Page 1

96158E

DL-CL1

User’s Manual (FD-S)

Read this manual before using the product in order to

achieve maximum performance.

Keep this manual in a safe place for future reference.

CC-Link Compatible Network Unit

Page 2

Introduction

This manual describes the basic operations and hardware functions of the DL-CL1. Read

the manual carefully to ensure safe performance and function of the DL-CL1.

Keep this manual in a safe place for future reference.

Ensure that the end user of this product receives this manual.

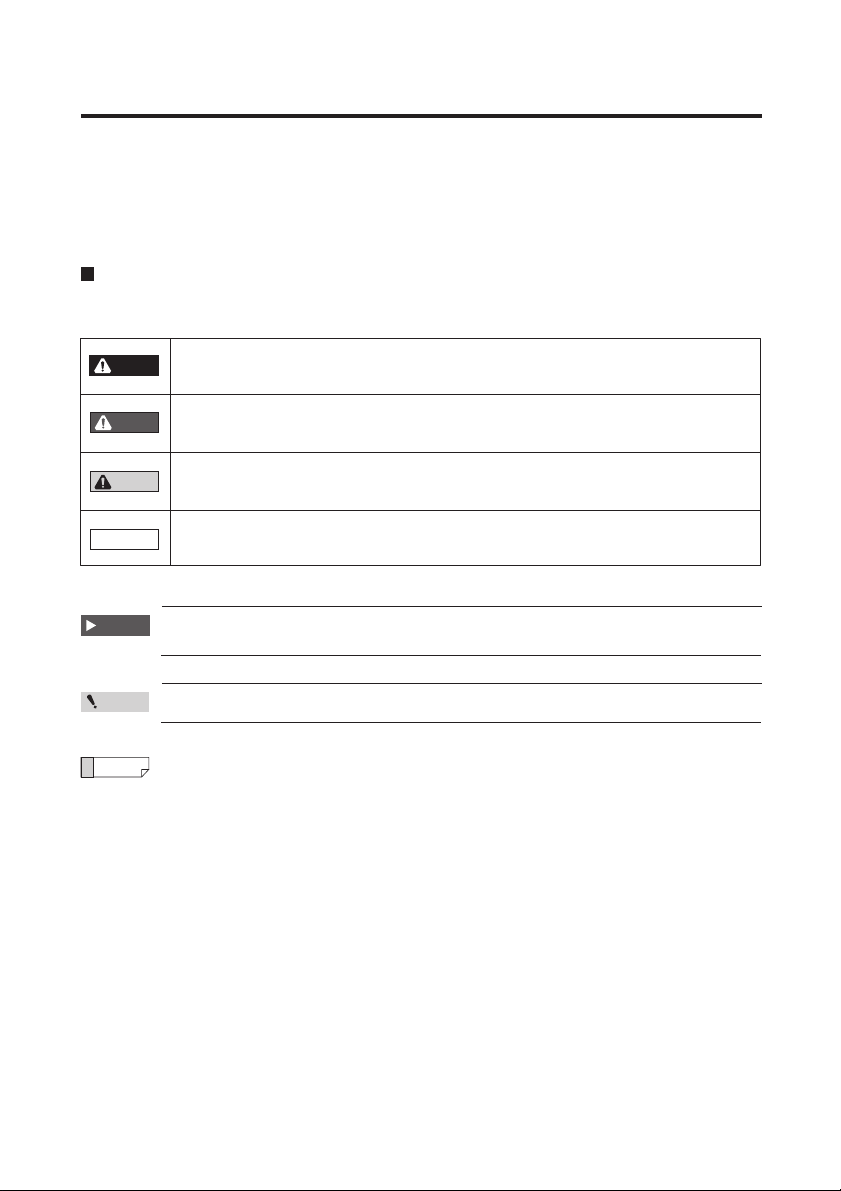

Symbols

The following symbols alert you to matters concerning the prevention of injury and product

damage.

It indicates cautions and limitations that must be followed during operation.

It indicates additional information on proper operation.

It indicates tips for better understanding or useful information.

The names of systems and products used in this manual are the trademarks or registered

trademarks of their respective owners.

It indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

It indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

It indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

It indicates a situation which, if not avoided, could result in product

damage as well as property damage.

Point

Important

CAUTION

DANGER

NOTICE

WARNING

Reference

Page 3

Safety Precautions

CAUTION

NOTICE

General Precautions

• Before and while operating this product, confirm that it provides its functions

and performance correctly.

• Implement sufficient safety measures to prevent human and physical damages

in case this product fails.

• Be aware that the product functions and performance are not warranted if the

product is used outside the range of stated specifications or is modified by t

customer.

• Combining this product with other equipment requires sufficient consideration

because the proper functions and performance may not be provided depending

on the environment.

• Do not use this product in applications for human protection.

• Do not expose equipment, including peripherals, to rapid temperature changes.

Equipment failure may result from dew condensation.

Precautions for Use

• In the following cases, immediately turn off the power. Leaving

the equipment in unusual condition in may result in human

injury or equipment failure.

- Water or foreign matter entered the main unit;

-The case is broken, for example if it is dropped;

- Smoke or unusual smell comes out of the product.

• Use the correct power voltage. Failure to observe may result in

injury or failure.

• Do not disassembly or modify this product. Failure to observe

may result in injury.

he

Do not turn off the power while you are setting any item. Doing this

may cause loss of data settings wholly or partially.

96158E

1

Page 4

Equipment Environment

For safe, trouble-free operation of this product, the product must not be installed on

the following locations:

• Humid, dusty, or ill-ventilated.

• Exposed to direct sunlight or heating source.

• Exposed to corrosive or flammable gases.

• Exposed directly to vibration or shock.

• Exposed to water, oil, or chemical splashes.

• Exposed to static electricity.

Noise Protection

If this product is installed on a location near a noise source, e.g., power source or

high-voltage line, it may malfunction or fail because of noise. Use protection mea-

sures, such as using a noise filter or running the cords separately.

About Power Supply

• Noise superimposed on the power supply could cause malfunction. Use a stabilized DC power supply configured with an isolation transformer.

• When using a commercially available switching regulator, be sure to ground the

frame ground terminal or ground terminal.

Notes on Regulations and Standards

UL Certificate

This product is an UL/C-UL Listed product.

• UL File No. E207185

• Category NRAQ, NRAQ7

Be sure to consider the following specifications when using this product as an UL/CUL Listed Product.

• Use a power supply with Class 2 output defined in NFPA70 (NEC: National Electrical Code).

• For wiring to the CC-Link connector, use the AWG 12-24 copper wire with temperature rating 60

• Use this product under pollution degree 2

• This product is an open type device. Therefore, it must be installed in an enclosure

with IP 54 or higher. (e.g. Industrial control panel)

2

ο

C or more.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 5

CE Marking

Keyence Corporation has confirmed that this product complies with the essential

requirements of the applicable EC Directive, based on the following specifications.

Be sure to consider the following specifications when using this product in the Member State of European Union.

■ EMC Directive

EMI : EN55011, Class A

EMS : EN61000-6-2

• Install this product in a conductive enclosure. (e.g. Industrial control panel)

Remarks

These specifications do not give any guarantee that the end-product with this

product incorporated complies with the essential requirements of EMC Directive.

The manufacturer of the end-product is solely responsible for the compliance on

the end-product itself according to EMC Directive.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3

Page 6

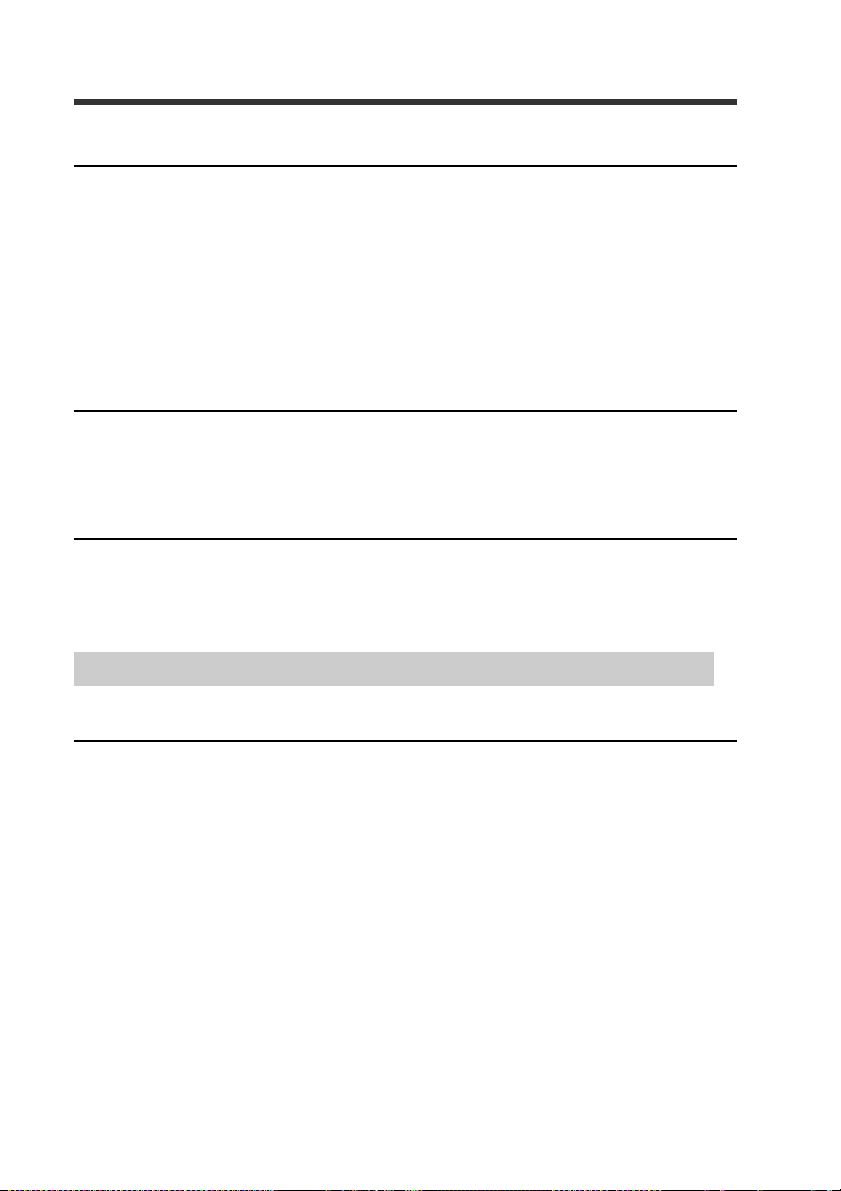

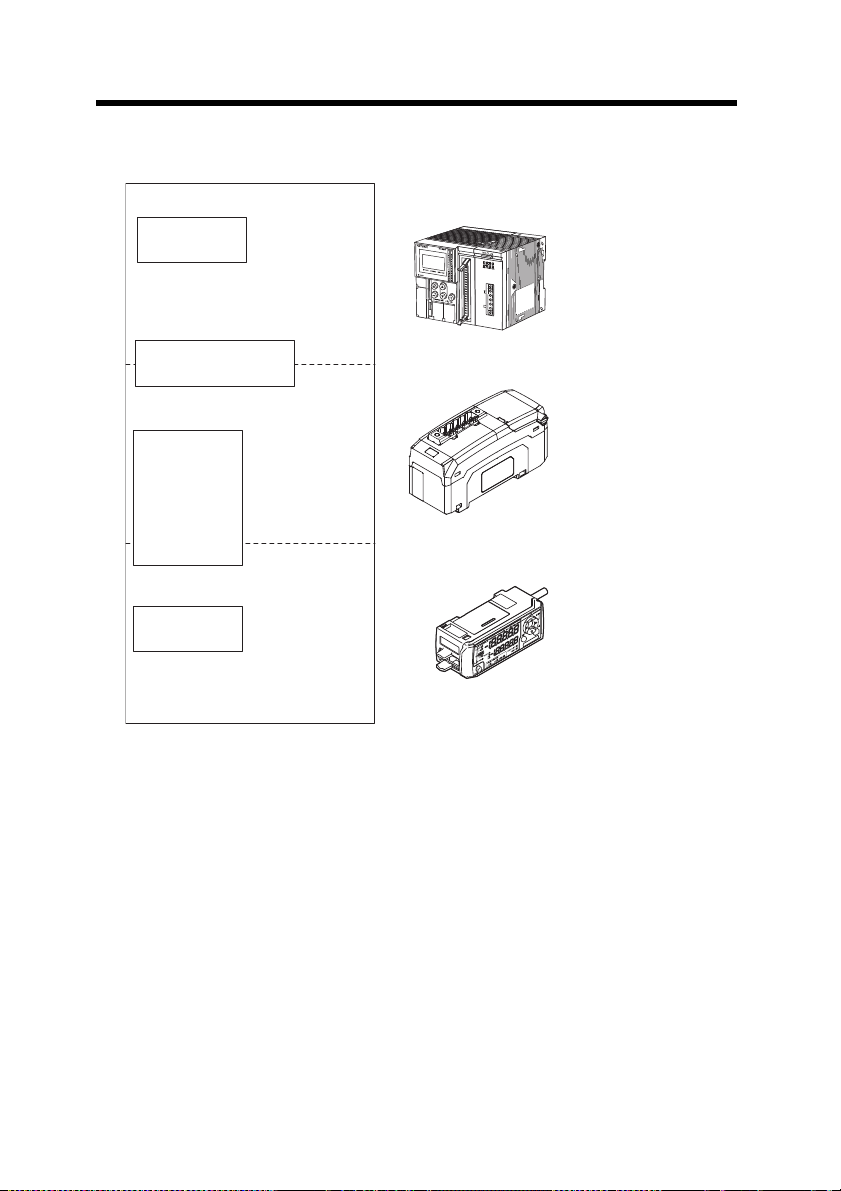

Relevant Manuals

Sensor amplifier

Manuals relevant

to CPU unit

Manuals relevant to

CC-Link master unit

Manuals of sensor

amplifier main unit

PLC CPU unit

CC-Link master unit

DL-CL1 (This unit)

This manual

Example:

・

FD-S series instruction manual

Example: KV-5000 user's manual

Example: KV-CL20 user's manual

The manuals to relevant to this document are as follow s:

4

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 7

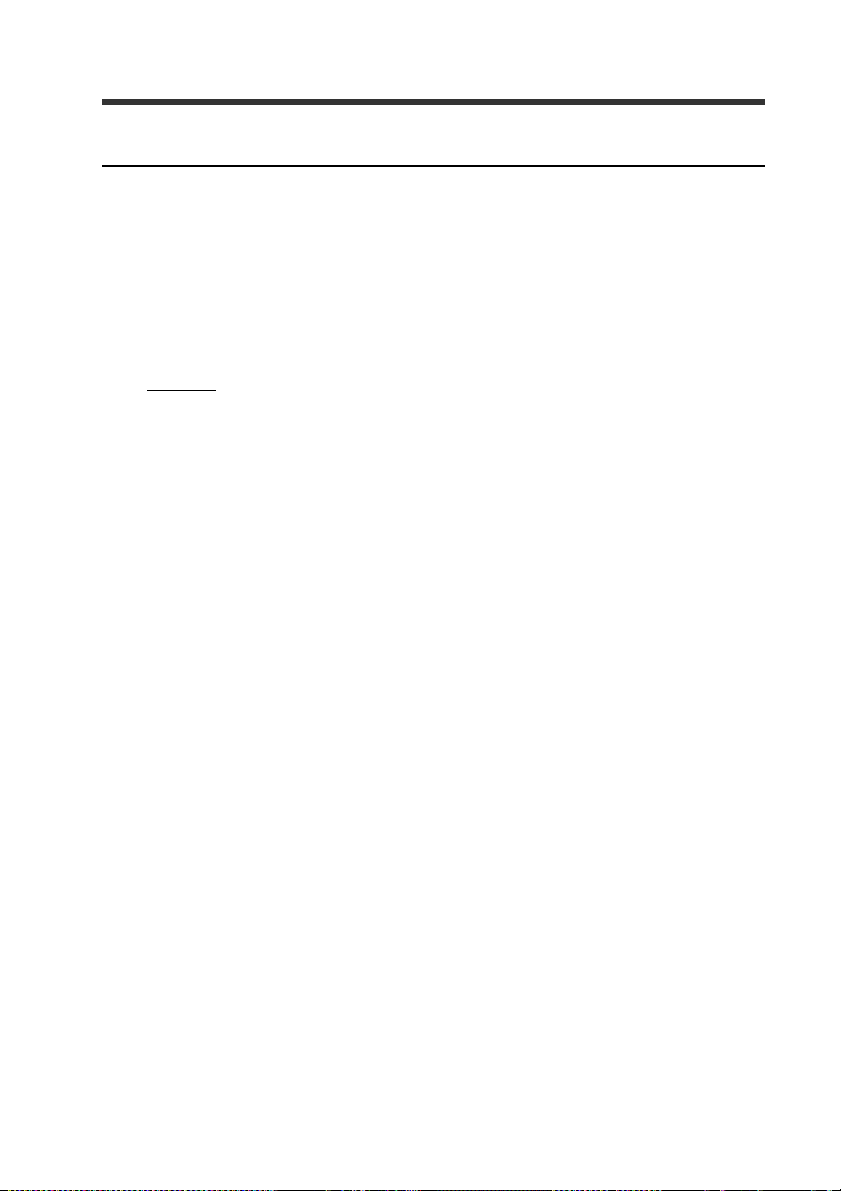

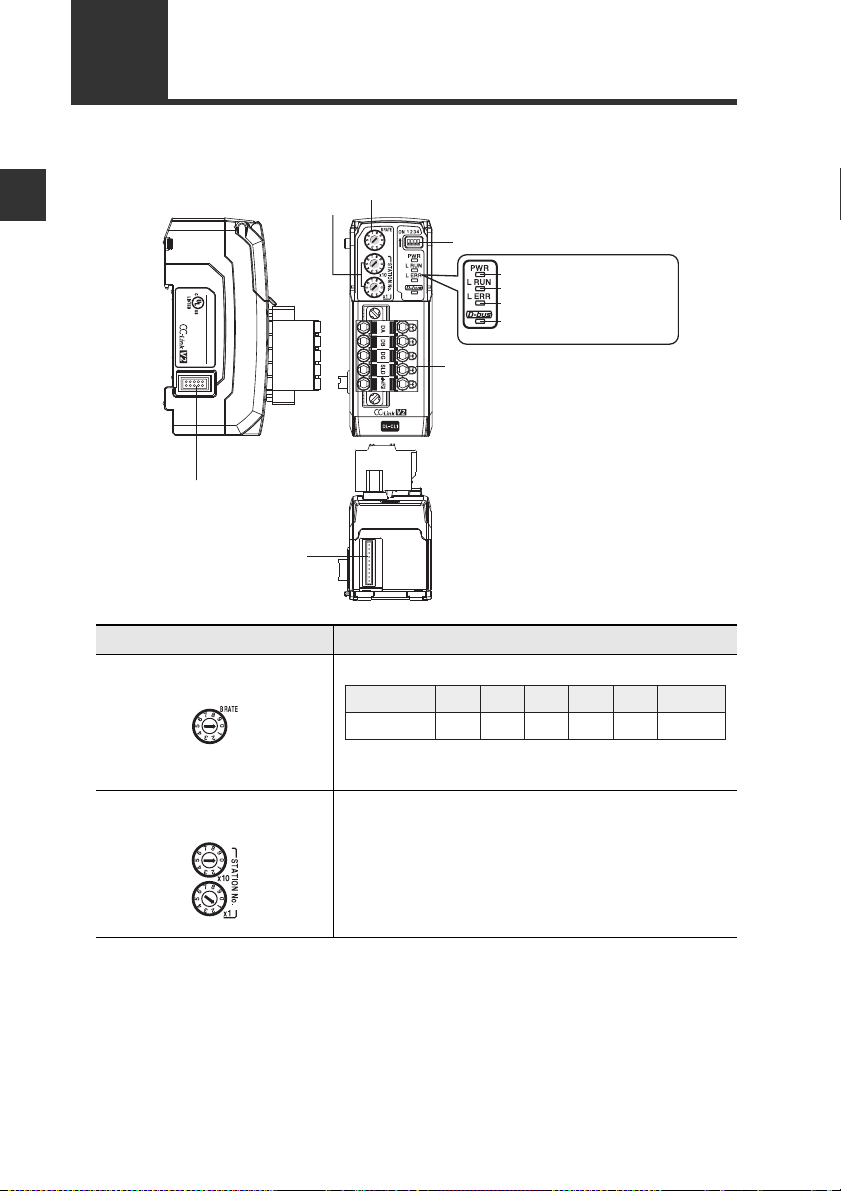

Manual Organization

This chapter provides an overview of the DL-CL1

and describes its part names and functions.

Before Using

1

This chapter explains the procedures for

connecting sensor amplifiers to the DL-CL1

and how to configure the data link.

Connection and

Configuration

2

This chapter describes the configuration of the

memory linked to the CC-Link master station and

provides communication time charts.

3

Provides the parameter list, as well as

troubleshooting instructions.

Appendix

5

This chapter describes the specifications

and dimensions of the DL-CL1.

Specifications

4

Communicating

with the FD-S

series

1

2

3

4

5

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

5

Page 8

Table of Contents

Safety Precautions.............................................................................1

General Precautions .......................................................................... 1

Precautions for Use ........................................................................... 1

Notes on Regulations and Standards ................................................ 2

Relevant Manuals...............................................................................4

Manual Organization..........................................................................5

Table of Contents............................................................................... 6

Ter ms Used in This Document ......................................................... 8

Chapter 1 Before Using

1-1 DL-CL1 Overview ............................................................................... 1-2

Overview......................................................................................... 1-2

Ty pe s and Number of Connectable Sens or Amplifiers ................... 1-2

1-2 Checking the Package Contents ...................................................... 1-3

Package Content............................................................................. 1-3

List of Optional Parts....................................................................... 1-3

1-3 Names and Functions of Each Part ................................................. 1-4

Chapter 2 Connection and Configuration

2-1 Installation and Connection to Sensor Amplifiers ......................... 2-2

ID Number Assignments to Sensor Amplifiers................................ 2-2

Installation and Connection to Sensor Amplifiers ........................... 2-3

2-2 Wiring.................................................................................................. 2-6

Connecting to the CC-Link System................................................. 2-6

2-3 Configuring the Data Link............................................................... 2-10

Configuring the Master Station ..................................................... 2-10

Configuring the DL-CL1 ................................................................ 2-10

Chapter 3 Communicating with the FD-S series

3-1 CC-Link Communication and Operating Modes ............................. 3-2

Data Exchanged by Cyclic Transfer ................................................ 3-2

Selecting an Operating Mode of the DL-CL1.................................. 3-3

3-2 Device Maps ....................................................................................... 3-4

Device Maps for Small-Memory Mode 1,

Small-Memory Mode 2, and Monitor Mode 1.................................. 3-4

Device Maps for Monitor Mode 2, Full Mode 1, and Full Mode 2.. 3-10

3-3 Communication Methods ................................................................ 3-17

Reading an Output from a Sensor Amplifier ................................. 3-17

6

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 9

Table of Contents

Entering an External Input into a Sensor Amplifier....................... 3-17

Reading Current Valu es (Instantaneous Flow Rate)

from Sensor Amplifiers.................................................................. 3-18

Issuing a Motion Command to a Sensor Amplifier........................ 3-20

Rewriting a Setting Value of a Sensor Amplifier ........................... 3-21

Reading/Writing Settings or Status of a Sensor Amplifier ............ 3-21

3-4 Command Parameter List ............................................................... 3-24

Common Command Parameter List.............................................. 3-24

Command Parameter List for FD-S Series ................................... 3-25

Chapter 4 Specifications

4-1 Specifications .................................................................................... 4-2

4-2 Data Processing Times ..................................................................... 4-3

4-3 Dimensions ........................................................................................ 4-4

Chapter 5 Appendix

5-1 Troubleshooting................................................................................. 5-2

5-2 Index ................................................................................................... 5-5

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

7

Page 10

Terms Used in This Document

This document uses the following terms:

Ter m Description

Sensor A sensor amplifier.

Main unit A sensor amplifier that has a power line and can operate alone.

Expansion unit

D-bus

A sensor amplifier that does not have a power line and must be

connected to a main unit.

The name of KEYENCE's wiring-saving system for sensor amplifi-

ers.

Supports FD-S Series colioris t

ype digital flow sensors and others.

8

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 11

Before Using

This chapter provides an overview of the DL-CL1 and describes its

part names and functions.

1-1 DL-CL1 Overview ............................................... 1-2

1-2 Checking the Package Contents ........................ 1-3

1-3 Names and Functions of Each Part....................1-4

1

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

1-1

Page 12

1-1

DL-CL1 Overview

1

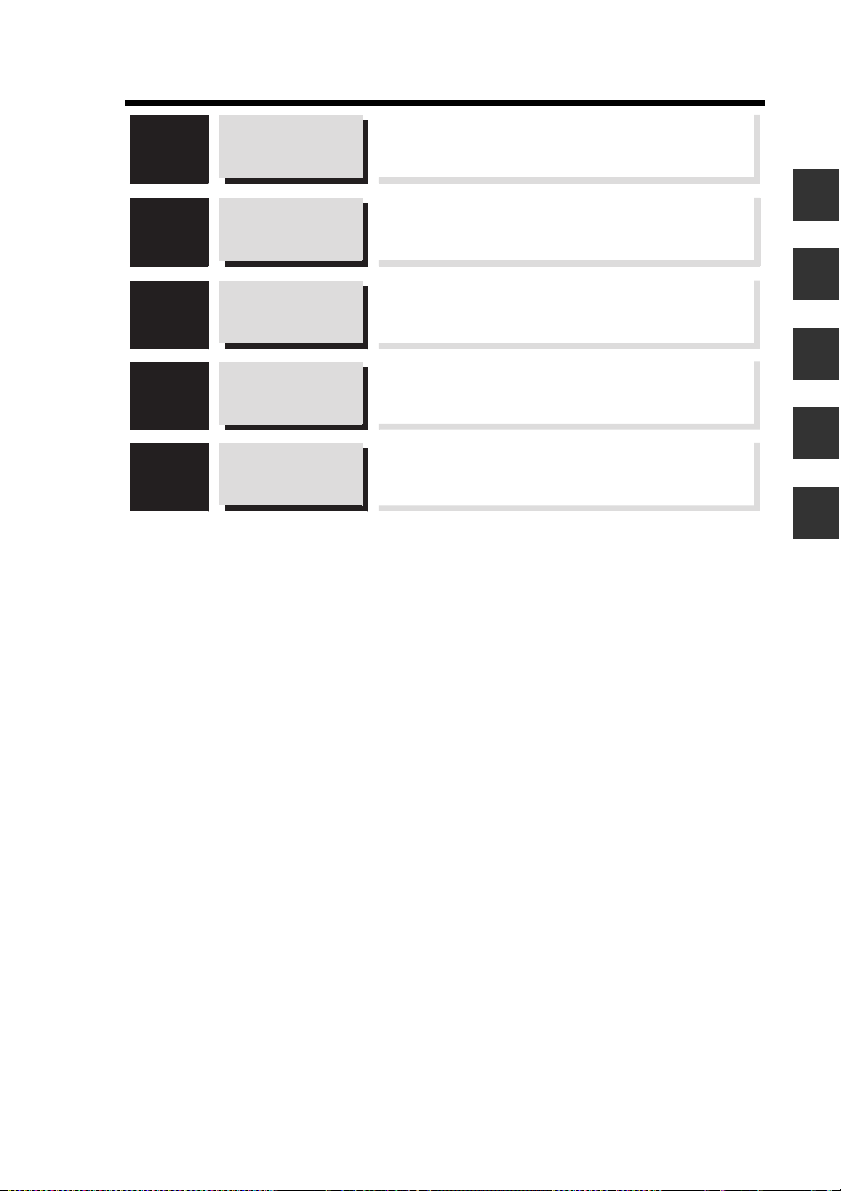

Overview

Before Using

This unit operates as a remote device station (Ver. 1.1 and 2 switchable) of a CC-Link

system. Using CC-Link communications, the sensor amplifiers and other units connected to the DL-CL1 can transmit their ON/OFF control signals and current values as

communication data to PLC or other equipment.

The DL-CL1 supports cyclic transfer and extended cyclic transfe r, enabli

cation without the need of a ladder program. In addition, remote input/output sig-

muni

nals can be used as handshake signals to read/write settings of sensor amplifiers and

to execute motion commands on the sensor amplifiers.

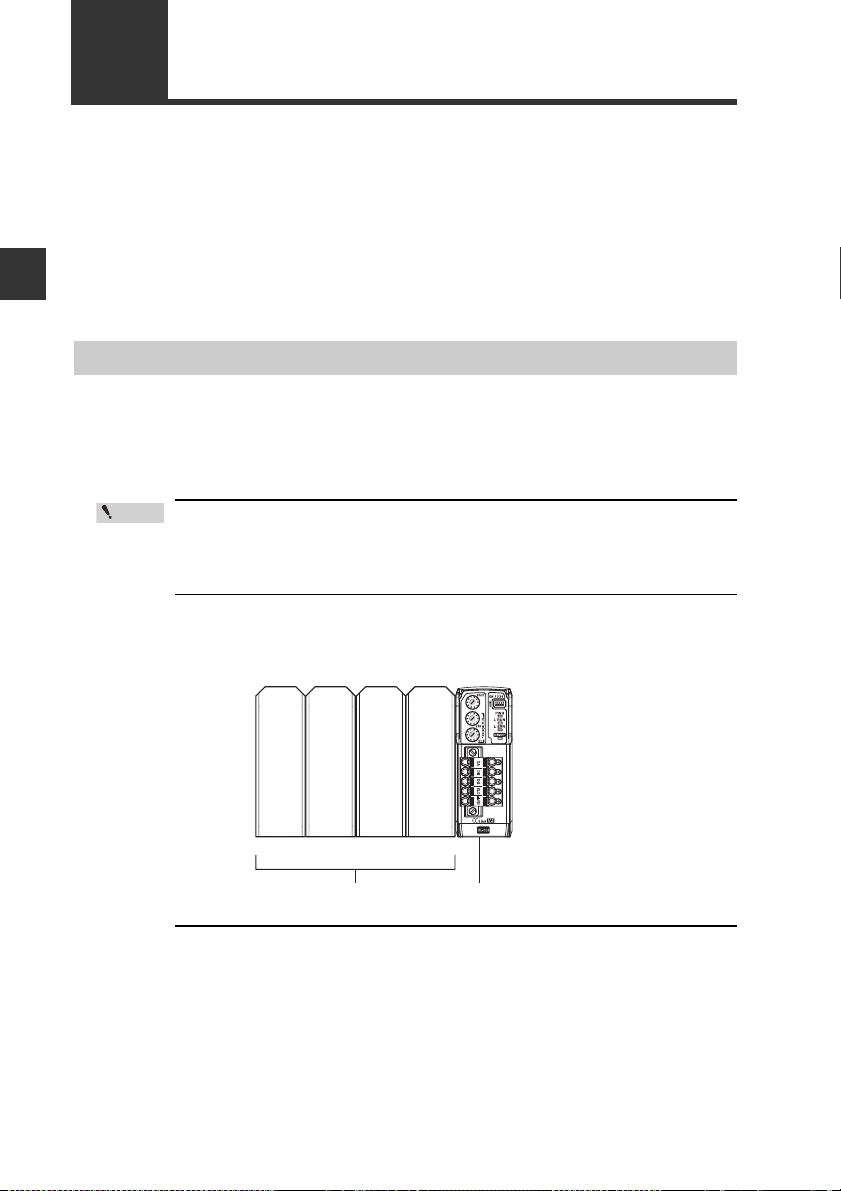

System configuration example

Type s and Number of Connectable Sensor Amplifiers

DL-CL1 (This unit)

D-bus compatible sensor amplifier

PLC or other host device

(CC-Link master unit)

ng data com-

CC-Link slave

Number of Connectable Sensor Amplifiers

Name Amplifier form Main unit

FD-S

Series*

*Cannot be connected to a pane

The DL-CL1 can connect multiple sensor amplifiers (a single main unit and multiple

expansion units) which support D-Bus. "D-bus" is the name of KEYENCE's wiringsaving system for sensor amplifiers.

Different types of sensor amplifiers with D-bus support can be connected to the single

DL-CL1 unit.

How many and what different types of sensor

on the sensor amplifiers or units to be connected. Please inquire for details.

1-2

DIN rail

mounting type

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

FD-SA1NA

FD-SA1PA

Expansion

unit

FD-SA2NA

FD-SA2PA4(1 main unit, 3 expansion units)

l mounting type.

amplifiers

Maximum number of

connectable units

can be connected depends

Page 13

1-2

Before using the DL-CL1, make sure that the following equipment and accessories

are included in the package.

We have thoroughly inspected the package contents before shipment. However, in the

event of defective or broken items, contact your nearest KEYENCE office.

Checking the Package Contents

Package Content

DL-CL1 main unit x 1 CC-Link connector x 1 Expansion connector

sticker x 1

1

Before Using

End unit x 2 Resistor

110Ω 1/2W

(brown/brown/brown/gold)

List of Optional Parts

OP-79426 (CC-Link Ver. 1.10 compatible cable, 20 m)

OP-79427 (CC-Link Ver. 1.10 compatible cable, 100 m)

Cable x 1

Instruction manual x 1

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

1-3

Page 14

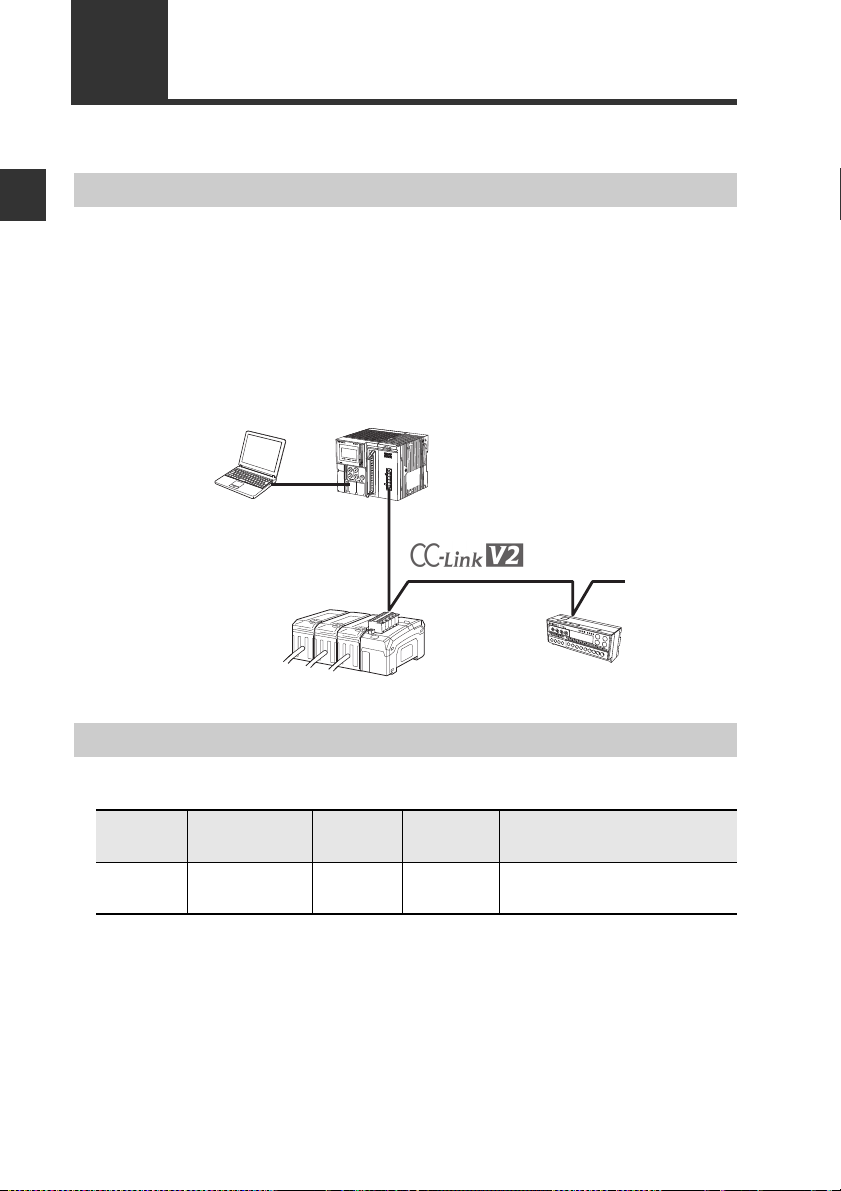

1

(5)

Communication indicator (green)

(6) Communication error indicator (red)

(7) Sensor communication indicator

(red/green)

(4) Power indicator (green)

(9) Sensor amplifier connector

(for DIN rail mounting type)

(8) CC-Link connector

(1) Transmission rate setting switch

(3) Operating mode setting switch

(2) Station number setting switch

(10) Sensor amplifier connector

(for panel mounting type

and large display type)

DL

CL1

20-30V DC, Class2

15JN

IND.CONT.EQ.

No.

0 1 2 3 4 5 to 9

Transmission rate

(bps)

156k 625k 2.5M 5M 10M

Cannot be set

1-3

Names and Functions of Each Part

This section describes the part names and functions of the DL-CL1.

Before Using

Name Description

(1) Transmission rate setting

Sets the transmission rate of CC-Link.

switch

(2) Station number setting

switch

1-4

Default value: 0

Sets the station number of the DL-CL1 in the CCLink.

x10: Ten's digit

x1: One's digit

Setting range: 01 to 64

Default value: 01

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 15

Name Description

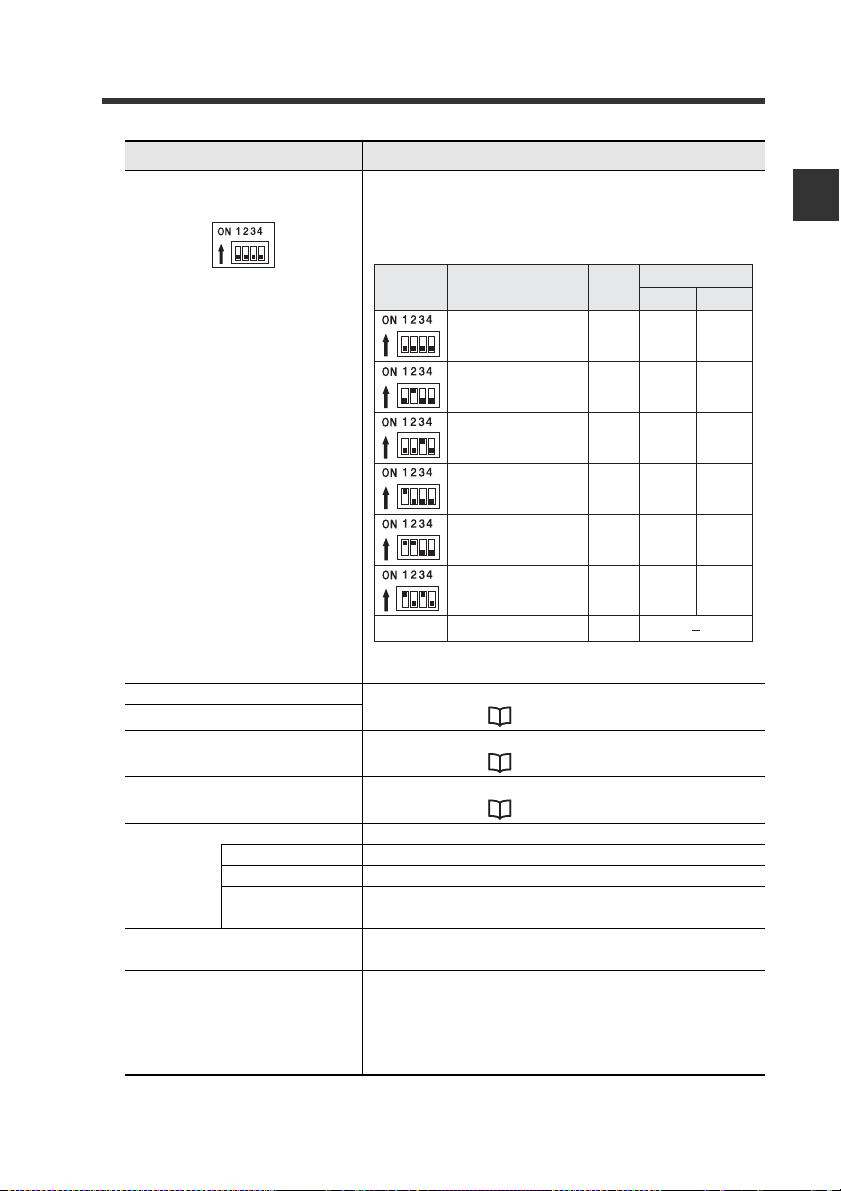

Switch setting

Operating mode

Station

configuration

Number of link points

RX/R Y

RW w/ RW r

Small-memory mode 1

(1-output, 1-input)

1-station, 1x

32

4

Small-memory mode 2

(3-output, 3-input)

64

8

Monitor mode 1

(5-output, 5-input, current value,

BANK change)

128

16

128

32

Full mode 1

(5-output, 5-input, current value,

BANK change, setting value change)

384

64

Others Cannot be set −

224

32

2-station, 1x

4-station, 1x

1-station, 8x

4-station, 2x

2-station, 8x

Monitor mode 2

(5-output, 5-input, current value,

BANK change)

Full mode 2

(5-output, 5-input, current value,

BANK change, setting value change)

(3) Operating mode setting

switch

1-3 Names and Functions of Each Part

Sets the operating mode of the DL-CL1 in the CCLink. The specific data that can be communicated

using cyclic transfer varies with each operating

mode.

1

Before Using

(4) Power indicator When normal: Lit in green

(5) Communication indicator

(6) Communication error

indicator

(7) Sensor communication

indicator

(8) CC-Link connector Attach the CC-Link cable to this connector.

(9) Sensor amplifier connec-

tor (for DIN rail mounting)

(10)Sensor amplifier

connector

(for panel mounting/large

display)*

* Not used with the FD-S series.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Default value: Small-memory mode 1

For details, see "Troubleshooting" (page 5-2).

When normal: Not lit

For details, see "Troubleshooting" (page 5-2).

When normal: Lit in green

DA/DB/DG Communication signal

SLD Connect the shielded wire of the CC-Link cable.

For details, see "Troubleshooting" (page 5-2).

FG Ground this functional ground terminal.

(Ground resistance: 100 ohm or less)

Attach the sensor amplifier to this connector.

Attach the sensor amplifier to this connector.

When shipped from the factory, a protective sticker

is installed.

The optional expansion cable (OP-35361) is used

for this connection.

1-5

Page 16

1

1-3 Names and Functions of Each Part

MEMO

Before Using

1-6

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 17

Connection and Configuration

This chapter explains the procedures for connecting sensor

amplifiers to the DL-CL1 and how to configure the data link.

2-1 Installation and Connection to Sensor Amplifiers

........................................................................... 2-2

2-2 Wiring ................................................................. 2-6

2-3 Configuring the Data Link.................................2-10

2

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

2-1

Page 18

2

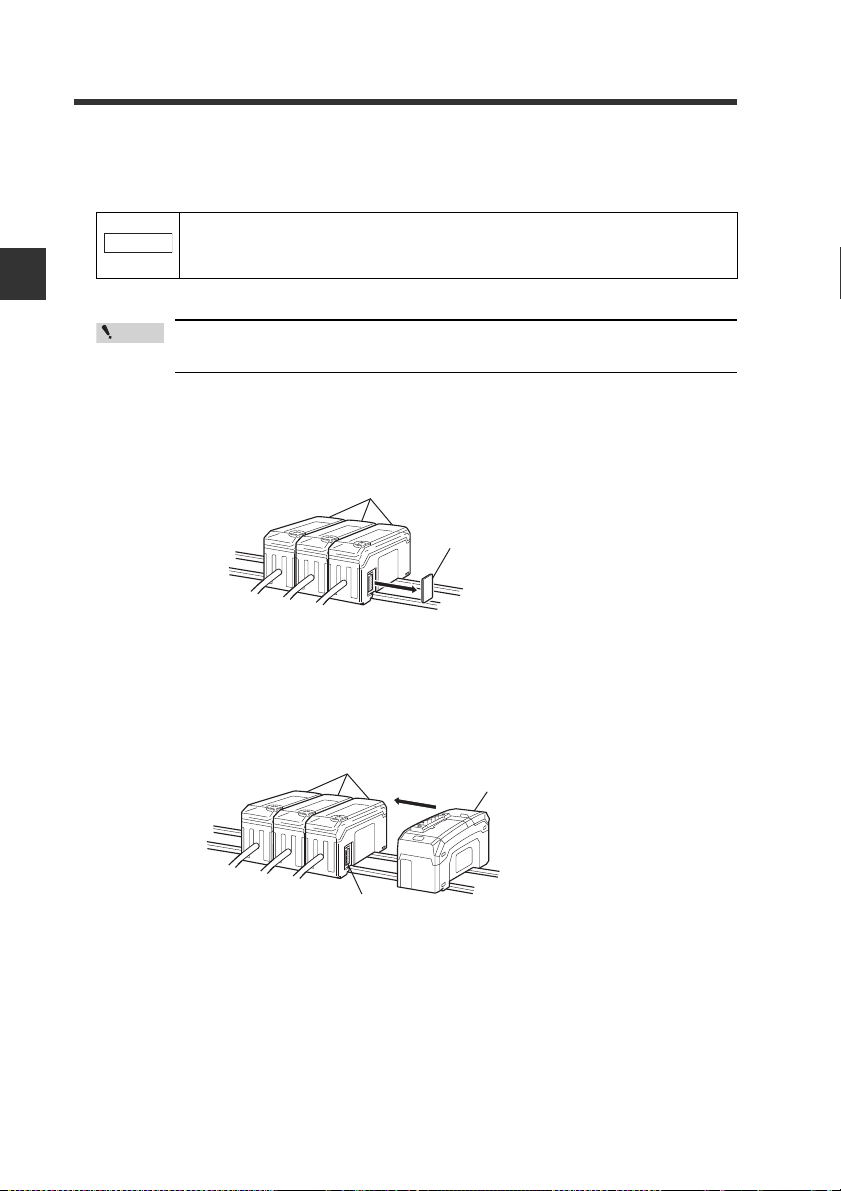

Point

ID number

01

Main unit

Expansion unit Expansion unit Expansion unit

02

...

04

Sensor amplifier DL-CL1

2-1

This section provides the procedures for installing the DL-CL1 and connecting to

sensor amplifiers.

The DL-CL1 can be connected with the expansion units of sensor amplifiers which

support D-bus. ("D-bus" is the name of KEYENCE's wiring-saving system for sensor

amplifiers.) How many sensor amplifiers can be connected depends on the sensor

amplifiers or units to be connected. For specif

Connection and Configuration

manual of each sensor amplifier.

Installation and Connection to Sensor Amplifiers

ic numbers of connections, refer to the

ID Number Assignments to Sensor Amplifiers

When connecting the DL-CL1 to a sensor amplifier which can be configured with

expansion units, the main unit will be assigned ID number 01, with the expansion units

assigned ID numbers of 02 to 04.

• The ID number assignments to sensor amplifiers cannot be

changed by the user.

• In this manual, ID number 01 to ID number 04 are denoted as ID 01

to ID 04, respectively.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

2-2

Page 19

2-1 Installation and Connection to Sensor Amplifiers

(1)

(2)

(3)

Installation and Connection to Sensor Amplifiers

Mounting on a DIN rail

Align the claw on the bottom of the amplifier with the DIN rail. While push-

1

ing the amplifier in the direction of arrow (1), press down in the direction

of arrow (2).

To remove the DL-CL1, raise the main unit in the direction of arrow (3)

2

while pushing it the direction of arrow (1).

2

Connection and Configuration

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

2-3

Page 20

2

Point

2-1 Installation and Connection to Sensor Amplifiers

Procedures for connecting to sensor amplifiers

The CC-Link compa tible communication unit DL-CL1 must be connected to sensor

amplifiers before it can provide its function.

Make sure that the power to the sensor amplifier is off before starting to

NOTICE

connect the CC-Link compatible communication unit DL-CL1. Performing the procedure with the power on may damage the DL-CL1.

Connection and Configuration

1

2

For the instructions on connecting additional sensor amplifiers, refer

to the instruction manual of the sensors amplifiers.

Remove the expansion protective cover from the sensor amplifier to be

connected.

Sensor amplifier

Expansion protective cover

Install the CC-Link compatible communication unit DL-CL1 on the DIN rail

and connect to the sensor amplifier.

Ensure a tight connection, leaving no space between the CC-Link compatible

communication unit DL-CL1 and the sensor amplifier.

Sensor amplifier

CC-Link compatible

communication unit DL-CL1

2-4

Connector

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 21

2-1 Installation and Connection to Sensor Amplifiers

Make sure that the sensor amplifier connector (for DIN rail mounting

type) is not askew on the side face of the CC-Link compatible communication unit DL-CL1, as shown below. If the connector is askew, the DL-

CL1 may become damaged when connected to the sensor amplifier.

Sensor amplifier connector

NOTICE

CC-Link compatible

communication unit DL-CL1

Mount the supplied end units (OP-26751: a set of two pieces) on the outer

3

side faces of the amplifier and the CC-Link compatible communication

unit DL-CL1. Then, fix the end units with the screws on the top of each

end unit (2 points x 2 units). (Tightening torque: 0.6 N•m or less)

Mount the end units in the same way as the CC-Link compatible communication

unit DL-CL1.

End unit

2

Connection and Configuration

NOTICE

End unit

Press the CC-Link compatible communication unit DL-CL1 into full

engagement with the sensor amplifier. If the DL-CL1 is connected in

slant position or not pressed fully, it may be damaged when the power is

turned on.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

2-5

Page 22

2

Point

Point

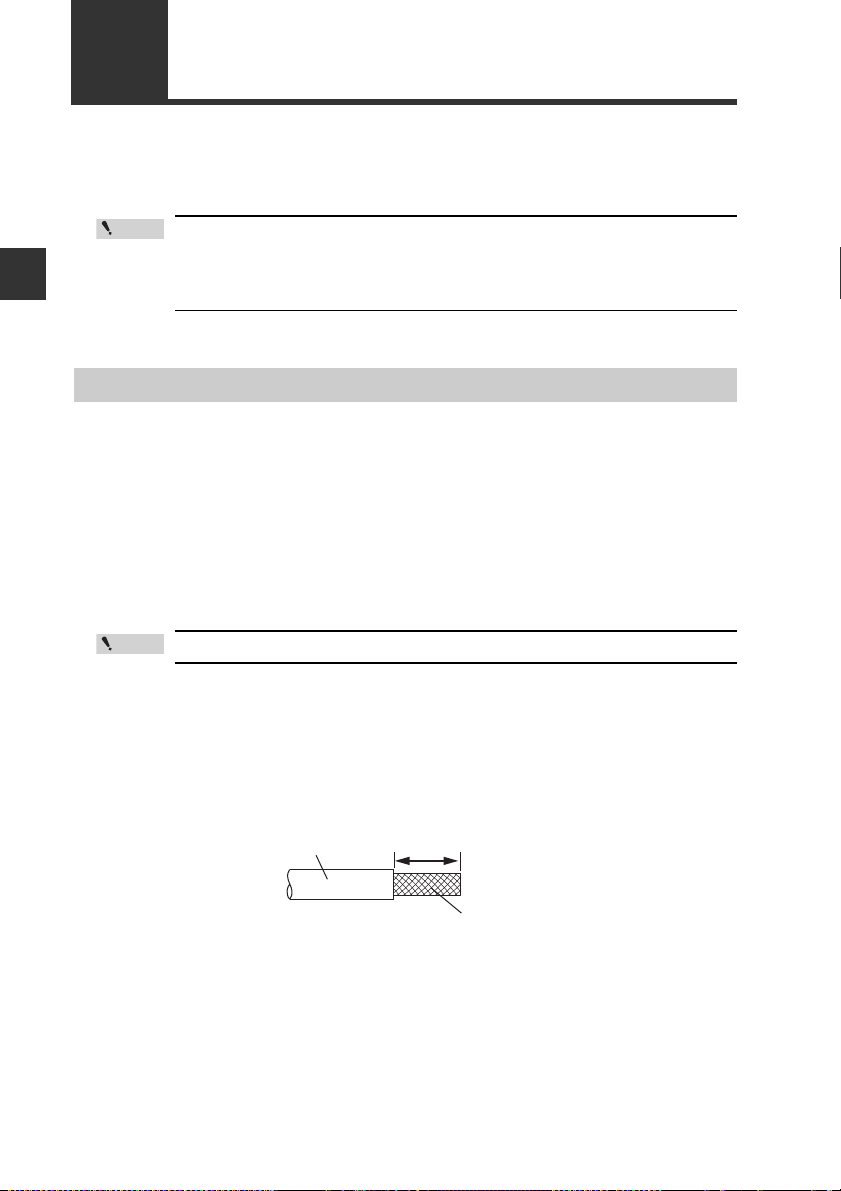

Sheath

Shield braid

Approx. 50 mm

2-2

Connection and Configuration

Connecting to the CC-Link System

Usable cables

Wiring

This section describes how to wire the DL-CL1.

• Turn off the power before starting the cabling operation.

• For more information about the CC-Link system, including cable

length and cabling methods, refer to the document of the CC-Link

master unit.

Use the following procedures to connect the DL-CL1 to the CC-Link system.

For connection between the DL-CL1 and the CC-Link system, use CC-Link cables

(Ver. 1.10 or later) accredited by the CC-Link Partner Association.

CC-Link cables (for Ver. 1.10) are available as optional items.

OP-79426 (20 m) OP-79427 (100 m)

To e nsure normal communication, only use the CC-Link cables.

Trimming the cable

1

2-6

Strip the cable sheath.

Strip approximately 50 mm of the sheath from the end of the CC-Link cable,

with care to avoid damaging the shield braid of the cable.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 23

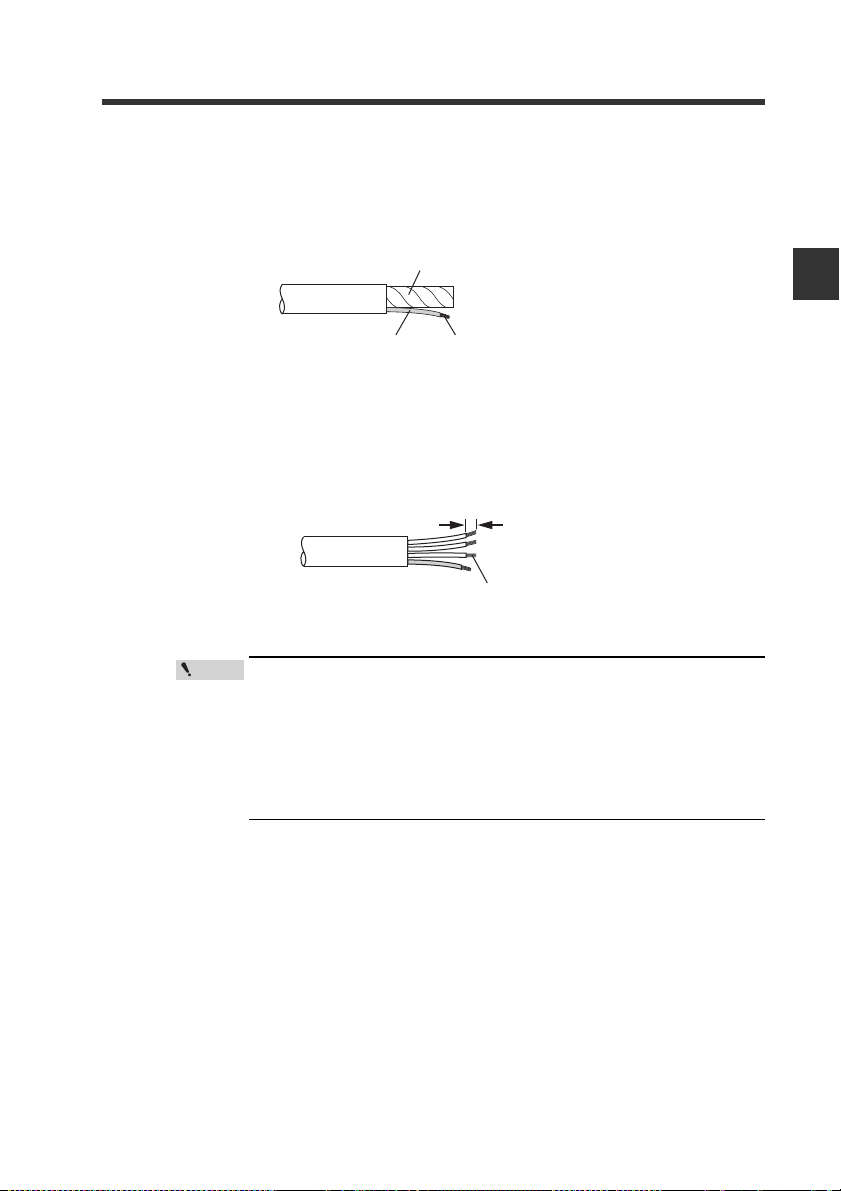

Tri m the shield.

Aluminum polyester laminated tape

Insulating tube

Shield braid twisted together

Twist together the conductors

Approx. 10 mm

2

Upbraid the shield braid carefully. Find the bare drain wire (twisted or flying)

inside the shield braid. Twist together the unbranded shield braid and the drain

wire securely, and then put on the insulating tube.

Strip the sheathed conductors.

3

Strip approximately 10 mm of sheath from each signal wire, by removing the

aluminum polyester laminated tape. Take care not to damage the signal wires.

Tw ist together the exposed conductors securely.

2-2 Wiring

2

Connection and Configuration

Point

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

• If you are using solderless terminals, perform cable wiring/

trimming appropriately to suit the specifications of the particular terminals.

Recommended solderless terminals: Phoenix Contact's A/AI

Series

• Do not perform soldering (pre-soldering) on the trimmed end

of the cable.

2-7

Page 24

2

Terminal name

Function

DA/DB/DG

Communication signal

SLD Connect the shielded wire of the CC-Link cable.

FG

Ground this functional ground terminal. (Ground resistance: 100 ohm or less)

2-2 Wiring

Connecting the cable

Use the following procedures to connect to the CC-Link connector supplied with the

DL-CL1.

Connect the trimmed cable to the CC-Link connector.

1

Insert the cable completely.

Connection and Configuration

Attach the CC-Link connector to the DL-CL1.

2

Plug the connector into the DL-CL1 and screw it down with the screws on each

end.

(Tightening torque: 0.2 to 0.3 N•m)

2-8

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 25

2-2 Wiring

Connecting the termination resistor

If the DL-CL1 is at the end of the CC-Link system, connect the supplied termination

resistor to DA/DB of the CC-Link connector.

Type of cable Termination resistor

CC-Link Ver. 1.10 compatible cable 110Ω, 1/2 W (brown/brown/

brown/gold)

2

Connection and Configuration

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

2-9

Page 26

2

Point

Reference

Reference

Operating mode setting switch

Transmission rate

setting switch

Station number

setting switch

2-3

Use the following configuration procedures for connecting the DL-CL1 to the CC-Link

system.

Connection and Configuration

Configuring the Master Station

To connect the DL-CL1 to the CC-Link master unit, it is necessary to configure the

slave attribute and memory allocation settings.

Slave attribute settings

Register the DL-CL1 to the CC-Link master unit as a remote device station.

Yo u can also configure the settings by importing a CSP file into the software for the

master unit (ladder programming software or CC-Link configuration software).

Configuring the Data Link

This manual covers only the functions and settings of a CC-Link mas-

ter station which are required for communication with the DL-CL1. For

the functions and settings related to the communication between the

CC-Link master unit and CPU unit, refer to the manuals shipped with

your master unit or CPU unit.

Memory allocation settings

Configuring the DL-CL1

2-10

The CSP file can be downloaded from the KEYENCE web site

http

://www.keyence.com

In order to exchange data between the DL-CL1 and CC-Link master station, configure

the memory allocation settings using the software for the master station (ladder

programming software or CC-Link configuration software).

Where multiple slave units are connected, the memory allocation for each

slave unit is done automatically based on the spe

The allocation information for each slave unit can be checked using the

CC-Link configuration software.

Use the following procedures to configure the data link of the DL-CL1.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

ied starting address.

cif

:

Page 27

2-3 Configuring the Data Link

Setting the transmission rate

Set the transmission rate of the DL-CL1 to the same value as set in the CC-Link

master station.

Do this using the transmission rate setting switch on the DL-CL1.

• Default value: 0

No. 0 1 2 3 4 5 to 9

Tr ansmission rate (bps) 156 k 625 k 2.5 M 5 M 10 M

Cannot be set.

Setting the station number

Using the station address setting switch, set the station number (slave ID) assigned to

the DL-CL1.

• Default value: 01

e: 0

• Setting rang

1 to 64

Selecting an operating mode

Using the operating mode setting switch, set the combination of the number of

stations occupied by the DL-CL1 and the extended cyclic setting. The specific data

that can be communicated using cyclic transfer varies with each operating mode.

See the section "Selecting an Operating Mode of the DL-CL1" and select the

appropriate operating mode that suits the desired function of sensor amplifiers.

• Default

value: Small-memory mode 1

• The contents of output and current value vary depending on the sensor amplifiers

to be connected.

Examples: 3-level judgment output for 3-output mode; 5-level judgment output for

5-output mode. Current value: judgment value.

Number of link points

Switch setting

Others Cannot be set −

Operating mode

Small-memory mode 1

(1-output, 1-input)

Small-memory mode 2

(3-output, 3-input)

Monitor mode 1

(5-output, 5-input, current value,

BANK change)

Monitor mode 2

(5-output, 5-input, current value,

BANK change)

Full mode 1

(5-output, 5-input, current value,

BANK change, setting value change)

Full mode 2

(5-output, 5-input, current value,

BANK change, setting value change)

Station

configuration

1-station, 1x

2-station, 1x

4-station, 1x

1-station, 8x

4-station, 2x

2-station, 8x

RX/R Y

32

64

128

128

224

384

RW w/ RW r

4

8

16

32

32

64

2

Connection and Configuration

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

2-11

Page 28

2

Point

2-3 Configuring the Data Link

Each switch should be set before turning on the power. If any setting

is changed while the DL-CL1 is operating, the new setting will not be

applied until the power is turned on again. (The communication error

indicator flashes intermittently.)

Connection and Configuration

2-12

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 29

Communicating with the FD-S series

This chapter describes the configuration of the memory linked to the

CC-Link master station and provides communication time charts.

3-1 CC-Link Communication and Operating Modes.3-2

3-2 Device Maps....................................................... 3-4

3-3 Communication Methods.................................. 3-17

3-4 Command Parameter List................................. 3-24

3

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3-1

Page 30

3

3-1

CC-Link Communication and Operating Modes

The DL-CL1 operates as a remote device station of a CC-Link system.

This section describes the data that the DL-CL1 can exchange through the CC-Link,

and available operating modes.

Data Exchanged by Cyclic Transfer

The DL-CL1's data is linked with the CC-Link maser station as shown below.

Sensor amplifier

Communicating with the FD-S series

CC-Link master station DL-CL1

(1) RX (Remote inputs)

RWr (Remote registers)

(3)

Output

Current value

Error information

Read parameter

(2) RY (Remote inputs)

RWw (Remote registers)

(4)

Request to change setting value

Changed setting value

External input

Write parameter

Output

Current value

・・・・・・

・・・・・・

Error information

・・・・・・

・・・・・・

Setting value

External input

・・・・・・

Output

Current value

・・・・・・

・・・・・・

Errror information

・・・・・・

・・・・・・

・・・・・・

設定値

外部

・・・・・・

Output

Current value

・・・・・・

・・・・・・

Errror information

・・・・・・

・・・・・・

設定値

外部

・・・・・・

Read/write parameters

Through the link, the CC-Link master station is enabled to:

• Communicate the output signal, current value, an

d error status of sensor amplifiers

without the need of a ladder program.

• Use the remote input RX and remote output RY areas as handshake signals to

execute external inputs to, or change the setting values of, sensor amplifiers.

• Execute motion commands on sensor amplifiers.

• Directly read and write the parameters of sensor amplifiers. This capability gives

the ability to use functions that can be executed on sensor amplifiers.

3-2

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 31

3-1 CC-Link Communication and Operating Modes

Selecting an Operating Mode of the DL-CL1

Select an operating mode of the DL-CL1 to suit the functions of the sensor amplifiers

to be used.

The specific CC-Link device configuration and the data that can be communicated

using cyclic transfer vary with each operating mode of the DL-CL1. An appropriate

operating mode should be determined by considering the number of link points the

data that can be communicated.

"Configuring the Data Link" (page 2-

Method of

communication

with the master

station

Remote input RX Read out-

Remote register RWr Read current value

Remote output RY External

Remote register

RWw

Handshake co ntrol

*3

program

(Command

communication)

Available function

of sensor

amplifier

puts 1 - 5

(instantaneous fl ow

*4

rate)

inputs 1-5

Rewrite setting

*4

value

Motion command No No Yes Ye s Ye s Ye s 3-20

Read output

Read current value

Read setting/status

Write setting/status

Small-

memory

mode 1

*1

1-station, 1x2-station, 1x4-station, 1x1-station, 8x4-station, 2x2-station,

Output 1

Ye s Ye s Ye s Ye s Ye s Ye s 3-4

Output 2

Output 3

Unused

Unused

Integration

Ye s Ye s Ye s Ye s Ye s Ye s

reset

Flow rate

hold reset

Zero

adjust-

ment

Te m p e r a-

ture hol d

reset

Unused

10)

Operating mode of DL-CL1

Small-

Monitor

mode 1

Ye s

Monitor

mode 2

*2

memory

mode 2

p. 3-4 p. 3-10

No Yes Ye s Ye s Ye s Ye s

No Yes Ye s Ye s Ye s Ye s

------

------

No No

No Yes Ye s Ye s Ye s Ye s

No Yes Ye s Ye s Ye s Ye s

No No Yes Ye s Ye s Ye s

------

No No No No Yes Ye s

No No Yes Ye s Ye s Ye s

Full

mode 1

Ye s Ye s Ye s

Full

mode 2

8x

Reference

page for

communica tion

method

3-6

3-12

3-16

3-17

3

Communicating with the FD-S series

Ye s: Available with sensor amplifiers of ID 01 to 04. No: Not available.

*1 For details of the functions assigned for motions commands and setting/status read/write, see

"Device Maps" (page 3-4) and "Command Parameter List" (page 3-24).

*2 In remote register RWw, specify the ID number of the sensor amplifier from which to read.

*3 To use this communication method, create a program that controls

commands by handshaking

between a remote input/output and remote register.

*4 It is possible to read instantaneous flow rate or rewrite setting value regardless of the detection

mode setting.

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3-3

Page 32

3

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Small-memory mode 1

Small-memory mode 2

Monitor mode 1

RX[n] + 00

to 03

Output-1 ID 01

to ID 04

*1

Sends the output-1 state (ON/OFF) of the

sensor amplifi er.

The output-1 of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0: OFF

1: ON

RX[n] + 0F Error state -

The DL-CL1 is not communicating properly

with the sensor amplifi er, or an error exists

with the sensor amplifi er.

If an error exists, the error code is stored in

error code (RWr[n] + 00).

0:No Error

1:Error

RX[n] + 10

to 13

Output-2 ID 01

to ID 04

*1

Sends the output-2 state (ON/OFF) of the

sensor amplifi er.

The output-2 of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0: OFF

1: ON

RX[n] + 1F (Not used) - - -

RX[n] + 20

to 23

Output-3 ID 01

to ID 04

*1

Sends the output-3 state (ON/OFF) of the

sensor amplifi er.

The output-3 of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0: OFF

1: ON

RX[n] + 2F System reserved - Unusable

RX[n] + 30

to 33

(Not used) - - -

RX[n] + 3F System reser

ved

- Unusable

RX[n] + 40

to 43

(Not used) - - -

RX[n] + 4F System reserved - Unusable

RX[n] + 50 Sensor ready *3

Used when communicating under handshake

control program.

This is output when command execution is

ready.

0: In preparation

1: Ready

RX[n] + 51

Command

complete

*3

Used when communicating under handshake

control program.

This is output when command execution is

complete.

0->1: Execution

complete

RX[n] + 52 Command error *3

Used when communicating under handshake

control program.

This is output when an error occurs during

command execution.

0:No Error

1:Error

3-2

Device Maps

The device maps vary as described in "Selecting an Operating Mode of the DL-

CL1" (page 3-3). Select an operating mode suited for the functions of the sensor

amplifiers to be used, before accessing each device.

Device Maps for Small-Memory Mode 1, Small-Memory Mode 2, and Monitor Mode 1

The following device maps are used for when the operating mode is small-memory

mode 1, small-memory mode 2, or monitor mode 1.

In cases of monitor mode 2, full mode 1, and full mode 2, see "Device Maps for

Monitor Mode 2, Full Mode 1, and Full Mode 2" (page 3-10).

Communicating with the FD-S series

Remote Input RX (DL-CL1 -> Master Station)

3-4

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 33

3-2 Device Maps

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Monitor mode 1

RX[n] + 53

Current

Value Update

Locked

-

This is output when current value update is

locked (current value update lock request (RY[n]

+ 53) is enabled).

0: Update

enabled

1: Update

locked

RX[n] + 54

to 5D

System

reserved

- Unusable

RX[n] + 5E

Current value

page change

complete

*2

Used for reading the current value.This is output

when the current value page has been changed.

0->1: Change

complete

RX[n] + 5F

Current value

page change

error

*2

Used for reading the current value.This is output

if an error occurs while changing the current

value page.

0:No Error

1:Error

RX[n] + 60

to 63

(Not used) - - -

RX[n] + 6F (Not used) - - RX[n] + 1B

Remote ready -

This is output when the DL-CL1 is correctly

connected to the CC-Link system.

1: Proper communication is provided.Data from

the sensor amplifi er will be updated.

0: Proper communication is not provided.Data

from the sensor amplifi er will not be updated.

0: In preparation

1: Ready

RX[n] + 3B

RX[n] + 7B

Number [n] denotes the first relay number assigned to the DL-CL1.

*1 See "Reading an Output from a Sensor Amplifier" (page 3-17).

*2 See "Reading Current Values (Instantaneous Flow Rate) from Sensor Amplifiers" (page 3-18).

*3 See "Reading/Writing Settings or Status of a Sensor Amplifier" (page 3-21).

See "Issuing a Motion Command to a Sensor Amplifier" (page 3-20).

Remote Output RY (Master Station -> DL-CL1)

3

Communicating with the FD-S series

Operating

Small-memory mode 1

Device no.

mode

(HEX)

Small-memory mode 2

Monitor mode 1

RY[n] + 00

to 03

RY[n] + 0F System reserved - Unusable

RY[n] + 10

to 13

RY[n] + 1F System reserved - Unusable

RY[n] + 20

to 23

RX[n] + 2F System reserved - Unusable

RY[n] + 30

to 33

RX[n] + 3F System reserved - Unusab

Name

Integration reset

input

ID 01 to ID 04

Flow rate hold

reset input

ID 01 to ID 04

Zero adjustment

input

ID 01 to ID 04

Temperature

hold reset input

ID 01 to ID 04

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Communication

method

Receives integration reset input by assigning

*1

each sensor amplifi er (ID 01 to ID 04) to each

RY.

Receives fl ow rate hold reset input by

*1

assigning each sensor amplifi er (ID 01 to ID

04) to each RY.

Receives zero adjustment input by assigning

*1

each sensor amplifi er (ID 01 to ID 04) to each

RY.

Receives temperature hold reset input by

*1

assigning each sensor amplifi er (ID 01 to ID

04) to each RY.

Description Writing range

le

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

0: OFF

1: ON

3-5

Page 34

3

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Writing range

Monitor mode 1

RY[n] + 40

to 43

(Not used) - - -

RY[n] + 4F

to 50

System reserved - Unusable

RY[n] + 51

Request for

command

*3

Used when communicating under handshake

control program.

This is input when requesting command

execution.

0->1: Request

execution

RY[n] + 52 System reserved - Unusable

RY[n] + 53

Current Value

Update Request

-

Used to lock data update in current value

boxes (RWr[n] + 08 to 0D).

This may be used to obtain the current values

of multiple sensor amplifi ers at the same

timing.

The comparator value is locked while the

update request is held.

The update lock state can be checked by the

current value update lock state (RX[n] + 53).

0: Do not lock

update

1: Request

update lock

RY[n] + 54

to 5D

System reserved - Unusable

RY[n] + 5E

Request to

change current

value page

*2

Used for reading the current value.

This is input when requesting to change the

current value page (the ID number of the

sensor amplifi er to read from).

0->1: Request

change

R

Y[n] + 5F System reserved - Unusable

RY[n] + 60

to 63

(Not used) - - -

RY[n] + 6F (Not used) - - -

3-2 Device Maps

Communicating with the FD-S series

Number [n] denotes the first relay number assigned to the DL-CL1.

*1 See "Entering an External Input into a Sensor Amplifier" (page 3-17).

*2 See "Reading Current Values (Instantaneous Flow Rate) from Sensor Amplifiers" (page 3-18).

*3 See "Reading/Writing Settings or Status of a Sensor Amplifier" (page 3-21).

See "Issuing a Motion Command to a Sensor Amplifier" (page 3-20).

Remote Register RWr (DL-CL1 -> Master Station)

Operating

mode

Small-memory mode 1

3-6

Device no.

Small-memory mode 2

(HEX)

Monitor mode 1

RWr[n] + 00 Error code -

RWr[n] + 01

RWr[n] + 02 to

03

(2 words)

Command

response

Read data *3

Communication

Name

method

*3

Stores an error code when error state (RX[n] + 0F)

turns ON.

Used for communicating under handshake control

program. Stores details of command execution result.

Used when communicating under handshake control

program.

Stores the parameter data read from the sensor amplifi er.

Description

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Reading

range

*4

*5

*6

Page 35

3-2 Device Maps

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Small-memor y mode 2

Monitor mode 1

RWr[n] + 04

Integration

reset input

response

*1

Stores the integration reset input response of

the sensor amplifi er.

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 05

Flow rate

hold reset

input

response

*1

Stores the fl ow rate hold reset input response

of the sensor amplifi er.

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 06

Zero

adjustment

input

response

*1

Stores the zero adjustment input response of

the sensor amplifi er. The response is output

by assigning sensor amplifi ers (ID 01 to ID

04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 07

Current value

property

*2

Used for reading the instantaneous fl ow rate

value.

This property is output by assigning IDs (ID

01 to ID 04) to bits 0 - 3.

The output occurs when the instantaneous

fl ow rate value read from the sensor amplifi er

is nonnumeric: "over" or "invalid."

0: Normal current

value

1: "over" or "invalid

(-----)"

RWr[n]

+08 to 09

(INT32)

Current

value: box 1

*2

Used for reading the instantaneous fl ow rate

value. The instantaneous fl ow rate value of the

sensor amplifi er of the ID number specifi ed

page number (RWw[n] + 08) is output.

Data type:

INT3

2 (LITTLE)

Page 0: ID 01

Page 1: ID 04

RWr[n]

+0A to 0B

(INT32)

Current

value: box 2

*2

Used for reading the instantaneous fl ow rate

value.The instantaneous fl ow rate value of the

sensor amplifi er of the ID number specifi ed

page number (RWw[n] + 08) is output.

Data type: INT32 (LITTLE)

Page 0: ID 02

Page 1: (Not used)

RWr[n]

+0C to 0D

(INT32)

Current

value: box 3

*2

Used for reading the instantaneous fl ow rate

value.

The instantaneous fl ow rate value of the

sensor amplifi er of the ID number specifi ed

page number (RWw[n] + 08) is output.

Data type: INT32 (LITTLE)

Page 0: ID 03

Page 1: (Not used)

RWr[n] + 0E

Temperature

hold reset

input

response

*1

Stores the temperature hold reset input

response of the sensor amplifi er.

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 0F (Not used) - -- --

3

Communicating with the FD-S series

Number [n] denotes the first data memory number assigned to the DL-CL1.

*1 See "Entering an External Input into a Sensor Amplifier" (page 3-17).

*2 See "Reading Current Values (Instantaneous Flow Rate) from Sensor Amplifiers" (page 3-18).

*3 See "Reading/Writing Settings or Status of a Sensor Amplifier" (page 3-21).

See "Issuing a Motion Command to a Sensor Amplifier" (page 3-20).

*4 See "Error information list" (page 3-8).

*5 See "Command response list" (page 3-8).

See "Command Parameter List" (page 3-24).

*6

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3-7

Page 36

3

3-2 Device Maps

Error information list

Error

Information

*

(HEX)

0000 No error - -

0001

0002

0005

0003 Model error

Communicating with the FD-S series

0004 Mixed connection error

0006 Number-of-units error

0007 Sensor-to-sensor communication error

nn01

nn02

nn03

nn04

nn05

nn06

nn07

nn08

nn09

nn0A

nn0B

nn0C

Description Cause Corrective action

Initialization error

Error 1 for sensor amplifier of ID number nn

Error 2 for sensor amplifier of ID number nn

Error 3 for sensor amplifier of ID number nn

Error 4 for sensor amplifier of ID number nn

Error 5 for sensor amplifier of ID number nn

Error 6 for sensor amplifier of ID number nn

Error 7 for sensor amplifier of ID number nn

Error 8 for sensor amplifier of ID number nn

Error 9 for sensor amplifier of ID number nn

Error 10 for sensor amplifier of ID number nn

Error 11 for sensor amplifier of ID number nn

Error 12 for sensor amplifier of ID number nn

Error encountered during

initialization.

There is connected a

sensor amplifier of a

model incompatible with

the DL-CL1.

A foreign sensor amplifier

(i.e., one that cannot be

intermixed) is connected.

More sensor amplifiers are

connected than are

permitted.

An error exists in the

communication between

sensor amplifiers.

(Not used)

Head connection error

Overcurrent error

EEPROM Error

Dry water error

Backflow error

(Not used)

(Not used)

(Not used)

Drive gain error

Te m p er ature low error

Te m p er ature high error

Check the number of connected

sensor amplifiers and the

connection to the sensor

amplifiers, and then cycle power.

If the error remain, contact your

nearest sales office.

Connect a sensor amplifier of a

compatible model.

Remove the foreign sensor

amplifier.

Observe the number of

connectable sensor amplifiers.

Check the connections of the

sensor amplifiers, and then turn

off the power and back on.

Refer to the FD-S series

instruction manual.

* "nn" denotes the ID number in hexadecimal of sensor amplifier. (Example: 01h for ID01, ..., 04h for

ID04)

If there are multiple errors, the smallest error code is stored in the remote register.

Command response list

3-8

Response

(HEX)

0000 Successfully completed. The command has been processed successfully.

0001 Command number erro r The command number is out of range.

0002 Data category error The data category value is out of range.

0003 ID number out of range The ID number of sensor amplifier is out of range.

0004 Data number out of range The data number is out of range.

0007 Sensor-to-sensor communication error An error exists in the communication between sensors.

0008 Motion command access error Cannot read/write to motion command data numbers.

0009

000A Motion command execution error Failed to execute the motion command.

000B Read inhibit Write-only data number. Cannot be read.

Motion command data number out of range

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Name Description

The data number of motion command is out of range.

Page 37

3-2 Device Maps

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Writing range

Small-memor y mode 1

Small-memor y mode 2

Monitor mode 1

RWw[n] + 00

Data categor y/

command

number

*2

Used when communicating under handshake

control program.

Specifi es the data category and command

number of the parameter to be communicated.

·Upper byte:

00h - FFh

·Lower byte:

00: Read

01: Write

02: Motion

command

RWw[n] + 01 Data number *2

Used when communicating under handshake

control program.

Specifi es the data number of the parameter to

be communicated.

0000h - FFFFh

RWw[n] + 02

to 03

(2 words)

Data to write *2

Used when communicating under handshake

control program.

Specifi es the data to be written in the

parameter to be communicated.

*3

RWw[n] + 04 (Not used) - - RWw[n] + 05

to 07

System reser ved - Unusable -

RWw[n] + 08

Select current

value box page

number

*1

Used for reading the current value.Specifi es

the page number corresponding to the sensor

amplifi er ID number to be stored in the current

value box.

0: Page 0

1: Page 1

2: Page 2

3: Page 3

RWw[n] + 09

to 0F

System reser ved - Unusable -

Response

(HEX)

000C Operating status error

000D Write error/Operating status error

FFFF(-1)

FFFE(-2)

……

FFF7(-9)

FFF6(-10)

Decimal point position of read data

Name Description

Command communication (reading) is temporarily

prohibited because of the operating status of the

sensor amplifier.

This data number cannot be written.

Data written is out of write range.

Command communication is temporarily prohibited

because of the operating status of the sensor amplifier.

The command has been processed successfully.

The data being read has one decimal place.

********.*

The command has been processed successfully.

The data being read has two decimal places.

********.**

*

The command has been processed successfully.

The data being read has nine decimal places.

*.*********

The command has been processed successfully.

The data being read has ten decimal places.

0.**********

*This response is provided specifically for data category 10. If the read data has decimal-point position

information and the command is successfully processed, the decimal-point position information is

added to the command response. For details of category 10, see "Command Parameter List"

(page 3-24).

Remote Register RWw (Master Station -> DL-CL1)

3

Communicating with the FD-S series

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3-9

Page 38

3

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Monitor mode 2

Full mode 1

Full mode 2

RX[n] + 00

to 03

Output-1

ID 01 to ID 04

*1

Sends the output-1 state (ON/OFF) of the

sensor amplifi er.

The output-1 of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0: OFF

1: ON

RX[n] + 0F Error state -

The DL-CL1 is not communicating properly

with the sensor amplifi er, or an error exists

with the sensor amplifi er.

If an error exists, the error code is stored in

error code (RWr[n] + 00).

0:No Error

1:Error

RX[n] + 10

to 13

Output-2

ID 01 to ID 04

*1

Sends the output-2 state (ON/OFF) of the

sensor amplifi er.

The output-2 of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0: OFF

1: ON

RX[n] + 1F (Not used) - - -

RX[n] + 20

to 23

Output-3

ID 01 to ID 04

*1

Sends the output-3 state (ON/OFF) of the

sensor amplifi er.

The output-3 of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0: OFF

1: ON

RX[n] + 2F System reserved - Unusable

RX[n] + 30

to 33

(Not used) - - -

RX[n] + 3F System reser

ved

- Unusable

3-2 Device Maps

Number [n] denotes the first data memory number assigned to the DL-CL1.

*1 See "Reading Current Values (Instantaneous Flow Rate) from Sensor Amplifiers" (page 3-18).

*2 See "Reading/Writing Settings or Status of a Sensor Amplifier" (page 3-21).

See "Issuing a Motion Command to a Sensor Amplifier" (page 3-20).

*3 See "Command Parameter List" (page 3-24).

Device Maps for Monitor Mode 2, Full Mode 1, and Full Mode 2

The following device maps are used when the operating mode is monitor mode 2, full

mode 1, or full mode 2.

In cases of small-memory mode 1, small-memory mode 2, and monitor mode 1,

Communicating with the FD-S series

see "Device Maps for Small-Memory Mode 1, Small-Memory Mode 2, and Monitor

Mode 1" (page 3-4).

Remote Input RX (DL-CL1 -> Master Station)

3-10

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 39

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Monitor mode 2

Full mode 1

Full mode 2

RX[n] + 40

to 49

(Not used) - -- --

RX[n] + 4F System reserved - Unusable

RX[n] + 50 Sensor ready *2

Used when communicating under

handshake control program.

This is output when command execution is

ready.

0: In preparation

1: Ready

RX[n] + 51 Command complete *2

Used when communicating under

handshake control program.

This is output when command execution is

complete.

0->1: Execution

complete

RX[n] + 52 Command error *2

Used when communicating under

handshake control program.

This is output when an error occurs during

command execution.

0:No Error

1:Error

RX[n] + 53

::Current Value

Update Locked

-

This is output when current value update is

locked (current value update lock request

(RY[n] + 53) is enabled).

0: Update

enabled

1: Update locked

RX[n] + 54

to 5D

System reser ved - Unusable

RX[n] + 60

to 63

(Not used) - - -

RX[n] + 6F (Not used) - - -

RY[n] + 70

to 73

Instantaneous fl ow

rate setting-1 (P1)

rewrite complete ID

01 to ID 04

*3

Used when re

writing a setting v

alue.

This is output when the instantaneous fl ow

rate setting value 1 (P1) has been rewritten.

The output of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0->1: Rewrite

complete

RX[n] + 7F

Instantaneous fl ow

rate setting-1 (P1)

rewrite error

*3

Used when rewriting a setting value.

This is output if an error occurs with a

sensor amplifi er of any ID number during

rewriting of instantaneous fl ow rate setting

value 1 (P1).

0:No Error

1:Error

RX[n] + 80

to 83

Instantaneous fl ow

rate setting-2 (P2)

rewrite complete ID

01 to ID 04

*3

Used when rewriting a setting value.

This is output when the instantaneous fl ow

rate setting value 2 (P2) has been rewritten.

The output of each sensor amplifi er (ID 01

to ID 04) corresponds to each RX.

0->1: Rewrite

complete

RX[n] + 8F

Instantaneous fl ow

rate setting-2 (P2)

rewrite error

*3

Used when rewriting a setting value.

This is output if an error occurs with a

sensor amplifi er of any ID number during

rewriting of instantaneous fl ow rate setting

value 2 (P2).

0:No Error

1:Error

RX[n] + 90

to 93

Temperature upper

limit setting rewrite

complete ID 01 to

ID 04

*3

Used when rewriting a setting value.

This is output when the temperature upper

limit setting value has been rewritten. The

output of each sensor amplifi er (ID 01 to ID

04) corresponds to each RX.

0->1: Rewrite

complete

RX[n] + 9F

Temperature upper

limit rewrite error

*3

Used when rewriting a setting value.

This is output if an error occurs with a

sensor amplifi

er of an

y ID number dur

ing

rewriting of temperature upper limit setting

value.

0:No Error

1:Error

RX[n] + A0

to A3

Temperature lower

limit setting rewrite

complete ID 01 to

ID 04

*3

Used when rewriting a setting value.

This is output when the temperature lower

limit setting value has been rewritten. The

output of each sensor amplifi er (ID 01 to ID

04) corresponds to each RX.

0->1: Rewrite

complete

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3-2 Device Maps

3

Communicating with the FD-S series

3-11

Page 40

3

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Monitor mode 2

Full mode 1

Full mode 2

RX[n] + AF

Temperature

lower limit

rewrite error

*3

Used when rewriting a setting value.

This is output if an error occurs with a sensor

amplifi er of any ID number during rewriting of

temperature lower limit setting value.

0:No Error

1:Error

RX[n] + B0

to B3

Integrated

fl ow quantity

setting-1 rewrite

complete ID 01

to ID 04

*3

Used when rewriting a setting value.

This is output when the integrated fl ow

quantity setting value 1 has been rewritten.

The output of each sensor amplifi er (ID 01 to

ID 04) corresponds to each RX.

0->1: Rewrite

complete

RX[n] + BF

Integrated

fl ow quantity

setting-1 rewrite

error

*3

Used when rewriting a setting value.

This is output if an error occurs with a sensor

amplifi er of any ID number during rewriting of

integrated fl ow quantity setting value 1.

0:No Error

1:Error

RX[n] + C0

to EF

System

reserved

- Unusable

RX[n] + 7B

Remote ready -

This is output when the DL-CL1 is correctly

connected to the CC-Link system.

1: Proper communication is provided.Data

from the sensor amplifi er will be updated.

0: Proper communication is not provided.Data

from the sensor amplifi er will not be updated.

0: In preparation

1: Ready

RX[n] + DB

RX[n] + 17B

Operating

mode

Device

no. (HEX)

Name

Communication

method

Description Writing range

Monitor mode 2

Full mode 1

Full mode 2

RY[n] + 00

to 03

Integration reset

input

ID 01 to ID 04

*1

Receives integration reset input by assigning

each sensor amplifi er (ID 01 to ID 04) to each

RY.

0: OFF

1: ON

RY[n] + 0F System reserved - Unusable

RY[n] + 10

to 13

Flow rate hold

reset input

ID 01 to ID 04

*1

Receives fl ow rate hold reset input by

assigning each sensor amplifi er (ID 01 to ID

04) to each RY.

0: OFF

1: ON

RY[n] + 1F System reserved - Unusable

RY[n] + 20

to 23

Zero adjustment

input

ID 01 to ID 04

*1

Receives zero adjustment input by assigning

each sensor amplifi er (ID 01 to ID 04) to each

RY.

0: OFF

1: ON

RY[n] + 2F System reserved - Unusable

RY[n] + 30

to 33

Temperature

hold reset input

ID 01 to ID 04

*1

Receives temperature hold reset input by

assigning each sensor amplifi er (ID 01 to ID

04) to each RY.

0: OFF

1: ON

RY[n] + 3F System reserved - Unusab

le

R

Y[n] + 40

to 43

(Not used) - - -

RY[n] + 4F

to 50

System reser ved - Unusable

RY[n] + 51

Request for

command

*2

Used when communicating under handshake

control program. This is input when requesting

command execution.

0->1: Request

execution

RY[n] + 52 System reserved - Unusable

3-2 Device Maps

Communicating with the FD-S series

Number [n] denotes the first relay number assigned to the DL-CL1.

*1 See "Reading an Output from a Sensor Amplifier" (page 3-17).

*2 See "Reading/Writing Settings or Status of a Sensor Amplifier" (page 3-21).

See "Issuing a Motion Command to a Sensor Amplifier" (page 3-20).

*3 See "Rewriting a Setting Value of a Sensor Amplifier" (page 3-21).

Remote Output RY (Master Station -> DL-CL1)

3-12

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 41

3-2 Device Maps

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description

Writing

range

Monitor mode 2

Full mode 1

Full mode 2

RY[n] + 53

Current Value

Update Request

-

Used when locking data update of current

value. This may be used to obtain the current

values of multiple sensor amplifi ers at the

same timing.

The current value is locked while the update

request is held. The update lock state can

be checked by the current value update lock

state (RX[n] + 53).

0: Do not lock

update

1: Request

update lock

RY[n] + 54

to 5F

System reser ved - Unusable

RY[n] + 60

to 63

(Not used) - - -

RY[n] + 6F (Not used) - - -

RY[n] + 70

to 73

Request to rewrite

instantaneous fl ow

rate setting-1 (P1)

ID 01 to ID 04

*3

Used when rewriting a setting value.

This is input when requesting to rewrite the

instantaneous fl ow rate setting value 1 (P1) of

each sensor amplifi er.

The request input is received by assigning each

sensor amplifi er (ID 01 to ID 04) to each RY.

0->1:

Request to

rewrite

RY[n] + 7F

Clear instantaneous

fl ow rate setting-1

(P1) rewrite error

*3

Used when rewriting a setting value.

This is input when clearing an instantaneous

fl ow rate setting-1 (P1) rewrite error.

0->1: Clear

error

RY[n] + 80

to 83

Request to rewrite

instantaneous fl ow

rate setting-2 (P2)

ID 01 to ID 04

*3

Used when rewriting a setting value.

This is input when requesting to rewrite the

instantaneous fl ow rate setting value 2 (P2) of

each sensor amplifi er.

The request input is received by assigning each

sensor amplifi er (ID 01 to ID 04) to each RY.

0->1:

Request to

rewrite

RY[n] + 8F

Clear instantaneous

fl ow rate setting-2

(P2) rewrite error

*3

Used when rewriting a setting value.

This is input when clearing an instantaneous

fl ow rate setting-2 (P2) rewrite error.

0->1: Clear

error

RY[n] + 90

to 93

Request to rewrite

temperature upper

limit setting

ID 01 to ID 04

*3

Used when rewriting a setting value.

This is input when requesting to rewrite the

temperature upper limit setting value of each

sensor amplifi er.

The request input is received by assigning each

sensor amplifi er (ID 01 to ID 04) to each RY.

0->1:

Request to

rewrite

RY[n] + 9F

Clear temperature

upper limit setting

rewrite error

*3

Used when rewriting a setting value.

This is input when clearing a temperature

upper limit setting-value rewrite error.

0->1: Clear

error

RY[n] + A0

to A3

Request to rewrite

temperature lo

wer

limit setting

ID 01 to ID 04

*3

Used when rewriting a setting value.

This is input when requesting to rewrite the

temperature lower limit setting value of each

sensor amplifi er.

The request input is received by assigning each

sensor amplifi er (ID 01 to ID 04) to each RY.

0->1:

Request to

rewrite

RY[n] + AF

Clear temperature

lower limit setting

rewrite error

*3

Used when rewriting a setting value. This is

input when clearing a temperature lower limit

setting-value rewrite error.

0->1: Clear

error

RY[n] + B0

to B3

Request to rewrite

integrated fl ow

quantity setting-1

ID 01 to ID 0 4

*3

Used when rewriting a setting value.

This is input when requesting to rewrite the

integrated fl ow quantity setting value 1 of

each sensor amplifi er.

The request input is received by assigning each

sensor amplifi er (ID 01 to ID 04) to each RY.

0->1:

Request to

rewrite

RY[n] + BF

Clear integrated

fl ow quantity

setting-1 rewrite

error

*3

Used when rewriting a setting value.

This is input when clearing an integrated fl ow

quantity setting-1 rewrite error.

0->1: Clear

error

R

Y[n] + C0

to EF

System reser

ved - Unusable

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

3

Communicating with the FD-S series

3-13

Page 42

3

Operating

mode

Device no.

(HEX)

Name

Communication

method

Description Reading range

Monitor mode 2

Full mode 1

Full mode 2

RWr[n] + 00 Error code -

Stores an error code when error state (RX[n]

+ 0F) turns ON.

*4

RWr[n] + 01

Command

response

*2

Used when communicating under handshake

control program.

Stores details of command execution result.

*5

RWr[n] + 02

to 03

(2 words)

Read data *2

Used when communicating under handshake

control program.

Stores the parameter data read from the

sensor amplifi er.

The data type

depends on the

parameter type.

RWr[n] + 04

Integration reset

input response

*1

Stores the integration reset input response of

the sensor amplifi er.

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 05

Flow rate hold

reset input

response

*1

Stores the fl ow rate hold reset input response

of the sensor amplifi er.

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 06

Zero adjustment

input response

*1

Stores the zero adjustment input response of

the sensor amplifi er.

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 07

Temperature

hold reset input

response

*1

Stores the temperature hold reset input

response of the sensor amplifi er

The response is output by assigning sensor

amplifi ers (ID 01 to ID 04) to bits 0 - 3.

0: Input OFF

1: Input ON

RWr[n] + 08 (Not used) - - -

RWr[n] + 09

Current value

"invalid"

*3

If the instantaneous fl ow rate values for

sensor amplifi ers (ID 01 to ID 04) are invalid

(-----), they are output by assigning them to

bits 0 - 3.

0: Normal value

1: Invalid

RWr[n] + 0A

Current value

"over"

*3

If the instantaneous fl ow rate values for

sensor amplifi ers (ID 01 to ID 04) are

"over"(FFFF), they are output by assigning

them to bits 0 - 3.

0: Normal value

1: Over

RWr[n] + 0B

Current value

"under"

*3 Not used with the FD-S series. -

RWr[n] +0C

to 0D

(INT32)

Current Value ID

01

*3

Used for reading the instantaneous fl ow rate

value.

Outputs the instantaneous fl ow rate value of

the sensor amplifi er (ID 01).

INT32 (LITTLE)

R

Wr[n] +0E

to 0F

(INT3

2)

Current Value ID

02

*3

Used for reading the instantaneous fl ow rate

value.

Outputs the instantaneous fl ow rate value of

the sensor amplifi er (ID 02).

INT32 (LITTLE)

RWr[n] +10

to 11

(INT32)

Current Value ID

03

*3

Used for reading the instantaneous fl ow rate

value.

Outputs the instantaneous fl ow rate value of

the sensor amplifi er (ID 03).

INT32 (LITTLE)

3-2 Device Maps

Number [n] denotes the first relay number assigned to the DL-CL1.

*1 See "Entering an External Input into a Sensor Amplifier" (page 3-17).

*2 See "Reading/Writing Settings or Status of a Sensor Amplifier" (page 3-21).

See "Issuing a Motion Command to a Sensor Amplifier" (page 3-20).

*3 See "Rewriting a Setting Value of a Sensor Amplifier" (page 3-21).

Remote Register RWr (DL-CL1 -> Master Station)

Communicating with the FD-S series

3-14

- CC-Link Compatible Network Unit DL-CL1 User’s Manual (FD-S) -

Page 43

3-2 Device Maps

Operating

mode

Monitor mode 2

Full mode 1

Full mode 2

Device no. (HEX) Name

RWr[n] +12 to 13

(INT32)

RWr[n] +14 to 15

(INT32)

RWr[n] +16 to 17

(INT32)

RWr[n] +18 to 19

(INT32)

RWr[n] + 1A to 1B

(INT32)

RWr[n] + 1C to 1D

(INT32)

RWr[n] +1E to 1F

(INT32)

RWr[n] +20 to 21

(INT32)

RWr[n] +22 to 23

(INT32)

R

Wr[n] +24 to 25

2)

(INT3

RWr[n] +26 to 27

(INT32)

RWr[n] +28 to 29

(INT32)

RWr[n] + 2A to 3F

Current Value

ID04