Page 1

96M11880

3D Laser Scanning Microscope

VK-X100K/X105/X110

VK-X200K/X210

User’s Manual

Read this manual before using the system in order to achieve maximum

performance.

Always keep this manual in a safe place for future reference.

Getting Started

1

Set-Up

2

Before Measuring

3

Mounting Optional Devices

4

5

Appendix

Maintenance

Dimensions/Specifications

Page 2

Introduction

CAUTION

This manual describes the handling, operating procedures and precautions for the “3D Laser Scanning

Microscope VK-X100K/X200K Series.”

Read this manual thoroughly before using the system to get the maximum performance out of the “3D

Laser Scanning Microscope VK-X100K/X200K Series.”

Keep this manual at hand for reference whenever needed.

Symbols

This manual uses the following symbols to show important information at a glance.

Be sure to read this section.

DANGER

WARNING

NOTICE

Important

Reference

It indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

It indicates a situation which, if not avoided, could result in product

damage as well as property damage.

It indicates cautions and limitations that must be followed during

operation.

Point

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

It indicates reference pages in this manual or other manual.

Precautions

• Reprinting any part or all of this manual without permission is prohibited.

• Please note that the content of this manual is subject to change without notice for the purpose of

improvement.

• Should you find any problem with the content of this manual, such as an unclear point, mistake, or erro-

neous omission, contact your nearest KEYENCE office.

• If there are missing or misplaced pages, we will provide a new copy of this manual.

The company names and product names used in this manual are registered trademarks or trademarks of

their respective companies.

Page 3

Safety Information for VK-X100K/VK-X200K Series

WARNING

CAUTION

NOTICE

To prevent damage and to correctly use the “3D Laser Scanning Microscope VK-X100K/X200K Series”

(VK-X100K/X200K Series), follow the precautions below.

Precautions for use

• Do not use this product for the purpose to protect a human body or a part of human body.

• This product is not intended for use as explosion-proof product. Do not use this product

in a hazardous location and/or potentially explosive atmosphere.

• Confirm that the components of our product are working normally before use.

• Considering the possibility of our product failing, use the product after implementing

sufficient safety measures to prevent any damage.

• Do not allow any foreign material to enter inside. It may result in fire, electric shock,

malfunction or accident.

• Never remove the case cover of the VK-X100K/X200K Series. Touching the inside may

result in an electric shock.

• Do not touch the lens revolver while it is moving, doing so risks catching hands or fingers

in the mechanism.

• The VK-X100K/X200K Series is grounded to the case. Make sure that the device is properly

insulated if installed in a high-noise environment or a positive ground situation. Failure to

do so may cause damage or electric shock.

• Please note we cannot guarantee the function and performance of products that are

modified or used outside of the ratings shown in the specifications.

• When our product is used in conjunction with equipment from other companies, the

normal function and sufficient performance may not be attained depending on the

condition of use and the environment. Be sure to make sufficient assessment before such

use.

• As the VK-X100K/X200K series uses precision optics, avoid any vibration or impact. Doing

so may cause damage.

• Make sure that the power of the VK-X100K/X200K Series is turned off before removing/

inserting the power cable, controller cable, or camera cable. Doing so may cause failure.

• Make sure that the lens does not come in contact with the sample. Doing so may cause

damage.

• Do not place objects that weigh more than 5 kg on the X-Y stage. Doing so may cause

damage.

not

• Do

• Do not remove/insert the USB cable while the ACCESS lamp on the control unit is lit. Doing

turn the power off during measurement. Otherwise, some or all of the settings may

be lost.

so may cause damage.

96M11880

1

Page 4

Safety Information for VK-X100K/VK-X200K Series

Important

CAUTION

NOTICE

CAUTION

NOTICE

Important

• Make sure that the ambient temperature is stable during measurements.

• Wait one hour or more for preheating after turning on the power before taking

measurements.

• When the lens section is dirty, clean it with the lens blower or with a cotton swab

dipped in alcohol.

• Make sure that the device is not subject to vibration during measurement. It is

recommended that an anti-vibration stand be used.

• The measurement unit, the controller cable A/B, and the camera cable are adjusted

together as a set. Make sure that all of them bear the same serial number.

Precautions for abnormalities

Turn off the power immediately in the following cases. Using the unit in abnormal conditions

could cause fire, electric shock, or accident. Contact your nearest KEYENCE office for repair.

• If water or foreign material enters inside the VK-X100K/X200K Series.

• If the unit is dropped or the case is damaged.

• If the unit emits smoke or odor.

Back up all data saved on the control PC before sending it in for repairs. The repair procedure

carries a risk of data loss.

Additionally, regular periodic backups are recommended.

Precautions for installation

Install the VK-X100K/X200K series so that it is level. There is a risk of the falling unit causing

injuries.

• Do not obstruct the ventilation hole or the ventilation fan of the control unit. Internal

temperature increases may result in damage.

Avoid installation in the following locations. Doing so may cause failure.

• Locations where the device will be subject to direct vibrations

• Locations where the ambient temperature drops below 15°C or exceeds 28°C

• Locations where the ambient humidity drops below 35% RH or exceeds 65% RH (no

condensation)

• Locations where the temperature changes rapidly

• Locations where the device will be exposed to a direct breeze from an air conditioner

• Locations where there are corrosive gases or volatile inflammable materials

• Locations with large amounts of airborne dust, salt, iron or greasy fumes

• Locations with a risk of exposure to airborne water, oil or chemical droplets

• Locations where a strong magnetic or electric field is generated

• Locations where the voltage varies greatly

• It is recommended that the device be installed on a commercially available anti-

vibration stand.

2

VK-X100K/X200K User’s Manual

Page 5

Precautions for the power supply

WARNING

CAUTION

The VK-X100K/VK-X200K Series is Class I equipment. When installing this device, connect

the protective grounding terminal of the power supply cord set to the protective grounding

conductor of the installation place.

Otherwise, it may cause electric shock or product damage.

• Do not bend forcefully or put any heavy objects on the power cable. Doing so may lead to

a cable break, resulting in fire or electric shock. Do not use a damaged cable.

• Make sure to use the VK-X100K/X200K Series under proper power supply voltage;

otherwise, an electric shock, fire or product malfunctions may occur.

• The power supply cord set is not provided with the VK-X100K/X200K Series. Use a power

cable that complies with the regulations and standards in the country or the region in

which the VK-X100K/X200K Series are used.

Safety Information for VK-X100K/VK-X200K Series

VK-X100K/X200K User’s Manual

3

Page 6

Safety Information for VK-X100K/VK-X200K Series

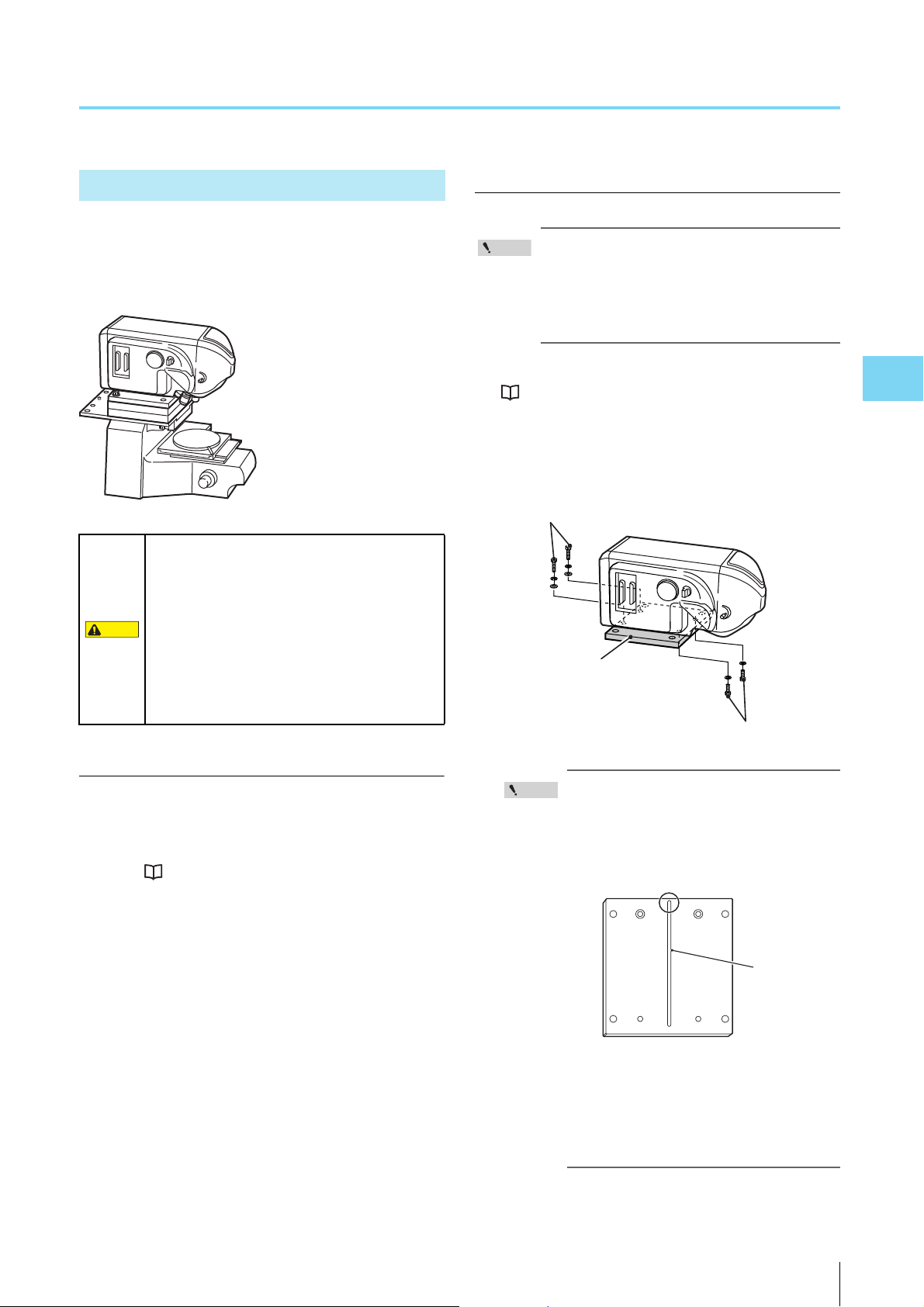

CAUTION

Fixing metal fittings

Precautions for transportation

• When transporting the device, carry it by holding the indentation in the measurement unit

or the handle of the pedestal. Carrying the device by the measurement portion may

damage it. There is also a chance of injury or damage if the device falls.

• Carry the measurement portion of the device by the recessed portions on the front and

back of the unit.

• Be sure to fix the X-Y stage with a fixture before transportation. Be sure to also lock the Z

stage using the focusing handle.

4

VK-X100K/X200K User’s Manual

Page 7

• As the VK-X100K/X200K series uses precision optics, avoid any vibration or impact. Doing

NOTICE

Important

NOTICE

NOTICE

so may cause damage.

• Be sure to remove the objective lenses from the revolver when transporting. Doing so may

cause damage.

• Be sure to use packaging materials specified by KEYENCE for transportation. Doing so

may cause damage.

• The VK-X100K/X200K Series is a super precision optical instrument. Sudden changes in

temperature may result in damage, including condensation and misalignment of the

optical axis. Leave the device at room temperature (between 15°C and 28°C) for 24 hours

after unpacking.

• The removed fixing metal fittings and the lens cases are required when the VK-X100K/

X200K Series are transported. Be sure to keep them in a secure location.

Precautions for storage

Safety Information for VK-X100K/VK-X200K Series

• Store the device in its packaging if it will not be used for a long period of time. Doing so

may cause failure.

Avoid storing in the following locations. Doing so may cause failure.

• Locations where the device will be subject to direct vibrations

• Locations where the ambient temperature drops below 0°C or exceeds +40°C

• Locations where the ambient humidity drops below 35% RH or exceeds 65% RH (no

condensation)

• Locations where the temperature changes rapidly

• Locations where there are corrosive gases or volatile inflammable materials

• Locations with large amounts of airborne dust, salt, iron or greasy fumes

• Locations with a risk of exposure to airborne water, oil or chemical droplets

• Locations where a strong magnetic or electric field is generated

• Locations where the device may be exposed to direct sunlight, wind, or rain

• Locations that are unstable or where the device may fall

Other precautions

When VK-X100K/X105/X110/X200K/X210 gets dirty, clean with a dry cloth.

VK-X100K/X200K User’s Manual

5

Page 8

Safety Precautions on Laser Products

WARNING

WARNING

Use of controls, adjustments or procedures other than those specified herein may result in

hazardous laser radiation exposure.

The VK-X100K/X200K Series employ a semiconductor laser as the light source.

Model VK-X100K/X105/X110 VK-X200K/X210

Wavelength 658 nm (Red laser) 408 nm (Violet laser)

Output 0.95 mW 0.95 mW

Pulse width 1 ns —

Follow the instructions mentioned in this manual. Otherwise, injury to the human body (eyes

and skin) may result.

Precautions on Class 2 Laser Products

• Do not disassemble this product. Laser emission from this product is not automatically

stopped when it is disassembled.

• Do not stare into the direct or specularly reflected beam.

• Do not direct the beam at people or into areas where people might be present.

• Be careful of the path of the laser beam. If there is a possibility that the operator may be

exposed to the specular or diffuse reflections, block the beam by installing a protective

enclosure.

• Install this product so that the path of the laser beam is not as the same height as that of

human eye.

A Warning label is attached to the microscope unit as shown below.

VK-X105/X110

6

VK-X100K/X200K User’s Manual

Page 9

VK-X210

Laser Aperture

Warning label

Label Location

Safety Precautions on Laser Products

VK-X100K/X200K User’s Manual

7

Page 10

Precautions on Regulations and Standards

Wind so that 3 cables are going through

the clamp.

Install so that 1 cable is going through

the clamp.

CE Marking

Keyence Corporation has confirmed that this product complies with the essential requirements of the

applicable EC Directives, based on the following specifications. Be sure to consider the following specifi-

cations when using this product in a Member State of the European Union.

EMC directive (2004/108/EC)

• Applicable Standard EMI: EN61326-1, Class A

EMS: EN61326-1

1 Install the sleeve ferrite clamp ZCAT3035-1330 (TDK) at both ends of the USB cable.

2 Install the sleeve ferrite clamp ZCAT2035-0930A-BK(TDK) at the end of the camera cable (at the

side of the measurement unit).

8

VK-X100K/X200K User’s Manual

Page 11

Precautions on Regulations and Standards

Remarks:

These specifications do not give any guarantee that the end-product with this product incorporated com-

plies with this essential requirements of EMC Directive. The manufacturer of the end-product is solely

responsible for the compliance on the end-product itself according to EMC Directive.

Low-Voltage directive (2006/95/EC)

• Applicable Standard EN61010-1

EN60825-1 Class 2 laser product

• Overvoltage Category II

• Use this product under pollution degree 2.

• Install this product at an altitude of 2000 m or less.

• Indoor use only.

• This product is designed as a Class I equipment. Be sure to connect the protective earthing terminal on

the AC power cable to the protective earthing conductor in the building installation.

• The AC power inlet falls under a disconnecting device. Install this product to be able to remove the AC

cord set from the AC power inlet in abnormal situations immediately.

CSA Certification

This product complies with the following CSA and UL standards and has been certified by CSA.

• Applicable standard: CAN/CSA C22.2 No. 61010-1

UL61010-1

Be sure to consider the following specifications when using this product as a product certified by CSA.

• Overvoltage category II

• Use this product under pollution degree 2.

• Install this product at an altitude of 2000 m or less.

• Indoor use only.

• This product is designed as a Class I equipment. Be sure to connect the protective earthing terminal on

the AC power cable to the protective earthing conductor in the building installation.

• The AC power inlet falls under a disconnecting device.

Install this product to be able to remove the AC cord set from the AC power inlet in abnormal situations

immediately.

VK-X100K/X200K User’s Manual

9

Page 12

Precautions on Regulations and Standards

MEMO

10

VK-X100K/X200K User’s Manual

Page 13

Organization of This Manual

1

2

3

4

5

A

Chapter

1

Getting Started

Chapter

2

Set-Up

Chapter

3

Before Measuring

Chapter

4

Mounting Optional Devices

Chapter

5

Maintenance

Appendix

Dimensions/Specifications

This chapter describes the principles of the VK-X100K/X200K, the contents of the

packaging and the names of each part.

This chapter describes how to assemble the microscope unit and how to connect

each device.

This chapter describes the preparation and basic adjustments to be made before

taking measurements.

This chapter describes the optional devices and how to install them.

This chapter describes the procedure for replacing the lamp and the fuse in the

control unit.

This chapter describes the specifications and dimensions of the device.

VK-X100K/X200K User’s Manual

11

Page 14

Table of Contents

Safety Information for VK-X100K/VK-X200K Series .............................................................. 1

Safety Precautions on Laser Products ................................................................................. 6

Label Location .................................................................................................................7

Precautions on Regulations and Standards ......................................................................... 8

CE Marking ...................................................................................................................... 8

CSA Certification ............................................................................................................. 9

Organization of This Manual ............................................................................................... 11

Table of Contents ............................................................................................................... 12

Chapter 1 Getting Started

Summary of the VK-X100K/X200K Series ......................................................................... 1-2

Principles of the VK-X100K/X200K Series .................................................................... 1-2

System Configuration ................................................................................................... 1-5

Operating Environment ................................................................................................ 1-6

Unpacking ......................................................................................................................... 1-8

Unpacking the Control Unit and Control PC ................................................................ 1-8

Unpacking the Microscope Unit .................................................................................. 1-8

Checking the Package Contents ....................................................................................... 1-9

Checking the Installation Environment ............................................................................ 1-11

Part Names and Functions .............................................................................................. 1-12

Microscope Unit (Left/Front View) .............................................................................. 1-12

Microscope Unit (Right/Front View) ........................................................................... 1-13

Control Unit (Front View) ............................................................................................ 1-14

Control Unit (Rear View) ............................................................................................. 1-14

Chapter 2 Set-Up

Assembling the Microscope Unit ...................................................................................... 2-2

Unlocking the X-Y Stage Lock ..................................................................................... 2-2

Mounting the Rotating Stage ........................................................................................ 2-2

Mounting Optional Devices .......................................................................................... 2-2

Mounting the Objective Lenses ................................................................................... 2-3

Connections ...................................................................................................................... 2-4

Connection Diagram .................................................................................................... 2-4

Connection Procedure ................................................................................................. 2-6

12

VK-X100K/X200K User’s Manual

Page 15

Table of Contents

Chapter 3 Before Measuring

Sequence of Preparation before Measuring ..................................................................... 3-2

Startup and Shutdown ....................................................................................................... 3-3

Starting Up the System ................................................................................................ 3-3

Shutting Down the System ........................................................................................... 3-4

Measurement Basics (For Proper Measurement) ............................................................. 3-5

A Variety of the Standard Objective Lens and How to Select One .............................. 3-5

Correction in the Film Thickness Measurement ........................................................... 3-6

Adjusting the Positions of the Laser and the Camera .................................................. 3-7

Adjusting the Measurement Unit ....................................................................................... 3-8

Initializing Lens Position ............................................................................................... 3-8

Adjustment of the Observation Position/Magnification ................................................ 3-9

Adjusting Focus/Brightness ....................................................................................... 3-10

Chapter 4 Mounting Optional Devices

List of Optional Devices .................................................................................................... 4-2

Removing/Mounting the Measurement Unit ...................................................................... 4-4

Removing the Measurement Unit ................................................................................. 4-4

Conditions for Mounting the Measurement Unit ........................................................... 4-5

Mounting the Measurement Unit .................................................................................. 4-6

Mounting the Spacer for the VK-X210 ............................................................................... 4-7

Package List ................................................................................................................. 4-7

How to Use the Spacer ................................................................................................ 4-7

Mounting Spacers ...................................................................................................... 4-10

Mounting the Spacer for the VK-X105/X110 .................................................................... 4-12

Package List ............................................................................................................... 4-12

How to Use the Spacer .............................................................................................. 4-12

Mounting Spacers ...................................................................................................... 4-15

Mounting a 300 mm Wafer X-Y Stage ............................................................................. 4-17

Package List ............................................................................................................... 4-17

Mounting a 300 mm Wafer X-Y Stage ........................................................................ 4-17

Names and Functions of the Components of the 300 mm Wafer X-Y Stage ............. 4-19

Mounting the Stand for VK .............................................................................................. 4-20

Package List ............................................................................................................... 4-20

Mounting the Stand for VK ......................................................................................... 4-21

How to Use the Stand for VK ...................................................................................... 4-22

VK-X100K/X200K User’s Manual

13

Page 16

Table of Contents

Chapter 5 Maintenance

Replacing the Lamp in the Control Unit ............................................................................ 5-2

Replacing the Fuse ........................................................................................................... 5-4

Appendix

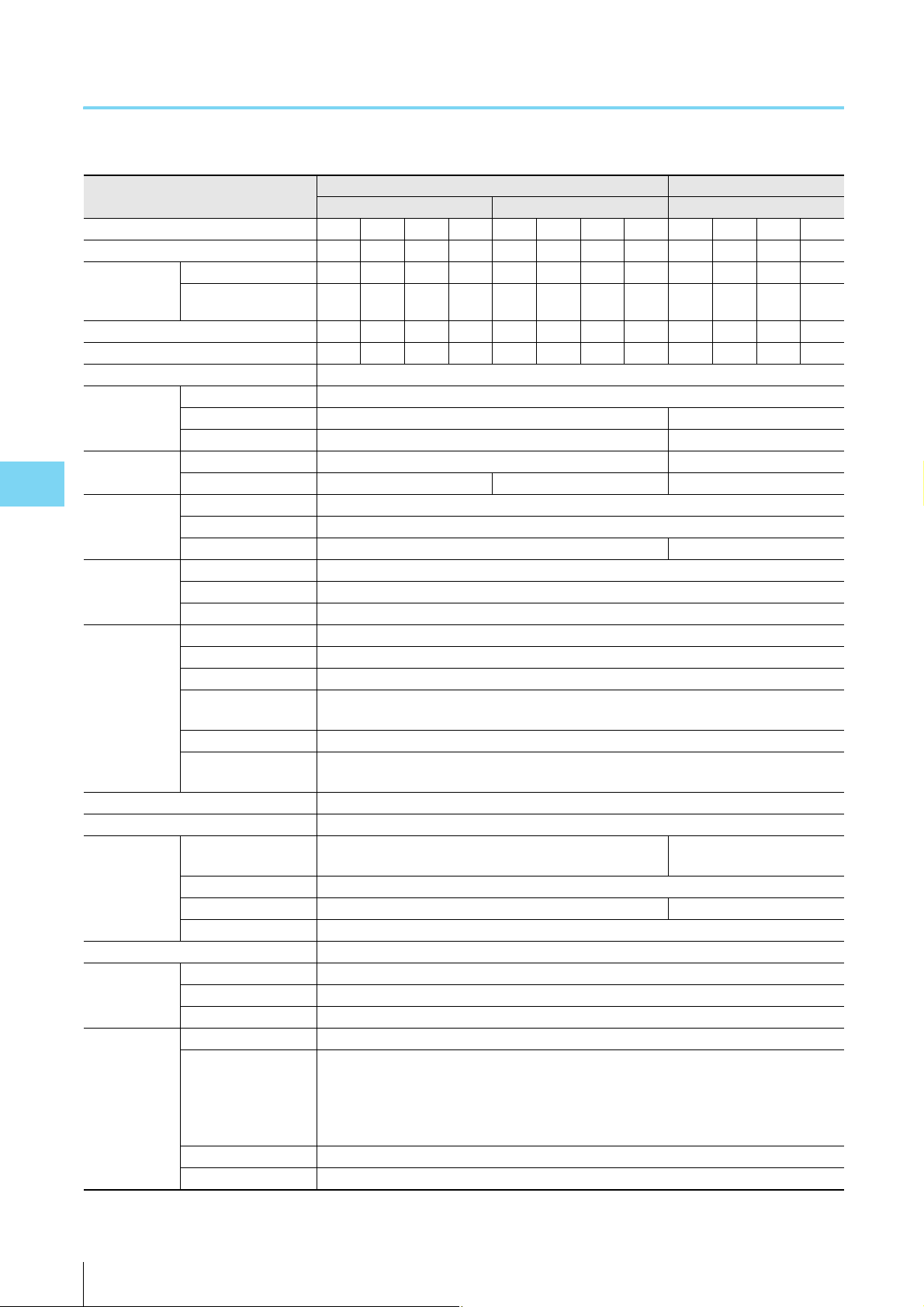

Specifications ....................................................................................................................A-2

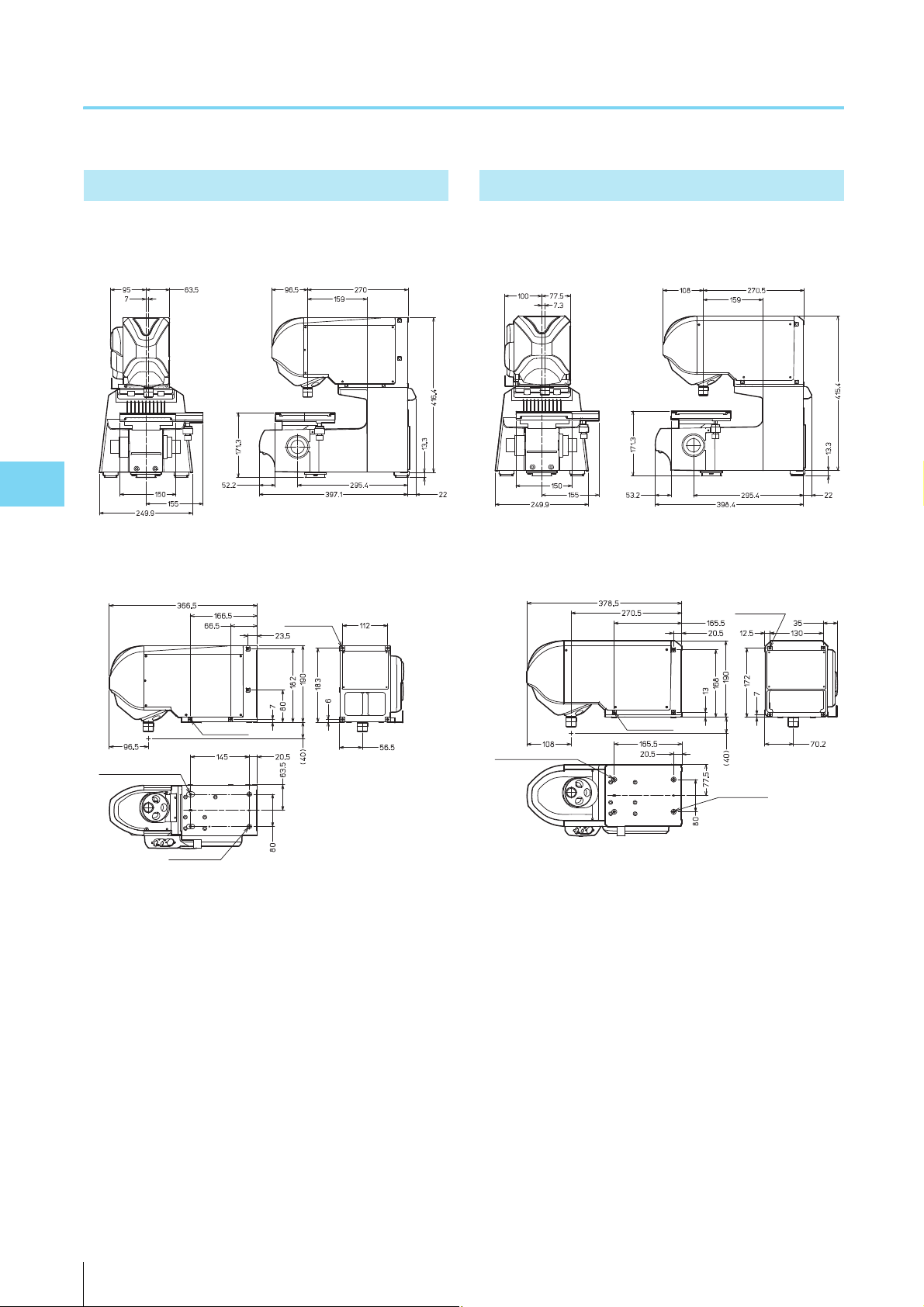

Dimensions ........................................................................................................................A-4

VK-X105/X110 .............................................................................................................. A-4

VK-X210 ....................................................................................................................... A-4

VK-X100K/X200K (Control Unit) ...................................................................................A-5

Index ..................................................................................................................................A-6

14

VK-X100K/X200K User’s Manual

Page 17

1

Chapter

1

Getting Started

This chapter describes the principles of the VK-

X100K/X200K, the contents of the packaging and

the names of each part.

Getting Started

Summary of the VK-X100K/X200K Series ............ Page 1-2

Unpacking ............................................................. Page 1-8

Checking the Package Contents ........................... Page 1-9

Checking the Installation Environment .................Page 1-11

Part Names and Functions .................................. Page 1-12

VK-X100K/X200K User’s Manual

1-1

Page 18

1

Summary of the VK-X100K/X200K Series

Conventional optics

Laser

Half

Mirror

Photoreceptor

Sample

Confocal laser optics

Laser

Half

Mirror

Photoreceptor

Sample

Pinhole

Laser

Half

Mirror

Photoreceptor

Sample

Laser

Half

Mirror

Photoreceptor

Sample

Pinhole

Conventional optics

Confocal laser optics

This manual gives a summary of the VK-X100K/X200K

Series, which offers both magnified observation and height

measurements.

Getting Started

Principles of the VK-X100K/X200K Series

Confocal laser optics

The VK-X100K/X200K Series is equipped with laser confo-

cal technology that obtains images with a large depth of

field that are in focus across the entire screen and that

detect the finest details in the sample shape data.

In the laser confocal optics, a pinhole in front of the position

where the reflected light from the sample forms an image

(photoreceptor) ensures that no light other than that which

passes through the focal point of the objective lens reaches

the photoreceptor. Use of this type of optics as a sensor

allows for the maximum possible amount of light to reach

the photoreceptor and allows changes in the focal point to

be measured and used as height information. Additionally,

use of this technology in a microscope creates a device

with almost no flare and significantly better contrast than a

standard optical microscope.

The VK-X100K/X200K Series combines this laser confocal

optics with a high-speed X-Y scanner to create a high res-

olution focal image and gather height information (shape

and roughness) from the sample.

When out of focus

While conventional optics allow all of the reflected light into

the photoreceptor, confocal laser optics allow only a frac-

tion.

When in focus

Both conventional optics and confocal laser optics allow all

of the reflected light to enter the photoreceptor.

1-2

VK-X100K/X200K User’s Manual

Page 19

1

Principles of operation of the VK-X100K/X200K Series

Laser light source

Focusing lens

Pinhole

Photoreceptor

Polarizing

beam splitter

Objective lens

Sample

Half

mirror

Color CCD camera

X-Y Scan

Optics

White light source

Summary of the VK-X100K/X200K Series

Getting Started

The VK-X100K/X200K Series uses a two-way light source

comprised of a laser light source and a white light source.

The two light sources together provide the colors, laser

intensity and height information necessary to create deep

field color images, laser intensity images or height images.

Detection of intensity and height with laser

light

The light emitted from the laser light source of the laser

microscope is focused onto the surface of the sample via X-

Y scan optics and objective lens. The focused spot light

scans the image area within the field of view using the X-Y

scan optics. By dividing the field of view into 1024×768 pix-

els*1 to scan the image, the reflected light at each pixel is

detected by the photoreceptor.

By driving the objective lens in the Z axis to repeat the scan

of the image, the intensity of each pixel at every position on

the Z axis is obtained. With the Z axis position of the highest

intensity being the focal point, the height information and

the laser intensity are detected. This allows for in focus

laser intensity and height images to be obtained.

*1 When the measurement quality is “Fine”, 2048×1536 pixels

are used, and when “Super fine”, 3072×2403 pixels are used.

Height

information

Z axis position

[Z position]

Color

information

Received light intensity

[Intensity]

The device reads the intensity of each Z position for each of

the pixels on the 1024×768 pixel screen and determines

the Z axis position (= focal point) of the maximum intensity,

and records the intensity and color information for that posi-

tion. Based on this information, three types of image data

are constructed, a deep field color image, a laser intensity

image and a height image.

Creating a color image with a CCD camera

On the other hand, the light reflected from the white light

source is detected by the CCD camera. Color observation

in the natural colors as seen by the naked eye is achieved

by obtaining the color information for each pixel at the focal

point detected by the laser.

Focal point

Intensity

information

VK-X100K/X200K User’s Manual

Introduction to the digital microscope

functions

The VK-X100K/X200K Series have the same optics design

as a metal microscope with lens barrel, coaxial incident

light illumination optics and CCD camera built-in in the

measurement unit.

1-3

Page 20

Summary of the VK-X100K/X200K Series

1

1024 x 768 pixels

Laser light

1

2

3

4

Scan with the

laser in the

XY direction

Move the

objective lens

along the Z

axis and scan

with the laser

again

Repeat as

many times

as the Z

measurement

distance

End of

measurement

Z measurement

distance

The CCD image sensor is equipped with a pixel shift

method CCD camera with a maximum of 21.6 million

recording pixels, allowing for the capture of clear and high

resolution magnified observation images. Combined with

Getting Started

the digital zoom function, this offers high magnification

observation of up to 18000x*2.

*2 The VK-X200K Series allows observation at up to 24000x

magnification.

Data acquisition flow

Optics (area image sensing)

Electric signal processing

7. Each time the lens moves, the laser intensity, the RGB

data from the CCD camera and the linear scale value

at the time of storing the data are recorded in the focal

point memory (1024 × 768 pixels) of the control unit

(VK-X100K/X200K Series).

8. During the data acquisition, the laser intensity at each

pixel is monitored. This means that laser intensities

higher than those stored in the memory of the control

unit (VK-X100K/X200K Series) (i.e. light that is not

attenuated when it reaches the photoreceptor after

passing through the pinhole) will replace the previous

CCD camera RGB data, laser intensity and linear scale

values.

* When RPD mode is active, the peak value (focal point

position) of the laser intensity is calculated based on changes

in the laser intensity values gathered according to the pitch

set by the numerical aperture of the objective lens and the

result is stored in memory.

Output data creation

1. Laser light from a semiconductor laser scans first by a

resonant (horizontal) scanner in the horizontal direc-

tion.

2. The light then scans by a galvano (vertical) scanner in

the vertical direction producing an area scanning

beam.

3. The laser light that reflects off of the sample passes

through a polarized beam splitter in front of the laser

light source and then reaches the focusing lens, the

pinhole and the photoreceptor (photomultiplier).

4. Light that has passed through the focusing lens and is

focused at the pinhole only passes through the pinhole

reaching the photoreceptor (laser light that is out of

focus does not reach the photoreceptor).

5. The electrical signal sent by the photoreceptor upon

receiving the laser light is transformed into an image

(area information) based on sampling coupled with the

vertical and horizontal movements of the scanner.

6. Once image area scanning has completed, the lens

moves one step in the Z direction, where one step is

equal to the pitch, and repeats the scan.

1-4

VK-X100K/X200K User’s Manual

9. By repeating the optics and electrical signal process-

ing operations (steps 1 through 8), at the end of gath-

ering data, each pixel contains the RGB values to be

stored from the CCD camera, the laser intensity, and

the linear scale value of the location where the laser

intensity is highest.

By combining the data, a color image that is completely

in focus, a black and white image based on the laser

intensity, and a height (contrast) image based on the

linear scale value can be created.

Page 21

1

System Configuration

Stand (OP-82693)

Measurement unit (VK-X105/X110/X210)

Spacer (OP-38162/51246)

Large sample stage

Control unit (VK-X100K/X200K)

Display

Control

PC

Anti-vibration stand

300 mm wafer X-Y stage

(OP-51498)

Electric X-Y stage

(VK-S100K/S105/S110)

Observation Application

(VK-H1XVE)

Analysis Application

(VK-H1XAE)

Basic system Option

Particle Analysis Module

(VK-H1XG)

Image Assembling Application

(VK-H1XJ)

Measurement Analysis Module

(VK-H1XP)

ISO-25178 Surface Texture

Measurement Module (VK-H1XR)

The VK-X100K/X200K Series offers basic system along with optional devices and applications.

Summary of the VK-X100K/X200K Series

Getting Started

VK-X100K/X200K User’s Manual

1-5

Page 22

Summary of the VK-X100K/X200K Series

1

Important

•Measurement unit (VK-X105/X110/X210)

Measurement unit with semiconductor laser, color CCD

camera and scan optics built-in. This is used as a micro-

scope mounted on the pedestal provided.

Getting Started

• Control unit (VK-X100K/X200K)

The laser, CCD camera controller, scanner control board,

100 W halogen lamp that serves as the light source, and

so on are all built-in the control unit.

•Observation Application (VK-H1XVE)

This software controls the VK-X100K/X200K Series to cre-

ate laser intensity and height images. It adjusts the cam-

era shutter, the gain on the photoreceptor and the

scanning format.

The Observation Application is not

functional unless a control unit (VK-X100K/

X200K) is connected.

• Analysis Application (VK-H1XAE)

This software obtains data for color observation with high

contrast, image processing for 3D displays, and opera-

tion/analysis processing of shape measurement and sur-

face roughness from the laser intensity data and height

data obtained by the Observation Application.

Operating Environment

To activate the VK-X100K/X200K Series, an environment

that meets the following conditions is required.

Control PC main specifications

Item Specifications

Control

PC

OS Windows 7 Professional 32-bit

CPU Intel Core™2 Duo E6300 or higher

Memory 2048 MB or more

USB port USB 2.0

HDD 160 GB or more

Video card KEYENCE-specified product (NVIDIA

The control PC that can be used with the VK-

X100K/X200K Series is KEYENCE-specified one.

Windows 7 Professional 64-bit

Windows Vista Business 32-bit (SP1 or later)

Windows XP Professional Edition 32-bit

(SP3 or later)

must be pre-installed.

(DirectX 9 or later)

®

Quadro®

FX600 1024 MB)

• Control PC

This is the control PC for the VK-X100K/X200K Series

(KEYENCE-specified product).

•Display

Use a display recommended by KEYENCE or a commer-

cially available one.

• Optional devices

For the optional devices and installation, refer to

“Chapter 4 Mounting Optional Devices” (Page 4-1).

1-6

VK-X100K/X200K User’s Manual

Page 23

1

•Log on to the control PC with administrator

Important

privileges.

• Set all of the power settings to “None” on

the Power Options Properties dialog box for

the control PC.

• Do not use other software while the

Observation Application and the Analysis

Application are running. Doing so may

interfere with the device control.

•During measurement, the sleep feature of

the energy saving function is disabled. (It is

not necessary to disable the screen saver,

etc.)

• When you perform the sleep operation from

the Start Menu, the PC goes to sleep mode

even if measurement is in progress. In this

case, measurement is interrupted and the

measurement result will not be saved.

• If the control unit is connected while the

Observation Application is in use, using

Windows sleep feature may result in the

control unit being in the disconnected state

when recovering from sleep mode. Turn the

control unit power off and turn it on again or

pull out and re-insert the USB cable to re-

connect the control unit.

•Performing the sleep operation during 3D

display may result in the image on display

disappearing. Switch to another image

temporarily to display the 3D again.

• When using external media like USB device

or HDD (Hard Disk Drive) at the same time,

connect them to ports attached to a

different root hub.

Plugging/Unplugging other USB devices

with the same root hub as this device may

result in malfunction.

Summary of the VK-X100K/X200K Series

Getting Started

Display main specifications

Item Specifications

Resolution 1920 × 1080 pixels or more

VK-X100K/X200K User’s Manual

1-7

Page 24

1

Unpacking

NOTICE

Corner pad

Inner box

Outer box

Upper lid

Storage box

Cushion

Pad

Cushion pad

• Unpack after leaving it at 15 to 28ºC for 24

hours or more.

Getting Started

Unpacking the Control Unit and

The VK-X100K/X200K Series is a high

precision optical instrument. Sudden

changes in temperature may result in

damage, including condensation and

misalignment of the light beam.

• Save the packaging after installing the

device. Make sure to use this packing

material when shipping.

Control PC

Unpack the box containing the control unit and take out the

accessories and control unit.

Also unpack the boxes for the control PC and the display.

Unpacking the Microscope Unit

The microscope unit is packed in a special box. Unpack

according to the steps below.

1 Remove the corner pads and inner box from the

outer box.

3 Remove the cushion pads, taking the microscope

unit out.

When removing the microscope unit, carry it

by holding the indentation in the

NOTICE

measurement unit and the handle of the

pedestal. Holding the revolver unit (the part

where the lenses attach) may cause damage.

2 Remove the upper lid from the inner box and open

the storage box.

The flaps with round corners will be on the inside of the

storage box.

1-8

VK-X100K/X200K User’s Manual

When stored

Follow these procedures in reverse to transport the device

etc.

The flaps with round corners should be on the inside of the

storage box when closing it.

Page 25

1

Checking the Package Contents

Control unit: 1

* Between VK-X100K and VK-X200K, the

designs are partially different.

Controller A cable (male) 3 m: 1

Controller B cable (female) 3 m : 1

Standard Chart (OP-51633) : 1

Camera cable 3 m : 1

Fiber optic cable 3 m : 1

SCAN CONTROL cable 3 m : 1

* Packed with 3 cables bundled.

USB cable 3 m : 1

User’s Manual (this manual)

Hexagonal wrench: 1

Sleeve ferrite clamp ZCAT3035-1330 (TDK) : 2

ZCAT2035-0930 (TDK) : 1

When you unpack the VK-X100K/X200K Series, check that the parts and equipment listed below are included in the pack-

age.

We have thoroughly inspected the package contents before shipment. However, in the event of defective or broken items,

please contact the nearest KEYENCE office.

Control unit (VK-X100K/X200K)

Getting Started

VK-X100K/X200K User’s Manual

1-9

Page 26

Checking the Package Contents

1

Measurement unit: 1

Rotating stage: 1

Pedestal: 1

Standard objective lens 1 each

CF IC EPI Plan 5X (Nikon)

CF IC EPI Plan 10X (Nikon)

CF IC EPI Plan 20X (Nikon)

CF IC EPI Plan 50X (Nikon)

Measurement unit: 1

Rotating stage: 1

Pedestal: 1

Standard objective lens 1 each

CF IC EPI Plan 10X (Nikon)

CF IC EPI Plan 20X (Nikon)

CF IC EPI Plan 50X (Nikon)

CF IC EPI Plan 100X (Nikon)

Measurement unit: 1

Rotating stage: 1

Pedestal: 1

Standard objective lens 1 each

CF IC EPI Plan 10X (Nikon)

CF IC EPI Plan 20X (Nikon)

CF IC EPI Plan Apo 50X (Nikon)

CF IC EPI Plan Apo 150X (Nikon)

Microscope unit (VK-X105)

Getting Started

Microscope unit (VK-X110)

Microscope unit (VK-X210)

1-10

VK-X100K/X200K User’s Manual

Page 27

1

Checking the Installation Environment

170

Installation surface

Installation

surface

Top vi e w

Unit: mm

100

100

100

Top vie w

Unit: mm

The installation location of the VK-X100K/X200K Series

needs to meet the following conditions.

Installation environment

Item Conditions

Ambient

temperature

Humidity 35 to 65% RH (No condensation)

Floor

Vibration

+15 to +28°C

-3

1.5 x 10

Hz, the amplitude should be less than 3 μm)

m/s2 or less (For frequencies less than 5

Space requirement

Microscope unit

Control unit

Getting Started

• It is recommended that the control unit be installed at

least 100 mm from any walls or other structural objects.

• Be sure to ground the earth terminal attached to the AC

power connector of the device.

• Leave at least 170 mm of space to insert the cable.

• Use the installation surface to install the measurement

unit on the device or installation mount. Make sure that

the measurement unit is installed so that vibrations from

the frame are not transferred to the measurement unit.

• The outside cases of the devices are used as the ground

potentials for the circuits. Make sure that the device is

properly insulated if installed in a high-noise environ-

ment or a positive ground situation.

Control PC and display

Make sure to check the manuals that come with the control

unit and display to secure required installation space.

Power

Secure 3 power outlets for the control unit, control PC and

display.

VK-X100K/X200K User’s Manual

1-11

Page 28

1

Part Names and Functions

1

9

12

11

10

7

8

5

4

3

2

13

6

1

9

12

11

10

7

8

6

4

3

2

5

13

Reference

Reference

Microscope Unit (Left/Front View)

The VK-X100K/X200K Series microscopes use a measure-

ment unit that contains both a CCD camera and confocal

Getting Started

laser optics as well as a pedestal that includes the stage.

VK-X105/X110

VK-X210

4 LIGHT connector

Connects to the control unit via the provided fiber optic

cable.

5 SCAN CONTROL connector

Use the provided SCAN CONTROL cable to connect to

the control unit.

6 CAMERA connector

Connects to the control unit via the provided camera

cable.

7Focusing handle (Coarse)

8Focusing handle (Fine)

The focus can be adjusted by moving the X-Y stage up

and down.

Use Coarse for rough adjustment and Fine for precise

movement.

Focusing handles (Coarse and Fine) are

found on both sides of the device. The han-

dles on both sides operate exactly the same

way and produce the same adjustments.

1 LASER SHUTTER (Beam stop)

Switch OPEN/CLOSE for the laser aperture. The laser

can pass through to the sample when this is OPEN and

cannot when it is CLOSED.

2 CONTROLLER B connector

Connect this to the control unit with the provided con-

troller B cable.

3 CONTROLLER A connector

Connect this to the control unit with the provided con-

troller A cable.

1-12

VK-X100K/X200K User’s Manual

9 Y axis stage lock

Prevents the X-Y stage from moving in the Y axis.

10 X axis stage lock mechanism

Prevents the X-Y stage from moving in the X axis.

11 Rotating stage

Rotates, allowing the sample to be viewed from many

angles.

12 APERTURE SHUTTER (Aperture iris shutter)

You can adjust the brightness of the image by opening

and closing the aperture iris shutter.

Press the knob to open the shutter and brighten the

image.

Pull on the knob to close the shutter and darken the

image.

For the connection of each connector and

the cable, refer to “Connections” (Page

2-4).

13 Cord hook

Hook Fiber optic cable, SCAN CONTROL cable and

Camera cable to fix.

Page 29

Part Names and Functions

1

2

1

4

9

3

8

56 7

2

1

4

9

3

8

56 7

Microscope Unit (Right/Front View)

VK-X105/X110

VK-X210

4Focusing handle lock

Locks the focusing handles for transporting the micro-

scope unit.

LOCK : Locks the focusing handles.

RELEASE : Release the focusing handles.

Make sure the focusing handle lock

NOTICE

mechanism is in the LOCK position when

transporting the microscope unit.

5Focusing handle (Coarse)

6Focusing handle (Fine)

The focus can be adjusted by moving the X-Y stage up

and down.

Use Coarse for rough adjustment and Fine for precise

movement.

Reference

Focusing handles (Coarse and Fine) are

found on both sides of the device. The han-

dles on both sides operate exactly the same

way and produce the same adjustments.

Getting Started

7 X axis stage handle (left/right movement)

Moves the X-Y stage to the left or right.

8 Y axis stage handle (front/back movement)

Moves the X-Y stage forward or backward.

9Objective lens

VK-X105 : 5x, 10x, 20x, and 50x are available.

VK-X110 : 10x, 20x, 50x and 100x are available.

VK-X210 : 10x, 20x, 50x and 150x lenses are avail-

able.

1 Laser radiation emission warning

Lights up when the power to the control unit is ON.

2Revolver

Switches the lens magnification.

3 X-Y stage

A stand for the sample to rest on.

VK-X100K/X200K User’s Manual

1-13

Page 30

Part Names and Functions

1

1

3

2

Important

6

1

8

4

2

5

7

3

Reference

Control Unit (Front View)

VK-X100K/X200K

Getting Started

1 ACCESS lamp

Illuminates when the Observation Application is acti-

vated.

Pressing the POWER switch will not turn

the device off while the ACCESS lamp is

lit.

Terminate the Observation Application to

turn the power off.

2 Laser radiation emission warning

Lights up when the power to the control unit is ON.

3POWER switch

Turns the power to the control unit on or off.

“Startup and Shutdown” (Page 3-3)

Control Unit (Rear View)

1 PC connector

Connects to the control PC with the USB cable.

2 CONTROLLER A connector

Connects to the measurement unit with the provided

controller A cable.

3 CONTROLLER B connector

Connects to the measurement unit with the provided

controller B cable.

4 CAMERA connector

Connects to the measurement unit via the provided

camera cable.

5 SCAN CONTROL connector

Connects to the control unit. with the provided SCAN

CONTROL cable.

6 Main power switch

Turns the main power to the control unit on or off.

“Startup and Shutdown” (Page 3-3)

1-14

7AC power inlet

Connects to the power supply with the appropriate AC

power cable.

8 LIGHT connector

Connects to the measurement unit via the provided

fiber optic cable.

For the connection of each connector and

the cable, refer to “Connections” (Page

2-4).

VK-X100K/X200K User’s Manual

Page 31

2

Chapter

2

Set-Up

This chapter describes how to assemble the micro-

scope unit and how to connect each device.

Set-Up

Assembling the Microscope Unit ...........................Page 2-2

Connections ..........................................................Page 2-4

VK-X100K/X200K User’s Manual

2-1

Page 32

2

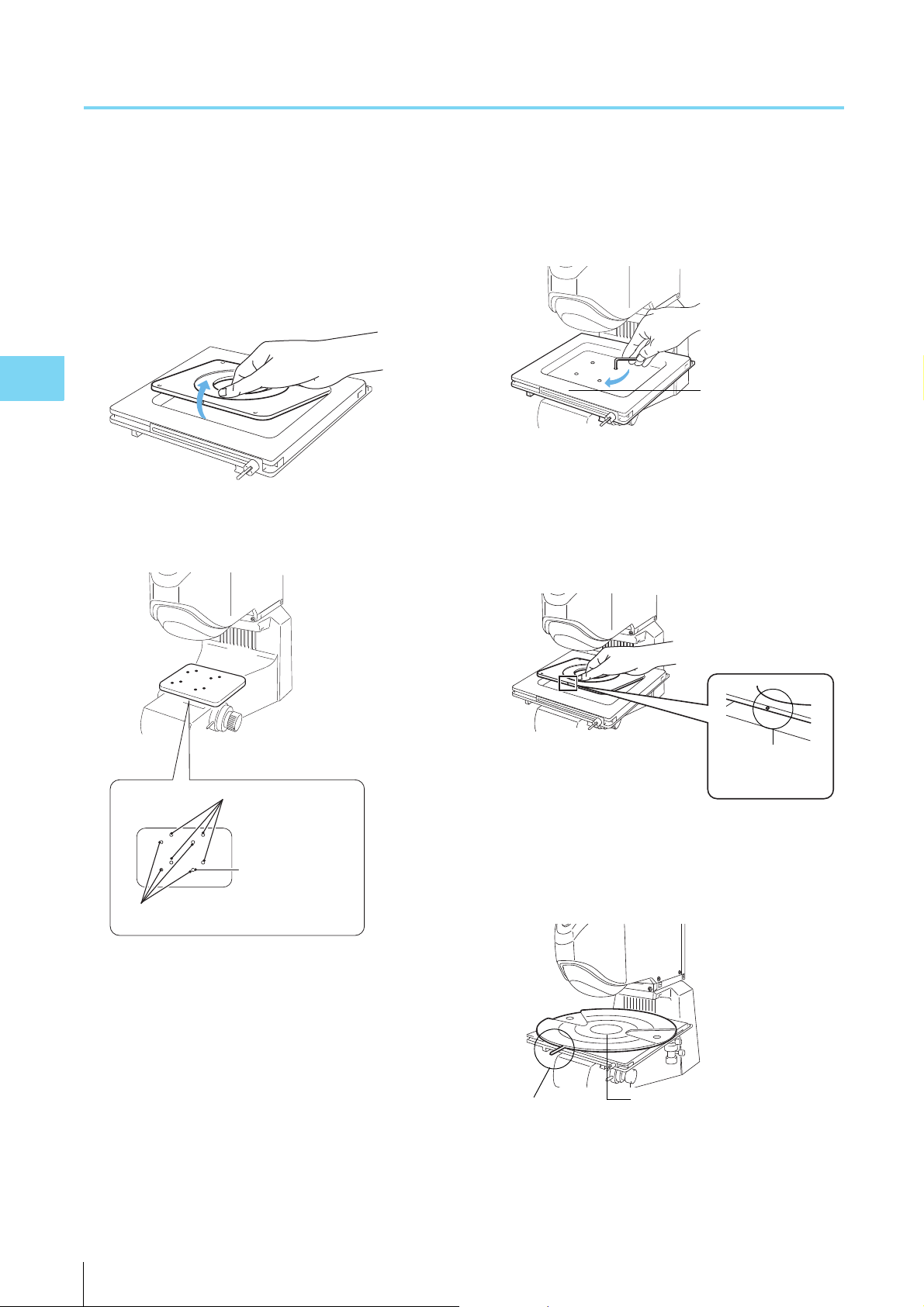

Assembling the Microscope Unit

Point

Fixing

Important

To prevent damage from vibration, when transporting the

microscope unit the X-Y stage should be locked and the

rotating stage as well as the objective lenses should be

removed.

Before connecting to each device, unlock the X-Y stage

and install the accessories.

Set-Up

Unlocking the X-Y Stage Lock

Removing the fixing metal fittings

A Phillips head screwdriver is required to remove

the fixing metal fittings.

1 Remove the 2 screws that mount the fixing metal fit-

tings on the corners of the X-Y stage using a Phil-

lips head screwdriver.

Unlocking the focusing handle lock

1 Tilt the lever for the focusing handle lock toward

RELEASE.

The X-Y stage now can be moved up/down.

Mounting the Rotating Stage

1 Mount the rotating stage on the X-Y stage.

Removing the fixing metal fittings allows the X-Y stage

to move front/back and left/right.

The removed fixing metal fittings are

required when transporting the VK-

X100K/X200K Series. Be sure to keep

them in a secure location.

2-2

VK-X100K/X200K User’s Manual

Mounting Optional Devices

Install optional devices, such as spacers or different

stands, before installing the objective lens.

“Chapter 4 Mounting Optional Devices” (Page 4-1)

Page 33

Assembling the Microscope Unit

2

Important

Revolver

Reference

Revolver

Mounting the Objective Lenses

When mounting the objective lens, make sure

the LASER SHUTTER is in the CLOSE

position.

For the LASER SHUTTER position, refer to

“Part Names and Functions” (Page 1-12).

1 Remove the objective lens out of the lens case.

The lens case is required when

Important

transporting the VK-X100K/X200K Series.

Be sure to keep it in a secure location.

2 Install the least-magnification objective lens at the

installation position located forward-most of the

revolver when viewing from the front.

3 Turn the revolver in the direction shown in the

picture.

Set-Up

The next objective lens mounting position comes

toward you when viewing the microscope from the

front.

4 Mount the second-least-magnification lens there.

5 Follow the same procedure to mount the rest of the

objective lenses.

• When unpacked, it is mounted so that the

installation position of the least-magnifica-

tion objective lens comes forward-most

when viewing the microscope unit from

the front.

• If you are unsure where each lens should

be installed after removing all the lenses

for relocation etc., select [Mount lens]

from the [Tool] menu in the Observation

Application. As the lens registered for the

forward-most mounting position is dis-

played on the top of the list, mount the

lenses accordingly.

For the operation details, refer to “VK-

X100K/X200K Observation/Image Assem-

bling Application Reference Manual.”

VK-X100K/X200K User’s Manual

Mount them so that the magnification of the lens gets

greater as the revolver is turned clockwise.

2-3

Page 34

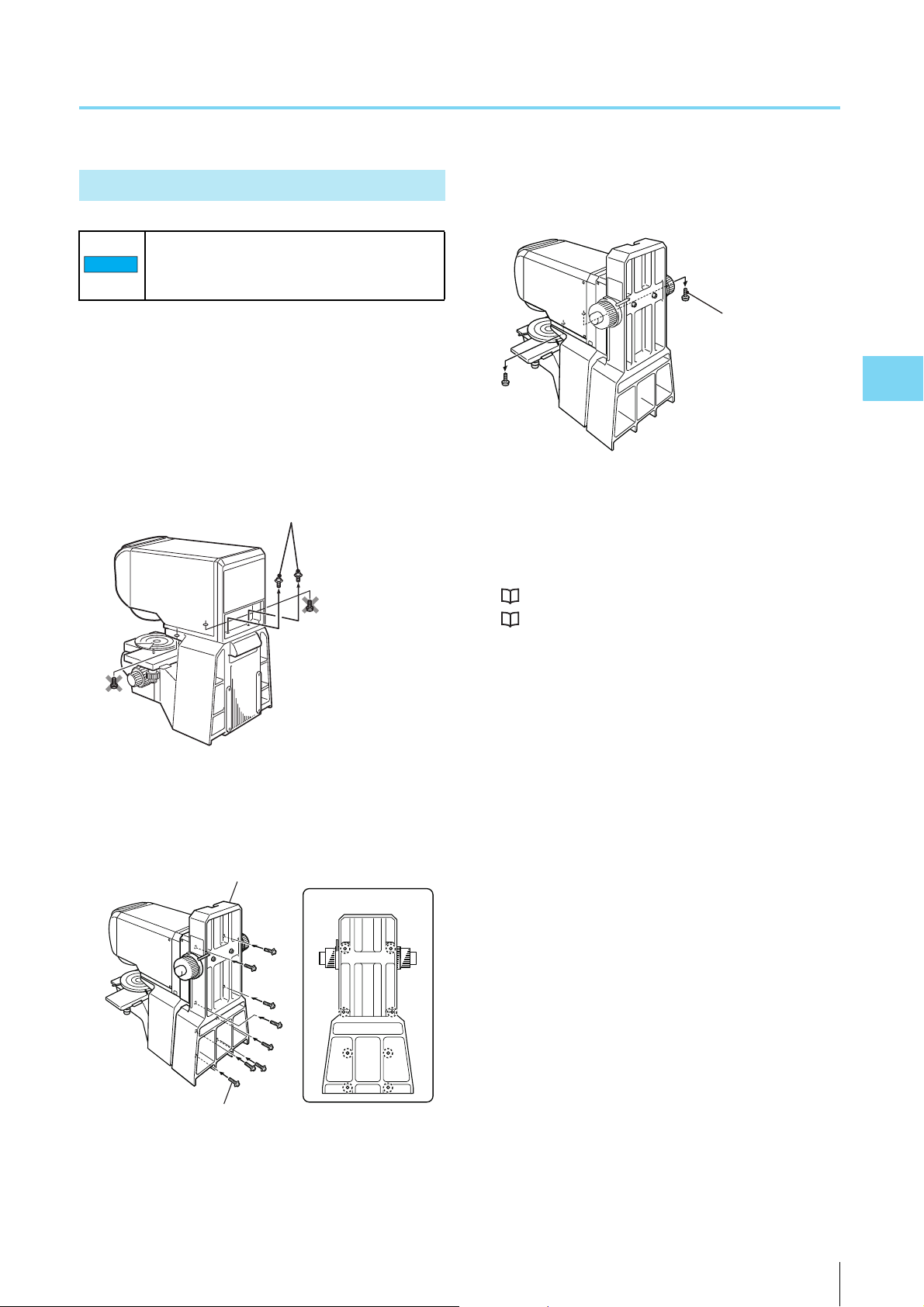

2

Connections

PC

A

CONTROLLER

CAMERA

LIGHT

100~240V AC

50/60Hz 3.5A

B

B

CONTROLLER

A

CLOSE

OPEN

LIGHT

SCAN

CONTROL

CAMERA

APERTURE

SHUTTER

LASER

SHUTTER

USB Cable

Control Unit

(VK-X100K/X200K)

Control

PC

Display

Power

Measurement Unit

(VK-X105/X110/X210)

Camera Cable

Fiber Optic Cable

Controller B Cable

Controller A Cable

AC 100 V to

240 V

SCAN CONTROL Cable

CAUTION

NOTICE

This section describes how to connect the equipment and accessories.

Connection Diagram

Microscope unit - Control unit - Control PC

Set-Up

Microscope unit (VK-X105/X110/X210), Control unit (VK-X100K/X200K), as well as the Control unit and Control PC, should

be connected as shown below.

For the details of the connection, refer to “Connection Procedure” (Page 2-6).

2-4

• Be sure to connect the power cable to an outlet that has a grounding terminal.

• Looking directly at the light from the LIGHT connector on the control unit (VK-X100K/X200K) may cause eye

damage.

Make sure that the power to the unit is off when installing the fiber optic cable.

• Make sure that power to the VK-X100K/X200K and all peripherals are off when connecting cables.

• Do not use too much force when connecting cables, as this can break the connector pins.

• Use screws to secure the connectors once they are connected.

• When connecting the cable, use caution not to mistake the control unit side for the measurement unit side.

Doing so may cause damage.

• Connect the USB cable to the USB connector located at the rear of the control PC.

Connecting to the front USB connector of the control PC may make the communication unstable.

VK-X100K/X200K User’s Manual

Page 35

2

Control PC - Peripherals

B

CONTROLLER

A

CLOSE

OPEN

LIGHT

SCAN

CONTROL

CAMERA

APERTURE

SHUTTER

LASER

SHUTTER

PC

A

CONTROLLER

CAMERA

LIGHT

100~240V AC

50/60Hz 3.5A

B

Mouse

Keyboard

Control Unit

(VK-X100K/X200K)

Control

PC

Video Board Connector

Monitor Cable

Measurement Unit

(VK-X105/X110/X210)

AC power source

Display

Important

Connect the control PC and peripherals (display, mouse, keyboard) as shown below.

Connections

Set-Up

Specifications may be changed or updated without notice. This may cause the connection diagram to

change.

VK-X100K/X200K User’s Manual

2-5

Page 36

Connections

2

NOTICE

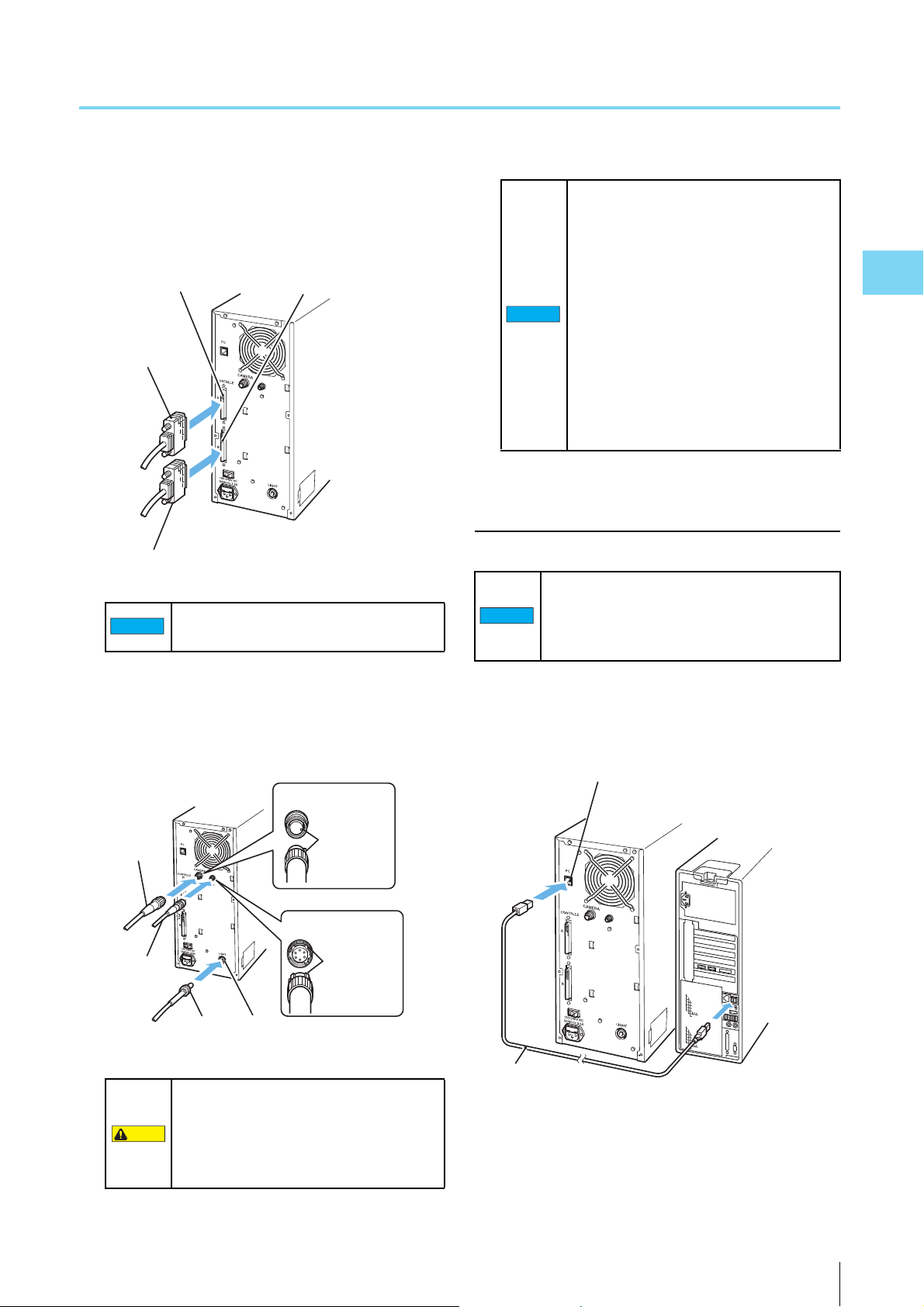

Controller

B Cable

Controller

A Cable

CONTROLLER

B Connector

CONTROLLER

A Connector

CAMERA Connector

Insert with

the cut-outs

aligned.

Insert with the

ridge and the

valley aligned.

SCAN CONTROL

Connector

LIGHT Connector

Fiber Optic Cable

Camera Cable

SCAN CONTROL Cable

Cord Hook

Connection Procedure

Connecting the microscope unit and

control unit

Set-Up

Turn off the power to the control unit and

control PC before connecting the cables.

Connecting cables while the power is on could

cause product failure.

1 Connect the controller A cable/B cable to the con-

troller A connector/B connector located on the side

of the microscope unit.

NOTICE

• Inserting the cables in the wrong

orientation may cause the connector

pins to break.

• Do not use too much force when

connecting cables, as this can break the

connector pins.

• Any dust or dirt on the connector face of

the fiber optic cable ends may cause

degradation of the cable.

• When connecting the cable, use caution

not to mistake the control unit side for

the measurement unit side. Doing so

may cause damage.

NOTICE

Use screws to secure the connectors once

they are connected.

2 Connect the fiber optic cable to the LIGHT connec-

tor on the side of the microscope unit, with the cam-

era cable to the CAMERA connector and the SCAN

CONTROL cable to the SCAN CONTROL connector.

2-6

VK-X100K/X200K User’s Manual

3 Hold the cables with the cord hook after connected.

Page 37

Connections

2

Controller

A Cable

CONTROLLER

A Connector

CONTROLLER

B Connector

Controller B Cable

NOTICE

Camera

Cable

Fiber Optic

Cable

CAMERA Connector

LIGHT Connector

Insert with

the cut-outs

aligned.

Insert with

the ridge and

the valley

aligned.

SCAN CONTROL

Connector

SCAN

CONTROL

Cable

CAUTION

NOTICE

USB

Cable

Control Unit

(VK-X100K/X200K)

PC Connector

Control

PC

4 Connect the CONTROLLER A cable/B cable to the

controller A connector/B connector located on the

rear of the microscope unit.

Use screws to secure the connectors once

they are connected.

• Inserting the cables in the wrong

orientation may cause the connector

pins to break.

• Do not use too much force when

connecting cables, as this can break the

connector pins.

NOTICE

• Any dust or dirt on the connector face of

the fiber optic cable ends may cause

degradation of the cable.

• Turn off the power to the control unit

before connecting the cables. Connect-

ing cables while the power is on could

cause product failure.

Connecting the control unit to the control

PC

Connect the USB cable to the USB connector

located at the rear of the Control PC. Connect-

ing to the front USB connector of the control PC

may make the communication unstable.

Set-Up

5 Connect the fiber optic cable to the LIGHT connec-

tor on the side of the microscope unit, with the cam-

era cable to the CAMERA connector and the SCAN

CONTROL cable to the SCAN CONTROL connector.

The SCAN CONTROL connector is high

voltage (150V DC). Do not connect other

than the provided SCAN CONTROL cable

of the VK-X100K/X200K Series. An

electric shock or malfunction may occur.

VK-X100K/X200K User’s Manual

1

Connect the USB cable to PC connector on the back

of the control unit and to the USB connector on the

back of the control PC.

2-7

Page 38

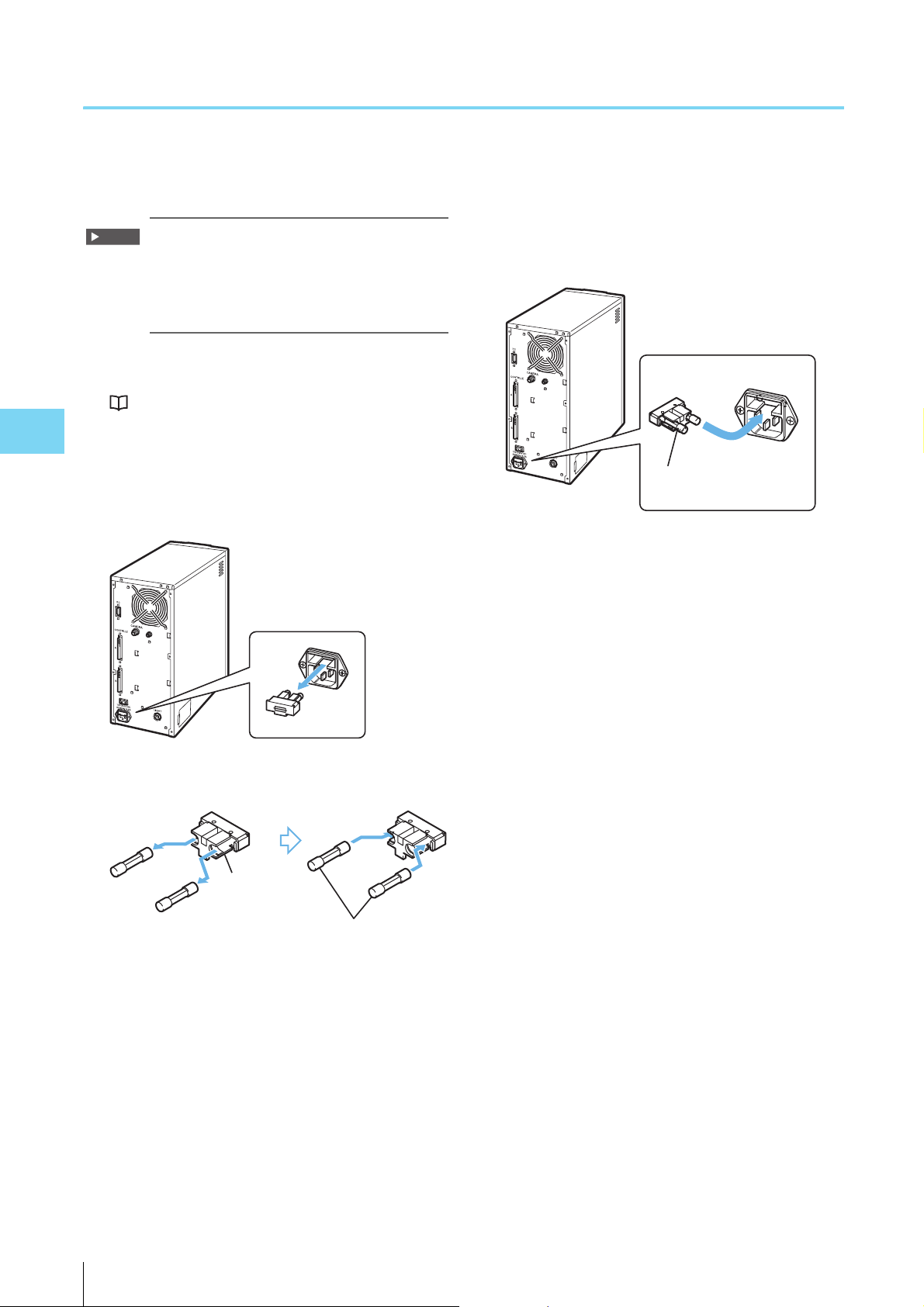

Connections

2

NOTICE

NOTICE

For two-prong outlets

Conversion

adapter

AC power supply

cable

Grounding line

Grounding

screws

For three-prong outlets

CAUTION

Connecting the control PC and the

peripherals

Connect the control PC and the peripherals

Set-Up

with the power of the control unit and the

control PC turned off. Connecting cables while

the power is on could cause product failure.

1 Connect the display, keyboard and mouse to the

control PC.

“Connection Diagram” (Page 2-4)

Connecting the power

Connect the control unit, the control computer and the dis-

play to an AC power source once all of the devices are con-

nected.

Make sure that the power turned off on the

control unit and the control PC etc., when

connecting the AC power cable. Connecting

cables while the power is on could cause

product failure.

1 Connect AC power cable to the control unit and the

control PC.

“Connection Diagram” (Page 2-4)

2 Connect the cables of the control unit, the control

PC and the display to an AC power source.

• Make sure that the earth terminal (the

earth wire) of the AC power cable is

grounded. Otherwise, an electric shock

or malfunction may occur.

• If the AC power source is a two-prong

outlet, connect the cable using the

supplied 3 to 2 conversion adapter. In

such a case, be sure to ground the earth

cable.

2-8

VK-X100K/X200K User’s Manual

Page 39

Chapter

3

3

Before Measuring

This chapter describes the preparation and basic

adjustments to be made before taking measure-

ments.

Before Measuring

Sequence of Preparation before Measuring...........Page 3-2

Startup and Shutdown ...........................................Page 3-3

Measurement Basics (For Proper Measurement) ..Page 3-5

Adjusting the Measurement Unit ............................Page 3-8

VK-X100K/X200K User’s Manual

3-1

Page 40

3

Sequence of Preparation before Measuring

1st Observation/Measurement

Turn on the power of the control unit and the control PC. Turn the power of the

control unit on at least 60 minutes or more before starting the measurement.*

“Starting Up the System” (Page 3-3)

2nd Observation/Measurement

After starting the Observation Application, initialize the lens position

(Returning to the origin).

“Initializing Lens Position” (Page 3-8)

Use the Observation Application to observe/measure the sample.

“VK-X100K/X200K Observation/Image Assembling Application Reference Manual”

Place the sample on the rotating stage for observation/measurement.

“Loading the sample” (Page 3-9)

Turn the revolver to select the objective lens.

“Selecting magnification” (Page 3-9)

Turn the X axis stage handle and Y axis stage handle to move the sample to the observation position.

“Adjusting the observation position” (Page 3-10)

Turn the focusing handle to adjust the focus.

“Adjusting the focus” (Page 3-10)

Use the APERTURE SHUTTER (Aperture iris shutter) to adjust the intensity of the illumination.

“Adjusting brightness” (Page 3-11)

Starting Up the System

Observation/Measurement

Adjusting Brightness

Adjusting the Focus

Adjusting the Observation Position

Selecting Magnification

Loading the Sample

Initializing Lens Position

Before Measuring

* Wait one hour after turning on the power of the control unit before taking measurements.

Measurements may fluctuate with the default drift if the temperature of the device is not stable.

3-2

VK-X100K/X200K User’s Manual

Page 41

3

Startup and Shutdown

Point

Lit in Orange

POWER

Switch OFF

POWER

Switch ON

Starting Up the System

1 If the power is not on, turn on the main power switch

located on the rear of the control unit.

When the POWER switch on the front of the

control unit is lit in orange, the power is

already on. No operation to switch the main

power switch on the rear is required.

Turn the power of the control unit on at

Important

least 60 minutes or more before starting

the measurement.

To prevent fluctuations in measurements

caused by the default drift with the

internal temperature kept stable, 60

minutes or more of the pre-heating time is

required.

3 When using the electric X-Y stage (VK-S100K/S105/

S110), turn the power for the stage driver on.

“Special Electric X-Y Stage VK-S100K/S105/S110

for 3D Laser Scanning Microscope User’s Manual”

4 Turn on the power for the control PC.

Before Measuring

2 Turn on the POWER switch located on the front of

the control unit.

The POWER switch light changes into green with the

LASER ON (Laser radiation emission warning) lit.

VK-X100K/X200K User’s Manual

Reference

• While the control unit and the control PC

may be turned on in a different order, it will

take several seconds for communication

to be established after the control PC rec-

ognizes the control unit.

• Log into the control PC using administra-

tor privileges.

3-3

Page 42

Startup and Shutdown

3

POWER

Switch ON

POWER

Switch OFF

Reference

Shutting Down the System

1 Shut down Windows.

The control PC power turns off.

2 Turn off the POWER switch on the front of the con-

trol unit.

Before Measuring

The LASER ON (Laser radiation emission warning)

goes off with the POWER switch light changed to

orange.

You do not need to turn off the main power

every time you finish operation. Turn the

main switch on the rear of the control unit off

when the unit will not be used for a long time

or when you are transporting the unit.

3-4

VK-X100K/X200K User’s Manual

Page 43

3

Measurement Basics (For Proper Measurement)

This section describes what you need to know before taking measurements.

A Variety of the Standard Objective Lens and How to Select One

In VK-X105/X110/X210, each has the following 4 types of the standard objective lenses to mount. Select them according to

their use.

Model Standard objective lenses Depth of

Field

(µm)*

VK-X105 CF IC EPI Plan 5X 38.9 7.47 Aligning the Position for

CF IC EPI Plan 10X 7.31 17.5

CF IC EPI Plan 20X 3.11 27.4 Shape and Film Thickness

CF IC EPI Plan 50X 1.03 53.1

VK-X110 CF IC EPI Plan 10X 7.31 17.5 Aligning the Position for

CF IC EPI Plan 20X 3.11 27.4

CF IC EPI Plan 50X 1.03 53.1 Shape and Film Thickness

CF IC EPI Plan 100X 0.73 71.8 X

VK-X210 CF IC EPI Plan 10X 4.53 17.5 Aligning the Position for

CF IC EPI Plan 20X 1.91 27.4 Shape and Film Thickness

CF IC EPI Plan Apo 50X 0.45 71.8

CF IC EPI Plan Apo 150X 0.45 71.8 X

*1

This is the depth of field in the laser images. The values listed above are theoretical values.: Suited to the measurement.

1

Angle char-

acteristics

Plane

measure-

ments

Width

measure-

ment

Height

measure-

ment

X

Film thick-

ness mea-

surement

: May be used depending on the condition.

: Cannot be used for measurement.

Main use (Yardstick)

Measurement

Measurement

Measurement

Measurement

Measurement

Measurement

Before Measuring

Points for selecting the lens

When measuring the height in high precision

Under normal circumstances, the standard 50x, 100x

and 150x objective lenses are suited to height measure-

ments.

In the measurement unit using confocal laser optics, the

shallower the depth of field (range when the image is

focused) of the objective lens, the better the repeat accu-

racy.

The highest magnification lens possible should be used

for high-resolution height images.

VK-X100K/X200K User’s Manual

For measurements with a long Z measurement

distance

The VK-X100K/X200K Series can set up to 7 mm in the Z

measurement distance. However, when performing

actual measurements, the size of the objective lens you

are using will dictate the measurable Z measurement dis-

tance.

When taking measurements with broad Z measurement

distance, it is recommended that you use the 10x or 20x

objective lenses or lenses available on the market (long

range or ultra-long range lenses).

For high-resolution plane or width

measurements

Plane measurements can be carried out with any stan-

dard objective lens.

When taking plane measurements, the narrower the field

of view, the higher the resolution. Additionally, setting the

measurement quality to super-fine detail will allow you to

3-5

Page 44

Measurement Basics (For Proper Measurement)

3

Point

Far

Distance from

objective lens

Near

Front peak

Rear peak

Low

High

Received light intensity

read high-resolution images even with a low magnifica-

tion lens.

For a large area plane measurement

Under normal circumstances, the standard 10x and 20x

objective lenses are suited for plane measurements.

About the long range/ultra-long range

Before Measuring

objective lenses

When a long focal distance (Z measurement distance) is

preferred, long range/ultra-long range lenses on the market

may be used. Select the best objective lens according to

the size and shape of the sample.

Some functions may not be available for mea-

surement of the film thickness of a transparent

object (top surface) etc. For more details, contact

our Sales Dept.

Objective lens*1 Monitor

magnification

Long distance

20X

Long distance

50X

Long distance

100X

Ultra-Long

distance 20X

Ultra-Long

distance 50X

Ultra-Long

distance 100X

*1 All of these lenses are made by Nikon.

*2 Depending on differences between the individual lenses, the

operating distance may be smaller than the above stated

values. Make a judgement upon confirming the actual

conditions.

400X 11.0 mm 0.4

1000X 8.7 mm 0.55

2000X 2.0 mm 0.8

400X 20.5 mm 0.35

1000X 13.8 mm 0.45

2000X 4.7 mm 0.73

Operating

distance*

2

aperture (N.A.)

Numerical

Correction in the Film Thickness Measurement

There will be two focal points when measuring transparent

samples, one in front and one behind. This means that the

photoreceptor will also see two peaks. The VK-X100K/

X200K Series can measure the thickness of a film by mea-

suring the distance between those two peaks.

The value returned when measuring film thickness may be

less than the actual thickness due to the refractive index of

the material. These errors can be corrected by inputting the

value for a master sample.

“

For the error correction method, refer to

X200K Observation/Image Assembling Application Refer-

ence Manual.”

VK-X100K/

3-6

VK-X100K/X200K User’s Manual

Page 45

3

Adjusting the Positions of the Laser and the Camera

This feature allows you to correct for displacement of the

camera or laser due to transportation or changes in temper-

ature. These adjustments should be performed when regis-

tering a new lens or when you notice that the color or light

intensity in color images are misaligned.

For the position adjustment method, refer to

X200K Observation/Image Assembling Application Refer-

ence Manual.”

“VK-X100K/

Measurement Basics (For Proper Measurement)

Before Measuring

VK-X100K/X200K User’s Manual

3-7

Page 46

3

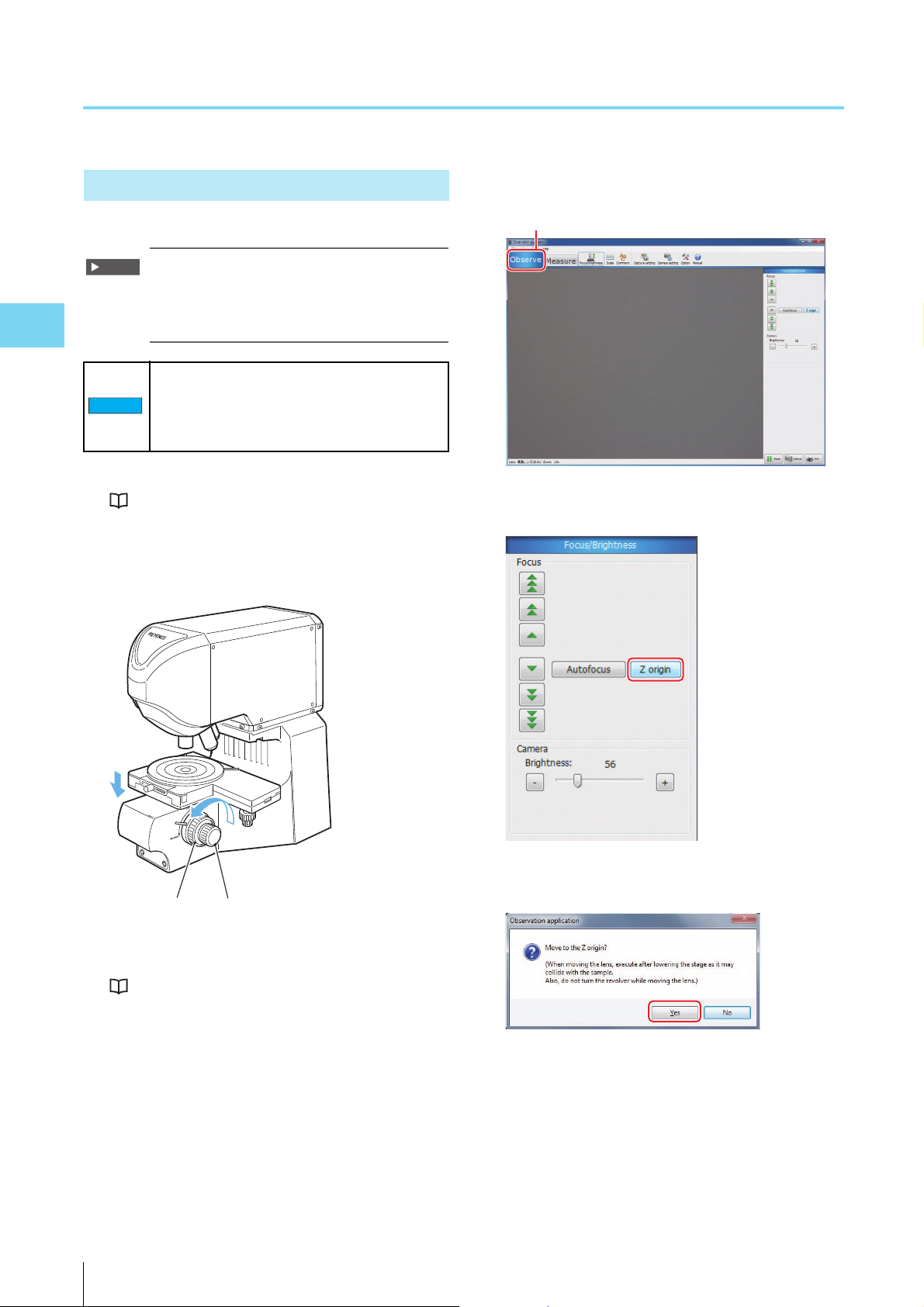

Adjusting the Measurement Unit

Important

NOTICE

Fine Coarse

<1>

Initializing Lens Position

Initialize the lens position (“Returning to the origin”).

It is recommended that you initialize the lens

position once per day when starting up the

system. The lens position does not need to be

initialized after each measurement.

Before Measuring

When initializing the lens position, do not place

the sample on the rotating stage.

Contact between the objective lens and the

sample could damage either one.

1 Start the system.

“Starting Up the System” (Page 3-3)

2 Turn the focusing handle (Coarse/Fine) to lower the

X-Y stage to the lowest level possible.

4 Select the [Observe] tab (<1>) in the tool bar.

5 Click the [Z origin] button.

3 Start the Observation Application.

“VK-X100K/X200K Observation/Image Assembling

Application Reference Manual”

3-8

6 Click [Yes] in the confirmation message.

The revolver moves up/down automatically with the

objective lens moving to the Z origin.

VK-X100K/X200K User’s Manual

Page 47

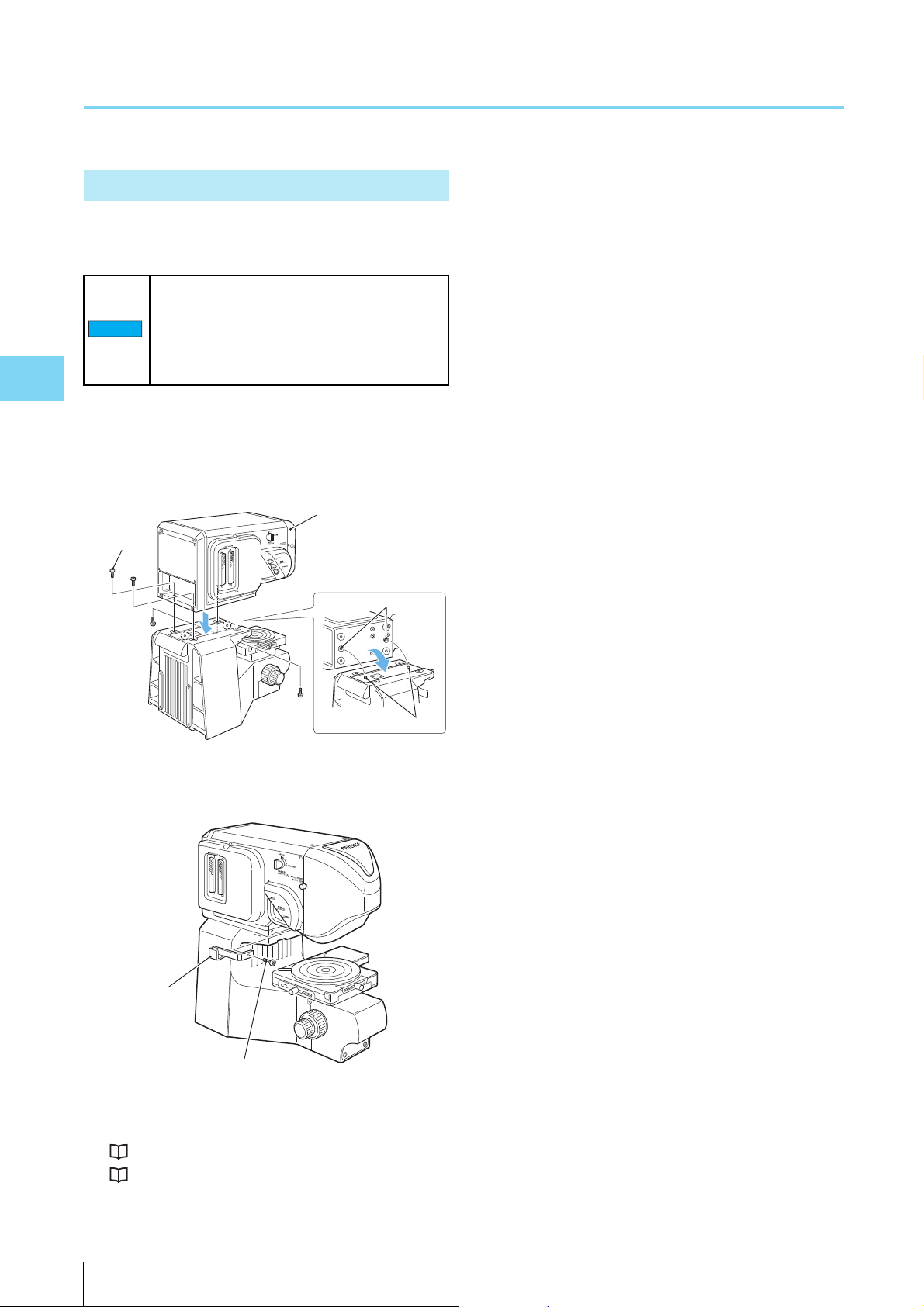

Adjusting the Measurement Unit

3

NOTICE

Revolver

Adjustment of the Observation Position/Magnification

Loading the sample

1 Place the sample to be observed on the rotating

stage.

Selecting magnification

1 Turn the revolver manually, selecting the objective

lens preferred for the observation.

Do not bring the sample into contact with

NOTICE

the objective lens when turning the

revolver.

Doing so may cause failure.

Before Measuring

Reference

The standard X-Y stage can accommodate

samples up to 28 mm in height and 5 kg in

weight.

If the sample height is larger than what can

be accommodated by the standard stage, it

is recommended that you install an optional

spacer or stand.

“Mounting the Spacer for the VK-X210”

(Page 4-7)

“Mounting the Spacer for the VK-X105/

X110” (Page 4-12)

“Mounting the Stand for VK” (Page 4-20)

VK-X100K/X200K User’s Manual

3-9

Page 48

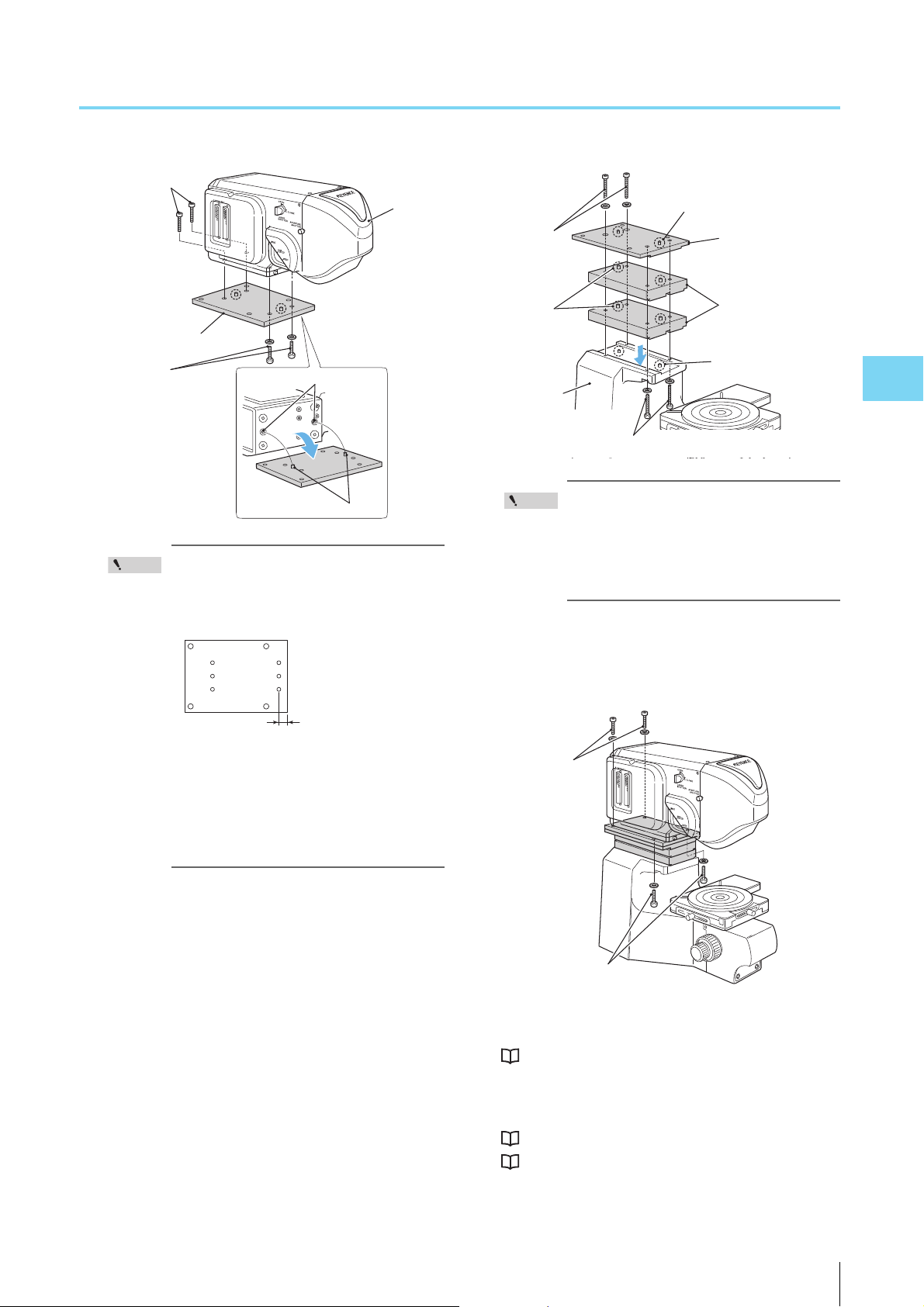

Adjusting the Measurement Unit

3

Left and right motion

Forward and backward motion

Fine Coarse

Adjusting the observation position

1 Turn the X axis stage handle (left/right) and Y axis

stage handle (forward/back) to move the sample to

the observation position.

Before Measuring

Adjusting Focus/Brightness

Adjusting the focus

1 Turn the focusing handle (Coarse/Fine) to adjust the

focus.

Handle Maximum

X axis stage handle