KitchenAid KESC300H, KESH307H, KESC307H User Manual

KAC-34

TECHNICAL EDUCATION

SELF-CLEANING SLIDE-IN ELECTRIC RANGE

Models KESC300H, KESC307H, KESH307H

JOB AID 4317335

FORWARD

This KitchenAid Job Aid, “Self-Cleaning Slide-In Electric Range,” (Part No. 4317335), provides the technician with information on the installation, operation, and service of the Self-Cleaning SlideIn Electric Range. It is to be used as a training Job Aid and Service Manual. For specific information on the model being serviced, refer to the “Use and Care Guide,” or “Wiring Diagram” provided with the electric range.

The Wiring Diagram and Strip Circuits used in this Job Aid are typical and should be used for training purposes only. Always use the Wiring Diagram supplied with the product when servicing the unit.

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide detailed information that will enable the service technician to properly diagnose malfunctions and repair the KitchenAid Self-Cleaning Slide-In Electric Range.

The objectives of this Job Aid are to:

•Understand and follow proper safety precautions.

•Successfully troubleshoot and diagnose malfunctions.

•Successfully perform necessary repairs.

•Successfully return the range to its proper operational status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on our products by anyone other than Authorized Service Technicians.

Copyright © 2002, Whirlpool Corporation, Benton Harbor, MI 49022

- ii -

TABLE OF CONTENTS

|

Page |

GENERAL............................................................................................................................... |

1-1 |

Safety First......................................................................................................................... |

1-1 |

KitchenAid Model & Serial Number Designations.............................................................. |

1-3 |

Model & Serial Number Label Location ............................................................................. |

1-4 |

Specifications..................................................................................................................... |

1-5 |

KitchenAid Electric Range Warranty.................................................................................. |

1-7 |

INSTALLATION INFORMATION ........................................................................................... |

2-1 |

Electrical Supply Requirements ......................................................................................... |

2-1 |

Moving The Range ............................................................................................................ |

2-8 |

THEORY OF OPERATION ..................................................................................................... |

3-1 |

Air Flow—Rear Panel ........................................................................................................ |

3-1 |

Cooling Fan Air Flow ......................................................................................................... |

3-2 |

The Bimetal Switches ........................................................................................................ |

3-3 |

The Surface Element Limiter ............................................................................................. |

3-4 |

The Door Lock Solenoid & Door Latch Switch................................................................... |

3-5 |

How The Self-Clean Cycle Works ..................................................................................... |

3-6 |

COMPONENT ACCESS ......................................................................................................... |

4-1 |

Component Locations ........................................................................................................ |

4-1 |

Removing The Control Panel, An Infinite Switch & Bimetal Switch ................................... |

4-2 |

Removing The Electronic Oven Control And An Indicator Light ........................................ |

4-4 |

Removing An Element & Limiter And The Hot Surface Indicator Assembly ...................... |

4-5 |

Removing The Cooktop Glass ........................................................................................... |

4-7 |

Removing The Door Latch Assembly & The Door Switch ............................................... |

4-10 |

Removing The Dual Broil Element And The Hidden Bake Element ................................ |

4-12 |

Removing The Convection Bake Element & Fan Motor .................................................. |

4-14 |

Removing An Oven Light Socket Assembly .................................................................... |

4-16 |

Removing The Meat Probe Jack ..................................................................................... |

4-17 |

Removing The Oven Temperature Sensor ...................................................................... |

4-18 |

Removing A Side Panel ................................................................................................... |

4-19 |

Removing The Double Line Break (DLB) Relay And The Cooling Fan Motor ................ |

4-20 |

Removing The Oven Door ............................................................................................... |

4-22 |

Removing The Decorative Glass, The Oven Door Handle, The Hinges, |

|

And The Oven Door Glass........................................................................................... |

4-23 |

Removing The Oven Door Gasket................................................................................... |

4-25 |

- iii -

|

Page |

COMPONENT TESTING ........................................................................................................ |

5-1 |

Bimetal Switch ................................................................................................................... |

5-1 |

Single Element Infinite Switches........................................................................................ |

5-2 |

Dual Element Infinite Switch (Optional) ............................................................................. |

5-3 |

Surface Elements & Limiters ............................................................................................. |

5-4 |

Door Switch ....................................................................................................................... |

5-6 |

Door Latch Assembly......................................................................................................... |

5-6 |

Hidden Bake Element ........................................................................................................ |

5-7 |

Dual Broil Element ............................................................................................................. |

5-7 |

Convection Bake Element ................................................................................................. |

5-8 |

Convection Fan Motor ....................................................................................................... |

5-8 |

Oven Temperature Sensor ................................................................................................ |

5-9 |

Cooling Fan Motor ............................................................................................................. |

5-9 |

Double Line Break (DLB) Relay....................................................................................... |

5-10 |

DIAGNOSIS & TROUBLESHOOTING ................................................................................... |

6-1 |

Diagnosis ........................................................................................................................... |

6-1 |

Failure / Error Display Codes—Tech Sheet #9753028, Rev. B ..................................... |

6-1 |

Fault Error Code Charts................................................................................................ |

6-2 |

Troubleshooting Charts ..................................................................................................... |

6-3 |

Oven Temperature Calibration .......................................................................................... |

6-6 |

WIRING DIAGRAM & STRIP CIRCUITS ............................................................................... |

7-1 |

Wiring Diagram— #9753028, Rev. B................................................................................. |

7-1 |

Strip Circuits ...................................................................................................................... |

7-3 |

- iv -

GENERAL

SAFETY FIRST

Your safety and the safety of others is very important.

We have provided many important safety messages in this Job Aid and on the appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These words mean:

DANGER

DANGER

WARNING

WARNING

You can be killed or seriously injured if you don’t immediately follow instructions.

You can be killed or seriously injured if you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

WARNING

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

WARNING

WARNING

Electrical Shock Hazard

Plug into a grounded 3-prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

1-1

WARNING

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or electrical shock.

WARNING

WARNING

Tip-Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic control assembly. The new control assembly may appear to work well after repair is finished, but failure may occur at a later date due to ESD stress.

•Use an antistatic wrist strap. Connect the wrist strap to the green ground connection point, or to an unpainted metal surface in the appliance.

-OR -

•Touch your finger repeatedly to a green ground connection point, or to an unpainted metal surface in the appliance.

•Before removing the part from its package, touch the antistatic bag to a green ground connection point, or to an unpainted metal surface in the appliance.

•Avoid touching electronic parts, or terminal contacts. Handle the electronic control assembly by the edges only.

•When repackaging the failed electronic control assembly in an antistatic bag, observe the previous instructions.

1-2

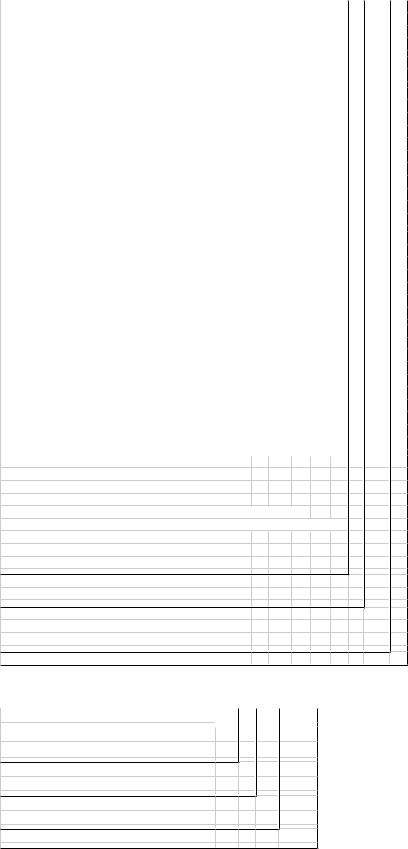

KITCHENAID MODEL & SERIAL NUMBER DESIGNATIONS

MODEL NUMBER

MODEL NUMBER |

|

K |

ES |

C |

30 |

0 H BL 4 |

||||||||

INTERNATIONAL SALES IND. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OR MARKETING CHANNEL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IF PRESENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PRODUCT GROUP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K = KITCHENAID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PRODUCT IDENTIFICATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DD = DUAL FUEL DROP-IN / SLIDE-IN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DR = DUAL FUEL RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ED = ELECTRIC DROP-IN RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EE = ELECTRIC EYE-LEVEL RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ER = ELECTRIC STANDARD RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ES = ELECTRIC SLIDE-IN RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GD = GAS DROP-IN RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GE = GAS EYE-LEVEL RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GR = GAS STANDARD RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GS = GAS SLIDE-IN RANGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MERCHANDISING SCHEME |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C = CERAMIC GLASS TOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H = CERAMIC W/HALOGEN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I = IMPERIAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P = PROFESSIONAL / COMMERCIAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S = STANDARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T = TEMPERED GLASS TOP |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAPACITY / SIZE / SERIES / CONFIGURATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1ST POSITION |

2ND POSITION |

|

|

|

||||||||||

1 = DROP-IN |

0 = 30″ WIDE |

|

|

|

|

|

|

|

|

|

|

|

||

2 = DROP-IN / SLIDE-IN COMBO |

6 = 36″ WIDE |

|

|

|

|

|

|

|

|

|

|

|

||

3 = SLIDE-IN |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 = COMMERCIAL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5 = STANDARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 = EYE-LEVEL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 = 48″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9 = 60″ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FEATURES

0 = STANDARD FEATURES

2 = PLUS FEATURES OR SEALED BURNERS

W / GRILL / CONVECTION OVEN

3 = SEALED BURNERS W / GRIDDLE / CONVECTION OVEN

4 = SEALED BURNERS W / GRILL & GRIDDLE / CONVECTION OVEN

5 = DELUXE FEATURES

7 = DELUXE FEATURES / CONVECTION OR

SEALED BURNERS / CONVECTION OVEN

YEAR OF INTRODUCTION

H = 1999, J = 2000, K= 2001, L - 2002

COLOR CODE

BL = BLACK, WH = WHITE, BT = BISCUIT

BS = BLACK ON STAINLESS

ENGINEERING CHANGE (NUMERIC)

SERIAL NUMBER

SERIAL NUMBER |

IM K 31 73981 |

||||||

|

|

|

|

|

|

|

|

MANUFACTURING SITE

IM = MONTMAGNY

YEAR OF PRODUCTION

K = 2000, L = 2001, M = 2002

WEEK OF PRODUCTION

31 = 31ST WEEK

PRODUCT SEQUENCE NUMBER

1-3

MODEL & SERIAL NUMBER LABEL LOCATION

The Model/Serial Number label location is shown below.

Model & Serial Number Location

(Located Behind Storage Drawer)

1-4

SPECIFICATIONS

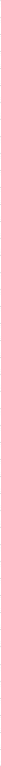

Model |

KESC300H WH/BL/BT |

KESC307H WH/BT/BS |

KESH307H WH/BL/BS |

Model Description |

Slide-In |

Slide-In |

Slide-In Radiant/Halogen |

Dimensions/Specifications |

|

|

|

Exterior Dimensions |

|

|

|

Height To Maintop (in) |

3 6 " |

3 6 " |

3 6 " |

Overall Depth Inc Hrdwr/Hndl (in) |

26.75" |

26.75" |

26.75" |

Depth Without Handle (in) |

24.5" |

24.5" |

24.5" |

Door Swing (in) |

21.75" |

21.75" |

21.75" |

Shipping Weight (lbs) |

160 |

160 |

160 |

Exterior |

|

|

|

Cabinet Finish |

Painted |

Painted |

Painted |

Front Frame |

Porcelain |

Porcelain |

Porcelain |

Leveling Legs |

Yes |

Yes |

Yes |

Oven Window Size and Type |

Large/Glass |

Large/Glass |

Large/Glass |

Removable Door and Hinges |

Yes |

Yes |

Yes |

Door Liner Finish |

Porcelain |

Porcelain |

Porcelain |

Door Type |

Glass |

Glass |

Glass |

Control Panel Location |

Front |

Front |

Front |

Control Panel Color |

White |

White |

White |

Control Panel Construction |

Glass |

Glass |

Glass |

Control Knob Type, #, Fcn |

Infinite Switch Single Blade |

Infinite Switch Single Blade |

Infinite Switch Single Blade |

Simmer Specialty Switch |

Yes |

Yes |

Yes |

Keep Warm Switch |

Yes |

Yes |

Yes |

Cooktop Features |

|

|

|

|

|

|

|

Cooktop Material |

Ceran Top |

Ceran Top |

Ceran Top |

Hot Surface Indicator |

4 Neon Cluster |

4 Neon Cluster |

4 Neon Cluster |

Burner Box Finish |

Galvanized |

Galvanized |

Galvanized |

Cooktop Support Rods |

No |

No |

No |

Electric Cooktop Element |

Yes |

Yes |

Yes |

Electric Element Configuration |

6", 7", 8", 9.5" |

6", 7", 8", 9.5" |

6", 7", 8", 9.5" |

Electric Element Type |

Radiant |

Radiant |

Radiant |

Electric Right Front Size |

7 " |

7 " |

7 " |

Electric RF Output (w@240/208v) |

1800W |

1800W |

1800W/Halogen |

Electric Left Front Size |

9.5" |

9.5" |

9.5" |

Electric LF Output (w@240/208v) |

2500W/1500W |

2500W/1500W |

2500W/1500W |

Electric Right Rear Size |

8 " |

8 " |

8 " |

Electric RR Output (w@240/208v) |

2200W |

2200W |

2200W |

Electric Left Rear Size |

6 " |

6 " |

6 " |

Electric LR Output (w@240/208v) |

1500" |

1500" |

1500" |

Oven Controls |

EOC |

EOC |

EOC |

Oven Control Type |

Glass Capacitive |

Glass Capacitive |

Glass Capacitive |

Oven Control Location |

Front |

Front |

Front |

Control Lock Out |

Yes |

Yes |

Yes |

Delayed Cooking Option |

Yes |

Yes |

Yes |

Timer |

in EOC |

in EOC |

in EOC |

1-5

Model |

KESC300H WH/BL/BT |

KESC307H WH/BT/BS |

KESH307H WH/BL/BS |

Interior |

|

|

|

Main Oven |

|

|

|

Cooking System |

Conventional |

Fan Convection |

Fan Convection |

Cleaning System |

Self Cleaning |

Self Cleaning |

Self Cleaning |

Auto Self Clean Latch |

Yes |

Yes |

Yes |

Oven Liner Finish |

Porcelain |

Porcelain |

Porcelain |

Oven Volume (cu ft) |

3.62 cu ft |

3.28 |

3.28 |

Oven Height (in) |

15.75" |

15.75" |

15.75" |

Oven Width (in) |

23 1/16" |

23 1/16" |

23 1/16" |

Oven Depth (in) |

18.25" |

16 5/16" |

16 5/16" |

Rack Guides # |

5 |

5 |

5 |

Oven Racks # |

2 |

3 |

3 |

Oven Rack Type & # Each |

2 Flat |

|

|

Oven Rack |

Yes |

Yes |

Yes |

Broiler Pan |

Yes |

Yes |

Yes |

Broiler Pan Finish |

Porcelain |

Porcelain |

Porcelain |

Broiler Pan Grid Finish |

Porcelain |

Porcelain |

Porcelain |

Oven Light Number |

1 Incandescent |

2 Incandescent |

2 Incandescent |

Main Electric Oven |

Yes |

Yes |

Yes |

Hidden Bake Element |

No |

Yes |

Yes |

Bake (W@240/208v) |

2500W |

|

|

Broil Inner Elem (W@240/208v) |

1665W |

1665W |

1665W |

Broil Outer Elem (W@240/208v) |

1000W |

1000W |

1000W |

Oven Lower Panel/ Door |

Yes |

Yes |

Yes |

Drawer/Panel Front |

Painted |

Painted |

Painted |

Storage Drawer Liner |

Yes |

Yes |

Yes |

Drawer/Panel Height (in) |

5.1" |

5.1" |

5.1" |

Drawer/Panel Width (in) |

23.3" |

23.3" |

23.3" |

Drawer/Panel Depth (in) |

2 0 " |

2 0 " |

2 0 " |

Glides |

Nylon Rollers |

Nylon Rollers |

Nylon Rollers |

Lower Drawer Handle Type/Material |

Formed at Top |

Formed at Top |

Formed at Top |

Lower Drawer Handle Color |

White |

White |

White |

Product Literature |

|

|

|

|

|

|

|

Cookbook |

No |

Yes |

Yes |

Installation Instructions |

9752043 B |

9752043 B |

9752043 B |

Tech Sheet |

9753027 |

9753027 |

9753027 |

Use & Care Guide |

Yes |

Yes |

Yes |

Other |

Ceran Polish Incl |

Ceran Polish Incl |

Ceran Polish Incl |

Agency Approvals |

UL,CSA |

UL,CSA |

UL,CSA |

Anti-tip Device With Unit |

Floor |

Floor |

Floor |

1-6

KITCHENAID ELECTRIC RANGE WARRANTY

LENGTH OF WARRANTY |

KITCHENAID WILL PAY FOR: |

FULL ONE YEAR WARRANTY Replacement parts and repair labor costs to correct defects in materials From Date of Purchase. or workmanship. Service must be provided by a KitchenAid designated

servicing outlet.

SECOND THROUGH FIFTH YEAR Replacement parts for any electric element to correct defects in materi- LIMITED WARRANTY als or workmanship. Replacement ceramic glass if breakage is due to From Date of Purchase. defects in materials or workmanship. Replacement parts for solid state

touch control system to correct defects in materials or workmanship.

SECOND THROUGH TENTH Replacement parts for the porcelain oven cavity / inner door if the part YEAR LIMITED WARRANTY rusts through due to defects in materials or workmanship.

From Date of Purchase.

KITCHENAID WILL NOT PAY FOR:

A.Service calls to:

1.Correct the installation of the range.

2.Instruct you how to use the range.

3.Replace house fuses or correct house wiring.

B.Repairs when range is used in other than normal, single family household use.

C.Damage resulting from accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation, or installation not in accordance with local electrical codes.

D.Any labor costs during the limited warranties.

E.Replacement parts or repair labor costs for units operated outside the United States and Canada.

F.Pickup and delivery. Your range is designed to be repaired in the home.

G.Repairs to ceramic glass cooktop if it has not been cared for as recommended in the Use and Care Guide.

H.Repairs to parts or systems resulting from unauthorized modifications made to the appliance.

I. In Canada, travel or transportation expenses to customers who reside in remote areas.

KITCHENAID OR KITCHENAID CANADA DO NOT ASSUME ANY RESPONSIBILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states or provinces do not allow the exclusion or limitation of incidental or consequential damages, so this exclusion or limitation may not apply to you. This warranty gives you special legal rights, and you may also have other rights which vary from state-to-state or province-to-province.

Outside the United States and Canada, a different warranty may apply. For details, please contact your authorized KitchenAid dealer.

If you need service first see the “Troubleshooting” section of the Use and Care Guide. After checking ”Troubleshooting,” additional help can be found by checking the “Requesting Assistance or Service” section, or by calling our Customer Interaction Center telephone numbers, listed below, from anywhere in the U.S.A. or Canada.

KitchenAid: 1-800-422-1230

Canadian Residents call: 1-800-807-6777

1-7

— NOTES —

1-8

INSTALLATION INFORMATION

ELECTRICAL SUPPLY REQUIREMENTS

WARNING

WARNING

Electrical Shock Hazard

Electrically ground range.

Failure to do so can result in death, fire, or electrical shock.

GENERAL

2.Wire sizes and connections must conform to the requirements of the National Electrical Code, ANSI/NFPA 70—latest edition*, or CSA Standard C22.1, Canadian Electrical Code, Part 1—latest edition**, and all local codes and ordinances for the kilowatt rating of the range.

Copies of the standards listed may be obtained from:

*National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

**CSA International

8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575

If codes permit, and a separate grounding wire is used, it is recommended that a qualified electrician determine that the grounding path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure that the range is grounded.

Do not have a fuse in the neutral or ground circuit.

1.When a 4-wire or 3-wire, single-phase, 120/240-volt, 60-Hz, AC-only electrical supply is available, a 50-ampere maximum circuit protection is required, (or, if specified on the model/serial plate, when a 4-wire, or 3-wire, single-phase, 120/ 208-volt, 60 Hz, AC-only electrical supply is available, a 40-ampere maximum circuit protection is required), fused on both sides of the line. A time-delay fuse, or circuit breaker is recommended. The model/serial rating plate is located behind the storage drawer (see page 1-4).

3.This range can be connected directly to the fused disconnect, or circuit breaker box, through flexible, armored, or nonmetallic sheathed, copper cable (with ground wire). Locate the junction box to allow two to three feet of slack in the line so that the range can be moved, if servicing is ever necessary. Do not cut the conduit.

A U.L.-listed conduit connector must be provided at each end of the power supply cable, at the range, and at the junction box. Wire sizes, (copper wire only), and connections, must conform with the rating of the range.

2-1

ELECTRICAL CONNECTIONS (Not used for Canadian Installations)

This range can be connected directly to the fuseddisconnect,orcircuitbreakerbox,through flexible, armored, or nonmetallic sheathed, copper cable with a grounding wire. Allow two to three feet of slack in the line so that it can be moved if servicing is ever necessary.

A U.L.-listed conduit connector must be provided at each end of the power supply cable at the range, and at the junction box.

brass |

terminal |

|

terminal |

||

block cover |

||

nuts |

||

|

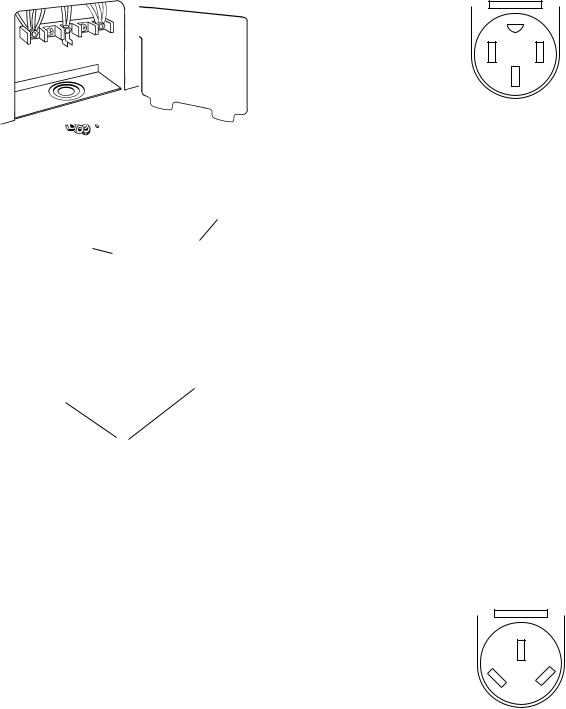

Remove the terminal block cover located on the back of the range.

knockout |

knockout |

opening for |

opening for |

40-ampere |

power |

power supply |

supply cable |

cord |

|

Depending on the electrical supply, make the 4-wire or the 3-wire connection to the range, following the instructions under the “Power Supply Cord Connection,” (page 2-3), or the “Direct Wire Connection” (page 2-5).

4-Wire Electrical System

This range is manufactured with the ground connected to the cabinet. The ground must be revised so that the green grounding wire of the 4-wire power supply cord is connected to the cabinet (refer to the “4-wire Electrical Connection” section).

4-Wire |

G |

|

Y X |

||

Receptacle |

||

14-50R |

W |

|

|

When a 4-wire receptacle of NEMA type 1450R is used, a matching U.L.-listed, 4-wire, 250-volt, 40-ampere range power supply cord (pigtail) must be used.

This cord contains four copper conductors with ring terminals at the appliance end, terminated in a NEMA type 14-50P plug on the supply end. The fourth (grounding) conductor must be identified by a green or green/yellow cover, and the neutral conductor by a white cover. The cord should be type SRD, or SRDT, with a U.L.- listed strain relief, and be at least four feet long.

The minimum conductor sizes for the copper 4-wire power cord are:

(2) #8 conductors

(1) #10 white neutral

(1) #8 green grounding

3-Wire Electrical System

Local codes may permit the use of a U.L.- listed, 250-volt, 40-ampere range power supply cord (pigtail). This cord contains three # 10 copper wires, and matches a three-wire receptacle of NEMA Type 10-50R.

3-Wire |

W |

|

Receptacle |

||

Y X |

||

10-50R |

Connectors on the appliance end must be provided at the point the power supply cord enters the appliance.

2-2

POWER SUPPLY CORD

CONNECTION

WARNING

WARNING

Electrical Shock Hazard

Turn power supply off before connecting wires.

Electrically ground range.

Failure to do so can result in death, fire, or electrical shock.

Warning: Improper connection of the equip- ment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician, or serviceman, if you are in doubt as to whether the appliance is properly grounded.

Do not modify the power supply cord plug. If it will not fit the outlet, have a proper outlet installed by a qualified electrician.

1.Disconnect the power supply.

2.Remove the screws from the terminal block cover.

3.Remove the 3/8″ brass nuts that are attached to the knockout opening and set them aside. Use these brass nuts to secure the ring-type terminals on the power supply cord to the terminal block screws.

NOTE: Use only ring-type terminals to connect the power supply cord.

4.Remove the knockout for the 40-ampere power supply cord.

5.MountaU.L.-listedstrainreliefintheknock- out opening.

6.Insert the power supply cord through the strain relief, and allow enough slack so you can easily attach the wiring to the terminal block.

7.Depending on the type of electrical system, proceed to “4-Wire Electrical Connection,” or “3-Wire Electrical Connection,” (on page 2-4), and complete the wiring.

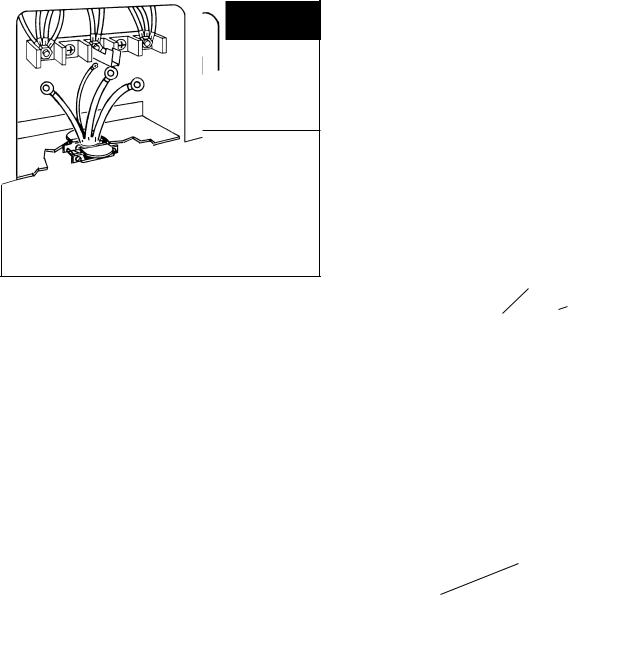

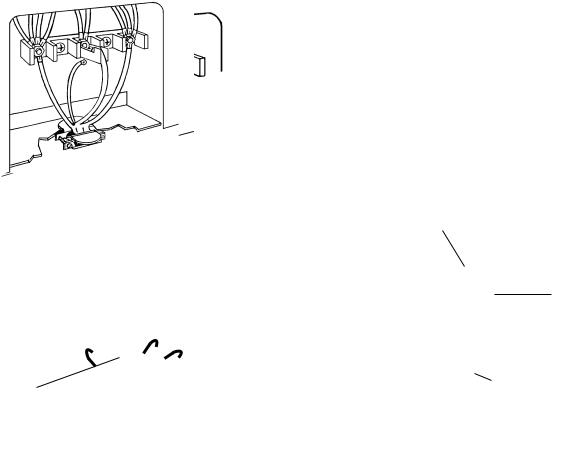

4-Wire Electrical Connection

Use this method for mobile homes, and whenever 4-wire installation is required.

1.Remove the ground-link screw from the range frame and set the screw aside.

2.Bend the ground link up so that it does not contact the range.

ground link |

ground-link |

|

screw |

||

|

3.Connect the green ground wire on the power supply cord to the ground link screw hole in the range with the ground-link screw you removed earlier. Make sure that the bare ground wire does not contact the adjacent terminal block connections.

ground-link  screw

screw

green ground wire

2-3

NOTE: Do not loosen the factory-installed nuts on the terminal block when you perform the following steps.

4.Connect the neutral (white) wire of the power supply cord to the center, silver-

colored terminal screw on the terminal block, and secure it with one of the 3/8″ brass nuts that you set aside earlier.

5.Connect the remaining two power supply

cord wires to the outer terminals of the terminal block, and secure them with 3/8″ brass nuts.

6.Tighten the strain relief screws to secure the power supply cord.

7.Install the terminal block cover.

silver-colored terminal block screw

neutral wire (center wire)

green ground wire

U.L. listed strain relief and 40-ampere range power supply cord

3-Wire Electrical Connection

Use this method only if local codes permit connecting a cabinet-grounded conductor to the neutral wire of the power supply cord.

NOTE: Do not loosen the factory-installed nuts on the terminal block when you perform the following steps.

1.Connect the neutral (white) wire of the power supply cord to the center, silver-

colored terminal screw on the terminal block, and secure it with one of the 3/8″ brass nuts that you set aside earlier.

2.Connect the remaining two power supply

cord wires to the outer terminals of the terminal block, and secure them with 3/8″ brass nuts.

3.Tighten the strain relief screws to secure the power supply cord.

4.Install the terminal block cover.

silver-colored terminal block screw

|

line 2 |

ground |

neutral |

link |

(center wire) |

line 1 |

U.L.-listed strain relief |

|

|

|

and 40-ampere range |

|

power supply cord |

2-4

DIRECT WIRE CONNECTION

WARNING

WARNING

Electrical Shock Hazard

Turn power supply off before connecting wires.

Electrically ground range.

Failure to do so can result in death, fire, or electrical shock.

4.Disconnect the power supply.

5.Remove the screws from the terminal block cover.

6.Remove the 3/8″ brass nuts that are attached to the knockout opening and set them aside. Use these brass nuts to secure the ring-type terminals on the power supply cord to the terminal block screws.

NOTE: Use only ring-type terminals to connect the power supply cord.

7.Remove the knockout for the 40ampere power supply cord.

8.MountaU.L.-listedstrainreliefintheknock- out opening.

This range must be connected to a grounded, metallic, permanent wiring system, or a ground connector should be connected to the ground terminal, or to the ground wire lead on the range.

The conductors at the terminal block must be copper wire only.

If the house has aluminum wiring, perform steps 1 through 3, otherwise skip those steps.

1.Connect a section of 8-gauge, solid copper wire to the terminal block.

2.Connect the aluminum wiring to the added section of copper wire using special connectors that were designed by Underwriters Laboratories for joining copper to alu minum. Follow the procedure recom mended by the manufacturer to connect the wires.

3.Thealuminum-to-copperconnectionsmust conform with local codes and industry accepted wiring practice.

U .L.-listed conduit connector

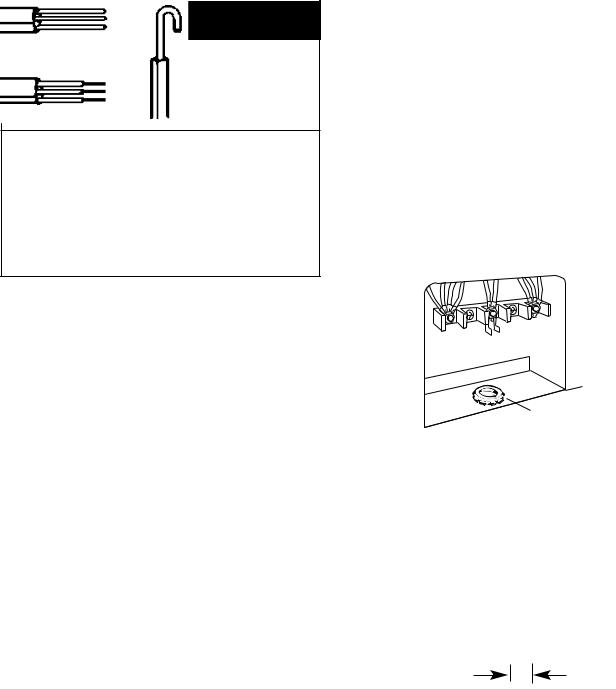

9.Strip 3″ of outer covering from the end of each wire on the power supply cord.

10.Form a hook in the bare wire ends of the power supply cord.

3"

3"

1"

11.Insert the power supply cord through the strain relief, and allow enough slack so you can easily attach the wiring to the terminal block.

12.Depending on the type of electrical system, proceed to “4-Wire Electrical Connection,” (on page 2-6), or “3-Wire Electrical Connection,” (on page 2-7), and complete the wiring.

2-5

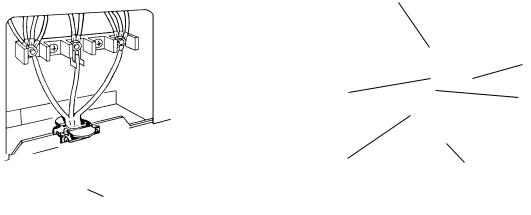

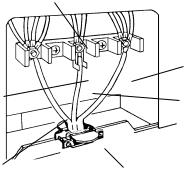

4-Wire Electrical Connection

1.Remove the ground-link screw from the range frame and set the screw aside.

2.Bend the ground link up so that it does not contact the range.

|

ground-link |

ground link |

screw |

3.Connect the green ground wire on the power supply cord to the ground link screw hole in the range with the ground-link screw you removed earlier. Make sure that the bare ground wire does not contact the adjacent terminal block connections.

ground-link  screw

screw

bare wire from power supply cable

NOTE: Do not loosen the factory-installed nuts on the terminal block when you perform the following steps.

4.Connect the neutral (white) wire of the power supply cord to the center, silver-

colored terminal screw on the terminal block, and secure it with one of the 3/8″ brass nuts that you set aside earlier.

5.Connect the remaining two power supply

cord wires to the outer terminals of the terminal block, and secure them with 3/8″ brass nuts.

6.Tighten the strain relief screws to secure the power supply cord.

7.Install the terminal block cover.

silver-colored terminal block screw

neutral wire (white wire)

bare wire  from power

from power

supply cable

U.L. listed conduit connector and power supply cable

2-6

3-Wire Electrical Connection

Use this method only if local codes permit connecting a cabinet-grounded conductor to the neutral wire of the power supply cord.

NOTE: Do not loosen the factory-installed nuts on the terminal block when you perform the following steps.

1.Connect the neutral (white) wire of the power supply cord to the center, silver-

colored terminal screw on the terminal block, and secure it with one of the 3/8″ brass nuts that you set aside earlier.

2.Connect the remaining two power supply

cord wires to the outer terminals of the terminal block, and secure them with 3/8″ brass nuts.

3.Tighten the strain relief screws to secure the power supply cord.

4.Install the terminal block cover.

silver-colored terminal block screw

|

line 2 |

ground |

neutral wire |

link |

(white wire) |

line 1 |

U.L. listed conduit |

|

|

|

connector and power |

|

supply cable |

2-7

MOVING THE RANGE

WARNING

WARNING

Tip-Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

Before moving the range, slide it onto a piece of cardboard, or hardboard, to prevent damaging the floor covering, and perform the following steps:

1.Unplug range or disconnect power.

2.Slide the range forward and disengage the foot with the anti-tip bracket. IMPORTANT: Make sure the anti-tip bracket is securely attached to floor.

3.Slide range back so the rear foot engages in the anti-tip bracket.

4.Check to see that the range is level.

5.Reconnect the electrical supply cord.

2-8

THEORY OF OPERATION

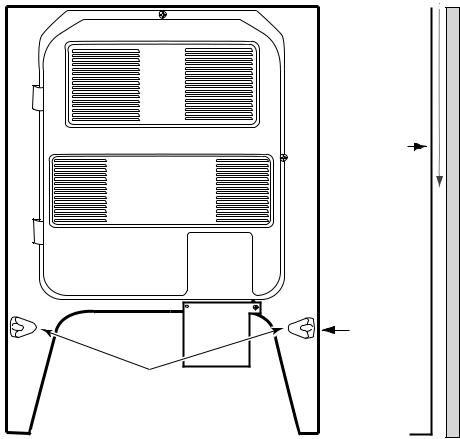

AIR FLOW — REAR PANEL

The electric range needs sufficient air to properly cool the oven. In addition, proper air flow through the electric range also keeps the front control panel from becoming too hot while the elements are operating, and causing operational problems.

To help provide the proper air flow along the back of the range, the rear panel of the range has a spacer on each side toward the bottom.

When the range is installed, these spacers should just come in contact with the surface of the wall. If they are accidentally bent in, proper spacing will be lost, and the oven will not heat properly. Also, the front control panel may become overly warm, and cause the bimetal switches to trip, shutting down the operation. If any of these problems occur, it is most likely because of air flow restrictions.

AIRFLOW

REAR

PANEL

WALL

SPACER

EXTRUDED

SPACERS

ON REAR PANEL

SIDE VIEW

3-1

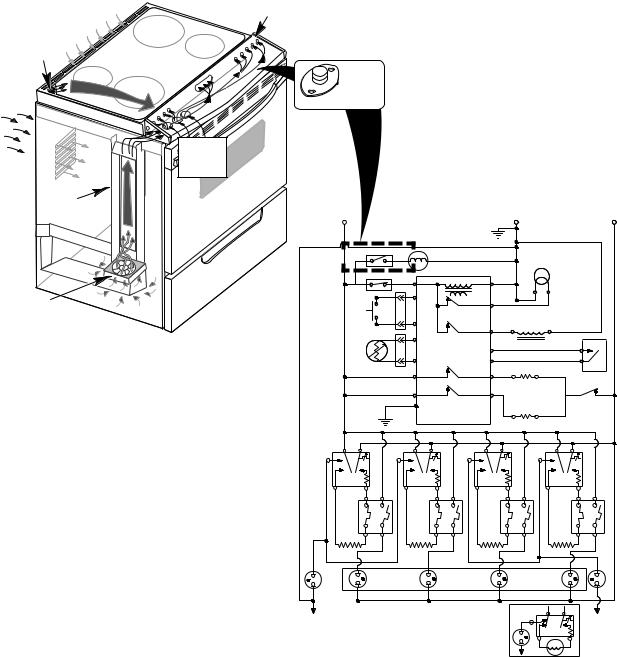

COOLING FAN AIR FLOW

The cooling fan is in series with the cooling fan bimetal switch, which is located under the right side of the control panel. When the temperature of the chassis reaches 40˚C (104˚F), the bimetal switch closes, and turns on the cooling fan.

The cooling fan draws air from inside the base of the cabinet. It forces the air up the air channel, which is located under the left side panel,

to the opening at the end of the control panel. Air then flows across the chassis below the control panel, and cools it. Air enters through the series of holes in front of the range top, flows beneath it, and exits to the outside through slots in the rear panel. When the control panel chassis temperature drops below 40˚C (104˚F), the bimetal switch opens, and turns the cooling fan off.

OVEN VENT FOR

OVEN EXHAUST

AIR FLOWS

INTO

REAR PANEL

LOUVERS

AIR CHANNEL

COOLING FAN

AIR FLOWS FROM

CONTROL PANEL

UNDER RANGE TOP

COOLING FAN

BIMETAL SWITCH

AIR INLETS

UNDER

UNDER

CONTROL

PANEL

L2

R

|

|

|

|

|

|

|

|

GND |

|

|

|

|

|

|

|

BI - METAL SW FAN N.O. |

M |

|

|

|

|

|

|

|

|

|

|

||

|

Y |

|

Y |

|

W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

BI-METAL SW |

|

|

OVEN CONTROL |

|

|

|

|

OVEN LT. |

|

||||

|

AMBIENT N.C. |

|

|

|

|

|

|

|

||||||

|

BK P4-3 |

TRANSFORMER P4-1 |

W |

|

|

|

|

|||||||

|

BK |

|

|

|

|

|

|

|

||||||

|

|

|

Y |

P3-3 |

|

|

|

|

|

W |

|

|

|

|

|

|

|

|

|

|

P4-4 |

R |

|

|

|

|

|

|

|

|

DOOR |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

OVEN LIGHT |

|

|

|

|

|

|

|

|

||

|

SW. |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P3-4 |

|

|

|

|

|

DOOR LOCK |

|

|

|

||

|

|

|

|

|

|

|

BR |

|

W |

|

|

|||

|

|

|

|

|

|

|

P4-5 |

|

SOLENOID |

|

|

|||

|

|

|

V |

P3-6 |

LATCH RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

OVEN |

|

|

|

|

|

P3-1 |

BU |

|

|

|

|

|

|

|

TEMP |

|

|

|

|

|

|

|

|

|

|

N.O. |

||

|

SENSOR |

|

V |

P3-7 |

|

|

|

BU |

|

|

|

|

||

|

|

|

|

P3-2 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

COM |

|||

|

|

|

|

|

|

|

|

|

BROIL ELEMENT |

|

||||

|

BK |

|

|

P2-2 |

|

|

P2-1 |

V |

BU |

|

DOOR |

|||

W |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

BROIL RELAY |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

LATCH SW. |

|||

|

|

|

|

P2-3 |

|

|

|

|

|

|

|

|||

|

BK |

|

|

|

|

P2-4 |

|

|

|

|

|

|

R |

|

|

|

|

OR P6 |

|

R |

|

|

|

|

|

||||

|

|

G |

|

P3-5 |

BAKE RELAY |

|

|

|

|

|

|

|

DLB RELAY |

|

|

|

|

|

|

|

|

|

BAKE ELEMENT |

|

|

||||

|

|

|

|

|

|

|

|

|

|

R |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

L1 |

L2 |

|

L1 |

|

L2 |

|

L1 |

|

L2 |

|

L1 |

L2 |

||

P |

LF |

P |

|

LR |

|

P |

|

RF |

|

|

P |

RR |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

H1 |

H2 BK |

2B |

H1 |

|

H2 Y |

2B |

H1 |

H2 |

BR |

|

H1 |

H2 |

BU |

|

BK |

2A |

Y |

|

2A |

BR |

2A |

2B |

|

R |

2A |

2B |

|||

|

1A |

1B |

|

1A |

1B |

|

1A |

1B |

|

|

1A |

1B |

||

|

V |

|

|

|

V |

|

|

|

|

V |

|

|

|

V |

|

|

|

|

|

|

|

BU |

|

|

|

BU |

|

SURF |

|

BU |

|

|

|

|

|

|

|

|

|

|

|

IND. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

LIGHT |

|

SURF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IND. |

LF |

|

|

|

LR |

HOT SURFACE |

|

|

RF |

|

RR |

|

|

|

LIGHT |

|

|

|

IND. LIGHTS |

|

|

|

|

|

|||||

N |

|

|

|

|

|

|

|

|

|

SUR. |

L1 |

L2 |

N |

|

|

|

|

|

|

|

|

|

|

IND. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

LIGHT P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INF. SWITCH |

|

|

|

|

|

|

|

|

|

|

|

H1 |

H2 |

|

(OPTIONAL) |

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

COIL ELEMENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-2

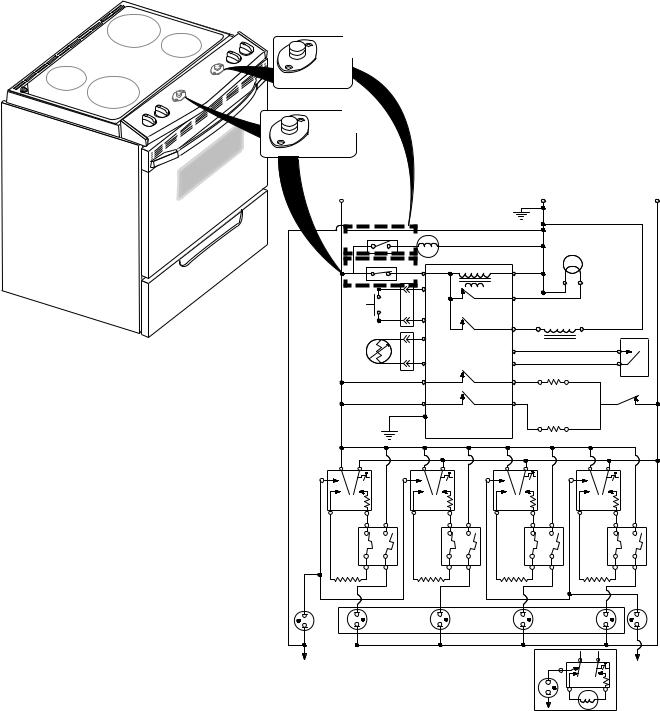

THE BIMETAL SWITCHES

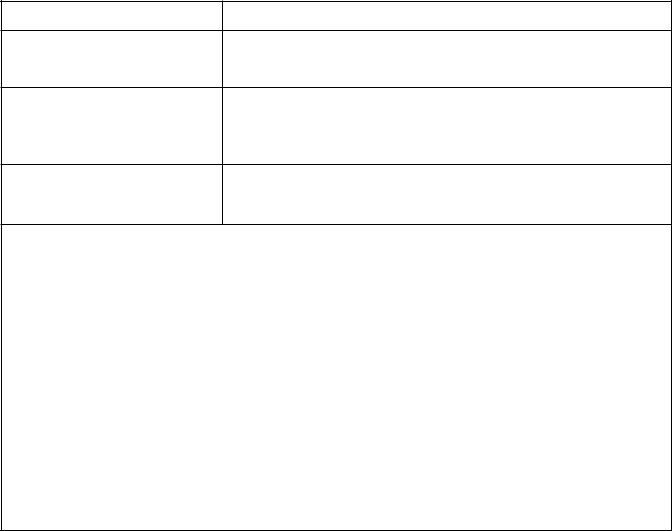

There are two bimetal switches on the electric range. The switches operate as follows:

•Ambient Bimetal Switch (N.C.)

(Inset #1) —This switch is located under the left side of the control console. It opens the L1 circuit to the electronic control board if the console temperature reaches 96˚C/205˚F.

•Cooling Fan Bimetal Switch (N.O.) (Inset #2) —This switch is located under the right side of the control console. It turns the cooling fan on if the console temperature reaches 70˚C/158˚F.

Inset #2

COOLING

FAN BIMETAL

SWITCH

Inset

AMBIENT

BIMETAL SWITCH

L1 |

|

|

|

L2 |

BK |

|

|

|

R |

|

|

|

GND |

|

|

|

|

|

|

BI - METAL SW FAN N.O. |

M |

|

|

|

Y |

Y |

W |

|

|

|

|

|||

BI-METAL SW |

|

|

OVEN CONTROL |

OVEN LT. |

AMBIENT N.C. |

|

|

||

|

P4-3 TRANSFORMER P4-1 W |

|||

BK |

BK |

|

||

Y |

P3-3 |

|

W

P4-4 R

|

DOOR |

|

|

|

OVEN LIGHT |

|

|

|

|

|

|

|

|

|

|

SW. |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

Y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P3-4 |

|

|

|

|

|

DOOR LOCK |

|

|

|

||

|

|

|

|

|

|

|

BR |

W |

|

|

||||

|

|

|

|

|

|

|

P4-5 |

SOLENOID |

|

|

||||

|

|

|

V |

P3-6 |

LATCH RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

OVEN |

|

|

|

|

|

P3-1 |

BU |

|

|

|

|

|

|

|

TEMP |

|

|

|

|

|

|

|

|

|

|

N.O. |

||

|

SENSOR |

|

V |

P3-7 |

|

|

|

BU |

|

|

|

|||

|

|

|

|

P3-2 |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

COM |

|||

|

|

|

|

|

|

|

|

|

BROIL ELEMENT |

|

||||

|

BK |

|

|

P2-2 |

|

|

P2-1 |

V |

BU |

|

DOOR |

|||

W |

|

|

|

|

|

|

|

|

||||||

|

|

|

|

BROIL RELAY |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

LATCH SW. |

|||

|

|

|

|

P2-3 |

|

|

|

|

|

|

|

|||

|

BK |

|

|

|

|

P2-4 |

|

|

|

|

|

|

R |

|

|

|

|

OR P6 |

|

R |

|

|

|

|

|

||||

|

|

G |

|

P3-5 |

BAKE RELAY |

|

|

|

|

|

|

|

DLB RELAY |

|

|

|

|

|

|

|

|

|

BAKE ELEMENT |

|

|

||||

|

|

|

|

|

|

|

|

|

|

R |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BK |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

L1 |

L2 |

|

L1 |

|

L2 |

|

L1 |

|

L2 |

|

L1 |

L2 |

||

P |

LF |

P |

|

LR |

|

P |

|

RF |

|

|

P |

RR |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

H1 |

H2 BK |

2B |

H1 |

|

H2 Y |

2B |

H1 |

|

H2 |

BR |

|

H1 |

H2 |

BU |

BK |

2A |

Y |

|

2A |

BR |

|

2A |

2B |

|

R |

2A |

2B |

||

|

1A |

1B |

|

1A |

1B |

|

|

1A |

1B |

|

|

1A |

1B |

|

|

V |

|

|

|

V |

|

|

|

|

V |

|

|

|

V |

|

|

|

|

|

|

|

|

BU |

|

|

|

BU |

|

SURF |

BU |

|

|

|

|

|

|

|

|

|

|

|

|

IND. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

LIGHT |

|

SURF |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

IND. |

LF |

|

|

|

LR |

HOT SURFACE |

|

|

RF |

|

RR |

|

|

|

LIGHT |

|

|

|

IND. LIGHTS |

|

|

|

|

|

|||||

N |

|

|

|

|

|

|

|

|

|

SUR. |

L1 |

L2 |

N |

|

|

|

|

|

|

|

|

|

|

IND. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LIGHT P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INF. SWITCH |

|

|

|

|

|

|

|

|

|

|

|

H1 |

H2 |

|

(OPTIONAL) |

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

COIL ELEMENT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-3

Loading...

Loading...