Page 1

UHF FM TRANSCEIVER

TK-8180

SERVICE MANUAL

© 2004-7 PRINTED IN JAPAN

B51-8692-00 (N) 1007

Microphone

(T91-0639-05)

Cabinet

(A01-2194-11)

CONTENTS

GENERAL .................................................................. 2

SYSTEM SET-UP ...................................................... 3

REALIGNMENT ......................................................... 4

INSTALLATION ......................................................... 7

DISASSEMBLY FOR REPAIR ................................. 13

CIRCUIT DESCRIPTION .......................................... 16

SEMICONDUCTOR DATA ...................................... 20

COMPONENTS DESCRIPTION .............................. 22

PARTS LIST ............................................................. 24

EXPLODED VIEW.................................................... 33

PACKING ................................................................. 34

ADJUSTMENT ........................................................ 35

TERMINAL FUNCTION ........................................... 46

PC BOARD

DISPLAY UNIT (X54-3480-10) ............................ 50

TX-RX UNIT (X57-6990-10) (A/3, C/3) ............... 52

Key top

(K29-9312-21)

TX-RX UNIT (X57-6990-10) (B/3) ....................... 54

SCHEMATIC DIAGRAM

DISPLAY UNIT (X54-3480-10) ............................ 58

TX-RX UNIT (X57-6990-10) ................................ 60

INTERCONNECTION DIAGRAM ............................ 69

BLOCK DIAGRAM ................................................... 70

LEVEL DIAGRAM .................................................... 72

OPTIONAL ACCESSORIES

KRK-10

KAP-2 (Horn Alert/P.A. Relay unit) ................... 79

KCT-40 (Radio Interface Cable).......................... 79

KCT-46 (Ignition Sense Cable) ........................... 79

KMC-35 (Microphone) ........................................ 79

KMC-36 (Keypad Microphone) .......................... 79

SPECIFICATIONS ................................. BACK COVER

(Control Head Remote Kit: 23ft/7m) ......

Panel assy

(A62-1094-23)

74

Page 2

TK-8180

GENERAL

INTRODUCTION

SCOPE OF THIS MANUAL

This manual is intended for use by experienced technicians familiar with similar types of commercial grade communications equipment. It contains all required service information for the equipment and is current as of this publication

date. Changes which may occur after publication are covered

by either Service Bulletins or Manual Revisions, which are

issued as required.

ORDERING REPLACEMENT PARTS

When ordering replacement parts or equipment information, the full part identification number should be included.

This applies to all parts : components, kits, and chassis. If the

part number is not known, include the chassis or kit number

of which it is a part and a sufficient description of the required

component for proper identification.

PERSONAL SAFETY

The following precautions are recommended for personal

safety :

•DONOT transmit if someone is within two feet (0.6

meter) of the antenna.

•DONOT transmit until all RF connectors are secure and

any open connectors are properly terminated.

• SHUT OFF this equipment when near electrical blasting

caps or while in an explosive atmosphere.

• All equipment should be properly grounded before power-

up for safe operation.

• This equipment should be serviced by only qualified tech-

nicians.

PRE-INSTALLATION CONSIDERATIONS

1. UNPACKING

Unpack the radio from its shipping container and check for

accessory items. If any item is missing, please contact

KENWOOD immediately.

2. LICENSING REQUIREMENTS

Federal regulations require a station license for each radio

installation (mobile or base) be obtained by the equipment

owner. The licensee is responsible for ensuring transmitter

power, frequency, and deviation are within the limits permitted by the station license.

Transmitter adjustments may be performed only by a licensed technician holding an FCC first, second or general

class commercial radiotelephone operator’s license. There is

no license required to install or operate the radio.

3. PRE-INSTALLATION CHECKOUT

3-1. Introduction

Each radio is adjusted and tested before shipment. However, it is recommended that receiver and transmitter operation be checked for proper operation before installation.

3-2. Testing

The radio should be tested complete with all cabling and

accessories as they will be connected in the final installation.

Transmitter frequency, deviation, and power output should

be checked, as should receiver sensitivity, squelch operation,

and audio output. Signalling equipment operation should be

verified.

4. PLANNING THE INSTALLATION

4-1. General

Inspect the vehicle and determine how and where the radio antenna and accessories will be mounted.

Plan cable runs for protection against pinching or crushing

wiring, and radio installation to prevent overheating.

4-2. Antenna

The favored location for an antenna is in the center of a

large, flat conductive area, usually at the roof center. The

trunk lid is preferred, bond the trunk lid and vehicle chassis

using ground straps to ensure the lid is at chassis ground.

4-3. Radio

The universal mount bracket allows the radio to be

mounted in a variety of ways. Be sure the mounting surface

is adequate to support the radio’s weight. Allow sufficient

space around the radio for air cooling. Position the radio close

enough to the vehicle operator to permit easy access to the

controls when driving.

4-4. DC Power and wiring

1. This radio may be installed in negative ground electrical

systems only. Reverse polarity will cause the cable fuse to

blow. Check the vehicle ground polarity before installation

to prevent wasted time and effort.

2. Connect the positive power lead directly to the vehicle

battery positive terminal. Connecting the Positive lead to

any other positive voltage source in the vehicle is not rec-

ommended.

3. Connect the ground lead directly to the battery negative

terminal.

4. The cable provided with the radio is sufficient to handle

the maximum radio current demand. If the cable must be

extended, be sure the additional wire is sufficient for the

current to be carried and length of the added lead.

5. INSTALLATION PLANNING – CONTROL STATIONS

5-1. Antenna system

Control station. The antenna system selection depends on

many factors and is beyond the scope of this manual. Your

KENWOOD dealer can help you select an antenna system

that will best serve your particular needs.

5-2. Radio location

Select a convenient location for your control station radio

which is as close as practical to the antenna cable entry point.

Secondly, use your system’s power supply (which supplies

the voltage and current required for your system). Make sure

sufficient air can flow around the radio and power supply to

allow adequate cooling.

2

Page 3

GENERAL / SYSTEM SET-UP

SERVICE

This radio is designed for easy servicing. Refer to the

schematic diagrams, printed circuit board views, and alignment procedures contained in this manual.

TK-8180

NOTE

• If you do not intend to use the speaker 3.5-mm jack and

the D-sub 25-pin connector, fit the supplied speaker-jack

cap and D-sub cap to stop dust and sand from getting in.

• If the transceiver is turned ON or OFF when the power-on/

off status message is enabled, the transceiver sends the

status.

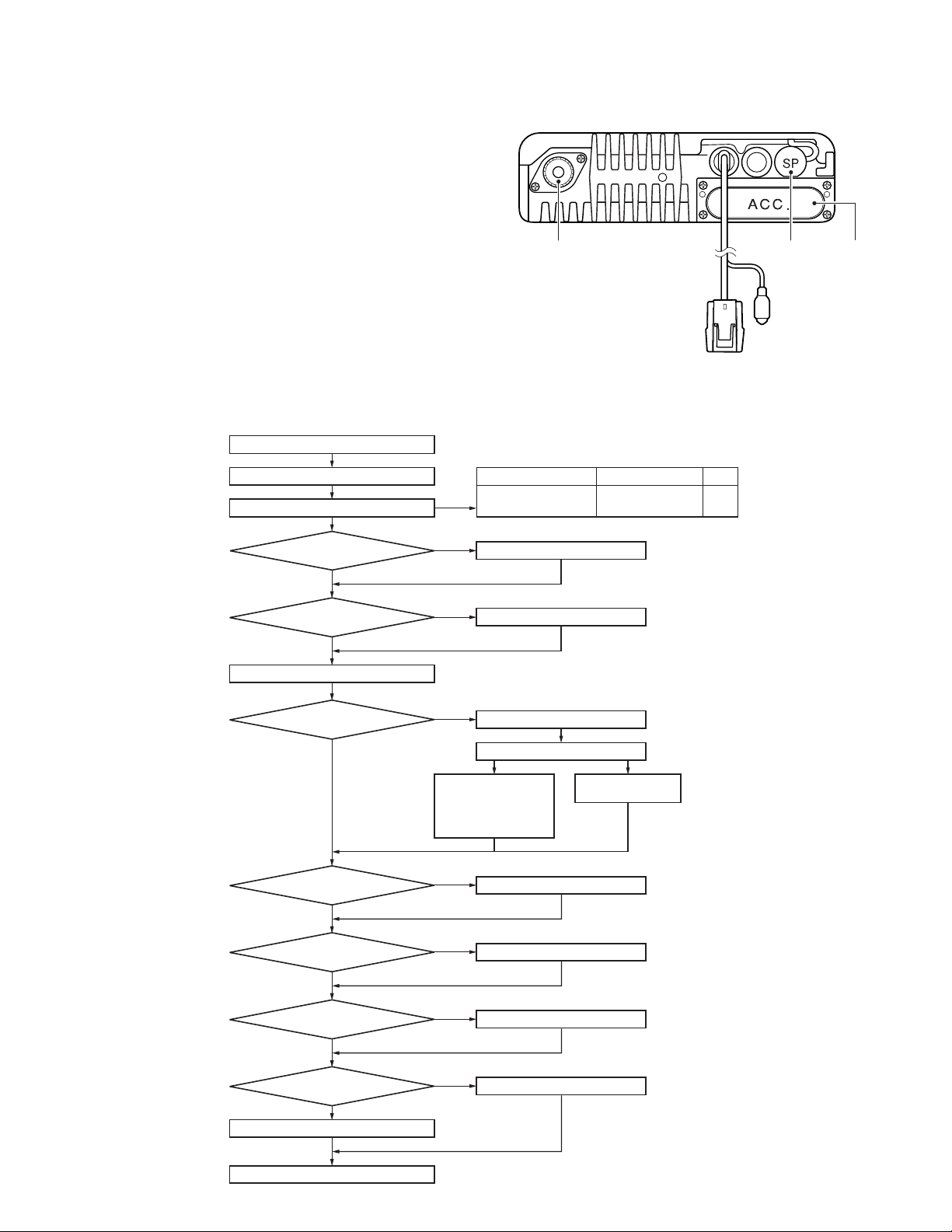

SYSTEM SET-UP

Merchandise received

License and frequency allocated by FCC

Choose the type of transceiver

Are you using

the remote kit?

NO

Are you using

the ignition sense cable?

NO

Transceiver programming

Are you using

the radio interface cable?

NO

YES

YES

See page 4.

A personal computer (IBM PC or compatible), programming

interface (KPG-46), and programming software (KPG-89D)

are required for programming.

YES

Antenna

connector

Power input

connector

Frequency range RF power Type

450~520MHz

KRK-10

KCT-46

KCT-40

KCT-36 Extension cable

30W

(490~520MHz : 25W)

See page 9.

(Option)

See page 7.

(Option)

See page 7.

(Option)

(Option)

K

Speaker

jack cap

Ignition

sense cable

D-sub

cap

Are you using

the public address?

NO

Are you using

the voice guide & storage

unit?

NO

Are you using

the external speaker?

NO

Are you using

the keypad microphone?

NO

Supplied microphone

Delivery

KGP-2A

Modem GPS receiver

or

KGP-2B

Modem GPS controller

(Option)

YES

YES

YES

YES

KES-3 or KES-5 External speaker

KMC-32 or KMC-36

or

KAP-2

VGS-1

KDS-100

Mobile data terminal

Desk top microphone KMC-9C

(Option)

See page 8.

(Option)

See page 10.

(Option)

(Option)

(Option)

3

Page 4

TK-8180

KPG-89D

IBM PC

KPG-46 or

KPG-46 +

Tuning cable

(E30-3383-05)

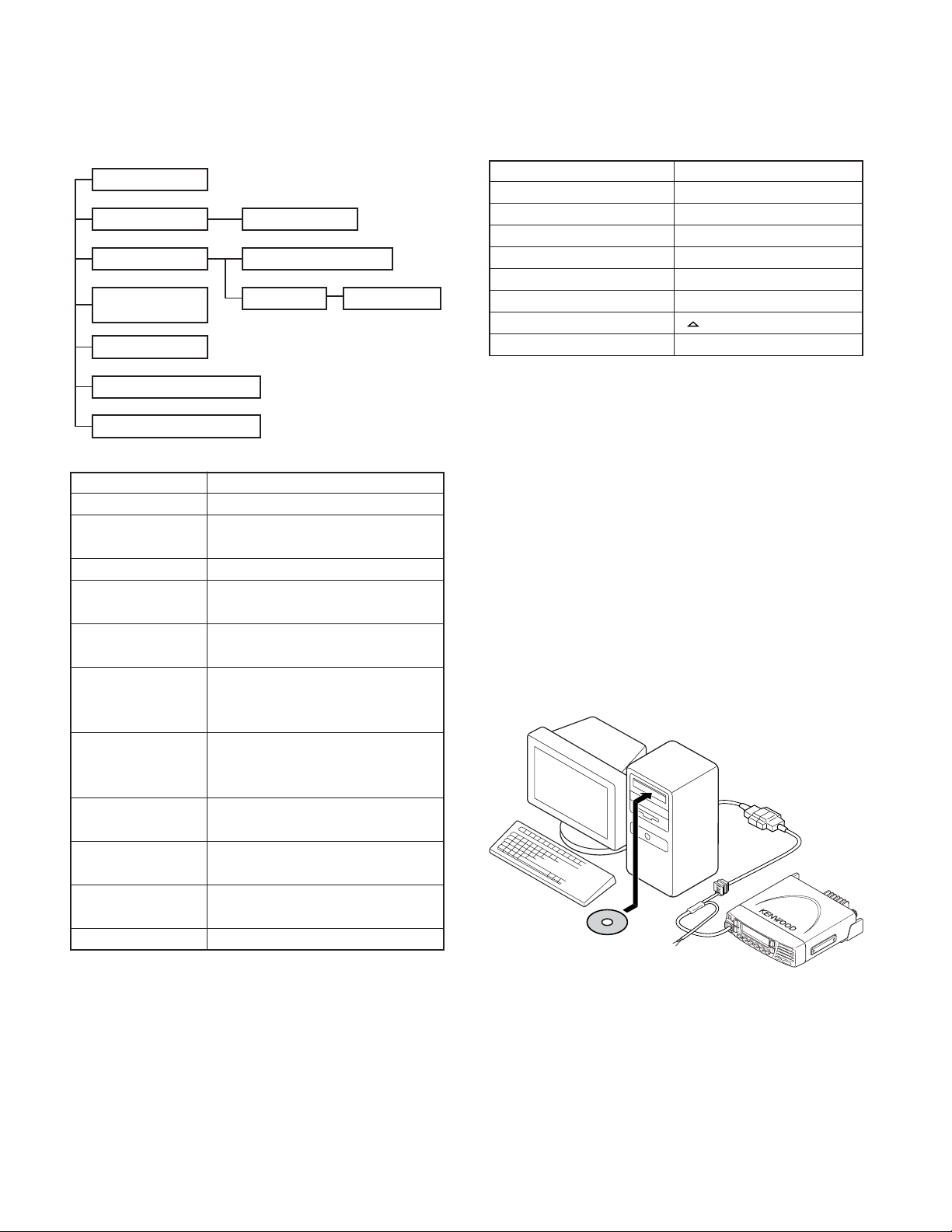

REALIGNMENT

1. Modes

User mode

Panel test mode

PC mode

Firmware

programming mode

Clone mode

Firmware version information

Clock adjustment mode

Mode Function

User mode For normal use.

Panel test mode Used by the dealer to check the funda-

Panel tuning mode Used by the dealer to tune the radio.

PC mode Used for communication between the

Data programming Used to read and write frequency data

mode and other features to and from the radio.

PC test mode Used to check the radio using the PC.

PC tuning mode Used to tune the radio using the PC.

Firmware Used when changing the main program

programming mode of the flash memory.

Clone mode Used to transfer programming data from

Firmware version Used to confirm the internal firmware

information version.

Clock adjustment mode

Panel tuning mode

Data programming mode

PC test mode

mental characteristics.

radio and PC (IBM compatible).

This feature is included in the FPU.

See panel test.

This feature is included in the FPU.

See panel tuning.

one radio to another.

Used to adjust date and time.

PC tuning mode

2. How to Enter Each Mode

Mode Operation

User mode Power ON

Panel test mode [A] + Power ON

PC mode Received commands from PC

Panel tuning mode [Panel test mode] + [S]

Firmware programming mode [S] + Power ON

Clone mode [B] + Power ON

Firmware version information [ ] + Power ON

Clock adjustment mode [C] + Power ON

3. Panel Test Mode

Setting method refer to ADJUSTMENT.

4. Panel Tuning Mode

Setting method refer to ADJUSTMENT.

5. PC Mode

5-1. Preface

The transceiver is programmed by using a personal computer, programming interface (KPG-46) and programming

software (KPG-89D).

The programming software can be used with an IBM PC

or compatible. Figure 1 shows the setup of an IBM PC for

programming.

Fig. 1

4

Page 5

REALIGNMENT

TK-8180

5-2. Connection procedure

1. Connect the transceiver to the personal computer with

the interface cable.

2. When the POWER switch on, user mode can be entered

immediately. When PC sends command the radio enter

PC mode, and “PROGRAM” is displayed on the LCD.

When data transmitting from transceiver, the red LED is

lights.

When data receiving to transceiver, the green LED is

lights.

Note:

• The data stored in the personal computer must match

model type, when it is written into the flash memory.

5-3. KPG-46 description

(PC programming interface cable: Option)

The KPG-46 is required to interface the transceiver to the

computer. It has a circuit in its D-subconnector (25-pin) case

that converts the RS-232C logic level to the TTL level.

The KPG-46 connects the modular microphone jack of the

transceiver to the computers RS-232C serial port.

5-4. Programming software KPG-89D description

The KPG-89D is the programming software for the trans-

ceiver supplied on a CD-ROM. This software runs under MSWindows 98, ME, Windows 2000 or XP on an IBM-PC or

compatible machine.

The data can be input to or read from the transceiver and

edited on the screen. The programmed or edited data can be

printed out. It is also possible to tune the transceiver.

6. Firmware Programming Mode

6-1. Preface

Flash memory is mounted on the transceiver. This allows

the transceiver to be upgraded when new features are released in the future. (For details on how to obtain the firmware, contact Customer Service.)

6-2. Connection procedure

Connect the transceiver to the personal computer (IBM

PC or compatible) with the interface cable (KPG-46). (Connection is the same as in the PC Mode.)

Note :

You can only program firmware from the 8-pin micro-

phone connector on the front panel. Using the 25-pin logic

interface on the rear panel will not work.

6-3. Programming

1. Start up the firmware programming software (Fpro.exe).

2. Set the communications speed (normally, 115200 bps)

and communications port in the configuration item.

3. Set the firmware to be updated by File name item.

4. Turn the transceiver power ON with the [S] key held

down. Then, the orange LED on the transceiver lights and

“PROG 115200” is displayed.

5. Check the connection between the transceiver and the

personal computer, and make sure that the transceiver is

in the Program mode.

6. Press write button in the window. When the transceiver

starts to receive data, the [PG] display is blinking.

7. If writing ends successfully, the checksum is calculated

and a result is displayed.

8. If you want to continue programming other transceivers,

repeat steps 4 to 7.

Notes:

• This mode cannot be entered if the Firmware Programming mode is set to Disable in the Programming software.

• When programming the firmware, it is recommend to

copy the data from the floppy disk to your hard disk before

update the radio firmware.

Directly copying from the floppy disk to the radio may not

work because the access speed is too slow.

6-4. Function

1. If you press the [■ ] key while “PROG 115200” is displayed, the display changes to “PROG 19200” (The LED

blinks green) to indicate that the write speed is low speed

(19200 bps). If you press the [■] key again while “PROG

19200” is displayed, the display changes to “PROG

38400” (The LED lights red and orange alternatively). If

you press the [■] key again while “PROG 38400” is displayed, the display changes to “PROG 57600” (The LED

blinks orange). If you press the [■ ] key again while

“PROG 57600” is displayed, the display returns to “PROG

115200” (The LED lights orange).

2. If you press the [

played, the checksum is calculated, and a result is displayed. If you press the [

checksum is displayed, “PROG 115200” is redisplayed.

] key while “PROG 115200” is dis-

] key again while the

Note:

Normally, write in the high-speed mode.

7. Clone Mode

Programming data can be transferred from one radio to

another by connecting them via their 8-pin microphone connectors. The operation is as follows (the transmit radio is the

master and the receive radio is a slave).

1. Turn the master transceiver power ON with the [B] key

held down. If the read authorization password is set to the

transceiver, the transceiver displays “CLONE LOCK”. If

the password is not set, the transceiver displays “CLONE

MODE”.

2. When you enter the correct password, and “CLONE

MODE” is displayed, the transceiver can be used as the

cloning master. The following describes how to enter the

password.

5

Page 6

TK-8180

REALIGNMENT

3. How to enter the password with the microphone keypad;

If you press a key while “CLONE LOCK” is displayed, the

number that was pressed is displayed on the transceiver.

Each press of the key shifts the display in order to the left.

When you enter the password and press the [✳] key,

“CLONE MODE” is displayed if the entered password is

correct. If the password is incorrect, “CLONE LOCK” is

redisplayed.

How to enter the password with the [

If the [

displayed, numbers (0 to 9) are displayed flashing. When

you press the [C] key, the currently selected number is

determined. If you press the [S] key after entering the

password in this procedure, “CLONE MODE” is displayed

if the entered password is correct. If the password is incorrect, “CLONE LOCK” is redisplayed.

4. Power on the slave transceiver.

5. Connect the cloning cable (Part No. E30-3382-05) to the

modular microphone jacks on the master and slave.

6. Press the [S] key on the master while the master displays

“CLONE MODE”. The data of the master is sent to the

slave. While the slave is receiving the data, “PROGRAM”

is displayed. When cloning of data is completed, the master displays “END”, and the slave automatically operates

in the User mode. The slave can then be operated by the

same program as the master.

7. The other slave can be continuously cloned. When the [S]

key on the master is pressed while the master displays

“END”, the master displays “CLONE MODE”. Carry out

the operation in step 4 to 6. Can not be cloned if the overwrite password is programmed to the slave.

] and [ ] keys is pressed while “CLONE LOCK” is

] and [ ] keys;

8. Firmware Version Information

Turn the transceiver ON with the [ ] key held down.

Then, the version is displayed during holding the [

] key.

9. Clock Adjustment Mode

9-1. Flow chart of operation

[C] + Power ON

YEAR

[S]

MONTH

[S]

DAY

[S]

HOUR

[S]

MINUTE

[S]

[ ] and [ ] keys

[ ] and [ ] keys

[ ] and [ ] keys

[ ] and [ ] keys

[ ] and [ ] keys

Completion

Note:

Only the same models can be cloned together.

Cloning cable

(E30-3382-05)

Fig. 2

6

Page 7

KDS-100, KGP-2A,

KGP-2B or through

KCT-36 extension cable

q

e

w

INSTALLATION

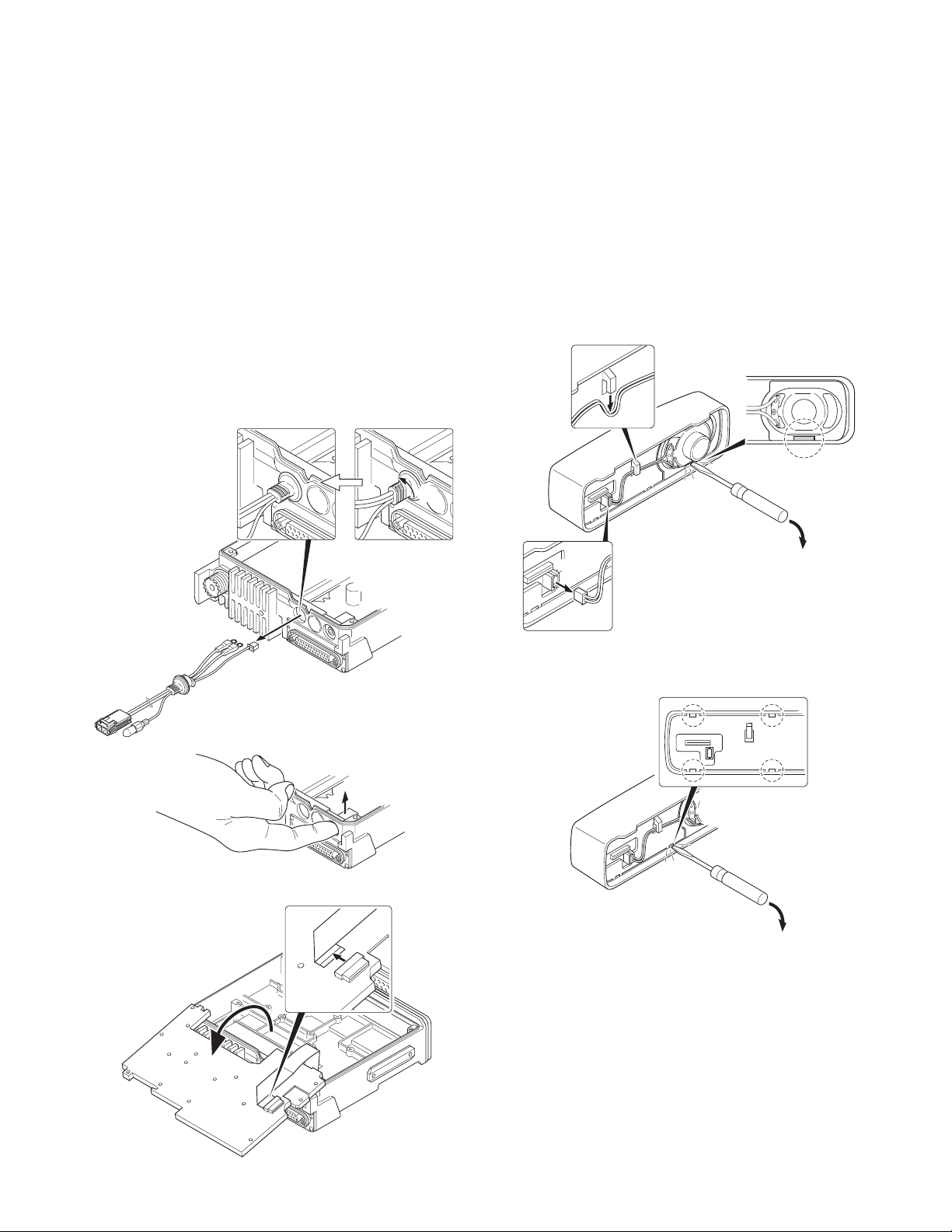

1. Ignition Sense Cable (KCT-46 : Option)

The KCT-46 is an optional cable for enabling the ignition

function. The ignition function lets you turn the power to the

transceiver on and off with the car ignition key.

1-1. Connecting the KCT-46 cable to the transceiver

1. Open the KCT-46 fuse holder and insert a mini blade fuse

(3A). ( q )

2. While holding a clear protective cover, remove the black

cap at the end of the yellow cable (ignition sense cable) of

the transceiver. ( w )

3. Connect the plug of the KCT-46 to the yellow cable termi-

nal of the transceiver. ( e )

4. Connect the other end of the KCT-46 to the ignition line of

the car. ( r )

Note : You must setup using the KPG-89D.

TK-8180

Fig. 2

w

e

F52-0019-05

q

r

Iginition line

of the car

Fig. 1

2. Radio Interface Cable (KCT-40 : Option)

The KCT-40 connection cable kit is used to connect the

TK-8180 transceiver to the KDS-100 (Mobile data terminal),

KGP-2A (Modem GPS receiver), KGP-2B (Modem GPS controller) or through the KCT-36 extension cable.

2-1. Connecting the KCT-40 cable to the transceiver

1. Remove the D-sub cap on the rear of the transceiver. ( q )

2. Connect the D-sub connector of the KCT-40 to the D-sub

25-pin terminal of the transceiver. ( w )

3. Connect the 15-pin connector of the KCT-40 to a KDS-100,

KGP-2A, KGP-2B or through a KCT-36 extension cable.

( e )

Note : You must setup using the KPG-89D.

2-2. Terminal function

D-sub 25-pin

Pin No. Function Pin No. Function Function

1- ---

2- ---

3- ---

4- ---

5DI5DO DO

6- ---

7 GND 3 GND GND

8 AIO8 9 TXS/LOK TXS/LOK

9 TXD2 15 RXD RXD

10 RXD2 14 TXD TXD

11 - ---

12 AIO7 11 MM MM

13 AIO6 6 PTT PTT

14 SB 1 SB SB

15 - ---

16 - ---

17 - ---

18 - ---

19 DEO 4 DI DI

20 AIO5 8 SQ SQ

21 AIO4 10 AM AM

22 AIO3 13 - DISP OFF

23 AIO2 12 - -

24 AIO1 7 DTC DTC

25 - ---

TK-7180

Molex 15-pin

KDS-100 KGP-2A/2B

7

Page 8

TK-8180

INSTALLATION

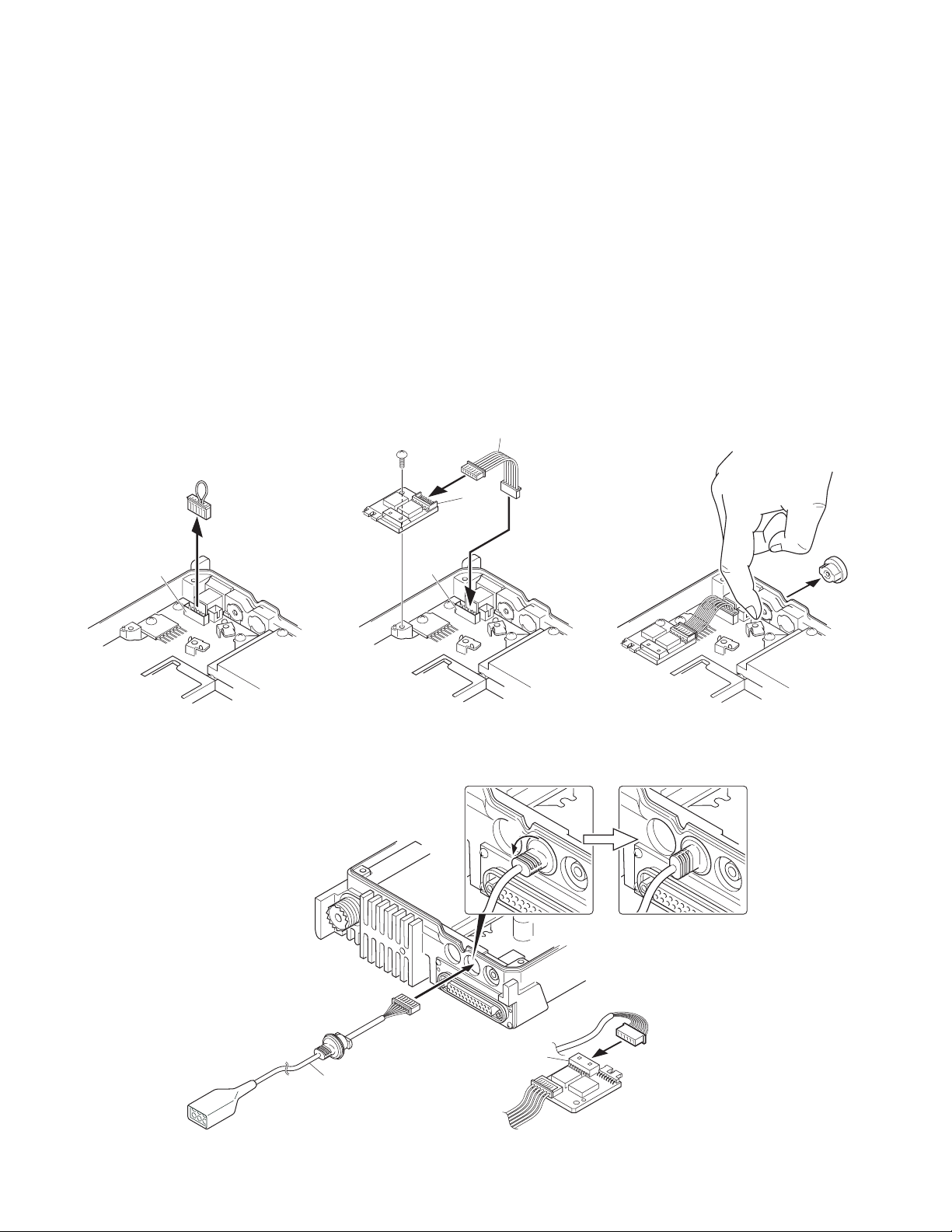

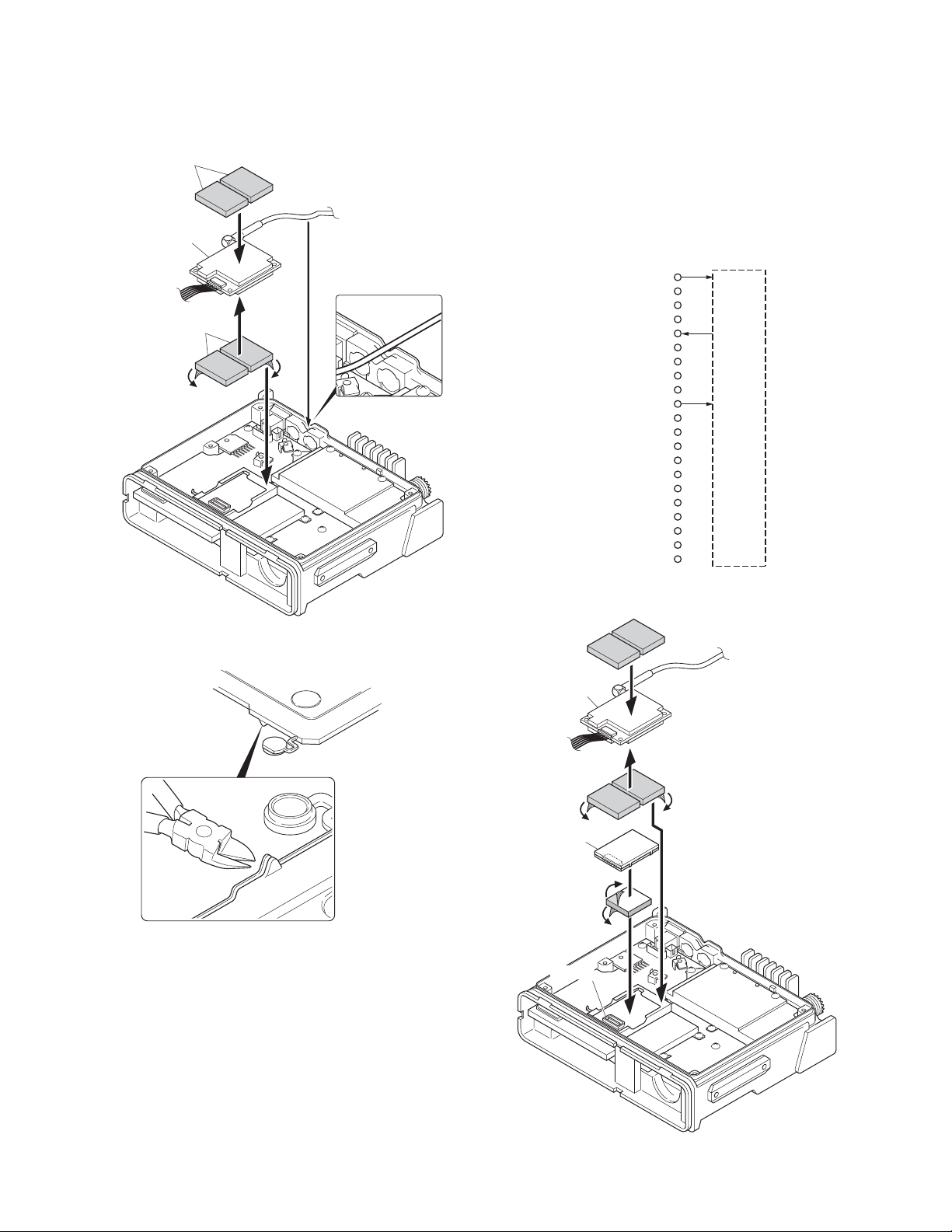

3. Horn Alert/P.A. Relay Unit (KAP-2 : Option)

The Horn alert (max. 2A drive), Public address and External

speaker function are enabled by installing the KAP-2 in the

TK-8180 transceiver.

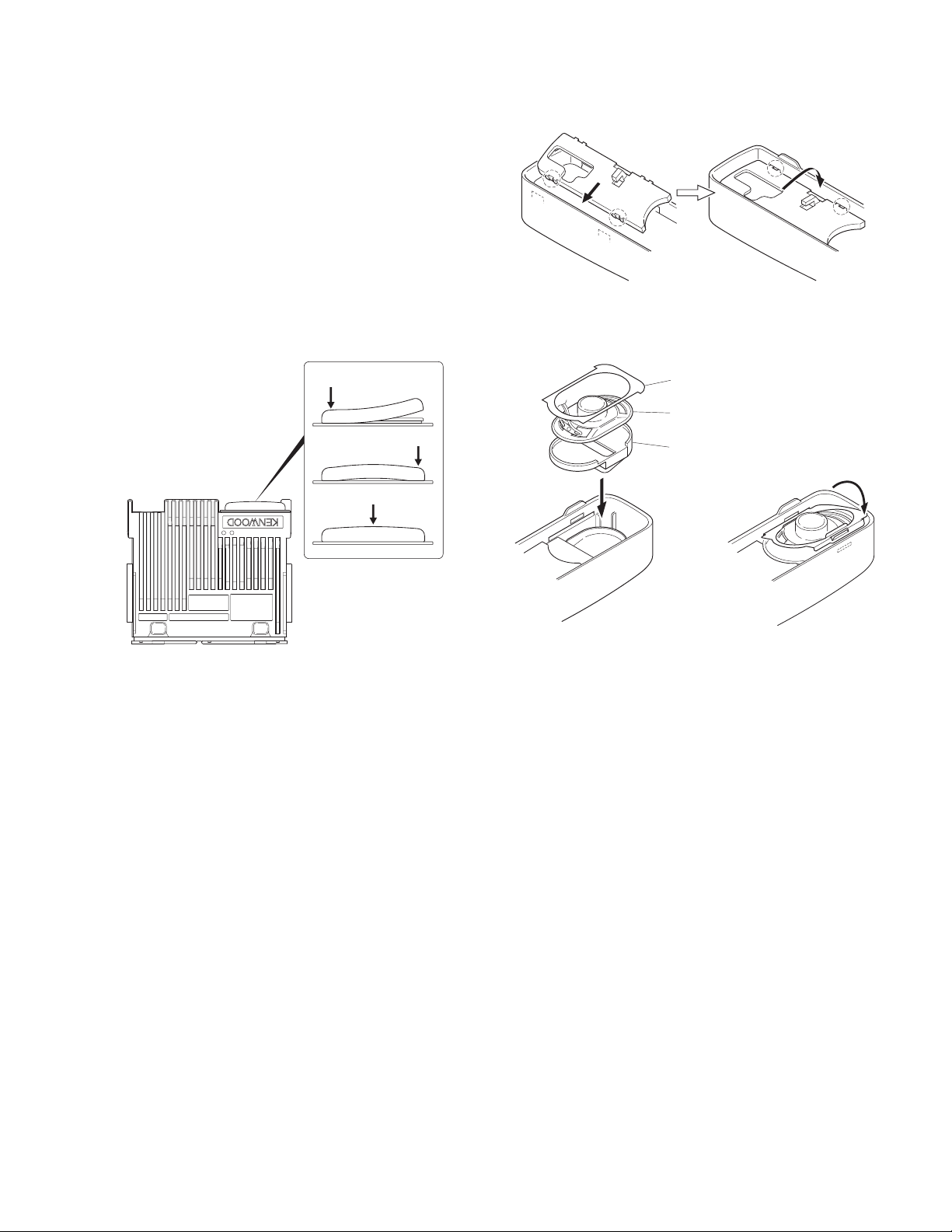

3-1. Installing the KAP-2 unit in the transceiver

1. Remove the cabinet, top packing and shielding plate of the

transceiver.

2. Set the KAP-2 relay unit jumper pins according to the purpose of use.

3. Remove the 6-pin jumper connector inserted in the TX-RX

unit (B/3) connector (CN428). ( q )

4. Insert one side of the lead wire with connector (E37-1114-

05) into the relay unit connector (CN3) ( w ) and the other

side into the TX-RX unit (B/3) connector (CN428) ( e ).

5. Place the relay unit at the position shown in Figure 3-2 and

secure it to the chassis with a screw.

6. Remove the cap on the rear of the chassis by pushing it

from the inside with your finger. ( r )

7. Pass the 6-pin connector of the cable (E37-1113-05)

through the chassis hole ( t ) and insert the bush into the

chassis hole.

8. Rotate the bush of the cable 90 degrees counterclockwise

as viewed from the rear of the chassis. ( y )

9. Insert the 6-pin connector of the cable into the connector

(CN2) of the KAP-2 relay unit. ( u )

Note : You must setup using the KPG-89D.

E37-1114-05

w

CN3

e

q

CN428

CN428

Fig. 3-1 Fig. 3-2 Fig. 3-3

y

r

t

CN2

E37-1113-05

u

Fig. 3-4

8

Page 9

CN1

KRK-10 main panel

u

i

INSTALLATION

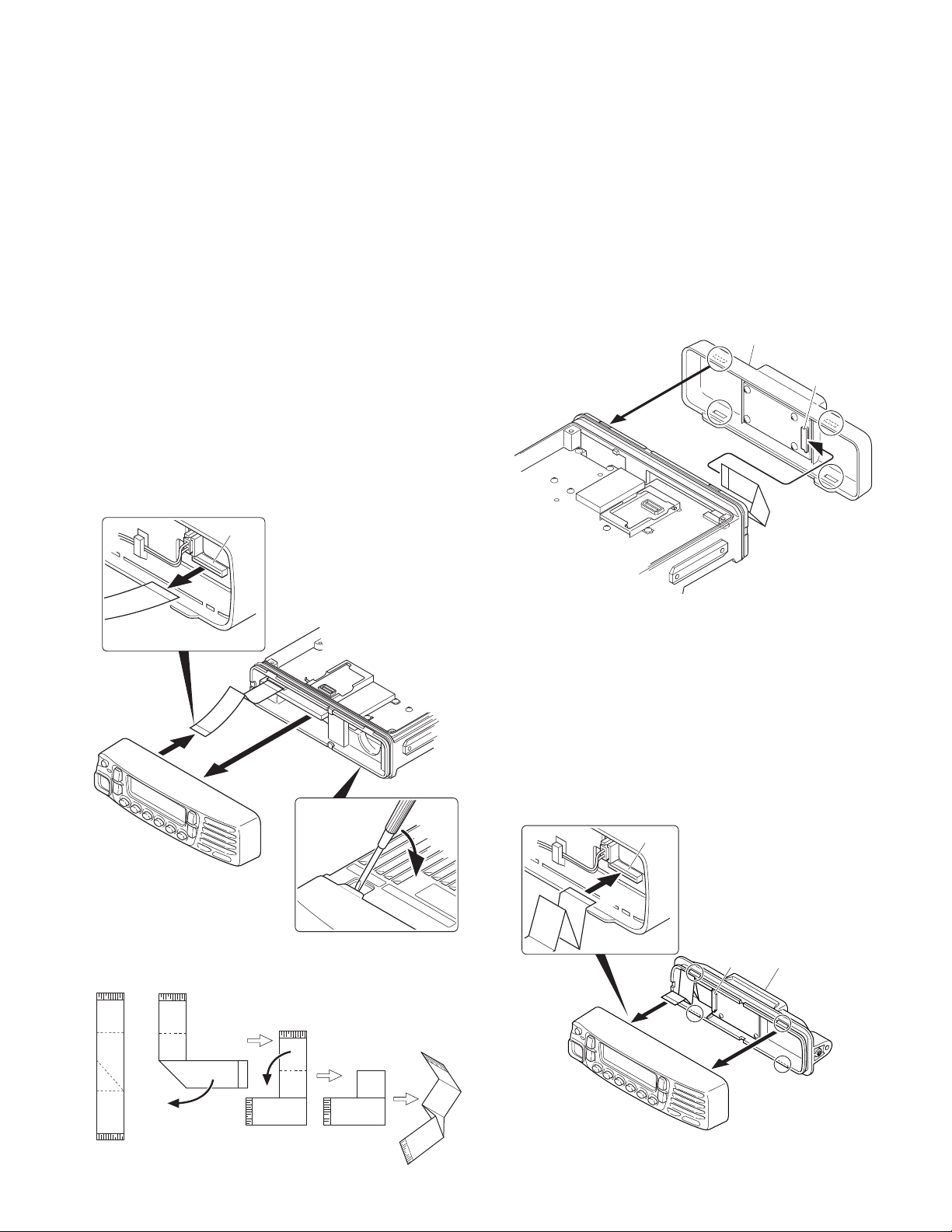

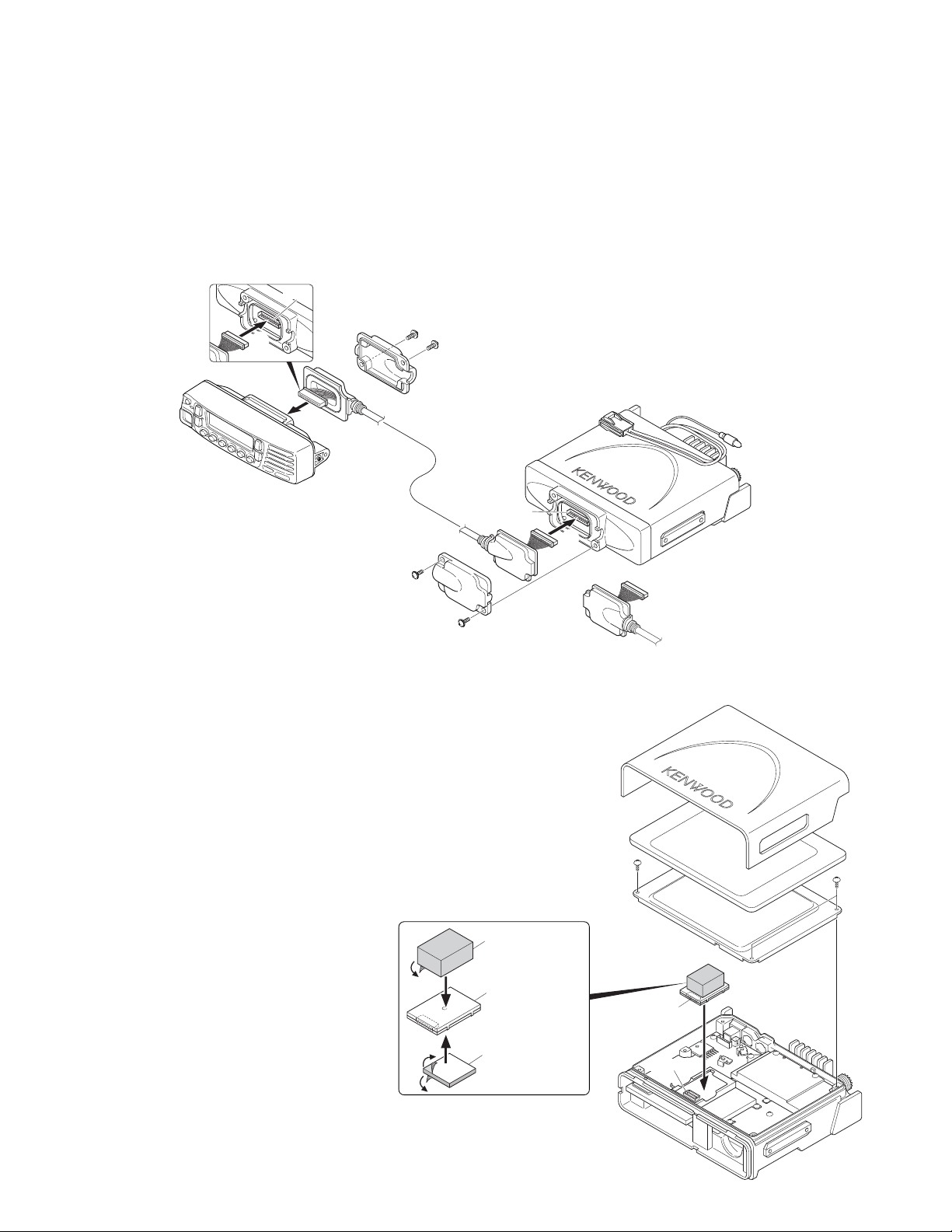

4. Control Head Remote Kit (KRK-10 : Option)

The KRK-10 remote kit is used to remotely operate a TK-

8180 transceiver.

4-1. Installing the KRK-10 kit to the transceiver

1. Remove the front panel from the transceiver.

2. Install the KRK-10 main panel onto the transceiver.

3. Install the KRK-10 rear panel onto the front panel.

4. Connect the KRK-10 main panel to the rear panel with the

cable.

■ Remove the front panel from the transceiver

1. Lift the two tabs of the panel on the bottom of the transceiver with a flat-head screwdriver ( q ) and remove the

panel from the chassis ( w ).

Note : Confirm that the tabs of the speaker hardware fixture and holder is securely fitted in the front panel.

2. Remove the flat cable from the connector (CN902) of the

display unit of the panel. ( e )

3. Fold the black line of the flat cable (in three parts) as

shown in Figure 4-2. ( r, t, y )

TK-8180

■

Install the KRK-10 main panel onto the transceiver

4. Insert the flat cable that was removed in step 2 above into

the connector (CN1) of the interface unit (A/2) of the KRK10 main panel (A62-1101-01). ( u )

Note : The terminal side of the flat cable must face down

when inserting the flat cable into the connector.

5. Fit the main panel with four tabs onto the front of the

chassis. ( i )

Note : When installing the main panel onto the front of the

chassis, hold down the flat cable with your fingers to prevent it from being caught.

Chassis

side

r

CN902

e

w

Fig. 4-1

q

Fig. 4-3

■ Install the KRK-10 rear panel onto the front panel

6. Insert the flat cable attached to the interface unit (B/2) of

the KRK-10 rear panel (A82-0056-01) into the connector

(CN902) of the display unit of the panel ( o ). (The flat

cable has been pre-inserted in the connector (CN2) of the

rear panel at the time of shipping.)

Note : The terminal side of the flat cable must face down

when inserting the flat cable into the connector.

7. Fit the four tabs of the rear panel into the front panel. ( !0 )

CN902

o

CN2

KRK-10 rear panel

y

r

t

Panel

side

t

Fig. 4-2

y

!0

Fig. 4-4

9

Page 10

TK-8180

CN1

CN403

q

w

Cushion

(G13-1994-04)

20 x 30 x 12 mm

Cushion

(G13-1992-04)

21 x 21 x 2.5 mm

VGS-1

CN4

■ Connect the KRK-10 main panel to the rear panel

with the cable

8. Insert one 14-pin connector of the cable (E30-7514-05)

into the connector (CN3) of the interface unit (A/2) of the

main panel. ( !1 )

9. Secure the cable bush on the main panel and fit the water-

proof packing (orange) ( !2 ) securely over top.

!5

!6

INSTALLATION

10. Install the molded cover ( !3 ) over the connector on the

main panel and secure it with two screws ( !4 ).

11. Insert the other 14-pin connector of the cable into the

connector (CN4) of the interface unit (B/2) of the rear

panel. ( !5 )

12. Secure the cable bush on the rear panel and fit the waterproof packing (orange) ( !6 ) securely over top.

13. Install the molded cover ( !7 ) over the connector on the

rear panel and secure it with two screws ( !8 ).

Note : A cable can be connected from the left side as shown

in the Figure 4-5 or from right side.

However, the 14-pin connector must be connected to correct

direction.

!7

!8

!8

!4

5.

Voice Guide & Storage Unit (VGS-1 : Option)

5-1. Installing the VGS-1 unit in the transceiver

1. Remove the cabinet, top packing and shielding plate of the

transceiver.

2. Attach two cushions to VGS-1 as shown in Figure 5. ( q )

Note : Be sure not to cover the connector with the bottom

cushion.

3. Insert the VGS-1 connector (CN1) into the TX-RX unit (B/3)

connector (CN403). ( w )

Note : You must setup using the KPG-89D.

!3

!4

Fig. 4-5

CN3

!1

!2

!2

(Right side)

10

Fig. 5

Page 11

INSTALLATION

6. Voice Scrambler Board Connection

1. Remove the front panel from the transceiver.

2. Solder each lead of the scrambler board to a necessary

location of each landing on the component side of the TXRX unit (B/3).

3. Wrap the scrambler board in a cushion and install it on the

front of the chassis as shown in Figure 7-2.

Note : You must setup using the KPG-89D.

TX-RX unit (B/3)

Solder land

GND (GND)

RXD1

TXD1 (PTT)

TXD2

OPT1 (CODE SELECT1)

OPT3 (CODE SELECT2)

OPT4 (ECHO PTT)

OPT5 (CODE SELECT8)

OPT2 (SCRAMBLE)

RXEO (RX OUT)

OPT6 (CODE SELECT4)

7. ANI Board Connection

1. Remove the front panel from the transceiver.

2. Solder each lead of the scrambler board to a necessary

location of each landing on the component side of the TXRX unit (B/3).

3. Wrap the scrambler board in a cushion and install it on the

front of the chassis as shown in Figure 7-2.

Note : You must setup using the KPG-89D.

OPT1 (CH BUSY)

OPT5 (EMERGENCY)

DTI (DATA OUT)

TCTL (TONE CTRL)

AUDIH (AUDIO INHIB)

OPT2 (AUX I/O)

STON (SIDE TONE)

RXD2

DTI

TCTL

TXO (TX OUT)

AUDIH

STON

TXI (TX IN)

RXEI (RX IN)

8C (+V)

Fig. 6

TX-RX unit (B/3)

Solder land

GND (A–)

RXD1

TXD1

TXD2

RXD2

OPT3 (KEY)

OPT4 (PTT)

5E (A+)

TXO

RXEO

TXI

RXEI

OPT6

8C

Fig. 7-1

5E

Voice scrambler

ANI board

TK-8180

ANI board

3M double coated cushion

No. 4008 (or No.4408)

25 x 110 mm

Voice scrambler board

Fig. 7-2

8. GPS Receiver Connection

8-1. Installing the GPS receiver

1. Remove the cabinet, top packing and shielding plate of the

transceiver.

2. Remove the front panel from the transceiver.

3. Attach two cushions to the top of the GPS receiver.

4. Attach the GPS receiver to the shield case with two cushions as shown in Figure 8-2.

5. Solder each lead of the GPS receiver to a necessary location of each landing on the component side of the TX-RX

unit (B/3).

6. Place the GPS antenna cable in the hollow at the rear of

the chassis. (Fig. 8-2 q )

Note : If the GPS receiver is installed, cut the base of the

convex tab of the top packing with a pair of nippers, or

similar tool. (Fig. 8-3 w )

If the convex tab of the top packing is cut off, the water

proofing property is no longer guaranteed.

Note : You must setup using the KPG-89D.

TX-RX unit (B/3)

Solder land

RXD1 (DATA OUT1)*

GND (GND)

RXD2 (DATA OUT1)*

*1 : Depending on the connected optional accessory, the

DATA OUT1 may connect to either RXD1 or RXD2.

TXD1

TXD2

OPT1

OPT3

OPT4

OPT5

5E (+5V)

DTI

TCTL

TXO

AUDIH

OPT2

STON

RXEO

TXI

RXEI

OPT6

8C

Fig. 8-1

1

1

GPS receiver

11

Page 12

TK-8180

TX-RX unit (B/3)

Solder land

GND (GND)

RXD1

TXD1

TXD2

RXD2 (DATA OUT1)

OPT1

OPT3

OPT4

OPT5

5E (+5V)

DTI

TCTL

TXO

AUDIH

OPT2

STON

RXEO

TXI

RXEI

OPT6

8C

GPS receiver

INSTALLATION

3M Double coated cushion

No. 4016 (or No. 4416)

30 x 25 mm

GPS receiver

3M Double coated cushion

No. 4016 (or No. 4416)

30 x 25 mm

4. Insert the VGS-1 connector (CN1) into the TX-RX unit (B/3)

connector (CN403).

5. Perform step 3 to 6 of “8-1. Installing the GPS receiver”

described on page 11.

Note : You must setup using the KPG-89D.

q

Fig. 8-4

8-2.

1. Remove the cabinet, top packing and shielding plate of the

2. Remove the front panel from the transceiver.

3. Attach a cushion to the bottom of the VGS-1 as shown in

12

Fig. 8-2

w

Fig. 8-3

Installing the GPS receiver together with the VGS-1

transceiver.

Figure 8-5.

Note : Be sure not to cover the connector with the cushion.

GPS receiver

VGS-1

CN1

CN403

Fig. 8-5

Page 13

CN901

w

q

e

DISASSEMBLY FOR REPAIR

TK-8180

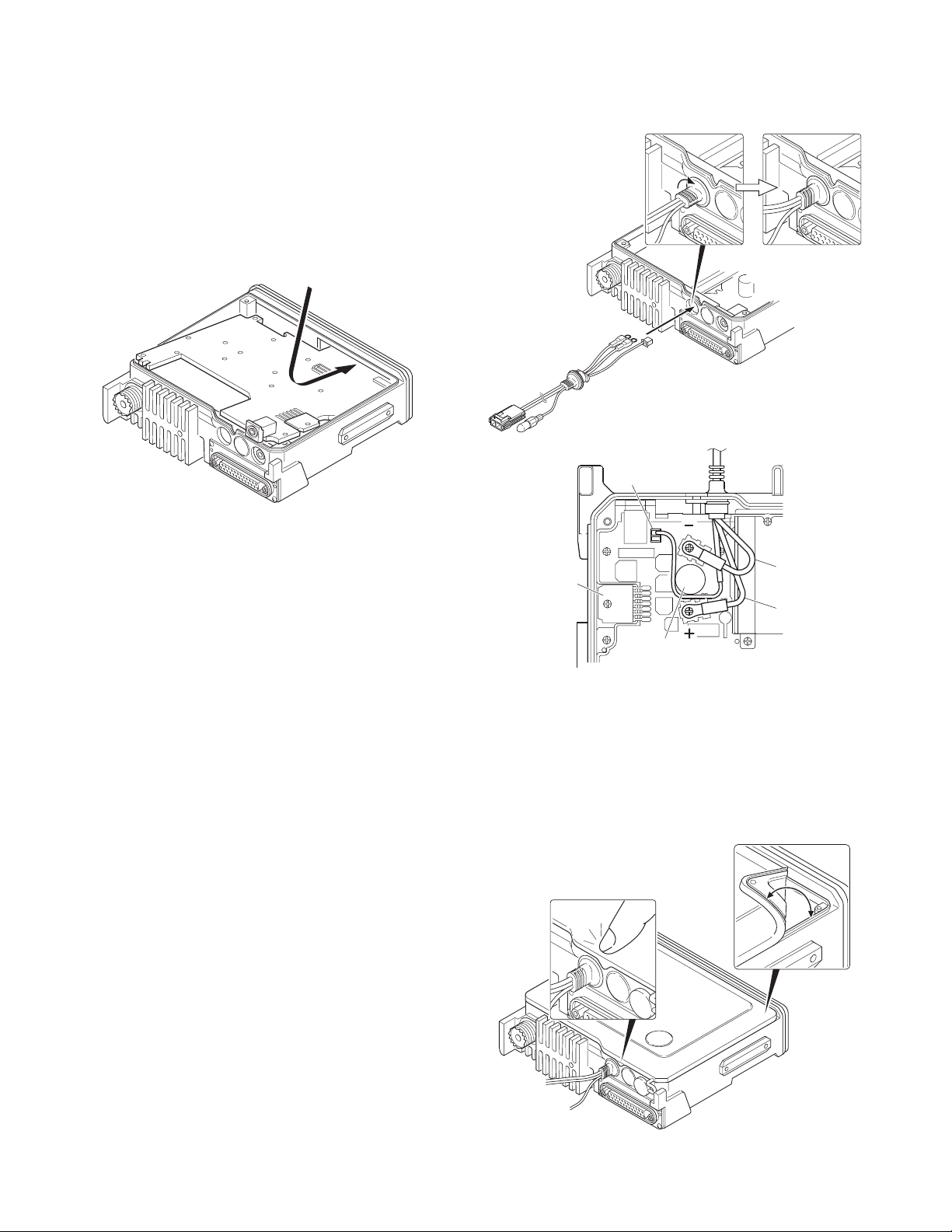

1. Precautions on Disassembly

■ TX-RX PCB (TX-RX unit B/3) Disassembly

1. Remove all screws and antenna terminals on the TX-RX

PCB.

2. Rotate the bush of the power supply cable 90 degrees

counterclockwise as viewed from the rear of the chassis

( q ) and remove the power supply cable from the chassis

( w ).

3. When the speaker phone jack is pushed up, using your

finger, from the rear of the chassis ( e ), the TX-RX PCB is

removed from the chassis.

Note : The TX-RX PCB and D-sub PCB (TX-RX unit A/3) are

connected with a flat cable. Remove them carefully.

4. Turn the TX-RX PCB over and remove the flat cable from

the connector (CN427). ( r )

5. Remove the TX-RX PCB from the chassis.

q

■ Removing the speaker hardware fixture

(J21-8481-03) and holder (J19-5468-03)

1. Remove the speaker lead from the holder hook. ( q )

2. Remove the speaker connector from the display unit con-

nector (CN901). ( w )

3. When removing the speaker hardware fixture, insert a flat-

head screwdriver at the position shown in Figure 2-1 and

tilt it in the direction shown by the arrow. ( e )

4. To remove the holder, insert a flat-head screwdriver into

tab of the holder and tilt it in the direction shown by the

arrow. ( r )

w

Fig. 1-1

Fig. 1-2

Fig. 2-1

e

r

r

Fig. 2-2

CN427

Fig. 1-3

13

Page 14

TK-8180

DISASSEMBLY FOR REPAIR

2. Precautions on Reassembly

■ TX-RX PCB (TX-RX unit B/3) Reassembly

1. With the TX-RX PCB turned over, insert the flat cable from

the D-sub PCB (TX-RX unit A/3) into the connector

(CN427) on the TX-RX PCB.

2. Place the TX-RX PCB at its original position, tilt the TX-RX

PCB and install the chassis as shown in Figure 3.

w

q

Fig. 4-1

CN804

Fig. 3

■ Securing the Audio IC (IC417) with screws

The screws for the audio IC are 8mm screws. These are

longer than the other screws, so take care not to confuse

them.

■ FINAL shield case (F10-2489-03) installation

procedure

1. Place the shield case on the final section of the TX-RX unit

(B/3).

2. The shield case is installed on the positioning boss of the

chassis by pushing down on “PUSH2” (on the shield case)

while pushing “PUSH1” (stamped on two parts on the

shield case) to the right.

■ Power supply cable installation procedure

1. Pass the power supply cable through the chassis hole

( q ) as shown in Figure 4-1 and insert the bush into the

chassis hole.

2. Rotate the bush of the power supply cable 90 degrees

clockwise as viewed from the rear of the chassis. ( w )

3. Align the ignition sense connector (yellow) of the power

supply cable around the chemical capacitor (C801) and

connect it to the TX-RX unit (B/3) connector (CN804).

4. Align the + (positive) terminal of the power supply cable

(red) as shown in Figure 4-2 and fix it to the terminal strip

with a screw.

5. Align the – (negative) terminal of the power supply cable

(black) as shown in Figure 4-2 and fix it to the terminal strip

with a screw.

IC417

Black

Red

C801

Fig. 4-2

■ Top packing installation procedure

1. Place the top packing over the shielding plate.

2. Fit the convex tab of the top packing into the hollow of the

chassis. ( q )

3. Fit the chassis into the groove of the top packing. ( w )

Verify that the top packing is in close contact with the

chassis.

w

q

14

Fig. 5

Page 15

q

w

DISASSEMBLY FOR REPAIR

■ D-sub cap installation procedure

To improve water resistance, fit the D-sub cap into the Dsub terminal hardware fixture of the transceiver in the following order:

1. Fit the left side ( q ) of the D-sub cap into the hardware

fixture.

2. Fit the right side ( w ) of the D-sub cap into the hardware

fixture.

3. Fit the center ( e ) of the D-sub cap into the hardware fix-

ture.

Verify that the D-sub cap is in close contact with the hard-

ware fixture.

TK-8180

Fig. 7-1

q

w

e

Fig. 6

■ Installing the holder (J19-5468-03) and speaker

hardware fixture (J21-8481-03)

1. Insert two tabs of the holder (J19-5468-03) into the hol-

lows in the top of the panel. ( q )

2. Push the two tabs of the holder in on the opposite side of

those in step 1 above and fit them into the hollow in the

bottom of the panel. ( w )

Note : Push in the holder until it snaps in place.

3. Install the speaker holder onto the panel. ( e )

Note : To improve water resistance, fit the panel into the

groove of the holder.

4. Place the speaker into the speaker holder.

Note : The speaker must not ride on the holder rib.

5. Place the spacer on the speaker.

6. Insert the hardware fixture (J21-8481-03) into the hollow

of the panel as shown in Figure 7-3, then push two parts

of the hardware fixture and fit it into the hollow of the top

of the panel. (Fig. 7-3 r )

Note : Push in the hardware fixture until it snaps in place.

7. Insert the speaker connector into the display unit connec-

tor (CN901).

8. Place the speaker lead on the holder hook.

Spacer

Speaker

Speaker holder

e

Fig. 7-2 Fig. 7-3

r

15

Page 16

TK-8180

CIRCUIT DESCRIPTION

1. Outline

The TK-8180 is a UHF/FM transceiver designed to operate

in the frequency range of 450 to 520MHz. Transmission output power is 30 watts (490~520MHz : 25W). The maximum

channel capacity is 512.

The unit consists of receiver, transmitter, phase-locked

loop (PLL) frequency synthesizer, and control circuits.

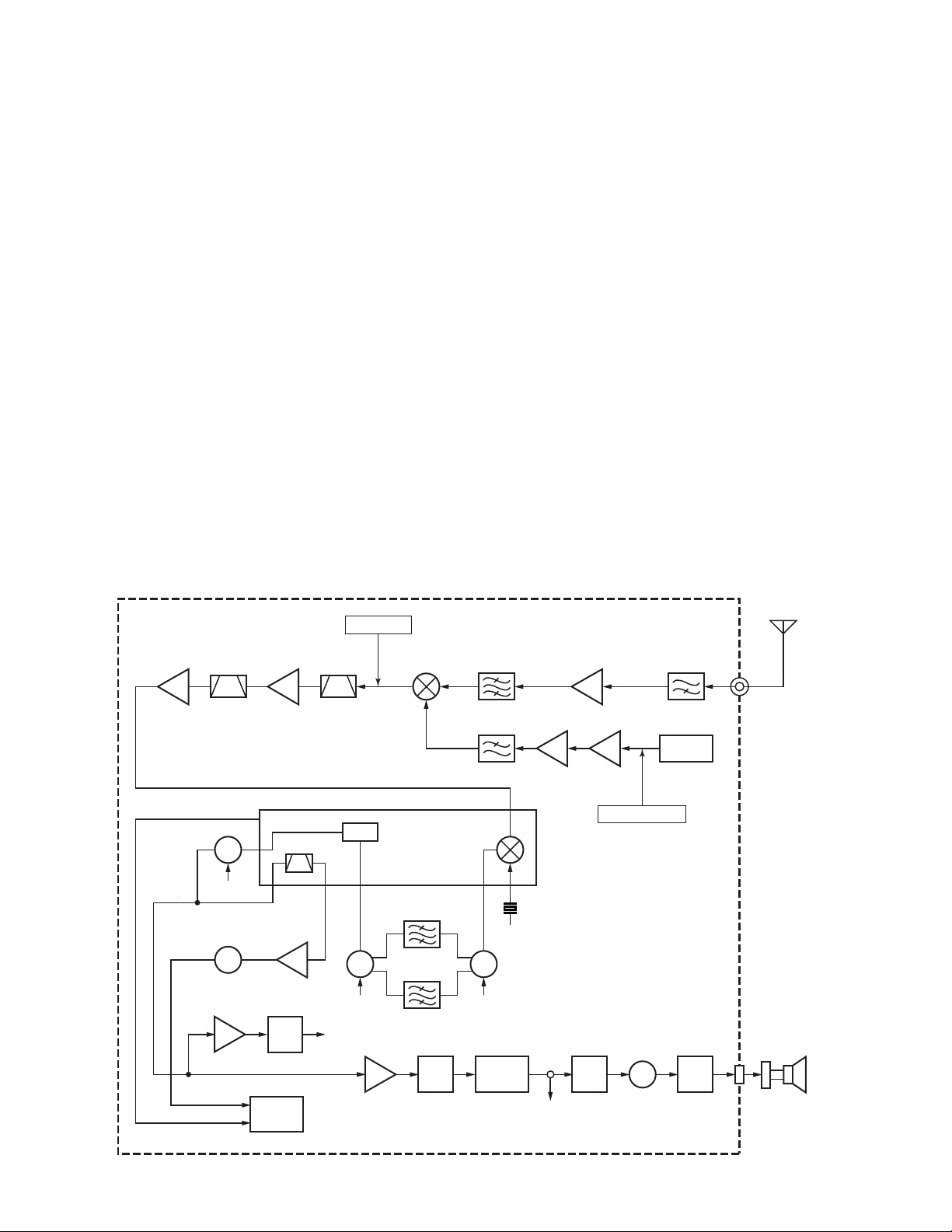

2. Receiver Circuit

The receiver is double conversion superheterodyne, de-

signed to operate in the frequency range of 450MHz to

520MHz.

The receiver circuit consists of the following : 2-1 front-

end circuit, 2-2 first mixer, 2-3 IF amplifier circuit, 2-4 audio

amplifier circuit, and 2-5 squelch circuit.

2-1. Front-end Circuit

The front-end circuit consists of former HPF (D107, D108,

D109 and D110), RF amplifier Q103, and latter BPF (D103,

D104, D105 and D106). The BPF covers frequency ranges

450 to 520MHz.

The latter BPF (D103, D104, D105 and D106) attenuates

the unwanted signals, and sends only the necessary signal to

the first mixer.

TX-RX UNIT (X57-699)

44.85MHz

IF AMP

Q172

MCF MCF

IF AMP

Q171

1st MIX DBM

IC171

2-2. First Mixer

The signal from the BPF is heterodyned with the first local

oscillator signal from the PLL frequency synthesizer circuit at

the first mixer DBM (IC171) to become a 44.85MHz first intermediate frequency (IF) signal. The first IF signal is fed

through a monolithic crystal filter (XF171) to further remove

spurious signals.

2-3. IF Amplifier

The first IF signal is amplified by Q171 and Q172, and then

enters IC172 (FM system IC). The signal is heterodyned

again with a second local oscillator signal (44.395MHz) with

in IC172 to become a 455kHz second IF signal. The second

IF signal is fed through a 455kHz ceramic filters (CF172;

Wide, CF171; Narrow) to further eliminate unwanted signal,

and the quadrature detection circuit FM-detects the signal to

produce a base-band signal and output it from pin 9.

2-4. Audio Amplifier

The demodulated audio signal from IC172 goes to IC415

through the AF amplifier (IC412) and IC413. The audio signal

goes to an electronic volume (IC410) and is amplified to drive

a loudspeaker by an audio power amplifier (IC417). The audio

output can be provided to external 4Ω speaker through the

speaker jack output (J401) on the rear panel. Q419 is a mute

switch.

450~520MHz

RX ANT

BPF

D103~D106

RF AMP

Q103

HPF

D107~D110

RSSI

DET

SQL

XF171

(2/2)

Q178

SW

W/N

NOISE DET

D173

DET

IC407

ASQ

RSSI

XF171

(1/2)

FM SYSTEM IC : IC172

QUD

NOISE

AMP

Q175

SW

D172

IC410

DAC

IC404

CPU

CFSW

DEO

AMP

IC412 (B/2)

CF172

(Wide)

CF171

(Narrow)

455kHz

IC413

SW

LPF

SW

CFSW

IC415

AQUA

D171

-L

Buff AMP

Q313

X171

44.395MHz

AFO

Buff AMP

Q311

RX

–44.85MHz

f

405.15~475.15MHz

IC410

DAC

Q419

MUTE

Q306

RX VCO

IC417

AF

AMP

INT. SP

16

Fig. 1 Receiver circuit

Page 17

CIRCUIT DESCRIPTION

TK-8180

2-5. Squelch Circuit

The output signal from IC172 enters FM IC again, then

passed through a band-pass filter.

The noise component output from IC172 is amplified by

Q175 and rectified by D173 to produce a DC Voltage corresponding to the noise level. The DC voltage is sent to the

analog port of the CPU (IC404).

IC172 outputs a DC voltage (RSSI) corresponding to the

input of the IF amplifier.

3. Transmitter Circuit

The transmitter circuit consists of the following circuits : 31 microphone circuit, 3-2 modulation level adjustment circuit,

3-3 driver and final power amplifier circuit, and 3-4 automatic

power control circuit.

3-1. Microphone Circuit

The audio signal from the microphone goes into TX-RX

unit (X57-699) from the display unit (X54-348) and passes

through the mute switch (Q416). The audio signal is amplified by the microphone amplifier (IC414) and is input into the

TXIN terminal of the audio processor (IC415) after passing

through the multiplexer (IC413).

The input audio signal is output from the MOD terminal of

the audio processor (IC415) and is amplified by the audio frequency amplifier (IC412) after passing through the electric

volume (IC410).

DISPLAY UNIT

(X54-348) TX-RX UNIT (X57-699)

3-2. Modulation Level Adjustment Circuit

The audio signal amplified by the audio frequency amplifier (IC412) is added to the low speed data LSD passed

through the low pass filter (IC409). The combined signals is

supplied to the VCO (voltage controlled oscillator) and the

VCXO (voltage controlled crystal oscillator) X301, respectively.

3-3. Driver and Final Power Amplifier Circuit

The transmit signal obtained from the TX VCO buffer amplifier Q311, is amplified to approximately +17dBm by the

driver amplifiers Q313, Q1 and Q2. This amplified signal is

passed to the power amplifier module (power module) IC1,

which consists of a MOS-FET amplifier and is capable of

transmission output power.

3-4. Automatic Power Control Circuit

The automatic transmission power control (APC) circuit

stabilizes the transmitter output power at a predetermined

level by detecting the power module output with a diodes

D6, D7 and D8. Diodes D6, D7 and D8 apply a voltage to DC

amplifier IC72 (A/2). IC72 (B/2) compares the APC control

voltage (PC) generated by microprocessor IC404 and DC amplifier IC71 (A/2, B/2) with the detection output voltage

from IC72 (A/2) to control the Vgg pin of IC1, and stabilizes

transmission output.

The APC circuit is configured to protect over-current of the

power module due to fluctuations of the load at the antenna

end and to stabilize transmission output at voltage and temperature variations.

J901

Mojular

jack

MIC

SW

SW

D-SUB

MI2

IC414Q416

AMP

Q417

IC413

Multi-

plexer

TXIN

D-SUB

DI

LSDO

AQUA-L

IC409

LPF

MOD

IC410 IC412IC415

DAC

AMP

IC408

DC

AMP

Fig. 2 Microphone and modultion level adjustment circuit

Q313

Drive

AMP

Q1

Drive

AMP

PC

MP

Q2

Drive

AMP

DC

AMP

IC71 IC72

IC1

Final

AMP

DC

AMP

Gate

bias

D2,D3,

D11

SW

D6 D7

DET

DET

D8

DET

MOD

MB

Q307

TX VCO

VCXO

16.8MHz

X301

Q311

Buff

AMP

Fig. 3 Drive and Final power amplifier and automatic power control circuit

MOD

(for VCO)

MB

(for VCXO)

ANT

17

Page 18

TK-8180

CIRCUIT DESCRIPTION

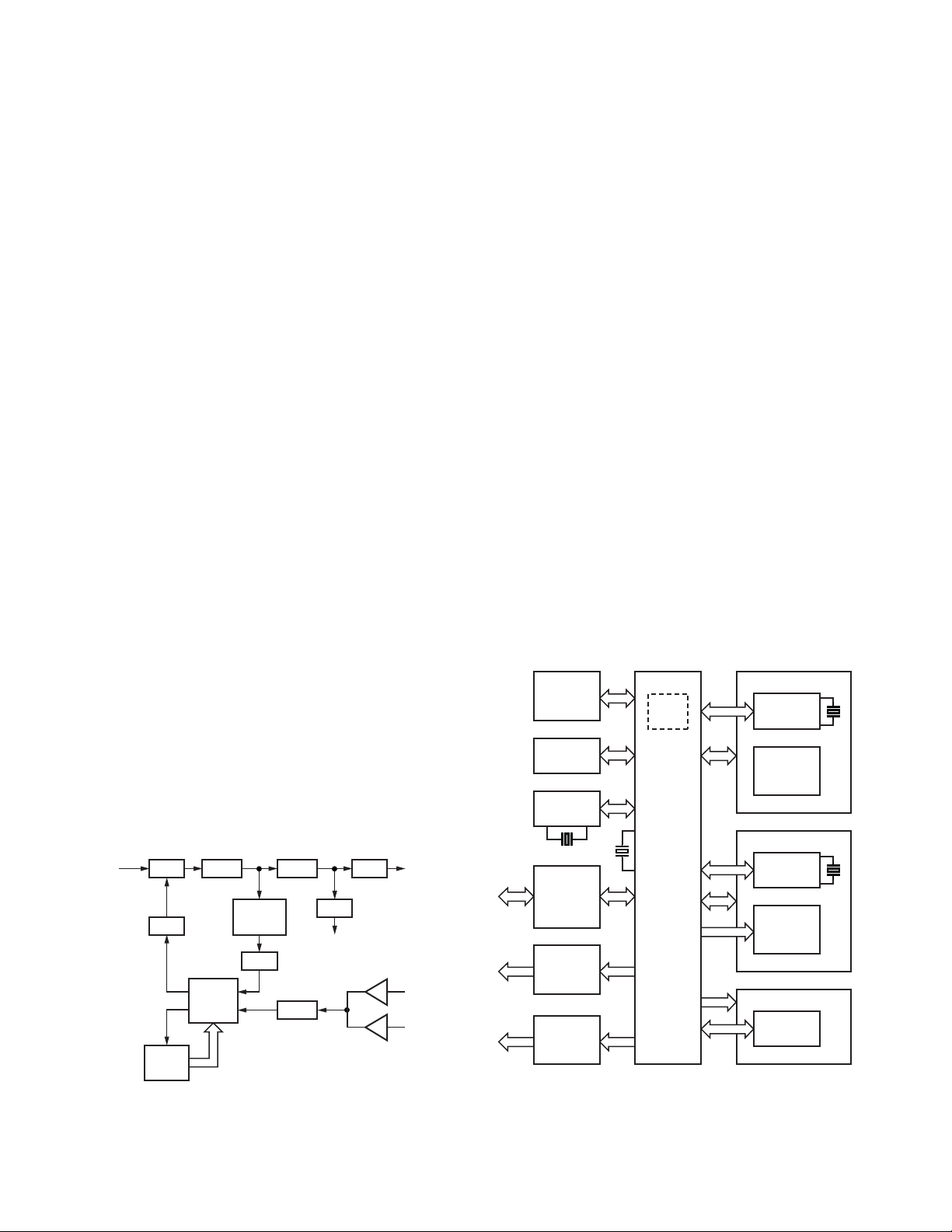

4. Frequency Synthesizer Unit

4-1. Frequency Synthesizer

The frequency synthesizer consists of the TCXO (X301),

VCO, PLL IC (IC301) and buffer amplifiers.

The TCXO generates 16.8MHz. The frequency stability is

2.5ppm within the temperature range of –30 to +60°C. The

frequency tuning and modulation of the TCXO are done to

apply a voltage to pin 1 of the TCXO. The output of the TCXO

is applied to pin 8 of the PLL IC.

The VCO consists of 2VCO and covers a dual range of the

405.15~475.15MHz and the 450~520MHz. The VCO generates 405.15~475.15MHz for providing to the first local signal

in receive. The operating frequency is generated by Q307 in

transmit mode and Q306 in receive mode. The oscillator frequency is controlled by applying the VCO control voltage, obtained from the phase comparator (IC301) to the variable capacitor diodes (D308 and D311 in transmit mode and D309

and D313 in receive mode).

The T/R pin of IC404 goes “high” in receive mode causing

Q307 and Q309 to turn off, and Q306, Q308 and Q310 turn

on. The T/R pin goes “low” in transmit mode.

The outputs from Q306 and Q307 are amplified by buffer

amplifier (Q311) and doubled by Q301 and then sent to PLL

IC.

The PLL IC consists of a prescaler, reference divider,

phase comparator, charge pump (The frequency step of the

PLL circuit is 20 or 25kHz). The input signal from the pins 8

and 5 of the PLL IC is divided down to the 20 or 25kHz and

compared at phase comparator. The phase comparator output signal is fed into a low-pass filter (Q302 and Q303) before

being applied to the VCO as a frequency control voltage. This

low-pass filter’s power is supplied by the DC/DC converter

(IC251 and Q251). The DC signal is applied to the CV of the

VCO and locked to keep the VCO frequency constant.

PLL data is output from DT (pin 112), PCK (pin 82) and PLE

(pin 81) of the microprocessor (IC404). The data are input to

the PLL IC when the channel is changed or when transmission is changed to reception and vice versa. A PLL lock condition is always monitored by the pin 80 (UL) of the microprocessor. When the PLL is unlocked, the UL goes low.

T/R

(TX : Low)

Q302

Q303

T/R

LPF

UL

CPU

IC404

CV

IC301

20

PLL

15

DT,PCK,PLE

Q311

BUFF

Q301

Doubler

x2

BPF

5

8

Q313

BUFFVCO

TCXO

X301

SW

To mixer

MB

D316

SW

D315

IC408

To

drive

amp

FC

BAL

5. Control Circuit

The block diagram of the control circuit is shown in Figure

5.

The CPU (IC404) is a 16-bit microcomputer that contains a

256k-byte Mask ROM and a 20k-byte RAM. This CPU is connected with an external 512k-byte Flash ROM (IC405) and

operates in memory expansion mode.

The Firmware Program is stored in the Flash ROM and the

user data and adjustment data are stored in the EEPROM

(IC401). The CPU and Flash ROM are connected with an 8 bit

bus and the EEPROM and RTC IC (IC402) are connected with

a I2C bus (*1). The RTC IC (IC402) has a clock function and is

controlled by the CPU (IC404).

Serial communication with a PC is performed through two

paths: through the 232C Level converter IC (IC416) and

through the Display Unit Panel CPU (IC902). The 8 bit Shift

Register (IC403) is used as an 8-port Extended Output Port.

IC410 is an 8 bit-8ch D/A converter. The channels are set as

follows:

Ch1 : Modulation balance

Ch2 : Deviation Factor

Ch3 : Max Power Level

Ch4 : Reception tuning circuit

Ch5 : Deviation Factor

Ch6 : Speaker volume

Ch7 : VCXO control voltage

Ch8 : DEO output level

*1: I2C bus is a registered trademark of PHILIPS of the Netherlands.

IC405

Flash

ROM

IC401

EEPROM

IC402

RTC IC

IC416

232C

Level

converter

IC403

8bit Shift

register

IC410

D/A

converter

Mask

ROM

IC404

CPU

Fig. 5 Control circuit block diagram

Display unit

IC902

CPU

IC903

LCD

driver

Signal block

IC415

AQUA-L

IC413

Multi-

plexer

RF block

IC301

PLL IC

18

Fig. 4 PLL block diagram

Page 19

CIRCUIT DESCRIPTION

TK-8180

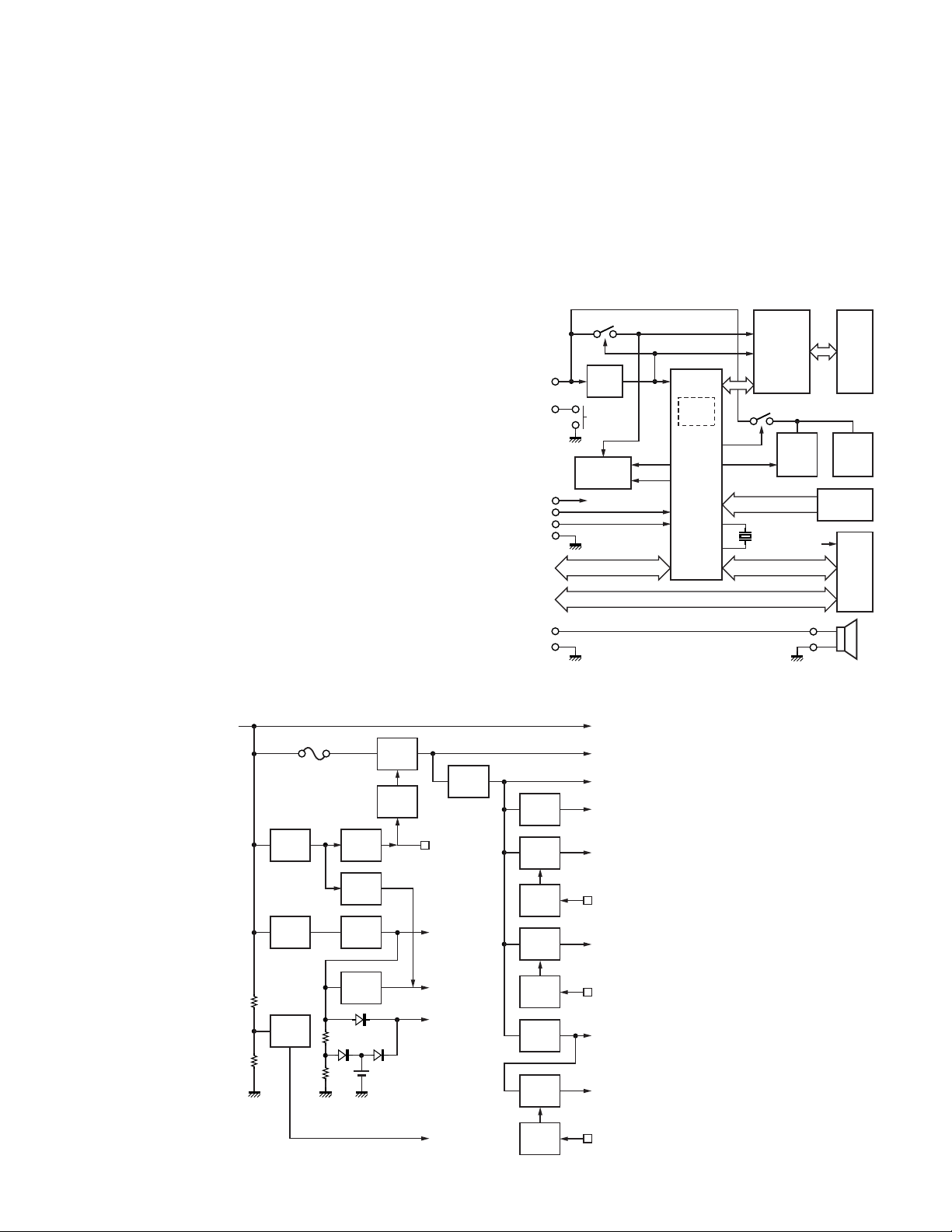

6. Power Supply Circuit

The block diagram of the power supply circuit is shown in

Figure 6.

Power is always supplied from +B to the circuit (5M, +B)

that is always started and the circuits (SB, 8C, 5E, 8T, 8R, 5C,

5R) controlled by the CPU (IC404). When +B is supplied to

the transceiver, Q801, D805 and IC805, regulate the voltage

(5M) which is supplied to the circuit around the CPU. The

CPU starts.

When the CPU detects that the +B voltage is higher than

the voltage prescribed by IC802, the transceiver power (SB)

is turned ON by controlling the SBC signal (Low: transceiver

power OFF, High: transceiver power ON).

The CPU controls the TXC signal (Low: Transmission system power OFF, High: Transmission system power ON) during transmission to supply power (8T) to the transmission circuit. The CPU controls the RXC signal (Low: Reception system power OFF, High: Reception system power ON) during

reception to supply power (8R, 5R) to the reception circuit.

When the CPU detects the PSW (Power Switch) signal,

IGN (Ignition Sense) signal or INT signal, it controls the SBC

signal and turns the transceiver power (SB) OFF.

If +B is not provided to the transceiver, power is supplied

to only the RTC IC (IC402) through the secondary battery connected with CN401 to back up the clock.

7. Display Circuit

The display unit consists of the Panel CPU (IC902), the

LCD driver (IC903), the TX/BUSY LED, the KEY detection, the

Backlight and the Microphone jack circuits.

The Panel CPU is a 16-bit microcomputer that contains a

64k-byte Mask ROM and a 2k-byte RAM.

Power supply : 10.8~15.7V

F801

5A

D804

DET

Q801,D805

REG

Q802

SW

Q812

SW

IC805

AVR

Q810

SW

Q807

SW

5M

SBC

CPU

Flash memory

EEPROM

Ext-I/O

IC803

AVR

The Panel CPU performs serial communication with the

Main CPU (IC404) on the TX-RX unit (B/3) and the Panel CPU

detects keys and sends data communication contents

through the MIC Jack to the Main CPU. The Panel CPU receives commands from the Main CPU and controls the display system.

The LCD operates with 1/9 duty under the LCD driver

(IC903) control. The LCD and KEY Backlights are controlled

by Q909. The display brightness of the LCD Backlight can be

changed.

Q910

IC903

8C

PSW

SB

RST2

SHIFT

PSENS

SPO

GND

IC901

AVR

POWER

SW

TX/Busy

LED

RXD, TXD

RED

GRN

Mask

ROM

IC902

CPU

MIC, ME

LCD

driver

Q909

BLCI

DIMM

HK, PTT, DM, BLC2

LCD

back

light

FKEY [1~10]

LCD

KEY

back

light

Function

KEY

SB

MIC

jack

SP

Fig. 7 Display circuit

+B

Final amp.

SB

Audio amp, PA connector

Panel block, D-sub block

8C

Internal option

Panel block

5E

IC807

AVR

Q803

SW

Q806

SW

Q804

SW

Internal option

TX-drive

8T

APC block

ANT SW

TXC

8R

IF block

IC802

DET

IC801

DET

CN401

CPU #17

: RST1

RTC IC

CPU #24

: INT

Fig. 6 Power supply circuit

Q808

SW

IC804

AVR

Q805

SW

Q809

SW

RXC

VCXO, VCO, PLL IC

IF detection IC

5C

DC/DC converter

D/A converter

MIC amp, AQUA

AF block

5R

IF block

RXC

19

Page 20

TK-8180

SEMICONDUCTOR DATA

Microprocesser : 30625MGP-169GP (TX-RX unit IC404)

Pin No. Port Name I/O Function

1VREF-+5V

2 AVCC - +5V

3 SBC O Switched B control

4 RXC O RX control

5 TXC O TX control

6PCOTX APC adjust

7 HSDO O High speed data output

8 STSW O Side tone switch

9 RTCL/EEPCL O RTC/EEPROM clock

10 HSDIN I High speed data input

11 NC - Non-connection

12 RTDT/EEPDAT I/O RTC/EEPROM data

13 BYTE - +5V

14 CNVSS - DGND (Vss)

15 DMUTE O Det mute

16 AM2 O Audio mute 2

17 RST I Reset

18 Xout O 11.0592MHz clock output

19 DGND - DGND (Vss)

20 Xin I 11.0592MHz clock input

21 VCC1 - +5V

22 NMI - +5V

23 PSW I Power switch input

24 INT I BATT voltage INT

25 INTRA I RTC INT

26 SHIFT/MODEL I/O Beat shift/Model select

27 BEEP O Beep output

28 SPSTB O Shift register strobe

29 SOE O Shift register output enable

30 AIO5 I/O AUX I/O 5

31 AIO9 I/O AUX I/O 9

32 DSTB O D/A converter LD

33 LSDO O Low speed data output

34 RXD2 I RXD2

35 TXD2 O TXD2

36 TXD1 O TXD1/PTT (Scrambler board)

37 Vcc1 - +5V

38 RXD1 I RXD1

39 DGND - DGND (Vss)

40 MM1 O MIC mute 1

41 PSENS I Panel sense

42 TXD O TXD

43 RXD I RXD

44 AFDAT O BB TDATA and DTRCLK

45 AFDIO I/O BB DI/O

46 AFDIR O BB DIR

47 DTRLOAD O BB DTMF enable

48 AFSTD I BB STD

Pin No. Port Name I/O Function

49 LSW O BB LIM switch

50 RDY - +5V

51 NC - Non-connection

52 HOLD - +5V

53 NC - Non-connection

54~57 AIO4~AIO1 I/O AUX I/O 4~1

58 NC - Non-connection

59 RD O Read (RD)

60 NC - Non-connection

61 WR O Write (WR)

62~64 AIO8~AIO6 I/O AUX I/O 8~6

65,66 NC - Non-connection

67 RST2 O Display µ-com reset

68 CS0 O Chip select 0

69 NC - Non-connection

70~79 A18~A9 O Address bus 18~9

80 UL I PLL unlock

81 PLE O PLL enable

82 PCK O PLL clock

83 NC - Non-connection

84 OPT6 I/O Option boad I/F 6

85 VCC2 - +5V

86 A8 O Address bus 8

87 DGND - DGND (Vss)

88~95 A7~A0 O Address bus 7~0

96 IGN I Ignition sense

97 AFRTM I BB RDF/FD

98 TCLK/DTRDO I BB TCLK and DTRDO

99 MM2 O MIC mute2

100 T/R O TX/RX switch

101 AM1 O Audio mute 1

102 EMTON O EM tone switch

103 NC - Non-connection

104~111 D7~D0 I/O Data bus7~0

112 DT O Serial data

113 CK O Serial clock

114 W/N O Wide/Narrow switch

115~117 OPT 1~OPT 3 I/O Option boad I/F 1~3

118,119 OPT 4, OPT 5 O Option boad I/F 4, 5

120 H/L O High/Low power switch

121 THP I TX thermal input

122,123 NC - Non-connection

124 ASQ I RX analog SQ. input

125 RSSI I RX RSSI input

126 NC - Non-connection

127 AGND - AGND (Vss)

128 LSDIN I Low speed data input

20

Page 21

SEMICONDUCTOR DATA

Microprocesser : 30302M8-8Z7GP (Display unit IC902)

Pin No. Port Name I/O Function

1~4 NC - Non-connection

5 SHIFT O Beat shift

6BYTE-+5V

7 CNVSS - GND

8,9 NC - Non-connection

10 RST I Reset

11 Xout O 14.7456MHz clock output

12 GND - GND

13 Xin I 14.7456MHz clock input

14 VCC - +5V

15 NMI - +5V

16 BLC2 O MIC backlight control

17 BLC1 O Key & LCD backlight control

18 DIMM O Dimmer control

19 LEDG O LED green

20 LEDR O LED red

21 NC - Non-connection

22 LCDCK O LCD serial clock

23 LCDDT O LCD serial data

24 LCDCS O LCD chip select

25 LCDRST O LCD reset

26 NC - Non-connection

27 RXD2 I RXD2 (Main µ-com)

28 TXD2 O TXD2 (Main µ-com)

29 PTT/TXD I/O PTT/TXD (COM0)

30 NC - Non-connection

31 DM O MIC DM

32,33 NC - Non-connection

34 HK/RXD I HOOK/RXD (COM0)

35~44 NC - Non-connection

45 TP1 I LCD check

46~59 NC - Non-connection

60 VCC - +5V

61 NC - Non-connection

62 VSS - GND

63~70 NC - Non-connection

71~82 S22~S11 I Non-connection

Pin No. Port Name I/O Function

83 S10 I Front panel key (R down [ ])

84 S9 I Front panel key (R up [ ])

85 S8 I Front panel key ( ■ )

86 S7 I Front panel key (C)

87 S6 I Front panel key (B)

88 S5 I Front panel key (A)

89 S4 I Front panel key (S)

90 S3 I Front panel key ( )

91 S2 I Front panel key (L down [ ])

92 S1 I Front panel key (L up [ ])

93 NC - Non-connection

94 AVSS - GND

95 NC - Non-connection

96 VREF - +5V

97 AVCC - +5V

98~100 NC - Non-connection

Shift Register : BU4094BCFV (TX-RX unit IC403)

Pin No. Port Name I/O Function

1 STRB I Storage enable input

2 DATA I Serial data input

3 CLK I Serial clock input

4Q1OAUX output 1

5Q2OPublic address

6Q3OHorn alert

7Q4OScrambler switch

8 Vss -

9Qs O

10 Q’s O

11 Q8 O Ceramic filter switch

12 Q7 O Non-connection

13 Q6 O AUX output 2

14 Q5 O Gate switch

15 OE I Output enable

16 VDD -

TK-8180

21

Page 22

TK-8180

COMPONENTS DESCRIPTION

Display unit (X54-3480-10)

Ref. No. Part Name Description

IC901 IC Voltage regulator/ 5V

IC902 IC Microprocessor

IC903 IC LCD driver

Q901,902 Transistor HOOK switch

Q904 Transistor TX indication LED switch

Q905 Transistor BUSY indication LED switch

Q906 Transistor Dimmer switch control

Q907 Transistor Dimmer switch

Q909 Transistor Backlight control switch

Q910 Transistor 8C switch

Q911 Transistor 8C switch control

Q913 Transistor Backlight control

D901,902 Zener diode Voltage protection

D903 Varistor Current limitter

D904~906

D907 LED TX/Busy indication

D909~920

D921~930

Diode Surge protection

LED LCD backlight

LED KEY backlight

TX-RX unit (X57-6990-10)

Ref. No. Part Name Description

IC1 IC Power module

IC71,72 IC DC amp for TX APC

IC171 IC RX 1st mixer

IC172 IC FM IF system IC

IC251 IC DC-DC converter

IC301 IC PLL system IC

IC302 IC PLL CP switch

IC401 IC EEPROM

IC402 IC RTC processor

IC403 IC Shift register

IC404 IC Microprocessor

IC405 IC Flash memory

IC406 IC HSD BPF/HSD compalator

IC407 IC DET amp/Data LPF (DB-25)

IC408 IC LSD buffer amp/VCXO bias amp

IC409 IC LSD LPF/Voltage DC-reference

IC410 IC D/A converter

Ref. No. Part Name Description

IC411 IC RF BPF tuning voltage DC amp

IC412 IC Modulation LPF/DET amp

IC413 IC AF switch IC

IC414 IC MIC amp

IC415 IC AQUA-L

IC416 IC Level converter IC (RS-232C)

IC417 IC Audio IC

IC801 IC Voltage detector (CPU Reset)

IC802 IC Voltage detector (INT)

IC803 IC Voltage regulator/ 8V

IC804,805

IC807 IC Voltage regulator/ 5V

Q1 Transistor TX pre-driver

Q2 Transistor TX driver

Q3 Transistor TX gate switch

Q70 Transistor High/Low power switch

Q72 FET High/Low power switch

Q103 Transistor Front-end LNA

Q171,172 Transistor IF amp

Q173,174 Transistor W/N CF switch control

Q175 Transistor Noise Amp

Q176 FET DET mute switch

Q177 Transistor W/N CF switch control

Q178 Transistor W/N discrete switch

Q179 Transistor W/N CF switch control

Q251 Transistor Ripple filter

Q301 Transistor PLL f-in doubler amp

Q302,303 Transistor PLL LPF

Q306,307 FET TX/RX VCO

Q308~310

Q311 Transistor VCO buffer amp

Q312 Transistor Ripple filter

Q313 Transistor VCO buffer amp

Q402 Transistor Beat shift switch

Q403 FET AF switch (Voice)

Q405 Transistor AQUA control switch

Q406 FET AF switch (LSD)

Q409 Transistor AF mute switch

Q410,411 Transistor MIC AGC

Q412 FET AF mute switch

IC Voltage regulator/ 5V

Transistor TX/RX VCO switch

22

Page 23

COMPONENTS DESCRIPTION

TK-8180

Ref. No. Part Name Description

Q413,414 FET AF Switch

Q415 FET AF Switch (Voice)

Q416,417 FET MIC mute switch

Q418 Transistor AF mute control switch

Q419 Transistor AF mute switch

Q600 Transistor MIC mute switch

Q701,702 Transistor Inverter switch

Q801 Transistor Voltage regulator/ 8.5V

Q802 Transistor SB control switch

Q803 Transistor 8T switch

Q804 Transistor 8R switch

Q805 Transistor 5R switch

Q806 Transistor 8T control switch

Q807 Transistor SB control switch

Q808 Transistor 8R control switch

Q809 Transistor 5R control switch

Q810 FET SB switch

Q811 Transistor Ignition sense control switch

Q812 Transistor CPU reset switch

D1 Zener diode Voltage protection

D2,3 Diode ANT switch

D6~8 Diode RF detector

D103~110

D111 Diode ANT switch

D171,172 Diode W/N CF switch

D173 Diode SQ noise-amp detector

D174 Diode DET mute switch control

Variable RF BPF tuning

capacitance diode

Ref. No. Part Name Description

D251 Diode Reverse voltage protection

D308,309 Variable

capacitance diode

D311 Variable Frequency control for TX/RX VCO

capacitance diode

D313 Variable Frequency control for TX/RX VCO

capacitance diode

D314 Variable Modulation control for TX VCO

capacitance diode

D315,316 Diode TX/RX band switch

D402~404

D405,406 Zener diode Voltage protection

D407 Diode DC detector

D408,409 Diode MIC-amp AGC detector

D412~414

D416 Diode AF mute control

D417,418 Diode Isolator

D421~423

D600,601 Diode MIC mute control

D701 Zener diode Voltage protection

D702,703 Diode Voltage protection

D704~708

D709,710 Zener diode Voltage protection

D711~713

D714 Zener diode Voltage protection

D801 Surge absorber Voltage protection

D802 Diode DC reverse connection protect

D804,805 Zener diode Voltage protection

Diode RTC battery control

Diode Surge protect

Diode Voltage protection

Diode Surge protect

Diode Surge protect

Frequency control for TX/RX VCO

23

Page 24

TK-8180

PARTS LIST

✽ New Parts. indicates safety critical components.

Parts without Parts No. are not supplied.

Les articles non mentionnes dans le Parts No. ne sont pas fournis.

Teile ohne Parts No. werden nicht geliefert.

TK-8180 (Y51-5030-10)

DISPLAY UNIT (X54-3480-10)

Address

New

Parts No. Description

parts

Ref. No.

TK-8180 DISPLAY UNIT (X54-3480-10)

11B✽ A01-2194-11 CABINET

23A✽ A62-1094-23 PANEL ASSY

42A✽ B09-0681-03 CAP (KAP-2)

51D✽ B62-1766-10 INSTRUCTION MANUAL

72BE04-0167-05 RF COAXIAL PECEPTACLE (M)

82B✽ E30-7520-05 DC CORD (PIG TAIL)

92C✽ E30-7523-05 DC CORD ASSY (WATER-PROOF)

10 2A ✽ E37-1110-05 FLAT CABLE (30P/D-SUB)

11 1A ✽ E37-1118-05

12 2A ✽ E37-1120-05 FLAT CABLE (30P/TX-RX)

13 3B ✽ E37-1124-05

15 2B ✽ F10-2488-02 SHIELDING PLATE (CHASSIS)

16 1A ✽ F10-2489-03 SHIELDING CASE (FINAL)

17 1A ✽ F10-2490-03 SHIELDING CASE (VCO)

18 1C F52-0024-05 FUSE (BLADE) 15A/32V

20 3B ✽ G10-1342-04 FIBROUS SHEET (BIRITSUKI)

21 2A ✽ G11-4290-04 RUBBER SHEET (CHASSIS)

22 1B ✽ G11-4343-04 SHEET

23 1A G13-2018-04 CUSHION

24 2B ✽ G13-2047-04 CUSHION (DC SCREW)

25 1B ✽ G53-1613-01 PACKING (SHIELD PLATE)

26 3A ✽ G53-1614-23 PACKING (CHASSIS)

27 1A ✽ G53-1616-03 PACKING (PHONE JACK)

28 2B ✽ G53-1626-03 PACKING (D-SUB OUTER)

29 3B ✽ G53-1643-04 PACKING (DC CORD)

LEAD WIRE WITH CONNECTOR (SHORT CABLE)

LEAD WIRE WITH CONNECTOR (2P/SP)

Destination

L : Scandinavia K : USA P : Canada

Y : PX (Far East, Hawaii) T : England E : Europe

Y : AAFES (Europe) X : Australia M :Other Areas

Ref. No.

101 3B ✽ B11-1825-04 FILTER (LCD)

102 3B ✽ B38-0888-05 LCD

D907 B30-2151-05 LED (R/G)

D909-920 ✽ B30-2281-05 LED (Y)

D921-930 ✽ B30-2282-05 LED (Y)

C904 CC73GCH1H101J CHIP C 100PF J

C906 CK73GB1H103K CHIP C 0.010UF K

C907,908 CK73HB1H102K CHIP C 1000PF K

C909-911 CC73GCH1H101J CHIP C 100PF J

C912,913 CK73GB1H102K CHIP C 1000PF K

C914 CC73GCH1H101J CHIP C 100PF J

C915 CK73GB1H102K CHIP C 1000PF K

C916,917 CK73GB1C104K CHIP C 0.10UF K

C918 C92-0628-05 CHIP-TAN 10UF 10WV

C920 CC73GCH1H101J CHIP C 100PF J

C921 CK73GB1H102K CHIP C 1000PF K

C922 CK73GB1H103K CHIP C 0.010UF K

C924,925 CC73GCH1H100D CHIP C 10PF D

C926-928 CK73GB1H102K CHIP C 1000PF K

C930 CK73GB1H103K CHIP C 0.010UF K

C931 C92-0784-05 CHIP-TAN 4.7UF 10WV

C932-934 CK73GB1H103K CHIP C 0.010UF K

C935 CK73GB1H471K CHIP C 470PF K

C936 CK73GB1C104K CHIP C 0.10UF K

C937 CK73GB1H103K CHIP C 0.010UF K

C938 CK73GB1H102K CHIP C 1000PF K

Address

New

parts

Parts No. Description

Destination

30 3B ✽ G53-1645-03 PACKING (D-SUB INNER)

31 2A ✽ G53-1662-04 PACKING (O RING)

32 2C ✽ H02-0624-03 INNER PACKING CASE

33 2D ✽ H12-3170-01 PACKING FIXTURE (LOWER)

34 1D ✽ H12-3171-03 PACKING FIXTURE (UPPER)

36 2D H25-2352-04 PROTECTION BAG (250/350/0.07)

37 3D ✽ H52-2069-02 ITEM CARTON CASE

39 1C J19-1584-05 HOLDER (ACCESSORY)

40 3B ✽ J19-5464-13 HOLDER (SP)

41 3B ✽ J19-5468-02 HOLDER (PANEL)

42 2B ✽ J21-8479-02 HARDWARE FIXTURE (D-SUB)

43 3B ✽ J21-8481-03 HARDWARE FIXTURE (SP)

44 2C J29-0662-03 BRACKET (ACCESSORY)

45 3B ✽ J30-1289-04 SPACER (SP)

47 3A ✽ K29-9312-21 KEY TOP

A2BN09-2409-05 HEXAGON HEAD SCREW (D-SUB)

B 1A,2A ✽ N67-3008-48

C

D1AN87-2608-46

49 2C ✽ N99-2039-05 SCREW SET (ACCESSORY)

51 3B ✽ T07-0750-05 SPEAKER

52 1C ✽ T91-0639-05 MICROPHONE (ACCESSORY)

54 2A W09-0971-05 LITHIUM CELL

1A,2A,2B

✽ N87-2606-48

PAN HEAD SEMS SCREW W (FINAL IC)

BRAZIER HEAD TAPTITE SCREW (ANT,PCB)

BRAZIER HEAD TAPTITE SCREW (AUDIO IC)

103 3B ✽ E29-1202-04 INTER CONNECTOR (LCD)

CN901 E40-5704-05 PIN ASSY

CN902 ✽ E40-6372-05 FLAT CABLE CONNECTOR

J901 3B E08-0877-05 MODULAR JACK

104 3B ✽ G11-4342-04 SHEET

105 3B ✽ J19-5467-03 HOLDER (LCD)

106 3B ✽ J21-8470-03 HARDWARE FIXTURE (LCD)

- ✽ J31-0551-05 COLLAR

L901,902 L40-1095-85 SMALL FIXED INDUCTOR (1.0UH)

L903-907 L92-0140-05 FERRITE CHIP

L908,909 L92-0163-05 BEADS CORE

X901 ✽ L77-1956-05 CRYSTAL RESONATOR (14.7456MHZ)

CP901-911 RK75HA1J101J CHIP-COM 100 J 1/16W

R901 RK73GB1J102J CHIP R 1.0K J 1/16W

R903 RK73GB1J471J CHIP R 470 J 1/16W

R904 RK73GB1J102J CHIP R 1.0K J 1/16W

R905 RK73GB1J472J CHIP R 4.7K J 1/16W

R907 RK73GB1J333J CHIP R 33K J 1/16W

R909-911 RK73GB1J473J CHIP R 47K J 1/16W

R913-916 RK73HB1J474J CHIP R 470K J 1/16W

R917 RK73FB2A471J CHIP R 470 J 1/10W

R918 RK73FB2A271J CHIP R 270 J 1/10W

R919 RK73HB1J102J CHIP R 1.0K J 1/16W

R920 R92-1368-05 CHIP R 0 OHM

R925 RK73HB1J471J CHIP R 470 J 1/16W

R926 RK73HB1J473J CHIP R 47K J 1/16W

24

Page 25

Ref. No.

R927-935 RK73HB1J102J CHIP R 1.0K J 1/16W

R936 RK73HB1J103J CHIP R 10K J 1/16W

R939 RK73GB1J472J CHIP R 4.7K J 1/16W

R940 RK73HB1J101J CHIP R 100 J 1/16W

R941 RK73HB1J102J CHIP R 1.0K J 1/16W

Address

New

Parts No. Description

parts

PARTS LIST

Destination

Ref. No.

C44 C93-0573-05 CHIP C 120PF J

C45 C93-0553-05 CHIP C 3.0PF C

C47 CC73GCH1H0R5B CHIP C 0.5PF B

C48 CC73GCH1H030B CHIP C 3.0PF B

C49 CC73GCH1H101J CHIP C 100PF J

Address

New

parts

TK-8180

DISPLAY UNIT (X54-3480-10)

TX-RX UNIT (X57-6990-10)

Parts No. Description

Destination

R942 RK73EB2B470J CHIP R 47 J 1/8W

R943 RK73EB2B101J CHIP R 100 J 1/8W

R944 R92-1368-05 CHIP R 0 OHM

R945 RK73GB1J103J CHIP R 10K J 1/16W

R947-950 RK73FB2A101J CHIP R 100 J 1/10W

R951,952 RK73FB2A391J CHIP R 390 J 1/10W

R953,954 RK73FB2A821J CHIP R 820 J 1/10W

R955-958 RK73HB1J472J CHIP R 4.7K J 1/16W

R959 RK73HB1J103J CHIP R 10K J 1/16W

R962,963 RK73GB1J103J CHIP R 10K J 1/16W

R967 RK73HB1J271J CHIP R 270 J 1/16W

R969 R92-1368-05 CHIP R 0 OHM

R970 RK73GB1J103J CHIP R 10K J 1/16W

R971 RK73HB1J102J CHIP R 1.0K J 1/16W

D901,902 02DZ18(X,Y) ZENER DIODE

D903 MINISMDC020 VARISTOR

D904-906 DA204U DIODE

IC901 TA78L05F MOS IC

IC902 ✽ 30302M8-8Z7GP MCU

IC903 ✽ LC75810T-8726 MOS IC

Q901,902 DTC144EE DIGITAL TRANSISTOR

Q904-906 DTC114EE DIGITAL TRANSISTOR

Q907 2SC2873(Y) TRANSISTOR

Q909,910 ✽ 12A02CH TRANSISTOR

Q911 DTC114EE DIGITAL TRANSISTOR

Q913 DTC114EE DIGITAL TRANSISTOR

TH901 ✽ S1R103J440H THERMISTOR

TX-RX UNIT (X57-6990-10)

C1 CK73GB1H102K CHIP C 1000PF K

C2-5 CC73GCH1H101J CHIP C 100PF J

C6 C92-0585-05 CHIP-TAN 4.7UF 16WV

C7,8 CC73GCH1H101J CHIP C 100PF J

C9 CC73GCH1H060D CHIP C 6.0PF D

C50 C93-0558-05 CHIP C 8.0PF D

C51 CC73GCH1H101J CHIP C 100PF J

C52 CC73GCH1H0R5B CHIP C 0.5PF B

C53 C93-0560-05 CHIP C 10PF D

C55 CC73GCH1H020B CHIP C 2.0PF B

C56 CC73GCH1H101J CHIP C 100PF J

C57 CC73GCH1H0R5B CHIP C 0.5PF B

C58 CC73GCH1H020B CHIP C 2.0PF B

C59 CC73GCH1H101J CHIP C 100PF J

C60 C93-0556-05 CHIP C 6.0PF D

C61,62 CC73GCH1H101J CHIP C 100PF J

C74 CC73GCH1H101J CHIP C 100PF J

C76,77 CK73GB1H471K CHIP C 470PF K

C79,80 CK73GB1H471K CHIP C 470PF K

C119 CC73GCH1H050B CHIP C 5.0PF B

C121 CK73GB1H471K CHIP C 470PF K

C124 CC73GCH1H100D CHIP C 10PF D

C125 CK73GB1H471K CHIP C 470PF K

C127 CC73GCH1H220J CHIP C 22PF J

C128 CC73GCH1H090B CHIP C 9.0PF B

C129 CK73GB1H471K CHIP C 470PF K

C130 CC73GCH1H050B CHIP C 5.0PF B

C131 CK73GB1H471K CHIP C 470PF K

C132 CC73GCH1H220J CHIP C 22PF J

C133 CC73GCH1H060B CHIP C 6.0PF B

C134 CC73GCH1H030B CHIP C 3.0PF B

C135 CC73GCH1H220J CHIP C 22PF J

C136 CC73GCH1H040B CHIP C 4.0PF B

C137 CK73GB1H471K CHIP C 470PF K

C138 CC73GCH1H050B CHIP C 5.0PF B

C139 CK73GB1H471K CHIP C 470PF K

C140 CC73GCH1H220J CHIP C 22PF J

C141 CC73GCH1H090B CHIP C 9.0PF B

C142 CK73GB1H471K CHIP C 470PF K

C143 CK73GB1H103K CHIP C 0.010UF K

C10 CC73GCH1H101J CHIP C 100PF J

C13-15 CC73GCH1H101J CHIP C 100PF J

C16 CC73GCH1H060D CHIP C 6.0PF D

C17 CC73GCH1H220J CHIP C 22PF J

C18 CK73GB1H471K CHIP C 470PF K

C19 CC73GCH1H470J CHIP C 47PF J

C20 CC73GCH1H101J CHIP C 100PF J

C21 CK73FB1H471K CHIP C 470PF K

C22 CK73GB1H471K CHIP C 470PF K

C24 C92-0606-05 CHIP-TAN 4.7UF 10WV

C25 C93-0550-05 CHIP C 1.0PF C

C26 CC73GCH1H220J CHIP C 22PF J

C27 CC73GCH1H470J CHIP C 47PF J

C28 CC73GCH1H101J CHIP C 100PF J

C29-31 CK73GB1H471K CHIP C 470PF K

C32 ✽ C92-0834-05 ELECTRO 47UF 25WV

C33-35 CC73GCH1H101J CHIP C 100PF J

C38-40 CC73GCH1H220J CHIP C 22PF J

C42 C93-0555-05 CHIP C 5.0PF C

C43 CC73FCH1H030C CHIP C 3.0PF C

C144 CC73GCH1H070B CHIP C 7.0PF B

C145 CC73GCH1H1R5B CHIP C 1.5PF B

C146 CK73GB1H471K CHIP C 470PF K

C147 CC73GCH1H050B CHIP C 5.0PF B

C148 CC73GCH1H010B CHIP C 1.0PF B

C149 CK73GB1H471K CHIP C 470PF K

C150 CC73GCH1H050B CHIP C 5.0PF B

C151 CC73GCH1H010B CHIP C 1.0PF B

C152 CK73GB1H471K CHIP C 470PF K

C153 CC73GCH1H050B CHIP C 5.0PF B

C154 CC73GCH1H1R5B CHIP C 1.5PF B

C155,156 CK73GB1H471K CHIP C 470PF K

C171 CC73GCH1H060B CHIP C 6.0PF B

C173 CC73GCH1H120J CHIP C 12PF J

C175 CC73GCH1H060B CHIP C 6.0PF B

C176-178 CK73GB1H471K CHIP C 470PF K

C181 CK73GB1H471K CHIP C 470PF K

C182,183 CK73GB1H103K CHIP C 0.010UF K

C184 CK73GB1H471K CHIP C 470PF K

C185 CK73GB1H103K CHIP C 0.010UF K

25

Page 26

TK-8180

TX-RX UNIT (X57-6990-10)

Address

New

Parts No. Description

parts

Ref. No.

C186 CC73GCH1H330J CHIP C 33PF J

C187 CC73GCH1H390J CHIP C 39PF J

C188,189 CC73GCH1H040B CHIP C 4.0PF B

C190 CC73GCH1H390J CHIP C 39PF J

C192-194 CK73GB1H103K CHIP C 0.010UF K

PARTS LIST

Destination

Ref. No.

C318 C92-0657-05 CHIP-TAN 2.2UF 20WV

C320 C92-0657-05 CHIP-TAN 2.2UF 20WV

C322 CK73GB1E473J CHIP C 0.047UF J

C323 CK73GB1H471K CHIP C 470PF K

C324 CK73GB1C104K CHIP C 0.10UF K

Address

New

parts

Parts No. Description

Destination

C195 CK73GB1H471K CHIP C 470PF K

C196,197 CK73GB1H103K CHIP C 0.010UF K

C198 CC73GCH1H680J CHIP C 68PF J

C199 CC73GCH1H390J CHIP C 39PF J

C200,201 CC73GCH1H040B CHIP C 4.0PF B

C202 CC73GCH1H390J CHIP C 39PF J

C204-206 CK73GB1H103K CHIP C 0.010UF K

C207 CK73GB1H471K CHIP C 470PF K

C208,209 CK73GB1H103K CHIP C 0.010UF K

C210 CC73GCH1H680J CHIP C 68PF J

C211 CC73GCH1H100D CHIP C 10PF D

C212 CK73GB1H471K CHIP C 470PF K

C213 CK73GB1H103K CHIP C 0.010UF K

C214 CK73GB1C104K CHIP C 0.10UF K

C215 CC73GCH1H180J CHIP C 18PF J

C216 CC73GCH1H150J CHIP C 15PF J

C217 CK73GB1H102K CHIP C 1000PF K

C218 CK73GB1H103K CHIP C 0.010UF K

C219 CK73FB1C105K CHIP C 1.0UF K

C220,221 CK73GB1C104K CHIP C 0.10UF K

C222 CK73GB1H102K CHIP C 1000PF K

C223 CK73GB1C104K CHIP C 0.10UF K

C224,225 CC73GCH1H271J CHIP C 270PF J

C226,227 CK73GB1H102K CHIP C 1000PF K

C228 CK73GB1C104K CHIP C 0.10UF K

C229 CK73GB1C333K CHIP C 0.033UF K

C230 CK73GB1H103K CHIP C 0.010UF K

C231 CC73GCH1H820J CHIP C 82PF J

C232,233 CK73GB1H102K CHIP C 1000PF K

C234 CK73FB1C224K CHIP C 0.22UF K

C325 CK73GB1H102K CHIP C 1000PF K

C327 CK73FB1E224K CHIP C 0.22UF K

C331 CK73GB1H103K CHIP C 0.010UF K

C333 CC73GCH1H050B CHIP C 5.0PF B

C334 CK73GB1H102K CHIP C 1000PF K

C335 CK73GB1C223K CHIP C 0.022UF K

C338 C92-0502-05 CHIP-TAN 0.33UF 35WV

C339 CK73GB1H471K CHIP C 470PF K

C342 CK73GB1H102K CHIP C 1000PF K

C343 C92-0628-05 CHIP-TAN 10UF 10WV

C346,347 CC73GCH1H220G CHIP C 22PF G

C350 CC73GCH1H080D CHIP C 8.0PF D

C351 CC73GCH1H0R5B CHIP C 0.5PF B

C352 CC73GCH1H120J CHIP C 12PF J

C353 CC73GCH1H471J CHIP C 470PF J

C354 CC73GCH1H040B CHIP C 4.0PF B

C355 CC73GCH1H050B CHIP C 5.0PF B

C356 CC73GCH1H0R5B CHIP C 0.5PF B

C357 CC73GCH1H060B CHIP C 6.0PF B

C358 CC73GCH1H050B CHIP C 5.0PF B

C359,360 CC73GCH1H070B CHIP C 7.0PF B

C361-363 CC73GCH1H471J CHIP C 470PF J

C364 CC73GCH1H0R5B CHIP C 0.5PF B

C365 CC73GCH1H0R3B CHIP C 0.3PF B

C367 CK73GB1H102K CHIP C 1000PF K

C368 CC73GCH1H471J CHIP C 470PF J

C369,370 CK73GB1H471K CHIP C 470PF K

C371 C92-0560-05 CHIP-TAN 10UF 6.3WV

C372 CC73GCH1H220J CHIP C 22PF J

C373 CC73GCH1H471J CHIP C 470PF J

C235 CK73GB1C104K CHIP C 0.10UF K

C236 CK73GB1H103K CHIP C 0.010UF K

C237 C92-0712-05 CHIP-TAN 22UF 6.3WV

C238 CK73GB1H103K CHIP C 0.010UF K

C239,240 CK73GB1C104K CHIP C 0.10UF K

C241 CK73GB1H102K CHIP C 1000PF K

C251,252 CK73GB1H471K CHIP C 470PF K

C253 CK73GB1H103K CHIP C 0.010UF K

C255 C92-0694-05 CHIP-TAN 10UF 16WV

C256 CK73GB1H103K CHIP C 0.010UF K

C257 C92-0519-05 CHIP-TAN 1.0UF 25WV

C258 C92-0516-05 CHIP-TAN 4.7UF 16WV