KBRC-240D

Full-Wave 4-Quadrant Regenerative Drive

for Speed & Torque Control of PM & Shunt DC Motors

NEMA-4X / IP-65

Rated for 1/10 - 1 HP (90 Volts DC) @115 Volts AC, 50/60 Hz

and 1/5 - 2 HP (180 Volts DC) @ 208/230 Volts AC, 50/60 Hz

W

ashdown and Watertight for Indoor and Outdoor Use

*

Conveyors • Feeders • Packaging Equipment

•

• Positioners • Textile Equipment • Indexers

TYPICAL APPLICATIONS

DATASHEET D-430

odel KBRC-240D

M

KB Part No. 8840

Black Case)

(

KB Part No. 8841

White Case)

(

STANDARD FEATURES

• Industrial Duty Die-Cast Aluminum Case: Available in black finish

(P/N 8840) and white FDA approved finish (P/N 8841).

Front Panel LEDs:Power On (ON), Stop (STOP) and Overload (OL).

•

• PC Board LEDs: Power On (PWR ON), Overload (OL), Forward

Enable (FWD EN) and Reverse Enable (REV EN).

• Run Relay: Used to signal a warning or to shut down other equipment

if the control is put into “stop” or times out in TCL.

• Start/Stop Switch: Provides electronic start and stop functions.

• Barrier Terminal Blocks: Facilitates wiring of motor, AC line, Tach-

generator and run relay.

PROTECTION FEATURES

• AC Line Transient Protection: Provides protection to power devices

from AC line transients.

• Auto-Inhibit®: Allows rapid, safe cycling of the AC line.

• Motor Burnout Protection (I x t): Shuts down control if the motor is

overloaded for a predetermined amount of time.

• Regeneration Overspeed Protection: Prevents power bridge failure

in extreme overhauling conditions.

TRIMPOT ADJUSTMENTS

• Offset (OFFSET) • Reverse CL (REVCL)

• Reverse Accel (RACC) • IR Comp (IR)

• Forward Accel (FACC) • Response (RESP)

• Maximum Speed (MAX) • Dead Band (DB)

Forward CL

•

(FWDCL) •

imed CL

T

(TCL)

JUMPER SELECTABLE FEATURES

• J1/J2 (115V, 230V): Selects AC line input voltage.

• J3 (A90, A180, T7, T50): Selects motor voltage or tach feedback.

• J4 (1.7A, 2.5A, 5A, 7.5A, 10A): Selects motor current.

• J5 (10V, 15V): Selects analog input voltage.

• J6 (SPD, TRQ): Selects control mode.

J7 (S/L, NL):

•

•

J8 (TCL, NTCL):

J9 (RTS, CTS):

•

J10 (NC, NO):

•

1 (EN):

J1

•

Selects Linear or Non-Linear

Selects current limit mode.

Selects stopping mode.

Selects run relay output contacts.

Enable Jumper

.

Torque Mode.

OPTIONAL ACCESSORIES

• Forward-Stop-Reverse Switch (P/N 9485): Provides motor revers-

ing and regenerative braking.

• Power On/Off Switch (P/N 9486): Disconnects the AC line.

• Signal Isolator SIRC (P/N 8842): Provides isolation between a non-

isolated signal voltage source and the KBRC-240D.

• Auto/Manual Switch (P/N 9487): Selects signal input from either the

SIRC Signal Isolator or the Main Speed Potentiometer.

Note: * Requires CE RFI filter KBRF-200A

(KB P/N 9945) or equivalent.

DESCRIPTION

The KBRC-240D is a Full-W

IP-65 washdown and watertight enclosure. It is designed to operate 90 and

180 Volt Permanent Magnet and Shunt Wound DC motors in a bidirectional

mode. It provides 4-quadrant operation, which allows forward and reverse

torque in both speed directions. This allows the control to maintain constant

speed with overhauling loads and provides rapid instant reversing and

controlled braking. Because of its excellent performance, the control can

replace servo drives in many applications.

The KBRC-240D has a Regeneration Overspeed Protection Circuit,

which prevents failure of the power bridge in extreme overhauling conditions. Motor overload protection (I x t) will shut down control if the motor is

overloaded for a predetermined amount of time. The exclusive Auto-Inhibit

circuit allows safe, smooth starting during rapid cycling of the AC line.

Due to its user-friendly design, the KBRC-240D is easy to install and

operate. Tailoring to specific applications is accomplished via selectable

jumpers and trimpot adjustments. However, for most applications, no

adjustments are necessary.

The KBRC-240D can be operated from a two or three wire start/stop

circuit or can be started from the AC line. A set of dedicated normally open

or normally closed relay contacts are provided, which are activated via the

start/stop circuit. They can be used to turn on or off equipment or to signal

a warning if the control is put into Stop Mode or times out in TCL.

Main features of the KBRC-240D include Speed or Torque control

modes. In Linear Torque mode (S/L), speed and torque vary linearly as a

function of main speed potentiometer rotation or input signal. In Non-Linear

Torque mode (NL), the torque is varied by the main speed potentiometer or

input signal, and remains constant throughout the motor’s entire speed

range. In addition, Regenerate-to-Stop (R

ing modes are also provided.

Standard front panel features of the KBRC-240D include diagnostic

LEDs (for Power On, Stop and Overload), a Start/Stop Switch and a Main

Speed Potentiometer. Other features include Barrier Terminal Blocks (facilitates wiring of the AC line, motor, tach-generator and run relay), adjustable

trimpots (OFFSET

TCL), selectable jumpers (AC line voltage, motor voltage or tach feed

and

back, motor current, analog input voltage, control mode, torque mode, cur

rent limit mode, regeneration mode, run relay and enable) and LEDs (Power

On, Overload, Forward Enable and Reverse Enable).

Optional accessories for the KBRC-240D include a Forward-StopReverse Switch, a Power On/Off Switch, a Signal Isolator and an

Auto/Manual Switch. Quick-connect terminals are provided for easy

installation of all accessories.

, RACC, FACC, MAX, FWDCL, REVCL, IR, RESP, DB

ave Regenerative Drive in a NEMA-4X/

TS) or Coast-to-Stop (CTS) stop-

-

-

®

Complete Line of Motor Drives

A

DATASHEET D-430

127

5.00

Maximum Depth

O

LSTOPON

REGENERATIVE

DC MOTOR SPEED CONTROL

60

70

90

80

100

50

40

30

1

0

20

0

R

EV

FWD

STOP

START

MANUAL

AUTO

NEMA-4X / IP-65

0.357

9.07

8.88

8.23

209

225

9.49

241

5

.89

150

5.47

1

39

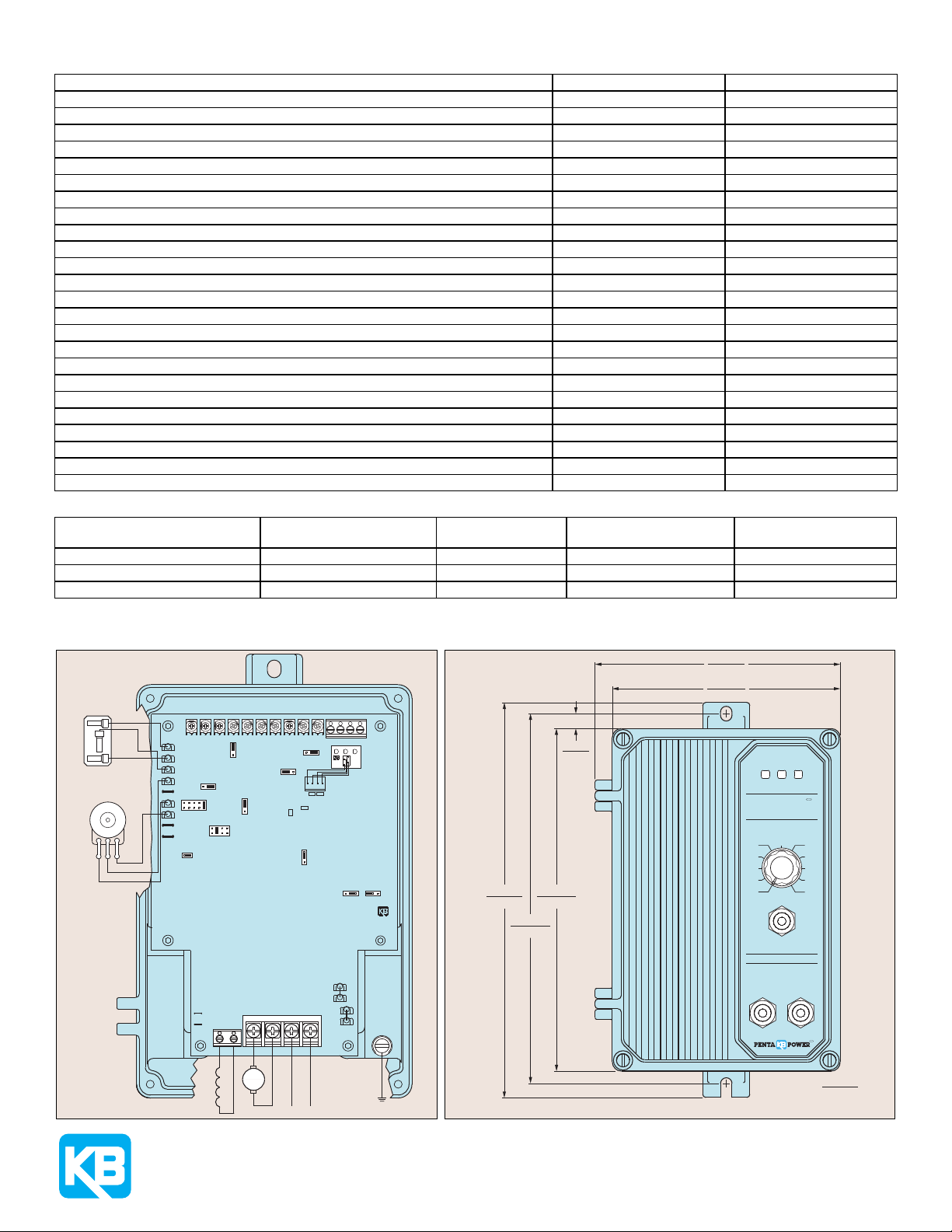

KBRC-240D Shown with optional Forward-Brake-Reverse and Auto/Manual Switches

R

ecommended

Mounting Screw: 1/4" (M6)

PENTA-DRIVE

™

™

%

BLK

RED

WHT

STOP

CL

ON

B

G

R

Y

START/STOP

SWITCH

WHT

POTENTIOMETER

MAIN SPEED

ORG

VLT

GROUND

(EARTH)

AC LINE

+

+

FIELD

-

MOTOR

(SHUNT MOTORS ONLY)

L2A L2B

L2

M2 L1

TB1

M1

F-

F1

F2

TB2

F+

M

-

J1

KBRC

115V230V

J2

115V

L1A L1B

230V

FWD

EN

REV

EN

R

TS

J9

J11

E

N

C

TS

N

L

J

7

S

/L

A180

T50

T7

J3

A90

N

TCL

CON1

J8TCL

PWR ON

O

L

J

6

T

RQ SPD

5A

7.5A

10A

1.7A

2.5A

J4

L

ED BOARD

TB3

NO

N

C

J

10

15V

1

0V

J

5

STOPSIG STARTRETC OM +15VEN COM -15V

T+T-TCLDBIR RESPFWDCLFACC MAXRACCOFFSET REVCL RELAY

MODEL KBRC-240D (KB Part Nos. 8840 and 88411) – GENERAL PERFORMANCE SPECIFICATIONS

arameter

P

C Line Input Voltage (Volts AC, ±10%, 50/60 Hz)

A

rmature Voltage Range at 115 Volts AC Line (Volts DC)

A

rmature Voltage Range at 208/230 Volts AC Line (Volts DC)

A

ield Voltage at 115 Volts AC Line (Volts DC)

F

ield Voltage at 208/230 Volts AC Line (Volts DC)

F

ignal Following Input (Non-Isolated

S

ignal Following Linearity (% Base Speed)

S

ine Regulation (% Base Speed)

L

rmature Feedback Load Regulation (% Base Speed)

A

ach-Generator Feedback Load Regulation (% Set Speed)

T

aximum Load Capacity (% for 2 Minutes)

M

urrent Ranges (Amps DC)

C

peed Range (Ratio)

S

perating Temperature Range (°C)

O

ffset Trimpot (OFFSET) Range (% Base Speed)

O

everse Acceleration Trimpot (RACC) Range (Seconds)

R

orward Acceleration Trimpot (FACC) Range (Seconds)

F

aximum Speed Trimpot (MAX) Range (% Base Speed)

M

orward Current Limit Trimpot (FWDCL) Range (% Range Setting)

F

3

Range (Volts DC)

)

Reverse Current Limit Trimpot (REVCL) Range (% Range Setting) 0 – 200 150

R Compensation Trimpot (IR) Range at 90 Volts DC Output (Volts DC at Full Load)

I

IR Compensation Trimpot (IR) Range at 180 Volts DC Output (Volts DC at Full Load) 0 – 30 10

eadband Trimpot (DB) Range (% Base Speed)

D

imed Current Limit Trimpot (TCL) Range (Seconds)

T

pecification

S

15 and 208/230

1

– ±90

0

2

– ±90

0 – ±180

0

,

00/50

1

00/100

2

– ±10, 0 – ±15

0

1 —

0.5

±

1

±

1

±

50

1

.7, 2.5, 5, 7.5, 10

1

0:1

5

– 45

0

– ±10

0

.2 – 15

0

.2 – 15

0

0 – 110

7

– 200

0

– 15

0

– ±3

0

– 15

0

actory Setting

F

2

– ±180

0

– ±15

0

1

1

0

ELECTRICAL RATINGS

AC Line Input Voltage ±10%, 50/60 Hz

(Single Phase Volts AC)

115

208/230

208/230

Notes: 1. KB Part No. 8841 is white FDAapproved finish., 2. Step-down operation: Motor may have reduced brush life. Consult motor manufacturer.

3. Requires an isolated signal. If a non-isolated signal is used, install the Signal Isolator SIRC (P/N 8842).

CONTROL LAYOUT & CONNECTION DIAGRAM

Maximum AC Line Input Current

(Amps AC)

15

15

15

Nominal Output Voltage

(Volts DC)

0 – ±90 11

0 – ±180

2

0 – ±90

MECHANICAL SPECIFICATIONS (Inches / mm)

Maximum Output Load Current

(Amps DC)

11

11

Maximum Horsepower Rating

HP, (KW)

1, (0.75)

2, (1.5)

1, (0.75)

30

—

—

—

—

—

—

—

0

1

—

—

0

1

1

00

50

—

.5

5

KB ELECTRONICS, INC.

12095 NW 39th Street, Coral Springs, FL 33065-2516 • (954) 346-4900 • Fax (954) 346-3377

Outside Florida Call

www.kbelectronics.com

TOLL FREE (800) 221-6570 • E-mail – info@kbelectronics.com

(A42104) – Rev

. B – 8/2003

Loading...

Loading...