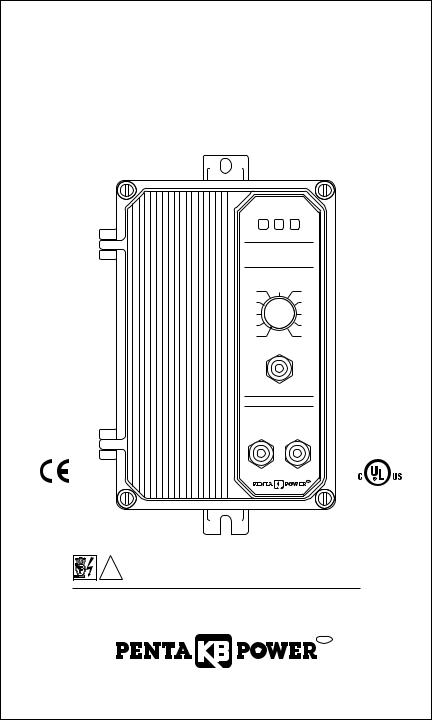

Kb Electronics KBPW-240D User Manual

INSTALLATION AND OPERATION MANUAL

MODEL KBPW-240D

KB Part No. 8401 (Black Case) • Part No. 8402 (White Case)

NEMA 4X, IP-65

PWM DC Motor Speed Control For PM and Shunt Wound Motors Rated 7.5 Amps DC, 11.5 Amps AC @ 115/230 VAC

ON STOP OL

PENTA-DRIVE™

PWM DC MOTOR SPEED CONTROL

40 |

50 |

60 |

|

||

30 |

|

70 |

20 |

|

80 |

10 |

|

90 |

0 |

% |

100 |

|

|

FWD

BRK

REV

NEMA-4X / IP-65

START RUN

STOP JOG

™

! See Safety Warning on Page 2

The information contained in this manual is intended to be accurate. However, the manufacturer retains the right to make changes in design which may not be included herein.

TM

A COMPLETE LINE OF MOTOR DRIVES

©2002 KB Electronics, Inc. See back cover

|

TABLE OF CONTENTS |

|

Section |

Page |

|

i. |

Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 |

I. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 |

II. |

Simplified Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

III. |

Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

IV. |

Setting Selectable Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

V. |

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

VI. |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

VII. AC Line Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 13 |

|

VIII. Trimpot Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 13 |

|

IX. |

Diagnostic LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 14 |

X. |

Optional Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. .15 |

XI. |

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 16 |

Tables |

|

|

1. |

Electrical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 3 |

2. |

General Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 3 |

3. |

Terminal Block Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

4. |

Field Connection (Shunt Wound Motors Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

5. |

Setting Motor Current (SCR & PWM Motor Horsepower Ratings) . . . . . . . . . . . . . . . . . . |

. 10 |

Figures |

|

|

1. |

Control Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 4 |

2. |

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .5 |

3. |

Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

4. |

Full Voltage Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

5. |

Half Voltage Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

6. |

Remote Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

7A. |

Remote 3-Wire Start/Stop Switch with Normally Open Start Contact |

|

|

and Normally Open Stop Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

7B. |

Remote 3-Wire Start/Stop Switch with Normally Open Start Contact |

|

|

and Normally Closed Stop Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

7C. |

Remote 2-wire Start/Stop Switch with Normally Open Start/Stop Contact . . . . . . . . . . . . |

. . 8 |

8. |

Start/Stop Function Eliminated (Jumper Installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

9. |

Voltage Following . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

10. |

Inhibit Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

11. |

Enable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

12. |

Enable Circuit Using Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

13. |

DC Tach-Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 9 |

14. |

Motor Voltage Selection (J1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

15. |

Motor Current Selection (J2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

16. |

Removing Resistor R35 (for low current selection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

17. |

Current Limit Mode Selection (J3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

18. |

DC Tach-Generator Voltage Selection (J4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

19. |

DC Tach-Generator with Addition of RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

ii |

|

|

20. Run Relay Output Mode Selection (J5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 21. Stop Switch Type Selection (J6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 22. Enable Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 23. ACCEL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 24. DECEL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 25. MAX Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 26. MIN Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 27. JOG Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 28. CL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 29. TCL Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 30. IR Trimpot Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

iii

Electrical Hazard Warning Symbol: Failure to observe this warning could result in electrical shock or electrocution.

Operational Hazard Warning Symbol: Failure to observe this warning could result in ! serious injury or death.

i.

! SAFETY WARNING! Please read carefully

! SAFETY WARNING! Please read carefully

This product should be installed and serviced by a qualified technician, electrician, or electrical maintenance person familiar with its operation and the hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other overcurrent protection, and grounding can reduce the chance of electrical shocks, fires, or explosion in this product or products used with this product, such as electric motors, switches, coils, solenoids, and/or relays. Eye protection must be worn and insulated adjustment tools must be used when working with control under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding, and filtering of this product can reduce the emission of radio frequency interference (RFI) which may adversely affect sensitive electronic equipment. If further information is required on this product, contact the factory. It is the responsibility of the equipment manufacturer and individual installer to supply this Safety Warning to the ultimate end user of this product. (SW effective 11/1992.)

This control contains electronic Start/Stop circuits that can be used to start and stop the control. However these circuits are never to be used as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

Be sure to follow all instructions carefully. Fire and/or electrocution can result due to improper use of this product.

PWM Safety Warning! This control contains a safety circuit which is designed to prevent ! full speed runaway in the event the main power transistor fails. However, this safety circuit is not infallible and may itself fail to operate and therefore allow a full speed runaway condition to exist. The installer of this product should take proper precautions to include other means to protect the operator or the machine involved (such as mechanical disconnects, warn-

ing notices, etc.).

This product complies with all CE directives pertinent at the time of manufacture. Contact the Sales Department for detailed installation and Declaration of Conformity. Installation of a CE approved RFI filter (KBRF-200A [P/N 9945C] or equivalent) is required. Additional shielded motor cable and/or AC line cables may be required along with a signal isolator (KBSI-240D [P/N 9431] or equivalent).

I.INTRODUCTION

Thank you for purchasing the KBPW-240D. KB Electronics, Inc. is committed to providing total customer satisfaction by producing quality products that are easy to install and operate. The KBPW-240D is manufactured with surface mount components incorporating advanced circuitry and technology.

The KBPW-240D is a Pulse Width Modulated (PWM) control in a NEMA-4X / IP-65 watertight and washdown enclosure designed to operate PWM and SCR rated Permanent Magnet and Shunt Wound motors ranging from 0.2 Amps DC to 7.5 Amps DC. It operates at a switching frequency greater than 16kHz to provide high motor efficiency and quiet operation. Special circuitry automatically accepts AC line input voltages of 115 Volts AC to 208/230 Volts AC (±10%, 50/60Hz) without having to make a jumper selection.

Standard panel mounted features include diagnostic LEDs (power on, stop, and overload), Start/Stop switch, and speed potentiometer. Other features include barrier terminal blocks (facilitate wiring of AC line, motor armature, motor field, tach-generator and run relay connections), adjustable trimpots (acceleration, deceleration, maximum speed, minimum speed, jog speed [used with optional Run/Jog switch], current limit, timed current limit and IR Comp.)

1

Optional accessories include On/Off AC Line Switch, FWD-BRK-REV Switch, Run-Stop-Jog Switch, Signal Isolator, and Anti-Plug Reversing Module. Quick-connect terminals are provided for easy installation of all optional accessories. The control is available in black finish (P/N 8401) and FDA approved white finish (P/N 8402).

STANDARD FEATURES

•Short Circuit Protection – Protects control from a short circuit at motor connections.

•Electronic Motor Burnout Protection – Timed Current Limit shuts down the control if a prolonged overload condition exists.

•Active Bridge – Limits the AC line inrush current when power is turned on and also prevents high speed runaway if the power transistor shorts.

•Heat Spreader – Allows power transistor to operate safely during momentary overload conditions.

•Auto AC Line Select – Control automatically adjusts for 115 or 208/230 Volt AC line input.

•Start/Stop Switch – Provides electronic start and stop functions.

•Diagnostic LEDs – For power on (ON), stop (STOP) and motor overload (OL).

•Trimpots – Provide adjustment for acceleration (ACCEL), deceleration (DECEL), maximum speed (MAX), minimum speed (MIN), jog speed (JOG), current limit (CL), timed current limit (TCL), and IR compensation (IR).

•Selectable Jumpers – Provide settings for armature voltage or tach-generator feedback (J1), motor current (J2), timed or non-timed current limit (J3), tach-generator voltage (J4), and run relay output (J5).

•Barrier Terminal Blocks – Facilitate wiring of AC line, motor armature and field, tach-genera- to, run relay output, and thermal or enable switch.

•Quick-Connect Terminals – Facilitate connecting Start/Stop switch, Run-Stop-Jog switch, FWD-BRK-REV switch, and Inhibit switch.

II.SIMPLIFIED OPERATING INSTRUCTIONS

IMPORTANT – You must read these simplified operating instructions before proceeding. These instructions are to be used as a reference only and are not intended to replace the detailed instructions provided herein. You must read the Safety Warning, on page 1, before proceeding.

A.Power Connection – Connect the AC line to L1 and L2 terminals of TB1 and the ground wire (Earth) to the green ground screw as shown in Figure 3, on page 6, and as described in Section IIIA, on page 6, and Section IIIB, on page 6.

B.Permanent Magnet (PM) Motor Connection (Two-Wire Type) – Connect the motor armature to A1 (+) and A2 (-) terminals of TB1 as shown in Figure 3, on page 6, and as described in Section IIIC, on page 6. Be sure that jumper J3 is set to the corresponding motor voltage position as described in Section IVA, on page 10. Do not use F1 and F2 terminals of TB2 for any purpose other than to power the field of a shunt wound motor. Do not use F1 and F2 terminals for PM motors.

Note: Motor performance and efficiency, including brush life, may be adversely affected when operating the control in stepdown mode (208/230 Volt AC line with 90/130 Volt DC motors).

C.Shunt Wound Motors (Four-Wire Type) – Connect the motor armature as described in Section IIIC, on page 6. Connect full voltage field wires (90 Volt DC motors with 100 Volt DC field and 180 Volt DC motors with 200 Volt DC field) to F1 (+) and F2 (-) terminals of TB2 as described in Section IIID, on page 7. Connect half voltage field wires (90 Volt DC motors with 50 Volt DC field and 180 Volt DC motors with 100 Volt DC field) to F1 (+) terminal of TB2 and L1 (-) terminal of TB1 as described in Section IIIE, on page 7.

Note: Do not connect motor armature leads to F1 and F2 terminals.

2

D.Motor Current – Jumper J2 is factory set for 7.5 Amp motors. For lower current motors, set jumper J2 to the corresponding motor current as described in Section IVB, on page 10.

Note: The factory setting for Current Limit is 150% of the nominal current setting (example: if jumper J2 is set to “5A” position, the CL trimpot is calibrated for 7.5 Amps).

E.Trimpot Settings – All trimpots have been factory set as shown in Figure 1, on page 4. Trimpots may be readjusted as described in Section VIII, on page 13.

F.Diagnostic LEDs – After power has been applied, observe the LEDs to verify proper control function as described in Section IX, on page 14.

G.Start/Stop Switch – The control is supplied with a prewired Start/Stop switch as described in Section IIIG, on page 7. This switch must be used to start the control each time the AC power is lost or the control shuts down due to TCL. To override this function, see Section IIIG, on page 7.

TABLE 1 – ELECTRICAL RATINGS

AC Line Voltage |

|

Maximum AC |

Maximum |

Maximum Horsepower |

|

|

Motor Voltage |

HP, (kW) |

Field Voltage |

||||

(±10%, 50/60 Hz) |

Line Current |

Load Current |

|

|

||

(Volts AC) |

(Volts DC) |

(Amps RMS) |

(Amps DC) |

SCR Rated |

PWM Rated |

(Volts DC) |

|

|

|||||

|

|

|

|

Motors |

Motors |

|

|

|

|

|

|

|

|

115 |

0 – 90, 130 |

11.5 |

7.5 |

3/4, (0.5) |

1, (0.75) |

100 |

|

|

|

|

|

|

|

208 – 230 |

0 – 180, 260 |

11.5 |

7.5 |

11⁄2, (1) |

2, (1.5) |

200 |

|

|

|

|

|

|

|

TABLE 2 – GENERAL PERFORMANCE SPECIFICATIONS

Parameter |

Specification |

Factory Setting |

|

Operating Frequency (kHz) |

|

>16 |

– |

|

|

|

|

Operating Temperature Range at Full Rating (ºC) |

0 |

– 50 |

– |

|

|

|

|

Current Range (High Scale) (Amps DC) |

1.7, 2.5, 3.5, 5.0, 7.5 |

7.5 |

|

|

|

|

|

Current Range (Low Scale) (Amps DC)1 |

0.2, 0.3, 0.4, 0.5, 0.8 |

– |

|

ACCEL and DECEL Range (Seconds) |

0.5 – 10 |

1 |

|

|

|

|

|

Jog Speed (% Base Speed) |

0 |

– 50 |

15 |

|

|

|

|

MIN Speed Range (% Base Speed [90VDC & 180VDC Motors]) |

0 |

– 30 |

0 |

|

|

|

|

MAX Speed Range (% Base Speed [90VDC & 180VDC Motors]) |

50 |

– 140 |

100 |

|

|

|

|

IR Comp Range at 90 Volts DC Output (∆Volts DC at Full Load) |

0 |

– 15 |

4 |

|

|

|

|

IR Comp Range at 180 Volts DC Output (∆Volts DC at Full Load) |

0 |

– 30 |

8 |

|

|

|

|

CL Range (% Range Setting) |

0 – 200 |

150 |

|

|

|

|

|

Timed Current Limit (TCL) Range (Seconds) |

0.5 – 10 |

5 |

|

|

|

|

|

AC Line Input Voltage (Volts AC, ±10%, 50/60 Hz) |

115 – 208/230 |

– |

|

|

|

|

|

AC Line Regulation (% Base Speed) |

|

0.5 |

– |

|

|

|

|

Armature Voltage Range at 115 Volts AC Line Input (Volts DC) |

0 – 130 |

90 |

|

|

|

|

|

Armature Voltage Range at 208/230 Volts AC Line Input (Volts DC) |

0 – 1302, 0 – 260 |

90 |

|

Armature Feedback Load Regulation (% Base Speed) |

|

1 |

– |

|

|

|

|

Tach-Generator Feedback Load Regulation (% Set Speed) |

|

1 |

– |

|

|

|

|

Field Voltage at 115 Volts AC Line Input (Volts DC) |

100/50 |

– |

|

|

|

|

|

Field Voltage at 208/230 Volts AC Line Input (Volts DC) |

200/100 |

– |

|

|

|

|

|

Speed Range (Ratio) |

50:1 |

– |

|

|

|

|

|

Voltage Following Linearity (% Base Speed) |

±0.5 |

– |

|

|

|

|

|

1.For low current operation, remove resistor R35 as described in section IVB, on page 10

2.Step-down operation.

3

Loading...

Loading...