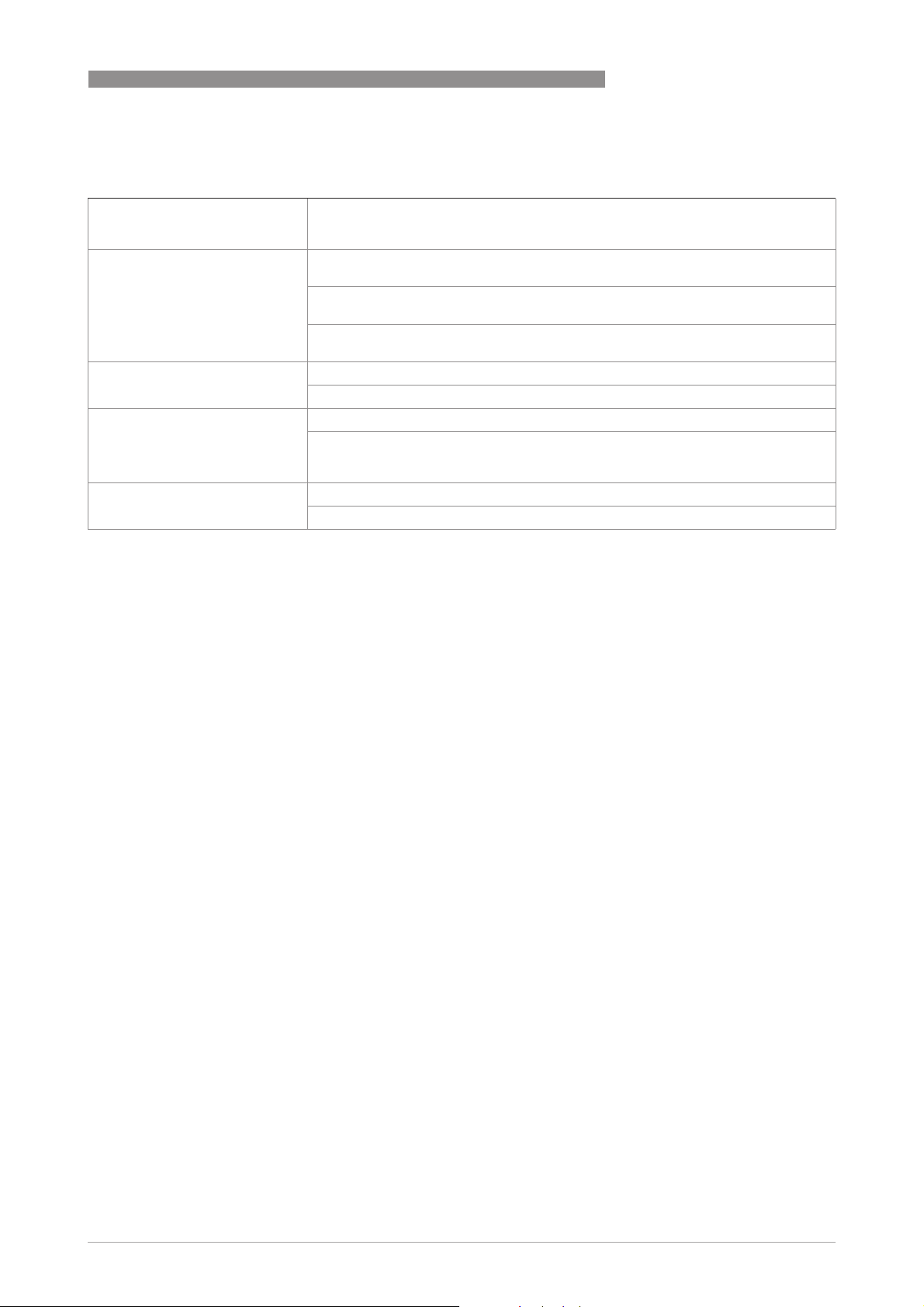

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Refer to technical data for the flow sensor.

Ambient temperature Depending on the version and combination of outputs.

It is a good idea to protect the signal converter from external heat sources such as

direct sunlight as higher temperatures reduce the life cycle of all electronic

components.

Ambient temperatures below -25°C/ -13°F may affect the readability of the display.

Storage temperature -40…+70°C/ -40…+158°F

Pressure

Pressure

PressurePressure

Medium Refer to technical data for the flow sensor.

Ambient pressure Atmospheric

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Electrical conductivity All media except for water: ≥ 5 µS/cm

State of aggregation Conductive, liquid media

Solid content (volume) ≤ 10% for OPTIFLUX flow sensors

Gas content (volume) ≤ 3% for OPTIFLUX flow sensors

Flow rate For detailed information, refer to chapter "Flow tables".

Other conditions

Other conditions

Other conditionsOther conditions

Ingress protection according to

IEC 60529

(also refer to the technical data for the flow sensor)

Water: ≥ 20 µS/cm

Standard version with aluminium housing: IP66/67 (according to NEMA 4/4X)

Optional version with stainless steel housing: IP69

IFC 100

Installation conditions

Installation For detailed information, refer to chapter "Installation".

Inlet / outlet sections Refer to technical data for the flow sensor.

Dimensions and weight For detailed information refer to chapter "Dimensions and weight".

Materials

Signal converter housing Standard: Aluminium with a polyester topcoat

Option: Stainless steel 1.4404 / AISI 316L

Flow sensor For housing materials, process connections, liners, grounding electrodes and

gaskets, refer to technical data for the flow sensor.

10

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 11

IFC 100

TECHNICAL DATA

Electrical connection

General Electrical connection is carried out in conformity with the VDE 0100 directive

Power supply 100…230 VAC (-15% / +10%), 50/60 Hz; non-Ex: standard; Ex: optional

Power consumption AC: 7 VA

Signal cable Only necessary for remote versions.

Cable entries Standard: M20 x 1.5 (8...12 mm)

"Regulations for electrical power installations with line voltages up to 1000 V" or

equivalent national specifications.

240 VAC + 5% is included in the tolerance range.

24 VDC (-55% / +30%); only available as non-Ex version

12 VDC - 10% is included in the tolerance range.

24 VAC/DC (AC: -15% / +10%; DC: -25% / +30%); non-Ex: standard; Ex: optional

12 V is not

not included in the tolerance range.

notnot

DC: 4 W

DS 300 (type A)

DS 300 (type A)

DS 300 (type A)DS 300 (type A)

Max. length: 600 m / 1968 ft (depending on electrical conductivity and flow sensor

version)

Option: 1/2 NPT, PF 1/2

2

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

11

Page 12

2

TECHNICAL DATA

Outputs

General All outputs are electrically isolated from each other and from all other circuits.

All operating data and output values can be adjusted.

Description of abbreviations U

Current output

Current output

Current outputCurrent output

Output data Volume flow, mass flow, diagnostic value, flow velocity, coil temperature,

Settings

Operating data

Operating data

Operating dataOperating data

Active U

= external voltage; RL = load + resistance;

ext

= terminal voltage; I

U

o

= nominal current

nom

conductivity

Without HART

Without HART

Without HARTWithout HART

®

Q = 0%: 0…20 mA; Q = 100%: 10…21.5 mA

Error identification: 20…22 mA

With HART

With HART

With HARTWith HART

®

Q = 0%: 4…20 mA; Q = 100%: 10…21.5 mA

Error identification: 3…22 mA

=20VDC

int, nom

IFC 100

I ≤ 22 mA

≤ 750 Ω

R

L

HART® at terminals A

Passive U

≤ 32 VDC

ext

I ≤ 22 mA

≥ 2V at I=22mA

U

0

RL≤ (U

ext-U0

)/I

max

HART® at terminals A

®

HART

HART

HARTHART

Description

HART® protocol via active and passive current output

HART® version: V5

Universal Common Practice HART® parameter: completely supported

Load

≥ 230 Ω at HART® test point;

Note maximum load for current output!

Multi-drop mode Yes, current output = 4 mA

Multi-drop address adjustable in operation menu 1…15

Device drivers Available for FC 375/475, AMS, PDM, FDT/DTM

Registration (HART

Yes

Communication Foundation)

12

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 13

IFC 100

Pulse output / frequency output

Pulse output / frequency output

Pulse output / frequency outputPulse output / frequency output

TECHNICAL DATA

Output data Pulse output: volume flow, mass flow

Frequency output: volume flow, mass flow, diagnostic value, flow velocity, coil

temperature, conductivity

Function Can be set as a pulse output or frequency output

Pulse rate/frequency 0.25...10000 Hz

Settings Pulses per volume or mass unit or max. frequency for 100% flow

Pulse width: adjustable as automatic, symmetric or fixed (0.05...2000 ms)

Operating data

Operating data

Operating dataOperating data

Passive U

≤ 32 VDC

ext

f

in operating menu set to f

max

max

≤ 100 Hz:

I ≤ 100 mA

2

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

U

= 0.2 V at I ≤ 10 mA

0, max

= 2 V at I ≤ 100 mA

U

0, max

f

in operating menu set to 100 Hz < f

max

max

≤10 kHz:

I ≤ 20 mA

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

= 1.5 V at I ≤ 1mA

U

0, max

= 2.5 V at I ≤ 10 mA

U

0, max

U

= 5.0 V at I ≤ 20 mA

0, max

Low flow cut off

Low flow cut off

Low flow cut offLow flow cut off

Function Switching point and hysteresis separately adjustable for each output, counter and

the display

Switching point Set in increments of 0.1%.

0…20% (current output, frequency output) or 0...±9.999 m/s (pulse output)

Hysteresis Set in increments of 0.1%.

0…5% (current output, frequency output) or 0…5 m/s (pulse output)

Time constant

Time constant

Time constantTime constant

Function The time constant corresponds to the elapsed time until 67% of the end value has

been reached according to a step function.

Settings Set in increments of 0.1 seconds.

0…100 seconds

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

13

Page 14

2

TECHNICAL DATA

Status output / limit switch

Status output / limit switch

Status output / limit switchStatus output / limit switch

Function and settings Adjustable as automatic measuring range conversion, display of flow direction,

Operating data

Operating data

Operating dataOperating data

Passive U

counter overflow, error, switching point or empty pipe detection

Valve control with activated dosing function

Status and/or control: ON or OFF

≤ 32 VDC

ext

I ≤ 100 mA

IFC 100

open:

I ≤ 0.05 mA at U

closed:

U

= 0.2 V at I ≤ 10 mA

0, max

= 2 V at I ≤ 100 mA

U

0, max

=32VDC

ext

Approvals and certificates

CE This device fulfils the statutory requirements of the relevant EU directives.

Non-Ex Standard

Hazardous areas

Hazardous areas

Hazardous areasHazardous areas

ATEX Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

IECEx Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

FM/CSA Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

The manufacturer certifies successful testing of the product by applying the CE

mark.

For full information of the EU directives & standards and the approved

certifications, please refer to the EU declaration or the manufacturer website.

Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

II 2 G Ex e [ia] mb IIC T4 (DN10...20; DN200...300; DN350...3000)

II 2 G Ex d e [ia] mb IIC T4 (DN25...150)

II 2 G Ex e [ia] mb q T4/T3 (DN25...150; DN200...300)

II 2 D Ex tD A21 IP64 T120°C (all nominal sizes)

Option (only W version)

Option (only W version)

Option (only W version)Option (only W version)

II 2 G Ex e [ia] mb IIC T4

II 2 D Ex tD A21 IP64 T135°C

Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

Ex e [ia] mb IIC T4 (DN10...20; DN200...300; DN350...3000)

Ex d e [ia] mb IIC T4 (DN25...150)

Ex tD A21 IP64 T120°C (all nominal sizes)

Option (only W version)

Option (only W version)

Option (only W version)Option (only W version)

Ex e [ia] mb IIC T4

Ex tD A21 IP64 T135°C

Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)Option (only OPTIFLUX 2100 C and OPTIFLUX 4100 C)

Class I, Div 2, Group A, B, C and D

Option (only W version)

Option (only W version)

Option (only W version)Option (only W version)

Class I, Div 2, Group A, B, C and D

Ordinary location

14

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 15

IFC 100

Other standards and approvals

Other standards and approvals

Other standards and approvalsOther standards and approvals

Electromagnetic compatibility

(EMC)

Shock and vibration resistance IEC 68-2-27, IEC 68-2-64

NAMUR NE 21, NE 43, NE 53

2004/108/EU in conjunction with EN 61326-1 (A1, A2)

2.2 Dimensions and weight

2.2.1 Housing

TECHNICAL DATA

2

Figure 2-1: Dimensions of the wall-mounted version, aluminium housing

a b c d e f g

Wall-mounted

version

Table 2-1: Dimensions and weight in mm and kg

241 161 95.2 257 19.3 39.7 40 1.9

a b c d e f g

Wall-mounted

version

Table 2-2: Dimensions and weight in inch and lb

9.50 6.34 3.75 10.12 0.76 1.56 1.57 4.2

Dimensions [mm] Weight [kg]

Dimensions [inch] Weight [lb]

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

15

Page 16

2

TECHNICAL DATA

IFC 100

Figure 2-2: Dimensions of wall-mounted and compact 10° version, stainless steel housing

a b c d e f g

Wall-mounted

version

Table 2-3: Dimensions and weight in mm and kg

268 187 110 276 29 53 40 Approx. 3.5

a b c d e f g

Wall-mounted

version

Table 2-4: Dimensions and weight in inch and lb

10.55 7.36 4.33 10.87 1.14 2.09 1.57 Approx. 7.2

The compact 10° version is without mounting plate.

e

g

g

g

f

Dimensions [mm] Weight [kg]

Dimensions [inch] Weight [lb]

16

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 17

IFC 100

Figure 2-3: Dimensions of compact 0° version, aluminium housing

1 4 x M 6

Dimensions [mm] Weight [kg]

a b c d e f g h

TECHNICAL DATA

2

0° version 161 40 155 81.5 257 - - Ø72 Std: 1.9

Ex: 2.4

Table 2-5: Dimensions and weight in mm and kg

Dimensions [inch] Weight [lb]

a b c d e f g h

0° version 6.34 1.57 6.1 3.21 10.12 - - Ø2.83 Std: 4.2

Ex: 5.3

Table 2-6: Dimensions and weight in inch and lb

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

17

Page 18

2

TECHNICAL DATA

Figure 2-4: Dimensions of compact 45° version, aluminium housing

1 4 x M 6

a b c d e f g h

IFC 100

Dimensions [mm] Weight [kg]

45° version 161 40 155 184 27.4 45° 186 Ø72 Std: 2.1

Ex: 2.6

Table 2-7: Dimensions and weight in mm and kg

Dimensions [inch] Weight [lb]

a b c d e f g h

45° version 6.34 1.57 6.10 7.24 1.08 45° 7.32 Ø2.83 Std: 4.6

Ex: 5.7

Table 2-8: Dimensions and weight in inch and lb

18

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 19

IFC 100

TECHNICAL DATA

2.2.2 Mounting plate of wall-mounted version, aluminium housing

2

Figure 2-5: Dimensions of mounting plate of wall-mounted version, aluminium housing

[mm] [inch]

a Ø6.5 Ø0.26

b 87.2 3.4

c 241 9.5

Table 2-9: Dimensions in mm and inch

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

19

Page 20

2

TECHNICAL DATA

2.2.3 Mounting plate of wall-mounted version, stainless steel housing

IFC 100

Figure 2-6: Dimensions of mounting plate of wall-mounted version, stainless steel housing

[mm] [inch]

a Ø6.5 Ø0.26

b 40 1.6

c 267.9 10.55

Table 2-10: Dimensions in mm and inch

20

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 21

IFC 100

2.3 Flow tables

Flow rate in m/s and m3/h

v [m/s] 0.3 1 3 12

DN [mm] Minimum flow Nominal flow Maximum flow

TECHNICAL DATA

Q

in m3/h

100 %

2.5 0.005 0.02 0.05 0.21

4 0.01 0.05 0.14 0.54

6 0.03 0.10 0.31 1.22

10 0.08 0.28 0.85 3.39

15 0.19 0.64 1.91 7.63

20 0.34 1.13 3.39 13.57

25 0.53 1.77 5.30 21.21

32 0.87 2.90 8.69 34.74

40 1.36 4.52 13.57 54.29

50 2.12 7.07 21.21 84.82

65 3.58 11.95 35.84 143.35

80 5.43 18.10 54.29 217.15

100 8.48 28.27 84.82 339.29

125 13.25 44.18 132.54 530.15

150 19.09 63.62 190.85 763.40

200 33.93 113.10 339.30 1357.20

250 53.01 176.71 530.13 2120.52

300 76.34 254.47 763.41 3053.64

350 103.91 346.36 1039.08 4156.32

400 135.72 452.39 1357.17 5428.68

450 171.77 572.51 1717.65 6870.60

500 212.06 706.86 2120.58 8482.32

600 305.37 1017.90 3053.70 12214.80

700 415.62 1385.40 4156.20 16624.80

800 542.88 1809.60 5428.80 21715.20

900 687.06 2290.20 6870.60 27482.40

1000 848.22 2827.40 8482.20 33928.80

1200 1221.45 3421.20 12214.50 48858.00

2

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

21

Page 22

2

TECHNICAL DATA

Flow rate in ft/s and US gallons/min

v [ft/s] 1 3.3 10 40

DN [inch] Minimum flow Nominal flow Maximum flow

1/10 0.02 0.09 0.23 0.93

1/6 0.06 0.22 0.60 2.39

1/4 0.13 0.44 1.34 5.38

3/8 0.37 1.23 3.73 14.94

1/2 0.84 2.82 8.40 33.61

3/4 1.49 4.98 14.94 59.76

1 2.33 7.79 23.34 93.36

1.25 3.82 12.77 38.24 152.97

1.5 5.98 19.90 59.75 239.02

2 9.34 31.13 93.37 373.47

2.5 15.78 52.61 159.79 631.16

3 23.90 79.69 239.02 956.09

4 37.35 124.47 373.46 1493.84

5 58.35 194.48 583.24 2334.17

6 84.03 279.97 840.29 3361.17

8 149.39 497.92 1493.29 5975.57

10 233.41 777.96 2334.09 9336.37

12 336.12 1120.29 3361.19 13444.77

14 457.59 1525.15 4574.93 18299.73

16 597.54 1991.60 5975.44 23901.76

18 756.26 2520.61 7562.58 30250.34

20 933.86 3112.56 9336.63 37346.53

24 1344.50 4481.22 13445.04 53780.15

28 1829.92 6099.12 18299.20 73196.79

32 2390.23 7966.64 23902.29 95609.15

36 3025.03 10082.42 30250.34 121001.37

40 3734.50 12447.09 37346.00 149384.01

48 5377.88 17924.47 53778.83 215115.30

Q

in US gallons/min

100 %

IFC 100

22

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 23

IFC 100

2.4 Measuring accuracy

Every electromagnetic flowmeter is calibrated by direct volume comparison. The wet calibration

validates the performance of the flowmeter under reference conditions against accuracy limits.

The accuracy limits of electromagnetic flowmeters are typically the result of the combined effect

of linearity, zero point stability and calibration uncertainty.

Reference conditions

• Medium: water

• Temperature: +5...+35°C / +41...+95°F

• Operating pressure: 0.1...5 barg / 1.5...72.5 psig

• Inlet section: ≥ 5 DN; outlet section: ≥ 2DN

TECHNICAL DATA

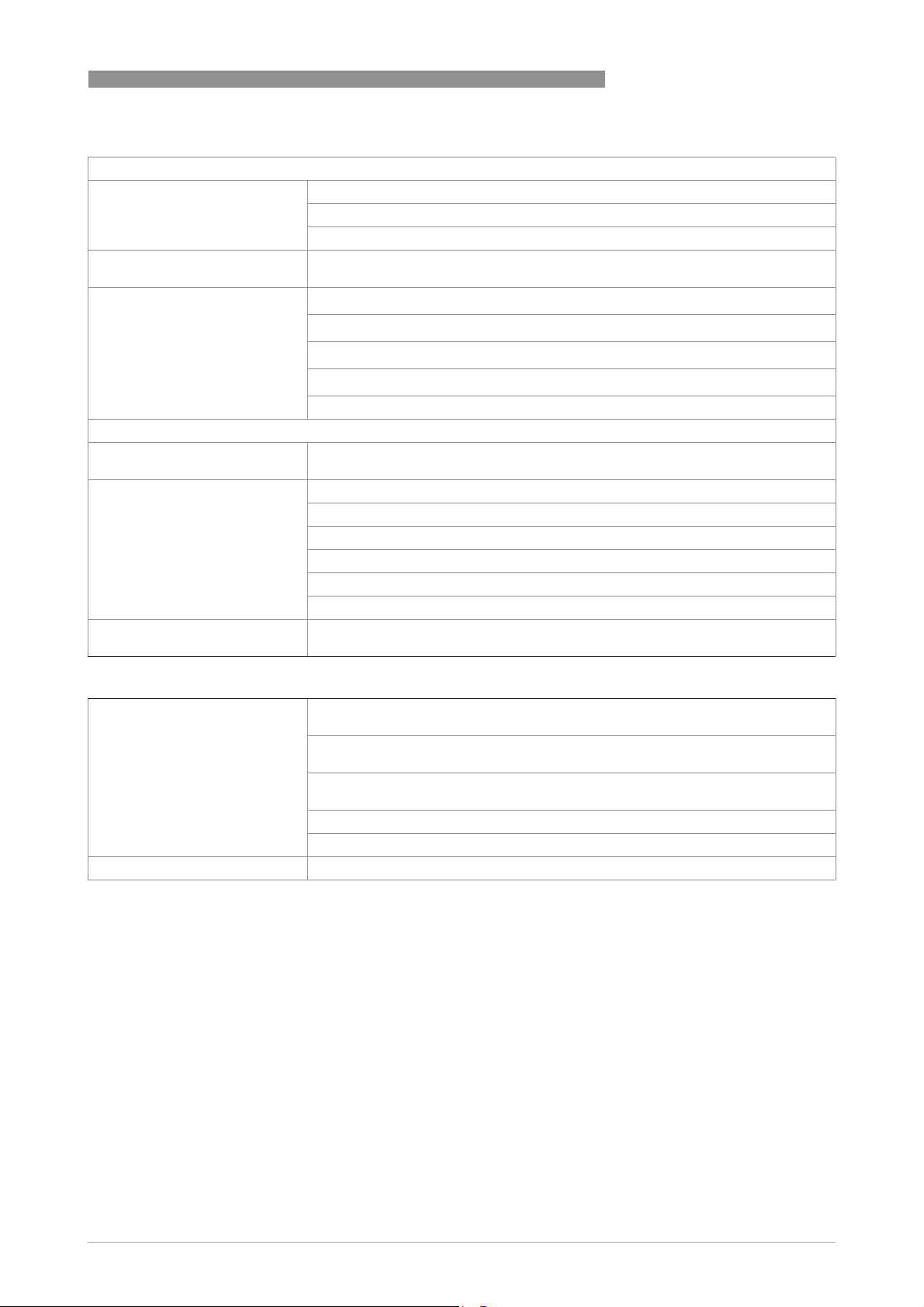

2

Figure 2-7: Measuring accuracy

X [m/s]: flow velocity

Y [%]: deviation from the actual measured value (mv)

DN [mm] DN [inch] Standard accuracy 1 Optimised accuracy 2

OPTIFLUX 1100 10…150 3/8…6 ±0.4% of mv ± 1mm/s;

OPTIFLUX 4100 / 5100 /

6100

OPTIFLUX 2100 / 4100 /

5100 / 6100

WATERFLUX 3100 25...600 1...24 ±0.3% of mv ± 1mm/s -

2.5…6 1/10…1/4

10…1200 3/8…48 ±0.3% of mv ± 1mm/s ±0.2% of mv ± 1.5 mm/s

as 1 + 0.1%

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

-

Extended calibration at

2points

23

Page 24

3

INSTALLATION

3.1 Intended use

The electromagnetic flowmeters are designed exclusively to measure the flow and conductivity

of electrically conductive, liquid media.

For devices used in hazardous areas, additional safety notes apply; please refer to the Ex

documentation.

If the device is not used according to the operating conditions (refer to chapter "Technical data"),

the intended protection could be affected.

This device is a Group 1, Class A device as specified within CISPR11:2009. It is intended for use in

industrial environment. There may be potential difficulties in ensuring electromagnetic

compatibility in other environments, due to conducted as well as radiated disturbances.

3.2 Installation specifications

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

The device must not be heated by radiated heat (e.g. exposure to the sun) to an electronics

housing surface temperature above the maximum permissible ambient temperature. If it is

necessary to prevent damage from heat sources, a heat protection (e.g. sun shade) has to be

installed.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibrations. The measuring devices are tested

for a vibration level as described in the chapter "Technical data".

IFC 100

3.3 Mounting of the compact version

Turning the housing of the compact version is not permitted.

The signal converter is mounted directly on the flow sensor. For installation of the flowmeter,

please observe the instructions in the supplied product documentation for the flow sensor.

24

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 25

IFC 100

3.4 Mounting the wall-mounted housing, remote version

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

3.4.1 Wall mounting

INSTALLATION

3

Figure 3-1: Mounting the wall-mounted housing

1 Prepare the holes with the aid of the mounting plate. For further information refer to

plate of wall-mounted version, aluminium housing

2 Fasten the device securely to the wall with the mounting plate.

on page 19.

Mounting

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

25

Page 26

3

INSTALLATION

Figure 3-2: Wall mounting of multiple devices (aluminium housing)

IFC 100

[mm] [inch]

a Ø6.5 Ø0.26

b 87.2 3.4

c 241 9.5

d 310 12.2

e 257 10.1

Table 3-1: Dimensions in mm and inch

26

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 27

IFC 100

INSTALLATION

e

3

Figure 3-3: Wall mounting of multiple devices (stainless steel housing)

[mm] [inch]

a Ø6.5 Ø0.26

b 268 10.5

c 40 1.6

d 336 13.2

e 257 10.1

Table 3-2: Dimensions in mm and inch

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

27

Page 28

4

ELECTRICAL CONNECTIONS

4.1 Important notes on electrical connection

Electrical connection is carried out in conformity with the VDE 0100 directive "Regulations for

electrical power installations with line voltages up to 1000 V" or equivalent national regulations.

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

•

Use suitable cable entries for the various electrical cables.

•

The flow sensor and signal converter have been configured together at the factory. For this

reason, please connect the devices in pairs. Ensure that the flow sensor constant GK/GKL

(see nameplates) are identically set.

•

If delivered separately or when installing devices that were not configured together, set the

signal converter to the DN size and GK/GKL of the flow sensor.

4.2 Preparing the signal and field current cables

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

IFC 100

4.2.1 Signal cable A (type DS 300), construction

• Signal cable A is a double-shielded cable for signal transmission between the flow sensor

and signal converter.

• Bending radius: ≥ 50 mm / 2"

Figure 4-1: Construction of signal cable A

1 Stranded drain wire (1) for the inner shield (10), 1.0 mm

2 Insulated wire (2), 0.5 mm

3 Insulated wire (3), 0.5 mm

4 Outer sheath

5 Insulation layers

6 Stranded drain wire (6) for the outer shield (60)

2

Cu / AWG 20

2

Cu / AWG 20

2

Cu / AWG 17 (not insulated, bare)

28

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 29

IFC 100

4.2.2 Length of signal cable A

For temperatures of the medium above 150°C / 300°F, a special signal cable and a ZD

intermediate socket are necessary. These are available including the changed electrical

connection diagrams.

ELECTRICAL CONNECTIONS

4

Flow sensor Nominal diameter Min. electrical

conductivity

DN [mm] [inch]

OPTIFLUX 1000 F 10...150 3/8...6 5 A1

OPTIFLUX 2000 F 25...150 1...6 20 A1

200...1200 8...48 20 A2

OPTIFLUX 4000 F 2.5...150 1/10...6 5 A1

200...1200 8...48 5 A2

OPTIFLUX 5000 F 2.5...100 1/10...4 5 A1

150...250 6...10 5 A2

OPTIFLUX 6000 F 2.5...150 1/10...6 5 A1

WATERFLUX 3000 F 25...600 1...24 20 A1

[µS/cm]

Curve for signal

cable A

Figure 4-2: Maximum length of signal cable A

1 Maximum length of signal cable A between the flow sensor and signal converter [m]

2 Maximum length of signal cable A between the flow sensor and signal converter [ft]

3 Electrical conductivity of the medium being measured [μS/cm]

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

29

Page 30

4

ELECTRICAL CONNECTIONS

4.2.3 Connection diagram for signal and field current cable

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

IFC 100

• A shielded 2-wire copper cable is used as the field current cable. The shielding MUST

MUST be

MUSTMUST

connected in the housing of the flow sensor and signal converter.

• The outer shield (60) is connected in the terminal compartment of the flow sensor directly via

the shield and a clip.

• Bending radius of signal and field current cable: ≥ 50 mm / 2"

• The following illustration is schematic. The positions of the electrical connection terminals

may vary depending on the housing version.

Figure 4-3: Connection diagram for signal and field current cable

1 Electrical terminal compartment in the signal converter

2 Signal cable A

3 Field current cable C

4 Electrical terminal compartment in the flow sensor

5 Functional ground FE

30

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 31

IFC 100

4.3 Connecting the power supply

The device must be grounded in accordance with regulations in order to protect personnel

against electric shocks.

• The housings of the devices, which are designed to protect the electronic equipment from

dust and moisture, should be kept well closed at all times. Creepage distances and

clearances are dimensioned to VDE 0110 and IEC 60664 for pollution severity 2. Supply

circuits are designed for overvoltage category III and the output circuits for overvoltage

category II.

• Fuse protection (I

breaker) to isolate the signal converter must be provided.

≤ 16 A) for the infeed power circuit, and also a separator (switch, circuit

N

ELECTRICAL CONNECTIONS

4

Figure 4-4: Terminal compartment for power supply

1 Retaining band of the cover

2 Cable entry for power supply, remote version

3 Cable entry for power supply, compact version

Version overview

Version Non-Ex Ex

100...230 VAC Standard Optional

24 VDC Standard -

24 VAC/DC Standard Optional

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

31

Page 32

4

ELECTRICAL CONNECTIONS

• Open the cover of the electrical terminal compartment by pressing down and pulling forwards

at the same time.

Figure 4-5: Power supply connection

1 100...230 VAC (-15% / +10%), 8 VA

2 24 VDC (-55% / +30%), 4 W

3 24 VAC/DC (AC: -15% / +10%; DC: -25% / +30%), 7 VA or 4 W

• Close the cover after the power has been connected.

IFC 100

100...230 VAC (tolerance range for 100 VAC: -15% / +10%)

100...230 VAC (tolerance range for 100 VAC: -15% / +10%)

100...230 VAC (tolerance range for 100 VAC: -15% / +10%)100...230 VAC (tolerance range for 100 VAC: -15% / +10%)

• Note the power supply voltage and frequency (50...60 Hz) on the nameplate.

240 VAC + 5% is included in the tolerance range.

24 VDC (tolerance range: -55% / +30%)

24 VDC (tolerance range: -55% / +30%)

24 VDC (tolerance range: -55% / +30%)24 VDC (tolerance range: -55% / +30%)

• Note the data on the nameplate!

• When connecting to functional extra-low voltages, provide a facility for protective separation

(PELV) (acc. to VDE 0100 / VDE 0106 and/or IEC 60364 / IEC 61140 or relevant national

regulations).

12 VDC - 10% is included in the tolerance range.

24 VAC/DC (tolerance range: AC: -15% / +10%; DC: -25% / +30%)

24 VAC/DC (tolerance range: AC: -15% / +10%; DC: -25% / +30%)

24 VAC/DC (tolerance range: AC: -15% / +10%; DC: -25% / +30%)24 VAC/DC (tolerance range: AC: -15% / +10%; DC: -25% / +30%)

• AC: Note the power supply voltage and frequency (50...60 Hz) on the nameplate.

• AC/DC: When connecting to functional extra-low voltages, provide a facility for protective

separation (PELV) (acc. to VDE 0100 / VDE 0106 and/or IEC 60364 / IEC 61140 or relevant

national regulations).

12 V is not

not included in the tolerance range.

notnot

32

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 33

IFC 100

4.4 Overview of outputs

4.4.1 Description of the CG number

Figure 4-6: Marking (CG number) of the electronics module and output variants

1 ID number: 0

2 ID number: 0 = standard; 9 = special

3 Power supply

4 Display (language versions)

5 Output version

4.4.2 Fixed, non-alterable output versions

This signal converter is available with various output combinations.

ELECTRICAL CONNECTIONS

4

• The grey boxes in the tables denote unassigned or unused connection terminals.

• In the table, only the final digits of the CG no. are depicted.

• Connection terminal A+ is only operable in the basic output version.

CG no. Connection terminals

C C- D D- S A+ A A-

1 0 0 Sp 1 Pp / Sp passive 1 2

Table 4-1: Basic outputs

1 Function change by software

2 Shielding

3 Function changed by reconnecting

I

I

a

P

p

S

p

Table 4-2: Description of used abbreviations

Current output active or passive

p

Pulse/frequency output passive

Status output / limit switch passive

Ip + HART® passive 3

Ia + HART® active 3

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

33

Page 34

4

ELECTRICAL CONNECTIONS

4.5 Laying electrical cables correctly

Figure 4-7: Protect housing from dust and water

1 For compact versions with nearly horizontally-oriented cable entries, lay the necessary elec-

tric cables with a drip loop as shown in the illustration.

2 Tighten the screw connection of the cable entry securely.

3 Seal cable entries that are not needed with a plug.

IFC 100

34

www.krohne.com 03/2018 - 4000040506 - TD IFC 100 R06 en

Page 35

IFC 100

NOTES

5

www.krohne.com03/2018 - 4000040506 - TD IFC 100 R06 en

35

Page 36

K

K

K

KROHNE – Process instrumentation and measurement solutions

•

Flow

•

Level

•

Temperature

•

Pressure

•

Process Analysis

•

Services

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.: +49 203 301 0

Fax: +49 203 301 10389

info@krohne.com

The current list of all KROHNE contacts and addresses can be found at:

© KROHNE 03/2018 - 4000040506 - TD IFC 100 R06 en - Subject to change without notice.

www.krohne.com

Loading...

Loading...