Page 1

INSTALLATION AND OPERATING INSTRUCTIONS

REGENERATIVE DRIVE

MODEL KBRG-225D

(P/N 8800)

FULL WAVE • 4 QUADRANT

FWD

FWD

REV

ACCEL

ACCEL

EN

REV

EN

PWR

ON

T1

DB

OFFSET

S/LT

NLT

MODEL KBRG-240D

(P/N 8802)

MAX

J8

IR REV FWD

RESPSPD

CLCOMP

CL

TCL

This manual

applies to

logic board

revision “L”

and newer

controls

only.

CL

ARMATURE

FUSE

TB2

M2L1 L2

F2

F1

(EARTH)

GND

TB1

21 3 4 65

TB1

F+ F-

F1

AC LINE

FUSE

R33

J3

1297 8 10 11 13

M1

See Safety Warning on Page 2

The information contained in this manual is intended to be accurate. However, the manufacturer

retains the right to make changes in design which may not be included herein.

See Page 2

™

A COMPLETE LINE OF MOTOR DRIVES

© 1997 KB Electronics, Inc.

Page 2

TABLE OF CONTENTS

Section Page

i. Simplified Setup and Operating Instructions ...................................1

ii. Safety Warning .........................................................2

I. General Information .....................................................2

II. Setting Mode of Drive (Speed or Torque Control) ...............................4

III. Setting Selectable Jumpers ...............................................6

IV. Mounting ..............................................................8

V. Wiring ................................................................8

VI. Fusing ...............................................................12

VII. Operation ............................................................12

VIII. Trimpot Adjustments ....................................................13

IX. Function Indicator Lamps ................................................15

X. Limited Warranty .......................................................22

TABLES

1. Electrical Ratings .......................................................2

2. General Performance Specifications .........................................4

3. Summary of Control Operation .............................................5

4. Jumper J2 Position vs Motor Horsepower .....................................6

5. Relationship of AC Line Input and Motor Voltage ...............................7

6. Terminal Block Wiring Information ..........................................8

7. Field Connections ......................................................10

8. Control State vs Relay Contact State .......................................12

9. Armature Fuse Chart ...................................................13

10. Current Limit Timer Settings ..............................................15

11. Parts List (Logic Board) ..............................................16, 17

12. Parts List (Power Board) .................................................19

FIGURES

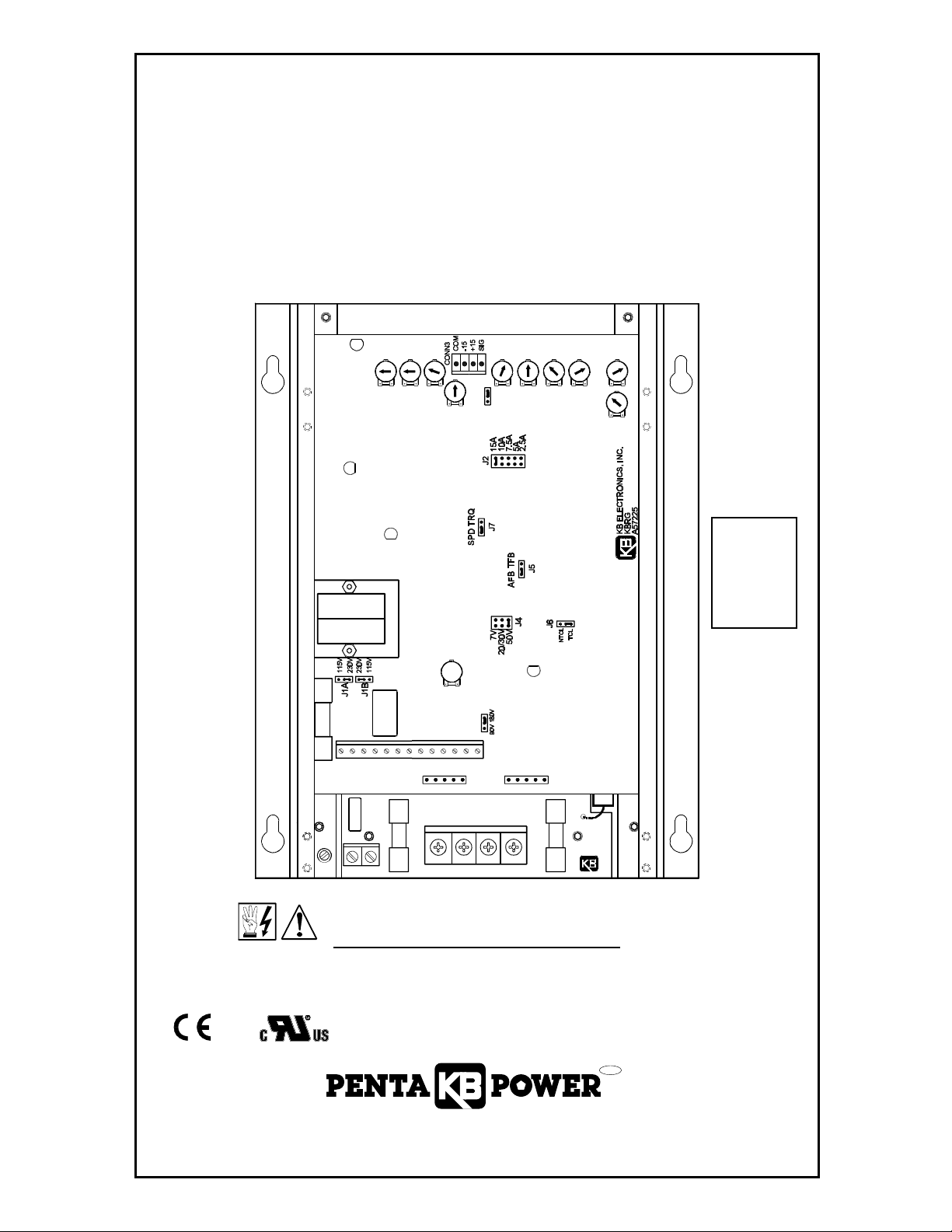

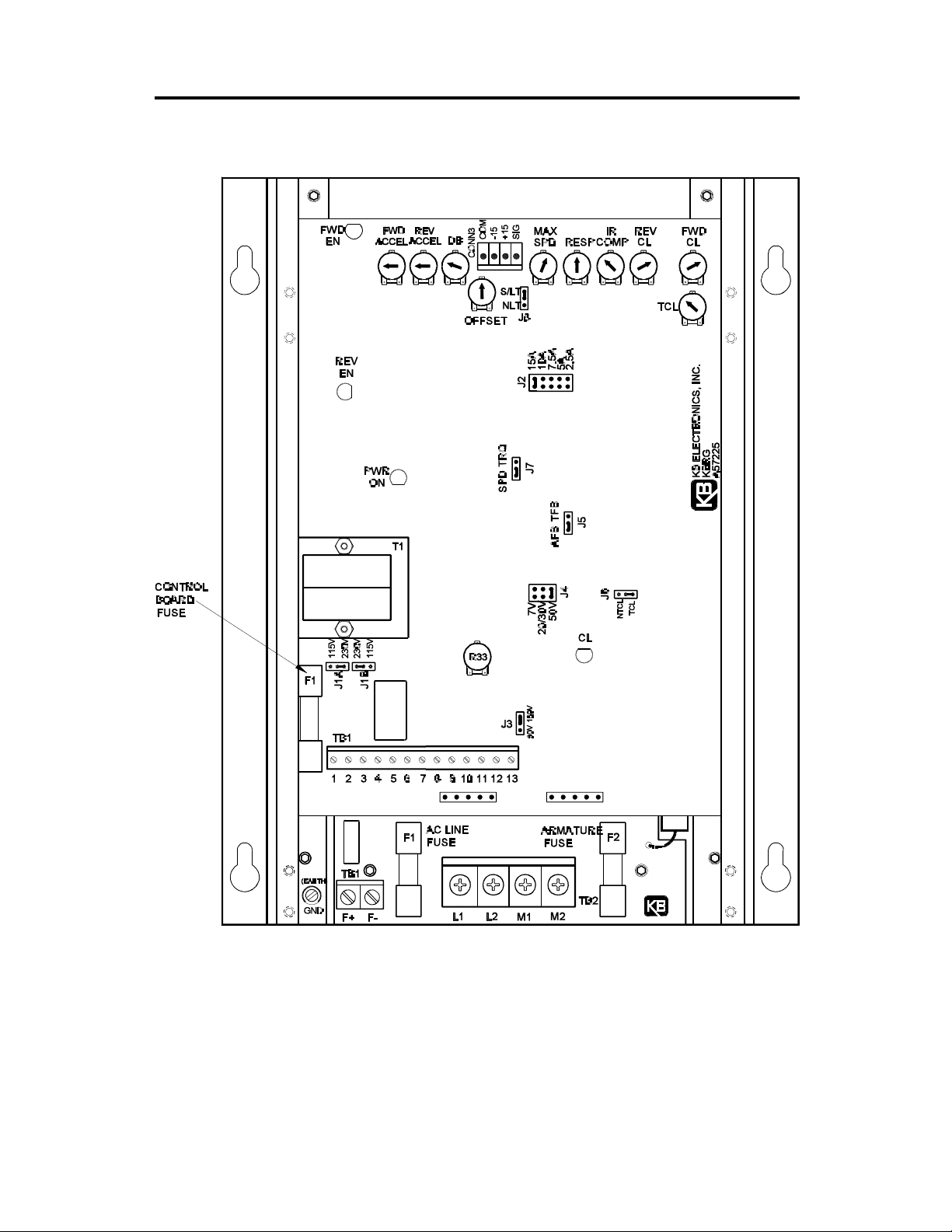

1. Control Layout .........................................................3

2A. Linear Torque Curve .....................................................5

2B. Non-Linear Torque Curve .................................................6

3. AC Line Voltage Jumper Setting ............................................7

4. Motor Armature Voltage Jumper Setting ......................................7

5. Mechanical Specifications .................................................9

6. AC Line and Armature Connection .........................................10

7A. Full Voltage Field ......................................................10

7B. Half Voltage Field ......................................................10

8. Main Speed Potentiometer Connections .....................................11

9A. Voltage Following ......................................................11

9B. Enable ..............................................................11

9C. Start/Stop Circuit .......................................................11

9D. Alarm Contacts ........................................................11

9E. Tach-generator Connection ...............................................12

10. Accel Trimpot Adjustment ................................................13

11. Offset Trimpot Adjustment ...............................................14

12. Deadband Trimpot Adjustment ............................................14

13. Logic Board Schematic ..................................................18

14. Power Board Schematic .................................................20

ii

Page 3

i. KBRG SIMPLIFIED OPERATING INSTRUCTIONS

IMPORTANT – You must read these simplified operating instructions

before you proceed. These instructions are to be used as a reference

only and are not intended to replace the detailed instructions provided

herein. You must read the Safety Warning on page 2 before proceeding.

1. CONNECTIONS.

A. AC Line – Wire AC line voltage to terminals L1 and L2. Be sure jumpers J1A and

J1B are both set to the correct input line voltage of 115 or 230 VAC. Connect

ground wire (earth) to green ground screw.

B. Motor.

1. Permanent Magnet (PM Type). Connect motor armature leads to M1+ and M2-.

Be sure jumper J3 is set to the proper position “90" for 90 volt DC motors and

“180" for 180 volt DC motors. Note: 180 volt DC motors must be used with 230

VAC line, 90 volt motors can be used with a 230 VAC or 115 VAC line. Note:

Motor performance and efficiency, including brush life, may be adversely

affected when using 90 volt motors with a 230 VAC line.

2. Shunt Wound Motors. Connect motor armature as above. Connect full voltage

shunt field wires (90 volt motors with 100 volt fields and 180 volt with 200 volt

fields) to F+ and F-. Connect half voltage field wires (90 volt motors with 50 volt

fields and 180 volt motors with 100 volt fields) to F+ and L1.

2. SPEED OR TORQUE MODE.

Jumper J7 is factory set for speed control operation (SPD). For torque control, set J7

to TRQ position. Note: J8 must be set to the “S/LT” position for speed control operation.

3. MOTOR CURRENT.

Jumper J2 is factory set for 15 amp motors (15A) on the KBRG-225D and 10 amp motors

(10A) on the KBRG-240D. For lower amperage motors, place J2 in the proper position.

If motor amperage is less than 2.5 amps, which is the lowest value on both models, use

the 2.5A position and readjust the IR and both CL trimpots according to section VIII D

and E on pages 14 and 15 .

Note: The factory setting for Current Limit is 150% of the nominal current setting (e.g.,

if J2 is selected for 5 amps, the actual CL setting will be 7.5 amps).

4. TRIMPOT SETTINGS.

All trimpots have been factory set in accordance with figure 1, page 3.

5. AC LINE FUSE.

The power board on all models contains a single AC line fuse (F1), 25A for KBRG-225D

and 20A for KBRG-240D. The AC line fuse protects the unit from catastrophic failure.

6. ARMATURE FUSE.

An armature fuse (F2) is also provided. A 25A armature fuse is installed on the

KBRG-225D and a 20A on the KBRG-240D. It is recommended that the correct size

armature fuse be installed depending on the rating of the motor and form factor. See

table 9, page 13.

7. SIGNAL INPUT.

Connect potentiometer or isolated analog input to terminal “10,” “11,” “12" and “13"

according to section V, E and F, on pages 10 and 11. Do not ground (earth) signal

inputs. Use a signal isolator when controlling multiple drives from a non isolated signal

source.

1

Page 4

ii. SAFETY WARNING! — PLEASE READ CAREFULLY

This product should be installed and serviced by a qualified technician, electrician or

electrical maintenance person familiar with its operation and the hazards involved. Proper

installation, which includes wiring, mounting in proper enclosure, fusing or other overcurrent

protection and grounding, can reduce the chance of electric shocks, fires or explosion in this

product or products used with this product, such as electric motors, switches, coils, solenoids

and/or relays. Eye protection must be worn and insulated adjustment tools must be used when

working with control under power. This product is constructed of materials (plastics, metals,

carbon, silicon, etc.) which may be a potential hazard. Proper shielding, grounding and filtering

of this product can reduce the emission of radio frequency interference (RFI) which may

adversely affect sensitive electronic equipment. If information is required on this product,

contact our factory. It is the responsibility of the equipment manufacturer and individual installer

to supply this safety warning to the ultimate user of this product. (SW effective 11/92)

This control contains electronic Start/Stop and Inhibit circuits that can be used to start and

stop the control. However, these circuits are never to be used as safety disconnects since they

are not fail-safe. Use only the AC line for this purpose.

The input circuits of this control (potentiometer, start/stop, Inhibit) are not isolated from AC

line. Be sure to follow all instructions carefully. Fire and/or electrocution can result due

to improper use of this product.

This product complies with all CE directives pertinent at the time of manufacture.

Contact factory for detailed installation instructions and Declaration of

Conformity. Installation of a CE approved RFI filter (KBRF-200A, KB P/N 9945C or

equivalent) is required. Additional shielded motor cable and/or AC line cables may be

required along with a signal isolator (SI-4X, KB P/N 8801 or equivalent).

I. GENERAL INFORMATION.

The KBRG is a full-wave regenerative control, capable of operating a DC motor (Permanent

Magnet or Shunt) in a bidirectional mode. It provides 4-quadrant operation which allows

forward and reverse torque in both speed directions. The drive offers excellent controllability,

which closely approximates the performance of servo-type drives. Ratings and specifications

are presented in tables 1 and 2. Be sure the drive is used within these ratings and

specifications.

(Note: Regenerative drives normally produce more motor heating than standard

unidirectional SCR speed controls, especially under low speed operation. This should

be taken into consideration when specifying motor rating.)

WARNING! Be sure to follow all instructions carefully. Fire or electrocution

can result due to improper use of this product. Read Safety Warning.

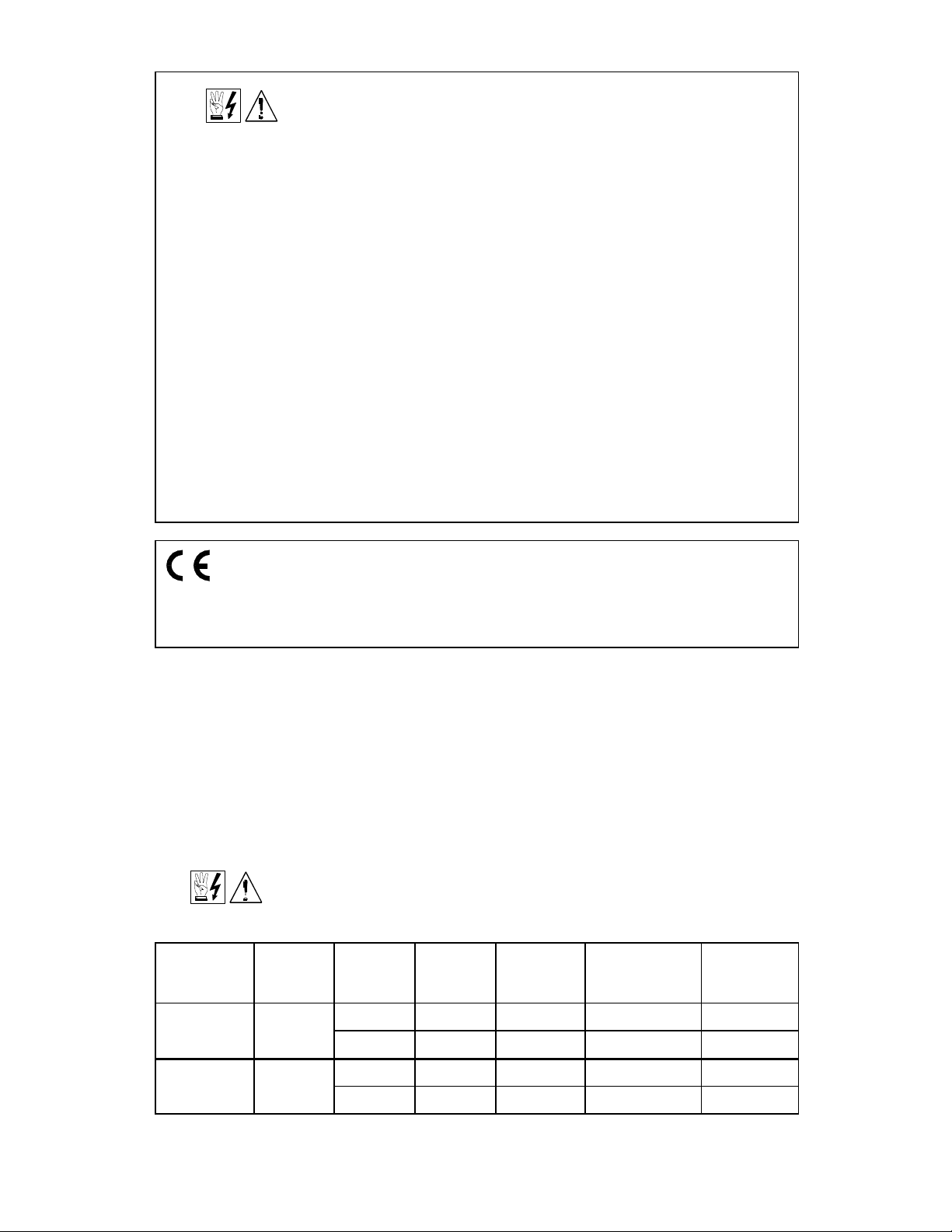

TABLE 1 – ELECTRICAL RATINGS

Model Part No.

KBRG-240D 8802

KBRG-225D 8800

Input

Voltage

(VAC)

115 16 0 – ±90 11 1, (.75)

230 16 0 – ±180 11 2, (1.5)

115 24 0 – ±90 16 1, (1)

230

Max. AC

Current

(RMS)

24

Output

Voltage

(VDC)

0 – ±180

Max. DC

Output

Current (ADC)

16

Horsepower

Max.

HP, (KW)

3, (2)

2

Page 5

FIG. 1 – CONTROL LAYOUT

Illustrates Factory Setting of Jumpers and Approximate Trimpot Settings

3

Page 6

TABLE 2 – GENERAL PERFORMANCE SPECIFICATIONS

Parameter Specification Factory Setting

AC Line Input Voltage (VAC ±10%,50/60 Hz)

AC Line Frequency (Hz), # of Phases

Arm Voltage Range at 115VAC Line (VDC)

Arm Voltage Range at 230VAC Line (VDC)

Field Voltage at 115VAC Line (VDC)

Field Voltage at 230VAC Line (VDC)

Service Factor

Duty

Max Load Capacity (% for 2 minutes)

Ambient Temperature Range (ºC)

Speed Range (Ratio)

Arm Feedback Load Regulation (% Base Speed)

Tach Feedback Load Regulation (% Set Speed)

Line Regulation (% Base Speed)

Current Ranges (ADC)

FWD and REV Accel Range (Secs.)

Dead Band Range (% Base Speed)

Max Speed Trimpot Range (% Base Speed)

IR Comp Range at 115VAC Line (VDC)

IR Comp Range at 230VAC Line (VDC)

FWD and REV CL Range (% Range Setting)

Timed CL Range (Sec.)

Voltage Following Input Range (VDC)

Voltage Following Linearity (% Base Speed)

Tach-generator Voltage Input (Volts)

115 or 230

50/60, 1

0 – ±90

0 – ±180, 0 – ±90

100/50

200/100

1.0

Continuous

150

(1)

0 – 50

50:1

±1

±1

±0.5

2.5, 5.0, 7.5, 10, 15

0.1 – 15

0 – ±3

70 – 110

0 – 15

0 – 30

0 – 150

1 – 15

0 – ±10, 0 – ±15

±0.5

7,20/30,50

(2)

230

—

—

0 – ±180

—

—

—

—

—

—

—

—

—

—

15 or 10

1

0

100

5

10

150

5

0 – ±15

—

50

Notes:

(1) Control mounted in vertical position. Maximum ambient temperature in horizontal position is 45 ºC.

(2) 15A current range on KBRG-225D only.

II. SETTING MODE OF DRIVE (SPEED OR TORQUE CONTROL).

The KBRG can be operated as a speed control or torque control by setting the position of

jumper J7. The main speed potentiometer controls the magnitude of the mode selected. Set

jumper J7 to "SPD" for speed control or to "TRQ" for torque control. (See fig. 1, p. 3.)

A. Speed Control Mode – When jumper J7 is set to the “SPD” position, the KBRG will vary

the motor speed as a function of the voltage on input terminals "12" (signal) and "13"

(common). IMPORTANT: When J7 is set for speed control (“SPD”), J8 must be set to

“S/LT” position (factory setting). The input voltage can be derived from the wiper of the

main speed potentiometer or from an isolated analog input (voltage following mode). Since

the KBRG is a 4-quadrant regenerative drive, the motor speed will follow both a positive

and negative wiper voltage and drive the motor in both the forward direction and reverse

direction. In addition, it will apply both forward and reverse torque in order to stabilize motor

speed.

To understand the concept of a regenerative drive, the operation of an elevator can be used.

If one were to enter the elevator on the first floor and press 10, the motor and control would

have to lift the elevator against gravity. In this mode, the drive would operate like a

conventional speed control which is called “motoring” (the applied load is opposite to the

direction of motor rotation). When the elevator is at floor 10 and floor 1 is pressed, gravity will

try to pull the elevator car down faster than the speed for which it is set. The control will then

provide reverse torque to keep the car form falling faster than the set speed. This operation

is regeneration (the applied load is in the same direction as the direction of motor rotation).

Table 3 on page 5 summarizes the different modes of regen operation.

4

Page 7

TABLE 3 – SUMMARY OF CONTROL OPERATION

Quadrant

I Motoring CW CW CCW

II Regeneration CCW CW CCW

III Motoring CCW CCW CW

IV Regeneration CW CCW

Type of

Operation

Motor Rotation

Direction

Motor Torque

Direction

Applied Load

Direction

CW

B. Torque Control Mode – When Jumper J7 is set to “TRQ” position, the KBRG will vary

motor torque. The KBRG has been redesigned and now contains two (2) types of torque

characteristics which are selectable with jumper J8. Speed/Linear Torque (S/LT) and Non

Linear Torque (NLT). In the “S/LT” position (factory setting), both output torque and

motor speed vary linearly as a function of the input signal. The “S/LT” type of torque is

most suitable for take up and pay out winders where the speed and torque requirements

vary as the winder roll diameter changes. The “S/LT” torque characteristics are shown in

fig. 2A.

FIG. 2A – LINEAR TORQUE CURVE

In the “NLT” position, only torque (not speed) is varied by the input signal. The motor

output torque remains constant over the motor’s full speed range unless the load is less

than the set torque. If the load torque decreases below the set torque, the motor will

rapidly increase to full speed. This type of torque control is applicable to processes where

the torque must remain constant over a wide motor speed range. The “NLT” torque

characteristics are shown in fig. 2B p. 6.

Because the KBRG is a regenerative control, torque will be applied in both forward and

reverse directions. The maximum torque can be set with the FWD CL and REV CL

trimpots, and by using the FWD ACCEL and REV ACCEL trimpots, the rate of change of

torque can be made more or less gradual. The maximum speed trimpot can be used to

set the maximum motor speed under a no load condition.

5

Page 8

FIG. 2B – NON-LINEAR TORQUE CURVE

III. SETTING SELECTABLE JUMPERS.

The KBRG has customer selectable jumpers which must be set before the control can be used

(refer to fig. 1 p. 3). Bold indicates Factory Setting. (See sec. II, p. 4 for J7 and J8 settings.)

A. J1A, J1B - Input AC Line Voltage – Select proper input line voltage, 115VAC or 230VAC,

by placing both jumpers (J1A and J1B) in the correct corresponding position, "115" or

"230." See fig. 3.

B. J2 - Armature Current – Select the J2 position (2.5, 5, 7.5, 10, 15) closest to the rated

motor current. (Note: The maximum output current is set to 150% of the J2 position, which

may be readjusted using the FWD CL and REV CL trimpots.) Note: On Model

KBRG-240D, position 10A is factory setting.

TABLE 4 – JUMPER J2 POSITION vs MOTOR HORSEPOWER

15A

10A

7.5A

5.0A

2.5A

J2

Jumper J2 Position

Motor Current

(DC Amps)

(1)

15A

10A 1 2

7.5A 3/4 1

5.0A 1/2, 1/3 1, 3/4

2.5A 1/4 1/2

Motor Horsepower

90VDC 180VDC

1 3

(1) 15A current range on KBRG-225D only.

C. J3 - Motor Armature Voltage – Select the desired armature voltage by placing J3 in the

proper position, "90" or "180." Note: For 115 volt AC line input, the armature voltage must

be set to "90." For 230 input, the armature voltage normally is set for "180." However, it

is also possible to set the armature voltage to "90" for step-down operation.

6

Page 9

FIG. 3 – AC LINE VOLTAGE

JUMPER SETTING

115VAC 230VAC 90VDC 180VDC

FIG. 4 – MOTOR ARMATURE

VOLTAGE JUMPER SETTING

TABLE 5 – RELATIONSHIP of AC LINE INPUT AND MOTOR

VOLTAGE with J1A, J1B and J3 JUMPER POSITION

AC INPUT VOLTAGE

115 115 90 90

230 230 180 180

230 230 90* 90*

J1A, J1B

POSITION

J3 POSITION MOTOR VOLTAGE

*A 90VDC motor can be used with a 230VAC line. However, speed range may be reduced and

motor overheating may result.

D. J4 - Tach-generator Voltage – (Note: Selection of the jumper position is not required if

armature feedback is used.) Place J4 jumper in the position "7V", "20/30V," "50V" that

corresponds to the tach-generator voltage in Volts/KRPM. Note: The tach voltage jumper

position is based on motor speed of 1,800 RPM.

For example, if the tach is 25V/KRPM and the motor speed is 3,600 RPM, use the "50V"

J4 position. For other tach-generator voltages and motor speeds, an external resistor

(RT) may be used as follows.

i. Install resistor in series with either tach-generator lead.

ii. Place J4 in "7V" position.

iii. The value of RT is calculated as follows.

RT = [(5.4 x Vt x S) - 68,000] VT = Tach voltage in volts/1000 RPM

Choose the closest standard watt S = Base Speed of motor in RPM

resistor value to the calculated value

E. J5 - Feedback Type – The KBRG can be operated in either armature feedback "AFB"

or tach-generator feedback "TFB." Armature feedback provides adequate load regulation

for most applications. For very precise performance, tach-generator feedback "TFB"

should be used. (Note: If tach feedback is desired, an external DC tach-generator must

be used and connected as per instructions.) (See section V J, p. 12 for tach-generator

wiring.) (Note: The IR Comp trimpot must be set to the minimum setting [CCW] for tach

feedback.)

F. J6 - Current Limit (CL) Mode – The KBRG contains electronic current limiting that limits

the maximum DC current to the motor. (Note: Current Limit is established with the

selection of the J2 position and the setting of the Forward and Reverse CL trimpots "FWD

CL" and "REV CL.")

7

Page 10

Two modes of current limit are provided:

1. Timed Current Limit "TCL" – Turns the drive off after a preset time. (The time period

is adjustable with the TCL trimpot from 1-15 seconds and is factory set for

approximately 5 seconds.) In order for the Timed CL feature to operate, the

Start/Stop circuit must be wired. To restart drive after it has "timed out," the Start

button must be pressed.

Application Note: The “TCL” feature cannot be used in either torque mode, since

nuisance tripping will occur.

2. Non-Timed Current Limit "NTCL" – In this mode, the drive will reach preset Current

Limit during overload and stay at that level until drive is turned "off" or fuse blows. If

Non-Timed CL is desired, move jumper J6 from the factory set "TCL" position to the

"NTCL" position.

IV. MOUNTING.

Mount the KBRG in a vertical position (connection terminals in down or up position) on a flat

surface free of moisture, metal chips, or corrosive atmosphere. (Note: If drive is mounted in

other than a vertical position, decrease maximum allowable ambient temperature by 10 ºC.)

(See Outline Drawing fig. 1, p. 3.) A 5K ohm Remote Speed potentiometer is provided with

each control. Install potentiometer using hardware provided. Be sure to install insulating disk

between potentiometer and inside of front panel.

Enclosure – When mounting the KBRG in an enclosure, it must be large enough to allow for

proper heat dissipation. A 12"x12"x24" enclosure is suitable for the KBRG-240D at full rating

and a 12"x24"x36" enclosure is suitable for the KBRG-225D at full rating. Smaller enclosures

may be used if full rating is not required.

V. WIRING. Warning! Read Safety Warning before attempting to use this control.

Warning! To avoid erratic operation do not bundle AC Line and motor wires with

potentiometer, voltage following, enable, inhibit or other signal wiring. Use shielded

cables on all signal wiring over 12" (30 cm) – Do not ground shield.

Wire control in accordance with National Electric Code requirements and other local codes

that apply. The KBRG contains a single AC line fuse wired in series with terminal L1. Be sure

to fuse each conductor which is not at ground potential (do not fuse neutral or grounded

conductors). (See section VI, p. 12, for fuse information.) Wire control in accordance with

connection diagram (see fig. 8 and 9, p. 11). A separate AC line switch or contactor must be

wired as a disconnect switch to control so that contacts open each ungrounded conductor.

See table 6.

TABLE 6 – TERMINAL BLOCK WIRING INFORMATION

Terminal Block

Designation

TB1 (Power Board) F+, F- 22 14 3.5

TB1 (Logic Board) Logic Connections 22 14 3.5

TB2 L1, L2, M1, M2 18 10 12

Connection

Designation

Supply Wire Gauge*

Minimum Maximum

Maximum Tightening

Torque (lbs inch)

*AWG, Cu wire only.

A. AC Line – Connect AC line to terminals L1 and L2. (Be sure jumpers J1A and J1B are

set to match the AC line voltage used. See table 4, p. 6.) See fig. 6, p. 10.

B. Motor Armature – Connect motor armature to terminal M1 and M2. (Be sure jumper J3

is set to match motor voltage. See table 4, p. 6.) See fig. 6, p. 10.

8

Page 11

0.30

(7.62)

10.00

(254.00)

1.00

(25.40)

8.00

(203.20)

FIG. 5 – MECHANICAL SPECIFICATIONS

7.70

(195.58)

7.10

(180.34)

T1

INCHES

[mm]

R0.089

[R2.3]

0.324

[8.2]

R0.172

[R4.4]

(4 PL)

(4 PL)

(4 PL)

3.440

[87.4]

F1

12

21 3 465

TB1

F+ F-

F1

AC LINE

FUSE

97 8 10 11

13

M1

ARMATURE

FUSE

TB2

M2L1 L2

F2

DWG#: C3900-1-00096

R69

NOTE: CONTROL SHOWN ABOVE IS MODEL KBRG-225D.

HEIGHT OF MODEL KBRG-240D IS 2.57" (65 mm).

9

Page 12

FIG. 6 – AC LINE AND ARMATURE CONNECTIONC. Field (For Shunt Wound

motors only) – Do not

use F+ and F- terminals for any

other motor type. Connect

motor shunt field to terminals

F+ and F- for 90VDC motors

with 100VDC fields and

180VDC motors with 200VDC

fields. For motors with half

voltage fields, 90VDC motors

with 50VDC fields and 180VDC

motors with 100 VDC fields,

connect field to terminals F+ and L1. See table 7 for

summary of Field Connections.

CAUTION – Shunt-Wound motors may be damaged if field remains connected

without motor rotating for an extended period of time.

FIG. 7A – FULL VOLTAGE FIELD FIG 7B – HALF VOLTAGE FIELD

TABLE 7 – FIELD CONNECTIONS (Shunt Wound Motors Only)

AC Line Voltage (VAC) Motor Voltage Field Voltage (VDC) Field Connection

115 90 100 F+, F115 90 50 F+, L1

230 180 200 F+, F230 180 100 F+, L1

230 90* 100

F+, L1

*Step down operation (see sec. III C, p. 6).

D. Ground – Be sure to ground (earth) the control via green screw located on chassis.

E. Main Speed Potentiometer – The main speed potentiometer can be connected in several

ways using terminals "10," "11," "12," "13." ( A 5K ohm potentiometer is supplied with

control. A 10K potentiometer can also be used.) [WARNING! Terminals “10,” “11,”

“12" and “13" are not isolated from AC line. Do not ground (earth).]

i. Unidirectional operation only – Connect potentiometer to terminals "10," "12," "13" for

forward direction. (To operate in reverse direction, connect to "11," "12," "13.")

ii. Bidirectional operation using reversing contacts – Connect to terminals "10," "11,"

"12," "13" as per fig. 8, p. 11.

iii. Bidirectional operation with potentiometer – Connect potentiometer to terminals "10,"

"11," "12" as per fig. 8, p. 11.

10

Page 13

FIG. 8 – MAIN SPEED POTENTIOMETER CONNECTIONS

FORWARD REVERSE

BIDIRECTIONAL

with REVERSING CONTACT

F. Voltage Following – An isolated analog voltage can be used in

lieu of main speed potentiometer. Connect signal to terminals "12"

BIDIRECTIONAL

with SPEED POT

FIG. 9A – VOLTAGE

FOLLOWING

and "13." Note: Terminal "13" is common. A positive signal with

respect to terminal "13" will produce a positive output to motor. A

negative signal with respect to terminal "13" will produce a

negative output. A 0 to ±10VDC is required to operate control

from 0 to ± full output. WARNING! Do not common multiple

drives without a signal isolator. A bipolar signal isolator, SI-4X,

is available as an option from your distributor.

G. Enable – Control may be electronically started and stopped with

Enable circuit. Connect Enable contacts between terminals "8"

and "9." When terminals "8" and "9" are joined, control is in

"ENABLE" state. When terminals "8" and "9" are open, control is in "INHIBIT" state. (See

fig. 9B.)

IMPORTANT! If Enable is not used, a jumper must be installed between terminals

"8" and "9" or control will not operate. (See Safety Warning on page 2.)

H. Start/Stop Circuit – A standard 3-wire start/stop circuit is provided (terminals "5," "6" and

"7"). This allows a remote momentary 2-button start/stop station to be installed. In this

mode, if AC power is removed, the start button must be used to restart the control. Also,

when the control is in the Timed Current Limit mode (J6 set to TCL) and has "timed out,"

it must be restarted using the start button. IMPORTANT! If the Start/Stop mode is not

required, a jumper must be installed between terminals "5" and "7." (Note: The Timed CL

function will operate only when the start/stop mode is used.) Control will not start using

Start/Stop circuit if AC line voltage is below 20% of nominal (95 volts on 115V circuit and

190V on 230V circuit). (See Safety Warning on page 2.)

FIG. 9B – ENABLE FIG. 9C – START/STOP CIRCUIT

FIG. 9D – ALARM CONTACTS

RY1

TB1

43

ALARM

CONTACTS

11

Page 14

I. Alarm Contacts – S.P.S.T. relay contacts (terminals "3" and "4") are used to signal a

warning or to shut other equipment down if control goes to an Inhibit state. Rating of

contacts are 1A-28VDC, .5A-115VAC. See table 8 for relay control state vs contact state.

(See fig. 9D, p. 11.)

TABLE 8 – CONTROL STATE vs RELAY CONTACT STATE

Relay Contact State

Description of Control State Using Start / Stop Start / Stop Bypassed

No power to control O O

Power applied O X

Control in Stop mode O NA

Control is started with Start button X NA

Control has “Timed Out” in TCL O NA

O – Open, X – Closed, NA – Not Applicable

J. Tach-generator Input – Terminals "1" and "2" are used

to connect a DC tach-generator and should be used only

when control is in tach-generator feedback mode (J5 is

in "TFB" position). Connect the positive (+) tach lead to terminal

"1" and the negative (-) tach lead to terminal "2." Note: The tachgenerator polarity must be phased so that the tach voltage is positive

(+) on terminal "1" when the voltage on terminal "12" is positive (+).

If the tach-generator is wired backwards, the control will run at full

speed only.

VI. FUSING.

A. Power Board.

1. AC Line Fuse – The Power Board on all models contains a single AC line fuse (F1) 25A

for KBRG-225D and 20A for KBRG-240D) which protects the unit from catastrophic

failure. CAUTION: Most electrical codes require that each ungrounded conductor

contain fusing. Separate branch circuit fusing may be required. Check local electrical

codes.

2. Armature Fuse – An armature fuse (F2) is also provided with a rating equal to the

maximum RMS rating of the control. It is recommended that the correct size armature

fuse be installed, depending on the rating of the motor and form factor (RMS/AVG

current). Fuse type should be Littlefuse 326 ceramic or Buss ABC, or equivalent. A

fuse chart is presented on page 13 (table 9) which suggests appropriate armature fuse

ratings. However, the specific application may require larger fuse ratings based on

ambient temperature, CL set point and duty cycle of operation (see table 9, p. 13).

Fuses may be purchased from your distributor.

FIG. 9E – TACH-GENERATOR

CONNECTION

B. Control Board Fuse – The logic control board contains a low amperage fuse (.150 amp

Littelfuse 3AG normal blo or equivalent) which protects the control transformer and other

components against catastrophic failure. Under normal circumstances, this fuse should

never blow. (See fig. 1, p. 3, for location.)

VII. OPERATION.

WARNING! Read Safety Warning on page 2 before attempting to operate or

severe injury or death can result.

After the KBRG has been set up (Jumpers are in appropriate position) and the drive has been

properly wired, the startup procedure can begin. Before initially starting, be sure main speed

pot is in minimum position. (Set main speed pot to full CCW position if wired for unidirectional

operation and to center position if wired for bidirectional control. (See fig. 8, p. 11.)

12

Page 15

TABLE 9 – ARMATURE FUSE CHART (F2 Power Board)

Motor Horsepower

90VDC 180VDC

1/8 1/4 1.3 2

1/6 1/3 1.7 2

1/4 1/2 2.5 4

1/3 3/4 3.3 5

1/2 1 5.0 8

3/4 1 7.5 12

1 2 10.0 15, 20*

1 3 15.0 25

Approx. DC Motor

Current Amps

Fuse Rating

(AC Amps)

* Use higher rated fuse for high ambient temperature or when rapid starting and stopping occur.

Start control by applying AC power. Enable circuit must be closed for control to start (jumper

terminals "8" and "9"). If wired for start/stop operation, press start switch. If not wired for

start/stop, terminals "5" and "7" must be jumpered. Rotate main speed potentiometer to control

motor speed.

VIII. TRIMPOT ADJUSTMENTS.

The KBRG contains many trimpots which have been factory adjusted for most applications.

(See table 2, p. 4. for factory settings.) (Note: fig. 1, p. 3 presents the various trimpots with

their locations. They are shown in the approximate adjustment position.) Some applications

may require readjustment of trimpots in order to tailor control to exact requirements. Readjust

trimpots as follows:

A. Forward Acceleration (FWD ACCEL) and Reverse Acceleration (REV ACCEL) – The

FWD ACCEL trimpot determines the amount of time it takes the control voltage to reach

full output in the forward direction. It also determines the amount of time it takes for the

control voltage, in the reverse direction, to reach zero output. (FWD ACCEL also sets the

Reverse Decel.)

The REV ACCEL trimpot determines the amount of time it takes the control voltage to

reach full output in the reverse direction and the time it takes for the control voltage, in the

forward direction, to reach zero output. (REV ACCEL is the Forward Decel.)

The FWD and REV ACCEL trimpots are factory adjusted to 1 second. The acceleration

times are adjustable to a maximum

FIG. 10 – ACCEL TRIMPOT ADJUSTMENT

of 15 seconds. (See fig. 10 for

graphic representation of ACCEL.)

Note: The FWD and REV CL trimpots settings may override the

rapid accel and decel settings.

Note: A 4-quadrant ACCEL/

DECEL accessory module is

available as an option. It provides

separate control of FORWARD

acceleration and deceleration and

REVERSE acceleration and

deceleration.

13

Page 16

B. Offset (OFFSET) – This trimpot

determines the amount of bias in the

forward or reverse direction. The

trimpot is factory set to provide approximately zero offset, which

means neither the forward nor the

reverse speed is favored. (See fig.

11 which illustrates the action of the

OFFSET trimpot.)

C. Deadband (DB) – The DB trimpot

sets the amount of main speed potentiometer rotation required to initiate control voltage output. It is factory adjusted to approximately 25%

of rotation.

The DB trimpot also determines the

amount of delay that will occur before regeneration starts. (Regeneration occurs when the applied load

torque is in the same direction as

the motor rotation.)

To readjust the DB to factory setting:

i. Set Main Speed pot to zero

speed position.

FIG. 11 – OFFSET TRIMPOT ADJUSTMENT

FIG. 12 – DEADBAND TRIMPOT ADJUSTMENT

ii. Set DB trimpot to full CCW posi-

tion.

iii. Adjust DB trimpot CW until mo-

tor hum is eliminated.

(See fig. 12 for graphic illustration of the DB trimpot.)

Note: If the deadband trimpot is set too low (CCW direction), the motor may oscillate

between forward and reverse. Adjust deadband trimpot CW until the instability

disappears. (Oscillation may also occur due to response setting. See section VIII, G, p.

15.)

D. Forward Current Limit (FWD CL) and Reverse Current Limit (REV CL) Trimpots –

These trimpots are used to set the maximum amount of DC current that the motor can

draw in both the forward and reverse directions. The amount of DC current determines

the amount of maximum motor torque in both the Speed Control Mode and Torque Control

Mode. They are factory set at 150% of the current established by the jumper J2 setting.

Readjust the CL trimpots as follows:

i. Turn CL trimpot to MIN (CCW) position. Be sure jumper J2 is in proper position

approximately equal to the motor DC ampere rating.

ii. Wire in a DC ammeter in series with armature lead. Lock shaft of motor.

iii. Apply power. Rotate CL trimpot CW until desired CL setting is reached (factory

setting is 1.5 times rated motor current). Be sure control is in Forward direction for

FWD CL trimpot adjustment and likewise with REV CL.

14

WARNING! Do not leave motor shaft locked for more than 2 – 3 seconds to prevent

motor damage.

CAUTION: Adjusting the CL above 150% of motor rating can cause overheating and

demagnetization of some PM motors. Consult motor manufacturer.

Page 17

E. IR Compensation (IR Comp) – The IR Comp is used to stabilize motor speed under

varying loads. (Note: If control is in Tach Feedback mode, the IR Comp should be set

to minimum - CCW.)

Readjust the IR Comp trimpot as follows:

i. Run motor at approximately 30-50% of rated speed under no load and measure actual

speed.

ii. Load motor to rated current. Rotate IR Comp trimpot so that loaded speed is the

same as the unloaded speed measured in the previous step.

Control is now compensated so that minimal speed change will occur over a wide range

of motor load. [Note: Too much IR Comp will cause unstable (oscillatory) operation.]

F. Maximum Speed (MAX) – The MAX trimpot is used to set the maximum output voltage

of the control which, in turn, sets the maximum speed of the motor. In the Torque Control

Mode, the MAX trimpot setting determines the unloaded motor speed. Adjust the MAX

trimpot as follows:

i. Rotate Main Speed potentiometer to full speed (CW).

ii. Adjust MAX trimpot to desired maximum motor speed.

(Note: Do not exceed maximum rated RPM of motor since unstable operation may result.)

G. Response (RESP) Trimpot – This trimpot determines the dynamic response of the control.

The factory setting is approximately 50% of full rotation. The setting may be increased if

a faster response is required. (Note: If response is made too fast, unstable operation may

result.)

H. Timed Current Limit (TCL) Trimpot – Trimpot is functional only when control is wired for

3-wire Start/Stop and J6 is in the TCL position. The TCL trimpot sets the delay time for the

Timed Current Limit. The trimpot is adjustable over a time range of 1-15 seconds and is

factory set for approximately 5 seconds. Calibrate the TCL trimpot by setting the trimpot

to the approximate desired delay time as follows: (See table 10.)

TABLE 10 – CURRENT LIMIT TIMER SETTINGS

Approx. Trip Time

(Secs)

1 Full CCW

8 Midway

15 Full CW

IX. FUNCTION INDICATOR LAMPS.

A. LED 1 Power On (PWR ON) – Indicates that the drive is energized with the AC line.

B. LED 2 Current Limit (CL) – Indicates that the drive is in Current Limit. If set in the timed

Current Limit mode (J6 set to "TCL") and has "timed out," the LED 2 will remain ON until

the drive is restarted.

C. LED 3 Forward Enable (FWD EN) – Indicates that the drive is engaged in the forward

direction. [Enable circuit closed (terminals "8" and "9" joined), the start circuit initiated and

a "forward" speed command.] The FWD EN lamp will also be lighted in the reverse direction

if the control is in regeneration.

Trimpot Position

D. LED 4 Reverse Enable (REV EN) – Indicates that the drive is engaged in the reverse

direction. [Enable circuit closed (terminals "8" and "9" joined), the start circuit initiated and

a "reverse" speed command.] The REV EN lamp will also be lighted in the forward direction

if the control is in regeneration.

15

Page 18

X – LIMITED WARRANTY

For a period of 18 months from date of original purchase, KB will repair or replace without

charge devices which our examination proves to be defective in material or workmanship.

This warranty is valid if the unit has not been tampered with by unauthorized persons,

misused, abused, or improperly installed and has been used in accordance with the

instructions and/or ratings supplied. The foregoing is in lieu of any other warranty or

guarantee, expressed or implied, and we are not responsible for any expense, including

installation and removal, inconvenience, or consequential damage, including injury to any

person, caused by items of our manufacture or sale. Some states do not allow certain

exclusions or limitations found in this warranty so that they may not apply to you. In any

event, KB's total liability, under all circumstances, shall not exceed the full purchase price

of this unit. (rev 4/88)

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065 • (954) 346-4900 • Fax (954) 346-3377

Outside Florida Call TOLL FREE (800) 221-6570 • E-mail – info@kbelectronics.com

www.kbelectronics.com

(A40260) – Rev. C – 1/98

Loading...

Loading...