Page 1

Note

OUT

LASER

1

2

CLP

OUT

LASER

TIM

BANK

SET

SEL

MODE

1

2

1

2

1 spotDATUM

series

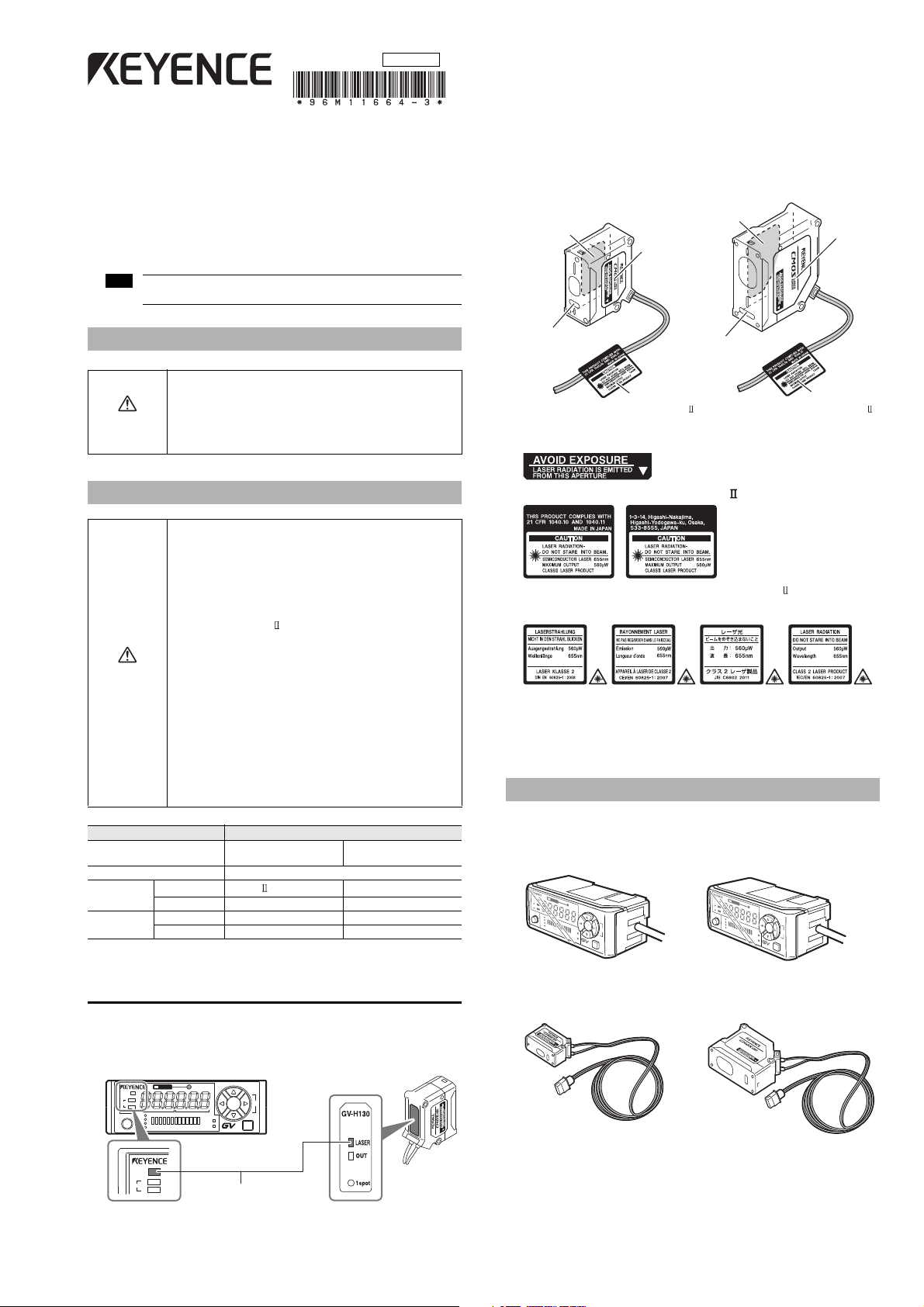

Laser radiation emission indicator

Sensor amplifier Sensor head

GV-H45(L)/GV-H130(L) GV-H450(L)/GV-H1000(L)

Aperture label

Aperture label

Laser

transmitter

FDA (CDRH)

warning label (Class )*

Aperture label

Aperture label

Laser

transmitter

FDA (CDRH)

warning label (Class )*

* Not included with GV-H45L/H130L/H450L/H1000L.

z Aperture label

z IEC warning/explanatory label (CLASS 2)

z FDA (CDRH) warning label (CLASS )

The FDA (CDRH) warning labels are only affixed to Class laser products.

GV-21/GV-21P (main unit)

GV-22/GV-22P (expansion unit)

Amplifier x1

Instruction manual x1

Amplifier x1

GV-H45(L)/H130(L) GV-H450(L)/H1000(L)

Sensor head x1

Insulating sheet x1

Mounting bracket x1

Board nut x1

M3 x L30 screw x2

Laser warning sticker* x1

Sensor head x1

Insulating sheet

X1

Mounting bracket x1

Board nut x1

M4 x L35 screw x2

Laser warning sticker* x1

* This is not included with GV-H45L/H130L/H450L/H1000L.

96M11664

Digital CMOS Laser Sensor

GV Series

Instruction Manual

Read this manual before using the software in order to achieve maximum

performance.

Keep this manual in a safe place after reading it so that it can be used at any time.

The displayed values indicate guidelines for distances and should not

be used in the actual applications for measurement.

Safety Precautions

•

This product is only intended to detect object(s). Do not use this

product for the purpose to protect a human body or part of a

human body.

•

WARNING

Safety Precautions on Laser Products

This product is not intended for use as an explosion-proof

product. Do not use this product in a hazardous location and/or

potentially explosive atmosphere.

Laser emission stop input

The laser emission stops when an emission stop (purple line) signal is input (for

20 ms or longer). The emission stops while the signal is input. The laser beam is

emitted a maximum of 20 ms after the signal input is canceled. The control

output functions according to the detection value even while laser emission

stop is input.

Laser warning labels

The following diagrams show the type and position of laser warning labels

according to the GV Series.

•

This product employs a semiconductor laser for its light source.

•

Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation

exposure.

•

Follow the instructions mentioned in this manual. Otherwise, injury

to the human body (eyes and skin) may result.

•

Do not disassemble this product. Laser emission from this product

is not automatically stopped when it is disassembled.

Precautions on class /2 laser products

• Do not stare into the beam.

• Do not direct the beam at other people or into areas

WARNING

where other people unconnected with the laser work

might be present.

• Be careful of the path of the laser beam.

If there is a danger that the operator may be exposed

to the laser beam reflected by specular or diffuse

reflection, block the beam by installing an enclosure

with the appropriate reflectance.

• Install the products so that the path of the laser beam

is not as the same height as that of human eye.

Precaution on class 1 laser products

• Do not stare into the beam.

Model

Item

GV-H45, GV-H130,

GV-H450, GV-H1000

Description

GV-H45L, GV-H130L,

GV-H450L, GV-H1000L

Wavelength 655nm

FDA (CDRH)

Part 1040.10

IEC 60825-1

* The laser classification for FDA(CDRH) is implemented based on IEC60825-1 in

accordance with the requirements of Laser Notice No.50.

Laser Class

Output 560μW220μW

Laser Class Class 2 Laser Product Class 1 Laser Product

Output 560μW220μW

Class Laser Product

Class 1 Laser Product*

The IEC warning/explanatory labels are only included with Class 2 laser

products.

When using this product in the countries and/or regions other than U.S., use the

IEC warning/explanatory label in the package of this product.

In this case, it can be affixed on the FDA (CDRH) warning label, which has

already been affixed to this product.

Checking the Package Contents

Check if the parts and equipment listed below are included in the package of the

model you purchased before using the unit.

Sensor amplifier

LASER

DATUM

1

OUT

1spot

2

SET

1

2

BANK

SEL

TIM

CLP

MODE

series

LASER

DATUM

1

OUT

1spot

2

SET

1

2

BANK

SEL

TIM

CLP

MODE

series

Safety measures for the laser

Laser radiation emission indicator

The laser radiation emission indicator lights up after turning on the power and

while the laser beam is being emitted.

Sensor head

We have thoroughly inspected the package contents before shipment.

However, in the event of defective, broken or missing items, please contact your

nearest KEYENCE office.

1

GV-IM-E

Page 2

Mounting and Wiring the Sensor Amplifier

(1)

(3)

(2)

Amplifier mounting bracket

Note

GV-21/

GV-21P

Expansion

protective

cover

Main

unit

Expansion

unit

Connector

End

unit

End

unit

Control output 1

Brown

*1

Blue

*1

Black

White

Pink

*2

Purple

Control output 2

External input

Laser emission

stop input

10-30 V DC

Laser receiver Mounting area

LASER

(Laser radiation

emission indicator)

OUT

(Control output

indicator)

Mounting area

1spot

(Spot reflection

indicator)

Laser

Connector

Connector

Unlocked

Locked

Note

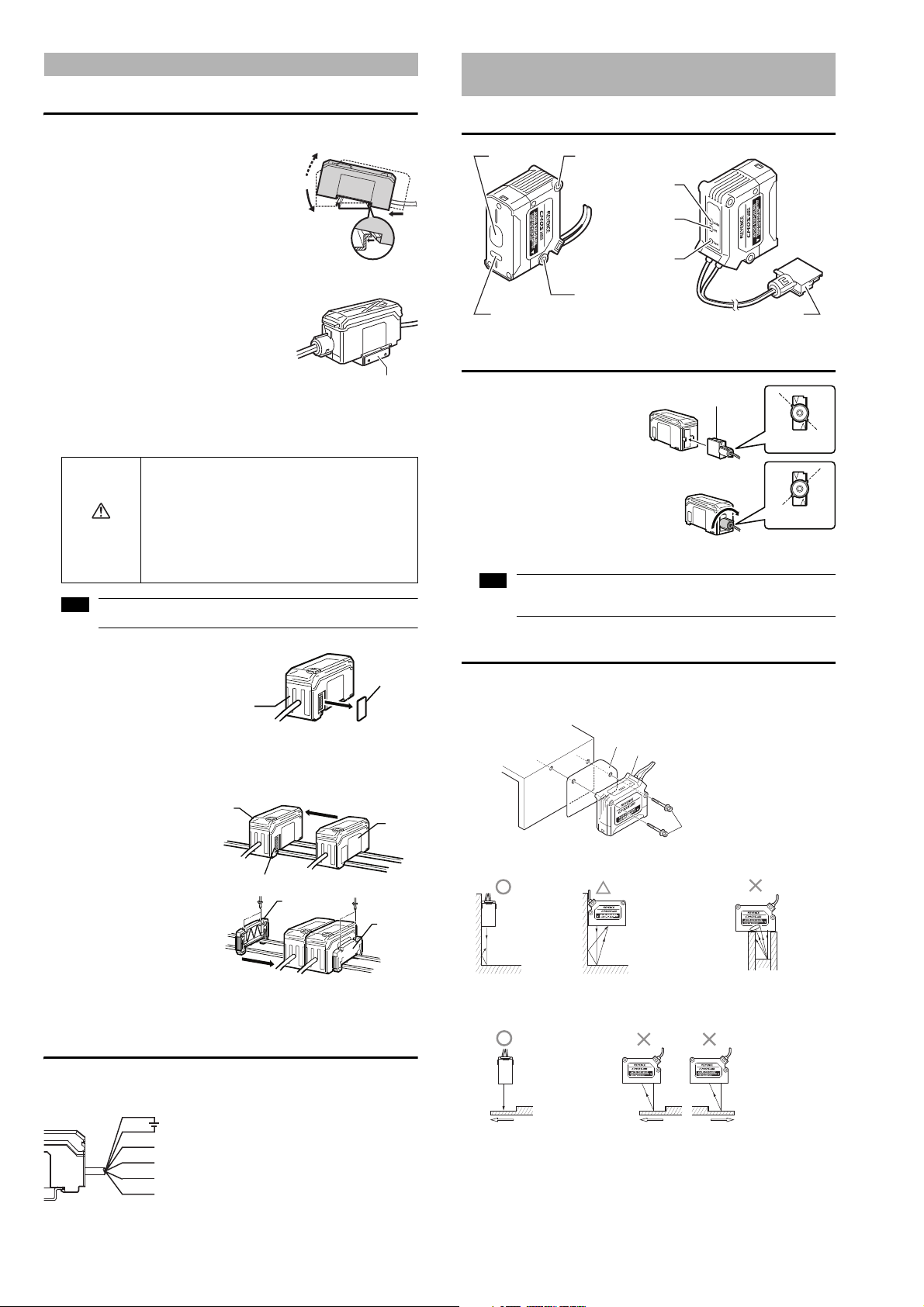

z Mounting when detecting

targets close to a wall

z Mounting when detecting

targets in a hole

Receives little effect

from stray laser light.

Variations in the detection

value with effects from

stray laser light.

The target cannot be detected

when the transmitter or receiver

are blocked.

Sensor head

Insulating sheet

Hexagon socket bolt

(Accessory)

z When detecting uneven workpieces

• Stable detection

even on uneven

areas.

• Incorrect values

can be detected

on the uneven

areas.

Mounting the sensor amplifier

Mounting the GV-21/GV-21P (main unit)

1 Align the claw at the bottom of the

main body with the DIN rail. While

pushing the main body in the

direction of the arrow 1, slant it in the

direction of the arrow 2.

2 To dismount the sensor, raise the

main body in the direction of the

arrow 3 while pushing the main body

in the direction of the arrow 1.

When using the amplifier mounting bracket

(OP-76877) (sold separately), mount it as

shown in the diagram to the right.

Mounting the GV-22/GV-22P (expansion unit)

Several expansion units can be used in connection with the main unit.

Up to three expansion units can be connected to one main unit.

•

When connecting multiple amplifiers (expansion units),

first check to make sure that the power is turned off to all

of the main and expansion units. Connecting the units

with the power turned on may cause damage to the units.

•

Push the amplifiers (expansion units) as far as possible into

CAUTION

Expansion units with different output types (such as a PNP output main

unit to an NPN output expansion unit) cannot be connected together.

the main unit. If they are connected at a slant or not inserted

securely, the units may be damaged.

•

Only GV Series amplifier can be connected (DL Series

cannot be connected). Connecting other amplifiers may

cause damage to the units.

Connecting and Mounting the Sensor Head

Sensor head part names

Connecting the sensor head

1 Unlock the sensor head

connector and insert it into

back of the amplifier.

2

Turn the round part of the

connector clockwise until a

clicking sound is heard to lock

it.

When shortening the sensor head cable, follow the instructions given in

the "Sensor Head Connector Assembly Manual" included with the sensor

head.

1 Remove the expansion

protective cover from the

GV-21/GV-21P (main unit)

2 Install the amplifiers (expansion units) on the DIN rail.

For more information about mounting, see "Mounting the GV-21/GV-21P (main

unit)".

3 Push the expansion unit into

the main unit connector until

a clicking sound can be

heard.

4

Install the end units

(OP-26751: 2 units in a set)

(sold separately) on either

side of the amplifiers (main or

expansion units). Secure the

end units in place with screws

on top (2 on each end unit).

The end units are mounted in the same way as the amplifiers.

Amplifier wiring

The following information shows the I/O cable.

For more information about the I/O circuit, see page 9 of this Instruction Manual.

GV-IM-E

*1

GV-22/GV-22P (expansion unit) do not

have brown or blue lines. Power is supplied

to the expansion units through GV-21/GV21P (main unit).

*2 The external input switches as shown

below depending on the amplifier

OPTIONAL settings.

• oFF ......... Input off

• SFt .......... External shift

• bnK ......... Bank switching

• tim........... Timing input

Mounting the sensor head

Use the dedicated mounting bracket to mount the sensor head.

When not using the dedicated mounting bracket, the included insulating sheet must be

inserted between the mounting surface and the sensor head as shown in the diagram.

(When using the dedicated mounting bracket, the insulating sheet is not necessary.)

2

Page 3

Sensor Amplifier

CLP

OUT

LASER

TIM

BANK

SET

SEL

MODE

1

2

1

2

1 spotDATUM

series

Reference surface (DATUM) detection

indicator

*1

(red)

Current value display

(red)

Setting value display

(green)

Spot reflection (1spot) indicator*2

(green)

Arrow

buttons

Output status indicator

(red)

Laser radiation emission

indicator (green)

[SET] button

Channel No. indicator (green)

LED bar

CLP function indicator*3

(red)

[MODE] button

Bank input indicator (green)

Timing input indicator

*4

(red)

DATUM

DATUM

DATUM

Setting value/current value display

Setting value (green)

Peak value (green) Bottom value (red)

Channel No. indicators

Current value (red)

Pressing the [MODE] button switches

the channels (channel No. indicators).

Peak value/bottom value display

Pressing the [UP] arrow button

resets the peak and bottom values.

Alternate

1

2

1

2

1

2

or

SET

MODE

SET

MODE

SET

MODE

Note

Note

Example

750

0

0mm

55mm

130mm

Current value

Distance

Minimum detection distance

Maximum detection distance

Reference

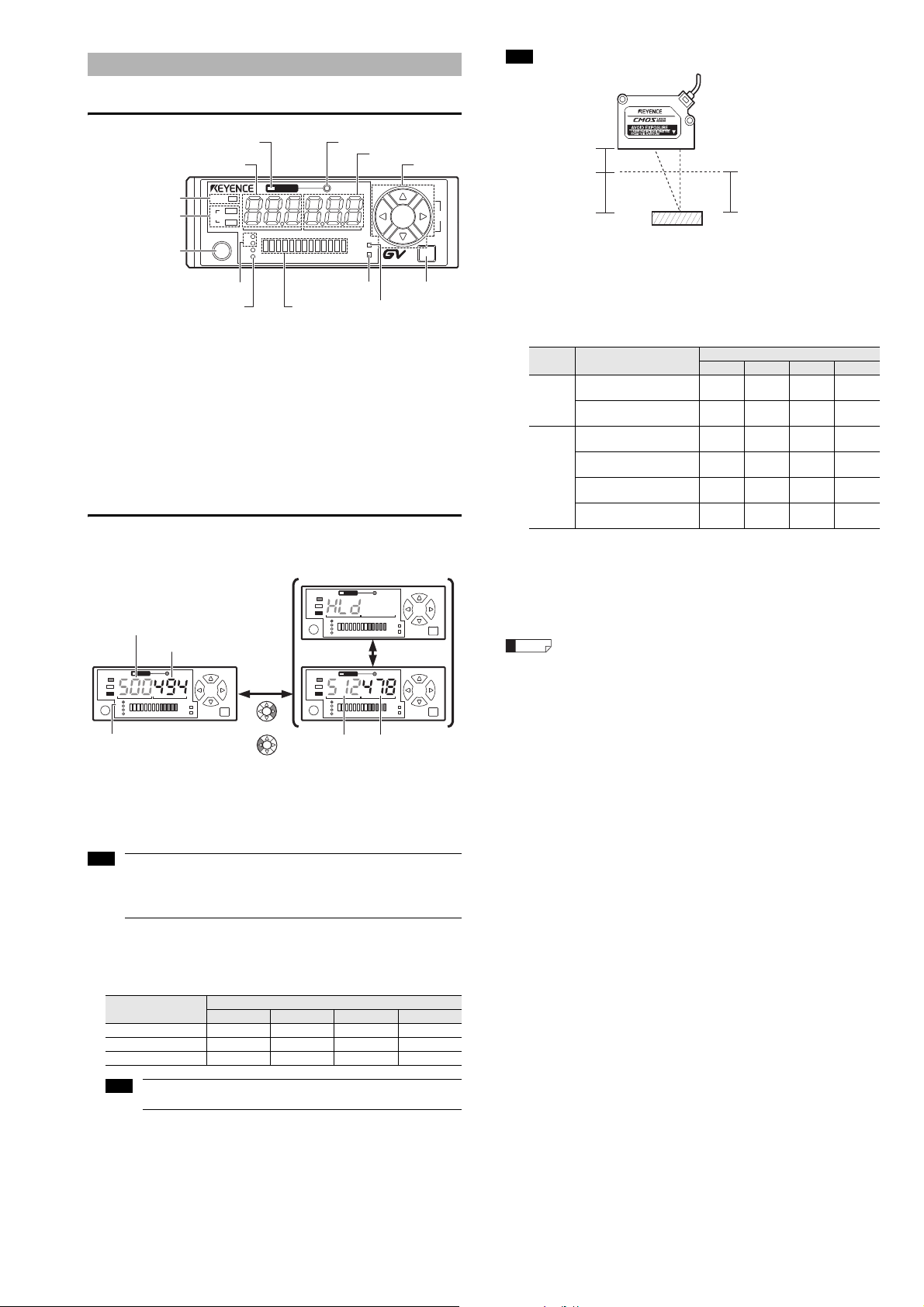

Sensor amplifier part names

*1 The reference surface (DATUM) detection indicator lights up when

*2

*3 For more information about the CLP (clamp) function indicator, see "4.

*4 For more information about the timing input indicator, see "8. External

Main screen

The main screen can be switched between "Current/setting value display" and

"Peak/bottom value display". The main screen can be switched even during

keylock.

performing reference surface detection. For more information, see

"Reference surface detection (DATUM) method (Application)" on page 5

of this Instruction Manual.

The spot reflection indicator lights up during normal detection and turns off

during multiple reflection (when multiple peaks of received light intensity

occurs due to diffuse reflection), insufficient light intensity, and when the

target is out of the detection range.

Clamp function setting" on page 8 of this Instruction Manual.

input setting" on page 8 of this Instruction Manual.

When using sensor head GV-H130

For example, when using the defaults with the setting value (green) at 500, the

comparator output turns on when the current value is 500 or greater and turns off

when it is less than 500.

If multiple reflection (when multiple peaks of received light intensity occurs due to

diffuse reflection) occurs during F-1, F-2, or A-1 modes, the value immediately

before the current value is held.

z Setting value

The following table shows the default setting values for each channel.

Operation

mode

Control output

(Channel 1 lit)

F-1, A-1,

A-2

Control output

(Channel 2 lit)

Control output 1 (black) HIGH

(Channel 1 lit)

Control output 1 (black) LOW

(Channel 2 lit)

F-2

Control output 2 (white) HIGH

(Channel 1

Control output 2 (white) LOW

(Channel 2 flashing)

Item

1 (black)

2 (white)

flashing

GV-H45 (L) GV-H130 (L) GV-H450 (L) GV-H1000 (L)

)

Default value

150 500 200 500

125 400 150 400

150 500 200 500

100 300 100 300

125 400 150 400

75 200 50 200

z Peak/bottom values

Peak value

Bottom value

: Resets when the detection value exceeds the setting value

and holds the maximum value (peak value) until the

detection value falls below the setting value again.

: Resets when the detection value falls below the setting value

and holds the minimum value (bottom value) until the

detection value exceeds the setting value again.

The held peak and bottom values can be cleared by pressing and hold

the [Up] arrow button.

Pressing the [Up] and [Down] arrow buttons simultaneously on the main screen

forces the current value (red) to 0

* With the default settings. For details, see "9. Shift target value setting" on page 9

of this Instruction Manual.

When the channel No. 1 indicator is lit, the control output 1 (black line)

setting value is displayed. When the channel No. 2 indicator is lit, the

control output 2 (white line) setting value is displayed.

Operations are different in F-2 mode. (See page 5 of this Instruction

Manual.)

z Current value and display resolution

In the default state, the current value shows 0 when the workpiece is located at

the maximum detection distance. Bringing the workpiece closer to the sensor

head gradually increases the value and displays it up to the minimum detection

distance.

Detecting range (mm)

Digital display (initial) 250 to 0 750 to 0 290 to 0 800 to 0

Display resolution1215

*

.

Item

GV-H45 (L) GV-H130 (L) GV-H450 (L)

20.0 to 45.0

The displayed values indicate guidelines for distances and should not

be used in the actual applications for measurement.

Current value

55.0 to 130.0

160 to 450 200 to 1000

GV-H1000 (L)

3

GV-IM-E

Page 4

Configure the sensitivity setting in F-1 mode (with the default settings).

2-point calibration

The setting is automatically calculated as the mean value detected from two

points: with the workpiece and without the workpiece.

1 Press the [SET] button once

without a workpiece in place.

The current value without the

workpiece is read.

2 Place a workpiece in the

detection position, and quickly

press the [SET] button once

again.

This concludes 2-point calibration

and the sensor returns to the

detection state.

If there is very little difference between the values obtained in

Step 1 and Step 2, then "---" flashes in the setting value display

area after calibration is complete. The setting value is still

updated.

Fine-tune setting value

Use the [Up] and [Down] arrow buttons to fine-tune the setting value.

Reference surface (DATUM) calibration

Use DATUM calibration when comparator output cannot be performed

correctly during 2-point calibration (due to problems such as chattering from

the surface of the workpiece).

3 Press the [SET] button once without a workpiece in place

(reference surface).

4 Using the same conditions,

Item Setting range

Setting

value

fine-

tuning

-199 to 999

Reference

DATUM

SET

MODE

1

2

Increases

the setting

value

Decreases

the setting

value

Using Basic Operations

Note

OFF

OFF

ON

LOW setting value

HIGH setting value

Only this will turn ON.

Control output 1

(black) HIGH setting

value

• Channel No. 1

indicator lights up

Control output 1

(black) LOW setting

value

• Channel No. 2

indicator lights up

Control output 2

(white) HIGH setting

value

• Channel No. 1

indicator flashes

Control output 2

(white) LOW setting

value

• Channel No. 2

indicator flashes

Configuring the Sensitivity Setting and Operation Mode

Detection method

The GV Series has two type of detection methods: "Distance detection method" and

"Reference surface (DATUM) detection method".

The reference surface (DATUM) detection method can only be used when

performing reference surface calibration.

Control output 2 is fixed to distance detection method for all operation modes.

Distance detection method (Normal)

Detects the distance between the detection target and the sensor head, and

then performs control output. The following table shows each operation mode

and the auto calibration that can be used.

Operation mode Description

Normal detection mode

General F-1

Special

The most general mode.

ON/OFF judgment is performed

based on one setting value.

Area detection mode

On/OFF judgment is performed

F-2

on an area based on two

settings.

Edge hold mode

Detects the change in distance

A-1

(derivation) to the target and

holds the display.

Surface detection mode

When multiple beams of light are

reflected from the detection

A-2

target, the closest reflected light

is judged as the detection value.

z Area detection mode (F-2 mode)

Operation image

Usable

auto calibration

2-point calibration

Full auto calibration

Maximum sensitivity

setting

2-point area calibration

1-point area calibration

2-point calibration

Full auto calibration

Maximum sensitivity

setting

2-point calibration

Full auto calibration

Maximum sensitivity

setting

When using the F-2 mode, the channel No. indicator switches in the following

order each time the [MODE] button is pressed.

MODE

Press once.

1

2

1

2

MODE

Press once.

1

2

MODE

Press once.

1

2

MODE

Press once.

GV-IM-E

4

Page 5

z Edge hold mode (A-1 mode)

Detection

value

Control

output

ON

OFF

0

Note

Reference

Influence of diffuse

reflection

(Multiple reflection)

Split spot

(Multiple reflection)

Insufficient light

intensity

Reference

Upper limit

Lower limit

Reference

This operation mode is suitable for detecting workpieces on a conveyer or

detecting workpieces with waving backgrounds. It ignores slow distance

changes and only detects workpieces (sudden changes in height).

When height differences greater than the setting value are detected (low areas

become high), the value at the detected time are held and displayed, and

control output starts.

If the difference is small and does not exceed the setting value, the display stays as 0.

When height differences greater than the setting value are detected (high areas

become low), detection value becomes 0 and control output is stopped.

Configuring the sensitivity setting for distance

detection method

2-point calibration (operation modes: F-1, A-1, A-2)

1 Press the [SET] button once without

a workpiece in place.

The current value without the workpiece is

read.

2 Place a workpiece in the detection

position, and quickly press the [SET]

button once again.

The setting value is calculated as the mean

value between the value obtained in step 1

and the value obtained in step 2.

This concludes 2-point calibration and the

sensor returns to the detection state.

• When edge hold mode (A-1 mode) is selected, edge hold mode only

operates on channel 1. Channel 2 operates under distance

measurement mode (F-1 mode).

• If the edges are gentle (such as spherical or tilted workpieces), this

mode may not be able to detect workpieces or may output the value

incorrectly.

• Send the workpiece past the sensor head so that the area for

detecting height differences is parallel to the sensor head. See

"When detecting uneven workpieces" (page 3).

•

When a detection value is being held, press and hold the [Up] and

[Down] arrow buttons at the same time to set the current value to 0

(regardless of the shift target value) and to turn off output. The

current value for channel 2 changes to 0 as well.

• If the external input function is set to "SFt" and the external input

(pink line) is turned on, the control output turns off and the current

value becomes 0. (When channel 2 is selected, the current value

becomes 0 as well. Turning the laser emission stop input on and

off performs a similar action, but it only changes the current value

of the channel to 0.)

Reference surface detection (DATUM) method (Application)

This method memorizes the background (reference surface) and uses it to

perform comparator output when there is a workpiece (when the state differs

from the reference surface).

The reference surface detection (reference surface calibration) can only be

used on Channel 1 of operation mode F-1/F-2.

Operation

mode

General F-1

Special F-2

Use the reference surface (DATUM) detection method in the following situations:

Description

Turns on control output when

the detected surfaces is not the

same as the memorized

reference surface.

The current value for the

memorized surface is forcibly

set to 0. (The display is

common for channels 1 and 2.)

Changes to the

setting value

The setting value can be

configured around 0.

Individual setting values

cannot be changed.

The setting value can be

configured around 0.

Individual setting values

can be adjusted.

If there is very little difference between the values obtained in Step 1 and

Step 2, then "---" flashes in the setting value display area after

calibration is complete. The setting value is still updated.

Maximum sensitivity setting (operation modes: F-1, A-1, A-2)

1 Press and hold the [SET] button for at least three seconds without a

workpiece in place.

2 Release the [SET] button when "SEt" flashes on the display.

This concludes maximum sensitivity calibration and the sensor returns to the

detection state.

Full auto calibration (operation modes: F-1, A-1, A-2)

This method performs calibration while the target is moving.

1 Press and hold the [SET] button for at

least three seconds while the target

workpiece is passing through the

detection area for the sensor.

The sensitivity is set according to the

detection value while the [SET] button is

pressed.

2 Release the [SET] button when "SEt"

flashes on the display.

This concludes calibration and the sensor

returns to the detection state.

Detection value

MAX

MIN

Setting

value

The value is set to the mean value

between the maximum and minimum

values detected while the [SET] button is

pressed down.

Time

During reference screen (DATUM) detection, the background is memorizes as

references. During the unstable situations noted above, a workpiece is judged

as present when the detected surface is different from the background.

This makes stable detection possible even when using workpieces with

unstable shapes.

The reference surface (DATUM) detection indicator lights up when using reference

surface detection after performing reference surface (DATUM) calibration.

DATUM

1

spot

DATUM

LASER

1

OUT

2

1

SET

2

BANK

TIM

CLP

series

2-point area calibration (operation mode: F-2)

1 Place a workpiece on the upper limit

that you want the sensor to detect,

and press the [SET] button once.

That upper limit becomes the HIGH setting

value.

2 Place a workpiece on the lower limit

that you want the sensor to detect,

and press the [SET] button once.

That lower limit becomes the LOW setting

value.

If there is very little difference between the values obtained in Step 1 and

Step 2, then "---" flashes in the setting value display area after

calibration is complete. The setting value is still updated.

SEL

MODE

5

GV-IM-E

Page 6

1-point area calibration (operation mode: F-2)

HIGH setting value

LOW setting value

Set the values for the

upper and lower

distance.

Note

Note

Reference

Reference

Reference

Note

Reference

Note

Note

DATUM

DATUM

BANK BANK

SET

MODE

1

2

SET

MODE

1

2

MODE

Bank A is in use : Bank indicator is off Bank B is in use : Bank indicator is on

1 Press and hold the [SET] button

for at least three seconds with the

workpiece that you want to detect

in place.

2 Release the [SET] button when

"SEt" flashes on the display.

This concludes 1-point area calibration

and the sensor returns to the detection

state.

Configuring the sensitivity setting for reference

surface (DATUM) detection method

Reference surface (DATUM) calibration (operation

mode: F-1, F-2)

This method memorizes the state without a workpiece (reference surface) and

use it to perform comparator output when the state differs from the reference

surface (when there is a workpiece).

1 Press the [SET] button once without

a workpiece in place.

2 Press and hold the [SET] button for at

least three seconds without the

workpiece in place.

Initial reset (initialization) and custom save function

Initial reset (initialization)

Returns all of the settings to the factory defaults.

1 While pressing the [MODE] button, press the [SET] button five times.

2 Press the [Down] arrow button to display "rSt no".

When "rSt no" is displayed, pressing the [MODE] button returns to the

main screen without initializing.

3

Press the [Up] or [Down] arrow button to select "rSt ini", and then

press the [MODE] button to initialize.

Custom save (Saving the settings)

Saves all of the settings. The saved settings can be loaded at a later time.

1 While pressing the [MODE] button, press the [SET] button five times.

2 Press the [Left] or [Right] arrow button to display "SAv".

3 Press the [Down] arrow button to display "SAv no".

When "SAv no" is displayed, pressing the [MODE] button returns to the

main screen without saving the settings.

4 Press the [Up] or [Down] arrow button to select "Sav YES", and then

press the [MODE] button to save the settings.

When performing reference surface calibration, the values are set for slightly above

and slightly below the reference surface. When the detection value falls within this

range, comparator output is turned off. When it falls outside of this range,

comparator output is turned on.

z Operations during F-1 mode

The setting value can be adjusted by using the [Up] and [Down] arrow buttons,

but the HIGH and LOW setting values cannot be adjusted individually.

z Operations during F-2 mode

The HIGH and LOW setting values can be adjusted individually by using the [Up]

and [Down] arrow buttons.

• Reference surface calibration cannot be used during the following

states. (Instead, 2-point calibration is performed.)

• The spot reflection indicator (1spot) is flashing on the sensor head or

sensor amplifier.

• The setting is control output 2.

• A mode other than F-1 mode or F-2 mode is being used.

• Reference surface calibration can only be set when the operation mode

is F-1 or F-2.

• When performing reference surface calibration, the current value is set

to 0.

Clearing reference surface (DATUM) detection

method

When the reference surface (DATUM) detection indicator is lit, press and hold

the [Up] and [Down] arrow buttons for at least three seconds. The reference

surface (DATUM) detection indicator turns off and the sensor returns to

distance detection method.

The value is canceled if a form of calibration other than reference surface

calibration.

Other Settings

Performing custom save overwrites the settings from the previous custom

save.

Custom reset (Loading the settings)

Loads the settings saved with custom save.

1 While pressing the [MODE] button, press the [SET] button five times.

2 Press the [Down] arrow button to display "rSt no".

When "rSt no" is displayed, pressing the [MODE] button returns to the

main screen without performing custom reset.

3 Press the [Up] or [Down] arrow button to select "rSt CSt", and then

press the [MODE] button to load the settings.

Performing custom reset erases the current settings.

Bank switching

The bank function allows two patterns of sensitivity settings to be saved in channels

1 and 2. (This is useful during operations such as switching the setup.)

•

The bank switching function can only be used when the external input is set to "bnk" in

the OPTIONAL settings.

•

Hold down the [MODE] button during main screen and press the [Up] arrow button to

switch banks, which allows the settings to be configured for each bank.

•

During the keylock state, the banks are switched with external input.

When the external input is off, bank A is used. When the external input is on,

bank B is used.

Zero point positioning

Sets the current value to zero (shift target value).

1 Press the [Up] and [Down] arrow buttons simultaneously without a

workpiece in place.

The current value becomes "0" and zero point positioning is complete.

When the shift target value is set, performing zero point positioning does not

make the current value "0". Instead, it becomes the set value for the shift

target value.

For more information about setting the shift target value, see page 9 of this

Instruction Manual.

Pressing the [Up] and [Down] arrow buttons simultaneously for at least

GV-IM-E

three seconds cancels the zero point (shift target value).

6

Page 7

Note

Note

DATUM

SET

MODE

1

2

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

SET

1

2

SET

1

2

SET

1

2

End of basic settings

MODE

MODE

MODE

MODE

Setting range: 1.5/3/10/20/50

(Unit: ms)

Setting range: noo/nCo/noC/nCC

1

Response speed

2

Output mode

Setting range: ON/OFF

When

is selected

Press for about 3 seconds

Setting range: t-1oFF/oFd/ond/

Sht/ondoFd/ondSht

4

Clamp function

Setting range: F-1/F-2/A-1/A-2

3

Operation mode

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

SET

1

2

MODE

SET

1

2

MODE

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

5

Delay timer 1 (Control output 1)

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

DATUM

End of optional settings

Setting range: Std/USr

7

Hysteresis

Setting range: oFF/SFt/bnK/tim

8

External input

Setting range: -199 to 999

(-198 to 998)

9

Shift target value

Setting range: nor/rEv

10

Distance display

Setting range: oFF/bAr/on

11

Eco display

Setting range: Varies depending

on the sensor head

model.

Hysteresis value

SET

MODE

1

2

Setting range: t-2oFF/oFd/ond/

Sht/ondoFd/ondSht

6

Delay timer 2 (Control output 2)

Setting range: 2 to 999 (Unit: ms)

Delay timer 1: Timer value T1

Delay timer 1: Timer value T2

Setting range: 2 to 999 (Unit: ms)

SET

MODE

1

2

Setting range: 2 to 999 (Unit: ms)

Delay timer 2: Timer value T1

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

Delay timer 2: Timer value T2

Setting range: 2 to 999 (Unit: ms)

SET

MODE

1

2

SET

MODE

1

2

SET

MODE

1

2

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

or

MODE

When

is selected

When

is selected

When

is selected

When

is selected

Reference

Keylock Function

The keylock function prevents accidental operation of the buttons during detection.

While using the keylock function, operations other than switching the display for the

main screen are prohibited.

The keylock settings can only be set in the main screen.

Setting/releasing keylock

While pressing the [MODE] button in the main

screen, press and hold the [UP] or [Down]

button for at least three seconds.

This sets (or releases) keylock and returns the

sensor to the main screen.

Interference protection function

The GV Series can prevent mutual interference that may occur when connecting

several expansion units.

The interference protection function only works when the following conditions are

met.

•

Interference protection functions on up to two adjacent units.

•

The main unit and expansion units use the same response speed.

•

The response speed is set to 1.5, 3, or 10.

Setting Each Type of Function

Press and hold the [MODE] button for at least three seconds in the main screen

(during detection) to change the settings.

The screen shown to the right is displayed

during keylock and basic settings cannot be

input.

SET

DATUM

1

2

During keylock

MODE

•

While configuring basic settings, pressing and holding the [MODE]

button for at least three seconds on any setting screen saves the

settings, ends basic setting, and displays the main screen.

• Press the [Left] arrow button to return to the previous setting item.

7

GV-IM-E

Page 8

1. Response speed setting

Reference

On-delay

Time

Setting value

Display

On-delay/

Off-delay

On-delay/

One-shot

Off-delay

One-shot

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

t1

t1

t1 t1

t1

t1 t1 t1

t2

t2

t2

t1

t1

t2

t1t1t1

t1: Timer value T1

t2: Timer value T2

Reference

Note

Reference

The response speed is the time from when the sensor head starts detection

until the value at the detection position is established as a comparator value.

Item Setting range Default value

Response

speed

* "20" for GV-H1000 (L) only.

1.5/3/10/20/50 (Unit: ms)

*

10

2. Output mode setting

Sets the control output mode for each control output.

Item Description Default value

Settings

Output mode noo

N.O. (normal open) and N.C. (normal close) operate in the following

manner.

noo N.O. N.O.

N.O. (normal open) ON

N.C. (normal close) OFF

Control

output 1

nCo N.C. N.O.

noC N.O. N.C.

nCC N.C. N.C.

Output mode During detection

Control

output 2

3. Operation mode selection

Sets the operation mode.

Operation mode Description Default value

F-1 General Normal detection mode

F-2

A-1 Edge hold mode

A-2 Surface detection mode

Area detection mode

Special

{

4. Clamp function setting

Set the operations when distance detection cannot be performed (such as

when the detection object does not enter the detection range, or when there is

insufficient light intensity).

Setting item Description Default value

on

oFF

Outputs the comparator output with the

detection value obtained immediately before

the distance was judged to be not detectable.

The current value display and LED bar

display are also saved for the immediately

preceding value.

If distance detection can be performed, then

the hold is released.

When the distance detection cannot be

performed and "---" is displayed, the

comparator output operates in the same way

as if a detection object appears at the

farthest point of the detection range.

5. (6.) Delay timer setting

Individual delay timers can be set for channels 1 and 2.

Setting item Description Default value

oFF Delay timer is not used

ond On-delay

oFd Off-delay

Sht One-shot

ondoFd On-delay/off-delay

ondSht On-delay/one-shot

{

{

7. Hysteresis setting

Sets the hysteresis for judgment with control outputs 1 and 2.

Setting item Description Default value

Std Run with the default values.

Usr Set custom values.

The hysteresis setting range and default value are as follows when "Usr" is

selected.

Head model Setting range Default value

GV-H45 (L) 0, 1 to 100 2

GV-H130 (L) 0, 2 to 100 4

GV-H450 (L) 0, 0.5, 1 to 100 0.5

GV-H1000 (L) 0, 1 to 100 5

8. External input function setting

Sets the function assigned to the external input (pink line).

Setting item Description Default value

oFF Do not use external input (input off).

SFt Used as "External shift input".

bnK Used as "Bank switching input".

tim Used as "Timing input".

The minimum external input time is 20 ms.

z External shift input

When external input is input, the current value is shifted by the value set for shift

target value.

(For information about the shift target value, see "9. Shift target value setting".)

z Bank switching input

When keylock is set for the amplifier, the bank switches with input to the external

input.

(For more information about bank switching, see "Bank switching".)

When edge hold mode (A-1 mode) is set, switching banks with the external

input resets the current value to 0.

z Timing input

Comparator output is only output over control output 1 when external input is

on.

The timing input indicator on the sensor amplifier lights up.

Control output 2 continues to output comparator output, regardless of

whether timing input is on or off.

{

{

GV-IM-E

8

Page 9

9. Setting the shift target value

Reference

1

2

1

2

1

2

5-40 V DC

10-30 V DC

Load

Black/white (control output 1/2)

Brown *

Blue *

Sensor main circuit

Overcurrent protection circuit

0 V

10-30 V DC

Load

Black/white (control output 1/2)

Brown *

Blue *

Sensor main circuit

Overcurrent protection circuit

PLC etc.

Purple/pink (input)

Sensor main circuit

Brown *

10-30 V DC

Set this value to shift the current value by another amount.

Item Setting range Default value

Shift target

value

• Press the [Up] and [Down] arrow buttons simultaneously to shift the current

-199 to 999 0

value to the set value with the shift target value.

The shift status is retained even if the power is turned off.

Press the [Up] and [Down] arrow buttons simultaneously and

hold them to clear the shifted target value.

• The amplifier does not retain the amount of shift when shifting with external

input. (It is cleared when the power is turned off.) To retain the amount of

shift, press the [Up] and [Down] arrow buttons simultaneously and perform

shift.

•

When performing reference surface calibration while edge hold mode (A-1

mode) is set, the value is always shifted to 0.

• Shift is only a effective on the selected bank.

10. Distance display setting

Sets whether to use the side close to the sensor head as the positive direction

(normal) or negative direction (reverse).

Setting item Description Default value

nor (Normal)

rEv (Reverse)

The display value increases as the target

comes closer to the sensor head.

The display value decreases as the target

comes closer to the sensor head.

11. Eco display setting

Set this parameter to reduce the consumption current or to stop displaying

specific values. When running in power saving (eco) mode, pressing any button

returns the sensor to normal operations.

The main screen switches to eco mode if no operations take place for 30

seconds.

Setting item Description Default value

oFF Turns off the eco display.

bAr Turns off the digital display.

on

The digital display (green) flashes in

sequence. Bar display and channel No.

indicators are turned off.

{

{

Troubleshooting

Problem Cause and solutions

The current value is

larger than the setting

value, but the output is

not reversed.

The external input does

not function.

The current settings can

no longer be

determined. The user

wants to return the unit

to the factory defaults.

This type of problem sometimes occurs when multiple

reflection occurs while using the distance detecting

method. If this problem occurs, use the reference

surface detection (DATUM) method and configure the

sensitivity setting.

If multiple reflection occurs, the spot reflection (1spot)

indicator turns off.

• "Distance detection method (Normal)" (page 4)

• "Reference surface detection (DATUM) method

(Application)" (page 5)

• "Sensor amplifier part names" (page 3)

Check the settings for the external input.

• "8. External input function setting" (page 8)

Perform initial reset (initialization).

• "Initial reset (initialization) and custom save function"

(page 6)

I/O Circuit Diagram

Output circuit

GV-21/22 (NPN output)

* GV-21 only

GV-21P/22P (PNP output)

Error Displays and Corrective Actions

Error indication Error contents Remedy

• Check that the sensor head is

connected.

• Check that the head cable is not

broken.

• Check the connection of the

head cable to the connector.

• After checking these points, turn

on the power again.

• Check the load and reduce the

current to be within the rated

range.

•

Check that the output wire does not

touch another wire or a frame.

If you need to write more data,

replace the amplifier unit.

Set a workpiece or background in

the distance for detection from the

sensor.

Set a workpiece or background in

the distance for detection from the

sensor.

Tilt the sensor head so that specular

reflection does not enter the sensor.

Head error

Overcurrent error

EEPROM error

1

2

1

2

1

2

Sensor head is not

connected.

Head cable is broken.

Sensor head is

damaged

Overcurrent is flowing

through the output wire

Data read/write error Perform initialization.

Data has been written in

the EEPROM over 1

million times and can no

longer be updated.

There is no workpiece

or background within

the detection distance

range, or no light is

entering the receiver.

Reading exceeds the

detection distance

range.

Light intensity is

saturated.

* GV-21P only

Power is supplied to the expansion unit GV-22(P) from the expansion connector on

the back of the main unit GV-21(P). The power wires (brown and blue) of the main

unit and those of the expansion unit are common inside through the connector.

Input circuit

GV-21/22 (NPN output)

5 V DC

Purple/pink (input)

PLC etc.

(Short-circuit current 1 mA max.)

Sensor main circuit

Blue *

0 V

* GV-21 only

GV-21P/22P (PNP output)

* GV-21P only

Purple line. . . . . . . Laser emission stop input

Pink line . . . . . . . . External input function

* The external input function can be set to one of the following.

•

Not used

•

Shift input

•

Bank switching input

•

Timing input

*

9

GV-IM-E

Page 10

Specifications

Environmental resistance

Surrounding light

Material

Sensor head

Model

Light source

FDA

(CDRH)

Part

1040.10

IEC

60825-1

Detection distance

(Amplifier display

value

Amplifier

display range

Standard

detection

deviation

Spot diameter

Operation

status

indicators

Cable length 2 m 3 m

Weight

*1 Guideline of the amplifier display value when the distance display for the

*2 For GV-H1000, when the response speed is set to 10 ms or less,

*3 For GV-H1000L, when the response speed is set to 10 ms or less,

*4 Including the connector cable.

*5 The laser classification for FDA(CDRH) is implemented based on

Sensor amplifier

Model

Amplifier type Main unit Expansion unit

Power voltage

Power consumption

Response time 1.5/3/10/20/50 ms

Control output

Control input

Environmental

resistance

Material

Weight

*1 11 to 30 VDC when amplifiers are extended.

*2 Including the cable (2 m).

GV-IM-E

Item Specifications

*1

)

Enclosure

rating

Surrounding air

temperature

Relative

humidity

Incandescent

lamp

Sunlight

Vibrati on

Housing

Lens cover Glass

Cable PVC

*4

detection distance is set to "nor".

Incandescent lamp: 5,000 lx, Sunlight: 3,000 lx

Incandescent lamp: 2,500 lx, Sunlight: 1,500 lx

IEC60825-1 in accordance with the requirements of Laser Notice No.50.

GV-

GV-

GV-

GV-

GV-

H45

H45L

H130

H130L

Short-range Mid-range Long-range

Visible semiconductor laser

Wavelength: 655 nm

Laser

Class

Output

Laser

Class

Output

Class

Class

560μW 220μW 560μW 220μW 560μW 220μW 560μW 220μW

Class 2Class 1Class 2Class 1Class 2Class 1Class 2Class 1

560μW 220μW 560μW 220μW 560μW 220μW 560μW 220μW

20 to 45 mm

(250 to 0)

259 to -34 768 to -98 295 to -50 810 to -175

0.5 mm 1 mm 3 mm

Approx. φ0.1 mm

(Detection distance

45 mm)

Control output: Red LED

Laser radiation emission indicator: Green LED

Other: Green LED

IP67

-10 to +50°C (No freezing)

35 to 85% RH (No condensation)

10,000

lx

20,000lx10,000lx20,000lx10,000lx10,000

10 to 55 Hz,

1.5 mm double amplitude in the X, Y, and Z directions,

2 hours respectively

Housing material: PBT Packing: NBR

Display: Polyarylate

Metal part: SUS304

Approx. 120 g Approx. 130 g Approx. 190 g Approx. 210 g

1

5,000

lx

*5

Class

Class

55 to 130 mm

(750 to 0)

Approx. φ0.3 mm

(Detection distance

130 mm)

10,000

lx

1

5,000

l x

*5

GV-

H450

H450L

Class

Class

160 to 450 mm

(290 to 0)

Approx. φ0.8 mm

(Detection distance

450 mm)

5,000lx2,500

lx

1

lx

5,000

lx

*5

GV-

H1000

H1000L

Super-Long-

range

Class

Class

200 to 1000 mm

(800 to 0)

20 mm (Detection

distance 200 to

800 mm),

30 mm (Detection

distance 800 to

1000 mm)

Approx. φ1.8 mm

(Detection distance

1000 mm)

*2

5,000

2,500

lx

lx

*2

10,000

5,000

lx

lx

Item Specifications

NPN output GV-21 GV-22

PNP output GV-21P GV-22P

*1

Surrounding air

temperature

Relative

humidity

Vibrati on

*2

10-30 VDC, Ripple (P-P): 10% max, Class 2

Normal: 2200 mW max. (at 30 V: 73.3 mA max.)

Eco-bar: 1700 mW max. (at 30 V: 56.7 mA max.)

Eco-all: 1600 mW max. (at 30 V: 53.3 mA max.)

NPN (PNP) open collector x 2ch, 40 V (30 V) DC max.

Max. 100 mA, residual voltage 1 V max.

Purple line .... Laser emission stop input

Pink line ....... Setting value bank switching input/

-10 to +55°C (No freezing)

35 to 85% RH (No condensation)

10 to 55 Hz, 1.5 mm double amplitude in the X, Y,

and Z directions, 2 hours respectively

Housing material, front sheet: Polycarbonate

Key top: Polyacetal

Cable: PVC

Approx. 110 g

shift input/timing input (selected with

the settings)

GV-

1

WARRANTIES AND DISCLAIMERS

(1) KEYENCE warrants the Products to be free of defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any

models or samples were shown to Buyer, such models or samples were

used merely to illustrate the general type and quality of the Products and

not to represent that the Products would necessarily conform to said

models or samples. Any Products found to be defective must be shipped to

KEYENCE with all shipping costs paid by Buyer or offered to KEYENCE

for inspection and examination. Upon examination by KEYENCE,

*5

*3

*

3

10

KEYENCE, at its sole option, will refund the purchase price of, or repair or

replace at no charge any Products found to be defective. This warranty

does not apply to any defects resulting from any action of Buyer, including

but not limited to improper installation, improper interfacing, improper

repair, unauthorized modification, misapplication and mishandling, such as

exposure to excessive current, heat, coldness, moisture, vibration or

outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various

Products. They are only suggestions, and it is Buyer's responsibility to

ascertain the fitness of the Products for Buyer’s intended use. KEYENCE

will not be responsible for any damages that may result from the use of the

Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are

not to be used internally in humans, for human transportation, as safety

devices or fail-safe systems, unless their written specifications state

otherwise. Should any Products/Samples be used in such a manner or

misused in any way, KEYENCE assumes no responsibility, and

additionally Buyer will indemnify KEYENCE and hold KEYENCE harmless

from any liability or damage whatsoever arising out of any misuse of the

Products/Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE

PROVIDED WITH NO OTHER WARRANTIES WHATSOEVER. ALL

EXPRESS, IMPLIED, AND STATUTORY WARRANTIES, INCLUDING,

WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE

LIABLE TO ANY PERSON OR ENTITY FOR ANY DIRECT, INDIRECT,

INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, WITHOUT LIMITATION, ANY DAMAGES RESULTING

FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF

INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF

PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF

SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR

ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE

OR INABILITY TO USE THE PRODUCTS, EVEN IF KEYENCE OR ONE

OF ITS AFFILIATED ENTITIES WAS ADVISED OF A POSSIBLE THIRD

PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers

or damage limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered

to a third party, Buyer must provide such third party with a copy of this

document, all specifications, manuals, catalogs, leaflets and written

information provided to Buyer pertaining to the Products/Samples.

E 1101-3

Copyright (c) 2011 KEYENCE CORPORATION. All rights reserved.

11664E 1043-3 96M11664 Printed in Japan

Loading...

Loading...