Page 1

DRF 400-450

WORKSHOP MANUAL

Publ. no VDRF03.02GB

Workshop Manual in original

Reachstackers 40-45 tonnes

Page 2

Page 3

Workshop

A Foreword

B Safety

C Preventive maintenance

0 Complete machine

1Engine

manual

2 Transmission

3 Driveline/axle

4 Brakes

5 Steering

6 Suspension

7 Load handling

8 Control system

9 Frame, body, cab and accessories

10 Common hydraulics

11 Common electrics

12 Common pneumatics

D Error codes

E Schematics

F Technical data

G Terminologi och Index

Page 4

Page 5

A Foreword 1

A Foreword

Table of Contents A Foreword

mm mm mm mm mm mm

Foreword......................................................................................................... 3

About the Workshop Manual ................................. ..................................... 3

General ............................................................................................................. 3

Conditions ......................................................................................................... 3

Storage ..................... .......................... ......................... .......................... ............ 3

About the machine version ................................................................................ 3

Copyright .................. .......................................................... ............................... 3

Reading instructions ...................................... ............................................. 4

Warning information .......................................................................................... 4

Important information ........................................................................................ 4

Read the Operator’s Manual ............................................................................. 4

Read the Maintenance Manual ......................................................................... 4

Workshop manual contents ............................................................................... 5

Function group structure ................................................................................... 6

References between different information types ............................................... 7

Product alternatives and optional equipment .................................................... 8

Machine card ..................................................................................................... 8

Function descriptions ........................................................................................ 9

About the documentation ...................................................... ................... 12

Documentation sections .................................................................................. 12

Ordering of documentation .............................................................................. 12

Feedback .................................................................................................. 13

Form for copying ............................................................................................. 13

Workshop manual DRF 400-450

VDRF03.02GB

Page 6

2 A Foreword

VDRF03.02GB

Workshop manual DRF 400-450

Page 7

mm mm mm mm mm mm

A Foreword – Foreword 3

Foreword

About the Workshop Manual

page –

page –

page –

General

Thank you for choosing Car gotec as you r machine s upplier. We ho pe

that we will meet your expectations.

Conditions

The instructions are b ased o n the us e of gene rally a vaila ble sta ndard

tools. All lifting d evices, such as slings, straps and ratchet blocks, mus t

meet governing national standards and regulations for lifting devices.

Cargotec will not accept any responsibility f or modificatio ns performed

without permission from Cargotec, or in the event of the use of lifting

devices, tools or work methods other than those described in this

manual.

Storage

NOTE

The workshop manual s hould be accessible to serv ice personnel.

page –

About the machine version

The information in this publication corresponds to the machine’s design and appearanc e at the time of delivery from Ca rgotec. Due to cu stomisations, there may be variations and/or deviations.

Cargotec r eserves the right to modify specifications and equipment

without prior notice. Al l informati on and data in this man ual are val id at

the time of publication.

DANGER

External equipment must only be used if it is

approved by Cargotec.

Danger to life and property!

Only use equipment approved by Cargotec.

page –

Workshop manual DRF 400-450

Copyright

Cargotec Sweden AB

Duplication of the c ontent in this manual , i n whole or in part , i s st ric tly

prohibited without written permission from Cargotec Sweden AB.

Duplication by any means such as copying, p rinting, etc., is prohibite d.

VDRF03.02GB

Page 8

4 A Foreword – Reading instructions

Reading instructions

page –

Warning information

Warnings inform on potential dangers which can, if the warnings are

not heeded, result in personal injury or product damage.

DANGER

Situation that may result in serious personal injury,

possible death, if the instruction is not followed.

WARNING

Situation that may result in serious personal injury if

the instruction is not followed.

CAUTION

page –

page –

Read the Operator’s Manual

page –

Read the Maintenance Manual

Situation that may result in damage to the product if

the instruction is not followed.

Important information

Important information ma rked with NOTE facilitates the work process,

operation/handling or increases understanding of the information.

NOTE

Information that is important without being safety related.

Read the Operator’s Manual

The symbol to the left is used in certain cases on the mach in e an d re fers to important information in the operator’s manual.

000262001128

Read the Maintenance Manual

The symbol to the left is sometim es foun d on the m achin e. It refers to

important information in the Maintenance Manual.

VDRF03.02GB

Workshop manual DRF 400-450

Page 9

A Foreword – Reading instructions 5

page –

Workshop manual contents

The Workshop Manual contains information to facilitate maintenance

(part replacement) and is a supplement to the Maintenance Manual.

Accompanying the Workshop Manual is supplier documentation for

engine, transmiss ion and drive axle. If poss ible, the Worksho p Manual

provides reference to supplier documentation instead of printing the

same information twi ce. Metho ds for pr eventive ma intenanc e and cer

tain checks are found in the Maintenance Manual, no references are

given. Use the fu nc tion g r oup s to lo cate the information i n t he Ma in te

nance Manual.

The workshop manual is divided into the following sections.

A Foreword General information about the workshop manual's purpose, contents and reading

instructions as well as survey for feedback of views and any inaccuracies.

B Safety Keep in mind for your safety.

C Preventive maintenance Reference to maintenance manual: Preventive maintenance.

0 Complete machine

1 Engine

2 Transmission

-

-

3 Driveline/axle

4 Brakes

5 Steering

Technical description, comprehensive function descriptions and a description of the

function of components included in the machine, divided into function groups.

The components used for each function are described under each subfunction.

Consequently, commo n components are described i n several places , but in general

6 Suspension

7 Load handling

8 Cont rol system

9 Frame, body, cab and

accessories

under the first function to use the component.

Together with the general description is a detailed description of what is unique

about the specific subfunction. The next subfunction to use the same component

only has a description what is unique for the new fun cti on.

Work instructions for corrective maintenance (replacement of components).

10 Common hydraulics

11 Common electrics

12 Common pneumatics

D Error codes Error code information and instructions for reading error code information.

E Schematics Wiring diagrams, hydraulic diagrams and list of electrical components.

F Technical data Technical data, conversion tables, information for conversion of units.

G Term ino log y and index General terminology and abbr eviations, explanati on of terms and abbreviations that

can appear in the sections, index for headings in the manual.

Workshop manual DRF 400-450

VDRF03.02GB

Page 10

6 A Foreword – Reading instructions

page –

Function group structure

The information in the man ual is divided into a st ructure of functions at

different levels based on machine structure and usage. The categories

are known as function groups.

The highest level (c alled m ain grou p) indic ates a rea, such as grou p 7

Load handling. The second level (called two-position) indicates func

tion, such as 7.2 Lifting/lowering . The third and fou rth level s are used

to break down functions into smaller parts (components).

The main group and two- position group le vel stru cture for t he functi on

groups is used for all Cargotec machines, e.g. 4.3 Power-assisted

brake system. Machine-specific function group adaptations are done

at the third and fourth group le vel, e.g . 4.3 .9 Wheel brake and 4.3.9.1

Disc assembly. Function groups (headings) are only included in the

documentation of a machine if the machine has that function or com

ponent. Thus, there may be gaps in function g roup numbering, e.g. th e

three-position heading level 4.8.7 Oil cooler is included for some ma

-

chines but not for others.

The function groups are intended as a search term to be able to find

various types of information between different se ctions and manuals.

The information of a function group is divided into smaller segments

based on type of content, such as description or replacement.

The Maintenance Manual and Workshop Manual contain different information. The Maintenance Manual only contains information required for preventive maintenance and minor troubleshooting. The

Workshop Manual contains more in-depth information and repair

instructions.

References between se ctions in the sa me manual are i ndicated usin g

section and group number, e.g., "see section

Wheel brake

number, e.g., "see

". Reference within a section are indicated with page

Sensor fuel level, description page 24

4 Brakes

, group

".

4.3.9

There are no references between the Ma intenance Manual and Workshop Manual. If more information on a function group is required,

search under the same function group in the other manual. For more

in-depth information on where different types of information are locat

ed and what referenc es ar e m ade , s ee

information types page 7

.

References between d iffe rent

-

VDRF03.02GB

Workshop manual DRF 400-450

Page 11

A Foreword – Reading instructions 7

page –

Function descriptions

(Technical description)

Component descriptions

(Technical description, usu al ly in Worksh op ma nual)

Diagnostics

(Technical description, group 8.4)

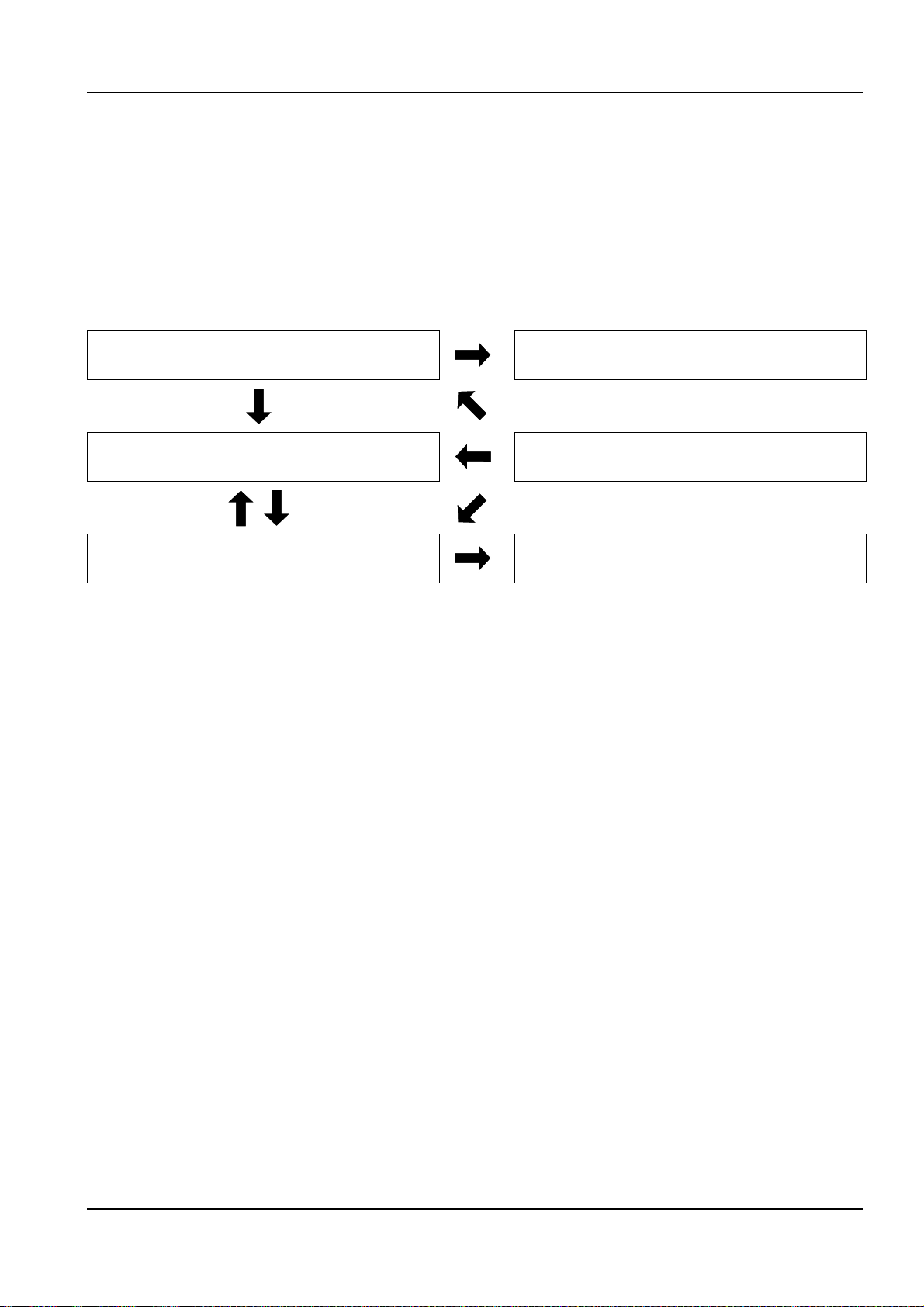

References between different information types

The maintenance manual and workshop manual are mainly divided

into function groups, see

Workshop manual con tent s page 5

parts are broken out as separate parts to increase usability, e.g.,

"Technical data".

The basic rule of searching for inf ormation is to use function groups to

find different types of informatio n regarding th e function or c omponent

in question. As a complement to this, there are references according

to the below.

Hydraulic diagrams

(Section E)

Error codes

(Section D)

Wiring diagrams

(Section E)

. Certain

• From Function description to Component description, to enable

fast finding of more information about the different components

that create a function.

• From Function description to Hydraulic diagram, to enable fast

finding of the right hydraulic diagram for the function in question.

• From Component description or Function description to Diagnostics, to enable fast find ing of the right di agnostic me nu that can be

used to check the component (only applies to electrical

components).

• From Diagnostics to Wiring diagrams. to en able fast findi ng of the

right circuit diagram for further troubleshooting.

• From Diagnostics to Component description or Function description. To enable fast finding of more information about the component's appearance and position when troubleshooting.

• From Error codes to Diagnostics , to enable fast finding of the right

diagnostic menu to troubleshoot component or function in

question.

• From Error codes to Function description or Component description, to enable fast fi nding of mo re informat ion about c omponent s

or function.

Workshop manual DRF 400-450

VDRF03.02GB

Page 12

8 A Foreword – Reading instructions

page –

Symbol for optional equipment

Product alternatives and optional equipment

The information in the manual is divided into modules. If a product alternative or optional equ ipm en t is fitte d, ha ndl ing may di ffer fro m th at

indicated in the modules depending on what is being described. See

below.

Special equipment is not described in the manual. If uncertain as to

what equipment is fitted to the machine, use the machine card to de

termine which information is relevant. See

Product alternative

Product alternative describes options that are fitted instead of a specific piece of standard equipment (e.g. engine alternative).

Equivalent informat ion fo r diffe rent p roduct altern ative s are describ ed

consecutively in separate segments within the same function group.

To indicate that there are diff erent alternatives, "Product alternat ive" is

added to the heading tog ether with a simple descripti on of the alterna

tive, e.g. "(Product alternative Climate control system ECC)". In addition, the alternative that is an option is marked with the symbol for

optional equipment.

Optional equipment

Optional equipment refers to options that can be added to standard

000264

equipment for more or improved functions.

Information on auxil iary equipmen t is described in se parate segment s

together with the standard equipment. The optional equipment de

scription covers how the eq uipment affects standard func tion and what

components are added.

Machine card page 8

-

.

-

-

page –

Machine card

NOTE

If the machine has been modified after delivery, information on

the machine card may be incomplete or incorrect.

The machine card indic ate s of wh ic h draw i ngs the mac hi ne co ns is ts,

in many cases these can be associated options and product alterna

tives. For more inform ation about hand ling of product alternatives an d

optional equipment, see

page 8

. The machine card is delivered with the parts catalogue.

Product alternatives and op tion al equ ipm en t

The machine card is divided into the same function groups as the

spare parts catalogue, maintenance manual and workshop manual.

For reasons of practicality, the machine card only uses the first and

second level of the function group register. The function groups are

written in groups of four char acters, e.g. group 0107 refers to group 1.7

Cooling system in the manual.

For more information on how the mach ine card is used to order spare

parts, see the foreword of the spare parts catalogue.

If the information on the card machine does not help, contact

Cargotec.

-

VDRF03.02GB

Workshop manual DRF 400-450

Page 13

A Foreword – Reading instructions 9

NOTE

All documents that accompany the machine are non-registered

documents. No notification is made regarding changes.

page –

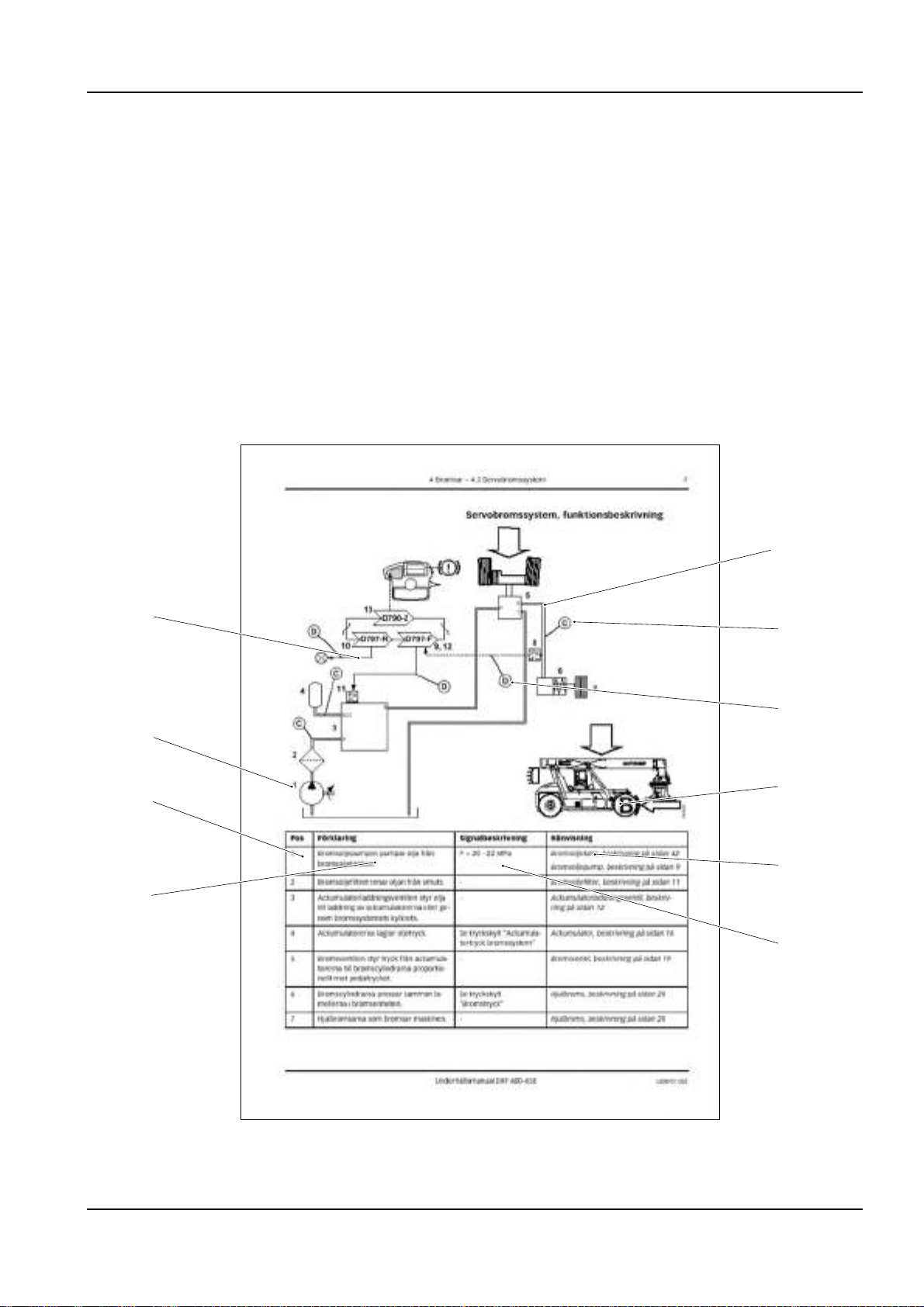

Function descriptions

Function descriptions are schematic overviews that describe how a

function works as well as which components and signals work

together.

Function descriptions describe the function i n a logic al flow from i nput

signal to desired output signal. Most functions require that preset con

ditions are fulfilled for the fu nctio n to be ac tivat ed. In th ese ca se s, the

conditions are listed above the illustration.

Function descriptions use symbols to illustrate components such as

valves, sensors, etc.

-

1

10

2

3

9

8

4

5

7

6

000520

Workshop manual DRF 400-450

VDRF03.02GB

Page 14

10 A Foreword – Reading instructions

Example of function description

1. Hydraulic force (solid double line)

2. Flag pressure check connection (Check point), indicates that

there is pressure check connection for checking pressure signal

3. Flag diagnostic test, indicates that the signal can be checked with

diagnostic test, see section

Diagnostics

4. Illustration of function, (apply brake)

5. Reference to description of component

6. Signal description, refer ence va lue for sig nal out from componen t

7. Description of component's function

8. Position number, reference to position in illustration

9. Position number in illustration, reference to row in table

10. Electric power (solid single line)

8 Control system,

group

8.4

VDRF03.02GB

Workshop manual DRF 400-450

Page 15

A Foreword – Reading instructions 11

12

34

56

78

M

910

11 12

D790-1

13 14

D797-F

15 16

17 18

˚C

19 20

˚C

21 22

Pa

23

˚C

Pa

24

25

26 27

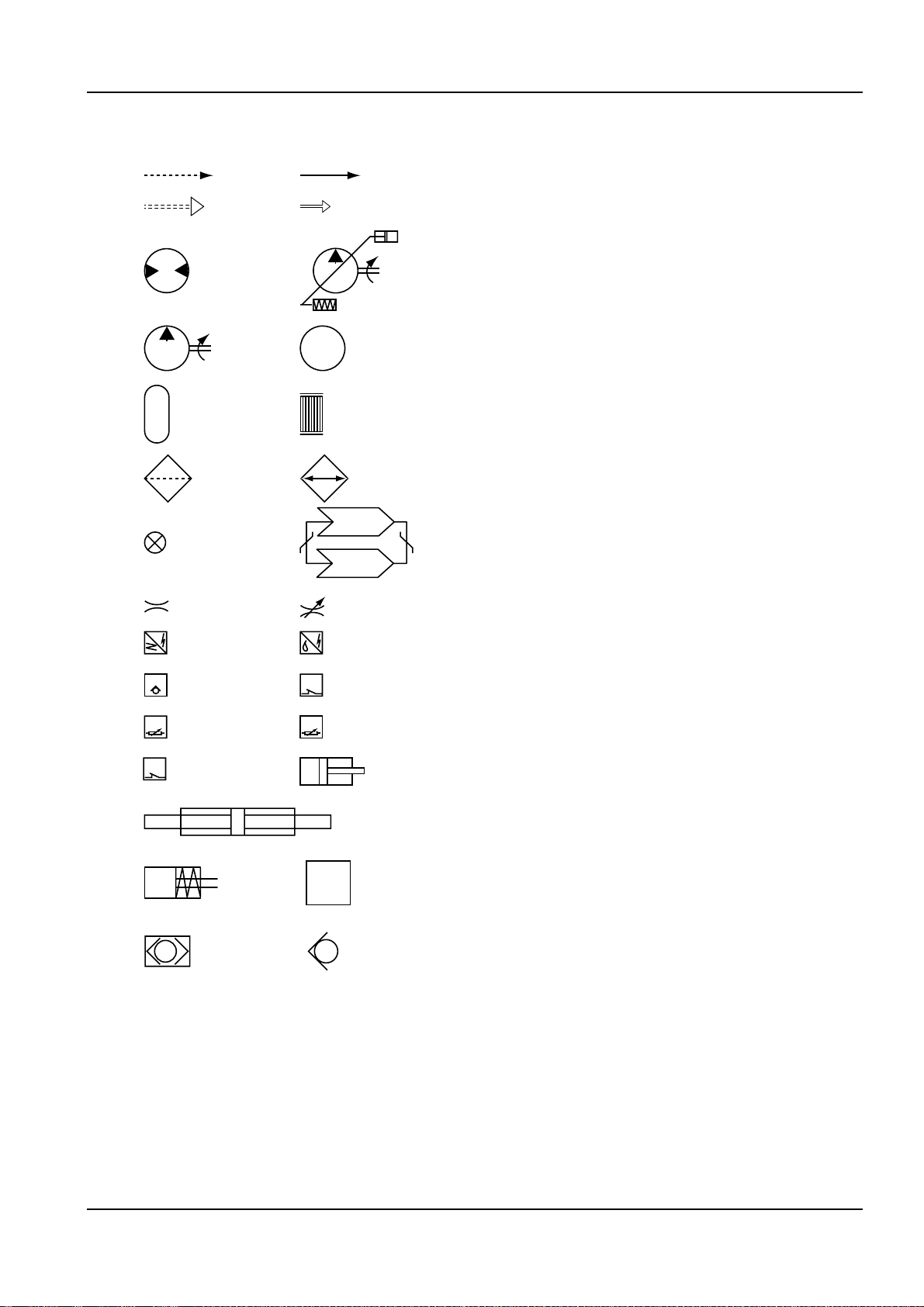

Symbol explanation function descriptions

The following symbols are used in function descriptions, the symbols

are based on stan dard symbols used in wiring and hy draulic diagrams .

1. Electric control signal

2. Electric force

3. Hydraulic control signal

4. Hydraulic force

5. Hydraulic motor

6. Hydraulic oil pump with variable displacement

7. Hydraulic oil pump with fixed displacement

8. Electric motor

9. Accumulator

10. Disc brake

11. Filter

12. Radiator

13. Bulb

14. Control system, two control units with CAN-bus

15. Restriction

16. Adjustable restriction

17. Inductive position sensor

18. Electrically controlled servo valve

19. Thermal bypass valve

20. Temperature-controlled sw i tch

21. Temperature sensor

22. Pressure sensor

23. Pressure-controlled switch

24. Hydraulic cylinder

25. Double-acting hydraulic cylinder

26. Spring brake cylinder

27. Valve block

28. Shuttle valve

29. Non-return valve

28 29

000523

Workshop manual DRF 400-450

VDRF03.02GB

Page 16

12 A Foreword – About the documentation

About the documentation

page –

Documentation sections

The documentation to the machine comprises the following sections:

Operator’s manual

The operator’s manual is supplied with the machine in the cab.

Documentation kit

Maintenance manu al and spare p arts catalogue wi th machine card are

supplied with the machine as a separate documentation kit.

Supplementary documentation

Supplementary documentation can be ordered for the machine.

• Workshop manual.

• Supplier documentation for engine, transmission and drive axle.

page –

Ordering of documentation

Documentation is ordered from your Cargotec dealer.

Always specify the publication number when ordering.

See the machine card for publication number.

VDRF03.02GB

Workshop manual DRF 400-450

Page 17

A Foreword – Feedback 13

Feedback

page –

To: Cargotec Sweden AB

Technical Documentation

Torggatan 3

SE-340 10 Lidhult

SWEDEN

Fax: +46 372 263 93

From:

Company / Sender: ..........................................................................................................................................

Telephone:

..........................................................................................................................................................

Form for copying

Cargotec’s ambition is that you who work with maintenance of a Kalmar machine shall have access to correct information.

Your feedback is important to be able to improve the information.

Copy this form, write dow n your views and s end it to us. Tha nk you for

your participation!

Manual

information

Suggestions,

views,

remarks,

etc.

E-mail:

.................................................................................................................................................................

Date: .................................... - .................. - ..................

Name / Publication number: .............................................................................................................................

Section / page n umber: ....... ................. ................. ................ ............ ................ ................. ................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

...........................................................................................................................................................................

Workshop manual DRF 400-450

VDRF03.02GB

Page 18

14 A Foreword – Feedback

VDRF03.02GB

Workshop manual DRF 400-450

Page 19

B Safety 1

B Safety

Table of Contents B Safety

mm mm mm mm mm mm

Safety .............................................................................................................. 3

General safety information ......................................................................... 3

Safety concerns everyone! ................................................................................ 3

A near accident is a warning! ............................................................................ 3

Safety instructions ...................................................................................... 4

General ............................................................................................................. 4

Service position ................................................................................................. 4

Hydraulic and brake systems, depressurising ................................................... 5

Oils .................................................................................................................... 6

Fuel system ....................................................................................................... 7

Clothing, etc. ..................................................................................................... 8

Several mechanics on the same machine ......................................................... 9

Working under machine .................................................................................... 9

Lifting heavy components ............................................................................... 10

Vibrations ........................................................................................................ 10

Noise ............................................................................................................... 11

Solvents .......................................................................................................... 11

Fire and explosion risks ................................................................................... 12

Fluid or gas under pressure ............................................................................ 13

Coolant ..................... .......................................................... ............................. 14

Refrigerant ...................................................................................................... 14

Air pollution ..................................................................................................... 15

Tensioned springs ........................................................................................... 16

Electric motors ................................................................................................. 16

Rotating components and tools ....................................................................... 17

Tyres and rims ............................. ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ... 18

Lifting equipment ......................... ....... ...... ...... ....... ...... ....... ...... ....... ...... ....... ... 18

Spare parts .. ...... ....... ...... ....... ...... .................................................................... 19

Non-ionised radiation ......................... ...... ...... ................................................. 20

Environment ............................................................................................. 21

General ........................................................................................................... 21

Workshop manual DRF 400-450

VDRF03.02GB

Page 20

2B Safety

VDRF03.02GB

Workshop manual DRF 400-450

Page 21

mm mm mm mm mm mm

B Safety – Safety 3

Safety

General safety information

page –

page –

Safety concerns everyone!

The safety information concerns everyone who works with the machine! Persons who do not follow the safety instructions given in this

manual must make abs olutely s ure that the work is perf ormed wi thout

risks of personal injury and without risk of damage to machine or ma

chine property!

Remember to:

• follow the instructions in this ma nual

• be trained for the work in question

• follow local laws, safety rules and regulations

• use the correct equipment and tools for the job

• wear the correct clothes

• use common sense and work carefully. Do not take any risks!

Cargotec has in this publication docum ented and warned f or situations

and risks that may occu r in connection w ith using as we ll as service or

repairs of the machine during normal circumstances.

That is why it is importa nt that all who work with the machi ne, or repair

or service the machine, read and follow the information in the Workshop Manual and Operator’s Manual.

A near accident is a warning!

A near-accident is an unexpected event where neither persons, machine or property are injured or damaged. However, a near-accident

indicates that there is an injury ri sk and acti ons must be ta ken to avoi d

the risk of injuries.

-

Workshop manual DRF 400-450

VDRF03.02GB

Page 22

4 B Safety – Safety instructions

Safety instructions

page –

General

Read, consider a nd follow the safety instructi ons below before starting

to work in the machine:

•

Service position page 4

•

Hydraulic and brake systems, depressurising page 5

•

Oils page 6

•

Fuel system page 7

•

Clothing, etc. page 8

•

Several mechanics on the same machine page 9

•

Working under machine page 9

•

Lifting heavy components page 10

•

Vibrations page 10

•

Noise page 11

•

Solvents page 11

•

Fire and explosion risks page 12

•

Fluid or gas under pressure page 13

•

Coolant page 14

•

Refrigerant page 14

•

Air pollution page 15

•

Tensioned springs page 16

•

Electric motors page 16

•

Rotating components and tools page 17

•

Tyres and rims page 18

•

Lifting equipment page 18

•

Spare parts page 19

•

Non-ionised radiation page 20

page –

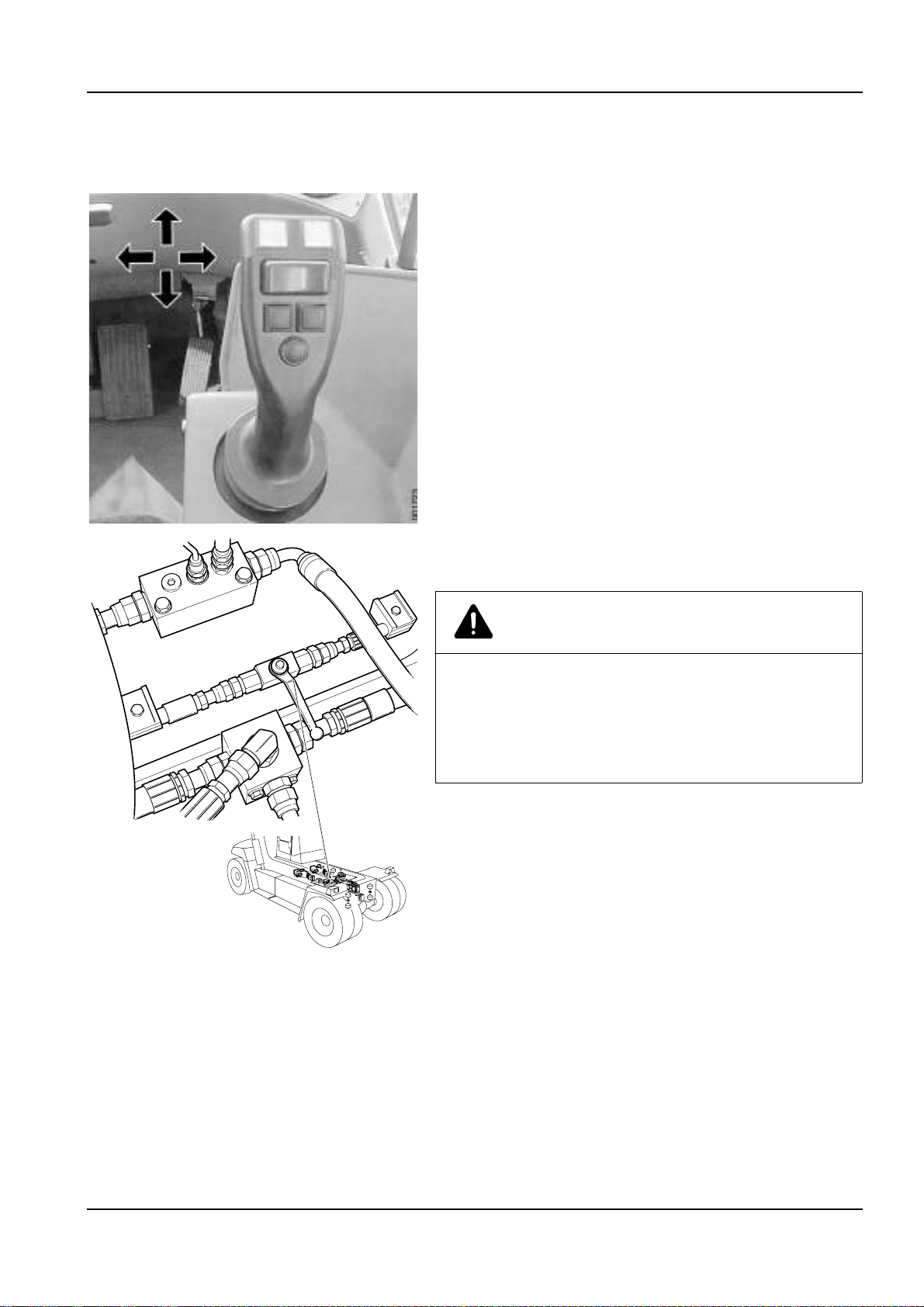

Machine with a fully retracted and lowered boom

VDRF03.02GB

Service position

General

Service position is us ed for servic e, mainten ance and ot her situations

when the machine needs to be secured.

Service position means:

• Machine parked, that is, parking brake applied.

• Boom fully retracted and lowered to horizontal position.

• Engine off.

• Main electric power off (with battery disconnec tor).

003603

Workshop manual DRF 400-450

Page 23

B Safety – Safety instructions 5

page –

Hydraulic and brake systems, depressurising

1 Machine in service position.

2 Depressurise the hydraulic system.

Turn the start key to position I and activate extension out, a

strong hissing sound is heard if there is pressure in the hy draulic

system. Activate lift, extension and side shift several times.

3 Turn the start key to position 0 and turn off the main electric

power.

4 Depressurise the attachment.

Open the relief valve for top lift.

The illustration above shows closed valve.

CAUTION

Hydraulic oil may be directed the wrong way.

Risk of damage to the fine filter for hydraulic oil.

Check that the relief valve top lift is closed before the

engine is started after the completion of work.

002269

Workshop manual DRF 400-450

VDRF03.02GB

Page 24

6 B Safety – Safety instructions

5 Depressurise the brake system by o pening the drain va lve on the

accumulator charging valve.

NOTE

Keep the drain valve open as long as work is in progress.

NOTE

After work is finished, c lose drain valv e and t ighten the loc k

ring.

page –

Oils

The following safety instructions shall be followed for work when handling oils.

WARNING

Warm and pressurised oil.

Always depressurise hydraulic and brake systems

completely before starting to work in the systems.

Hydraulic and brake systems are pressurised and the

oil may cause personal injuries.

Avoid skin contact with the oil, use protective gloves.

Warm oil can cause burn injuries, rashes and

irritation! The oil may also be corrosive to mucous

membranes in, e.g., the eyes, skin and throat.

IMPORTANT

VDRF03.02GB

Always clean the area around components and

connections before they are loosened. Dirt in oil

systems causes increased wear, resulting in

subsequent material damages.

Always take action to avoid spills. In places where

drain containers cannot be used, u se a pump or ho se

for safe handling.

Always check that plugs seal tight before collection

containers are moved.

Handle all oil as environmentally hazardous waste.

Oils freely released cause damage to the environment

and may also cause fires. Waste oils/fluids shall

always be handled by an authorised company.

Workshop manual DRF 400-450

Page 25

B Safety – Safety instructions 7

page –

Fuel system

The following safety instructions shall be followed for work when handling fuel.

DANGER

Pay attention to the risk of fire when working on the

fuel system.

Work on the fuel system shall be avoided when the

engine is warm since fuel can spill on hot surfaces

and may ignite.

Ensure that naked flames, sparks or glowing objects

have been removed before work begins on or near the

fuel system.

Do not smoke in the vicinity of the machine when

working on the fuel system.

WARNING

Use protective gloves and protective goggles. If a

component is to be disconnected, hold a rag over the

connection as protection and to collect fuel. The

engine’s fuel system operates at very high pressure.

The pressure is so high that the jet can injure the skin,

resulting in severe injuries. Risk of personal injuries.

Avoid skin contact with fuel, use protective gloves.

Fuel is corrosive to mucous membranes in, e.g., eyes,

skin and throat.

CAUTION

Always clean the area around components and

connections before they are loosened. Dirt in the fuel

may cause malfunctions and engine stop in

undesirable situations as well as increase wear,

resulting in subsequent material damages.

Workshop manual DRF 400-450

VDRF03.02GB

Page 26

8 B Safety – Safety instructions

IMPORTANT

Always take action to avoid spills. In places where

drain containers cannot be used, u se a pump or ho se

for safe handling.

Always check that plugs and connections seal tight

before moving collection containers.

Handle the fuel as environmentally hazardous waste.

Fuel freely released causes damage to the environ

ment and may also cause fires. Fuel shall always be

handled by an authorised company.

-

page –

Clothing, etc.

Clothes should be in good condition. Rem ove loosely hangi ng clothing

(tie, scarf, etc.). Do not wear clothes with wide sleeves, wide trouser

legs, etc.

Remove jeweller y as it m ay con duct e lectric ity an d get ca ugh t in moving parts.

Long hair should be adequately gathered since it can easily ge t caught

in moving parts. Be careful when working with welding or an open

flame since hair easily catches on fire.

VDRF03.02GB

Workshop manual DRF 400-450

Page 27

B Safety – Safety instructions 9

001977

page –

Several mech anics on the same machine

WARNING

If several mechanics are working on the same vehicle,

take extra care so that unintentional movements do

not injury another person. Communicate so that eve

ryone knows where all are and what they are doing.

Risks

Work with wheels or axle suspension, mountings, etc. may result in

components on the other side moving and causing damage/injury.

Movements performed from the operator’s s tati on, e.g., movement o f

lifting equipment, may cause severe personal injuries.

Safety precautions

• Make sure that the machine's lifting equipment is completely lowered or secured in another way.

• Move battery disconnector to position zero, remove the key.

• Be aware of the risks when several persons work around the

vehicle.

• Make your co-workers aware of what you’re working wi th.

• Do not work with drive wheels on the ma ch ine's both sides at the

same time.

-

page –

A

Locks on lift mast for securing the liftable cab in the

raised position.

Working under machine

Working under cab

On machines with liftable cab, the cab must be secured in the raised

position with the locks designed for this purpose.

Working under the frame

A raised vehicle may not, for an y reason, be supported or li fted in parts

that belong to the wheel sus pension or steering. Alway s support under

the frame or wheel axle.

Risks

Mechanical or hydraulic tools and lifting devices can fall over or accidentally be lowered due to malfunctions or incorrect use.

Safety precautions

Use axle stands and supports that stand securely.

Lifting tools should be inspected and type approved for use.

Workshop manual DRF 400-450

VDRF03.02GB

Page 28

10 B Safety – Safety instructions

page –

Lifting heavy components

WARNING

Careless handling of heavy components can lead to

serious personal injury and material damage.

Use type approved lifting tools or other devices to

move heavy components. Make sure tha t the device is

stable and intact.

Risks

Unsuitable lift slings, straps, etc. may break or slip.

The centre of gravity (balance point) of the component can change

during the course of the work, and the co mpone nt may t hen make unexpected movements which may cause severe personal injuries and

material damage.

A component lifted w ith lifti ng equipmen t can start to turn if the equi librium is upset.

A component lifted using an overhead crane may start to swing back

and forth, which can cause severe crushing injuries or material

damage.

Safety precautions

Lifting with lifting device. Use lifting tools or other tools, especially

when there are such adapted for certain work. See worksh op manu al

for methods.

If lifting must be performed without lifting device:

• Lift near the body.

• Keep your back vertical. Raise and lower with legs and arms, do

not bend your back. Do not rotate your body while lifting. Ask for

assistance in advance.

• Wear gloves. They're good protection against minor crushing injuries and cuts to fingers.

• Always use protective shoes.

page –

Vibrations

In case of long-term use of vibra ting tools, for exampl e, impact nut runners or grinders, injurie s may be sust ained a s vibr ations can be t ransmitted from tools to hands. Especially when fingers are cold.

Safety precautions

Use heavy gloves to protect against cold and somewhat against

vibrations.

Switch between work duties to give the body time to rest.

Vary work position a nd grip so that the body is not stres sed in only one

position by the vibrations.

VDRF03.02GB

Workshop manual DRF 400-450

Page 29

B Safety – Safety instructions 11

page –

Noise

Noise louder than 85 dB (A) that lasts for longer than 8 hours is considered harmful to hearing. (Limit values may vary between different

countries.) High tones (hig h frequencies) are more damaging th an low

tones at the same sound level. Impact noise can also be hazardous,

e.g. hammer blows.

Risks

At noise levels higher than the limits hearing damage can occur. In

more severe cases, hearing damage can become permanent.

Safety precautions

Use hearing protecti on. Make sure that it is tested and p rotects against

the noise level in question.

Limit noise with noise-absorbing dividers, for example, noise-absorbing materials in roof and on walls.

page –

Solvents

Fluids that (as opp osed to w ater) dissolve grease, paint, lacque r, wax,

oil, adhesive, rubber, etc. are called organic solvents. Examples:

White (petroleum) spirits, gasoline, thinner, alcohols, diesel, xylene,

trichloroethylene, toluene. Many solvents are flammable and consti

tute a fire hazard.

-

Risks

Products containing solvents produce vapours that can cause dizziness, headaches and nausea. They may also irritate mucous membranes in the throat and respiratory tracts.

If the solvent en ds up directl y on the skin it may dry o ut and crack . Risk

of skin allergies incre ases. Solv ents ma y also cause in jury if the y penetrate through the skin and are absorbed by the blood.

If the body is continuously exposed to solvents, the nervous system

may be damaged. Symptoms include sleep disorders, depressions,

nervousness, poor memory or gene ral tire dness and fat igue. C ontin u

ous inhalation of gasoline and diesel fumes is suspected to cause

cancer.

Safety precautions

Avoid inhaling sol vent fumes by providing go od ventil ation, or wearin g

a fresh-air mask or respiratory de vice with a sui table filter for the toxic

gases.

Never leave a solvent container without tight-sealing lid.

Use solvents with a low content o f aromatic substan ces. It reduces th e

risk of injury.

Avoid skin contact.

Use protective gloves.

Make sure that work clothes are solvent-resistant.

-

Workshop manual DRF 400-450

VDRF03.02GB

Page 30

12 B Safety – Safety instructions

page –

Fire and explosion risks

Examples of flammable and explosive substances are oils, gasoline,

diesel fuel oil, organic solvents (lacquer, plastics, cleaning agents),

rustproofing agents, welding gas, gas for heating (acetylene), high

concentration of dust particles consisting of combustible materials.

Rubber tyres are flammable and cause explosive fires.

Risks

Examples of cause of ignition is welding, cutting, smoking, sparks

when working with grinders, contact between hot machine parts and

flammable materials, heat development in rag drenched with oil or

paint (linseed oil) and oxygen. Oxygen cylinders , lines and val ves shall

be kept free from oil and grease.

Fumes from, e.g., gasoline are heavier than air and may "run" down

into a sloping plane, or down in a grease pit, where welding flames,

grinding sparks or cigarette embers may cause an explosion. Evapo

-

rated gasoline explodes very forcefully.

Special cases

Diesel fuel oil with added gasoline has a lower ignition point. Risk of

explosion already at room temper ature. The expl osion risk for warm ed

diesel fuel oil is higher than for gasoline.

When changing oil in the engine, hydraulic system and transmission,

keep in mind that the oil may be hot and can cause burn injuries.

Welding on or near machine . If diesel and or other oil s have leake d out

and been absorbed b y rags , absorb ent age nts, p aper o r other porous

material, hot welding sparks can cause ignition and explosive fires.

When a battery is charged, the battery fl uid is d ivided i nto oxyg en and

hydrogen gas. This mix ture is ve ry ex pl os iv e. The risk of explosion is

especially high when using a boo ster b atte ry or q uick-c harger , as th is

increases the risk of sparks.

Today’s machines contain a lot of electronic equipment. When welding, the control units must be disconnected and the electric power

must be turned off with the batte ry disconnector. Powe rful welding currents may otherwise short-circuit the electronics, destroy expensive

equipment or cause an explosion or fire.

Never weld on pai nted s urfaces (re mo ve pai nt, by bla sting a t leas t 10

cm around the weldi ng or c utting poi nt). Us e gloves , br eathin g protec

tion and protect ive g lass es. Als o, w eldin g work may not b e done near

plastic or rubber mat eria ls with out firs t pro tec tin g t hem fro m th e h eat .

Paints, plastics, a nd rubber deve lop a numbe r of substanc es that may

be hazardous to health when heated. Be careful with machines that

have been exposed to intense heat or fire.

-

VDRF03.02GB

Workshop manual DRF 400-450

Page 31

B Safety – Safety instructions 13

Safety precautions

Store hazardous substance in approved and sealed container.

Make sure that there is no ignition source near flammable or explosive

substances.

Make sure that ven tilation is adequ ate or there is an ai r extraction unit

when handling flammable substances.

page –

Fluid or gas under pressure

High-pressure lines can b e damaged during w ork, and fluid or gas c an

stream out.

There may be high pressure in a line even if the pump has stopped.

Therefore, gas or fluid can leak out when the connection to the hose

is loosened.

A gas cylinder subjected to careless handling can explode, for example, if it falls onto a hard surface. Gas can stream out through damaged valves.

Risks

Risk of damage/injuries in connection with work on:

• Hydraulic systems (e.g., working hydraulics and brake system).

• Fuel system.

• Tyre repairs.

• Air conditioning.

Safety precautions

• Use safety glasses and protective gloves.

• Never work on a pressurised system.

• Never adjust a pressure limiting valve to a higher pressure than

recommended by the manufacturer.

• A hydraulic hose that swells, for example, at a connection, is

about to rupture. Replace it as soon as possible! Check connections thoroughly.

• Use fluid when checking for leaks.

• Never blow clothes clean with compressed air.

• Discarded pressure a ccum ula tor s ha ll first be depressurised an d

then punctured before it is discarded (to avoid risk of explosion).

Carefully, drill a hole with 3 mm diameter after depressurising.

• Never use your hands directly to detect a leak. A fine high-pressure stream from a hydraulic hose can easily penetrate a hand

and causes very severe injuries.

Workshop manual DRF 400-450

VDRF03.02GB

Page 32

14 B Safety – Safety instructions

page –

Coolant

The coolant in the machine’s cooling system consists of water, anticorrosion compound and (when needed) anti-freeze fluid, for example,

ethylene glycol.

Coolant must not be drained into the sewer system or directly onto the

ground.

Risks

The cooling system operates at high pressure when the engine is

warm. Hot coolant c an j et ou t an d ca us e sc al din g in case of a leak or

when the expansion tank cap (filler cap) is opened.

Ingesting ethylene glyco l and anti - co rros io n com pou nd is danger ous

and hazardous to health.

Safety precautions

• Use protective gloves and safety glasses if there is a risk of

splashing or spraying.

• Open the filler cap first, to release the excess pressure. Open

carefully. Hot steam and coolant can stream out.

• If possible, avoid working on the cooling system when the coolant

is hot.

page –

Refrigerant

Refrigerant is used in the machine’s air conditioning system.

Work on the air cond itioning system must be performed by accredi ted/

authorised and traine d personnel a ccording to national leg islation and

local regulations.

Risks

The air conditioning operates at high pressure. Escaping refrigerant

can cause fr ostbite.

Refrigerant that is heated (e.g., when repairing leaking climate/AC

system), generates gases that are very dangerous to inhale.

Safety precautions

• Use special instructions and equipment for refrigerant according

to the manual when working on the air conditioning system. Spe

cial certification and authorisation is often required of the person

who may do the work. (Note national legislation and local

regulations!)

• Use protective glov es and s afety glasses if there’s a ri sk of leaks.

• Make sure that heat-p roducing sources o r objects are not cl ose by

(cigarette glow, welding flame).

-

VDRF03.02GB

Workshop manual DRF 400-450

Page 33

B Safety – Safety instructions 15

page –

Air pollution

Air pollution is the impurities in t he air arou nd us and whic h are regarded as hazardous to health. Certain pollution is more prominent in certain environments.

The following hea lth-hazard ous air pollutio n is e special ly promi nent in

workshops:

• Carbon monoxide (fumes) is present in exhaust fumes. Odourless and therefore especially dangerous.

• Nitrogen oxides (nitrous gases) are present in exhaust fumes.

• Welding smoke espec ially h azardous to health when wel ding on

oily surfaces, galvanised or lacquered materials.

• Oil mist for example, when applying anti-corrosion agent.

• Grinding dust and gases ge nera ted wh en g rin ding and heating

plastics, lacquer, anti-corrosion agents, lubricants, paint, etc.

• Isocyanates are present in certain paints, fillers, adhesives and

foam plastics used on machines.

Risks

Sulphuric acid mist is corrosive and injures the respiratory tracts.

(Generated when heating certain plastics and paints.)

Isocyanates can be released in the form of steam, dust (or may be

present in aerosols) when cut ting, grinding or w elding. Can irrit ate mu

cous membranes producing symptoms similar to asthma and impairing lung function . Even bri ef exposure to high concen trations can give

problems with persistent high sensitivity.

-

Safety precautions

• Make sure of adequate ventilation with fresh air when welding,

battery charging and other work when hazardous gases are

generated.

• Use suitable protective gloves and breathing protection when

there is a risk of oil m ist. Make sure tha t the protec tion is oil-pro of.

• Apply oil-resistant protective lotion to unprotected skin.

• Make sure that an eye-wash station is in the immediate vicinity

when working with corrosive substances.

• Avoid unnecessary operation of the machin e inside the works hop.

Connect an air extractor to the exhaust pipe so that the exhaust

fumes are removed from the workshop.

Workshop manual DRF 400-450

VDRF03.02GB

Page 34

16 B Safety – Safety instructions

page –

Tensioned springs

Examples of tensioned springs:

1. Torque springs in pedals for example

2. Return spring (cup springs) in parking brake cylinder.

3. Lock rings

4. Gas springs

Risks

If a tensioned spring releases, it is sho t out by the spring force and can

also take adjoining parts with it.

Small springs can cause eye injuries.

Parking brake springs are tensioned with high force and can cause

very severe accidents if they are accidentally released in an uncon

-

trolled manner.

Gas springs and gas-charged shock absorbers are tensioned with

high force and c an cause very seve re accidents if th ey are accidentally

released in an uncontrolled manner.

Safety precautions

• Use safety glasses.

• Lock rings should be of a suitable type and in good condition.

• Follow the instruct i ons in th is and other manual when perf orm ing

maintenance and changing parts and components.

• Always use recommended tools.

page –

Electric motors

Safety precautions

Always turn off the battery disconnector when working on electric

motors.

Always block the machine’s wheels and make sure that the parking

brake is activated and that the gear selector is in neutral position before starting any work on the machine.

VDRF03.02GB

Workshop manual DRF 400-450

Page 35

B Safety – Safety instructions 17

page –

Rotating components and tools

Examples of rotating components and tools:

• Cooling fan

•Drive belts

• Propeller shafts

•Drills

• Grinders

Risks

Rotating components, for example, fans or shafts, can cause severe

injuries if touched.

Drills, lathes, grind ers or other ma chines with ro tating par ts can cause

severe accidents if clot hes or hair get caught and are wound up in the

machine.

Safety precautions

• Do not use gloves when workin g with a drill.

• Remove loose, hanging clothing, scarf or tie.

• Never use clothing with wide sleeves or trouser legs.

• Make sure that clothing is intact and in good condition.

• Long hair should be gathered up in a hair-net or similar.

• Remove large or loose hanging jewellery from hands, arms and

neck.

Workshop manual DRF 400-450

VDRF03.02GB

Page 36

18 B Safety – Safety instructions

page –

Tyres and rims

DANGER

Tires shall be regarded as pressure reservoirs. If handled incorrectly, they constitute a fatal danger

Parts can be thrown with explosive force and may

cause severe injuries.

Never repair damaged tyres, rims or lock rings. Tyre

changes shall be performed by authorised personnel.

Risks

Dismantling wheels: Tyres, rims or lock rings can be thrown.

Inflating of wheels: Tires, rims or lock rings may be ejected.

Safety precautions

• Always deflate the tyre before starting to work on the wheel.

• Check that tyres, rims and lock rings aren’t damaged. Never repair damaged rims or lock rings.

• Wheels shall be infla ted on the machi ne or in a pro tective devic e,

designed and dimensioned so that it can handle or dissipate a

shock wave from a tyre explosion as well as catch the ejected

parts.

• Use protective screen and safety glasses.

page –

Lifting equipment

When working on the machine in general, and with the machine’s lifting equipment in particular, the greatest caution must be exercised

with respect to securing the boom and attachment.

For this reason, always be in the ha bit of having the boom fully lowered

and fully retracted during work on the machine.

Risks

Risk of crushing if the machine’ s lif ting equipment is not lowered or

secured.

Risk of crushing is extra high when depressurising the hydraulic system, see

Hydraulic and brake systems, depressurising page 5

.

Safety precautions

• Do not start work until the boom is lowered and fully retracted if

possible.

VDRF03.02GB

Workshop manual DRF 400-450

Page 37

B Safety – Safety instructions 19

page –

Spare parts

WARNING

The following parts must, for safety reasons, only be

replaced with original spare parts:

• Brake valve

• Drive axle

• Valve for mini-wheel/lever steering

• Steering valve (Orbitrol)

• Steering valve incl. priority valve

• Steering axle

• Steering cylinder

•Rims

• Lift boom

• Boom nose extension

• Lift cylinder

• Valve block lift

• Extension cylinder

• Valve block extension

• Rotation motor unit

• Tilt cylinder

• Twistlocks, lifting shoe

• Safety switch (for hydraulic function)

• Emergency switch

•Frame

• Accumulator

• Main valve load handling

• Accumulator charging valve

• All control units

Workshop manual DRF 400-450

VDRF03.02GB

Page 38

20 B Safety – Safety instructions

page –

Non-ionised radiation

WARNING

Extra equipment such as communication radio, RMI,

phone, etc. can emit non-ionised radiation.

Danger of disruption to active or inactive medical

products.

Use communication radio, RMI, phone, etc. when

there are no people with active or inactive medical

products in the vicinity.

NOTE

When there are no people wit h act iv e or ina cti ve pr odu ct s in th e

vicinity the phone and communication radio in the cab may be

used.

Equipment should not be used durin g ope ration or l oad h andlin g

as your concentration as operator is reduced.

Cargotec accepts no re sponsibili ty for equipment n ot installed by

Cargotec or with Cargotec approved installation.

VDRF03.02GB

Workshop manual DRF 400-450

Page 39

B Safety – Environment 21

Environment

page –

General

Ever-increasing indust rialisation o f our world is ha ving a sign ificant impact on our global environ ment. Nature , animals and man are sub jected daily to risks in conn ection with various forms of chemical h andling.

There are still no environmentally safe chemicals, such as oils and

coolants, available on the market. Therefore, al l w h o h and le , pe rform

service on or repair machines must use the tools, assisting devices

and methods necess ary to pro tect the enviro nment in an environ men

tally sound manner.

By following the simple rules below, you will contribute to protecting

our environment.

-

Recycling

Well-thought out re cycling o f the mach ine is the cornerstone of ending

its life cycle and being able to re-use materials in new products. Ac

cording to calculations by Cargotec, the machine can be recycled to

more than 90% by weight.

-

Environmentally hazardous waste

Components such as batteries , plastics , and other materi als that may

be considered as enviro nm enta ll y ha za rdous waste must be handl ed

in an environmentally correct manner.

Discarded batteries c ontain subs tances h azardous to p ersonal he alth

and the environment. Th erefore, handle batteries in an e nvironmental

ly safe manner and according to national regulations.

-

Oils and fluids

Oils freely discharged cause environmental damage and can also be

a fire hazard. Therefor e, when e mptying and draini ng oils or fuel, take

appropriate action to prevent unnecessary spills.

Waste oils and fluids must always be taken care of by an authorised

disposal company.

Pay close attention to oil leaks and other fluid leaks! Take immediate

action to seal the leaks.

Air conditioning unit

The refrigerant in the air conditioning unit for the cab contributes to the

greenhouse effect and may not be i ntentionally released in to the open

air. Special training is required for al l servic e work on the air condi tion

ing unit. Many coun tries d emand certi fication by a gov erning au thority

for such work.

Working in a contaminated area

The machine shall be equipped for work within a contaminated area

(environmental contam ina t io n o r hea lth - haz ard ous ar ea) b efo re w ork

is started. Also, special loc al regulations appl y to such handling and to

service work on such a machine.

-

Workshop manual DRF 400-450

VDRF03.02GB

Page 40

22 B Safety – Environment

Declarations

The machine does not contain asbestos.

The machines contains lead in batteries and in electric cabling. In cer-

tain models, there are lead castings as counterweight.

If the machine is equ ipped with air con ditioning , then re frigerant o f the

type R134a is used, in an amount between 1-3 kg.

VDRF03.02GB

Workshop manual DRF 400-450

Page 41

mm mm mm mm mm mm

C Preventive maintenance – C Preventive maintenance 1

C Preventive maintenance

C Preventive maintenance

page –

The information is found in the Maintenance Manual

The information is found in the Maintenance Manual.

For information on how to order the Maintenance Manual, see the

section

A Foreword

.

Workshop manual DRF 400–450

VDRF03.02GB

Page 42

2 C Preventive maintenance – C Preventive maintenance

VDRF03.02GB

Workshop manual DRF 400–450

Page 43

0 Complete mach ine 1

0 Complete machine

Table of Contents 0 Complete machine

mm mm mm mm mm mm

Complete machine......................................................................................... 3

Complete machine, description ....... ....... ...... ...... ....... ...... ....... ............................... 3

Troubleshooting, general work instructions ............................................................ 4

Troubleshooting without an error code, example ................................................... 5

Troubleshooting with error code, example ............................................................. 5

Troubleshooting cable harness .............................................................................. 7

Troubleshooting hydraulic hoses ............................................................................ 8

Workshop manual DRF 400-450

VDRF03.02GB

Page 44

20 Complete machine

VDRF03.02GB

Workshop manual DRF 400-450

Page 45

mm mm mm mm mm mm

0 Complete machine – Complete machine 3

Complete machine

page –

Complete machine, description

The Kalmar DRF 400–450 is a "Re achstacker" for co ntainer handli ng.

The machine a liftin g capaci ty of 40–4 5 tonnes d epending on versio n.

The drive source is a six-c ylinder, four-strok e diesel engin e with direct

injection.

The transmission is hydromechanical, with constant mesh gears. It

has four speeds forwards and fou r speeds in reverse. Engi ne power is

transmitted by a torque converter.

The driveline/axle comprises a propeller shaft and a rigid drive axle

with hub reduction. Drive is via the front wheels.

The service brake is of wet disc type, built together with drive wheel

hubs. The parking brake is a disc brake and acts on the drive axle in

put shaft.

Steering is via the rear wheels and a dou ble acting hydrau lic cylin der.

The steering axle is pendulum-suspended in the frame.

The wheels are mounted on the hubs with clamps. Twin wheels are

mounted on the drive axle, while the steering axle has single wheels.

Load handling comprises components and functions for managing

loads. Loads are lifted with and attachment that is fitted on a liftable

telescopic boom. Load handling is divided into lifting/lowering, exten

sion, side shift, spreading, rotation, tilt, levelling and load carri er fun ctions.

• Lifting/lowering is the function used to raise and lower the boom.

• Extension is the function to extend the boom in and out.

• Side shift is used to move th e lift attachment laterally in relati on to

the machine.

• Spreading is used to adjust the width between the attachment’s

lifting points.

• Rotation is rotating the load in relation to the machine.

• Tilt is angling the load in the longitudinal direction of the truck.

• Levelling is angling the load in the lateral direction of the truck.

• The load carriers are designed to hold a fixed load.

The control system is functions for warni ng the opera tor of dange rous

situations and machine faults. The control system has diagnostic re

sources that simplify troubleshooting.

The frame supports the machine. Mounted in the frame are the engine,

transmission, drive axle and steering. The side of the frame houses

tanks for fuel, hydrauli c oil and oil for the brake system. T he cab is cen

trally located and can be tilted longitudinally. As an option the cab is

available in a side-mounted version that can be raised and lowered.

-

-

-

-

Workshop manual DRF 400-450

VDRF03.02GB

Page 46

4 0 Complete machine – Complete machine

page –

Troubleshooting, general work instructions

When troubleshooting, it is important that the work is structured and

logical. The point of the troubleshoo ting describe d in the mainten ance

manual is to exclude components as error so urce so that the real e rror

source can be pin-po inted. A suggest ed structured w ork method is de

scribed below.

When troubleshoo ting , i t is i mp orta nt t o un derstand how the mach ine

functions. Certain m alfun ctions can be pi n-p ointed directl y using f unction descriptions. Sections

0–12

contain descriptions of the various

functions of the machine.

Troubleshooting procedure

1 Check that there is battery voltage available.

• Battery disconnector, must be in position 1.

• Battery voltage, should be 22–30 V.

• Fuses, check that they are intact.

2 Check that all oil and fluid levels are normal.

•Fuel

• Engine oi l

• Transmission oil

• Brake system fluid

• Hydraulic oil

• Coolant

• Washer fluid

3 Check if there are error codes.

4 If there are error codes, use the error code lists as a guide. See

Troubleshooting with error code, example page 5

In the error code lists there are recommended actions for every

error code. Error code lists are found in section

5 If there is no error code or the problem persis ts, use the functio n

description for the function in question in section

The function description contains information on which compo-

nents are involved in the function and how these components

work together. In some cases, there is information on what con

ditions are required in order for it to be possible to activate the

function. Measureme nt points a re marked wi th flags (C fo r meas

uring outlet, D for diagnostic me nu).

.

D Error codes

0–12

.

-

.

-

-

VDRF03.02GB

Workshop manual DRF 400-450

Page 47

0 Complete machine – Complete machine 5

page –

Troubleshooting without an error code, example

1 Choose suitable section

tion that have caused the symptom.

2 Read the function description for the function in question to get

an overall understanding of which components are affected and

how these interact.

3 Use the function description and check the signals for the func-

tion in question to find where in the function chain that signal or

reaction is incorrect.

4 The fault is probably between the two units where the signal is

failing. Start by checking the component that should send the

signal.

5 If the component that is to send the signal seems to be correct,

check transmission of the signal (electric wiring or hydraulic

hoses).

For electric cabling, see

For hydraulic hoses,

see

Troubleshooting hydraulic hoses page 8

6 If the leads or hoses between the components seem in order,

then check the component that receives the signal.

0–12

to find the function and sub-func-

Troubleshooting cable harness page 7

.

.

page –

Troubleshooting with error code, example

Error codes are strong i ndica tors of mal functi ons de tected by the control system. Many error codes are connected to elec trical malfunctio ns

but there are also error codes that inte rpret associati ons between one

or several signals th at ind icate a n on- electri cal mal functi on. It’ s imp or

tant to not draw conclusions too fast based on an error code.

1 Read out error codes from the display, e.g., error code 34.

2 Use the error code lists and search information about the error

code, see "Example of error code information in error code list"

below.

Error code lists are found in section

D Error codes

.

For detailed instructi on o n re adi ng o ut e rror c od e, s ee s ec tio n

Error codes

.

3 Follow the instructions in the field “Action”.

4 Use diagnostic menus and circuit dia grams to dete rmine if the in-

put signal to the control unit is correct; see section

system

, group

8.4 Diagnostics

as well as section

8 Control

E Schematics

5 Use the function group to find more information if needed.

In section

0–12

there is functio n descriptio n, the functi on's included components and their position as well as, in certain cases,

work instructions for how components are checked, cleaned or

adjusted.

-

D

.

Workshop manual DRF 400-450

VDRF03.02GB

Page 48

6 0 Complete machine – Complete machine

6 If possible, eliminate component fault by testing the component

individually.

Electric componen ts can s ometi mes be chec ked w ith resi stanc e

measurements using a multimeter.

Hydraulic componen ts are often checked by meas uring pressure

(then described in the function group and indicated in the

section

activated mechanica ll y to d eterm in e if th e ma lfunction is electric

or hydraulic.

7 If the component’s measuremen t values are correct , conti nue by

troubleshooting electric cables and hydraulic hoses.

For electric cabling, see

For hydraulic hoses, see

8

8 If the cable is not defective, then connect the lead to the control

unit.

C Preventive maintenance

.

NOTE

The main electric power shall be turned off with the battery

disconnector!

9 Disconnect the cable from the component in question.

10 Turn on the main electric power with the battery disconnector.

11 Turn the ignition key to the operating position.

12 Check that voltage reaches the component.

). Sometimes valves can be

Troubleshooting cab le harn es s p age 7

Troubleshooting hydraulic hoses page

.

Table 1. Ex ample of error code information in error code list

Code Description Limitation Action

34 Signal error from

parking brake

switch, indicates re

leased and applied

at same time or

nothing at all.

Parking brake

cannot be

-

released.

Check cabling

between the control

unit and the

component with

diagnostic menu.

Check component.

Connections

and

components

D791-1/K8:5 S107, K8:13 S107

Diagnostic menu

HYD,

5

menu

Function

group

4.1.2 Parking

brake control

VDRF03.02GB

Workshop manual DRF 400-450

Page 49

0 Complete machine – Complete machine 7

page –

Troubleshooting cable harness

NOTE

Perform troubleshooting for all cabl es in the sam e way to avo id

damage to control units, components or measuring equipment.

1 Study the circuit diagram in questi on, check where the suspected

cable is connected and if, and if so where, it is spliced.

2 Turn off the main electric power with the battery disconnector.

3 Unplug the connector at the control unit or component in

question.

CAUTION

Wipe and re-grease the connectors.

Risk of corrosion on contact surfaces.

Clean all connectors loosened during troubleshoot-

ing using electronic cleaner 923836.0826 and regrease them with connector grease 923836.0552.

4 Check if there is open circuit.

NOTE

Some components ca nnot be checked without p ower supply

to the component. In such an event, proceed to point 5.

a. Measure resistance between connection s for the component

in the connector at the control unit or component.

b. The resistance mus t correspond with the c om pon ent . O th er-

wise there may be an open circuit or short circuit in cable harness and/or component.

5 Check if there is short circuit to frame:

a. Unplug the conne ctor at bot h the con trol unit a nd the co mpo-

nent in question.

b. Measure the resistance of one lead at a time. Measure be-

tween the lead and a frame-connected part of the machine.

c. The multimeter should show endless resistance.

Workshop manual DRF 400-450

VDRF03.02GB

Page 50

8 0 Complete machine – Complete machine

page –

Troubleshooting hydraulic hoses

WARNING

Oil under high pressure!

Personal injury!

Always depressurise hydraulic and brake systems

before starting to work on the systems.

1 Depressurise the hydraulic and brake systems; see section

.

Safety

2 Study the relevant hydraulic diagra m, check between w hichever

components the suspec t hose i s conne cted and corres pondingl y

where it is spliced.

3 Locate the hose on the machine.

Start at one component and follow the hose to the next

component.

4 Inspect the entire hose and splicin g points with res pect to chafing

damage, pinching damage and leaks.

Change damaged hoses. When removing a hydraulic hose,

change of O-ring is always recomme nded on the hos es that have

these (ORFS).

B

VDRF03.02GB

Workshop manual DRF 400-450

Page 51

1 Engine 1

1 Engine

Table of Contents1 Engine

mm mm mm mm mm mm

1 Engine ............................................................................................................. 3

1.1 Controls and instruments ............................. ............................................ 23

1.1.1 Ignition switch ...................................................................................... 23

1.1.2 Accelerator pedal ................................................................................. 24

1.2 Fuel system .............................................................................................. 25

1.2.1 Fuel tank .............................................................................................. 25

1.2.2 Sensor, fuel level ................................................................................. 25

1.6 Air intake and exhaust outlet ................ .................................................... 26

1.6.1 Air cleaning system .............................................................................. 26

1.6.3 Exhaust syst em ................................................................ ................... 26

1.6.4 Intercooler ............................................................................................ 27

1.7 Cooling system ......................................................................................... 28

1.7.4 Radiator and expansion tank ............................................................... 29

1.7.5 Cooling fan ........................................................................................... 30

1.7.7 Coolant ................................................................................................ 32

1.7.10 Engine heater ...................................................................................... 35

1.9 Engine control system .............................................................................. 36

1.9.1 Control unit , engine ................................ ....................... .. ..................... 36

1.11 Start/stop .................................................................................................. 37

1.11.1 Starter motor ........................................................................................ 37

1.11.2 Stopping device ................................................................................... 37

Workshop manual DRF 400–450

VDRF03.02GB

Page 52

2 1 Engine

VDRF03.02GB

Workshop manual DRF 400–450

Page 53

mm mm mm mm mm mm

1 Engine 3

1 Engine

page –

Engine, general

Engine alternative

The machine can be equipped with one of the following engine

alternatives:

• Volvo TWD1240VE stage II as per Directive 97/68/EC

• Volvo TAD1250VE (stage III as per Directive 97/68/EC)

• Cummins QSM11 (stage III as per Directive 97/68/EC )

If there are differences between engine alternatives, this is written in

brackets after heading s or u nder fi gures to c larify that wh ich i s sho wn.

Volvo engines have many similarities. Descriptions and instructions

that are the same for both engine alternatives are denominated "(engine alternative Volvo)". If a description or set of instructions only applies to one engine alternative then the whole engine designation is

written out, for instance "(engine alternative Volvo TAD1250VE).

Component supplier documentation