Jamo R-909 Brochure

TECHNICAL DESCRIPTION

Jamo R 909

english

français

deutsch

english

2

CONTENTS

General description 4

Dipolar speaker – and the room 5

Driver principles 6

A dipolar speaker that generates serious bass? 6

The drivers 7

Woofers 7

Midrange 7

Tweeter 9

X-over 9

Front baffl e 10

To sum up… 10

Specifi cations 11

3

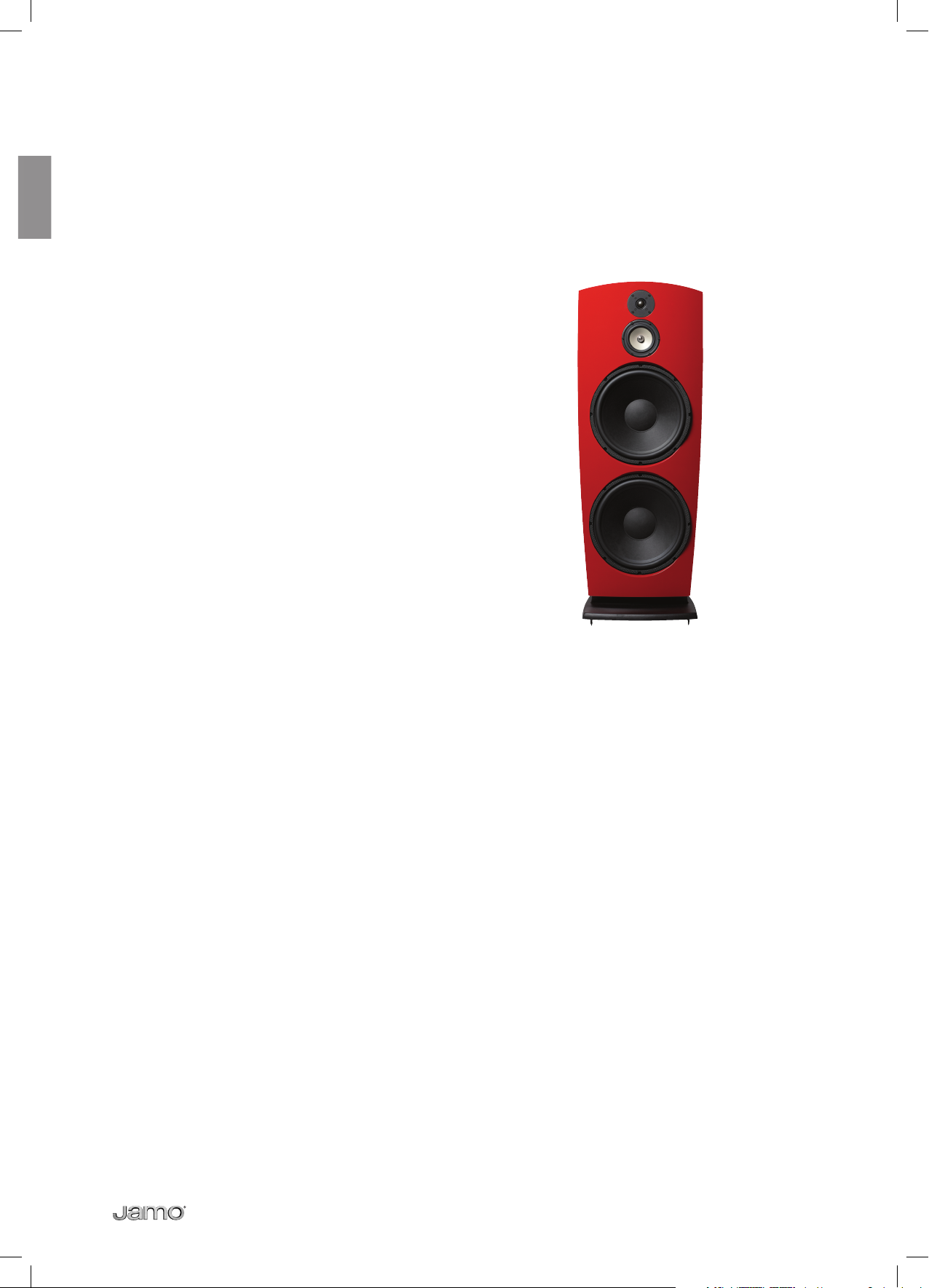

GENERAL DESCRIPTION

When we set out our design aims for the Jamo R 909 speaker we had just one goal

in mind… to deliver an exceptionally memorable experience. We wanted listeners

to forget about the speakers and the equipment and just enjoy what it’s all about…

entertainment.

Doing that wasn’t going to be easy though. If

you want to create full fi delity loudspeakers (and

so forget that you are actually listening to the

loudspeaker) your design needs to use a cabinet.

If you don’t use one, bass reproduction suffers

because of acoustic ‘short-circuiting’.

The total surface area of a cabinet’s surfaces is

typically 20 to 50 times the size of the cone area of

the drive units. So, no matter how much the cabinet

is damped it will always have resonance points at

which it – due to its sheer size – will contribute

substantially to the total sound generated by the

speaker.

There are fi xes of course. You can make the cabinet

extremely rigid – e.g. by using lots of internal bracing

- but doing so just shifts the points of resonance up

into the midrange frequencies, an area where any

sort of cabinet contribution is bad news.

So, it’s fair to say that any cabinet involves compromises to some extent: It needs to

be of a certain size in order to be able to deliver deep bass but it also needs to be

rigid if it is to avoid a ‘fat’, wobbly bass… but not so rigid that it affects midrange

clarity.

And then there’s the ‘suspension’ effect to consider. The air inside the cabinet

effectively works like a ‘spring’ attached to the cone and so actually holds back the

driver unit when it starts to move. In summary, the cabinet actually drains energy

from the drive units which naturally affects the dynamics, attack and precision.

Last but not least there are also the placement problems one routinely faces when

locating a cabinet speaker (or, to give it its technical name, a pressure transducer)

in a room.

It’s extremely diffi cult to fi nd a position that minimizes the infl uence of refl ections

and room modes. While you may be able to fi nd a listening position that’s great

for imaging and transparency it could also be at a ‘null’ point where the bass

reproduction is extremely poor. Or indeed, it might coincide with a peak point

where bass frequencies are greatly boosted.

A multitude of considerations then. Our eventual conclusion was that we had to

think ‘out of the box - literally - if we were to come up with a solution which avoided

the cabinet issues. And that’s exactly what we have done… the result is the R 909,

the fi rst open baffl e speaker to wear the Jamo badge.

In the following pages you will read about the innovative technical solutions we

have had to develop in order to overcome the diffi culties of using an open baffl e.

4

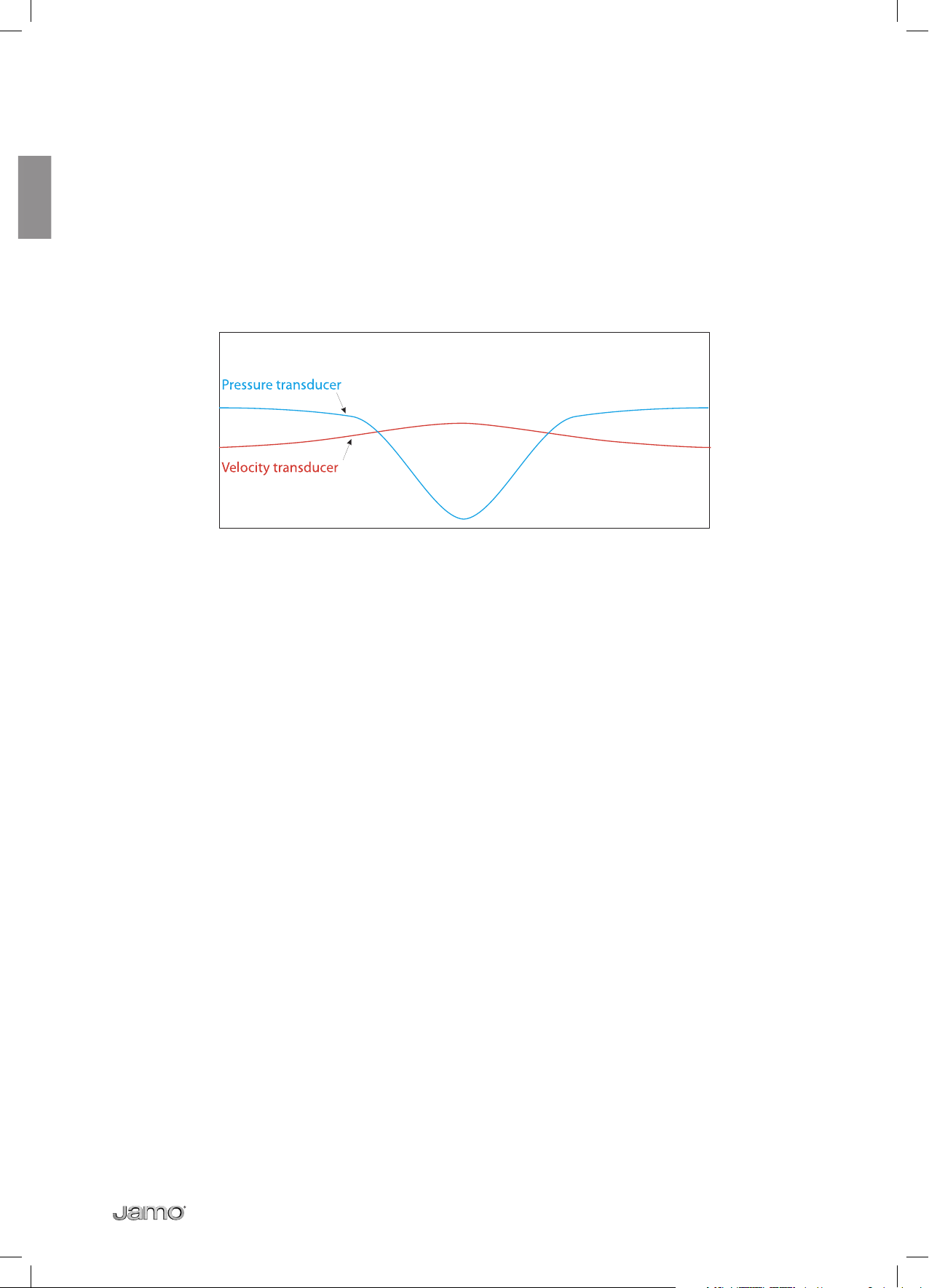

DIPOLAR SPEAKER – AND THE ROOM

As we have discussed earlier, placing a cabinet speaker (pressure transducer) in a

room creates its own unique challenges.

So exactly how does a dipolar speaker (or velocity transducer)”behave”?

Due the dipolar radiation pattern, sound is

distributed from the front and rear of the speaker

– in opposite phase. This is important because with

a conventional loudspeaker, side wall (i.e. 1st order)

refl ections typically are in opposite phase with the

direct transmitted sound from the drive units i.e.

they sound annoying.

However, with a dipolar radiation pattern there is

virtually no ‘sideways’ sound transmission and so

the critical 1st order sound refl ections are practically

eliminated.

But, you might ask, what about the sound

transmitted from the rear of the speaker… doesn’t

that destroy imaging and the soundstage?

Actually, when placed correctly the laws of psycho

acoustics come into play.

The human ear uses the fi rst sound received (the 1st

wave-front) to determine the direction of the sound (i.e.

where it’s coming from). That means that even if refl ected

sound is slightly delayed it doesn’t affect the brain’s ability

to determine direction.

If a dipolar speaker is placed a minimum of 3ft/1 m

away from the rear wall and angled in slightly (as a

serious listener with cabinet speakers would probably

do anyway), the refl ected sound will be delayed (due to

physical distance and the fact it will be bouncing off two

boundaries before reaching the listener’s ears) but it still

gives directional cues.

Now the 2nd order refl ections add ambience and give the listener the impression

of a much larger room.

5

A velocity transducer/dipole speaker couples with a room in a totally different

way, and actually, where you would normally experience a ‘bass null’ with a cabinet

speaker, you will actually experience a slight peak with a dipolar.

While there has been little research into the pros and cons of dipolar speakers in

rooms Jamo has conducted extensive research of its own. Our measurements of

different speakers in different sized rooms show that with speakers this size, the

room’s infl uence on the resulting sound is substantially less when using dipolar

speakers than when using traditional cabinet speakers.

DRIVER PRINCIPLES

Most dipolar speakers on the market today are either electrostatic or magnestatic in

nature, engineering arrangements that are known for their excellent transparency

and smooth fl owing midrange/treble reproduction. Equally, however, they are also

known for their inability to play deep bass with true authority, extremely poor

voltage sensitivity and - last but not least - for typically being very diffi cult loads for

an amplifi er to handle (because of their low impedance).

That’s why Jamo decided, quite early on in the development of the R 909, to opt for

an arrangement that used dynamic drivers.

A DIPOLAR SPEAKER THAT GENERATES SERIOUS BASS?

The major problem to overcome in dipolar designs, regardless of whether they are

designed to use dynamic or electrostatic principles, is the acoustic ‘short-circuiting’

effect which invariably occurs from approx 200Hz downwards.

For those unfamiliar with this bugbear here’s a brief explanation. When the bass

driver’s cone moves forward, part of the compressed air created in front of the cone,

will be counteracted by the under-pressure that’s created behind the cone. As a

consequence the resulting sound pressure level that’s generated is “phased out”

or acoustically short-circuited. And unfortunately it’s an effect that’s signifi cantly

more pronounced at lower frequencies.

That was another excellent justifi cation for using dynamic drivers in the R 909

- they are the only sort that are endowed with enough physical cone area/excursion

to move the amount of air you need to shift, in order to compensate for acoustic

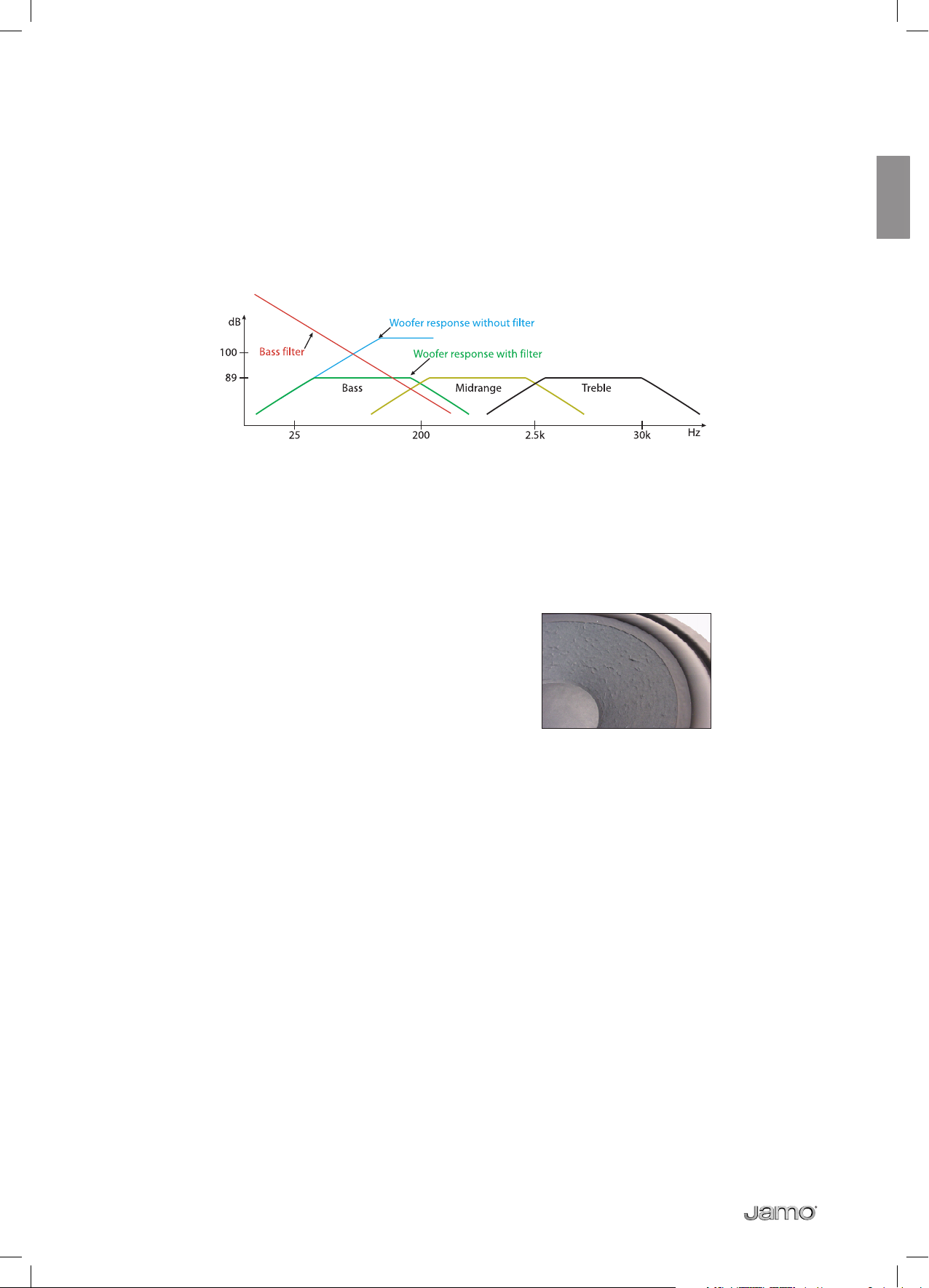

short circuiting. The woofers in R 909 actually deliver more than 100dB at 200Hz, an

output that then rolls off at 6dB/oct (caused by the acoustic short circuiting...) all

the way down to 25Hz.

6

A ‘low pass’ bass fi lter is applied to match the higher bass output to that of the

mid and treble levels, so that they integrate smoothly. However, at the lowest

frequencies the bass is not fi ltered at all, a tactic which allows the woofers to reach

down to an amazing 25Hz with unmatched precision and attack.

It may be hard to believe it’s possible but a quick demonstration is all it takes to be

convinced - sit down, take a listen to the R 909 and you’ll hear the proof!!

THE DRIVERS

WOOFERS

In order to obtain a full frequency response the woofer basically needs to fulfi l

two criteria: it has to be of high effi ciency and have suffi ciently low resonance

frequency.

As most woofers are developed to work in a cabinet

(which necessitates heavy cones in order to reach

the desired resonance frequency – typically around

45Hz) we had to develop a special woofer for this

open-baffl e application. A woofer constructed for a

dipole application is utterly different to a traditional

boxed driver.

The cones used, for instance, are lightweight air dried paper cones with rubber

suspension which allows both fast acceleration and deceleration. To optimize

air fl ow the sturdy magnesium basket is of a very open construction. In order to

minimize mechanical losses (created by over/under pressure behind the cone and

the huge 2in/50mm voice coil), the magnet also features a vented polepiece as well

as a ventilated basket behind the spider.

We actually managed to reach a resonance frequency of 27Hz!

The overall result is a driver capable of delivering an extremely fast and fi rm bass.

MIDRANGE

Designing a loudspeaker cone involves striking an optimum balance between

stiffness and low weight. Magnesium meets both criteria, resulting in highly

effective and dynamic sounding reproduction.

The end product is a cone that can reach up to 9k Hz before any signifi cant cone

break-ups occur. This makes for extremely low distortion throughout the range

plus a very open and detailed midrange for optimum voice reproduction.

7

The basket is also made of magnesium, for several very good reasons: Firstly it

makes it possible to create a very open basket – even behind the spider – thus

ensuring high airfl ow at low frequencies, lessens refl ections at high frequencies

and prevents under/over-pressure causing mechanical losses.

Secondly, as magnesium is a non-magnetic

material, the magnetic force from the magnet does

not spread out in the basket but stays concentrated

where it is needed… around the voice coil.

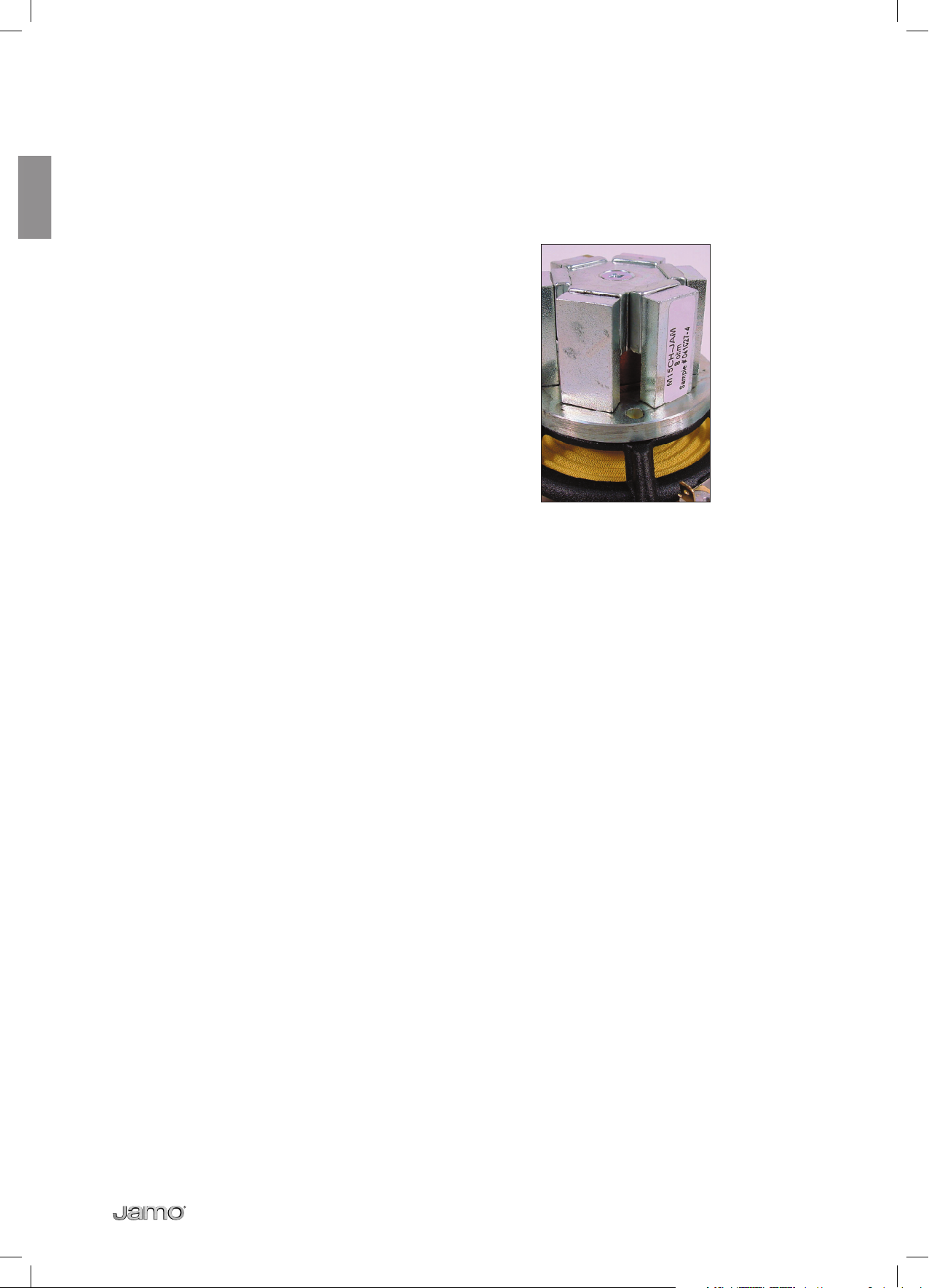

The ingenious magnet system is one that’s been

patented by Seas. Unlike conventional ferrite ringtype magnets this arrangement employs several

compact neodymium magnets (10x stronger than

ferrite magnets) strategically placed around the

voice coil.

Thanks to this arrangement, the voice coil is

completely ventilated which means there’s no

compression and so excellent heat dissipation.

The magnet system also features an integral copper ring which guarantees a signifi cant

reduction in distortion as it short-circuits the eddy currents that are inevitably sent

into the magnet system when a signal current runs through the voice coil.

However, the most conspicuous feature of this drive unit has to be the

mattchromated, solid brass centre-plug.

It replaces the traditional dust cap in the centre of the loudspeaker cone thereby

making the cone lighter and subjectively faster sounding.

This also eliminates the potential break-up points that would result as a consequence

of the dust cap being glued to the cone.

There’s more. It also prevents over and under pressure developing behind the dust

cap when the cone moves back and forth. The advantage here is a more dynamic

and precise sound quality.

Turned from solid metal the centre plug also has a cooling effect on the voice coil,

providing greater power handling capability and most importantly, extra sonic

stability when playing at high volume levels.

When a voice coil heats up, the impedance increases (it can actually double) which

means that the output will decrease and the cross-over points to the other drivers

will move. That’s why maintaining a stable temperature in the voice coil is essential

for optimum sound reproduction.

8

TWEETER

There was only one choice when it came to choosing a tweeter to reproduce the

delicate treble frequencies… the legendary Revelator from Scan Speak. However,

since this model features a relatively large face-plate, it would have needed to have

been placed further away from the midrange than would be ideal. So, in order to

obtain a seamless transition with the midrange driver, we chose to fi t a smaller

cast-alloy face plate.

The tweeter features a 1in textile dome

which is coated several times to obtain a

unique combination of dynamic linearity

and resonance damping, the result being

an incredibly smooth, linear, dynamic and

incredibly transparent sound.

The driver’s Symmetric Drive Technology - a copper ring on the pole that extends

past the voice coil, curving into the dome chamber - practically eliminates

electrical phase shift. And, just as it does with the midrange, it also lowers distortion

signifi cantly.

To eliminate turbulence the double-damped, optimized chamber behind the

magnet system is also equipped with an anti-resonator-plug.

And the specially designed chamber under the cloth surround minimizes air noise

and compression. Actually this tweeter is so carefully manufactured that damping

unwanted resonances using ferro-fl uid - the usual way - is rendered unnecessary!

X-OVER

As should be apparent from the drive unit descriptions above, we wanted to start

out with drivers of immense fundamental quality, precisely so that we would only

need minimal assistance from the cross-over!

Consequently, the cross-over in the Jamo R 909 is of a relatively simple – in the most

positive sense of the word – low-order confi guration.

The advantages of using the 2nd order fi lters that are in the R 909 is that both

electrical and phase angles are kept at very small values, something that’s of great

importance both in terms of sound quality and the eventual load on the amplifi er.

The use of quality Solen foil-capacitors and air-coils in the crossover further ensures

sound quality.

9

FRONT BAFFLE

The 1.7in/43mm thick front baffl e is made from no less than seven layers of MDF

board, glued together and shaped under high pressure.

The rounded shape provides optimum working conditions

for the drivers as it prevents diffraction and improves

rigidity even further.

The baffl e itself is attached to a 60lb/26kg cast-iron base

housing the cross-over network and the bi-wiring XL

binding posts.

A solid double 5x60mm stainless steel brace with a special

damper ensures a rock solid connection between the

baffl e and the base.

This is equipped with spikes which ensure a good

mechanical contact to the fl oor, irrespective of the fl oor

material underneath.

TO SUM UP…

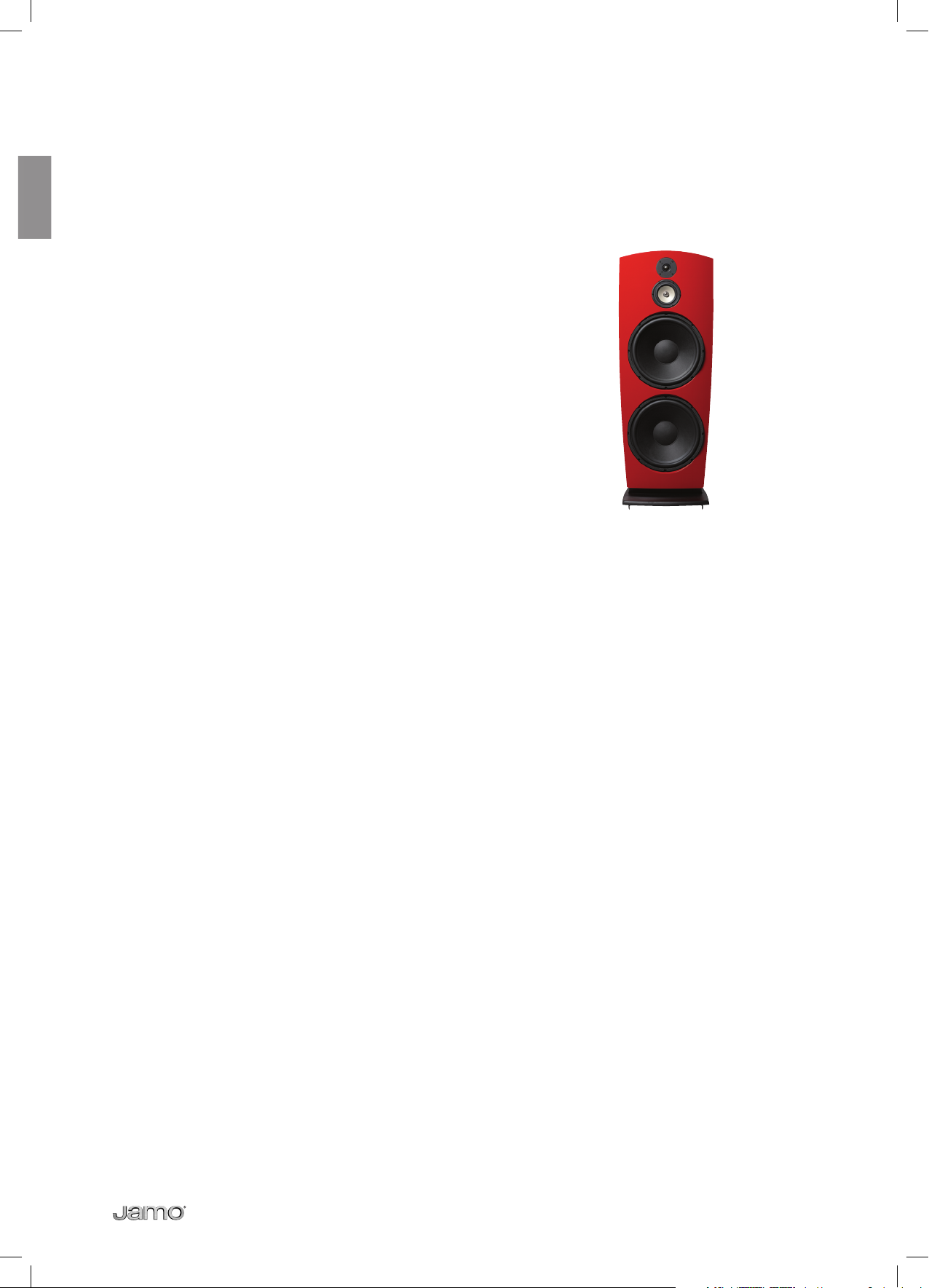

The Jamo R 909 is a true high-end speaker but one that, thanks to its unique

engineering, doesn’t need a small nuclear power station to drive it.

It is a speaker that produces a sound quality which can be described as being fi rm,

accurate but with sublime attack, precision and dynamics.

Signifi cantly, it also benefi ts from the absolute absence of unwanted colouration

and reverberation.

We believe that it is truly a statement audiophile product,

worthy of bearing the Jamo name.

10

SPECIFICATIONS

Type ..............................................................................................................................................R 909

System .......................................................................................................................... 3-way dipole

Woofer (In / mm) ....................................................................................................2 x 15 / 2 x 380

Midrange (In / mm) ........................................................................................................... 5½ / 150

Tweeter (In / mm) .................................................................................................................... 1 / 25

Short term power (W) ....................................................................................................... Min 800

Sensitivity (dB/2.8v@1 m) ........................................................................................................... 89

Frequency range (Hz) .................................................................................................. 25 - 30.000

Impedance (Ohm) ............................................................................................................................4

Crossover frequencies (Hz) .................................................................................250 and 2.000

Weight (Kg / lbs) ..........................................................................................................63,1 / 139.1

Dimensions (HxWxD mm / in) ......................................................................1276 x 488 x 541

................................................................................................................................. 50.2 x 19.2 x 21.3

11

français

Loading...

Loading...