KB Electronics KBWM-120 Instruction Manual

INSTALLATION AND OPERATING INSTRUCTIONS

TM

VARI-DRIVE

NEMA1 / IP20 SCR Variable Speed DC Motor Controls

Model KBWM-120 rated 1/100 - 1/3 HP (90 Volts DC) @ 115 Volts AC, 50/60 Hz

Model KBWM-240 rated 1/50 - 3/4 HP (180 Volts DC) @ 208/230 Volts AC, 50/60 Hz

|

VARI-DRIVE |

TM |

|

|

|

|

DC MOTOR |

|

|

SPEED CONTROL |

|

40 |

50 |

|

60 |

ON |

|

|

|

|

30 |

70 |

|

20 |

80 |

|

10 |

90 |

|

0 |

100 |

OFF |

|

||

|

(%) SPEED |

|

See Page 2

! See Safety Warning on Page 1

The information contained in this manual is intended to be accurate. However, the manufacturer retains the right to make changes in design which may not be included herein.

TM

A COMPLETE LINE OF MOTOR DRIVES

© 2001 KB Electronics, Inc.

|

TABLE OF CONTENTS |

|

Section |

Page |

|

i. |

Simplified Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 |

ii. |

Safety Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 1 |

I. |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

II. |

Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

III. |

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

IV. |

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

V. |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

VI. |

Trimpot Adjustments and Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 8 |

VII. Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 14 |

|

Tables |

|

|

1. |

General Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 2 |

2. |

Electrical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 3 |

3. |

Plug-in Horsepower Resistor® Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 5 |

4. |

Armature Fuse Selection Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

5. |

Terminal Block Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

6. |

Field Connection (Shunt Wound Motors Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 7 |

Figures

1. Control Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2. Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3. Motor Voltage Selection (J2) (Model KBWM-240 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . 6 4. AC Line and Armature Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 5A. Full Voltage Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 5B. Half Voltage Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 6A. Accel Trimpot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 6B. Decel Trimpot Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7. Internal Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ii

i.KBWM-120, 240 SIMPLIFIED OPERATING INSTRUCTIONS

IMPORTANT – You must read these simplified operating instructions before proceeding. These instructions are to be used as a reference only and are not intended to replace the detailed instructions provided herein. You must read the Safety Warning before proceeding.

A.Power Connection – Wire AC line to terminals L1 and L2. Be sure the model number corresponds to the correct input voltage.

B.Permanent Magnet (PM) Motor Connection (Two-Wire Type) – Wire the motor armature leads to terminals

MODEL NO. & VOLTAGE RATING

Model Number |

AC Line Voltage |

Armature |

|

VAC 50/60 Hz |

Voltage (VDC) |

KBWM-120 |

115 |

0 – 90 |

|

|

|

KBWM-240 |

208/230 |

0 – 90*, 180 |

|

|

|

A(+) and A(-). Be sure the motor volt- |

*See “G” below. |

age corresponds to the control voltage rating and model number. |

|

Note: Although control is specifically designed for PM motors it can also be used for shunt wound motors. (See Section IV D, page. 7.)

C.Ground – Be sure to earth ground the control by attaching a ground wire to the green stud located between the Bx knockouts.

D.Plug-in Horsepower Resistor®** – The correct Plug-in Horsepower Resistor® must be installed for optimum performance. (See Section II A, p. 5.)

E.Armature Fuse** – The correct value armature fuse must be installed for maximum protection. (See Section II C, p. 5.)

F.Trimpot Settings – All trimpots have been set according to Figure 1, page 3 and Section VI, page 8.

G.Jumper J2 is provided on Model KBWM-240 only and is factory set to “180V” position. For step-down operation (208/230 Volts AC line input and 0-90 Volts DC output), set J2 to the “90V” position. See Figure 3, on page 6.

**This control will not operate without installing the proper size Plug-in Horsepower Resistor® and armature fuse

– supplied separately.

ii.

! SAFETY WARNING! Please read carefully

! SAFETY WARNING! Please read carefully

This product should be installed and serviced by a qualified technician, electrician, or electrical maintenance person familiar with its operation and the hazards involved. Proper installation, which includes wiring, mounting in proper enclosure, fusing or other over current protection, and grounding can reduce the chance of electrical shocks, fires, or explosion in this product or products used with this product, such as electric motors, switches, coils, solenoids, and/or relays. Eye protection must be worn and insulated adjustment tools must be used when working with control under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding and filtering of this product can reduce the emission of radio frequency interference (RFI) which may adversely affect sensitive electronic equipment. If further information is required on this product, contact the Sales Department. It is the responsibility of the equipment manufacturer and individual installer to supply this Safety Warning to the ultimate end user of this product. (SW effective 9/2000).

This control contains electronic Start/Stop circuits that can be used to start and stop the control. However these circuits are never to be used as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

Be sure to follow all instructions carefully. Fire and/or electrocution can result due to improper use of this product.

1

This product complies with all CE directives pertinent at the time of manufacture. Contact factory for detailed installation and Declaration of Conformity. Installation of a CE approved RFI filter (KBRF-200A [P/N 9945C] or equivalent) is required. Additional shielded motor cable and/or

AC line cables may be required along with a signal isolator (KBSI-240D [P/N 9431] or equivalent).

I.INTRODUCTION

The KBWM™ Vari-Drive™ adjustable speed SCR control for DC motors offers proven reliability in a rugged all-metal NEMA-1 / IP20 enclosure. The Vari-Drives™ are equipped with the ultimate KBMM™ speed control module. They are specifically designed for fractional horsepower permanent magnet (PM) DC motors. Two models are offered. The KBWM-120 is designed for 115 VAC input and is rated 1/100-1/3 HP at 90 VDC. The KBWM-240 is designed for 208/230 VAC input and is rated 1/50 – 3/4 HP @ 180 VDC. Note: Model KBWM-240 can also be used on 90 Volt DC motors. See Section IID, on page 6.

KB’s exclusive Plug-in Horsepower Resistor®* automatically presets the drive’s IR Comp. for maximum performance and CL circuits for safe operation on various motors. Although factory calibrated, internal trimpots for MIN, MAX, IR, CL, ACCEL and DECEL can be used to fine-tune the KBWM™ for specific applications. Connections to the control are via a barrier terminal block. By changing the orientation of the front cover, the wiring can be brought in either from the bottom or the top of the control.

Motor failure due to demagnetization is eliminated by the patented ultra-fast Direct-Fed™ current limit circuit. The controls contain AC line and armature* fusing, which provide protection against catastrophic failure. Auto-Inhibit®, a KB exclusive, allows the drive to be turned on and off rapidly using the AC line without damage to the control and/or motor. The internal CL LED is a diagnostic indicator that lights when the motor is overloaded.

A conveniently located front panel lighted rocker switch controls AC line input power to the drive. *Plug-in Horsepower Resistor® and armature fuse supplied separately.

TABLE 1 – GENERAL PERFORMANCE SPECIFICATIONS

Parameter |

Specification |

|

|

Speed Range Ratio |

50:1 |

|

|

Armature Feedback Load Regulation (0 - Full Load, 50:1 Speed Range) (% Base Speed) |

1** |

|

|

Line Voltage Regulation at Full Load, ± 10% Line Variation (% Base Speed) |

1/2** |

|

|

Control Linearity (% Speed vs. Dial Rotation) |

2 |

|

|

CL/Torque Range (% Full Load) |

0 – 200 |

|

|

ACCEL Time Range (0 – Full Speed) (Secs.) |

0.2 – 10 |

|

|

DECEL Time Range (Full – 0 Speed) (Secs.) |

0.2 – 10 |

|

|

MIN Speed Trimpot Range (% Full Speed) |

0 – 30** |

|

|

MAX Speed Trimpot Range (% Full Speed) |

50 – 110** |

|

|

IR Comp. Trimpot Range (at Specified Full Load) (Volts) |

0 – 24 |

|

|

Maximum Allowable Ambient Temperature at Full Rating (ºC / ºF) |

50/122 |

|

|

**Performance is for SCR rated PM motors only. Lower performance can be expected with other motor types. Factory setting is for 3% load regulation. To obtain superior regulation, see Section VI F on page 10.

2

TABLE 2 – ELECTRICAL RATINGS

|

|

Input Voltage |

Max. AC |

Armature |

Max. DC |

Max. Horsepower |

|

Model No. |

Part No. |

Load Current |

Load Current |

||||

(VAC - 50/60 Hz) |

Voltage (VDC) |

HP, (kW) |

|||||

|

|

(RMS Amps) |

(DC Amps) |

||||

|

|

|

|

|

|||

KBWM-120 |

9380 |

115 |

5.0 |

0 – 90 |

3.5 |

1/3, (0.25) |

|

|

|

|

|

|

|

|

|

KBWM-240 |

9381 |

208/230 |

5.0 |

0 – 180 |

3.5 |

3/4, (0.50) |

|

|

|

|

|

||||

5.0 |

0 – 90* |

3.5 |

1/3, (0.25) |

||||

|

|

|

|||||

|

|

|

|

|

|

|

*Note – Step-down Operation: Motor may have reduced brush life. Consult motor manufacturer.

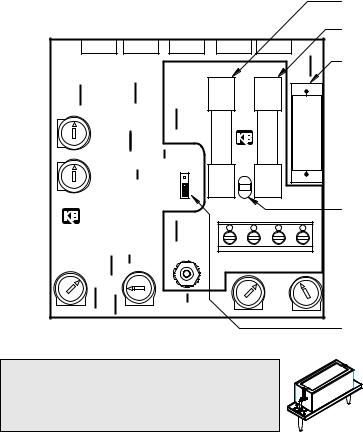

FIGURE 1 – CONTROL LAYOUT

(Illustrates Approximate Factory Setting of Trimpots and Jumper)

|

|

|

|

|

ARMATURE FUSE |

|

|

|

|

|

(CUSTOMER INSTALLED) |

|

|

|

|

|

SEE TABLE 4, PAGE 5 |

|

|

|

|

|

LINE FUSE |

|

|

|

|

|

(FACTORY INSTALLED) |

|

|

|

|

F- |

PLUG-IN |

L1 |

|

ARM |

LINE |

HORSEPOWER RESISTOR |

|

|

|

(CUSTOMER INSTALLED) |

|||

|

F1 |

F2 |

|

||

|

|

|

SEE TABLE 3, PAGE 5 |

||

DECEL |

L2 |

<![if ! IE]> <![endif]>SW3 WHT |

|

|

|

|

|

|

|

|

|

|

|

F+ |

|

|

|

|

|

B |

|

|

|

|

|

J2 |

|

|

|

|

T |

<![if ! IE]> <![endif]>90V |

|

|

|

|

|

|

|

|

|

ACCEL |

|

<![if ! IE]> <![endif]>180V |

|

|

CL LED |

|

|

|

|

TB1 |

|

|

|

<![if ! IE]> <![endif]>BLU |

|

|

|

|

|

|

|

|

|

P2 |

I1 |

SW6 |

L2 |

A+ |

A- |

|

|

L1 |

||||

|

P3 |

|

|

|

|

|

|

P1 |

|

|

|

|

|

|

|

|

I2 |

|

|

|

MAX |

|

MIN |

|

|

CL |

IR |

PLUG-IN HORSEPOWER RESISTOR

A Plug-in Horsepower Resistor® must be installed to match the drive to the motor horsepower and armature current. See Table 4, page 5 for the correct value. Plug-in Horsepower Resistors® are stocked by your distributor.

J2 IS INSTALLED

ON KBWM-240 ONLY

CAUTION: Be sure Plug-In Horsepower Resistor® is inserted completely into mating sockets.

3

Loading...

Loading...