Page 1

User’s Manual

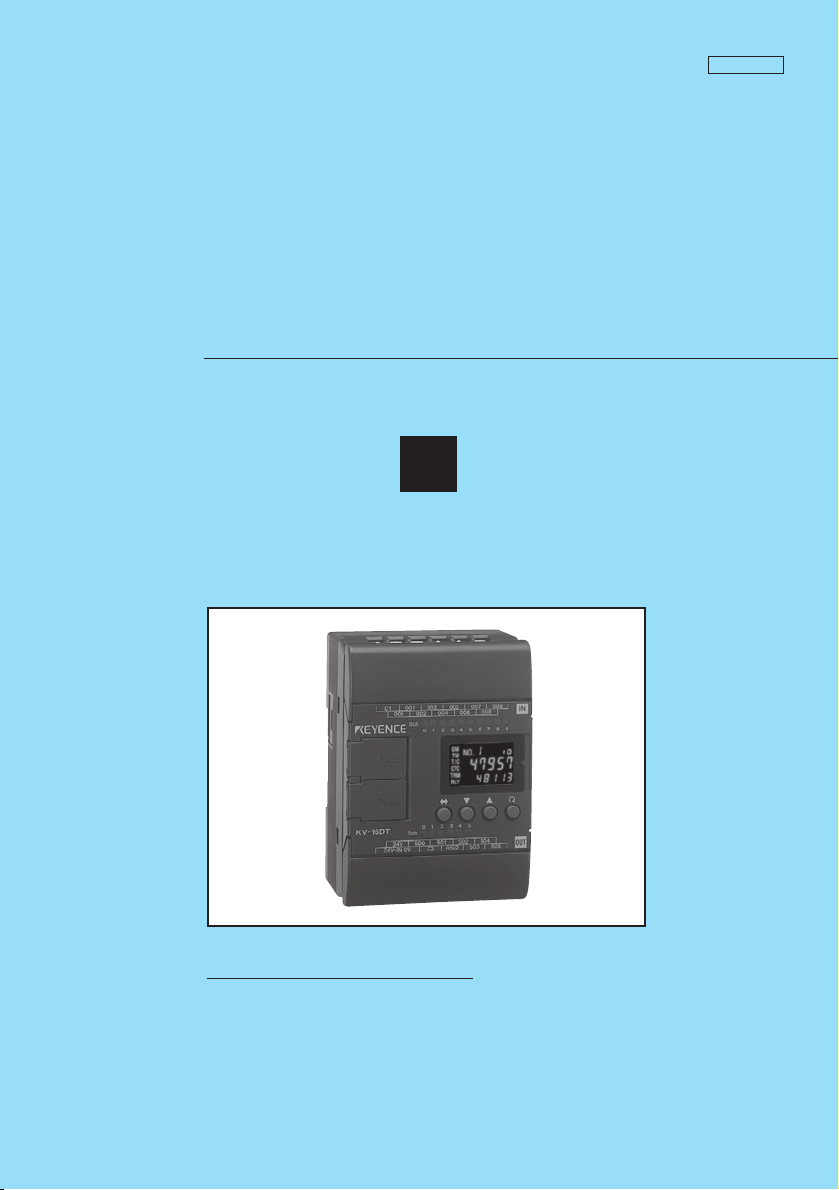

Visual KV Series

3

Programming

96M0366

How this manual is organized:

The Visual KV Series User’s Manual is composed of 3 separate

manuals; 1-Installation, 2-Support Software, 3-Programming.

Please read each manual relevant to your purpose.

Page 2

Safety Precautions

This instruction manual describes the operation and function of the KV Series PLC.

Read this manual carefully to ensure safe use and maximum performance from your

KV Series PLC.

Symbols

The following symbols alert you to important messages. Be sure to read these

messages carefully.

WARNING

Failure to follow instructions may lead to injury. (electric

shock, burn, etc.)

Note:

Conventions

This manual describes the operation/function of all Keyence KV Series PLC.

Note following conventions when you use.

Visual KV (Series) KV-10AR/AT/DR/DT KV-16AR/AT/DR/DT

KV-10xx, 16xx, 24xx, 40xx KV-24AR/AT/DR/DT KV-40AR/AT/DR/DT

Conventional KV (Series) KV-10R(W)/T(W) KV-16R(W)/T(W)

KV-300 (Series) KV-24R(W)/T(W) KV-40R(W)/T(W)

KV-10/80 (Series) KV-80R(W)/T(W)

General Precautions

• At startup and during operation, be sure to monitor the functions and performance of the KV Sereis PLC.

• We recommend that you take substantial safety measures to avoid any damage

in the event a problem occurs.

• Do not open or modify the KV Series PLC or use it in any way other than described in the specifications.

• When the KV Series PLC is used in combination with other instruments, functions and performance may be degraded, depending on operating conditions and

the surrounding environment.

• Do not use the KV Series PLC for the purpose of protecting the human body.

CAUTION

Failure to follow instructions may lead to product damage.

Provides additional information on proper operation.

KV-300

(1)

Note: The built-in display may show the error message "Error 40" blinking the very

first time you turn on the power supply to the Visual KV Series. Press any key

around the display to cancel this message.

The Visual KV Series shows this message when no program is loaded.

Page 3

Note to User

When using the Visual KV Series in the following conditions or environments, be

sure to use the Visual KV Series with sufficient margin regarding the rating and

functions, take appropriate safety precautions such as fail-safe, and contact our

sales personnel if any questions arise.

• Use in conditions or environments not described in this manual

• Use for nuclear power control, railway facilities, air service facilities, vehicles,

combustion devices, medical equipment, amusement machines, safety equipment, etc.

• Use for applications where large effects are predicted to be given on human lives

and properties and safety is especially requested.

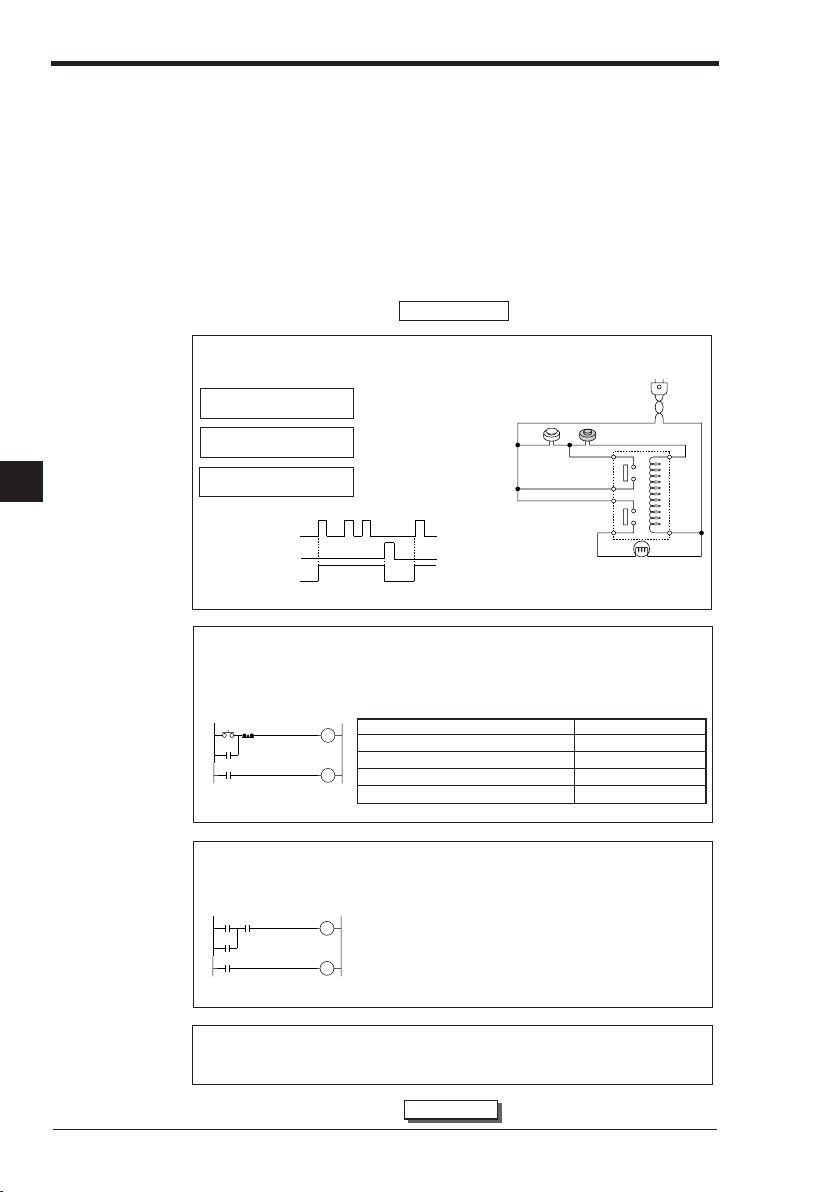

Restriction on Acquiring the CE Marking

■ Restriction to be compatible with EMC directives

• When using a relay output type unit (whose model name ends with "R"), connect

spark killers having the appropriate withstand voltage against the load to the

output terminals in parallel to contacts (because the unit discharges when a relay

contact becomes open and noise is generated). In our experiments, we use the

following models of spark killers.

XEB0101 0.1 µF-10 Ω manufactured by OKAYA DENKI SANGYO

The following 1-turn ferrite core is added to the AC power input circuit of the KV40AR/T, the KV-24AR/T and to the DC power input circuit of the KV-40DR/T.

ZCAT3035-1330 manufactured by TDK

Note: The contents above do not by themselves ensure that the entire machine

manufactured in accordance with the above contents is compatible with EMC

directives.

You must judge by yourself whether or not the entire machine is compatible with

EMC directives because compatibility may change depending on the component

configuration, wiring and location inside of the machine.

■ Restriction on compatibility with low-voltage directives (IEC-1010-1)

• Use insulated type crimp-style terminals.

• For wiring materials, use lead wires whose sheath is 0.4 mm or more.

• The Visual KV Series is allowed to be installed in a vertical position only.

(Spacers for expansion units are not available.)

• Be sure to use the Visual KV Series inside the control panel.

96M0366

(2)

Page 4

Features of the Visual KV Series

● Extremely small

The Visual KV Series is the smallest in the world among AC type PLCs equipped

with screw terminal blocks, and saves installation space.

● Extremely fast

The minimum scan time is 140 µs and minimum instruction execution time is 0.7

µs, which is the fastest control in its class.

● AC power built-in type newly added

AC power built-in type units are newly added. This type can be used in small

spaces where a switching power supply unit cannot be installed.

● Excellent Access Window

An Access Window with two-color backlight is adopted in all models to facilitate

changing and monitoring of device data. Changing between RUN mode and

PROGRAM mode, checking the error code when an error has occurred, etc. can

be performed in a Visual KV Series unit without the need for any handheld

programmer.

The analog trimmer, which has been popular in the conventional KV Series, is

digitized to enable more detail settings. [Digital trimmers]

● User message setting function

In the Access Window, 256 different user messages can be displayed. This

function can be used to give instructions on works on the production line, indicate

abnormalities in the units, etc.

● Program write in RUN mode

Ladder programs can be changed even while the system is running.

● Equipped with two serial ports

Visual KV Series basic units are equipped with two serial ports to connect peripheral units, improving the debug environment.

(The KV-10xx is equipped with only one serial port.)

● Easy Ramp-up/down control function

The one-axis motor control function is offered separately from high-speed

counters so that feedback control is enabled.

● Equipped with two 24-bit high-speed 30 kHz, two-phase counters

The Visual KV Series is equipped with two high-speed counters each with a twopoint comparator output function that enables high-speed encoder input.

● Specified frequency pulse output function

High-speed counters can function as pulse oscillators of 50 kHz maximum with

easy setting, without creating a complicated ladder program.

● Frequency counter function

High-speed counters can function as frequency counters with easy setting,

without creating complicated ladder programs.

● Cam switch function

High-speed counters can function as cam switches with easy setting, without

creating complicated ladder programs.

(3)

Page 5

● Interrupt function

The Visual KV Series is equipped with four high-speed interrupt inputs of

10 µs maximum.

● Input time constant change function

The time constant can be set in 7 steps from 10 µs to 10 ms.

● Double memory backup functions

In addition to a conventional SRAM battery backup function, the Visual KV Series

is also equipped with an EEPROM backup function.

Compatibility with Conventional KV Series Peripheral Units

The Visual KV Series functions as a high-end compatible model of the conventional

KV Series. Peripheral units of the conventional KV Series such as the ladder support

software "KV IncrediWare (DOS)" and "LADDER BUILDER for KV" and the

handheld programmer KV-P3E(01) can be used since they are part of the Visual KV

Series.

However, it should be noted that the contents have changed as follows.

• The internal clock cycle of high-speed counters consists of three types: 1 µs, 10

µs, and 100 µs.

• The time constant for an input relay specified by the HSP instruction is 10 µs.

• The analog trimmer function is set with the Access Window built into the basic

unit.

• The available device setting range of the TMIN instruction is from 0 to 65535.

[Handheld programmer KV-P3E(01) can display 0 to 9999 .]

• The RUN/PROGRAM LED is displayed in the Access Window provided on the

front face of the basic unit.

• Transistor output is not independent, but is common.

• With the transistor type, the output terminal layout is different.

• The specifications for output current of transistor outputs Nos. 500 to 502 is 100

mA.

• Conventional KV Series expansion units are not available as expansion units for

the Visual KV Series.

• The channel setting switch is not provided for expansion units. Channels are

determined in connection order.

• Scans in expansion I/O units are not synchronous with the scan time in Visual KV

Series basic units.

• Assignment of special utility relays has partially changed.

• Data memory device Nos. DM1000 to DM1999 are assigned as special data

memories.

(4)

Page 6

Cautions when using the previous version of ladder support software

Pay strict attention to the following items when using the ladder support software.

• When using the ladder support software "KV IncrediWare (DOS)" or "LADDER

BUILDER for KV Ver. 1.0x", set the model to "KV-300".

• DM0 to DM1999 are only available.

CAUTION

When the ladder support software "LADDER BUILDER for KV Ver. 1.0x" is

used, do not use the monitor’s Change All function. If the Change All function

is used, the basic unit may be damaged. Never use the Change All function.

Peripheral units and other units incompatible with the Visual KV Series

Peripheral units in the conventional KV Series and other units shown below are not

compatible with the Visual KV Series.

• Expansion I/O units for the conventional KV Series: KV-8ER/8ET/8EX/16EX/

8EYR/8EYT/16EYR/16EYT

• Analog I/O units for the conventional KV Series: KV-AD4/DA4

Cautions when Using the Serial Port

The KV-16xx/24xx/40xx units are equipped with two RJ-11 modular connectors for

serial communication.

When using them, pay strict attention to the following contents:

• Programs can be transferred and monitored using either communication port A or

B. However, never connect the ladder software and a handheld programmer to

the two ports at the same time.

• The KV-D20 operator interface panel can be connected to either communication

port A or B. However, only one KV-D20 unit can be connected to a single basic

unit.

• Never leave both the KV-D20 operator interface panel and KV-P3E(01) handheld

programmer on simultaneously for a long period of time.

(5)

Page 7

(6)

Page 8

How this manual is organized

The Visual KV Series User’s Manual is composed of 3 separate manuals;

1-Installation, 2-Support Software, 3-Programming. Please read each manual

relevant to your purpose.

1

Installation

Chapter 1 Configuration and Specifications [Visual KV Series Only]

Describes the system configuration of the Visual KV Series, the names and functions of

each part, and the specifications.

Chapter 2 System Installation [Visual KV Series Only]

Describes the installation and connection of each Visual KV Series unit as well as

system maintenance.

Chapter 3 Access Window [Visual KV Series Only]

Describes the Access Window used for changing and monitoring data.

Chapter 4 KV-D20 Operator Interface Panel [Visual KV Series Only]

Describes the KV-D20 Operator Interface Panel used for changing, monitoring, and

displaying the status of inside relays, timers, counters and data memories.

Chapter 5 KV-300, KV-10/80 Hardware [KV-300, KV-10/80 Series Only]

Describes the hardware specifications and wirings for KV-300 and KV-10/80 Series.

Chapter 6 Handheld Programmer

Describes how to use the handheld programmer and memory card.

Chapter 7 KV-L2 Serial Interface Module [KV-300 Series Only]

Describes the serial interface modules for KV-300 Series.

Chapter 8 KV-AN6 Analog I/O Module [KV-300 Series Only]

Describes the optional Analog I/O module for KV-300 Series

Chapter 9 KV-AD4/DA4 Analog I/O Unit [KV-10/80 Series Only]

Describes the optional Analog I/O unit for KV-10/80 Series.

Chapter 10 Troubleshooting

This chapter describes the error code list, countermeasures against problems, and error

indications for each unit.

Appendices

The appendix includes a list of ladder program applications and the index.

2Support Software

Chapter 1 Introduction

Describes the items included in the package, the product outline, the method to connect

a personal computer, the installation method, etc.

(7)

Page 9

Chapter 2 Editor

Describes the operating procedures in Editor mode.

Chapter 3 Simulator

Describes the operating procedures in Simulator mode.

Chapter 4 Monitor

Describes the operating procedures in Monitor mode.

Appendices

Includes instructions list, devices list, sample program list and quick reference for key

operation and shortcuts.

3Programming

Chapter 1 Programming

Describes basic knowledge including program creation procedures, device configuration,

relay assignments, special functions to set and confirm Visual KV Series operations, as

well as the extended ladder diagrams. Understand the contents described here completely at first before creating programs.

Chapter 2 Instructions

Describes the concrete usage of instructions in the KV Series.

Refer to "Chapter 3 Interrupts" on page 3-183 for details of interrupt instructions.

Refer to "Chapter 4 High-speed counters" on page 3-195 for details of the high-speed

counters used in the application instruction.

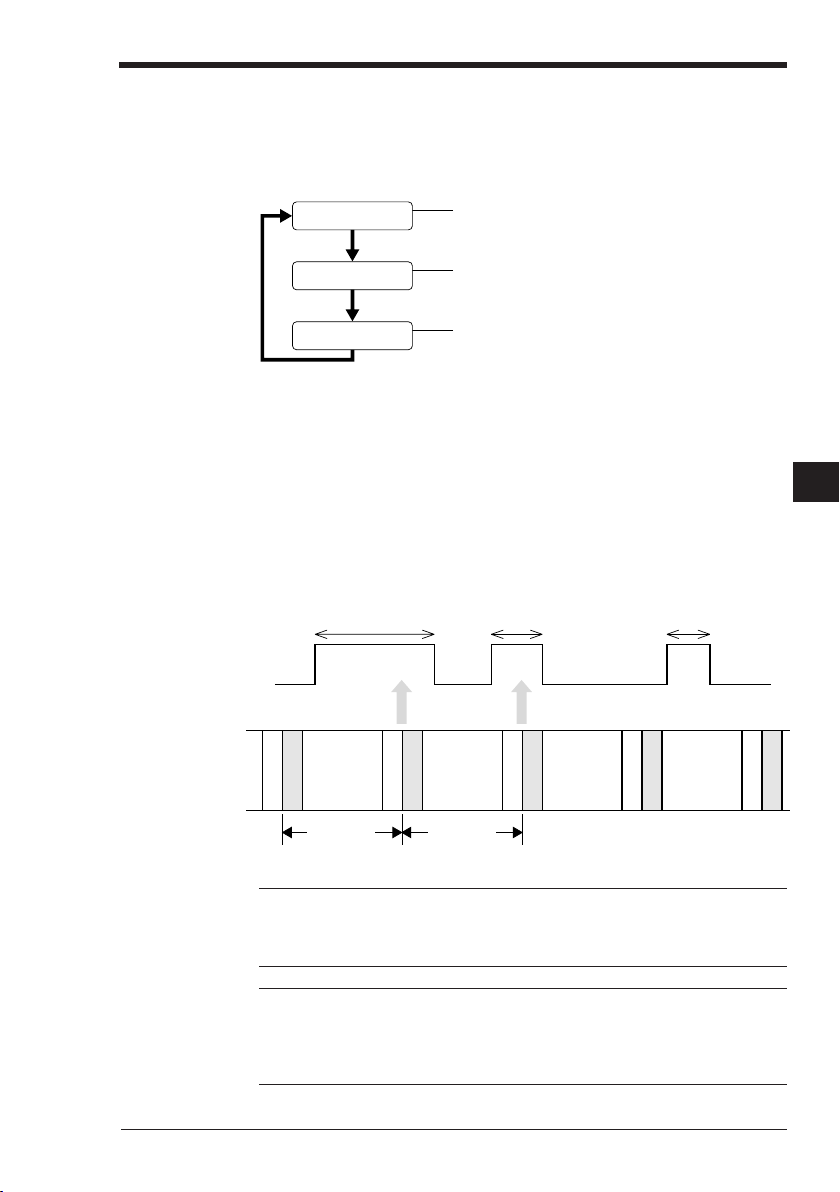

Chapter 3 Interrupts [Visual KV Series Only]

The interrupt processing function executes an interrupt program when an external input

or request from the high-speed counter comparator (interrupt factor) is encountered

during KV operation.

This chapter describes the types of interrupt factors as well as inputs and outputs

encountered during interrupt processing.

Chapter 4 High-speed Counters [Visual KV Series Only]

Describes high-speed counters and high-speed counter comparators, which allow highspeed pulse measurement and pulse output, independent of the scan time.

Chapter 5 Positioning Control [Visual KV Series Only]

Describes ramp-up/down control of stepping motors and servo motors.

Chapter 6

Interrupts, High-speed Counters, Positioning Control [KV-300, KV-10/80 Series Only]

Describes ramp-up/down control of stepping motors and servo motors.

Chapter 7 Serial Communication

The KV Series can be connected to an external device with an RS-232C interface to

establish communication.

This chapter describes communications specifications, how to connect the KV Series to

external devices, and how to perform communication.

Chapter 8 Programming Examples

Describes the typical programming examples for KV-10/80 Series. These programs can

be used for Visual KV Series. However, pay attention to the I/O addressing compatibility

before use.

(8)

Page 10

Contents

3Programming

Chapter 1 Programming

1.1 Before Creating Programs ..............................................................................3-2

1.1.1 Flow from Introduction to Operation ................................................................... 3-2

1.1.2 Scan Time ...........................................................................................................3-3

1.2 User Memory ....................................................................................................3-4

1.2.1 Program Capacity ...............................................................................................3-4

1.3 Device Configuration .......................................................................................3-5

1.3.1 Device List .......................................................................................................... 3-5

1.3.2 Relay No. ............................................................................................................3-7

1.3.3 Assigning Relay Nos. ..........................................................................................3-8

1.3.4 Input Relays ........................................................................................................3-9

1.3.5 Output Relays ...................................................................................................3-10

1.3.6 Internal Utility Relays ........................................................................................3-11

1.3.7 Special Utility Relays ........................................................................................ 3-12

1.3.8 Special Utility Relay List ................................................................................... 3-14

1.3.9 Timers and Counters ........................................................................................ 3-18

1.3.10 Data Memories ................................................................................................. 3-19

1.3.11 Temporary Data Memory ..................................................................................3-21

1.3.12 Relay Nos. and Functions .................................................................................3-22

1.4 Special Functions ..........................................................................................3-23

1.4.1 Input Time Constant Change Function .............................................................3-23

1.4.2 Modifying the Input Relay Time Constant .........................................................3-24

1.4.3 Constant Scan Time Mode ............................................................................... 3-25

1.4.4 Output Disabled Function ................................................................................. 3-26

1.4.5 Input Refresh Disabled Function ...................................................................... 3-26

1.4.6 Contact Comment Save Function .....................................................................3-27

1.4.7 Special Functions ............................................................................................. 3-28

1.5 Extended Ladder Diagrams ..........................................................................3-29

1.5.1 Features of Extended Ladder Diagrams ...........................................................3-29

1.5.2 Advantages of Extended Ladder Diagrams ......................................................3-30

1.5.3 Example of an Extended Ladder Diagram ........................................................3-31

Scan time .....................................................................................................3-3

Input response time delay ............................................................................3-3

Maximum number of lines in a program .......................................................3-4

Calculating the byte count used ...................................................................3-4

Relay list ...................................................................................................... 3-5

List of I/O relays in basic units ..................................................................... 3-5

List of relays in expansion units ...................................................................3-6

Address No. ................................................................................................. 3-7

Contact No. ..................................................................................................3-8

Channel No. .................................................................................................3-8

Basic unit ..................................................................................................... 3-9

Expansion unit ........................................................................................... 3-10

Output operation time ................................................................................ 3-10

Retentive function of internal utility relays ..................................................3-11

Description .................................................................................................3-12

Special relays and arithmetic operation flags ............................................ 3-14

Special utility relays for high-speed counter(0) ..........................................3-14

Special utility relays for high-speed counter(1) ..........................................3-15

Other special utility relays ..........................................................................3-15

Timer/Counter list .......................................................................................3-18

Description .................................................................................................3-18

Setting the input time constant for basic units using special utility relays ..3-23

Modification within the CPU .......................................................................3-24

Constant Scan Time Mode ........................................................................ 3-28

Output Disabled Function .......................................................................... 3-28

Input Refresh Disabled Function ................................................................3-28

(9)

Page 11

Chapter 2 Instructions

2.1 Instruction List [Visual KV Series] ..............................................................3-34

2.1.1 Basic Instructions ..............................................................................................3-34

2.1.2 Application Instructions .....................................................................................3-36

2.1.3 Arithmetic Instructions ...................................................................................... 3-38

2.1.4 Interrupt Instructions .........................................................................................3-41

2.1.5 Function No. List (Alphabetical order) .............................................................. 3-41

2.2 Instruction List [KV-300 Series, KV-10/80] .................................................3-42

2.2.1 Basic Instructions ..............................................................................................3-42

2.2.2 Application Instructions .....................................................................................3-45

2.2.3 Arithmetic Instructions ...................................................................................... 3-48

2.2.4 Interrupt Instructions .........................................................................................3-54

2.3 Convention Details ........................................................................................3-55

2.4 Instruction Details .......................................................................................... 3-56

2.4.1 Basic Instructions ..............................................................................................3-56

2.4.2 Application Instructions .....................................................................................3-95

2.4.3 Arithmetic Instructions .................................................................................... 3-134

2.5 Programming Notes ..................................................................................... 3-189

Chapter 3 Interrupts Visual KV

3.1 Interrupt Instructions ................................................................................... 3-192

3.2 Interrupt Processing ....................................................................................3-194

3.2.1 Interrupt Processing ........................................................................................3-194

3.2.2 Types of Interrupts ..........................................................................................3-195

3.2.3 Interrupt Priority .............................................................................................. 3-196

3.2.4 Interrupt Program ............................................................................................3-196

3.3 Direct Input/Output ......................................................................................3-197

3.3.1 Direct Input ..................................................................................................... 3-197

3.3.2 Direct Output ...................................................................................................3-197

3.4 Applications of Interrupt Programs ...........................................................3-198

3.4.1 Interrupt with a Signal Converter .................................................................... 3-198

3.4.2 Interrupt with a High-speed Counter ...............................................................3-199

3.4.3 Measuring the ON Time of High-speed Pulses .............................................. 3-200

3.4.4 Measuring the Period in which a Target Passes between Two Points ...........3-201

Chapter 4 High-speed Counters Visual KV

4.1 High-speed Counter Instructions ............................................................... 3-204

4.2 Outline of High-speed Counters .................................................................3-206

4.2.1 High-speed Counters and High-speed Counter Comparators ........................3-206

4.2.2 Internal Clock for High-speed Counters ..........................................................3-210

4.3 Setting and Operation of High-speed Counters ........................................ 3-211

4.3.1 Reading the Current Value of the High-speed Counter ..................................3-211

4.3.2 Preset Value of the High-speed Counter Comparator ....................................3-211

4.3.3 Comparator Output .........................................................................................3-211

4.3.4 Count Input Method ........................................................................................ 3-212

4.3.5 Resetting the High-speed Counter ................................................................. 3-214

4.3.6 Differences with the CTH Instruction between the

4.3.7 Applications of High-speed Counters ............................................................. 3-217

4.4 Extended Functions of High-speed Counters ...........................................3-221

4.4.1 24-bit High-speed Counter ..............................................................................3-221

4.4.2 Changing the Current Value of a 24-bit High-speed Counter .........................3-223

4.4.3 Application Example of 24-bit High-speed Counter (single-phase input) ....... 3-224

4.4.4 Ring Counter Function ....................................................................................3-225

4.4.5 Applications of Ring Counters ........................................................................ 3-226

4.5 Special Functions Using High-speed Counters ........................................3-228

Structure of high-speed counters and high-speed counter comparators .3-206

Specifications of high-speed counters ..................................................... 3-208

High-speed counter comparators .............................................................3-209

Conventional and Visual KV Series ................................................................3-216

(10)

Page 12

4.5.1 Specified Frequency Pulse Output Function .................................................. 3-228

4.5.2 Applications of the Specified Frequency Pulse Output ...................................3-229

4.5.3 Frequency Counter Function .......................................................................... 3-231

4.5.4 Applications of Frequency Counters ...............................................................3-232

4.5.5 Cam Switch Function ......................................................................................3-233

4.5.6 Application of the Cam Switch (Cam Switch Mode) ....................................... 3-236

4.6 Direct Clock Pulse Output ........................................................................... 3-237

4.6.1 Outline of Direct Clock Pulse Output .............................................................. 3-237

4.6.2 Pulse Output Setting with the High-speed Counter Comparator .................... 3-238

4.7 Examples of Direct Clock Pulse Output ....................................................3-242

4.7.1 Example of Outputting a Pulse with 1:1 ON/OFF Ratio ..................................3-242

4.7.2 Example of Outputting a Pulse with Variable ON/OFF Ratio ..........................3-245

4.7.3 Example of Stopping the Pulse Output at a Specified Pulse Count ............... 3-249

4.7.4 Application of Direct Clock Pulse Output (Ramp-up/down control) ................ 3-251

Cam switch mode .................................................................................... 3-233

Multi-step comparator mode .................................................................... 3-234

Setting method .........................................................................................3-234

Changing the pulse period and width .......................................................3-238

Calculating the pulse period and comparator preset value ......................3-239

Operation with special utility relays ..........................................................3-239

Chapter 5 Positioning Control Visual KV

5.1 Outline of Positioning Control ....................................................................3-254

5.1.1 Ramp-up/down Control ...................................................................................3-254

5.2 Parameter Setting and Operating Procedures .......................................... 3-255

5.2.1 Parameter Setting Procedure ......................................................................... 3-255

5.2.2 Operating Procedure ...................................................................................... 3-257

5.3 Examples of Using the Positioning Control Function ..............................3-258

5.3.1 Connection Example .......................................................................................3-258

5.3.2 Tips .................................................................................................................3-258

5.3.3 Application Examples of the Positioning Control Function ............................. 3-259

Chapter 6 Interrupts, High-speed Counters,

Positioning Control KV-300, KV-10/80

6.1 Interrupt Instructions ................................................................................... 3-268

6.1.1 Description of Interrupts ..................................................................................3-268

6.1.2 Interrupt Instructions .......................................................................................3-271

6.2 Direct Clock Pulse ........................................................................................ 3-276

6.2.1 Output of Direct Clock Pulse ...........................................................................3-276

6.3 Positioning Control ...................................................................................... 3-296

6.3.1 Positioning Control (Ramp-up/down Control) ................................................. 3-296

Input processing for routine program and interrupt routine ......................3-268

Types of interrupt .....................................................................................3-268

Interrupt priority ........................................................................................3-269

Interrupt routine ........................................................................................3-269

Direct output .............................................................................................3-270

Direct input ...............................................................................................3-270

Outline of High-Speed Counters ..............................................................3-276

Outline of Pulse Output ............................................................................3-279

Examples of Pulse Output ....................................................................... 3-284

Outline of positioning control ....................................................................3-296

Setting and application of parameters ..................................................... 3-297

Examples of stepping motor control .........................................................3-300

Chapter 7 Serial Communication

7.1 Communications Specifications ................................................................3-306

7.1.1 Communications Specification ........................................................................3-306

7.1.2 Connection with the KV Unit ...........................................................................3-306

7.1.3 Connecting the KV-300 CPU to a Personal Computer ...................................3-307

7.2 Serial Communication ................................................................................. 3-308

7.2.1 Command Transmission Procedure ............................................................... 3-308

(11)

Page 13

7.2.2 Format of Commands/Responses ..................................................................3-309

7.2.3 Communication Command/Response List ..................................................... 3-310

7.2.4 Setting Communication Commands and Responses to Commands ..............3-311

7.2.5 Other Response Codes .................................................................................. 3-315

7.2.6 Error Code List ................................................................................................3-316

7.2.7 Example Program ...........................................................................................3-317

7.3 Loading Text Data ........................................................................................3-318

7.3.1 Receiving Text Data ....................................................................................... 3-318

7.3.2 Transmitting Text Data ................................................................................... 3-319

7.3.3 Sample Program .............................................................................................3-320

7.4 ASCII Code List ............................................................................................ 3-321

Chapter 8 Programming Examples

8.1 List .........................................................................................................3-324

8.2 Details .........................................................................................................3-326

8.2.1 Reference Program Examples ........................................................................3-326

Basic Instructions .....................................................................................3-326

Application Instructions ............................................................................3-334

Arithmetic Instructions ..............................................................................3-343

WARRANTIES AND DISCLAIMERS 3-367

1Installation

Chapter 1 Configuration and Specifications Visual KV

1.1 System Configuration ...................................................................................... 1-2

1.1.1 System Configuration ......................................................................................... 1-2

1.2 Specifications ................................................................................................... 1-4

1.2.1 General Specifications ........................................................................................1-4

1.2.2 AC Power Specifications .................................................................................... 1-5

1.2.3 Performance Specifications ................................................................................1-6

1.3 Common I/O Specifications of Basic Units ...................................................1-8

1.3.1 Model of a Basic Unit ..........................................................................................1-8

1.3.2 Common I/O Specifications ................................................................................ 1-8

1.4 KV-10AR/AT(P)/DR/DT(P) (10-I/O Basic Unit) .............................................1-10

1.4.1 Part Names and Functions ............................................................................... 1-10

1.4.2 Terminal Layout Drawings and I/O Circuit Diagrams ........................................1-11

1.4.3 AC Power Input (KV-10AR/AT(P)) ....................................................................1-14

1.4.4

1.4.5 Dimensions .......................................................................................................1-16

1.5 KV-16AR/AT(P)/DR/DT(P) (16-I/O Basic Unit) .............................................1-17

1.5.1 Part Names and Functions ............................................................................... 1-17

1.5.2 Terminal Layout Drawings and I/O Circuit Diagrams ........................................1-18

1.5.3 AC Power Input (KV-16AR/AT(P)) ....................................................................1-21

1.5.4

1.5.5 Dimensions .......................................................................................................1-23

1.6 KV-24AR/AT(P)/DR/DT(P) (24-I/O Basic Unit) .............................................1-24

1.6.1 Part Names and Functions ............................................................................... 1-24

1.6.2 Terminal Layout Drawings and I/O Circuit Diagrams ........................................1-25

1.6.3 AC Power Input (KV-24AR/AT(P)) ....................................................................1-28

1.6.4

1.6.5 Dimensions .......................................................................................................1-30

1.7 KV-40AR/AT(P)/DR/DT(P) (40-I/O Basic Unit) ..............................................1-31

Visual KV Series operation at power interruption ........................................ 1-5

Data backup function against instantaneous power interruption ................. 1-7

KV-10AR/DR (Relay output type) .............................................................. 1-11

KV-10AT(P)/DT(P) (Transistor output type) ...............................................1-13

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

KV-16AR/DR (Relay output type) .............................................................. 1-18

KV-16AT(P)/DT(P) (Transistor output type) ...............................................1-20

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

KV-24AR/DR (Relay output type) .............................................................. 1-25

KV-24AT(P)/DT(P) (Transistor output type) ...............................................1-27

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

1-15

1-22

1-29

(12)

Page 14

1.7.1 Part Names and Functions ............................................................................... 1-31

1.7.2 Terminal Layout Drawings and I/O Circuit Diagrams ........................................1-32

1.7.3 AC Power Input (KV-40AR/AT(P)) ....................................................................1-35

1.7.4

1.7.5 Dimensions .......................................................................................................1-37

1.8 KV-E4X/E8X/E16X (Expansion Input Unit) .................................................. 1-38

1.8.1 Part Names and Functions ............................................................................... 1-38

1.8.2 Input Specifications ...........................................................................................1-38

1.8.3 Terminal Layout Drawings and Input Circuit Diagrams .................................... 1-39

1.8.4 Dimensions .......................................................................................................1-42

1.9 KV-E4R/E4T/E8R/E8T(P)/E16R/E16T(P) (Expansion Output Unit) ............. 1-43

1.9.1 Part Names and Functions ............................................................................... 1-43

1.9.2 Output Specifications ........................................................................................1-43

1.9.3 Terminal Layout Drawings and Input Circuit Diagrams .................................... 1-45

1.9.4 Dimensions .......................................................................................................1-51

1.10 KV-E4XR/E4XT(P) (Expansion I/O Unit) .......................................................1-52

1.10.1 Part Names and Functions ...............................................................................1-52

1.10.2 Input Specifications ...........................................................................................1-53

1.10.3 Output Specifications ........................................................................................1-53

1.10.4 Terminal Layout Drawings and Input Circuit Diagrams .................................... 1-54

1.10.5 Dimensions ....................................................................................................... 1-58

1.11 KV-D20 (Operator Interface Panel) ............................................................... 1-59

1.11.1 Part Names and Functions ...............................................................................1-59

1.11.2 General Specifications ......................................................................................1-60

1.11.3 Functional Specifications .................................................................................. 1-60

1.11.4 Dimensions ....................................................................................................... 1-61

KV-40AR/DR (Relay output type) .............................................................. 1-32

KV-40AT(P)/DT(P) (Transistor output type) ...............................................1-34

Relationship between Continuous Simultaneous ON Ratio and Ambient Temperature

KV-E4X (4-I/O expansion input unit) ..........................................................1-39

KV-E8X (8-I/O expansion input unit) ..........................................................1-40

KV-E16X (16-I/O expansion input unit) ......................................................1-41

KV-E4R/E8R/E16R (Relay output type) .....................................................1-44

KV-E4T/E8T(P)/E16T(P) [Transistor output type (NPN/PNP)] .................. 1-44

KV-E4R [4-I/O expansion output unit (relay output type)] ..........................1-45

KV-E4T [4-I/O expansion output unit transistor output type)] .................... 1-46

KV-E8R [8-I/O expansion output unit (relay output type)] ..........................1-47

KV-E8T(P) [8-I/O expansion output unit (transistor output type)] .............. 1-48

KV-E16R [16-I/O expansion output unit (relay output type)] ......................1-49

KV-E16T(P) [16-I/O expansion input unit (transistor output)] .................... 1-50

KV-E4XR (Relay output type) .................................................................... 1-53

KV-E4XT(P) (Transistor output type) .........................................................1-53

KV-E4XR (Relay output type) .................................................................... 1-54

KV-E4XT(P) (Transistor output type) .........................................................1-56

1-36

Chapter 2 System Installation Visual KV

2.1 Installation Environment ............................................................................... 1-64

2.1.1 Installation Environment ................................................................................... 1-64

2.1.2 Installation Position ...........................................................................................1-65

2.1.3 Installation Procedure .......................................................................................1-66

2.1.4 Cautions on Wiring for Each Unit ......................................................................1-67

2.1.5 Contact Protection ............................................................................................ 1-69

2.2 Connecting Visual KV Series Expansion Units .......................................... 1-70

2.2.1 Visual KV Series Expansion Units ....................................................................1-70

2.2.2 Connecting Visual KV Series Expansion Units .................................................1-71

2.2.3 Confirming the Connection Settings of Expansion Units .................................. 1-74

Expansion unit spacer ................................................................................1-66

Wiring procedures for basic units ...............................................................1-67

Cautions on wiring for I/O units ..................................................................1-68

Terminal .....................................................................................................1-68

Cautions on grounding ...............................................................................1-69

Connection methods ..................................................................................1-72

Number of connectable units ..................................................................... 1-73

Expansion unit relay list ............................................................................. 1-74

Connection information for expansion units ...............................................1-75

Input time constant for expansion units ..................................................... 1-76

(13)

Page 15

2.2.4 Transferring I/O Information between Expansion Units and the Basic Unit ......1-77

2.3 Inspection and Maintenance .........................................................................1-78

2.3.1 Inspection ......................................................................................................... 1-78

2.3.2 Maintenance ..................................................................................................... 1-78

Clearing the input value when disconnecting .............................................1-76

When inputting ...........................................................................................1-77

In the case of output .................................................................................. 1-77

Chapter 3 Access Window Visual KV

3.1 Overview of the Access Window ..................................................................1-80

3.1.1 What is the Access Window ............................................................................. 1-80

3.1.2 Access Window Use Examples ........................................................................ 1-80

3.2 Basic Operating Procedures ......................................................................... 1-81

3.2.1 Operation Mode ................................................................................................1-81

3.2.2 Access Window Modes .....................................................................................1-81

3.2.3 Part Names and Functions of the Access Window ...........................................1-82

3.2.4 Selecting Modes and Setting/Resetting Key Lock ............................................1-82

3.2.5 Turbo Function ..................................................................................................1-83

3.3 Digital Trimmer Mode ....................................................................................1-84

3.3.1 Function and Operating Procedure ...................................................................1-84

3.4 Device Mode ................................................................................................... 1-87

3.4.1 Function and Operating Procedure ...................................................................1-87

3.4.2 Screen Display for Each Device Type .............................................................. 1-91

3.5 System Mode ..................................................................................................1-94

3.5.1 Function and Operating Procedure ...................................................................1-94

3.6 Message Display ............................................................................................ 1-97

3.6.1 Error Messages and Error Status ..................................................................... 1-97

3.6.2 User Messages .................................................................................................1-97

Key operation and screen display ..............................................................1-84

Function and operating procedure .............................................................1-84

Devices that can be displayed and changed ............................................. 1-87

Key operation and screen display ..............................................................1-87

Selecting the device and displaying the current value/set value ................1-88

Changing a numeric value ......................................................................... 1-89

Holding the setting ..................................................................................... 1-91

Data memory (DM) .................................................................................... 1-91

Temporary data memory (TM) ...................................................................1-91

Timer/counter (T/C) ....................................................................................1-92

High-speed counter comparator (CTC) ......................................................1-92

Trimmer (TRM) .......................................................................................... 1-93

Relay (RLY) ............................................................................................... 1-93

Key operation and screen display ..............................................................1-94

LOAD mode and SAVE mode ....................................................................1-96

Display in LOAD/SAVE mode ....................................................................1-96

How to use the user messages ..................................................................1-98

Chapter 4 KV-D20 Operator Interface Panel Visual KV

4.1 Before Operation .......................................................................................... 1-100

4.1.1 Checking Package Contents .......................................................................... 1-100

4.1.2 Part Names and Functions ............................................................................. 1-101

4.1.3 Details about the KV-D20 ............................................................................... 1-102

4.1.4 Installation and Environment .......................................................................... 1-104

4.1.5 Inspection and Maintenance ...........................................................................1-106

4.2 Overview and Operation .............................................................................. 1-107

4.2.1 Use Examples for the KV-D20 ........................................................................1-107

General specifications ..............................................................................1-102

Functional specifications ..........................................................................1-102

Dimensions .............................................................................................. 1-103

Use environment ......................................................................................1-104

Panel mounting ........................................................................................1-105

Inspection .................................................................................................1-106

Maintenance ............................................................................................ 1-106

(14)

Page 16

4.2.2 Connection with the KV Series ....................................................................... 1-108

4.2.3 Overview of the KV-D20 ................................................................................. 1-109

4.2.4 Operator Mode ................................................................................................1-117

4.2.5 Device Mode ...................................................................................................1-130

4.2.6 System Mode ..................................................................................................1-134

4.3 Examples of Ladder Programs ................................................................... 1-135

4.3.1 Basic Ladder Programs .................................................................................. 1-135

4.3.2 Examples of Ladder Programs ....................................................................... 1-143

4.4 Appendix ....................................................................................................... 1-158

4.4.1 Troubleshooting ..............................................................................................1-158

4.4.2 Available Character List ..................................................................................1-162

4.4.3 Comment Draft Sheet .....................................................................................1-163

Connection ...............................................................................................1-108

Precautions ..............................................................................................1-108

Switching the display mode ..................................................................... 1-109

Overview of each display mode ...............................................................1-110

Assignment of relays/DM .........................................................................1-111

Other functions .........................................................................................1-112

Precautions about screen change function ..............................................1-115

Screen selection in operator mode .......................................................... 1-117

Operator screen .......................................................................................1-118

Direct access screen ................................................................................1-126

KV-I/O monitor screen ............................................................................. 1-127

Switch comment screen ...........................................................................1-128

Lamp comment screen ............................................................................ 1-128

Screen change permission in operator mode .......................................... 1-129

Device mode ............................................................................................1-130

Operation example for device mode ........................................................1-132

System mode ...........................................................................................1-134

Before creating ladder programs ............................................................. 1-135

Basic ladder programs .............................................................................1-136

Example of displaying user messages .....................................................1-143

Example of displaying messages with titles .............................................1-145

Example of position control ......................................................................1-146

Example of frequency counter ................................................................. 1-149

Example of 24-bit high-speed counter ..................................................... 1-152

Example of cam switch function ...............................................................1-154

Chapter 5 KV-300, KV-10/80 Hardware KV-300, KV-10/80

5.1 System Configuration .................................................................................. 1-166

5.1.1 KV-300 ............................................................................................................1-166

5.1.2 KV-10/80 .........................................................................................................1-167

5.2 Module/Unit Specifications ......................................................................... 1-168

5.2.1 Wiring: KV-U4 Power Supply Module .............................................................1-168

5.2.2 Wiring: KV-U5 DC Power Distribution Module ................................................1-169

5.2.3 Wiring: KV-300 CPU .......................................................................................1-170

5.2.4 Wiring: KV-C16X/C32X Connector Input Module ........................................... 1-171

5.2.5 Wiring: KV-C32T/B16R/B16S Connector Output Module ...............................1-172

5.2.6 Wiring: KV-R1A I/O Distribution Module .........................................................1-173

5.2.7 Wiring: KV-R8X/R16X/R8R/R16R/R8T/R16T I/O Terminal Modules ............. 1-174

5.2.8 Module Names and Functions ........................................................................1-175

5.2.9 Peripheral Equipment Names and Functions ................................................. 1-176

5.3 Module/Unit Connections ............................................................................ 1-178

5.3.1 Environmental Requirements ......................................................................... 1-178

5.3.2 Installation Guidelines .....................................................................................1-178

5.3.3 Assembling the System .................................................................................. 1-179

5.3.4 Mounting to the DIN Rail .................................................................................1-180

5.3.5 Removing the Terminal Block .........................................................................1-181

Parts and functions .................................................................................. 1-168

Parts and functions .................................................................................. 1-169

Parts and functions .................................................................................. 1-170

Parts and functions .................................................................................. 1-171

Parts and functions .................................................................................. 1-172

Parts and functions .................................................................................. 1-173

Parts and functions .................................................................................. 1-174

Connecting modules ................................................................................ 1-179

(15)

Page 17

5.3.6

Connecting the AC Power Supply Module and DC Power Distribution Module ....

KV-U4 AC Power Supply Module ............................................................ 1-182

5.3.7 I/O Connectors ................................................................................................1-183

5.3.8 I/O Terminal Modules: Communication Cables and Power Distribution .........1-187

5.3.9 Connector Assembly Instructions ................................................................... 1-189

5.3.10 KV-300 CPU I/O Indicators ............................................................................. 1-191

5.3.11 KV-10/80 Expansion Units ..............................................................................1-192

5.3.12 Mounting Environment .................................................................................... 1-194

KV-U5 DC Power Distribution Module ..................................................... 1-182

KV-300 CPU ............................................................................................ 1-183

KV-C16X/C32X ........................................................................................1-184

KV-C32T/B16R/B16S .............................................................................. 1-185

KV-R8X/R16X/R8R/R16R/R8T/R16T ......................................................1-186

Transmission distance by cable type .......................................................1-187

Connection patterns .................................................................................1-187

Incorrect wiring patterns ...........................................................................1-188

Power distribution .................................................................................... 1-188

1-182

Chapter 6 Handheld Programmer

6.1 Using the Handheld Programmer ...............................................................1-196

6.1.1 Outline of the Handheld Programmer .............................................................1-196

6.1.2 Precautions .....................................................................................................1-198

6.2 Basic Operations .........................................................................................1-200

6.2.1 Basic Programming Operation ........................................................................1-200

6.3 Functions ......................................................................................................1-216

6.4 Memory Card ................................................................................................ 1-230

6.4.1 Functions [used with KV-P3E(01)] ..................................................................1-230

6.4.2 Storage Capacity ............................................................................................ 1-230

Function Nos. list ..................................................................................... 1-216

ALL CLEAR ..............................................................................................1-217

HANDHELD PROGRAMMER CLEAR .....................................................1-217

COUNTER CLEAR .................................................................................. 1-218

HIGH-SPEED COUNTER CLEAR ...........................................................1-218

ALL DATA MEMORY CLEAR ..................................................................1-219

ALL LATCHING RELAYS RESET ........................................................... 1-219

PROGRAM SENT OR RECEIVED ..........................................................1-220

OFFLINE EDITOR START ...................................................................... 1-221

OFFLINE EDITOR STOP ........................................................................ 1-221

TIMER/COUNTER CURRENT VALUE CHANGE ................................... 1-222

TIMER/COUNTER SETTING CHANGE ..................................................1-224

RELAY ON/OFF .......................................................................................1-226

WRITE INTO DATA MEMORY ................................................................1-227

READ TRIMMER SETTING .....................................................................1-228

SYNTAX CHECK .....................................................................................1-228

PROGRAM CAPACITY CHECK ..............................................................1-229

CLEAR .....................................................................................................1-232

NEW .........................................................................................................1-233

ACCS .......................................................................................................1-234

ACCS: SAVE ........................................................................................... 1-235

ACCS: LOAD ........................................................................................... 1-236

ACCS: VERIFY ........................................................................................1-236

ACCS: DELETE .......................................................................................1-237

Chapter 7 KV-L2 Serial Interface Module KV-300

7.1 Outline .........................................................................................................1-240

7.1.1 Features ..........................................................................................................1-240

7.2 Configuration ...............................................................................................1-241

7.2.1 Parts and Functions ........................................................................................1-241

7.2.2 System Configuration ..................................................................................... 1-242

7.2.3 Outline of Operation Modes ............................................................................1-244

7.3 Installation .................................................................................................... 1-245

7.3.1 Setting the Operation Mode ............................................................................1-245

7.3.2 Communications Protocols .............................................................................1-247

7.3.3 Connector Wiring ............................................................................................1-248

(16)

Page 18

7.3.4 Connecting to External Units .......................................................................... 1-249

7.4 Software Setup .............................................................................................1-252

7.4.1 Using KV Software [KV IncrediWare (DOS)] .................................................. 1-252

Starting KV IncrediWare (DOS) from the KV-L2 ........................................................ 1-252

7.5 KV Mode Programming ...............................................................................1-253

7.5.1 Operating in KV Mode .................................................................................... 1-253

7.5.2 Serial Communications Procedure ................................................................. 1-255

7.5.3 Transmission and Reception of Text Data ......................................................1-262

7.6 Display Interface Mode Programming .......................................................1-270

7.6.1 Operating in Display Interface Mode .............................................................. 1-270

7.6.2 Command and Response Format ...................................................................1-273

7.6.3 Commands and Responses ........................................................................... 1-275

7.7 Non-procedure Mode Programming ..........................................................1-292

7.7.1 Operating in Non-procedure Mode ................................................................. 1-292

7.7.2 Assignment of Relay Nos. and Data Memory Address Nos. .......................... 1-294

7.7.3 Transmitting Text Data ................................................................................... 1-297

7.7.4 Receiving Text Data ....................................................................................... 1-298

7.7.5 ASCII code/Binary Conversion Function ........................................................ 1-300

7.8 Troubleshooting Guide ...............................................................................1-304

7.8.1 Troubleshooting ..............................................................................................1-304

7.8.2 Precautions .....................................................................................................1-305

7.9 Specifications ............................................................................................... 1-306

7.9.1 Specifications ..................................................................................................1-306

7.9.2 Dimensions .....................................................................................................1-307

7.10 Command List .............................................................................................. 1-308

7.10.1 List of Commands and Responses .................................................................1-308

7.10.2 List of Commands and Responses in Display Interface mode .......................1-309

Connecting to An External Display .......................................................... 1-249

Connecting to an IBM PC-AT Computer ..................................................1-249

Connecting to the KV-10/16/24/40/80 ......................................................1-250

Connecting KV-L2s ..................................................................................1-250

Communications protocol ........................................................................ 1-253

Command transmission procedure ..........................................................1-255

Command/response format ..................................................................... 1-256

Communications commands and responses ...........................................1-256

Communications commands ....................................................................1-257

Assigning relay nos. and data memory address nos. .............................. 1-262

Transmitting Text Data .............................................................................1-264

Receiving text data .................................................................................. 1-265

ASCII code/binary conversion function ....................................................1-266

Example program .....................................................................................1-269

Communications protocols .......................................................................1-270

Communications control procedure ......................................................... 1-271

List of commands and responses ............................................................ 1-275

Description of commands and responses ................................................1-277

End codes ................................................................................................1-291

Communications protocol ........................................................................ 1-292

Connecting to the KV-L2 ..........................................................................1-293

Assigning relay nos. and data memory address nos. .............................. 1-294

Data transmission and internal data memory addresses .........................1-297

Format of received data and data memory addresses ............................ 1-298

General specifications ..............................................................................1-306

Communications protocol ........................................................................ 1-306

RS-232C connector specifications ...........................................................1-306

RS-422A terminal block specifications .....................................................1-306

Chapter 8 KV-AN6 Analog I/O Module KV-300

8.1 Outline .........................................................................................................1-312

8.2 Configuration ...............................................................................................1-313

8.2.1 Parts and Functions ........................................................................................1-313

8.2.2 System Configuration ..................................................................................... 1-314

8.3 Installation .................................................................................................... 1-315

8.3.1 Terminal Nos. ................................................................................................. 1-315

Features ...................................................................................................1-312

(17)

Page 19

8.3.2 Removing the Terminal Block .........................................................................1-316

8.3.3 Example of Voltage I/O Wiring ........................................................................1-317

8.3.4 Example of Current I/O Wiring ........................................................................1-318

8.3.5 Setting I/O Ranges ......................................................................................... 1-319

8.4 Programming ................................................................................................ 1-320

8.4.1 Input Characteristics (A/D) ..............................................................................1-320

8.4.2 Calculating Input Data (A/D) ...........................................................................1-321

8.4.3 Output Characteristics (D/A) ...........................................................................1-322

8.4.4 Calculating Output Data (D/A) ........................................................................ 1-323

8.4.5 Assigning Data Memory (DM) Addresses .......................................................1-324

8.4.6 Reading Analog Input ..................................................................................... 1-325

8.4.7 Measuring Analog Input Average ................................................................... 1-326

8.4.8 Writing Analog Output .....................................................................................1-327

8.4.9 Converting Analog Input to Analog Output ..................................................... 1-328

8.5 KV-AN6 Appendices ....................................................................................1-329

8.5.1 Troubleshooting ..............................................................................................1-329

8.5.2 Precautions .....................................................................................................1-330

8.5.3 Specifications ..................................................................................................1-331

8.5.4 Dimensions .....................................................................................................1-332

Environmental specifications ................................................................... 1-331

System specifications .............................................................................. 1-331

Chapter 9 KV-AD4/DA4 Analog I/O Unit KV-10/80

9.1 Outline .........................................................................................................1-334

9.2 Configuration ...............................................................................................1-335

9.2.1 Part Names and Functions ............................................................................. 1-335