Page 1

High-accuracy Digital Contact Sensor

WARNING

NOTICE

WARNING

NOTICE

GT2-PA12K/PA12

Sensor head × 1

Precautions on Handling × 2

NOTICE

GT2-CH2M/5M/10M/20M

(M8 straight connector)

GT2-CHP2M/5M/10M

(M8 oil-resistant straight connector)

GT2-CHL2M/5M/10M/20M

(M8 L-shaped connector)

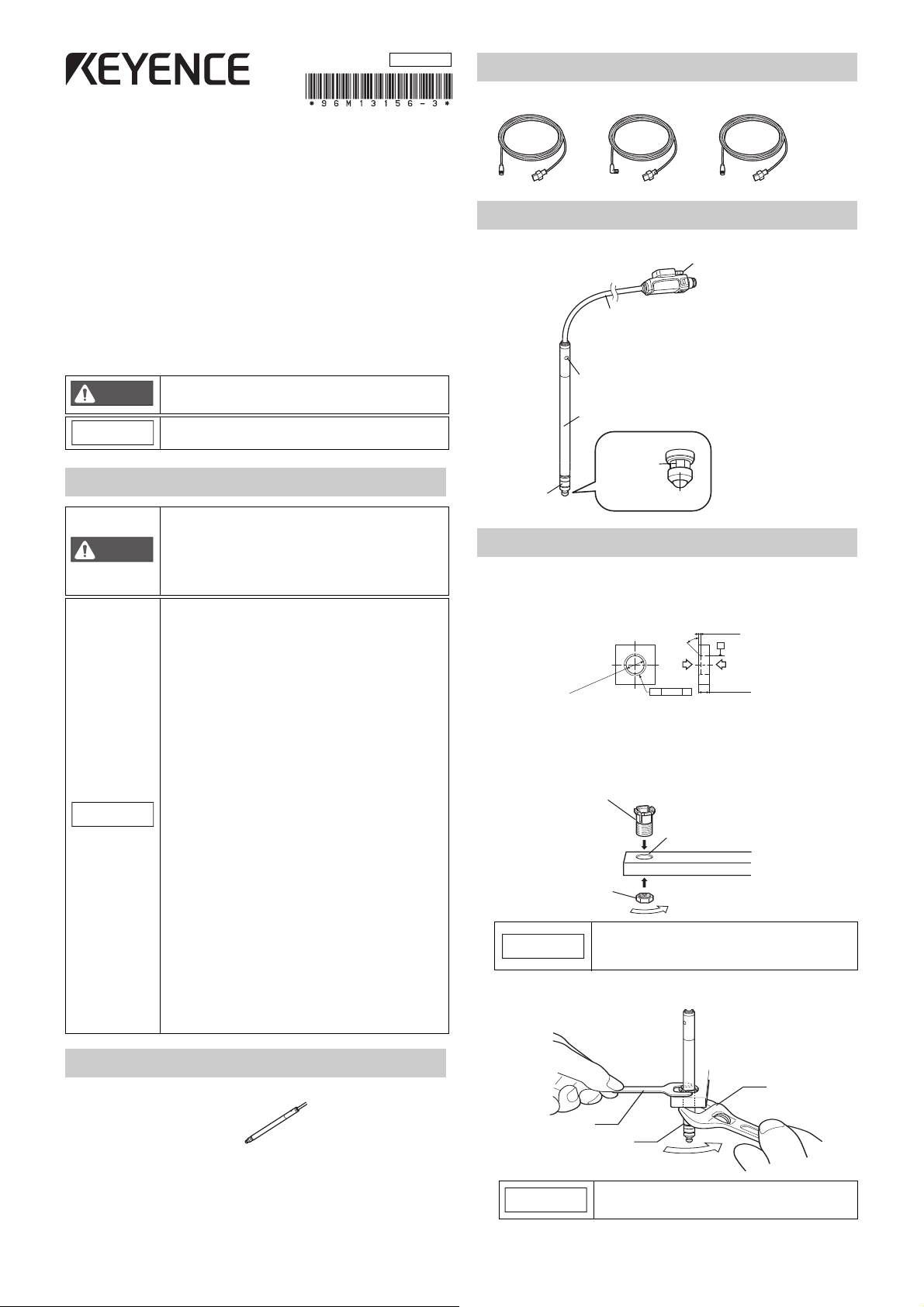

● GT2-PA12K/PA12

Cable connector

Cable between the sensor head and relay connector

Mounting fixture

Operation indicator

Air supply hole

Contact

Spindle

Dust seal

Chamfered side

Nut

Tightening sleeve

Dust seal

Wrench or similar

tool

Key wrench

GT2-PA12K/PA12

96M13156

Sensor head connection cable

Instruction Manual

Introduction

Read this instruction manual carefully prior to operating this product. For

connection, settings and precautions on use, make sure to read the GT2 Series

instruction manual included with the amplifier. Be sure to store this manual in a

convenient place so that it is readily accessible for reference. Ensure that the

personnel who will actually operate the product have access to this manual.

For details of each function, refer to the GT2 Series User’s Manual.

You can download the User’s Manual from KEYENCE homepage

(http://www.keyence.com/).

Safety precautions

Checking the package

It indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

It indicates a situation which, if not avoided, could

result in product damage as well as property damage.

• This product is designed to detect the target object.

Do not use this product to protect human bodies or

a part of a human body.

• This product is not intended for use as an explosionproof

product. Do not use this product in hazardous locations

and/or potentially explosive atmospheres.

Warming up

The circuit is not stable immediately after the power

turns ON, which sometimes causes the indicated

value to gradually fluctuate. Wait for about 5 minutes

after the power turns on before using.

Handling of the sensor head

• This device is a precision machine. Do not drop, or

cause any other impact to this device. Doing so may

cause damage or malfunction.

• Do not apply weight greater than what is listed

below to the spindle. Do not apply rotational torque.

Otherwise the spindle may break.

• The spindle can rotate a maximum of 4.5°. When

using an offset contact (OP-77683) or similar, if

pressure in the rotational direction is applied to the

contact, the measurement position may change.

• When attaching and removing contacts, make sure

that the sensor head is detached from any metallic

plates, etc. Apply a tightening torque of 0.2 N•m or

less when attaching the contact.

• If dust, metal powder, or similar becomes attached

to the sliding part of the sensor head, mechanical

responses may become slow. If this happens,

replace the end of the sensor head with a

replacement dust seal (OP-87932). Refer to the

instruction manual included with the replacement

dust seal (OP-87932) for instructions on how to

replace the dust seal.

• Although the GT2-PA12K/PA12 has a protection

rating of IP67, avoid using it immersed in water or in

places where liquid such as oil may come into

contact with it.

Names of parts of the sensor head

Mounting the sensor head

When mounting to the jig, make a round hole on the jig beforehand.

Using mounting bracket A/C

1 Work the sensor head mounting part as below.

2

*

0.5〜1.0

±1°

45°

A

A

Nut mounting side

5.5〜11.3

(Unit: mm)

2

*

Tightening

sleeve

1

*

+0.027

+0.005

φ10 G8( )

*1 For head mounting bracket C *2 Processing accuracy: ±0.05

+0.1

φ10

+0.005

insertion

side

◎

φ

0.025

2 Insert the tightening sleeve into the hole made in step 1 (from the

chamfered side), and loosely tighten with the nut.

Next, insert the sensor head.

If the nut is fully tightened when the sensor head

is not yet inserted, the fixture will become

deformed.

3 Secure the sensor head with the supplied key wrench and tighten the

nut with a wrench or similar tool.

If you find that a part is faulty or broken, contact your KEYENCE representative.

NOTICE

Apply a tightening torque of 5 to 7 N•m (the

recommended tightening torque is 5 N•m).

1

Page 2

Using mounting bracket F

NOTICE

NOTICE

8.5

8

+

0

.

2

0

0

+

0

.

0

0

5

M

4

x

0

.

7

Make sure that the metal plating

mounting bracket F attaches to is at

least 5 mm thick.

NOTICE

Air tube

Air supply hole

Relay connector

Relay connector

Air tube

Mist separato r

Air filter

Pressure

source

AIR

Solenoid valve

Precision regulator

Air su pply part

GT2-PA12K/PA12

Speed controller

1 Refer to the illustration below, and cut the jig to create a sensor head

mounting hole.

2 Loosen the screw on the side of mounting bracket F using the

supplied hexagonal wrench.

3 Align mounting bracket F with the hole made in step 1 and secure it

using the supplied hexagonal wrench.

4 Insert the sensor head, and tighten the screw loosened in step 2

using the supplied hexagonal wrench to secure. The recommended

tightening torque is 0.6 to 0.8 N•m. Make sure that the dust boot does

not obstruct the metal plating that mounting bracket F is attached to.

• When loosening the screw with the hexagonal

wrench, insert the long end of the hexagonal

wrench into the hex screw and rotate the small end

with your hand.

• Do not forcibly tighten the hex screw.

Installing the air tube (GT2-PA12K/PA12)

Compatible air tubes

Use a tube with the following specifications.

Recommended tubing material Urethane

Tubing size

How to attach/detach the air tube

• Attaching the air tube

Insert the air tube into the air supply hole on the relay amplifier.

• Detaching the air tube

To detach the air tube, pull the air tube in the direction of the arrow, as

indicated in the figure below.

Item Description

Outer

diameter

Inner

diameter

•

For best results, cut the end of the tube at a right

angle, ensure that the outer perimeter is not

damaged, and that it still maintains a circular cross

section.

•

If the tube is not properly inserted, air leakage may

result.

•

After attaching, pull on the tube to make sure it is

secure.

• Use a urethane tube. Make sure it also has a

bending radius of at least 50 mm.

4 mm

2.5 mm

Connecting the sensor head connection cable

1 Insert the sensor head connection cable

into the cable connector on the relay connector cable.

2 Secure the connector with the sensor

head connecting cable screw.

• When connecting the connector, be sure to insert it

straight, and tighten it securely. (Recommended

tightening torque: 0.4 to 0.5 N•m

If the connection is not tight enough, the connector

may be loosened by vibration or other causes,

leading to a connection failure.

(* After tightening it strongly by hand, use pliers or

other tools to rotate it about 30° for further

tightening.)

• When the head is attached to a moving part, and the

cable will be repeatedly bent, ensure that the cable

between the sensor head and relay connector does

not bend. Instead, bend the sensor head cable

connecting the relay connector and the amplifier.

*

)

NOTICE

Before detaching the tube, be sure to stop any air

flow.

Supplying air

• Refer to the diagram below to create a pneumatic circuit.

• Use an air filter, mist separator, etc. to provide clean dry air. Empty the

drainage from the filter regularly, before it exceeds the specified line.

• Make sure that the air pressure of the supplied air is constant and in the

range of 0.24 to 0.26 MPa. Use a precision regulator to control the air

pressure. If the air pressure is below 0.24 MPa, the spindle may not

extend fully.

• When supplying air (with the spindle extended), up to 3L/min of air will be

emitted from the tip of the dust seal.

• The measuring ability of the device changes according to the air pressure

of the air supply. Refer to "Specifications" for details.

NOTICE

If the air supply pressure exceeds 0.5 MPa, the sensor

head may become damaged.

2

Page 3

Adjustment of Spindle Movement Speed

NOTICE

Speed controller

Indication symbol

Air supply

Adjusting the speed

0123456789101112

Measuring force (N)

0.25 MPa

Spindle retracted

0.24 MPa

Spindle extended

Table 1. Relationship between spindle position and measuring force

grouped according to used air pressure.

(When installing side mounting, the measuring force is -0.05 N.

When installing upward mounting, the measuring force is -0.1 N.)

Spindle position (mm)

0.26 MPa

Applied pressure (MPa)

1.7

0.7

1.2

(Unit: mm)

To adjust the spindle movement speed, install a speed controller between

the cylinder and the air supply. Using OP-87970 is recommended.

• To further decrease spindle movement speed, use a

coil-shaped tube (OP-87986) or similar to increase

the distance between the air supply hole and the

speed controller.

• The speed controller will not operate if installed in

the reverse direction.

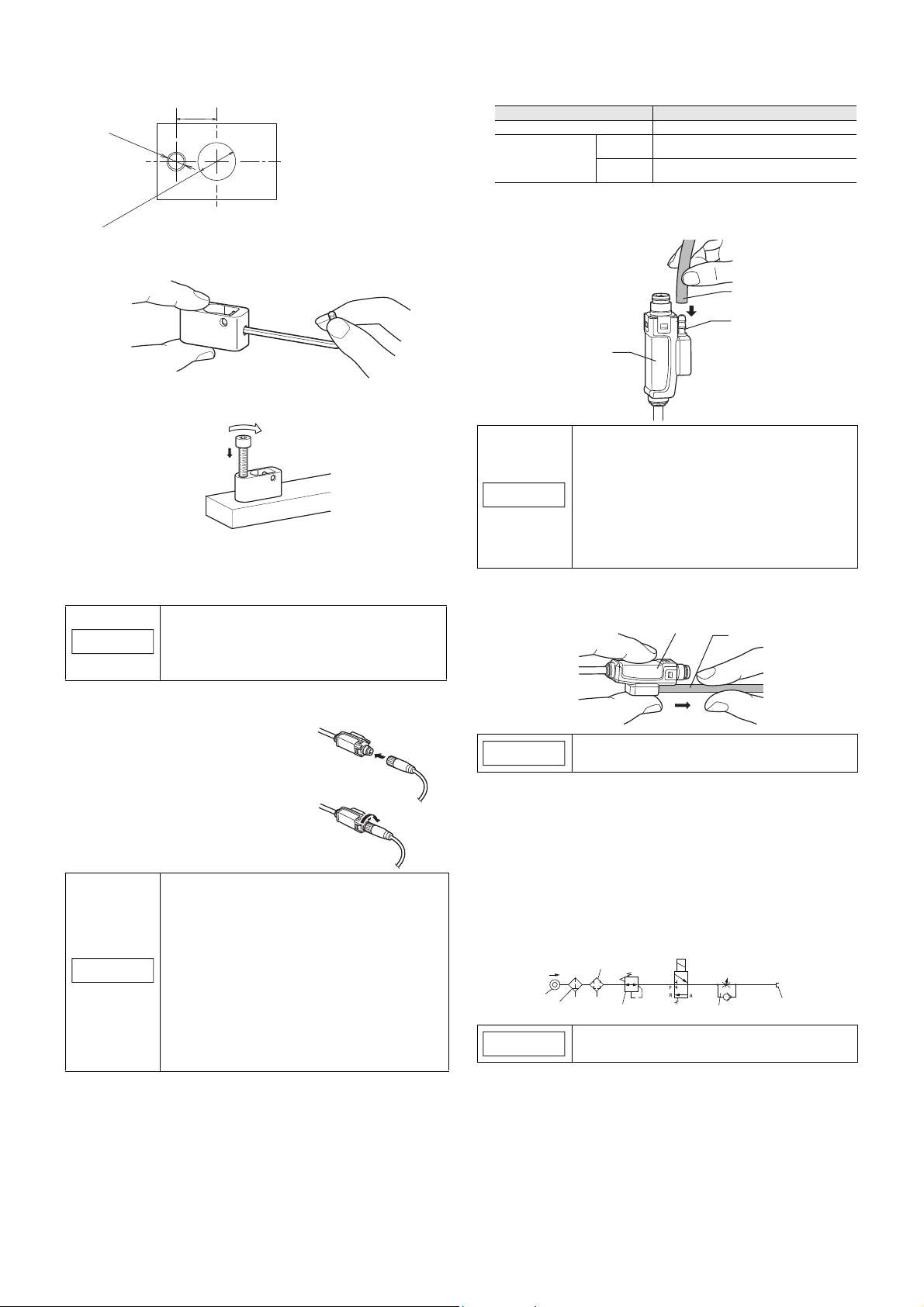

External dimensions

How to replace the dust seal

Refer to the instruction manual included with the replacement dust seal

(OP-87932).

Specifications

Sensor head

Model GT2-PA12K GT2-PA12

Detection system

Measuring range 12 mm

Resolution 0.1 m0.5 m

Indication accuracy

Measuring

*2

force

Sampling interval 4 ms

Pressure range 0.24 to 0.26 MPa

Max. pressure 0.5 MPa

Fluid to use Clean dry air

Operation indicator 2-color LED (red, green)

Environmental

resistance

Material

Head cable Sold separately (connected to relay connector)

Weight (ex cluding cable)

*1 When the surrounding temperature is 20°C.

*2 Representative value when using 0.25 MPa. The measuring force varies

depending on the air pressure used. See Table 1 for more details.

*3 The contact is a separately sold option.

*4 Including the relay connector.

Note: Cannot be used with amplifier units purchased before April 15th, 2014.

*1

When installed

facing down

When installed

sideways

When installed

facing up

Enclosure rating IP67 (IEC)

Surrounding air

temperature

Relative

humidity

Vibratio n

resistance

Shock

resistance

Main unit

*3

Contact

*4

1 m (P-P) 2 m (P-P)

10 to 55 Hz, Compound amplitude 1.5 mm,

Spindle: SUS430 (fluorine-based coating)

Cable between the sensor head and relay connector:

SUS303/SU304/aluminium (alumite treated)/

SUS304,

tungsten carbide

Scale shot system II

Absolute type (without tracking error)

1.2 N

1.15 N

1.1 N

°C (No freezing)

0 to +55

35 to 85% RH (No condensation)

2 hours each in X, Y, and Z axis

2

(IEC60068-2-27)

1000 m/s

Main unit cover: SUS303,

Head indicator: PET

PUR

Relay connector: PBT,

Dust seal (GT2-PA12K/PA12 only):

special polyester fiber

SUS304, SUS440C

Approx. 35 g

GT2-PA12K/PA12

4

3.8

8

75.2

13.6〜26.4

17.4〜30.2

0

0.030

-

4

3

(possible fixing range)

104.8

3.8

cord 150 mm long

Minimum

10

(11.9)

4.6

Minimum

44.2

44.2

16.5

12.8

10

Air supply valve

(For air tubes with an inner

diameter of 2.5 mm)

M8 cable connector

Page 4

Copyright (c) 2014 KEYENCE CORPORATION. All rights reserved.

96M13156E 1124-3 96M13156 Printed in Japan

4

Loading...

Loading...