Page 1

Kalmar DCF360-450CSG

Toplift container handlers

36 – 45 tonnes

Technical information

Page 2

Introduction

Welcome

Let us introduce to you the details about the

new ultimate top-lift handler – the Kalmar

DCF-series.

These heavy-duty container handlers have

been developed exclusively for ports and terminals with strong demands on productivity

and high quality operation. This is a machine,

which has long been asked for among demanding terminal operators all over the world.

So what about the special benefits?

The Two basic elements

in container handling.

The decision to develop a “brand new” machine came after getting input from terminal

operators for a basic type of machine, but

with superior performance characteristics. We

then decided to build a family of integrated

top-lift handlers that would surpass all existing machines.

Drawing on our global experience we know

that there are two basic elements in container

handling that ensures success in the working

day on every port and terminal. Two elements in the mind of operations, financial and

purchasing managers, but also in the mind of

drivers and maintenance staff.

These two elements were our top priority in

the design and development of the Kalmar

DCF.

Technical solutions are only the tool.

Not the goal.

There is new leveraging technology under the

skin of the DCF in order to provide the best

everyday performance and availability.

PERFORMANCE

PERFORMANCE

ERGONOMICS

ERGONOMICS

DRIVING

DRIVING

LIFTING

LIFTING

CAPACITY AND

CAPACITY AND

DIMENSIONS

DIMENSIONS

We have examined and evaluated every nut,

bolt and component to ensure we provided a

machine with the highest possible specification.

When appropriate simple technical solutions

were available we have applied them, and

when the need was for more sophisticated

systems we have installed them to boost your

uptime and productivity.

AVAILABILITY

AVAILABILITY

RELIABILITY

RELIABILITY

MAINTENANCE

MAINTENANCE

INTELLIGENCE

INTELLIGENCE

SIMPLICITY

SIMPLICITY

The technical optimisation of the Kalmar DCF

means that you will get the best technology

available but still have the feeling of having a reliable, simple, safe and hard working

machine.

Providing the highest possible

throughput.

This is what it’s all about. But of course you

have to add “at the lowest lifetime cost possible”. To reach such a goal you need to focus

on specific critical targets.

2

Page 3

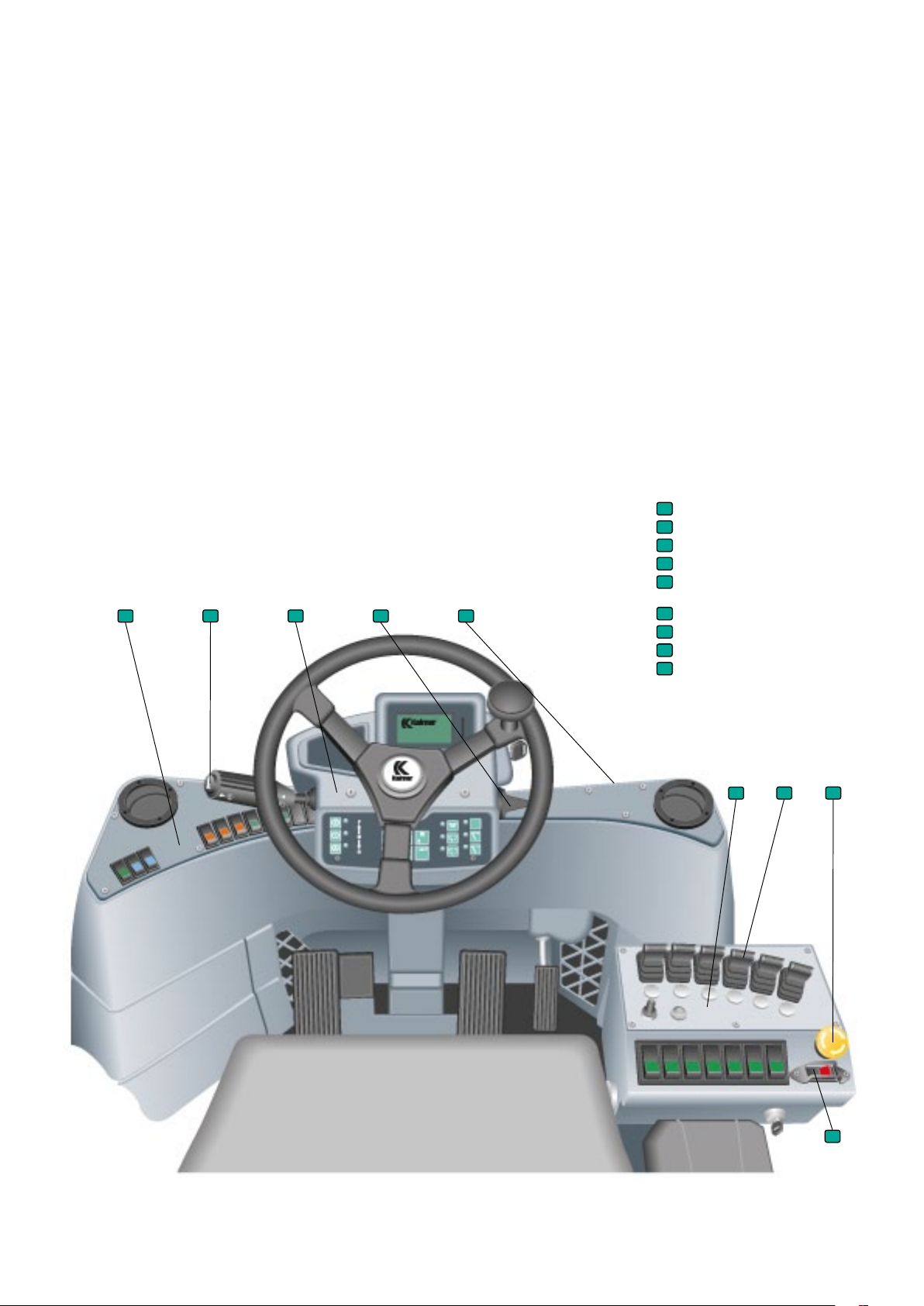

Ergonomics

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

I

A

A

B

A

B

C

D

A

B

C

D

E

A

B

C

D

E

A

B

C

D

E

F

G

A

B

C

D

E

A

B

C

D

E

F

A

B

C

D

E

F

G

A

B

C

D

E

F

G

H

A

A

B

A

B

C

A

B

C

D

A

B

C

D

E

The heart of top performance in top-lift handling

To obtain the maximum out of your investment, you can never underestimate the

importance of the drivers’ working environment. High throughput demands full driver

concentration and efficiency to keep up the

container moves, but also to avoid injuries

and costly damages.

This is what ergonomics is all about. Being

comfortable and aware.

The driver environment in Kalmar DCF is the

comfortable Spirit Delta high visibility cabin;

appreciated by professional drivers, proven

on thousands of Kalmar container handlers all

over the world.

We focus on four important

ergonomic areas:

• Operation

• Visibility

• Sound and vibrations

• Climate

The result is a cabin where everything is optimised to improve driver performance.

Consider this:

• Individually adjustable controls, steering

wheel and seat.

• Intuitively positioned instruments.

• Switches and buttons with lights.

• Comfort pedals.

• Electronic accelerator.

• Central operation/warning display.

• Separately suspended and isolated cabin.

• Shock absorption to minimise vibrations.

• Maximum sound level inside is 70 dB (A).

• Generous interior dimensions and floor

space.

• Optimised visibility – 360˚ all around.

• Electronically controlled heating/

ventilation.

• Filters for fresh air and recirculation.

• High performance air conditioning system,

optional.

• Pollen filter, optional.

Left ins trumen t panel

A

Gear sel ector and m ulti-fun ction lev er

B

Steerin g wheel pan el

C

Direct ion indica tors

Prepare d for termi nal and

dashbo ard atta chment

Hydraul ic control s

F

Panel for h ydraulic fu nctions

Emergen cy switch

Parking b rake

F

G

H

I

3

Page 4

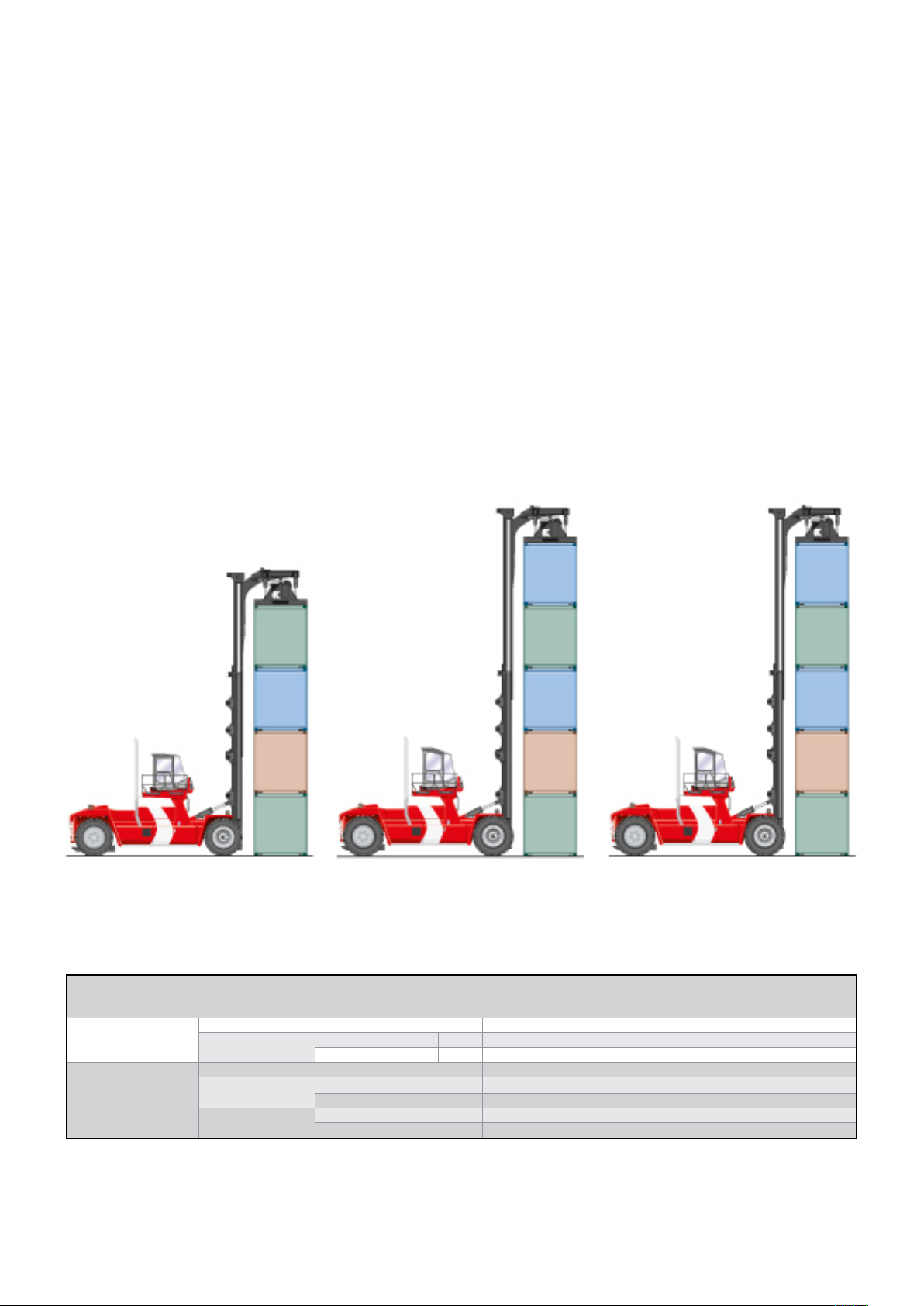

Capacity and dimensions

Matching your handling and throughput needs

When we designed the Kalmar DCF top-lift

we already knew the detailed status of all the

main alternatives on the market. Hence, we

designed a machine which meets or exceeds

the specifications of the others – on the spec

sheet and in reality.

You can choose between three basic models,

each optimised according to lifting capacity

– stability – overall dimensions – weight – toplift speed and driving performance.

Three models cover container handling

between 36 – 45 tonnes capacity, 20’-40’

containers and up to five high stacking at full

capacity. This means that you may easily find

the right machine or combination of machines

to suit your operational requirements.

The design of the chassis, mast, carriage and

spreader has resulted in machines with very

good dimensional-, stability- and operational

characteristics.

41000 kg

In spite of its size and capacity the Kalmar

DCF has a short turning radius. Together with

the optimised visibility and good manoeuvrability it saves terminal space and makes the

machine a smooth operator in confined aisles.

The counterweight and lifting height requirements have been matched with a modern

chassis to keep down the overall weight but

with no sacrifice in stability.

45000 k g

DCF360CSG DCF410CSG DCF450CSG

Capacity and weight

Lifting capacity Classification

Load cen tre attachment retracted

Weight Service weight

Weight front axle unloaded

Weight rear axle unloaded

36000 k g

36000 k g

36000 k g

36000 k g

attachment extended

at rated load

at rated load

41000 kg

41000 kg

41000 kg

41000 kg

DCF360CSG DCF410CSG DCF4 50CSG

kg 3600 0 41000 450 00

L4 mm 1750 1750 1750

L7 mm 1955 1955 1955

kg 6640 0 69750 75000

kg 41300 42290 44000

kg 94800 101450 110500

kg 25100 27460 31000

kg 7600 9300 9500

45000 k g

45000 k g

45000 k g

45000 k g

4

Page 5

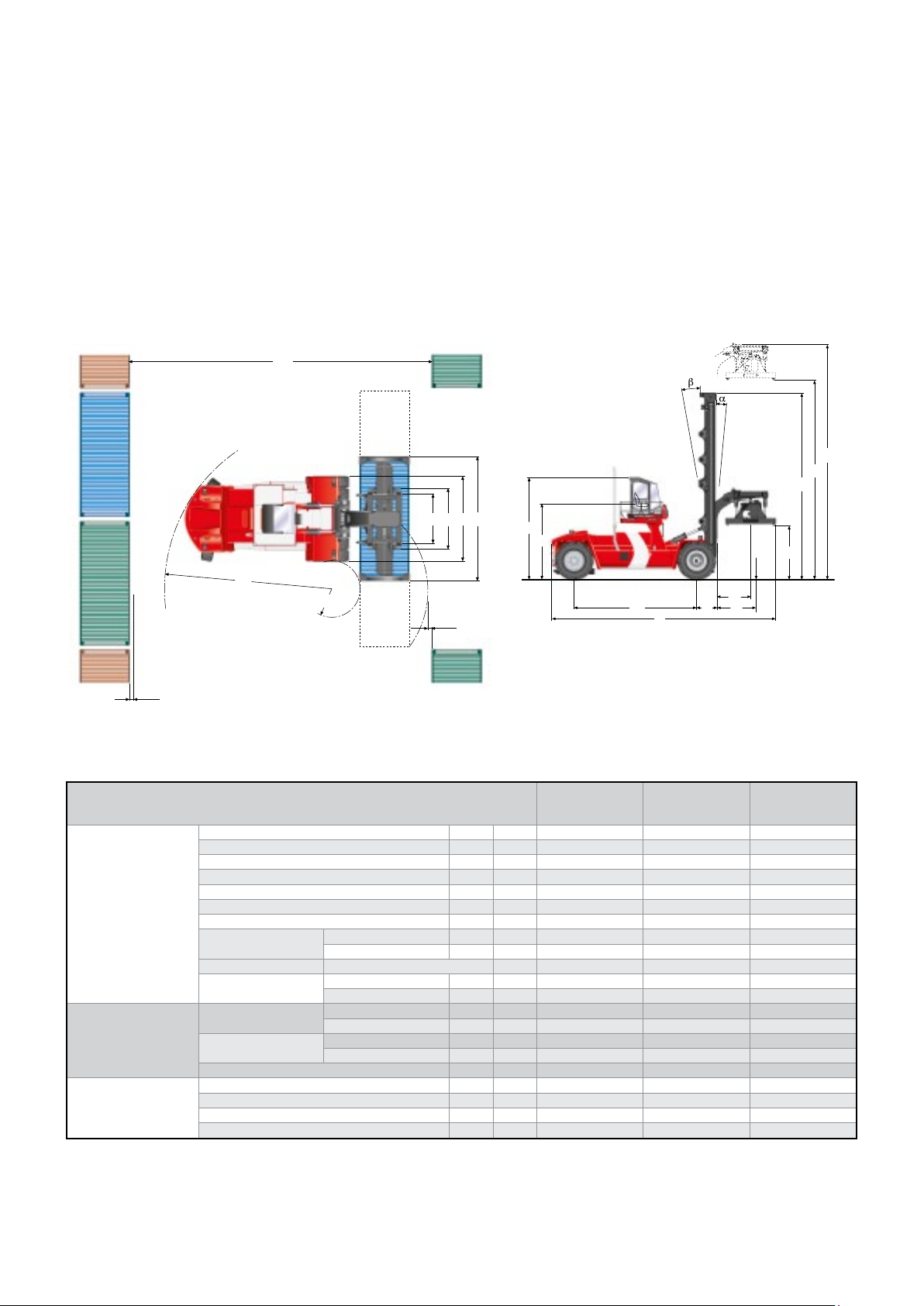

The mast and carriage are computer designed

and optimised (FEM and Catia V5) which allowed for a decrease in the front axle weight.

Together with Kalmar’s integrated high capac-

A1

A2

ity spreader it allows you to fully utilise the

capabilities of mast tilt, slewing, extension,

sideshift at full lifting height and full capacity.

No compromises.

S

B

V1

V

H6

H8

Additionally, we have ensured that every

single detail, component and system have

been selected and manufactured to provide

the highest possible reliability.

H5

H4

H3

H10

R1

100

Dimensions

Truck Truck leng th, with at tachm ent

Standa rd duplex mast

(5 high 8’6, 5 high 9’6)

Attachment Width, min – max

Truck width

Truck height

Seat heig ht

Distance between fron t axle cen ter – front side of mast

Wheelb ase

Track (c-c ), front – rear

Turning radius, outer

Ground cl earance min. unde r truck

Min. track with for 90º

stacking

Height under tw istlocks 4-high – 5 -high ma st

Mast height, min.

Mast tilting, for wards – b ackwards

Hydraulic slewing

Side shif t, ± eithe r side center

Levelling

R2

inner

with 20’ container

with 40’ c ontain er

min.

max

L3

100

DCF360CSG DCF410CSG DCF4 50CSG

L mm 10970 10970 11020

B mm 4450 4450 4450

H6 mm 4650 4720 4720

H8 mm 3560 3630 3630

L2 mm 900 900 950

L3 mm 6000 600 0 600 0

S mm 3020 – 2820 3020 – 2820 3020 – 2820

R1 mm 8 660 8 660 8 660

R2 mm 1090 1090 10 90

mm 280 280 280

A1 mm 11990 11990 11990

A2 mm 14680 14680 14680

H4 mm 12090 15160 15160

H10 mm 2080 2160 2160

H3 mm 7700 9190 9190

H5 mm 15170 17170 17170

α – β º 5 – 10 5 – 10 5 – 10

V mm 12170 – 6070 12170 – 6070 12170 – 6070

º ±3 ±3 ±3

V1 mm 400 400 400

º ±5 ±5 ±5

L

L4

L7L2

5

Page 6

Lifting performance

1

2

In the palm of your hands

The lifting equipment of Kalmar DCF is an integrated assembly consisting of mast, carriage,

spreader, hydraulics and control system. This

is to ensure you get a reliable and good running machine with high availability even after

long shifts and high load stresses.

A major objective in the development process has been to combine optimum functionality for the driver together with high performance in lifting and load handling.

To leverage operational productivity it’s essential that the driver has full control over every

moment of the handling sequence. This starts

with the 360º visibility from the Spirit Delta

cabin and is followed by the open design of

the mast and gantry. The visual contact with

the stack, container corners, twist-locks and

spreader is optimised.

3

1

Fine-tuning the spreader to handle uneven

levels or loads, mast tilt, extension, twist-lock

landing is accomplished utilising a powerful electronic support feedback and control

system.

Performance

Lifting speed unloade d

at rated load

Lowering speed unloaded

at rated load

Driving speed unloaded forwa rd

reverse

at rated load forwa rd

reverse

Gradea bility at 2 km/h unloaded

at rated load

max, unloaded

Drawbar pull max

DCF360CSG DCF410CSG DCF4 50CSG

m/s 0,42 0,42 0,42

m/s 0,25 0,25 0,25

m/s 0,31 0,31 0,31

m/s 0,36 0,36 0,3 6

km/h 26 26 26

km/h 26 26 26

km/h 23 23 23

km/h 23 23 23

% 38 38 38

% 27 27 27

% 38 38 38

kN 368 368 368

6

Page 7

1

2

1

1

2

2

Carriage

The integrated gantry with high-strength roller

bearings makes for a secure and durable

setup. The benefits of an integrated gantry are

increased capacity and a decreased loss of

load centre. The gantry is a completely new

design, made of solid steel instead of welded

beams, which improves reliability and see

through visibility.

1

Mast

The Kalmar DCF has as standard a duplex free

visibility mast, made of high strength steel to

provide a long life with minimal deflection at

high lifting heights. Maximum lifting height is

15160 mm or five containers high under the

twist-locks. The mast is equipped with the

new Kalmar high speed lifting system, which

provides very fast handling of loads up to 22

tonnes.

The mast is made for high reliability and simple maintenance. It requires only two hoses

and one cable passing over the mast roller to

feed the hydraulic and electrical functions of

the spreader.

Levelling 5˚Sideshif t ±40 0 mm

Key functions:

• Levelling – corrects the inclination of the

spreader to uneven containers.

• Slewing – compensates when the machine

is not positioned 90º to stack.

• Side-shift – compensates when the

machine is positioned right or left of the

container.

• Extend/Retract – extends the capability

when loading/unloading trucks or rail cars.

3

Spreader

The integrated spreader is suspended from

four (4) hydraulic cylinders, which compensate for unevenly loaded or stacked containers. Powered pile slope is optional. The

spreader is easily adjustable with the touch of

a button for 20’ or 40’ containers and can be

side-shifted 400 mm either side of centre. Two

additional hydraulic cylinders provide precise

control of the slewing function.

Slewing ± 3˚.

The mechanical and electrical safety inter-lock

systems prevent locking or releasing the

twist-locks if the spreader is not properly positioned on the container. It also prevents lifting

of the spreader when the twist-locks are not

fully engaged or fully released.

Extend /retract, 200 mm

The lowering interrupt system prevents chain

slack once it is landed on the container. Lights

on the instrument panel and spreader indicate proper use of the spreader and locked/

unlocked twist-locks.

The Kalmar spreader will handle all ISO standard containers ranging from 20’ to 53’ long

and 8’ wide to 8’6” wide. All containers must

have the standard ISO 20’ or 40’ footprint.

7

Page 8

Driving performance

1

1

2

1

2

3

1

2

3

4

1

2

3

4

5

1

2

3

The basic set up is a key factor for high productivity

Optimised ergonomics. Perfect matching of

capacity. Efficient lifting.

The forth key factor for high top-lift productivity is the basic machine set up. Heavy loads

and high lifting speed, for example, put critical

demands on the engine and hydraulic power

support. Fast positioning during the stacking cycle requires precise control with tight

turning radius, effective and reliable brakes

and high engine torque. Fast transportation

requires good stability, reliable brakes and

smooth transmission.

Of course, all the working components and

systems have to cope with the most demanding stresses during long shifts and heavy

operations everyday.

We have put highest priority on overall technical reliability. Looking at the choice of each

component, long running cycle times and

how it all comes together. We have incorporated into the DCF several major components

and systems from our extremely reliable

DRF reachstacker. More than 1000 of these

machines have been delivered in the past few

years and have proven the durability of the

components and systems, and its low running

costs.

2

Engine

The Cummins and Volvo engines provide

power for driving and the working hydraulics.

The engines are low-emission turbo diesels

with fuel injectors and intercoolers. The design of the combustion chambers, along with

the precise fuel injection control, ensures

more efficient combustion to provide lower

emissions with increased torque and power.

The engines meet the Tier 3 requirements,

and the sound and vibration standards.

The radiator is a 3 chamber design with a single fan to provide cooling for the engine and

transmission. The engine cooler’s separate

expansion chambers are fitted with a level

sensor that indicates low coolant level.

3

Transmission

The transmission transfers power from the

engine to the hydraulic pumps and drive line.

The engine and gearbox control systems

work together to find the optimum balance

between power and fuel economy at any

given time. The transmission system consists

of a torque converter and a gearbox. The

gearbox is automatic, but can partly be

shifted manually.

5

Steering system

The steering axle is built from a single piece

of high strength steel, which means as fewer

parts requiring less maintenance and higher

structural integrity. The suspension points on

the steering axle utilise a maintenance-free

plastic. The hydraulics that feed oil to the

steering cylinder is optimised for enhanced

driving feel. The orbitrol and the priority valve

jointly provide gentle yet precise steering

movements.

6

Brakes

The brake circuit is separated from the

hydraulic system and has its own tank,

cooler and high-pressure filter. A temperature

transmitter in the brake oil tank regulates

the cooling fan. The foot-brake valve, which

controls the oil feed to the brakes, is sensitive

enough so that the driver can brake optimally

yet gently. The parking brake is activated

automatically when the ignition is turned off.

4

Drive line

1

Chassis

The frame forms the basis of the machine’s

lifting and manoeuvring characteristics and

was designed exclusively for a top-lift operation. The beam construction, along with its

width, makes the DCF stable, torsion resistant

and service-friendly.

The propeller shaft and drive

axle transfer the power

from the transmission

to the driving wheels.

The mountings on the

propeller shaft are fitted

with cross-flanges for op-

timum strength. The drive axle

The frame is 3D modulated (Catia V5) and

designed (FEM) in order to eliminate critical tensions under various kinds of strain.

The mechanically welded chassis has been

gears down in two stages, differential

and hub reduction. The engine provides

maximum torque at the drive wheels, which

spares the transmission.

optimised according to strength, weight and

stability.

4

8

Page 9

Wheels and tyres

1

2

3

4

5

1

2

1

1

2

3

4

Tires are an important cost factor to consider

when improving operational performance.

Therefore the Kalmar DCF410 and 450 are

fitted with 18.00×33 tires, all models use

identical sizes on both drive and steer wheels.

This improves the machine stability, comfort

and reliability and requires only one single

spare tire. The larger dimension tires should

decrease the tire wear and tear and improve

the tire life.

2

5

1

3

6

Drive train

Engine Man ufactur er – type d esignat ion Cu mmins QSM11 Tier 3 Volv o TAD1250VE Tier 3

Transmissi on Manufacturer – t ype desi gnation

Driving axle Type Hub reduction Hub reduction

Fuel – typ e of engine Diesel – 4 s troke Diesel – 4 s troke

Displac ement

Rating IS O 3046

Peak torq ue ISO 304 6

Number o f cylinde rs – compre ssion

Fuel consu mption, n ormal driv ing

Alternator typ e – power

Start b atter y, voltage – ca pacity

Clutch, t ype Torque conve rter Torque conve rter

Gearbox , type Powersh ift Powershif t

Number s of gears, f orward – reverse

cm³ 10 80 1213

kW – rpm 261 – 2000 260 – 160 0

Nm – rpm 1830 – 1100 -1400 1760 – 1400

cm³ 6 – 18,1:1 6 – 16,3:1

l/h 18-22 18-22

W AC – 2400 AC – 2400

V – Ah 2×12 – 140 2×12 – 140

Standar d O ption

Dana 15.7 TE320 00 Dana 15.7 TE32000

4 – 4 4 – 4

9

Page 10

Intelligence

The simple way to put bits and pieces together

All vehicles today – cars, highway trucks,

wheel-loaders, cranes etc – are constructed

with more and more sophisticated components and systems. Each part interacts closely

with the others and to reach the full potential

requires computer assistance.

This built-in intelligence is designed to support

and leverage your container operations, not

confuse it.

The Kalmar DCF posses a well proven, thoroughly tested and optimised control system,

which supports your driver, mechanics and

financial controller. And it is simple to use.

It is designed to get the most out of the

machine during the top-lift operations, to

improve safety, to avoid unnecessary damage

on components, to advise of scheduled preventive maintenance, to get machine statistics

and so on.

KID

KIT

KCU

KDU

The reliable distributed control system.

Two things are needed for a command initiated by the driver to result in a particular

function, or for several functions to work

together: power-feed and communication.

The power-feed supplies the machine’s

electrical or electro-hydraulic functions with

voltage. The communication system controls

and checks that the functions have been

activated, waits in standby mode or indicates

faults.

EDC

TCU

The communication network layout.

Both the power-feed and communication

system form an integrated network distributed to the critical areas of the machine. The

main components of the network are the

control units (nodes). Each node has its own

processor and integrates with each other. All

communication, control signals and signal

information are sent via data buses. All nodes

in the network are talking and listening to

each other.

KDU

KDU

Kalmar Cabin Unit

Kalmar In formation Terminal

Kalmar In formation Display

Electronic Diesel Contro l

Transmission Control Unit

Kalmar Di stributed Unit

The data transfer is secured by a CAN-bus

(two-wire) technology, which means high reliability and extremely low risk for disruption.

CAN-bus loops have been used in the Kalmar

machines since 1995.

The power-feed for the functions are supplied

separately via distribution boxes located in

the cabin. The power is distributed and guided

by instructions generated from the communication network.

10

Page 11

Control functions – support the driver.

The driver and machine communicate very

simple via the Kalmar Information Terminal

and the Information Display located right in

front of the driver in the cabin. The two-way

communication – from the driver to the machine and opposite – is handled by the KCU

(Kalmar Cabin Unit) which is the control node

for the entire network.

Information to the driver comprises alarm

warnings, operating details and action-guided

information. Messages, status, fault indications etc are presented on the Information

Display, while warnings and other monitoring

indications are presented to the left.

Messages are only presented when they are

relevant to the driver and the operation, so

the driver can focus on the job instead of

checking meters and indicators.

Heating /Ventilation

and Air con ditioning.

Service information.

Engine revs, travelling speed,

time and fuel.

Batter y status.

Engine

Temperature

and pressure.

Transmissio n

Temperature

and pressure.

11

Page 12

Availability

We have made sure your

investment becomes profitable

To understand the full potential of your investment requires being aware of the details,

features and technical matters in a machine

like the Kalmar DCF.

But when it comes to availability it is critical

that it operates constantly and is kept in good

condition with an absolute minimum of maintenance and repairs.

Less stops and no stops.

The Kalmar DCF is designed for long shifts,

which means that you may have to replace

the driver before you have to call it in for fuel.

The good weight/engine power relationship

combined with a fuel tank designed for 50

hours of operation make these machines run

the extra hours you want them to.

The service intervals have been extended to

500 hours, which means that you don’t have

to take the machine out of work more than 6

times a year (3000 hours utilisation).

The DCF is designed for fast daily inspection

and preventive maintenance. All checkpoints

are easy accessible and concentrated to specific locations. Lubrication free components or

central lubrication points have been utilised.

The wet disc brake system is practically maintenance free.

The indicator and monitoring support built

into our control system make sure that the

machine won’t be misused or maintained

incorrectly. The driver and mechanics will

always get indications and guidance in time to

avoid unnecessary and costly wear and tear

or technical breakdowns. No unwanted stops.

Reliability starts already

at the concept stage.

One of the guiding principles in designing the

DCF was to minimise the number of potential

sources of error. Therefore the machines consist of as few components and moving parts

as possible. The functionality and operational

reliability is assured by extensive testing.

Fewer comp onents

makes for increased

reliability, only two hoses

and one harness runs

over the mast wheel.

12

Page 13

1

1

2

3

1

2

1

2

3

4

1

1

2

1

2

3

4

1

2

3

4

The reliable and maintenance

friendly hydraulic system.

3

5

1

2

The hydraulic system is critical.

No other part of the machine is working so

hard under continuous pressure. To secure

the reliability we have minimised the number

of hydraulic components and couplings.

The main valve has an integrated servo which

helps increase precision and control over the

oil flow. The hydraulic oil is fed to the carriage

Other improving features:

1

Large dimensions of hydraulic hoses

improves the hose´s lifetime (slower flow,

less friction and less heating).

2

Thermostatic cooling of both the main

system and the brake system improves

the oil lifetime (temperature control,

optimised working temperature).

3

High density filter improves the oil lifetime

(clean oil).

4

ORFS – leak proof couplings all around

improves reliability (minimises leakage).

5

All main hydraulic components at ground

level are gathered on a separate plate,

bolted to the chassis and therefore simple

to remove.

and spreader by a variable piston pump,

which saves a lot of power and energy compared to continuous oil circulation. Another

innovative solution – the valve for the gantry

and spreader functions has been mounted on

the gantry. The result is an instant and accurate connection between lever and function.

This also minimises the number of hydraulic

A safe communication network

The control and monitoring system is the

new Kalmar control system, but already successfully applied in more than 1000 Kalmar

machines worldwide.

components in the chassis.

This new reduntant CAN-bus system is proven

In order to maintain optimum functionality

in the system even under extreme operating conditions, cleaning and cooling of the

hydraulic oil is highly efficient. The hydraulic

brake circuit is separated from the main system and is fitted with its own filters.

to be excellent in functionality and reliability.

The network of control nodes allows for less

wiring and connectors which reduces the

number of sources of error. The power-feed

for each node and the transfer of control

signals are independent of the other nodes,

which means the risk of disruption becomes

minimal. The redundant design means that

there are always two paths to choose to

maintain communication, which results in

extra safety and reliability.

13

Page 14

Notes

14

Page 15

15

Page 16

Global presence and local service bring

our products and solutions closer to our customer.

Cargotec improves the efficiency of cargo flows on land and at sea – wherever cargo is on the move.

Cargotec’s daughter brands Hiab, Kalmar and MacGregor are recognised leaders in cargo and load handling

solutions around the world. Cargotec’s global network is positioned close to customers and offers extensive

services that ensure the continuous, reliable and sustainable performance of equipment.

Cargotec’s class B shares are quoted on the NASDAQ OMX Helsinki. www.cargotec.com

Cargotec Sweden AB

Torggatan 3

SE-340 10, Lidhult, Sweden

tel. +46 372 260 00

fax +46 372 263 90

www.cargotec.com

TI-LC 45-EN-WW / 2010.02.15

Loading...

Loading...