Page 1

KBRG-255

TM

®

REGENERATIVE DRIVE

FULL WAVE • 4 QUADRANT

For Speed and Torque Control of

PM and Shunt DC Motors

RATED – 5 Hp @ 230 VAC – 50/60 Hz

TYPICAL APPLICATIONS

• Conveyors • Indexers • Packaging Machinery

• Textile Equipment • Positioners • Feeders

• Converting Machinery • Web Control

DATA SHEET D-325

*

P/N 8821

▲

STANDARD FEATURES

• Enable Circuit

• Two (2) or Three (3) Wire Start/Stop

• Overload Shutdown with Timed CL

• External Relay Contacts

• Function Indicator Lamps: Power On, Current Limit,

Forward Enable, Reverse Enable

• Protection: Control Circuit Fusing, MOV Transient Protection,

Auto Inhibit

Overspeed Protection

®

, Rapid Response Current Limit Circuit, Regen

JUMPER SELECTABLE FEATURES

• Control Mode: Speed (SPD), Torque (TRQ)

• AC Line Voltage (VAC 50/60 Hz): 115, 230

• DC Ar mature Voltage (VDC): 90, 180

• Feedback Type: Armature, Tachometer

• Tachometer Voltage Input (VDC): 7, 20/30, 50

• Timed Current Limit: TCL, NTCL

• S/LT Speed Linear Torque

• NLT Non Linear Torque

Bold indicates factory setting.

TRIMPOT ADJUSTMENTS

• Forward Acceleration (FWD ACCEL)

• Reverse Acceleration (REV ACCEL)

• Deadband (DB) • Offset (OFFSET)

• Maximum Speed (MAX SPD)

• Response (RESP)

• IR Compensation (IR COMP)

• Reverse Current Limit (REV CL)

• Forward Current Limit (FWD CL)

• Timed Current Limit (TCL)

OPTIONAL FEATURES

• Bipolar Signal Isolator, SI-4X (P/N 8801)

• 4-Quad Accel/Decel (P/N 8803)

• Multi-Speed Board (P/N 8814)

• PID Board (P/N 8804)

* CE Compliance Requires KBRF-200A RFI Filter

▲

Shown with optional SI-4X Signal Isolator

DESCRIPTION

The KBRG-255 is a full-wave regenerativ e drive capab le

of operating DC PM or Shunt motors in a bidirectional

mode. Its 4-quadrant operation provides forward and

reverse torque in both speed directions. This allows the

control to maintain constant speed with overhauling loads

and provides rapid instant reversing and controlled braking.

Because of its excellent controllability and response time,

the KBRG-255 can replace servos in many applications.

The control is factory set for armature feedback, which

provides up to 1% load regulation over a motor base

speed of 50:1. However, tachometer feedback is also

available if superior regulation is required. By resetting

mode jumper J7 to the “TRQ”position, the KBRG-255 can

be changed from a speed control to a torque control.

The drive contains a variety of “selectable” jumpers

and adjustment trimpots to allow custom tailoring for exact

requirements.For example: jumper J6, when placed in the

“TCL” position, provides adjustable timed current limit from

1 to 15 seconds. This feature will protect the motor and

control by shutting the drive down after the preset time has

elapsed.

The KBRG-255 can be operated with either a two (2)

or three (3) wire start/stop circuit, or can be star ted from

the AC line.A set of dedicated relay contacts are provided

which are activated via the start/stop circuit. They can be

used to turn on or off corresponding equipment or to

sound an alarm if the drive stops.

Another important feature is the array of the LED’s,

which indicate the mode of operation the drive is in, and

also serve as a diagnostic tool. In addition, KB’s exclusive

Auto Inhibit®circuit provides safe, smooth starting during

rapid cycling of the AC line. The Overspeed Protect

Circuit prevents failure of the power bridge in extreme

overhauling conditions.

Reliability of the KBRG-255 is further enhanced with

the use of a high speed current limit circuit. MOV transient

protection is also included. A 5K remote potentiometer

and full operating instructions are supplied

28

A Complete Line of Motor Drives

Rev.______(A_______)

Page 2

SPECIFICATIONS

AC Line Input Voltage (VAC ±15%, 50/60 Hz).................................. 230

Arm Voltage Range at 230VAC Line (VDC) ............................ 0 – ±180

Field Voltage at 230VAC Line (VAC).......................................... 200/100

Max Load Capacity (% for 1 minute)................................................ 150

Ambient Temperature Range (°C)............................................ 0 – 50(1)

Speed Range (Ratio) ...................................................................... 50:1

Arm Feedback Load Regulation (% Base Speed) ............................ ±1

Tach Feedback Load Regulation (% Set Speed) .............................. ±1

Line Regulation (% Base Speed).................................................... ±0.5

FWD and REV Accel Range (Sec.) .......................................... 0.1 – 15

Dead Band Range (% Base Speed)............................................ 0 – ±3

Offset Range (% Base Speed).................................................... 0 – ± 5

Max Speed Trimpot Range (% Base Speed) .......................... 70 – 110

IR Comp Range at 230VAC Line (VDC) ...................................... 0 – 30

FWD and REV CL Range (% Range Setting)............................ 0 – 150

Timed CL Range (Sec.) .............................................................. 1 – 15

Voltage Following Input Range (VDC) ...................................... 0 – ±10

Voltage Following Linearity (% Base Speed) .................................. ±0.5

NOTES: (1) Control mounted in vertical position only.

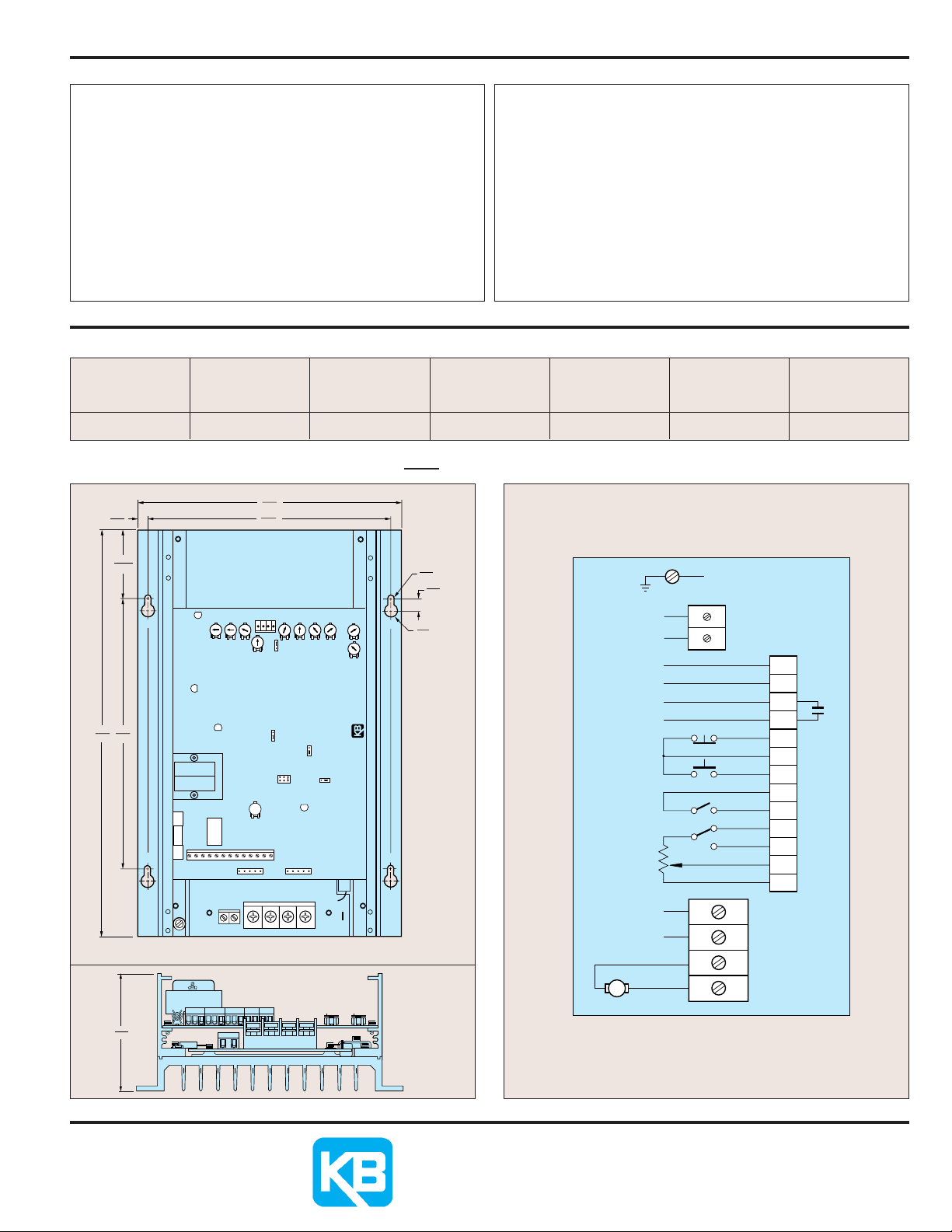

ELECTRICAL RATINGS

Model Number KB Part Number Motor Voltage (VDC)

AC Line Voltage

(VAC) ± 10%

50/60 Hz

KBRG-255 8821 230 0 – 180 38 26 5, (3.75)

INCHES

[mm]

7.700

[195.6]

0.300

[7.6]

7.100

[180.3]

Max. AC

Load Current

(RMS Amps)

CONNECTION DIAGRAMMECHANICAL SPECIFICATIONS

Max. DC

Load Current

(DC Amps)

Maximum Horsepower

Hp, (KW)

12.000

[304.8]

2.000

[50.8]

8.000

[203.2]

FWD

EN

REV

EN

F1

TB1

123

(EARTH)

GND

REV

FWD

ACCEL

DB

ACCEL

OFFSET

PWR

ON

T1

4 5 6 7 8 9 10 1112 13

TB1

F+

F-

MAX

COM

-15

+15

SIG

SPD

RESP

CONN3

S/LT

NLT

TRQ

J7

SPD

J4

7V

50V

20/30V

R33

L1 L2M1M2

COMP

TFB

AFB

R0.089

(4 PL)

[R2.3]

0.324

(4 PL)

[8.2]

IR

REV

FWD

CL

CL

TCL

KB ELECTRONICS, INC.

KBRG

A57225

J5

J6

TCL

NTCL

J1

TB2

R0.172

[R4.4]

(4 PL)

DWG#: C3900-1-01277

GND CHASSIS

FIELD

OUTPUT

F+

F-

TACH

INPUT

ALARM

CONTACTS

STOP

START

ENABLE

MAIN

SPEED

FWD

REV

POT

AC LINE

INPUT

L1

L2

M1

M

M2

T+

1

T-

2

C1

3

C2

4

SP

5

SC

6

ST

7

E1

8

E2

9

F

10

R

11

W

12

C

13

RY1

3.440

[87.4]

© 1998 KB Electronics, Inc.

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065-2516

(954) 346-4900 • FAX (954) 346-3377

Outside Florida Call TOLLFREE (800) 221-6570

www.kbelectronics.com

Rev.______(A_______)

29

Loading...

Loading...