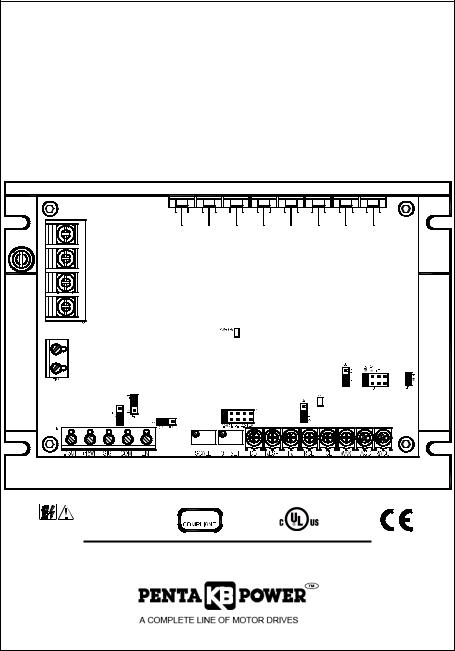

KB Electronics KBRG-212D User Manual

INSTALLATION AND OPERATION MANUAL |

REGENERATIVE DRIVE |

MODEL KBRG-212D |

Part No. 8819 |

VARIABLE SPEED SCR CONTROL |

FULL WAVE 4–QUADRANT |

L1 |

L2 |

M2 |

M1 |

F+ |

-F |

See Safety |

RoHS |

Warning, on page 5.

The information contained in this manual is intended to be accurate.

However, the manufacturer retains the right to make changes in design, which may not be included herein.

© 2009 KB Electronics, Inc.

(see back cover)

|

TABLE OF CONTENTS |

|

|

|

Section |

|

|

Page |

|

1 |

Quick-Start Instructions......................................................................... |

|

|

4 |

2 |

Safety Warning ..................................................................................... |

|

|

5 |

3 |

Introduction ........................................................................................... |

|

|

6 |

4 |

Important Application Information ......................................................... |

|

|

12 |

5 |

Mounting Instructions ............................................................................ |

|

|

12 |

6 |

Electrical Connections........................................................................... |

|

|

13 |

7 |

Setting Selectable Jumpers / Connector............................................... |

|

|

19 |

8 |

Recommended High Voltage Dielectric Withstand Testing (Hi-Pot) ..... |

23 |

||

9 |

Drive Operation ..................................................................................... |

|

|

24 |

10 |

Trimpot Adjustments ............................................................................. |

|

|

25 |

11 |

Diagnostic LED’s................................................................................... |

|

|

30 |

12 |

Troubleshooting .................................................................................... |

|

|

30 |

|

Limited Warranty ..................................................................... |

|

Back Cover |

|

Table |

|

|

|

Page |

1 |

Standard Features ................................................................................ |

|

|

7 |

2 |

Selectable Jumpers............................................................................... |

|

|

7 |

3 |

Trimpot Adjustments ............................................................................. |

|

|

8 |

4 |

Electrical Ratings .................................................................................. |

|

|

9 |

5 |

General Performance Specifications..................................................... |

|

|

9 |

6 |

Terminal Block Wiring Information ........................................................ |

|

|

13 |

7 |

Armature Fuse Chart............................................................................. |

|

|

14 |

8 |

Field Connection ................................................................................... |

|

|

15 |

9 |

Jumper J2 Setting vs. Motor Horsepower ............................................. |

|

|

19 |

10 |

Summary of Control (Regen) Operation ............................................... |

|

|

25 |

11 |

Troubleshooting Guide.......................................................................... |

|

|

30 |

Figure |

|

|

|

Page |

1 |

Control Layout............................................. ......................................... |

|

|

10 |

2 |

Mechanical Specifications........................... ......................................... |

|

|

11 |

3 |

AC Line and Armature Connection ............. ......................................... |

|

|

14 |

4 |

Full Voltage Field ........................................ ......................................... |

|

|

15 |

5 |

Half Voltage Field........................................ ......................................... |

|

|

15 |

6A |

Unidirectional Operation (Forward) ............. ......................................... |

|

|

16 |

6B |

Unidirectional Operation (Reverse)............. ......................................... |

|

|

16 |

6C |

Bidirectional Operation Reversing Contact . ......................................... |

|

|

16 |

6D |

Bidirectional with Potentiometer.................. ......................................... |

|

|

16 |

7A |

Voltage Following........................................ ......................................... |

|

|

17 |

7B |

Current Following ........................................ ......................................... |

|

|

17 |

7C |

J17 Voltage Scale ....................................... ......................................... |

|

|

18 |

7D |

J8 Current Scale ......................................... ......................................... |

|

|

18 |

8A |

Enable Mode ............................................... ......................................... |

|

|

18 |

8B |

Inhibit Mode................................................. ......................................... |

|

|

18 |

9 |

J1 Tach-Generator Connection................... ......................................... |

|

|

19 |

10 |

J2 Armature Current Jumper ...................... ......................................... |

|

|

19 |

11A |

J3 Armature Voltage (90V).......................... ......................................... |

|

|

20 |

11B |

J3 Armature Voltage (180V)........................ ......................................... |

|

|

20 |

12 |

J5 Speed /Torque........................................ ......................................... |

|

|

20 |

13 |

Speed Mode vs. Motor Load ....................... ......................................... |

|

|

20 |

14 |

Motor Speed vs. Applied Motor Load (Torque Mode) |

........................... |

21 |

|

15 |

J6 CTS / RTS Jumper................................. |

.......................................2 |

||

2

|

TABLE OF CONTENTS (Continued) |

|

|

Figure |

|

|

Page |

16 |

J8 15V / 10V Jumper .................................. |

.......................................22 |

|

17A |

J17 Analog Signal Input (Voltage Position). |

.......................................22 |

|

17B |

J17 Analog Signal Input (Current Position). |

.......................................22 |

|

18 |

J9 Enable / Inhibit Jumper .......................... |

.......................................22 |

|

19 |

Typical Hi-Pot Test Setup ........................... |

.......................................24 |

|

20A |

Forward and Reverse Acceleration Trimpot Position............................ |

26 |

|

20B |

ACCEL Trimpot Adjustment ........................ |

.......................................26 |

|

21 |

Maximum Speed Trimpot Position .............. |

.......................................26 |

|

22A |

Forward Current Trimpot Position ............... |

.......................................27 |

|

22B |

Reverse Current Trimpot Position............... |

.......................................27 |

|

23 |

IR Compensation Trimpot Position ............. |

.......................................27 |

|

24 |

Response Trimpot Position......................... |

.......................................28 |

|

25A |

Deadband Trimpot Position......................... |

.......................................28 |

|

25B |

Deadband Trimpot Adjustment ................... |

.......................................28 |

|

26A |

Offset Trimpot Position................................ |

.......................................29 |

|

26B |

Offset Trimpot Adjustment .......................... |

.......................................29 |

|

27A |

Scale Trimpot Position ................................ |

.......................................29 |

|

27B |

Scale Trimpot Adjustment........................... |

.......................................29 |

|

3

1 QUICK-START INSTRUCTIONS

Important: You must read these simplified instructions before proceeding. These instructions are to be used as a reference only and are not intended to replace the details provided herein. You must read the SAFETY WARNING, on page 5, before proceeding.

1.1. Connections (See Figure 3, on page 14).

Note: There are no AC Line or Armature fuses supplied with this control. See Section, 1.1.2.

1.1.1AC Line – Connect AC line voltage (115 or 230 VAC) to terminals L1 and L2. Connect ground wire (earth) to the green ground screw.

1.1.2Fusing – The KBRG-212D does not contain AC line or armature fusing. It is recommended that a 20 Amp fuse or circuit breaker be installed on each AC line conductor not at ground potential. Do not fuse ground or neutral wires.

1.1.3Ground Connection – Earth ground the control chassis using the green ground screw that is provided on the control,s heat sink (near TB2).

1.1.4Motor (See Figure 3, on page 14).

a. Permanent Magnet (PM Type). Connect motor armature leads to M1+ and M2-.

Note: Motor performance and efficiency, including brush life, can be adversely affected when using 90 volt motors with a 230 VAC line. Contact motor manufacturer for derating information.

b.Shunt Wound Motors. Connect motor armature leads as above. Connect full voltage shunt field leads (90 volt motors with 100 volt fields and 180 volt with 200 volt fields) to F+ and F-. Connect half voltage field leads (90 volt motors with 50 volt fields and 180 volt motors with 100 volt fields) to F+ and L1.

1.2ENABLE/INHIBIT– The control can be electronically stopped and started with this circuit function. To “Stop” the control, Terminals must be connected in the required position, by selecting the type of mode, via J9. See Figure 8B and Section 6.10, on page 18.

In the Enable Mode, the control can also be started and stopped with an Enable circuit (the Enable circuit functions opposite to that of the inhibit circuit; Inhibit: open to start, close to stop, Enable: open to stop, close to start). The Enable function can also be established by wiring a contact in series with the high side of the Main Speed Potentiometer lead connected to Terminal P3. See Figure 8A and Section 6.10, on page 18.

1.3SPEED OR TORQUE MODE: Jumper J5 is factory set for Speed (SPD) control operation. For torque control, set J5 to the Torque (TRQ) position. See Section 7.3, on page 20.

1.4JUMPER SETTINGS: All jumpers are set for the KBRG-212D version. The control is factory jumpered for the Enabled mode. See Section 7, on page 19.

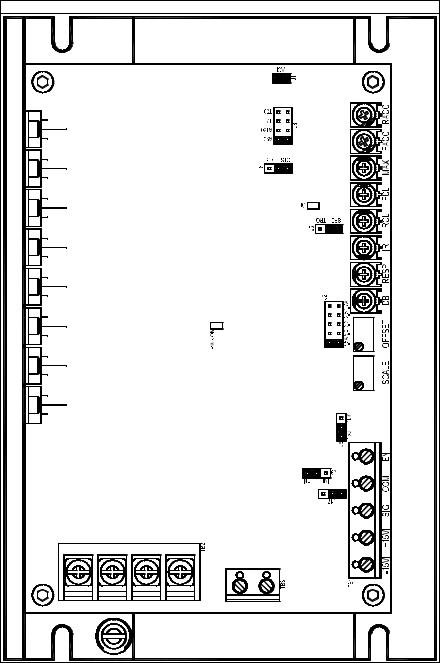

1.5TRIMPOT SETTINGS – All trimpots have been factory set. See Figure 1, on page 10 and Section 10, on page 25.

1.6SIGNAL INPUT – Connect potentiometer or analog input to TB1, terminals “-15,” “+15” “SIG,” and “COM” according to Section 6, on page 16.

4

2 SAFETY WARNING

Definition of Safety Warning Symbols

Electrical Hazard Warning Symbol: Failure to observe this warning could result in electrical shock or electrocution.

Electrical Hazard Warning Symbol: Failure to observe this warning could result in electrical shock or electrocution.

Operational Hazard Warning Symbol: Failure to observe this warning could result in serious injury or death.

Operational Hazard Warning Symbol: Failure to observe this warning could result in serious injury or death.

SAFETY WARNING! Please read carefully before proceeding.

This product should be installed and serviced by a qualified technician, electrician, or electrical maintenance person familiar with its operation and the hazards involved. Proper installation, which includes electrical connections, mounting and adequate enclosure, fusing or other current protection, and grounding can reduce the chance of electrical shocks, and/or fires in this product or products used with this product, such as electric motors, switches, coils, solenoids, and/or relays. Do not use this drive in an explosion-proof application. Eye protection must be worn and insulated adjustment tools must be used when working with drive under power. This product is constructed of materials (plastics, metals, carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding, and filtering of this product can reduce the emission of radio frequency interference (RFI) which may adversely affect sensitive electronic equipment. The input circuits of this drive may not be isolated from the AC line. Be sure to read and follow all instructions carefully. Fire and/or electrocution can result due to improper use of this product.

The drive may contain electronic start/stop circuits, which are used for "Start" and "Stop" functions. However, these circuits are never to be used as safety disconnects since they are not fail-safe. Use only the AC line for this purpose.

It is the responsibility of the equipment manufacturer and individual installer to supply this Safety Warning to the ultimate end user of this product. (SW 7/2009)

This product complies with all CE directives pertinent at the time of manufacture. Contact our Sales Department for Declaration of Conformity. Installation of a CE approved RFI filter is required. Additional shielded cable and/or AC line cables may be required along with a signal isolator.

This product complies with all CE directives pertinent at the time of manufacture. Contact our Sales Department for Declaration of Conformity. Installation of a CE approved RFI filter is required. Additional shielded cable and/or AC line cables may be required along with a signal isolator.

5

3 INTRODUCTION

Thank you for purchasing the KBRG-212D. KB Electronics is committed to providing total customer satisfaction by producing quality products that are easy to install and operate. The KBRG-212D is manufactured with Surface Mount Technology (SMT), incorporating advanced circuitry, components and technology.

The KBRG -212D has an Enable (EN) / Inhibit (INH) mode. The 212D version is factory set (J9 jumper) to Enable (EN). If the user requires the 213D Inhibit (INH) mode, the jumper, J9, is moved to that position.

The KBRG-212D is a full-wave regenerative drive capable of operating DC PM (Permanent Magnet) or Shunt motors in a bidirectional mode. Its 4-quadrant operation provides forward and reverse torque in both speed directions. This allows the control to maintain constant speed with overhauling loads and provides rapid instant reversing and controlled braking. Because of its excellent controllability and response time, the KBRG-212D can replace servos in many applications. The control is factory set for armature feedback, which can provide 1% load regulation over a motor base speed of 50:1. However, tachometer feedback is also available if superior regulation is required. By resetting mode jumper J5 to the “TRQ” position, the KBRG-212D can be changed from a speed control to a torque control.

In addition, the KBRG-212D is used to isolate, amplify, and condition DC voltage signals from any external source (power supplies, motors, tachometer generators, transducers, and potentiometers). The KBRG-212D also provides isolation for motor direction switching and an isolated power supply for transducer or potentiometer operation.

All input and signal connections are made via Terminal blocks and are electrically isolated from AC line and motor wiring.

The KBRG -212D features an Enable (EN) and Inhibit (INH) function (J9). Having both these features allows the drive to be used in applications that previously used the KBRG-212D (Enable) or the KBRG-213D (Inhibit). The control can be electronically stopped and started with the Enable / Inhibit circuit. (The Enable circuit functions opposite to that of the inhibit circuit; Inhibit: open to start, close to stop, Enable: open to stop, close to start).

The drive contains a variety of “selectable” jumpers and adjustment trimpots to allow for custom tailoring for exact requirements.

Another important feature is the LED indicators (PWR ON, OL), which indicate the mode of operation the drive is in, and also serves as a diagnostic tool.

Reliability of the KBRG-212D is further enhanced with the use of high speed current limiting and MOV transient protection. A 5kΩ remote potentiometer and full operating instructions are supplied. See Figures 1 and 2, on pages 10 and 11. In addition, see Tables 1 – 6, on pages 7 – 9.

WARNING! BE SURE TO FOLLOW ALL INSTRUCTIONS CAREFULLY. FIRE OR ELECTROCUTION CAN RESULT DUE TO IMPROPER USE OF THIS PRODUCT. READ SAFETY WARNING ON PAGE 5.

WARNING! BE SURE TO FOLLOW ALL INSTRUCTIONS CAREFULLY. FIRE OR ELECTROCUTION CAN RESULT DUE TO IMPROPER USE OF THIS PRODUCT. READ SAFETY WARNING ON PAGE 5.

6

TABLE 1 – STANDARD FEATURES

Feature |

|

Description |

|

Terminal Blocks |

Facilitates wiring of AC line, motor armature and field, |

||

TB1 (-15V, +15V, SIG, COM, EN), TB2 (L1, L2, M2, M1), TB3 |

|||

(See Section 6, on page 13.) |

|||

|

(F+, F-). |

||

Connectors |

J1, Tach-Generator Input – Connection point for an external |

||

(See Section 7, on page 19.) |

Tach-Generator. |

||

|

J2 |

- Motor Armature Current |

|

|

J3 |

- Motor Armature Voltage |

|

Selectable Jumpers |

J5 |

-SPD / TRQ – (Speed / Torque) |

|

J6 |

-CTS/RTS – (Coast to Stop / Regenerate to Stop) |

||

(See Section 7, on page 19.) |

|||

|

J8 |

-Signal Input Source (15V or 10V) |

|

|

J9 |

- Enable (EN) / Inhibit (INH) |

|

|

J17Analog Signal Input (Voltage/Current) |

||

|

Provide adjustment for Forward Acceleration (FACC), Reverse |

||

Trimpots |

Acceleration (RACC), Maximum (MAX), Forward Current Limit |

||

(FCL), Reverse Current Limit (RCL), IR Compensation (IR), |

|||

(See Section 10, on page 25.) |

|||

|

Response (RESP), Deadband (DB), Offset (OFFSET), and |

||

|

Scale (SCALE). |

||

Diagnostic LEDs |

For Power On (ON), and Current Limit (OL) indications. |

||

(See Section 11, on page 30.) |

(Current Overload gives indication that the control will trip). |

||

TABLE 2 – SELECTABLE JUMPERS (See Section 7, on page 19)

Feature |

Description |

|

J2-Motor Current, Refer to Section 7.1, on page |

For selection of the motor current being used. |

|

19. |

|

|

J3 – Motor Armature Voltage, Refer to Section |

For selection of the motor voltage being |

|

7.2, on page 20. |

used. |

|

J5-SPD / TRQ, Speed or Torque, Refer to |

Jumper position is selectable for either Speed |

|

Section 7.3, on page 20. |

(SPD) or Torque (TRQ) modes. |

|

|

For selection of Coast to Stop (CTS) and |

|

J6-CTS/RTS. Refer to Section 7.4, on page 21. |

Regenerate to Stop (RTS). Works in |

|

|

conjunction with the Enable circuit. |

|

J8-Signal Input (15V or 10V). Refer to Section |

Used for selection of potentiometer (15V) or |

|

7.5, on page 22. |

use if the control is to be used from a |

|

0 – ±10/±15VDC. |

||

|

||

|

Input signal connection for the use with the |

|

J17-Signal Input. Refer to Section 7.6, on page |

Main Speed Potentiometer. Used for |

|

22. |

accepting a 0 – ±10V or 0 – ±25V signal or |

|

|

4 – 20 ma. |

|

J9-EN (Enable) / INH (Inhibit). Refer to Section |

For selection of electronically starting and |

|

7.7, on page 22. |

stopping the motor. Used in conjunction with |

|

J6, CTS/RTS. |

||

|

7

TABLE 3 – TRIMPOT ADJUSTMENTS (See Section 10, on pages 25)

Trimpot |

Description |

|

|

Sets the amount of time for the motor to |

|

Forward Acceleration (FACC). Refer to Section |

accelerate from zero speed to full speed in the |

|

forward direction and the time it takes to |

||

10.1, page 25. |

decelerate in the reverse direction (FACC = |

|

|

Reverse Deceleration). Factory adjusted to 1 |

|

|

second. (Maximum of 15 seconds). |

|

|

Sets the amount of time for the motor to |

|

Reverse Acceleration (RACC). Refer to Section |

accelerate from zero speed to full speed in the |

|

reverse direction and the time it takes to |

||

10.1, on page 25. |

decelerate in the forward direction (RACC = |

|

|

Forward Deceleration). Factory adjusted to 1 |

|

|

second. (Maximum of 15 seconds). |

|

|

The MAX trimpot is used to set the maximum |

|

Maximum Speed (MAX SPD). Refer to Section |

output voltage of the control which, in turn, sets |

|

10.2, on page 26. |

the maximum speed of the motor. In the |

|

Torque Control Mode. The MAX trimpot setting |

||

|

||

|

determines the unloaded motor speed. |

|

|

Sets the maximum amount of DC current that |

|

Forward Current Limit (FCL). Refer to Section |

the motor can draw. This determines the |

|

10.3, on page 26. * |

amount of maximum motor torque in both the |

|

|

Speed Control Mode and Torque Mode. |

|

|

Sets the maximum amount of DC current that |

|

Reverse Current Limit (RCL) Refer to Section |

the motor can draw. This determines the |

|

10.3, on page 26. * |

amount of maximum motor torque in both the |

|

|

Speed Control Mode and Torque Mode. |

|

IR Comp (IR COMP). Refer to Section 10.4, |

The IR Comp is used to stabilize motor speed |

|

page 27. |

under varying loads. |

|

Response (RESP). Refer to Section 10.5, on |

This trimpot determines the dynamic response |

|

page 28. |

of the control. |

|

|

The DB trimpot sets the amount of main speed |

|

Deadband (DB). Refer to Section 10.6, on page |

potentiometer rotation required to initiate |

|

control voltage output. It is factory set to |

||

28. |

approximately 0%. The DB trimpot also |

|

|

determines the amount of delay that will occur |

|

|

before regeneration starts. |

|

|

This trimpot determines the amount of bias in |

|

Offset (OFFSET). Refer to Section 10.7, on |

the forward or reverse direction. The trimpot is |

|

page 29. |

factory set to provide approximately zero |

|

offset, which means neither the forward nor |

||

|

||

|

the reverse speed is favored. |

|

|

This trimpot works in conjunction with the |

|

Scale (SCALE). Refer to Section 10.8, on page |

MAX potentiometer for fine tuning of the |

|

29. |

(voltage or current) of the incoming analog |

|

|

signal. |

* FCL and RCL also determine the maximum amount of regenerative breaking torque depending on which direction is braking.

8

|

|

|

TABLE 4 B ELECTRICAL RATINGS |

|

Maximum |

|

||||

|

Input Voltage |

|

Maximum AC |

|

Output |

Maximum |

|

|

||

|

|

Line Current |

|

Voltage |

DC Output |

|

Horsepower |

|

||

|

(VAC) |

|

(Amps RMS) |

|

(Volts DC) |

Current (ADC) |

|

HP, (KW) |

|

|

|

115 |

|

12 |

|

0 – ±90 |

7.5 |

¾, (0.5) |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

208/230 |

|

12 |

|

0 – ±180 |

7.5 |

1.5, (1) |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

TABLE 5 B GENERAL PERFORMANCE SPECIFICATIONS |

|

|||||||

|

|

|

Parameter |

|

|

Specification |

|

Factory Setting |

|

|

AC Line Input Voltage (VAC, ±10%, 50/60 Hz) |

|

115 or 208/230 |

|

208/230 |

|

|||||

|

|

|

|

|

|

|||||

Armature Voltage Range at 115 VAC Line (VDC) |

|

0 – ±90 |

|

— |

|

|||||

|

|

|

|

|

|

|||||

Armature Voltage Range at 230 VAC Line (VDC) |

|

0 – ±90, 0 – ±180 |

|

0 – ±180 |

|

|||||

|

|

|

|

|

|

|

||||

Field Voltage at 115 VAC Line (VDC) |

|

|

100 / 50 |

|

— |

|

||||

|

|

|

|

|

|

|

||||

Field Voltage at 230 VAC Line (VDC) |

|

|

200 / 100 |

|

— |

|

||||

|

|

|

|

|

|

|

||||

Max Load Capacity (% for 2 Minutes) |

|

|

150 |

|

— |

|

||||

|

|

|

|

|

|

|

||||

Ambient Temperature Range (ºC / °F) |

|

|

0 – 40 / 32 – 104 |

|

— |

|

||||

|

|

|

|

|

|

|

||||

Speed Range (Ratio) |

|

|

50:1 |

|

— |

|

||||

|

|

|

|

|

|

|||||

Arm Feedback Load Regulation (% Base Speed) |

|

±1 |

|

— |

|

|||||

|

|

|

|

|

|

|||||

Tach Feedback Load Regulation (% Set Speed) |

|

±1 |

|

— |

|

|||||

|

|

|

|

|

|

|

||||

AC Line Regulation (% Base Speed) |

|

|

±0.5 |

|

— |

|

||||

|

|

|

|

|

|

|

||||

Current Ranges (Amps DC) |

|

|

1.7, 2.5, 5.0, 7.5 |

|

7.5 |

|

||||

|

|

|

|

|

|

|

||||

FWD and REV Accel Range (Seconds) |

|

|

0.1 – 15 |

|

1 |

|

||||

|

|

|

|

|

|

|

||||

Deadband Range (% Base Speed) |

|

|

0 – ±5 |

|

0 |

|

||||

|

|

|

|

|

|

|||||

Max Speed Trimpot Range (% Base Speed) |

|

55 – 110 |

|

100 |

|

|||||

|

|

|

|

|

|

|

||||

IR Comp Range at 115 VAC Line (VDC) |

|

|

0 – 20 |

|

5 |

|

||||

|

|

|

|

|

|

|

||||

IR Comp Range at 230 VAC Line (VDC) |

|

|

0 – 40 |

|

10 |

|

||||

|

|

|

|

|

|

|

||||

FCL and RCL Range (% Range Setting) |

|

|

0 – 175 |

|

150 |

|

||||

|

|

|

|

|

|

|

||||

Voltage Following Input Range (VDC) |

|

|

±5 – ±25 |

|

0 – ±10, 0 – ±15 |

|

||||

|

|

|

|

|

|

|||||

Voltage Following Linearity (% Base Speed) |

|

±0.5 |

|

— |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

9

|

|

FIGURE 1 B CONTROL LAYOUT |

|||

L1 |

L2 |

M2 |

M1 |

F+ |

F- |

10 |

|

|

|

|

|

Loading...

Loading...