Page 1

RS-232C Communication Unit

DL-RS1A

User's Manual (IB Edition)

Read this manual before using the system in order to

achieve maximum performance.

Keep this manual in a safe place for future reference.

96098E

Page 2

Introduction

This manual provides an overview of the RS-232C communication unit DL-RS1A and describes the

functions and procedures of the unit.

Be sure to read this manual carefully to ensure safe performance and function of the unit.

Keep this manual in a safe place for future reference.

Ensure that this manual is passed to the end user.

Symbols

The following symbols alert you to important messages. Be sure to read these messages carefully.

It indicates a hazardous situation which, if not avoided, will result in death or

DANGER

serious injury.

It indicates a hazardous situation which, if not avoided, could result in death

WARNING

or serious injury.

It indicates a hazardous situation which, if not avoided, could result in minor

CAUTION

or moderate injury.

It indicates a situation which, if not avoided, could result in product damage

NOTICE

as well as property damage.

Safety Precautions

General Cautions

• At startup and during operation, be sure to monitor the functions and performance of the DL-RS1A for p roper operations.

•

We recommend that you take substantial safety measures to avoid any damage in the event that a problem occurs.

• Do not modify the DL-RS1A or use it in any way other than described in the specifications.

• When the DL-RS1A is used in combination with other ins truments, functions and performance may be degraded,

depending on the operating conditions and surrounding environment.

• Do not use the DL-RS1A for the purpose of protecting the human body.

• Do not change the temperature drastically around the DL-RS1A and other devices including the accessories. Otherwise

condensation may be generated.

Handling Errors

Turn off the power immediately in the following cases. Using the unit in

abnormal conditions could cause fire, electric shock, or accident. Contact the

nearest KEYENCE office for repair.

NOTICE

• If fluids including water, chemicals, or debris enter the unit

• If the unit is dropped or the case is damaged

• If abnormal smoke or odor is present

Operating Precautions

Important

It indicates cautions and limitations that must be followed during operation.

Point

It indicates additional information on proper operation.

Reference

It indicates tips for better understanding or useful information.

• Do not use the DL-RS1A with a voltage other than specified voltage, as this

may cause fire, electric shock or equipment failure.

WARNING

• Do not disassemble or modify the DL-RS1A. Doing so may cause fire or

electric shock.

Be sure to turn off the power to the DL-RS1A and any connected devices before

•

NOTICE

■ Installation environment

To use the DL-RS1A correctly and safely, avoid installing it in the following locations. Failure to do so to

may cause fire, electric shock, and malfunction.

• Locations that are humid, dusty, or poorly ventilated

• Locations with a high temperature, such as a place exposed to direct sunlight

• Locations where there are flammable or corrosive gases

• Location where the unit may be directly subjected to vibration or impact

• Locations where water, oil, or chemicals may splash onto the DL-RS1A

• Locations where static electricity is easily generated

■ Noise countermeasures

Isolate the unit from devices that generate high frequency electrical signals, power supply lines, or

power lines. Otherwise, noise could cause a malfunction.

connecting or disconnecting the cables. Failure to do so may damage the unit.

• Do not turn off the power while setting a parameter. Otherwise, the settings

may be partially or completely lost.

Page 3

Contents

Safety Precautions

General Cautions

Handling Errors

Operating Precautions

Installation environment

Before Using the Unit

Connecting the Unit to Sensor Amplifiers

Connecting the Unit to External Devices

Communication Specifications

Commands and Responses

Parameters of Commands and Responses

Communication Response Time

Noise countermeasures

Checking the Package Contents ............................................................................ .........2

Part Names and Functions....... ........................................................................................ 2

Mounting the Unit ............................................................................................................. 3

Mounting the unit on the DIN rail.................................................................................................3

Connecting the Unit to Sensor Amplifiers ........................................................................ 4

Available sensor amplifiers .........................................................................................................4

Connecting the DL-RS1A to DIN rail mount sensor amplifiers.................................................... 4

Connecting the unit to panel mount sensor amplifiers................................................................5

Connecting to a large display type sensor amplifier...................................................................5

Communication Terminal Block ....................................................................................... 5

Terminal connection.................................................................................................................... 5

Connection wiring........................................................................................................................6

Optional cable............................................................................................................................. 6

Input circuit diagram ...................................................................................................................6

Communication Specifications.................................. .......................................................7

Sensor Amplifier ID Number Assignments.................................... ...................................7

DIN rail mount sensor amplifiers................................................................................................. 7

Panel mount sensor amplifiers.................................................................................................... 7

Overview of Commands and Responses...................................... ...................................7

Command format.........................................................................................................................7

Response ....................................................................................................................................8

Error response.............................................................................................................................8

Reading.................................... ........................................................................................ 9

Read from the specified sensor amplifier (SR command).......................................................... 9

Read all data from all sensor amplifiers (M0 command) ............................................................9

Read output states and data from all sensor amplifiers (MS command).................................... 9

Read with external input to the DRQ terminal (DRQ read)..........................................................9

Writing ............................................................................................................................ 10

Write to the specified sensor amplifier (SW command)............................................................ 10

Write to all sensor amplifiers (AW command)........................................................................... 10

Communication commands ......................................................................................................10

ID numbers................................................................................................................................10

Data numbers............................................................................................................................11

Relation between the data number 001 to 027 (data requesting the sensor amplifier operation)

and the data number 053 to 061 (data presenting the result of request/execution)................ 15

Error numbers............................................................................................................................16

Communication Response Time and Time Chart ................................................... .......16

SR command.............................................................................................................................16

M0 command and MS command.............................................................................................. 16

DRQ input..................................................................................................................................17

SW command and AW command............................................................................................. 17

Time Frames of Communication Response Time ................................................... .......17

T2 (DL-RS1A data processing time) .........................................................................................17

T3 (Command send time from external device)........................................................................17

96098E

T4 (DL-RS1A command processing time) ................................................................................17

T5 (Response send time from DL-RS1A) ..................................................................................18

Specifications

Troubleshooting

ASCII Code Table

T6 (Sensor amplifier settings change time)...............................................................................18

Performance Specifications ........................................................................................... 19

Communication Specifications.................................. .....................................................19

Dimensions................................................................ ..................................................... 19

When the unit is mounted on the DIN rail..................................................................................19

When the optional fixture (OP-60412) is used...........................................................................19

1

Page 4

Before Using the Unit

r

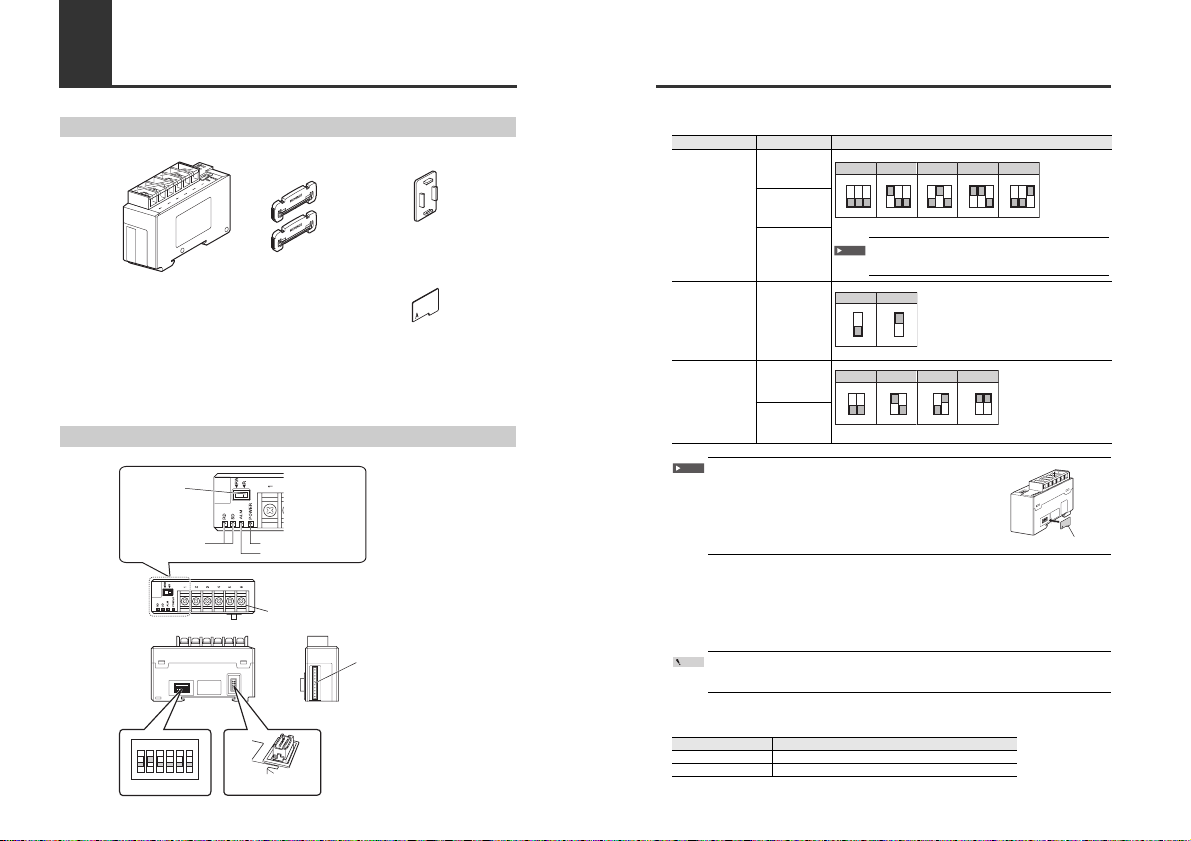

Checking the Package Contents

Before using the DL-RS1A, check that the following items are all included.

RS-232C communication unit

DL-RS1A

Instruction manual

All possible care was taken in packaging before shipment. However, in the event of defective

broken, or missing items, please contact your nearest KEYENCE office.

Part Names and Functions

6. Read/write

setting switch

4. Communication

status indicators (green)

D

G

102#345

6

10

2N345

Communication setup switch

1.

6

2

End unit x 2

OP-26751

7. Power indicator (green)

5. Alarm indicator (red)

8. Communication terminal block

2.

Sensor amplifier connector

(for DIN rail mount type)

3.

Sensor amplifier connecto

(for panel mount type/

large display type)*

* A sticker is attached as factory default.

Expansion connector cover

Switch protection sticker

(1) Communication setup switches

You can use different ON/OFF combinations to configure the communication settings.

Setting Switch No. Combination

1

2400bit/s 4800bit/s

ON

2

Baud rate

Data bit length

Parity

Important

• Make sure you cycle the power to the unit after modifying the

communication settings. The modifications are not applied to the

unit until it is powered down and power has been reapplied.

• Place the switch protection sticker supplied with the unit over the

switches after you modify the settings.

(2) Sensor amplifier connector (for DIN-rail mount type)

Use this connector to connect DL-RS1A to a DIN-rail mount type sensor amplifier.

(3) Sensor amplifier connector (for panel mount type)

Use this connector to connect DL-RS1A to a panel mount type sensor amplifier.

The optional extension cable (OP-35361) must be used for connection.

Point

You cannot connect DL-RS1A simultaneously to a DIN-rail mount type sensor amplifier and

a panel mount type sensor amplifier.

(4) Communication status indicators

These indicators show the communication status of DL-RS1A.

Indicator Behavior

SD Lights up in green while data is being transmitted.

RD Lights up in green while data is being received.

123 123 123 123 123

* Factory default positions are shown.

Important

3

8 bit* 7 bit

ON4ON

4

* Factory default positions are shown.

None* Even Odd None

5

ON56ON56ON56ON

6

* Factory default positions are shown.

9600bit/s*19200bit/s 38400bit/s

ON ON ONON

Do not use combinations other than those shown above for switches

1, 2, and 3.

4

56

Before Using the Unit

Switch protection sticker

Page 5

Before Using the Unit

Connecting the Unit to Sensor Amplifiers

(5) Alarm indicator

This indicator lights up in red.

For information on the actions you should take when an alarm occurs, refer to "Troubleshooting" (page 21).

After turning on the power, the alarm indicator lights for the following amount of time, and

communication cannot be performed during this time.

No. of connected units Incommunicable time

(6) Read/write setting switch

(7) Power indicator

(8) Communication terminal block

1 to 4 Approx. 2 s

Use this switch to allow or prohibit writing to the sensor amplifiers. (You can only manipulate this

switch while the unit is active (turned on).)

Position of the switch Description

R

(Factory default position)

RW

The unit can read data from the sensor amplifiers. However, it

cannot write settings to the sensor amplifiers.

The unit can both read data from and write settings to the

sensor amplifiers.

Lights up in green when the unit has power.

Use the terminals on the terminal block to attach communication cables for connecting the unit with external devices.

SG

RD

SD

SG

SG

DRQ

* Recommended communication cable

KPEV-SP(1P) wire with balanced type twisted shield (strand wire)

Nominal cross-section area 0.16mm

Terminal No.

Term inal Description

1SG

2 RD (input) Connects to the SD terminal of an external device via a communication cable.

3 SD (output) Connects to the RD terminal of an external device via a communication cable.

4 SG The terminals for SG (Nos. 1, 4, and 5) are internally short-circuited.

5 SG The terminals for SG (Nos. 1, 4, and 5) are internally short-circuited.

6 DRQ (input)

Point

A terminal cover is attached to the terminal block.

The terminal cover must be placed over the ter minal block when you finish connecting the cables.

Reference

The terminals for SG (Nos. 1, 4, and 5) are used in common with the blue wire of the sensor am plifier

main unit.

KPEV-SP(1P) wire with balanced

type twisted shield (strand wire)

Communication cable

2

Connects to the shielded wire of the communication cable.

The terminals for SG (Nos. 1, 4, and 5) are internally shor t-circuited.

When there is a short-circuit between DRQ and SG, the sensor amplifier data is

transmitted even without a command from the external device.

To external device

(AWG25) min.

This section describes how to mount a DL-RS1A and connect it to sensor amplifiers.

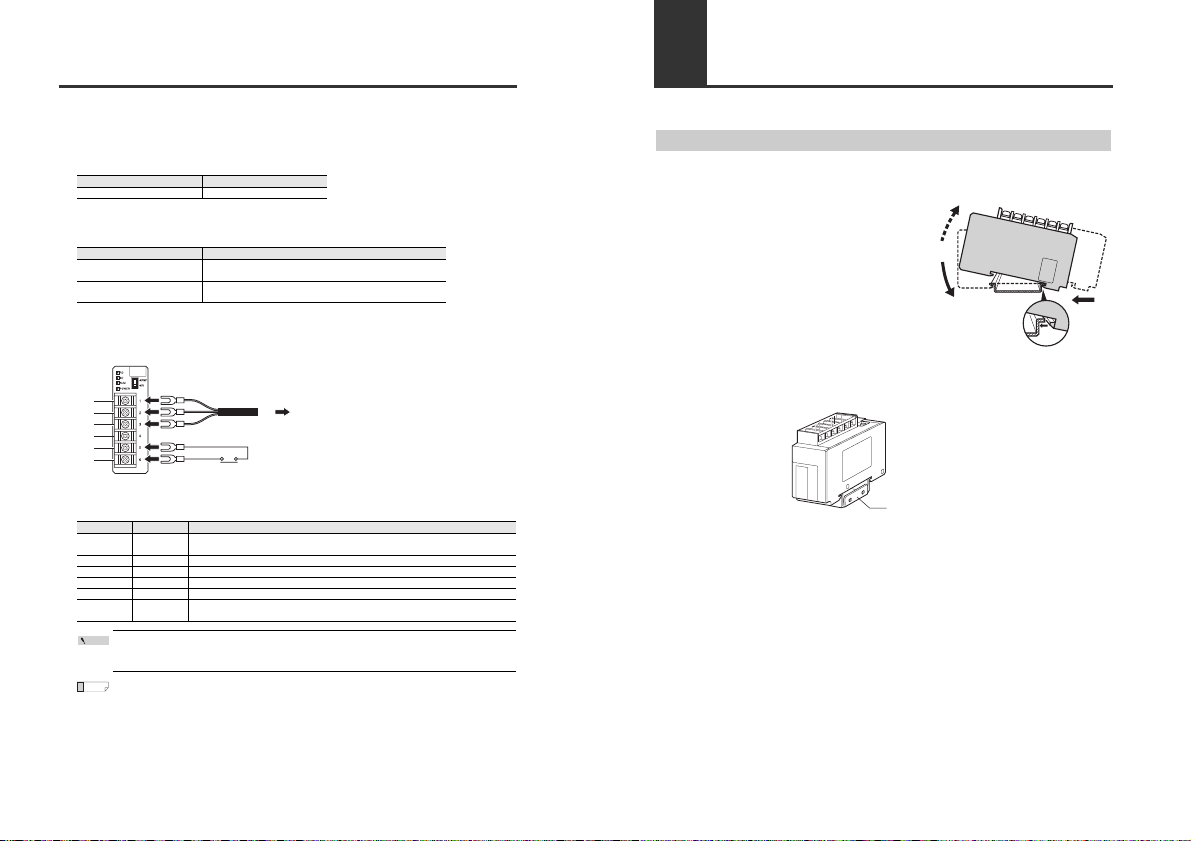

Mounting the Unit

■ Mounting the unit on the DIN rail

1 Fit the tab of the lower part of the unit to the

DIN rail. While inserting the unit in the

direction of arrow (1), push the body down in

the direction of arrow (2).

2 To detach the unit, lift the unit in the direction

of arrow (3) while pushing it in the direction

of arrow (1).

When using the mounting bracket (OP-60412), install it as shown in the illustration below.

(3)

(2)

Mounting bracket:OP-60412

(1)

3

Page 6

Connecting the Unit to Sensor Amplifiers

r

A

A

Connecting the Unit to Sensor Amplifiers

You use DL-RS1A by connecting it to sensor amplifiers. The connection method varies according to

the mounting type of the sensor amplifiers.

Before connecting DL-RS1A, you must install the main unit and expansion units of the sensor

amplifiers. For information on installing the sensor amplifiers, refer to the user's manual supplied with

the sensor amplifiers.

Make sure that the sensor amplifiers are turned off before connecting the RS232C communication unit DL-RS1A to them. Connecting the unit while the

NOTICE

sensor amplifiers are turned on may damage the unit.

■ Available sensor amplifiers

Name Type of amplifier Main unit

Thrubeam Laser

Detection Sensor

IB Series

*1 The GT-70A Series, GT2 Series, IG Series, IL Series and IB Series can be connected solely. In

addition, two or more models can be used together.

The maximum connectable numbers for each model are as follows.

• When connecting 1 model only

DIN-rail mount type IB-1000 IB-1050

Panel mount type IB-1500 IB-1550

Model Maximum connectable number (DL not included)

GT-70A Series 10 units

GT2 Series 15 units

IG Series 4 units

IL Series 8 units

IB Series 4 units

• When connecting 2 models together

Model Amplifier used together

GT-70A Series

GT2 Series

IG Series

IL Series IB Series 6 units

GT2 Series 10 units

IG Series 6 units

IL Series 8 units

IB Series 6 units

IG Series 6 units

IL Series 6 units

IB Series 6 units

IL Series 6 units

IB Series 6 units

• When connecting 3 or more models together

Model

GT-70A Series GT2 Series IL Series 8 units

When using 2 or more models together, the total connection number for each model must be the

maximum connectable number or less for connecting one model only.

(Examp le) When IB Series and IG Series are used together, sum of the 2 models must be 6 units or

4

Amplifier used

together 1

Other combinations 6 un its

less. In addition, the number of IB Series and IG Series must be 4 or less respectively.

(Connectable) IB Series 4 units, IG Series 2 units, Total 6 units

(Not connectable) IB Series 5 units, IG Series 1 units, Total 6 units

Expansion unit

Maximum connectable number

Amplifier used

together 2

Max. connectable number

4 units

(Main: 1, Expansion: 3, DL-RS1A: 1)

4 units

(Main: 1, Expansion: 3, DL-RS1A: 1)

(DL not included)

Maximum connectable number

(DL not included)

Connecting the Unit to Sensor Amplifiers

*2 As for the large display type, GT2-100 Series, up to 11 units of the sensor head can be

connected to 1 amplifier by adding the expansion board to the main unit.

GT2-100 Series cannot be used with other models.

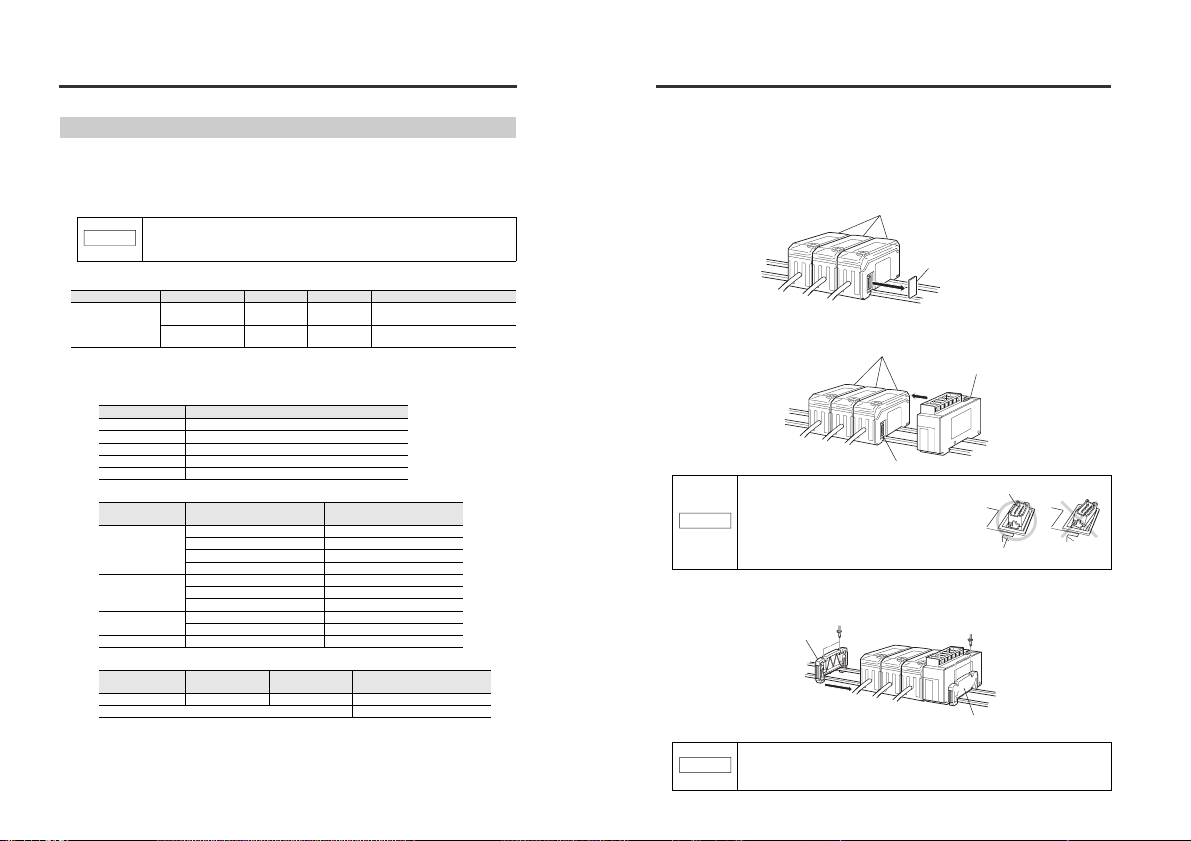

■ Connecting the DL-RS1A to DIN rail mount sensor amplifiers

1 Remove the expansion protective cover from the sensor amplifier that you want to connect to

the DL-RS1A.

2 Mount the DL-RS1A on the DIN rail and connect it to the sensor amplifier.

Make sure there is no space between the unit and the sensor amplifier.

Check that the sensor amplifier connector (for DIN

rail mounting) located on the side of DL-RS1A is

not installed at an angle as shown in the

NOTICE

illustration to the right. Connecting the unit with

its connector installed at an angle to a sensor

amplifier may damage the unit.

3 Mount the end units (OP-26751, two units included) on either side of the sensor amplifier and

DL-RS1A unit and tighten the two screws on the top of each end unit.

(You can mount the end units in the same way you mount DL-RS1A.)

End unit

Make sure you firmly insert DL-RS1A all the way into the sensor amplifier.

Turning the power on when the unit is not inserted straight or firmly connected

NOTICE

may damage the unit.

Sensor amplifier

Expansion protective cove

Sensor amplifier

DL-RS1

Connector

Sensor amplifier connector

RS-232C communication unit DL-RS1

End unit

Page 7

Connecting the Unit to Sensor Amplifiers

r

r

Connecting the Unit to External Devices

■ Connecting the unit to panel mount sensor amplifiers

1 Connect DL-RS1A to the sensor amplifiers using the optional expansion cable (OP-35361).

Remove the

Expansion cable (cable length: 300 mm)

(OP-35361)

• Make sure you securely connect the expansion cable while the unit is turned

off. Turning the power on when the cable is not inserted straight or firmly

NOTICE

connected may damage the unit.

• Removing or inserting the cable while the power is on may damage the unit.

2 Remove the sensor amplifier connector with pliers (

mounted sensor amplifiers

supplied with the unit.

) from DL-RS1A unit and install the expansion connector cover

Sensor amplifier connector

(for DIN rail mounting type)

■ Connecting to a large display type sensor amplifier

1 Connect the sensor amplifier to the RS-232C Communication Unit DL-RS1A using the optional

expansion cable (OP-35361).

• Turn OFF the power before connecting the expansion cable and connect

securely. Diagonal or otherwise improper insertion may damage the

equipment.

NOTICE

• Inserting or pulling the cable when the power is turned ON may damage the

equipment.

2 Detach the sensor amplifier connector (DIN rail mount type) of the RS-232C Communication

Unit DL-RS1A with pliers and mount the attached expansion connector.

Sensor amplifier connector

(for DIN rail mount type)

Detach the

protection sticker

Expansion cable (cable length: 300mm)

protection sticke

for DIN rail mounting when using with panel

Expansion connector cove

Detach the

protection sticker

Expansion connector cover

Communication Terminal Block

You can connect external devices such as a PC or PLC to the communication terminal block of

DL-RS1A via the communication cables.

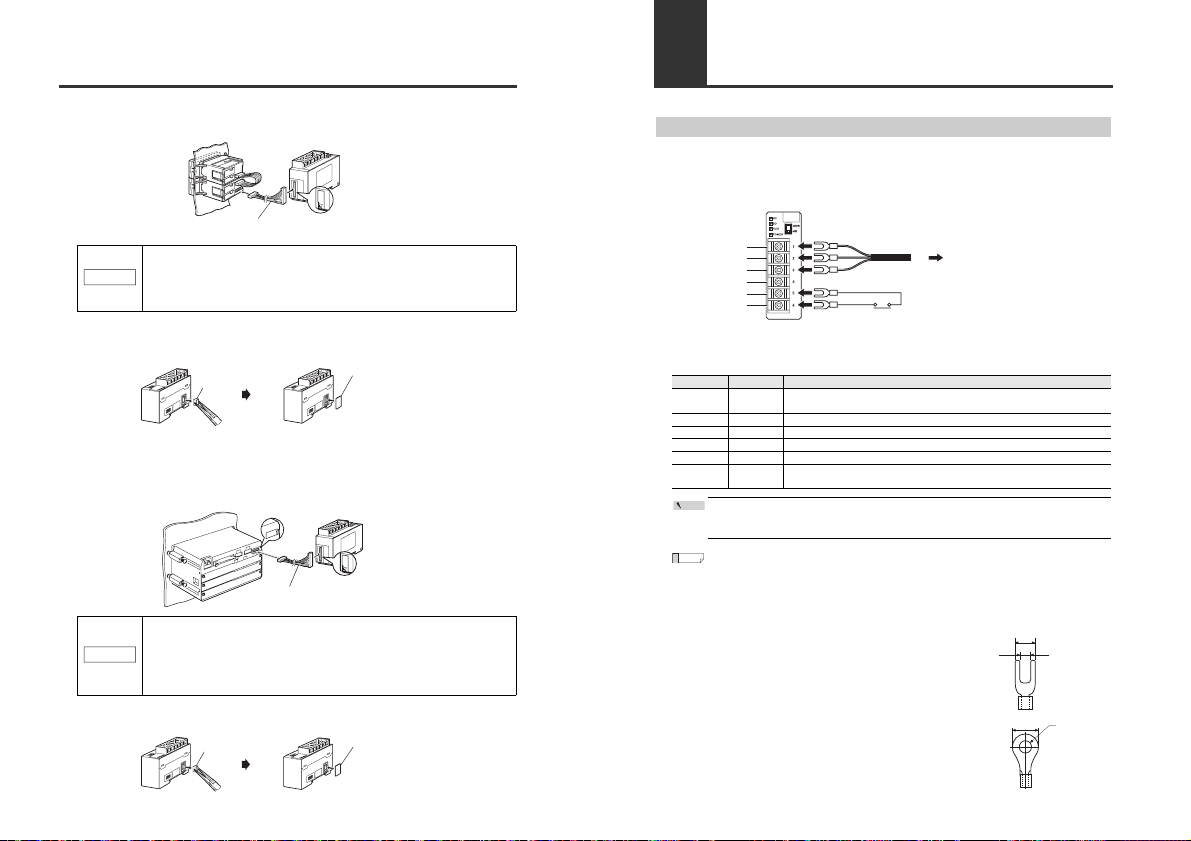

■ Terminal connection

KPEV-SP(1P) wire with balanced

type twisted shield (strand wire)

SG

RD

SD

SG

SG

DRQ

* Recommended communication cable

KPEV-SP(1P) wire with balanced type twisted shield (strand wire)

Nominal cross-section area 0.16mm

Terminal No.

Term inal Description

1SG

2 RD (input) Connects to the SD terminal of an exter nal device via a communication cable.

3 SD (output) Connects to the RD terminal of an external device via a communication cable.

4 SG The terminals for SG (Nos. 1, 4, and 5) are internally short-circuited.

5 SG The terminals for SG (Nos. 1, 4, and 5) are internally short-circuited.

6 DRQ (input)

Point

A terminal cover is attached to the terminal block.

The terminal cover must be placed over the ter minal block when you finish connecting the cables.

Reference

The terminals for SG (Nos. 1, 4, and 5) are used in common with the blue wire of the sensor am plifier

main unit.

Connects to the shielded wire of the communication cable.

The terminals for SG (Nos. 1, 4, and 5) are internally shor t-circuited.

When there is a short-circuit between DRQ and SG, the sensor amplifier data is

transmitted even without a command from the external device.

Communication cable

2

(AWG25) min.

To external device

● Crimp-type terminal

Use the Y or round terminal for wiring to the I/O terminal.

Use the Y or round terminal with the following dimensions.

Y terminal

Excerpted from dimensions of the Y terminal areas

B: Outer size of Y area

d: Width of inner Y area

(joint area with screw)

Round terminal

Excerpted from dimensions of the round terminal areas

B: Outer diameter

d: Inner diameter

(joint area with screw)

Applicable dimension

B: 6mm max.

d: 3.2mm min.

Applicable dimension

B: 6mm max.

d: 3.2mm min.

B

B

d

φd

5

Page 8

Connecting the Unit to External Devices

Connecting the Unit to External Devices

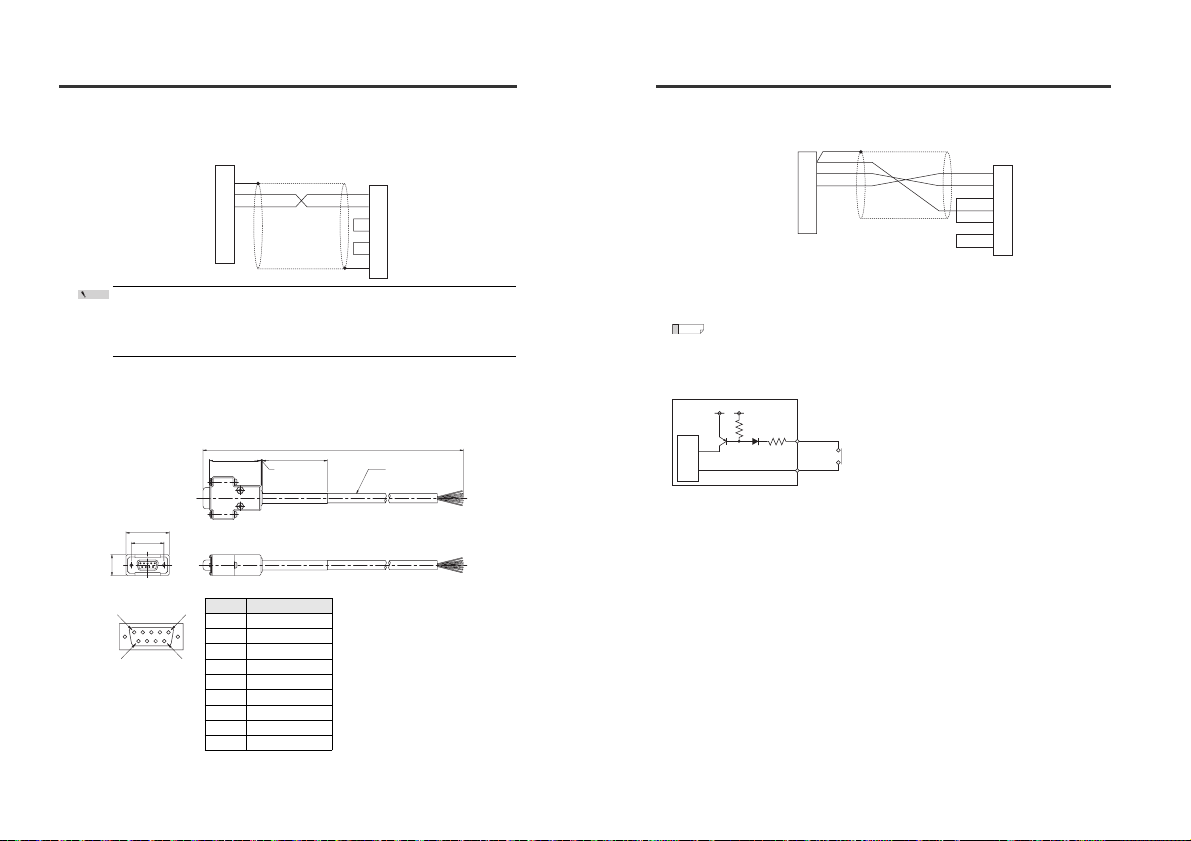

■ Connection wiring

Refer to the connection wiring diagram shown below when connecting DL-RS1A to an external

device such as a PC.

Point

• The length of the communication cable must not exceed 15 m.

•

Connect the shield wire of the communication cable to the SG terminal of the external device.

• Make sure that the shield wire does not touch other signal wires or the other terminals on

the terminal block.

DRQ

SG

RD

SD

SG

SG

DL-RS1A

1

2

3

4

5

6

Shield

External device

(D-sub 9-pin)

RD

SD

DR

ER

RS

CS

SG

■ Optional cable

An optional cable shown below is used to connect to an external device such as a PC that has

a D-sub 9-pin I/O connector.

Part number: OP-81283

39.5

33.2

25

16

Pin layout for D-sub 9-pin connector

5

Front

96

*1 Pin numbers 4 and 6 are connected inside the connector.

*2 Pin numbers 7 and 8 are connected inside the connector.

*3 Two cables (black and black/white) are connected to the pin number 5.

Pin No. Cable color

1

1-

2 Red/white

3Red

*1

4

-

5 Black, black/white

6*1-

*2

7

-

*2

8

-

9-

5000

50

1

φ7.1

*3

Sample wiring

DL-RS1A

(Communication terminal block)

*1 Insulate either the black or black/white cable that is not used.

*2 Connect the shield wire to the SG terminal of DL-RS1A. (Shield wire is connected to the

connector casing.)

Reference

The green and green/white-striped wires are not connected to any of the connector pins.

DRQ

SG

RD

SD

SG

SG

Black, Black/White

1

Red

2

Red/White

3

4

5

6

Shield

1

*

External device

(D-sub 9-pin)

*2

RD

2

3

SD

4

DR

5

SG

6

ER

7

RS

8CS

■ Input circuit diagram

+5V

6 (DRQ)

Main circuit

(Short-circuit current: 1 mA max.)

* The terminals for SG (Nos. 1, 4, and 5) are connected internally with the blue wire of the sensor

amplifier main unit.

1,4,5 (SG)

*

6

Page 9

Communication Specifications

Commands and Responses

This section provides the communication specifications of DL-RS1A and describes how to configure the unit.

Communication Specifications

The following table lists the communication specifications for DL-RS1A.

Item Specifications

Communication method Full duplex

Synchronization method Asynchronous

Transmission code ASCII

Communication speed 240 0, 4800, 9600, 19200, 38400 bit/s (Factory default: 9600 bit/s)

Data bit length 7 or 8 bits (Factory default: 8 bits)

Parity check None, even, odd (Factory default: none)

Stop bit length 1 bit

Data delimiter

For communication settings, refer to page 2.

Receive: automatically detect CR or CR + LF

Send: fixed to CR + LF

Sensor Amplifier ID Number Assignments

When the main sensor amplifier that is connected to DL-RS1A supports expansion units, the main

sensor amplifier ID number "00" is automatically assigned to the main unit and ID numbers "01 to 14"

to the expansion units.

Point

You cannot change the assignment of sensor amplifier ID numbers.

DIN rail mount sensor amplifiers

ID No. 00

01 02 04 05

Main Exp. Exp. Exp. Exp.

Sensor amplifier DL-RS1A

Panel mount sensor amplifiers

ID No. Sensor amplifier

00

01

02

04

05

Main

Exp.

Exp.

Sensor amplifier

DL-RS1A

Exp.

Exp.

Overview of Commands and Responses

ID No. 00

01 02 04 05

Main Exp. Exp. Exp. Exp.

Sensor amplifier DL-RS1A

Command or DRQ input

Response

or

error response

External device like PLC or PC

Command format

You can send specific commands based on ASCII codes from an external device to DL-RS1A.

For information on the parameters used in the command, refer to "Parameters of Commands and

Responses" (page 10).

Sample command format structure

S

R CR LFID No. Data No.

,,

(1) (2) (3) (4)

(1) With the first two bytes, specify the communication command.

(2) Specify the ID number assigned to the target sensor amplifier using two digits (ASCII characters).

(3) Specify the data number for the data you want to read from or write to the sensor amplifier using

three digits (ASCII characters).

(4) Insert CR or CR + LF as the command delimiter.

Important

You must use commas (,) to separate (1), (2), and (3).

Example

To read the "Hold function setting (data number: 136)" from an expansion unit of an active

IB Series (ID number: 01):

Command :

ASCII character conversion :

From an external device, 11-byte data will be sent to the DL-RS1A.

Important

The last byte of the command you send must be CR (0DH) or LF (0AH). Specifying a value

other than CR or LF results in an error response (error number: 00). For information on the

error responses, refer to "Error numbers" (page 16).

S

R CR LF0 1 1 3 6

,,

(53H) (52H) (2CH)(31H) (33H) (36H)(0DH)(0AH)(2CH)(30H) (31H)

Data memory 0

Data memory 1

Data memory 2

Data memory 3

Data memory 4

Data memory 5

bit

15

S

(53H)

,

(2CH)

1

(31H)

1

(31H)

6

(36H)

LF

(0AH)

R

(52H)

0

(30H)

,

(2CH)

3

(33H)

CR

(0DH)

Value to store in

bit

0

data memory (hexadecimal)

→ 5352

→ 2C30H

→ 312CH

→ 3133H

→ 360DH

→ 0A00H

H

7

Page 10

Commands and Responses

Commands and Responses

Response

When DL-RS1A successfully receives a command from the external device, it automatically returns a

response based on ASCII codes.

For information on the parameters used in the response, refer to "Parameters of Commands and

Responses" (page 10).

Sample response structure

S

R ID No. Data No.

,,

(1) (2) (3) (4) (5)

(1) Contains the same communication command as the received command.

(2) Contains the same ID number as the received command.

(3) Contains the same data number as the received command.

(4) Contains the data that DL-RS1A retrieved from the specified sensor amplifier. Contains maximum

of 10 bytes according to the specified data number (3).

(5) Contains CR + LF as the response delimiter.

Example

When the command format "SR,01,136CRLF" is sent to the IB Series (ID number: 01) in

operation and the response indicating that the setting is "Peak hold" is received:

Response format :

ASCII character conversion :

DL-RS1A sends the response to the external device.

,

S

R 0 1 1 3 6

(53H) (52H) (2CH)(31H) (33H) (36H)(2CH)(30H) (31H)

Value to store in

data memory

(hexadecimal)

5352

H →

2C30H →

H →

312C

3133

H →

362CH →

H →

310D

0A00

H →

CR LFData

,,

bit

15

S

(53H)

R

(52H)

,

(2CH)

0

(30H)

1

(31H)

,

(2CH)

1

(31H)

3

(33H)

6

(36H)

(2CH)

,

1

(31H)

CR

(0DH)

LF

(0AH)

,

(2CH)(31H) (0DH) (0AH)

bit

0

1 CR LF

Peak hold

Error response

If DL-RS1A could not receive a command from the external device or if the received command

included an error, it automatically returns an "error response" based on ASCII codes.

For information on the parameters used in the error response, refer to page 10.

Sample error response structure

E

R

(1) (2) (3)

(1) Contains "ER".

(2) Contains the same communication command as the received command.

(3) Contains a two-digit error number (ASCII characters) indicating the error type.

For information on the error numbers, refer to "Error numbers" (page 16).

(4) Contains CR + LF as the error response delimiter.

Example

Error No.

SR

,,

An error response indicating an "ID number error" as a response to the command

"SR,01,136CRLF":

CR LF

(4)

Error response :

ASCII character conversion :

E

R S R

,,

(45H) (52H) (2CH)(2CH)(53H) (52H)

Value to store

in data memory

4552

H →

2C53H →

H →

522C

3635

H →

H →

0D0A

bit

15

E

(45H)

,

(2CH)

R

(52H)

6

(36H)

CR

(0DH)LF(0AH)

6 5

(36H) (35H)

R

(52H)

S

(53H)

,

(2CH)

5

(35H)

CR LF

(0DH) (0AH)

ID No. error

bit

0

DL-RS1A sends the error response to the external device.

8

Page 11

Commands and Responses

Commands and Responses

Reading

External devices such as PLC's use the following communication commands to read data from

DL-RS1A.

Read from the specified sensor amplifier (SR command)

Command

SR CR LFID No. Data No.

,,

Response

SR Data*

ID No. Data No.

,, ,

1

CR LF

Error response

ER,SR

Error No.,CR LF

Read all data from all sensor amplifiers (M0 command)

Command

M 0 CR LF

Response

Data of the sensor

M0 CR LF

amplifier with ID:00*

,

Error response

ER CR LF

Read output states and data from all sensor amplifiers (MS command)

,M0,

Error No.

Command

M S CR LF

Response

Control

M

Data of the sensor

S

3

output

amplifier with ID:00*

*

,, ,,

Sensor amplifier with ID:00 Sensor amplifier with ID:01 Sensor amplifier with the last ID No.

Error response

ER CR LF

,MS,

Error No.

2

,

2

Data of the sensor

amplifier with ID:01*

Control

Data of the sensor

3

output

amplifier with ID:01*

*

2

……

Data of the sensor amplifier

with the last ID No.

,,

Control

Data of the sensor

…

3

2

output

amplifier with the last ID No.

*

,,

2

*

Read with external input to the DRQ terminal (DRQ read)

You can send an input signal (by short-circuiting DRQ (terminal number 6) and SG (terminal number

1, 4, or 5)) from an external device such as a PLC instead of sending a command.

SG

RD

SD

SG

SG

DRQ

Response

Control

DR

Data of the sensor

3

*

output

amplifier with ID:00*

,, ,,

Sensor amplifier with ID:00 Sensor amplifier with ID:01 Sensor amplifier with the last ID No.

Control

2

output

Error response

ER CR LF

*1 The data length is different depending on the data being read. (Up to 10 characters)

*2 Data length: 7 characters

When the measurement mode is displayed with %: ±***.** (Reading range: -999.99 to +999.99)

When the measurement mode is displayed with dimension: ±**.*** (Reading range: -99.999 to

+99.999)

*3 Data length: 2 characters

On the IB Series, the judgment output (HIGH/LOW/GO output) and the check output ON/OFF

are displayed with 2-digit number (ASCII characters). Convert the 2-digit number (ASCII

characters) read to a binary number and check the ON/OF status of each bit to check the

judgment output status.

CR LF

2

*

Reference

Error No.

,DR,

Bit

0

1

2

3

When N.O. When N.C.

0: HIGH judgment output OFF,

1: HIGH judgment output ON

0: LOW judgment output OFF,

1: LOW judgment output ON

0: GO judgment output OFF,

1: GO judgment output ON

0: Check output OFF,

1: Check output ON

When the read data is "05":

•

"05" is converted to the binary number "0101".

When N.O.

Bit 3: Check output OFF Bit 0: HIGH judgment output ON

Bit 2: GO judgment output ON Bit 1: LOW judgment output OFF

Input signal

ON

OFF

Data of the sensor

3

*

amplifier with ID:01*

Judgment output

0: HIGH judgment output ON,

1: HIGH judgment output OFF

0: LOW judgment output ON,

1: LOW judgment output OFF

0: GO judgment output ON,

1: GO judgment output OFF

0: Check output ON,

1: Check output OFF

…

2

2 ms min.

Control

Data of the sensor

3

*

output

amplifier with the last ID No.

,,

CR LF

2

*

9

Page 12

Commands and Responses

Parameters of Commands and Responses

Writing

External devices such as PLC's use the following communication commands to write data to

DL-RS1A.

Point

Attempting to write data with "read-only" attribute results in a communication error and an

error response (error number: 22).

Write to the specified sensor amplifier (SW command)

Command

SW CR LFID No. Data No.

,,

Response

SW CR LFID No. Data No.

,,

Error response

ER CR LF

SW,Error No.

,

* The data length is different depending on the data being written.

Setting data*

,

Write to all sensor amplifiers (AW command)

Command

AW CR LFData No.

,

Response

AW CR LFData No.

,

Error response

ER CR LF

,AW,

* The data length is different depending on the data being written.

,

Error No.

Setting data*

This section describes the parameters used with various commands and responses.

Communication commands

There are two types of communication commands: read commands and write commands.

Communication

command

DRQ input

Attribute Description

SR

M0

MS

SW

AW Writes setting data for the specified data number onto all sensor amplifiers.

Point

• For information on the data, refer to the instruction manual or user's manual supplied with

the sensor amplifiers.

• If commands are sent during the period of approx. 3 seconds after the power is turned on,

the communication error (error number: 22) will occur.

Reads the data for the specified data number from the sensor amplifier with the

specified ID number.

Reads the judgment value (P.V.) that DL-RS1A periodically retrieves from all

sensor amplifiers.

Reads the judgment output that DL-RS1A periodically retrieves from all sensor

Read

amplifiers, the ON/OFF state of the check output and the judgment value (P.V.)

collectively.

Reads the ON/OFF state of the judgment output and check output, and the

judgment value (P.V.) that DL-RS1A periodically retrieves from all sensor

amplifiers when a DRQ input is received.

Writes setting data for the specified data number onto the sensor amplifier with

the specified ID number.

Write

ID numbers

This parameter is used with communication commands "SR" and "SW". Specify the ID number of the

target sensor amplifier using two digits (ASCII characters).

(Example) Sensor amplifier with the ID number 00 = 00, sensor amplifier with the ID number 03 = 03

10

Page 13

Parameters of Commands and Responses

Parameters of Commands and Responses

Data numbers

Specify the data number using three digits (ASCII characters).

z Read-only data

The following table lists the types of data that can be read from the IB Series sensor amplifiers.

Point

Writing read-only data results in a communication error (error number: 22).

No. of

Data No. Data name Data format

033 Error status*

034 Warning status ***** 5 R

035 Warning function operating state ***** 5 R

036 Judgment output/Check output*

037 Judgment value (P.V.)*

038 Internal measurement value (R.V.)*

039 Peak-hold value in hold mode*

040 Bottom-hold value in hold mode*

042 Analog output value

043 Bank status * 1 R 0 to 3

044 Timing status * 1 R

050 Laser emission stop status * 1 R

051 Abnormal setting*

052 External input status ** 2 R 0 to 15*

053 EEPROM writing result*

054 Zero shift execution result*

055 Reset execution result * 1 R

056 System parameter current state*

058 Reference light registration result * 1 R

059 Adjust result * 1 R

060 Tuning result * 1 R

3

4

5

5

5

5

8

10

11

11

*1

***** 5 R 0 to 65535

** 2 R 0 to 15

*6

±***.**

*6

±***.**

*6

±***.**

*6

±***.**

±*.***

or

**.**

*1R

*1R

*1R

** 2 R

*2

Attribute

bytes

0: Check output OFF

1: Check output ON

(When N.O.)

0: Check output function disabled

1: Check output function enabled

7 R -999.99 to +999.99

7 R -999.99 to +999.99

7 R -999.99 to +999.99

7 R -999.99 to +999.99

Analog voltage output:

-5.000 to +5.000*

5 or 6 R

Analog current output

04.00-20.00*

0: Sampling

1: Not sampling

0: Emitting

1: Emission stopped

0: Normal setting

1: Abnormal setting

9

0: Writing

1: Normal termination

2: Abnormal termination

0: Executing

1: Normal termination

2: Execution impossible

0: Executing

1: Normal termination

2: Execution impossible

Main unit: 0 to 9

Expansion unit: 0 to 1

0:Executing

1:Normal te rmination

2:Reference light amount registration

error 1 (insufficient light amount error)

3:Reference light amount registration

error 2 (ambient light error)

0: Executing

1:Normal te rmination

2:Adjust error 1 (insufficient light amount

error)

3:Adjust error 2 (am bient light error)

4:Adjust error 3 (excessiv e light amount

error)

0: Executing

1: Normal termination

2: Execution impossible

Data range

7

7

No. of

Data No. Data name Data format

061 Correction result*

193 Product code **** 4 R

195 Transmitter head mode **** 4 R

196 Receiver head model **** 4 R

*1 In the Data format column, "±" indicates that the value can be either "+" or "-" and "*" signifies a

number from "0 to 9".

*2 R: Indicates that the data type can only be read from the sensor amplifiers.

*3 You can read data number "033" to check the error status of the sensor amplifiers.

Convert the 5-digit number (ASCII characters) read to a binary number and check the ON/OFF

state of each bit to check the error.

Bit Sensor amplifier errors

10 Adjust error

11 Ampli fier communication error

12

0 Overcurrent error

1 EEPROM error

2 Head error

3 Transmitter/Receiver reverse connection error

4 Transmitter internal failure error

5 Receiver error

6 Transmitter error

7 Transmitter laser error

8 Model mismatch error

9 Reference light amount registration error

*1

*1R

bytes

Attribute

*2

Data range

0: Executing

1: Normal termination

2: Execution impossible

Main unit: 4020

Expansion unit: 4021

0: When the sensor head is not

connected

or the receiver is connected

1:When IB-01 transmitter is connected

2:When IB-05 transmitter is connected

3:When IB-10 transmitter is connected

4:When IB-30 transmitter is connected

0:When the sen sor head is not

connected

or the transmitter is connected

1:When IB-01 receiver is connected

2:When IB-05 receiver is connected

3:When IB-10 receiver is connected

4:When IB-30 receiver is connected

For information on each error, refer to "IB Series User's Manual".

Reference

When the read data is "00033":

•

"33" is converted to the binary number "0000 0000 0010 0001".

Bit 5: Receiver error Bit 0: Overcurrent error

Therefore, "Receiver error" and "Overcurrent error" have occurred simultaneously at

the sensor amplifier from which data was read.

If no error has occurred at the sensor amplifier, the data "00000" is returned.

*4 You can read data number "036" to check the judgment output status.

•

11

Page 14

Parameters of Commands and Responses

Parameters of Commands and Responses

Convert the 2-digit number (ASCII characters) read to a binary number and check the ON/OFF

state of each bit to check the judgment output status and check output status.

Bit

0

1

2

3

Reference

*5 When the read data is one of the following values, it has a different meaning from that of an

evaluation value.

Read data Description

+EEE.EE The sen sor amplifiers is in the error status.

-999.99 The value is -99.998 or below the lower limit of the display range .

-999.98 The value is "-----".

*6 When reading data from the amplifier unit whose "1. Measurement mode" is set to "Dimension

mode", the data format is changed to ±**.*** (Reading range -99.999 to +99.999).

*7 When the sensor amplifier is in the error status or "-----" state, the analog voltage output is

+5.500 and analog current output is +03.00.

*8 When writing is perfor med to set the prohibited combination of functions, the value becomes 1.

For details of each function, refer to the User's Manual.

*9 When the external input is ON, the external input status is "1" and when it is OFF, the state is "0".

The bit 0,1,2,3 corresponds to the external input 1,2,3,4.

Reference

When N.O. When N.C.

0: HIGH judgment output OFF,

1: HIGH judgment output ON

0: LOW judgment output OFF,

1: LOW judgment output ON

0: GO judgment output OFF,

1: GO judgment output ON

0: Check output OFF,

1: Check output ON

When the read data is "05":

•

"05" is converted to the binary number "0101".

When N.O.

Bit 3: Check output OFF Bit 0: HIGH judgment output ON

Bit 2: GO judgment output ON Bit 1: LOW judgment output OFF

999.99 The value exceeds the upper limit of the display range.

When the read data is "06":

•

"6" is converted to the binary number "0110".

External input 4: OFF External input 1: OFF

External input 3: ON External input 2: ON

Judgment output

0: HIGH judgment output ON,

1: HIGH judgment output OFF

0: LOW judgment output ON,

1: LOW judgment output OFF

0: GO judgment output ON,

1: GO judgment output OFF

0: Check output ON,

1: Check output OFF

*10 This item includes the results for the initial reset request.

*11 You can read data number "056" to check the system parameter of the sensor amplifier.

The system parameter means the polarity of judgment output and check output, and the setting

for analog output.

Convert the 2-digit number (ASCII characters) read to a binary number and check the ON/OFF

state of each bit to check the system parameter.

Bit Default settings

0 0: NPN output, 1: PNP output

000: Analog output OFF

001: 0 to 5 V

3, 2, 1

010: -5 to 5 V

011: 1 to 5 V

100: 4 to 20 mA

Reference

When the read data is "006":

•

"6" converted to binary number is "0110".

Bit 3, 2, 1: 1 to 5 V Bit 0: NPN output

Therefore, the setting of the amplifier from which the data is read is "NPN output" and

"Analog output 1 to 5 V".

*12 "Measured correction" and "Logical correction" results can be confirmed.

This cannot be used when "Do not correct" for "Calibration function" is selected.

12

Page 15

Parameters of Commands and Responses

Parameters of Commands and Responses

z Read/write data

The following table lists the types of data that can be read from and written to IB Series sensor

amplifiers.

Point

When data is written while the initial reset is being performed, the parameter error will occur

(Error number: 22). When writing data after the initial reset is performed, confirm that the

EEPROM writing result (Data number: 053) shows "1: Normal termination" and then write

data.

Data

No.

Data name

001 Zero shift request * 1

002 Zero shift reset request * 1

003 Reset request * 1

004 Error clear request * 1

005 Initial reset request * 1

006 System parameter set request*5*1

Reference light registration

010

request

011 Adjust request * 1

012 Adjust reset request * 1

014 Tolerance tuning request * 1

2-point tuning HIGH side 1st

015

request

2-point tuning HIGH side 2nd

016

request

2-point tuning LOW side 1st

017

request

2-point tuning LOW side 2nd

018

request

Measured correction 1st

019

6*7

request*

Measured correction 2nd

020

6*7

request*

026 Logical correction 1st request*6*7*1

027 Logical correction 2nd request*6*7*1

Data

*1

format

*1

*1

*1

*1

*1

*1

*1

No. of

*2

Attribute

bytes

R 0 - 1: Last written value

W0 o 1: Perform zero shift*

R 0 - 1: Last written value

W0 o 1: Perform zero shift reset*

R 0 - 1: Last written value

W0 o 1: Perform reset*

R 0 - 1: Last written value

W0 o 1: Perform error clear *

R 0 - 1: Last written value

W0 o 1: Perform initial reset*

R 0 - 1: Last written value

W0 o 1: Perform system parameter set*

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W0 o 1: Perform adjust*

R 0 - 1: Last written value

W0 o 1: Perform adjust reset*

R 0 - 1: Last written value

W0 o 1: Perform tolerance tuning*

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W

R 0 - 1: Last written value

W0 o 1: Perform logical correction 1st p oint*

R 0 - 1: Last written value

W0 o 1: Perform logical correction 2nd point*

Data range Default value

0 o 1: Perform reference light amount

registration

0 o 1: Perform 2-point tuning HIGH side 1st

3

point*

0 o 1: Perform 2-point tuning HIGH side

3

2nd point*

0 o 1: Perform 2-point tuning LOW side 1st

3

point*

0 o 1: Perform 2-point tuning LOW side 2nd

3

point*

0 o 1: Perform measured correction 1st

3

point*

0 o 1: Perform measured correction 2nd

3

point*

3

3

3

3*4

3

3

3

3

3

3

3

Data

1

1

1

1

Data name

No.

065 HIGH setting value (BANK 0) ±***.** *87 R/W -999.99 to +999.99 20.00

066 LOW setting value (BANK 0) ±***.** *

067 Shift target value (BANK 0) ±***.** *

068 HIGH setting value (BANK 1) ±***.** *

069 LOW setting value (BANK 1) ±***.** *

070 Shift target value (BANK 1) ±***.** *

071 HIGH setting value (BANK 2) ±***.** *

072 LOW setting value (BANK 2) ±***.** *

073 Shift target value (BANK 2) ±***.** *

074 HIGH setting value (BANK 3) ±***.** *

075 LOW setting value (BANK 3) ±***.** *

076 Shift target value (BANK 3) ±***.** *

097 Key lock setting * 1 R/W

098 Bank setting*

099 Timing input*

9

10

100 Laser emission stop input*

1

1

1

1

1

1

1

1

1

104 Sub display's screen * 1 R/W

105 System parameter*

11

106 Tolerance tuning setting width ***.** *

107 Calibration function * 1 R/W

Measured/Logical correction

108

6*7

target 1*

Measured/Logical correction

109

6*7

target 2*

115 Logical correction measured 1*

116 Logical correction measured 2*

130 Measurement mode*

131 Received/Blocked light mode * 1 R/W

Data

No. of

*2

10

Attribute

*1

format

bytes

8

7 R/W -999.99 to +999.99 10.00

8

7 R/W -999.99 to +999.99 0.00

8

7 R/W -999.99 to +999.99 20.00

8

7 R/W -999.99 to +999.99 10.00

8

7 R/W -999.99 to +999.99 0.00

8

7 R/W -999.99 to +999.99 20.00

8

7 R/W -999.99 to +999.99 10.00

8

7 R/W -999.99 to +999.99 0.00

8

7 R/W -999.99 to +999.99 20.00

8

7 R/W -999.99 to +999.99 10.00

8

7 R/W -999.99 to +999.99 0.00

*1R/W

*1R/W

*1R/W

** 2 R/W

12

6 R/W 0.00 to 999.99 10.00

Data range Default value

0: Disabled

1: Key lock

0: Switch to bank 0

1: Switch to bank 1

2: Switch to bank 2

3: Switch to bank 3

0: Timing input OFF

1: Timing input ON

0: Laser emission stop input OFF

1: Laser emission stop input ON

0: R.V. value screen

1: Analog output screen

2: HIGH setting value screen

3: LOW setting value screen

4: Shift target value setting screen

Main unit: 0 to 9

Expansion unit: 0 to 1

0: Do not correct (Initial state)

1: Measured correction

2: Logical correction

±***.** *87 R/W -999.99 to +999.99 0.00

±***.** *87 R/W -999.99 to +999.99 100.00

6*7

±***.** *87 R/W -999.99 to +999.99 0.00

6*7

±***.** *87 R/W -999.99 to +999.99 100.00

13

*1R/W

0: % mode

1: Dimension mode

0: Received light mode

1: Blocked light mode

0

0

0

0

0

0

0

0

0

1

1

1

1

1

13

Page 16

Parameters of Commands and Responses

Parameters of Commands and Responses

Data

No.

133 Averaging/High-pass filter ** 2 R/W

134 Output mode * 1 R/W

136 Hold function setting * 1 R/W

137 Auto hold trigger level ±***.** *

138 Timing input * 1 R/W

139 Delay Timer * 1 R/W

140 Timer duration **** 4 R/W 1 to 9999 60

141 Hysteresis ***.** *

142 Analog output scaling*

143 Analog output upper limit*

144 Analog output lower limit*

145 External input setting*

146

147

148

Data name

External input 1 function

15

selection*

External input 2 function

15

selection*

External input 3 function

15

selection*

Data

No. of

*2

Attribute

*1

format

bytes

8

7 R/W -999.99 to +999.99 90.00

12

14

14

14

15

6 R/W 0.00 to 999.99 0.00

*1R/W

±***.** *87 R/W -999.99 to +999.99 100.00

±***.** *87 R/W -999.99 to +999.99 0.00

*1R/W

*1R/W

*1R/W

*1R/W

Data range Default value

Averaging

0: 1

1: 2

2: 4

3: 8

4: 16

5: 64

6: 256

7: 1024

8: 4096

9: 16384

High-pass filter

10: 0.1Hz

11: 0.2Hz

12: 0.5Hz

13: 1Hz

14: 2Hz

15: 5Hz

16: 10Hz

17: 20Hz

18: 50Hz

19: 100Hz

0: NO (Normally Open)

1: NC (Normally Close)

0: Sample hold

1: Peak hold

2: Bottom hold

3: Peak-to-peak hold

4: Auto peak hold

5: Auto bottom hold

0: Level

1: Edge

0: Delay timer off

1: On delay timer

2: Off delay timer

3: One shot timer

0: Do not scale (Initial state)

1: Free range

0: Initial state

1: User setting

0: Zero shift input

1: Bank A input

2: Bank B input

3: Laser emission stop input

4: Not use

0: Reset input

1: Bank A input

2: Bank B input

3: Laser emission stop input

4: Not use

0: Timing input

1: Bank A input

2: Bank B input

3: Laser emission stop input

4: Not use

Data

5

0

0

0

0

0

*1 In the Data format column, "±" indicates that the value can be either "+" or "-" and "*" signifies a

0

*2 Indicates that the data can only be read from (R), can only be written to (W), or can be both read

*3 The command is executed only when the data is changed from 0 to 1. Unless the setting is

0

0

*4 Reference light amount registration error [ErG] and Adjust error [ErAdJ] are cleared.

0

*5 The system parameter means the polarity of judgment output and check output, and the setting

*6 When requesting execution of the Measured correction (Logical correction), the data No. "107"

Data name

No.

External input 4 function

149

15

selection*

150 Bank switching method * 1 R/W

152 Save zero-shift state function * 1 R/W

154 Display digit * 1 R/W

155 Power save function * 1 R/W

157 Judgment indicator color * 1 R/W

158 P.V. value display color * 1 R/W

161 Save adjust state function * 1 R/W

162 Adjust level ** 2 R/W 1 to 30 20

163 Auto adjust function * 1 R/W

164 Auto adjust level **.** 5 R/W 0.50 to 20.00 3.00

165 Check output function * 1 R/W

166 Check output light level ** 2 R/W 1 to 30 10

167 Error output mode * 1 R/W

168 Hysteresis for trigger level * 1 R/W

Hysteresis set value for trigger

169

level

number from "0 to 9".

from and written to (R/W) the sensor amplifiers.

changed to 1 after the setting is changed to 0, the command is not executed.

If the sensor amplifier is turned OFF after the zero shift is performed, the previous state before

the zero shift function is used is restored. If you wish to keep the zero shift state even after the

power is turned OFF, set the Save zero-shift state function to ON.

If the sensor amplifier is turned OFF after the adjust function is performed, the previous state

before the adjust function is performed is restored. If you wish to keep the light amount

correction value even after the power is turned OFF, set the Save adjust state function to ON.

for analog output.

The execution result can be confirmed by the data number 056 (System parameter current state).

must be set to Measured correction (Logical correction) before setting.

Data

No. of

*2

Attribute

*1

format

bytes

*1R/W

12

6 R/W 0.00 to 999.99 1.00

***.** *

Data range Default value

0: Adjust input

1: Bank A input

2: Bank B input

3: Laser emission stop input

4: Not use

0: Button

1: External input

0: OFF

1: ON

0: Initial state

1: 0.0001

2: 0.001

3: 0.01

4: 0.1

5: 1

0: OFF

1: Half

2: All

0: GO only Green (Initial state)

1: GO only Red

2: All Green

3: All Red

0: GO Green (Initial state)

1: GO Red

2: All Green

3: All Red

0: OFF

1: ON

0: Disabled

1: Enabled

0: Disabled

1: Enabled

0: Normal mode (Initial state)

1: LX2 compatible mode

0: Initial state

1: User setting

4

0

0

0

0

0

0

0

0

0

0

0

14

Page 17

Parameters of Commands and Responses

Parameters of Commands and Responses

*7 If the the setting is changed between the 1st execution request and the 2nd execution request,

correction cannot be made.

When making correction, do not change other settings midway.

Also, the auto adjust function does not work between the 1st point execution request and the

2nd point execution request. Make sure to perform the 2nd point execution request next after

the 1st point execution request.

*8 When reading data from the amplifier unit whose "1. Measurement mode" is set to "Dimension

mode", the reading range is changed to ±**.*** (-99.999 to +99.999).

*9 This operates when "11. Bank switching method" is set to "Button".

*10 This operates as OFF only when data 0 is written and the external input for wiring is OFF.

*11 Specify the system parameter set when data number "006 (System parameter set request)" is

written. Convert the 2-digit number (ASCII characters) to a binary number and check the ON/

OFF state of each bit to specify the system parameter.

Bit Default settings

0 0: NPN output, 1: PNP output

000: Analog output OFF

001: 0 to 5 V

3, 2, 1

010: -5 to +5 V

011: 1 to 5 V

100: 4 to 20 mA

Reference

When the specified data is "06":

•

"6" converted to binary number is "0110".

Bit 3, 2, 1: 1 to 5 V Bit 0: NPN output

Therefore, the setting of the amplifier to which the data is written is "NPN output" and

"Analog output 1 to 5 V".

*12 When reading data from the amplifier unit whose "1. Measurement mode" is set to "Dimension

mode", the reading range is changed to **.***(00.000 to 99.999).

*13 When changing the measurement mode, the communication response time T4 becomes max. 1

second for 1 second after the setting is changed. Also, the same result is yielded when the

setting is changed using the button operation of the sensor amplifier.

*14 Writing onto expansion units results in a communication error (error number: 22).

*15 To reflect the setting written for the data number 146 to 149 to the sensor amplifier, write 1 (user

setting) for the data number 145 or set the external input setting to "User setting" with the button

operation on the sensor amplifier.

Relation between the data number 001 to 027 (data requesting the sensor

amplifier operation) and the data number 053 to 061 (data presenting the result

of request/execution)

When writing the data number 001 to 027 (data requesting the sensor amplifier operation), read the

data number 053 to 061 (data presenting the result of request/execution) and check that the request

is correctly reflected (1: Normal termination is read.) or the system parameter state presents the

setting value.

If the request is not correctly reflected and abnormal termination occurs, data other than 1: Normal

termination may be read by reading the data number 053 to 061. Thus, the request may not be

reflected to the sensor amplifier.

When 0 o 1 is written for the data number 001 to 027, the previous state of the data number 053 to

061 is cleared and the condition is updated.

The data number 053 to 061 keeps the result until 0 o 1 is written for the data number 001 to 027

next.

Example

Data number

• The data number 054 (Zero shift execution result) keeps the result of writing which either

the data number 001 (Zero shift request) or data number 002 (Zero shift reset request)

performed last.

• The data number 059 (Adjust result) keeps the result of writing which either the data

number 011 (Adjust request) or data number 012 (Adjust reset request) performed last.

• The data number 060 (Tuning result) keeps the result of writing which any of the data

number 016 (2-point tuning HIGH side 2nd request), data number 018 (2-point tuning

LOW side 2nd request) or data number 014 (Tolerance tuning request) performed last.

The data number 053 (EEPROM writing result) keeps "0: Writing" approx. for 2 seconds after the

contents written onto the nonvolatile memory (EEPROM) using the writing commands (SW, AW) are

sent last.

If writing starts after 2 seconds and finishes normally, 1: Normal termination results.

Example

If the writing commands (SW, AW) are continuously sent every second, 0: Writing results

always. After the last writing commands (SW, AW) are sent, 0: Writing is kept for 2 seconds,

writing is performed after 2 seconds and 1: Normal termination results.

However, when the initial reset is performed for the data number 005 (Initial reset request), writing

starts immediately. If the all parameters can be saved on the nonvolatile memory (EEPROM) after

approx. 3 seconds, 1: Normal termination results.

• When the Save zero-shift state function is ON, the data number 001 (Zero shift request) and 002

(Zero shift reset request) immediately start writing.

• When the Save adjust state function is ON, the data number 011 (Adjust request) and 012 (Adjust

reset request) immediately start writing.

• Regardless of the setting, 010 (Reference light registration request), 020 (Measured correction 2nd

request) and 027 (Logical correction 2nd request) immediately start writing.

15

Page 18

Parameters of Commands and Responses

Communication Response Time

Error numbers

The following table lists the error numbers that are returned as error responses when errors occur in

the communication with the IB Series.

Each error number is identified with two digits (ASCII characters).

Error

Error name Problem Action

number

Invalid command

00

error

20 Data length error

Number of

21

parameters error

22 Parameter error

29 Communication error

65 ID number error

66 Expansion line error

67 Write control error DL-RS1A is not writable.

Point

The commands are only sent and received when a response is returned from DL-RS1A to the

external device within 1 sec.

Take the appropriate action to resolve the problem by referring to "Troubleshooting" (page 21).

An invalid command was

received.

Data with the correct length was

not received.

The correct number of parameters

for the command was not

received.

· A parameter exceeds its range

of value.

· The external device is trying to

write a data type that cannot be

written.

· The external device is trying to

read a data type that cannot be

read.

· The data format is incorrect.

An error was detected with

RS-232C communication.

The ID number specified with the

command is incorrect.

The communication could not be

established due to a problem with

an expansion line.

Make sure that the external device has

sent a command listed in

"Communication commands" (page 10).

Make sure that the external device has sent

either "CR" or "CR + LF" as a data delimiter.

Make sure that the number of parameters

and the positions of the commas used as

data delimiters conform to the command

format shown in "Commands and

Responses" (page 7).

Make sure that the external device is

sending a command listed in

"Communication commands" (page 10).

Make sure that DL-RS1A and the exter nal

device have the same communication

settings configured. For information on

configuring DL-RS1A, refer to "(1)

Communication setup switches" (page 2).

Make sure that the sent data specified as

the ID number is a 2-digit number (ASCII

characters) according to the number of

connected units.

Check that each of the sensor amplifiers

and DL-RS1A are securely and properly

connected by referring to "Connecting

the Unit to Sensor Amplifiers" (page 3).

Make sure that sensor amplifiers that are

supported by DL-RS1A are connected

(refer to page 4).

Change the read/write setting switch to

the R/W position to enable writing to DLRS1A. For information on the read/write

setting switch, refer to "Part Names and

Functions" (page 2).

This section describes the communication response time for each communication command and

various time frames.

Communication Response Time and Time Chart

This section describes the concept of communication response time and the time chart for the

communication commands.

Point

When sending communication commands co nsecutively from the external device, wait to send

the next command after reception of the response for the previous command from DL-RS1A

completes.

SR command

The SR command directly reads data from a sensor amplifier during T4 (DL-RS1A command

processing time).

Time chart

External device

DL-RS1A

T3: Command format send time from external device

T4: DL-RS1A command processing time

T5: Response send time from DL-RS1A

* For the specific values (times) of T3 to T5, refer to

"Time Frames of Communication Response Time" (page 17).

T3

T5

T4

M0 command and MS command

The M0 and MS commands read the buffered data that DL-RS1A periodically retrieves from the

sensor amplifiers.

Therefore, the latest data detected by the sensors can only be read after T2 (DL-RS1A data

processing time) where DL-RS1A retrieves data from the sensor amplifiers.

Sensor amplifier

DL-RS1A

External device

T1: Sensor amplifier response time (Refer to the instruction manual of the sensor amplifier.)

T2: DL-RS1A data processing time

T3: Command format send time from external device

T4: DL-RS1A command processing time

T5: Response send time from DL-RS1A

* For the specific values (times) of T2 to T5, refer to

"Time Frames of Communication Response Time" (page 17).

Detection

T1

T5

T4

T2

T3

16

Page 19

Communication Response Time

Communication Response Time

DRQ input

The data read in response to a DRQ input is the buffered data that DL-RS1A periodically retrieves

from the sensor amplifiers.

Therefore, the latest data detected by the sensors can only be read after T2 (DL-RS1A data

processing time) where DL-RS1A retrieves data from the sensor amplifiers.

Time chart

Detection

Sensor amplifier

DL-RS1A

DRQ input

T1: Sensor amplifier response time (Refer to the instruction manual of the sensor amplifier.)

T2: DL-RS1A data processing time

T4: DL-RS1A command processing time

T5: Response send time from DL-RS1A

* For the specific values (times) of T2 to T5, refer to

"Time Frames of Communication Response Time" (page 17).

↓

T1

T5

T4

T2

2 ms min.

SW command and AW command

The SW and AW commands are write commands.

Time chart

External device

DL-RS1A

Sensor amplifier

T3: Command format send time from external device

T4: DL-RS1A command processing time

T5: Response send time from DL-RS1A

T6: Sensor amplifier setting change time

* For the specific values (times) of T3 to T6, refer to

"Time Frames of Communication Response Time" (page 17).

T3

T5

T4

T6

Time Frames of Communication Response Time

This section describes the communication time frames (T2 to T6).

Reference

The maximum time required is shown for each time frame. However, depending on

the actual environment, it may require more time.

T2 (DL-RS1A data processing time)

Number of connected

sensor amplifiers

17 ms

29 ms

313 ms

415 ms

Data processing time (T2)

IB Series

T3 (Command send time from external device)

Refer to the manual supplied with the external device connected to DL-RS1A.

T4 (DL-RS1A command processing time)

The processing time varies according to the command sent from the external device.

z Read commands

Communication command

SR

M0/MS/DRQ input

z Write commands

Communication command

SW

AW

Number of connected

sensor amplifiers

112 ms

213 ms

315 ms

416 ms

1 to 4

Number of connected

sensor amplifiers

121 ms

225 ms

330 ms

434 ms

157 ms

259 ms

360 ms

461 ms

Command processing time (T4)

Command processing time (T4)

IB Series

4 ms

IB Series

17

Page 20

Communication Response Time

Communication Response Time

T5 (Response send time from DL-RS1A)

The time required to send a response varies depending on the communication speed, data bit

length, and number of bytes.

For information on the communication settings, refer to page 2.

The response time can be calculated using the following formula:

T5 = (number of bytes) x (data bit length + 4) / (communication speed)

z Number of bytes for different commands

SR command : (number of bytes in the read data) + 12

M0 command : {(number of bytes in the read data) + 1} u number of connected sensor amplifiers + 4

MS command : {(number of bytes in the read data) + 3} u number of connected sensor amplifiers + 4

DRQ input : {(number of bytes in the read data) + 3} u number of connected sensor amplifiers + 4

SW command : 11

AW command : 8

* For information on the number of bytes in the write data and the number of bytes in the read data,

refer to "Parameters of Commands and Responses" (page 10).

Sample calculation

Number of bytes Data length Communication speed Response time

21 8 bit 9600 bps 26 ms

114 8 bit 9600 bps 143 ms

21 7 bit 38400 bps 6 ms

114 7 bit 38400 bps 33 ms

T6 (Sensor amplifier settings change time)

T6: 0ms

Data to which the setting changed after receiving response (after T5 elapses) is reflected can be

read using the data reading command (M0, MS) or DRQ input.

Point

When writing to the following data number using the SW or AW command, the sensor amplifier is

reset.

The measured value after the setting is reflected can be read after T elapses.

When reading using the data reading command (M0, MS) or DRQ input before T elapses, the P.V.

value is read as "-99.998" (-------).

003: Reset request

005: Initial reset request

006: System parameter set request