Page 1

SR Ivocap®System

Instructions for Use

Verarbeitungsanleitung

Mode d’emploi

Istruzioni d’uso

Instrucciones de uso

Instruções de Uso

For dental use only.

Caution: U.S. Federal Law restricts this device to

sale by or on the order of a licensed dentist.

Made in Liechtenstein

Ivoclar Vivadent AG, FL-9494 Schaan / Liechtenstein

Page 2

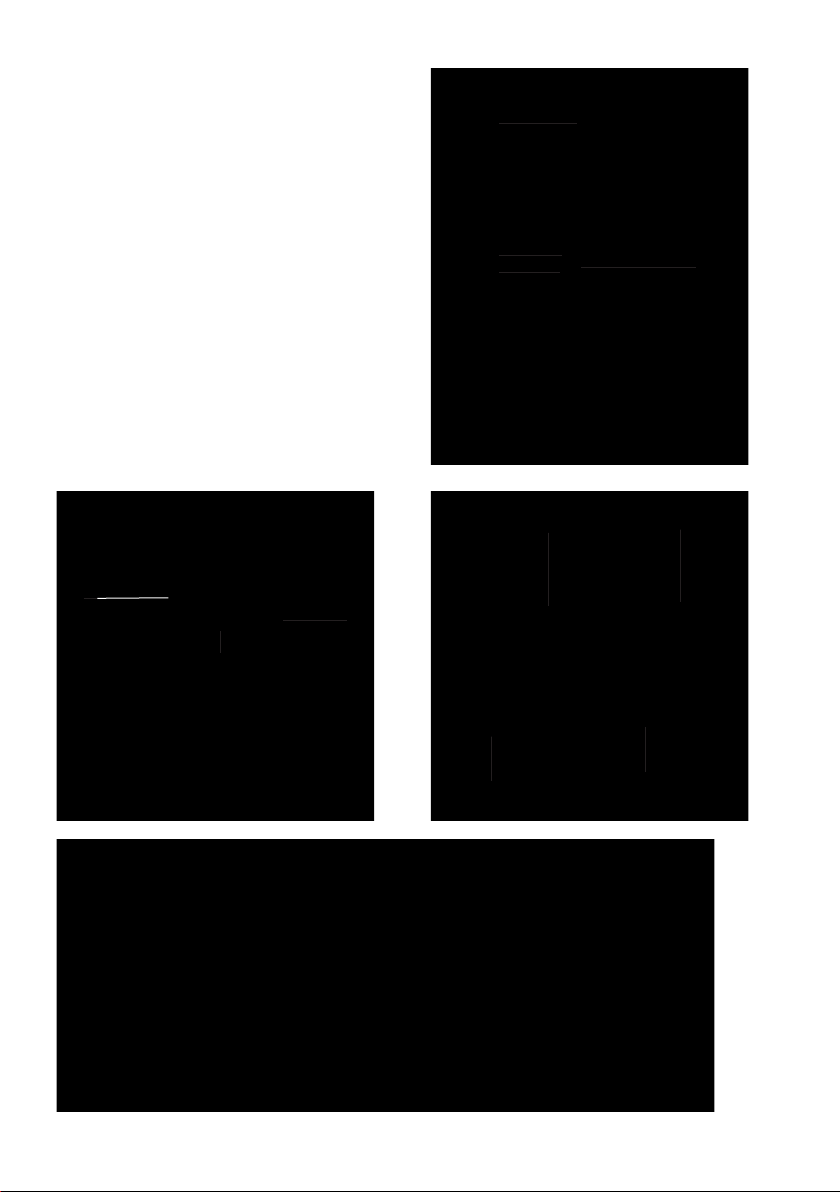

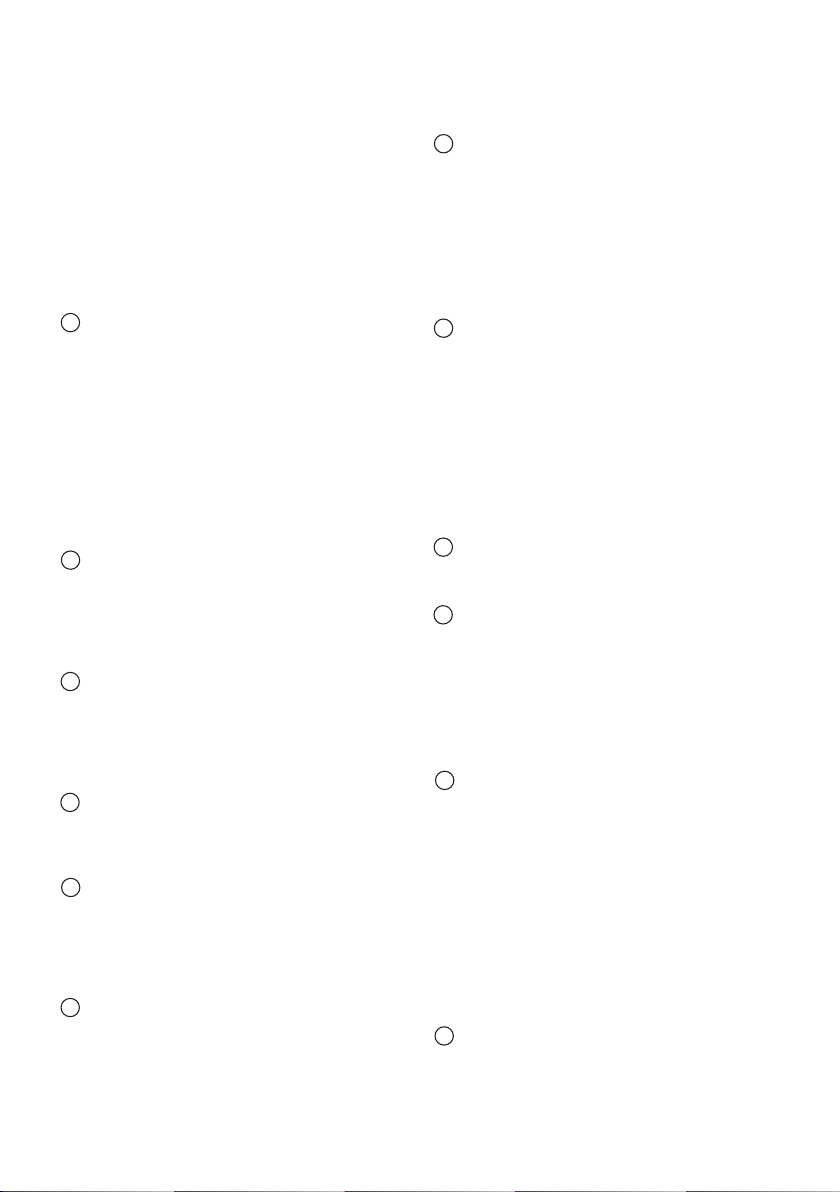

List of parts / Teileverzeichnis

Liste des composants / Elenco particolari /

Despiece / Lista de partes

A

A1

A3

A4

CB

C2

B1

B2

B3

C3

C1

A2

C4

D

E

G

F

Page 3

Page 4

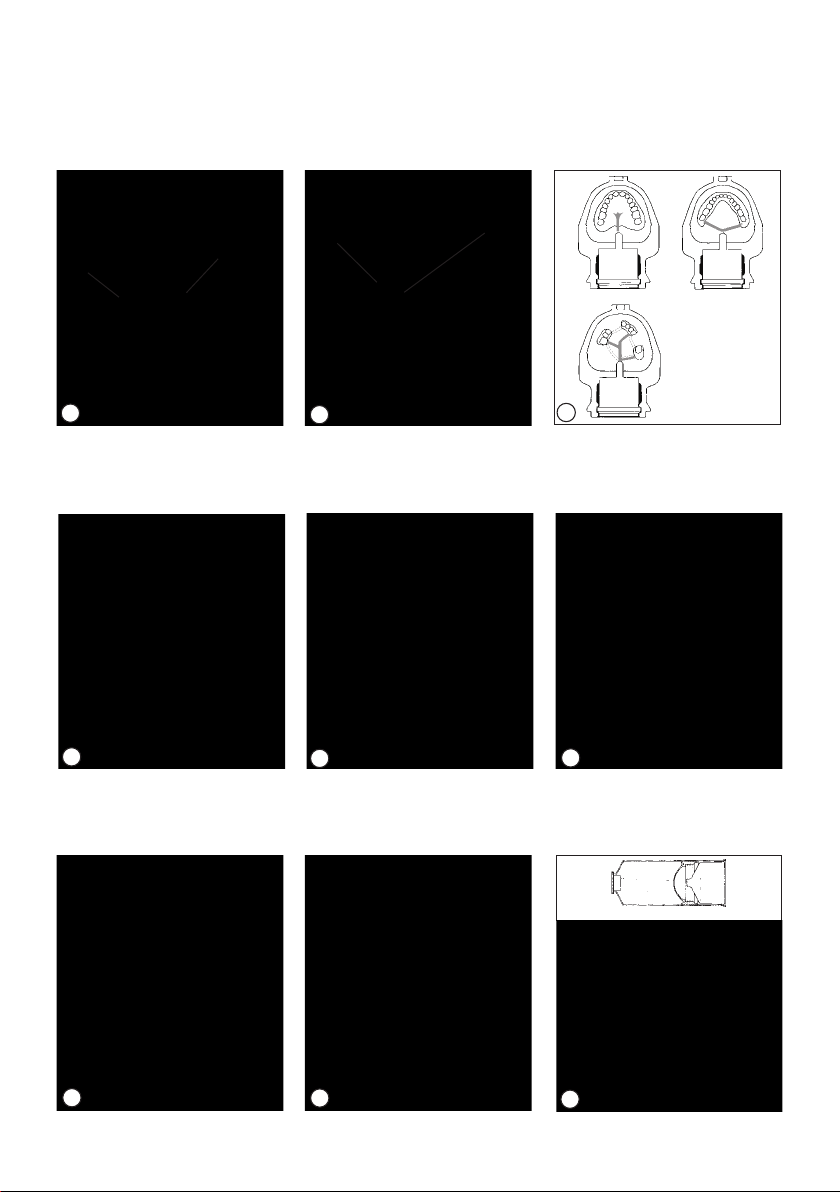

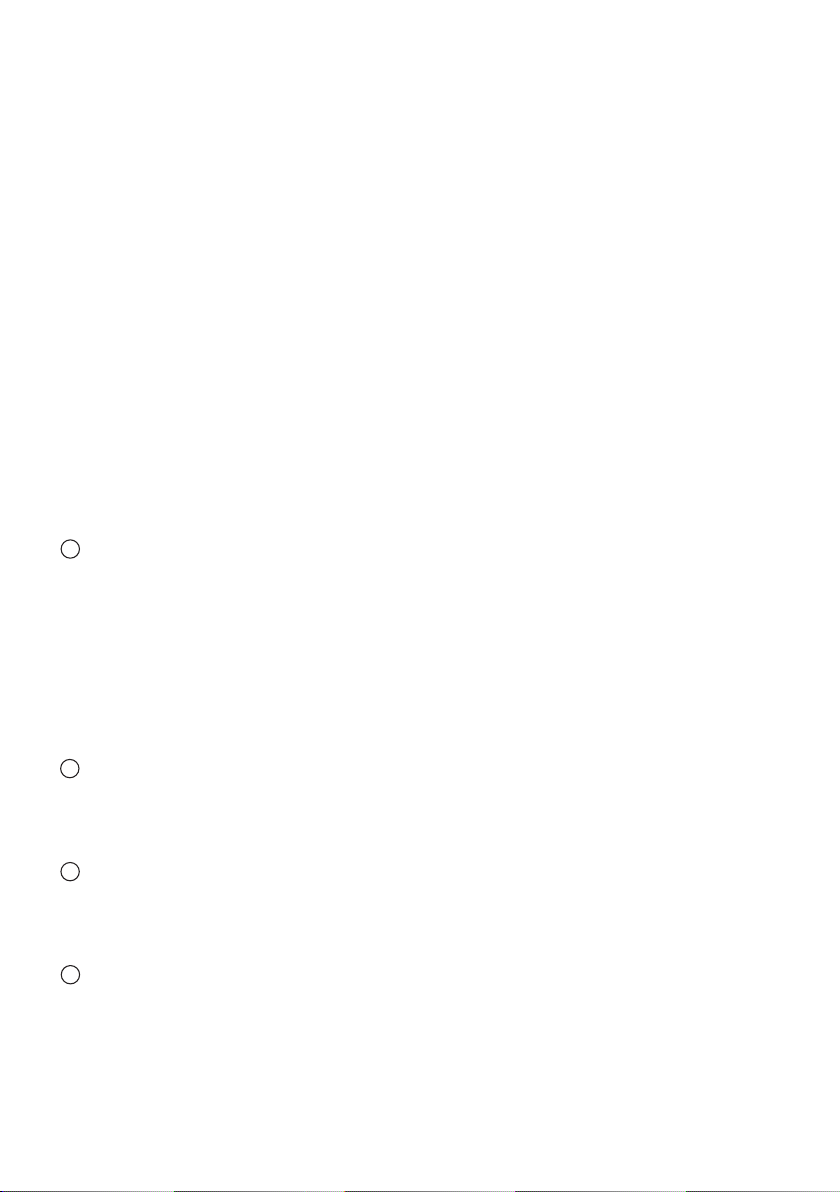

Verarbeitung / Step-by-step procedure / Mise en oeuvre / Istruzioni d’uso / Instrucciones de Uso /

1

2

3

7

8

4

5

6

9

Procedimento

1

2

3

4

3a 3b

3c

Page 5

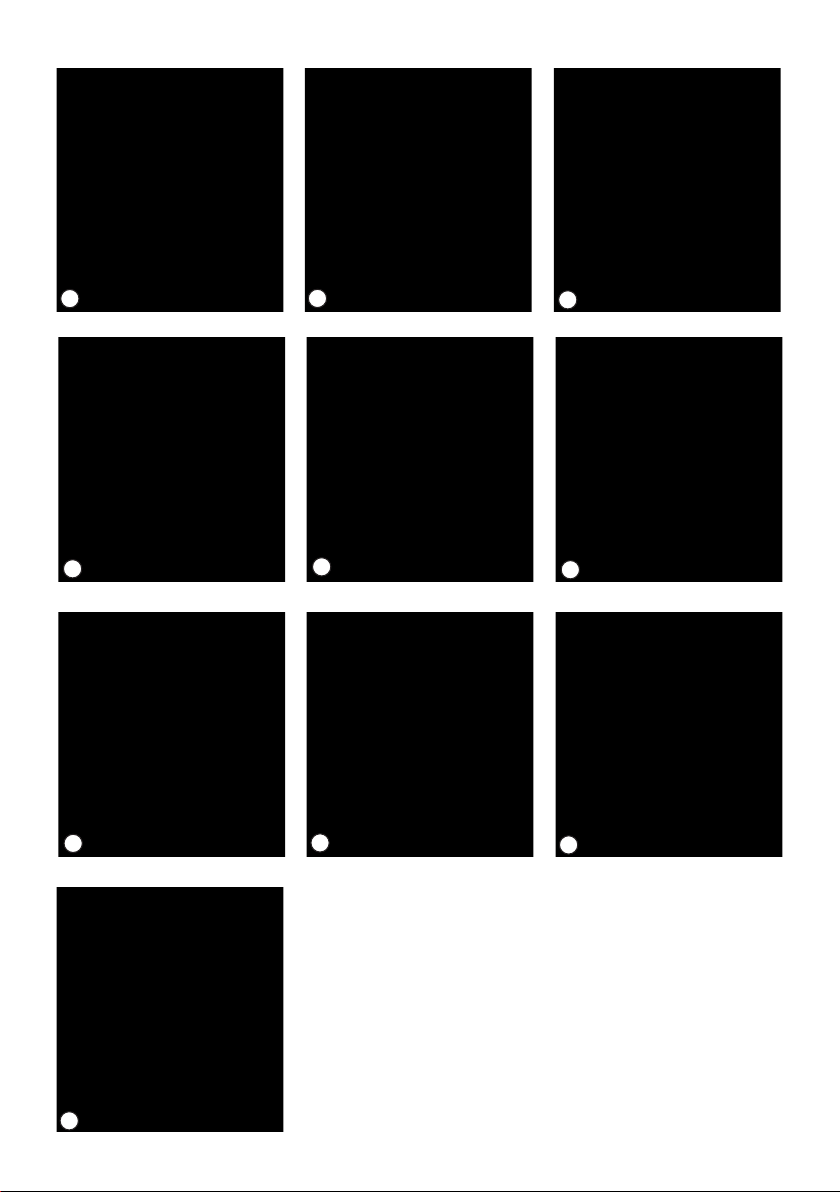

10

111213

14

15

161718➞19

Page 6

English

321

Instructions for Use

Contraindication

– Direct intraoral contact of unpolymerized material.

– If the patient is known to be allergic to any of the

components listed.

Product description

The SR Ivocap System is an injection technique, which has been

especially developed to compensate curing shrinkage.

Heat/pressure curing allows shrinkage of the acrylate during

polymerization to be compensated by inflowing material.

The SR Ivocap injection technique, therefore, permits the

fabrication of high quality products with excellent physical properties.

Composition

SR Ivocap High Impact

Powder:

Polymethyl methacrylate, Co-polymer, Benzoyl peroxide,

pigments

Liquid:

Methyl methacrylate, Dimethacrylate (cross-linking agent), Copolymer

SR Ivocap Clear

Powder:

Polymethyl methacrylate, Dibenzoyl peroxide

Liquid:

Methyl methacrylate, Dimethacrylate (cross-linking agent)

List of parts

SR Ivocap System

A) Pressure apparatus "ID2"

A1 = Manometer

A2 = Extrusion piston

A3 = Vise shank

A4 = Safety loop

B) Clamping frame

B1 = Thrust collar with lever

B2 = Pressure ring with lever

B3 = Pressing plate

C) Flask

C1 = Flask half M

C2 = Flask half W

C3 = Flask lidl

C4 = Injection funnel

D) Capsule plunger

E) Investment aid

F) Funnel

G) Timer

Indication

SR Ivocap High Impact, SR Ivocap Clear

– Complete dentures

– Partial dentures

– Bases and relines

– Orthodontic appliances

– Bite guard splints

Important notes

– Do not wet teeth with SR Ivocap monomer, as this will

weaken the bond to the tooth

– Soak models thoroughly before the investment

– Thoroughly isolate inner flask surfaces before the

investment

– Injection channels must have a diameter of 3–5 mm

– Thoroughly clean and isolate stone surfaces

– Observe polymerization and cooling times precisely

– Contact of solvents or monomer with the polymerized

denture base material can cause white discolouration

– If cervical areas have to be isolated when the SR Ivocap

procedure is used, Ivoclar Vivadent recommends Sil-Tech

Super. Other products may cause unfavourable reactions in

the denture base material.

Warnings

– The monomer contains methyl methacrylate (MMA)

– MMA is highly flammable and irritating –

flash point +10 ºC / 50 ºF

– MMA irritates the eyes, respiratory organs and skin

– Contact may evoke sensitive skin reaction.

– Avoid prolonged or repeated contact of skin with

monomer and unpolymerized material. Commercial medi-

cal gloves do not provide protection against the sensitizing

effect of methacrylates.

– Do not inhale vapours

– Keep the material away from sources of heat – do not

smoke

– Do not dispose of the monomer in the drainage system

– Avoid electrostatic charging

Step-by-step procedure

Investment (lower flask half)

Place the investment aid (1) in the flask, mix the stone

and invest the thoroughly water-soaked model. Remove

excess stone from the thermal insulating component (2)

and the flask edges.

Placing the funnel

Remove the investment aid after the stone has set and

position the injection funnel (3) and the funnel (4) in its

place.

Injection channels

For complete upper dentures, one injection channel is

sufficient, fanning out from the funnel tip towards the

palate (Fig 3a). In the case of complete lower dentures,

two channels to the dorsal extremities of the dentures are

to be supplied (Fig 3b). For cast metal frameworks with

individual extension bases, either each base must be

®

2

Page 7

provided with a channel at the distal end or an inter-

151413

12

11

1098

7

6

5

4

connecting ring channel (dotted line) can be fabricated

(Fig 3c).

Prior to investing the antagonist part, the injection channels are

formed with pink wax. This can also be done after boil-out or

before isolating by simply milling them in.

– Injection channels must have a diameter of

3–5 mm

– Choose the shortest path

– Make sure not to damage the investment edges

along the injection funnel; they form a seal

towards the posterior shoulder of the flask.

Investment (upper flask half)

Place the upper flask half on the lower one after isolating

it with Vaseline or Ivoclar Vivadent Separating Fluid. Mix

the plaster and pour over teeth, avoiding the formation of

bubbles, until the incisal and occlusal areas are lightly

covered.

To make deflasking easier, apply a paper insert as a

separation layer (the insert should be moistened with

water).

Then, fill the flask to the brim, put on the cover and completely

press down by hand.

Do not close the flask with a press!

Boil-out procedure

Preheat the flask in very hot water for at least

5 minutes. Remove wax and thoroughly boil out with hot

and clean water. Allow the flask halves to cool to room

temperature. Remove adhering plaster residue from the

flask edges and thermal insulation component.

Isolation

Isolate the still moist plaster surfaces twice with Ivoclar

Vivadent Separating Fluid. Separating with a suitable

spray gun is also possible. Avoid pooling, eg in the

gingivobuccal fold or interdental areas. Do not rinse

isolated areas with water.

Capsule preparation

Contents of capsule: 20 g polymer, 30 ml monomer

a) Remove monomer container from the capsule and

break open by twisting off the sealing cap.

b) Pour the monomer into the capsule.

c) Re-insert the monomer container into the capsule base

prior to mixing.

Start mixing immediately following the addition of the

monomer (5 min in the Cap Vibrator).

d) Mount the capsule in the Cap Vibrator, secure it with a

rubber band and mix for 5 minutes.

The SR Ivocap denture base material should form a ball in the

process. If this is not the case after 5 minutes of mixing, the

material can be mixed for an additional 30 seconds. The failure

of the material to form a ball does not influence the quality of

the denture base material.

Do not mix longer than 7 minutes, as the resin may

become too warm, which increases the risk of premature

polymerization.

e) Remove the empty monomer container, eg with

compressed air, place the capsule on the capsule plunger

and press the contents upward with light rocking

movements. Allow air to escape through the capsule

opening.

There should be no air between the plunger and the

contents. Previously mixed capsules can be

refrigerated in the dark for 5 days. Allow them to

regain room temperature before reuse.

Clamping of the flask

Place the injection funnel with the inserted funnel in the

lower flask half. Carefully bring together the two flask halves and ensure the correct fit of the flask lids.

Then, completely insert the flask into the clamping frame. Apply

3 tons / 6000 lbs pressure to the clamping frame with the flask

in a hydraulic press (corresponds to about 80 bar / 1133 psi

hydraulic pressure). At the same time, push the ratchet (B1) on

the clamping frame to the right. After that, cease applying pressure and remove the clamping frame with the flask from the

press.

Inserting the SR Ivocap capsules

Remove the cover from the capsule and fully insert the

capsule into the flask.

Mounting the pressure apparatus

Fully extend the plunger of the pressure apparatus, eg by

pulling the piston rod when the compressed air locking

valve is open.

Place the SR Ivocap pressure apparatus on the flask, lift the

safety loop (A1) and press the plunger into the capsule until

the vise shanks are correctly positioned on the flask. Then, pull

down the safety loop until it snaps into place.

Injection

Connect the pressure apparatus with the compressed air

locking valve closed to the compressed air supply (6 bar /

85 psi). Slowly open the locking valve. The plunger will

descend and press the SR Ivocap material into the mould.

– SR Ivocap material which is left over or which has

been in a mixed state for some time requires a longer injection time of 10 minutes.

– Allow leftover material to regain room temperature

before use.

– When the red ring on the piston rod becomes

visible during injection, mix a new capsule and

replace the empty one.

Polymerization

Place the SR Ivocap assembly in a suitable polymerization

bath. The surface of the water should be covered with plastic floaters in order to prevent unnecessary loss of heat

(isolation). When immersing the SR Ivocap assembly in the

polymerization bath, make sure that no plastic

floaters are trapped beneath the clamping frame.

3

Page 8

– The temperature of the water bath must be set in such a

191817

16

way that the water boils during the entire polymerization

period.

– The water level must reach the red mark on the clamping

frame and must be maintained at this level throughout the

polymeri zation period.

– The polymerization time once the water starts to boil is

exactly 35 minutes.

– Do not interrupt the boiling procedure by introducing other

flasks.

– Content of residual monomer according to ISO 20795-1

< 2.2%. In order to reduce the content of residual

monomer below 1%, the material must be polymerized for

90 minutes in boiling water. The residual material will set in

the capsule during this time.

Consequences of incorrect water level during

polymerization

– Over the red mark

– Capsule reservoir polymerizes; constant flow of the resin

during polymerization becomes impossible.

– Waste of material due to polymerization of leftover

material in the capsule.

– Below the red mark

– Partially unpolymerized areas in palatal, post dam or

retromolar areas

Cooling

After completion of the 35-minute polymerization

procedure, remove the SR Ivocap assembly from the

boiling water and immediately cool in cold water.

During the first 20 minutes of the cooling phase, the

pressure in the clamping frame and the injection

apparatus must remain unchanged.

After 20 minutes, the pressure apparatus can be removed. The

clamping frame together with the flask, however, must remain

in cold water for an additional 10 minutes.

Total cooling time: 30 minutes

A locking valve on the pressure apparatus maintains the

injection pressure at a constant level during the cooling

phase, irrespective of the compressed air supply. This

results in increased mobility, since the cooling bath does

not necessarily have to be near the air supply.

Deflasking

Mount the clamping frame in the press and re-apply 3 tons /

6000 lbs pressure. Move the ratchet (B1) back to the left

and release pressure. Remove the flask from the clamping

frame.

Recommended procedure

– Remove both plastic covers, insert flask with the narrow

side to the front into the press. Place any suitable object

between the plaster investment and the pressing plate, not

touching the flask edges. Close the press with minimal

pressure (Fig 19).

– Introduce a broad screwdriver into the joint beside the

guide piece and lever the upper flask half upwards (Fig 19).

– Remove the flask from the press and repeat the same

procedure with the flask reversed. The investment can now

be removed from the flask without difficulty and without

using force (eg hammer).

– Remove plaster in the usual way.

– Finish and polish as usual.

– Deflasking devices can also be used for this purpose.

Repairs

All the Ivocap materials are also available in cold-curing form.

Ivoclar Vivadent recommends its cold-curing polymers for

repairs. The Instructions for Use of these materials provide

detailed information about the repair methods available.

Please see the individual Operating Instructions of the different

apparatus.

Storage

– Store the material in a cool, dark and well-ventilated place

– Unmixed: storage temperature of 2–28 ºC / 36–82 ºF)

– Mixed: max 5 days, cool and protected from light at

8 ºC / 46 ºF

– If the material is refrigerated, the capsule should be

removed from the refrigerator one hour before use and

brought to room temperature.

– Do not use the product after the indicated expiry date.

– Store out of the reach of children.

Classification according to ISO 20795-1

Type 1, Class 1

Date information prepared: 11/2010

Manufacturer:

Ivoclar Vivadent AG, FL-9494 Schaan / Liechtenstein

The material has been developed solely for use in dentistry. Processing should be carried out

strictly according to the Instructions for Use. Liability cannot be accepted for damages resulting

from failure to observe the Instructions or the stipulated area of appli cation. The user is responsible for testing the material for its suitability and use for any purpose not explicitly stated in

the Instructions. Descriptions and data constitute no warranty of attributes and are not binding.

4

Page 9

Operating diagram

5

Page 10

Installation diagram

6

Page 11

Deutsch

3

2

1

Verarbeitungsanleitung

Kontraindikation

– Direkter Kontakt von unpolymerisiertem Material im

intraoralen Bereich.

– Bei erwiesener Allergie auf einen der Bestandteile

Produktbeschreibung

SR Ivocap System ist ein speziell entwickeltes, schrumpfungsausgleichendes Injektionsverfahren. Durch die gesteuerte Druck/Hitze-Polymerisation ist es möglich, die auftretende

Schrumpfung des Acrylats während der Polymerisation durch

nachfliessendes Material auszu gleichen.

Das SR Ivocap Injektionsverfahren ermöglicht somit

Qualitätsprodukte mit hervorragenden physikalischen

Eigenschaften.

Zusammensetzung

SR Ivocap High Impact

Pulver:

Polymethylmethacrylat, Co-Polymer, Benzoylperoxid, Pigmente

Flüssigkeit:

Methylmethacrylat, Dimethacrylat (Vernetzer), Co-Polymer

SR Ivocap Clear

Pulver:

Polymethylmethacrylat, Dibenzoylperoxid

Flüssigkeit:

Methylmethacrylat, Dimethacrylat (Vernetzer)

Teileverzeichnis

SR Ivocap System

A) Druckaufsatz "ID2"

A1 = Manometer

A2 = Auspresskolben

A3 = Zangenschenkel

A4 = Sicherheitsbügel

B) Spannrahmen

B1 = Sperrklinke

B2 = Druckring mit Hebel

B3 = Druckplatte

C) Küvette

C1 = Küvettenhälfte M

C2 = Küvettenhälfte W

C3 = Küvettendeckel

C4 = Zentriereinsatz

D) Kolbenschieber

E) Einbettschablone

F) Trichter

G) Timer

Indikation

SR Ivocap High Impact, SR Ivocap Clear

– Totalprothesen

– Partielle Prothesen

– Unterfütterungen

– KFO Arbeiten

– Aufbiss-Schienen

Wichtige Hinweise

– Die Zähne auf keinen Fall mit SR Ivocap Monomer be-

netzen, da dies zu einer Verschlechterung des

Zahnverbundes führt.

– Modelle vor dem Einbetten gründlich wässern.

– Küvetteninnenflächen vor dem Einbetten gründlich

isolieren.

– Einspritzkanäle müssen einen Durchmesser von 3–5 mm

aufweisen.

– Gipsflächen gründlich reinigen und gründlich isolieren

– Polymerisations- und Abkühlzeit genau einhalten

– Kontakt von Lösungsmitteln oder Monomer mit polymeri-

siertem Prothesenmaterial kann zu Weissfärbungen führen.

– Bei der Verwendung von Zahnhalsisolie rungen im

SR Ivocap Verfahren, empfiehlt Ivoclar Vivadent Sil-Tech

Super. Andere Produkte können zu negativen Reaktionen

des Prothesenmaterials führen.

Gefahrenhinweise

– Monomer enthält Methylmethacrylat (MMA)

– MMA ist leicht entzündlich und reizend, Flammpunkt

+ 10 °C

– MMA reizt die Augen, Atmungsorgane und Haut

– Sensibilisierung durch Hautkontakt möglich.

– Hautkontakt mit Monomer und unausgehärtetem Material

vermeiden. Handelsübliche medizinische Handschuhe bie-

ten keinen Schutz gegen den sensibilisierenden Effekt von

Methacrylaten.

– Dämpfe nicht einatmen.

– Von Zündquellen fernhalten – nicht rauchen.

– Monomer nicht in die Kanalisation gelangen lassen.

– Massnahmen gegen elektrostatische Aufladungen treffen.

®

Verarbeitung

Einbettung – untere Hälfte

Die Einbettschablonen (1) in die Küvette einsetzen, einen

beliebigen Hartgips anrühren und das gewässerte Modell

einbetten. Den Gipsüberschuss vom Wärmedamm (2) und

den Küvettenteilen entfernen.

Trichter einsetzen

Nach Erhärten des Gipses die Schablonen entfernen und

an deren Stelle Zentriereinsatz (3) mit Trichter (4) einsetzen.

Einspritzkanäle

Bei oberen Vollprothesen genügt ein Einspritzkanal, der

von der Trichterspitze zum Gaumen deltaförmig auslaufen

soll (Abb. 3a). Bei unteren Vollprothesen müssen immer

zwei Kanäle zu den dorsalen Prothesenenden angelegt

werden (Abb. 3b). Bei Modellgussprothesen mit einzelnen

Sätteln muss entweder jeder Sattel einzeln am distalen

Ende mit einem Kanal versorgt oder ein Ringkanal (strichlierte Linie) angelegt werden (Abb. 3c).

7

Page 12

Die Kanäle vor Anfertigung des Gegengusses aus rosa Wachs

9

876

5

4

14

131211

10

einlegen oder nach dem Ausbrühen und vor dem Isolieren einfräsen.

– Einspritzkanäle müssen einen Durchmesser von 3–

5 mm aufweisen

– den kürzesten Weg wählen

– die Gipskanten entlang des Einspritztrichters nicht

verletzen; sie dichten zur posterioren

Küvettenschulter hin ab.

Einbettung – obere Hälfte

Nach dem Isolieren der Gipskontaktflächen mit Vaseline

oder Ivoclar Vivadent Separating Fluid die obere

Küvettenhälfte aufsetzen. Gips anrühren, die Zähne

blasenfrei umgiessen, bis die Schneiden und Kauflächen

leicht bedeckt sind.

Um das Ausbetten zu erleichtern, wird nun eine

Papierfolie eingelegt, welche als Trennschicht wirkt

(Papierfolie befeuchten).

Die Küvette anschliessend bis zum Rand füllen, Deckel

aufsetzen und mit der Hand bis zum Anschlag aufdrücken.

Küvette nicht mittels Presse verschliessen!

Ausbrühen

Küvette für mindestens 5 Minuten in sehr heissem Wasser

vorwärmen, Wachs entfernen und dann mit kochendem,

sauberem Wasser gut ausbrühen. Kuvettenhälften danach

auf Raumtemperatur abkühlen lassen. Am Küvettenrand

und am Wärmedamm die anhaftenden Gipsreste

entfernen.

Isolation

Die noch feuchten Gipsflächen zweimal mit Ivoclar

Vivadent Separating Fluid isolieren. Die Verwendung einer

Isoliersprühpistole ist ebenfalls möglich. Pfützenbildung

z.B. an Umschlagfalte oder Zahnzwischenräumen vermeiden. Isolierschicht nicht mit Wasser abspülen.

Kapselvorbereitung

Kapselinhalt: Polymer 20g, Monomer 30 ml

a) Monomerbehälter der Kapsel entnehmen und durch

Abdrehen der Verschlusskappe an der Sollbruchstelle

die Kapsel öffnen.

b) Monomer in die Kapsel giessen.

c) Den leeren Monomerbehälter vor dem Mischen wieder in

die Kapsel einschieben. Mischung kurz aufschütteln.

Unmittelbar nach dem Zufügen des Monomers mit

dem Mischen (5 min. im Cap Vibrator) beginnen.

d) Kapsel in den Cap-Vibrator einsetzen, mit Gummiband

sichern und 5 Minuten mischen.

Dabei entsteht ein Ball aus angeteigtem SR Ivocap Prothesenkunststoff. Sollte nach korrektem Anmischen von 5 Min. keine

Ballbildung stattgefunden haben, kann 30 Sek. nachgemischt

werden. Fehlende Ballbildung beeinträchtigt die Qualität des

Prothesenkunststoffes in keiner Weise.

Nicht länger als insgesamt 7 Min. mischen, da sich der

Kunstoff durch den Mischvorgang erwärmt und so die Gefahr

einer vorzeitigen Polymerisation steigt.

e) Den leeren Monomerbehälter z.B. mit Pressluft entfernen, die Kapsel auf den Kolbenschieber setzen und den

Kunststoff unter leichten Kippbewegungen nach oben

drücken. Die Luft durch geöffneten Deckel entweichen

lassen.

Zwischen Kunststoff und Kolben soll sich keine Luft

mehr befinden. Gemischte Kapseln können gekühlt im

Dunkeln bis zu 5 Tage gelagert werden. Vor Wiedergebrauch auf Raumtemperatur bringen.

Einspannen der Küvette

Zentriereinsatz mit eingelegtem Trichter in der unteren

Küvettenhälfte platzieren. Danach beide Kuvettenhälften

vorsichtig zusammensetzen. Auf richtigen Sitz der

Küventtendeckel achten.

Nun Küvette bis zum Anschlag in den Spannrahmen einschieben. Spannrahmen mit eingelegter Küvette in einer

hydraulischen Dental-Presse mit 3 Tonnen belasten (entspricht

bei Dentalpressen in der Regel 80 bar hydraulischen Drucks).

Gleichzeitig die Sperrklinke (B1) am Spannrahmen nach rechts

schieben. Nun den Pressdruck ablassen und den Spannrahmen

mit der Kuvette der Presse entnehmen.

Einsetzen der SR Ivocap Kapsel

Kapseldeckel entfernen und Kapsel bis zum Anschlag in

die Küvette einschieben.

Aufsetzen des Druckaufsatzes

Kolben des Druckaufsatzes ganz ausfahren z.B. durch

Ziehen an der Kolbenstange bei geöffnetem DruckluftSperrhahn.

SR Ivocap Druckaufsatz auf die Küvette aufsetzen, Sicherheitsbügel (A4) anheben und Kolben in die Kapsel drücken, bis die

Schenkel an der Küvette richtig positioniert sind. Anschliessend

Sicherheitsbügel nach unten, bis er einrastet.

Injizieren

Druckaufsatz mit geschlossenem Druckluftsperrhahn an

Druckluftquelle (6 bar) anschliessen. Druckluftsperrhahn langsam öffnen. Der Kolben senkt sich nun und

presst das SR Ivocap Material in die Hohlform.

– Wird SR Ivocap Restmaterial ein zweites Mal ver-

wendet oder wurde es bereits vor längerer Zeit

angemischt, muss 10 Minuten injiziert werden.

– Das Restmaterial vor Gebrauch auf Raumtempe-

ratur temperieren.

– Erscheint beim Injizieren die rote Markierung an

der Kolbenstange, ist die Kapsel leer. Diese muss

durch eine neue, frisch angeteigte Kapsel ersetzt

werden.

8

Page 13

Polymerisation

181716

15

19

Die SR Ivocap Einheit in eine zweckmässige Polymerisationswanne stellen. Die Wasseroberfläche muss mit

Plastikschwimmkugeln abgedeckt werden, um einen

unnötigen Wärmeverlust des Wasserbades zu vermeiden

(Isolation). Es ist darauf zu achten, dass sich beim

Einsetzen der SR Ivocap Einheit keine Plastikschwimmkugeln unter dem Spannrahmen verfangen.

– Die Wasserbadtemperatur so einstellen, dass das Wasser

während der ganzen Polymerisationsdauer kocht.

– Das Wasserniveau muss bis zur roten Markierung am

Spannrahmen reichen und während der gesamten

Polymerisation beibehalten werden.

– Die Polymerisationszeit ab Kochbeginn beträgt genau

35 Minuten.

– Kochvorgang nicht durch nachträgliches Einsetzen anderer

Küvetten unterbrechen.

– Restmonomergehalt nach ISO 20795-1 <2.2%. Um den

Restmonomergehalt unter 1% zu senken, muss eine

Polymerisations zeit bei kochendem Wasser von 90 Min.

durchgeführt werden. Dies führt zu einem Aushärten des

Restmaterials in der Kapsel.

Folgen von unkorrektem Wasserstand bei der

Polymerisation

– über der roten Marke

– Kapselreservoir polymerisiert; ein konstantes Nachfliessen

während der Polymerisation wird unmöglich

– Materialverlust durch Polymerisation des restlichen

Kapselinhaltes

– unter der roten Marke

– teilweise unpolymerisierte Gaumen- oder A-Linien bzw.

Retromolarenpartien

Abkühlen

Nach Ablauf der 35-minütigen Polymerisation, die

SR Ivocap Einheit dem kochenden Wasser entnehmen und

direkt im kalten Wasser abkühlen.

Für die ersten 20 Minuten müssen Spannrahmen- und

Injektionsdruck unverändert beibehalten werden.

Nach 20 Minuten kann der Druckaufsatz abgenommen werden. Der Spannrahmen mit der Küvette verbleibt jedoch unbedingt für weitere 10 Minuten im kalten Wasser.

Gesamte Abkühlzeit: 30 Minuten.

Ein Sperrhahn auf dem Druckaufsatz erlaubt, den

Injektionsdruck unabhängig von der Druckluftversorgung

während des Abkühlens aufrecht zu erhalten. Daraus

resultiert eine grössere räumliche Mobilität, da das

Abkühlbecken nicht mehr in der Nähe der Druckluftversorgung sein muss.

Ausbetten

Spannrahmen in die Presse stellen und wieder mit

3 Tonnen belasten, die Sperrklinke (B1) nach links zurückschieben und Druck ablassen. Küvette aus Drucksatz

nehmen.

Empfohlene Vorgangsweise

– Beide Kunststoffdeckel abnehmen, Küvette mit der

Schmalseite nach vorne unter die Presse legen. Einen

geeigneten Aufsatz so zwischen Gips und Pressteller legen,

dass er die Küvette selbst nicht berührt. Anschliessend mit

geringem Druck belasten (Abb. 19).

– Einen breiten Schraubenzieher in den Spalt neben dem

Führungszapfen einführen und die obere Küvettenhälfte

nach oben anheben (Abb. 19).

– Die Küvette nun der Presse entnehmen, umkehren und den

Vorgang wiederholen. Das Gipsfutter kann nun problemlos

und ohne Gewalteinwirkung (z.B. Hammer) der Küvette

entnommen werden.

– Das weitere Entfernen des Gipses erfolgt wie üblich.

– Ausarbeiten und Polieren wie üblich.

– Für diesen Zweck können auch Küvettenausbettgeräte

angewendet werden.

Reparaturen

Alle SR Ivocap-Farben sind auch als Ivoclar Vivadent Kaltpoly merisate erhältlich. Für Reparaturen werden Ivoclar Vivadent

Kaltpolymerisate empfohlen. Die Verarbeitungsanleitungen

dieser Ivoclar Vivadent Materialien geben die Methode zur

Reparatur detailliert an. Bitte beachten Sie die entsprechenden

Betriebsanleitungen der einzelnen Geräte.

Lagerungshinweise

– Material an einem kühlen, dunklen und gut belüfteten Ort

aufbewahren

– ungemischt: Lagertemperatur (2–28° C / 36–82° F)

– gemischt: max. 5 Tage, kühl und lichtgeschützt, bei

8° C / 46° F

– Bei Kühlschranklagerung Kapsel 1 Stunde vor Gebrauch

entnehmen und auf Raumtemperatur temperieren.

– Produkte nach Ablauf des Verfalldatums nicht mehr

anwenden.

– Für Kinder unzugänglich aufbewahren.

Klassifikation nach ISO 20795-1

Typ 1, Gruppe 1

Erstellungsdatum der Verarbeitungsanleitung

11/2010

Hersteller

Ivoclar Vivadent AG, FL-9494 Schaan / Liechtenstein

Das Material wurde für den Einsatz im Dentalbereich entwickelt und muss gemäss

Verarbeitungsanleitung verarbeitet werden. Für Schäden, die sich aus anderweitiger

Verwendung oder nicht sachgemässer Verarbeitung ergeben, übernimmt der Hersteller keine

Haftung. Darüber hinaus ist der Verwender verpflichtet, das Material eigenverantwortlich vor

dessen Einsatz auf Eignung und Verwendungsmöglichkeit für die vorgesehenen Zwecke zu prüfen, zumal wenn diese Zwecke nicht in der Gebrauchsinfor mation aufgeführt sind.

9

Page 14

Anwendungsschema

10

Page 15

Installationsplan

11

Page 16

Français

3

2

1

Mode d’emploi

Description du produit

Le système SR Ivocap est un procédé d'injection spécialement

développé pour compenser le retrait de polymérisation. Grâce à

la polymérisation dirigée sous pression et chaleur, il est possible

de compenser le retrait de la résine par l'apport de matériau

frais.

Le procédé d'injection SR Ivocap garantit ainsi des produits de

qualité dotés d'excellentes propriétés physiques.

Composition

SR Ivocap High Impact

Poudre

Méthacrylate de méthyle, Copolymère, Peroxyde de benzoyle,

Pigment

Liquide

Méthacrylate de méthyle, Diméthacrylate (agent de réticulation),

Copolymère

SR Ivocap Clear (Thermopolymérisable)

Poudre

Polyméthacrylate de méthyle, Peroxyde de dibenzoyle

Liquide

Méthacrylate de méthyle, Diméthacrylate (agent de réticulation)

Liste des composants

SR Ivocap System

A) Cylindre "ID2"

A1 = manomètre

A2 = piston de pressée

A3 = bras de levier

A4 = bride de sécurité

B) Bride

B1 = cliquet d'arrêt

B2 = bride à cliquet

B3 = plateau

C) Küvette

C1 = moufle "partie inférieure" M

C2 = moufle "partie supérieure" W

C3 = couvercle du moufle

C4 = cylindre isolant

D) Piston poussoir

E) Plaque de positionnement

F) Entonnoir

G) Minuterie

Indication

SR Ivocap High Impact, SR Ivocap Clear

– prothèses totales

– prothèses partielles

– rebasages

– travaux orthodontiques

– gouttières

12

Contre-indications

– Contact direct du matériau non polymérisé avec les tissus

de la région intraorale.

– Dans le cas d'allergie à l'un des composants

Recommandations importantes

– veiller à ce qu'il n'y ait pas de projection de monomère

SR Ivocap, sur les dents, ce qui nuirait à la liaison !

– bien immerger les modèles dans l'eau avant la mise en

moufle

– isoler soigneusement les faces intérieures du moufle

– les canaux d'injection doivent avoir un diamètre de

3–5 mm

– nettoyer soigneusement les surfaces en plâtre et les isoler

– respecter exactement les temps de polymérisation et de

refroidissement

– le contact de solvants ou de monomère avec le matériau

polymérisé peut provoquer des blanchiments

– si l'on ne peut se passer d'isolant cervical avec le procédé

SR Ivocap, Ivoclar Vivadent suggère l'utilisation de Sil-Tech

Super.

Consignes de sécurité

– le monomère contient du méthacrylate de méthyle (MMA)

– le MMA est inflammable et irritant – point éclair + 10 °C

– MMA irrite les yeux, le système respiratoire et la peau

– une sensibilisation par contact cutané n'est pas exclue

– éviter le contact cutané avec le monomère puis avec le

matériau non durci. Les gants à usage médical disponibles

sur le marché ne protègent pas contre les effets de

sensibilisation au méthacrylate.

– ne pas inhaler les vapeurs

– tenir éloigné de toute source incandescente – ne pas fumer

– ne pas déverser le monomère dans les canalisations

– prendre les mesures contre l'électricité statique

Mode d'emploi

Mise en moufle – Partie inférieure

Placer la plaque de positionnement (1) dans le moufle

avant la mise en plâtre (utiliser un plâtre dur) puis mettre

en place le modèle précédemment immergé dans l'eau.

Eliminer toute trace de plâtre de la protection thermique

(2) et des parties métalliques du moufle.

Mise en place de l'entonnoir

Après durcissement du plâtre, retirer la plaque de

positionnement et la remplacer par le cylindre isolant (3)

muni de l'entonnoir (4).

Canaux d'injection

Pour les prothèses complètes du haut, prévoir un seul

canal d'injection, à section plus importante, s'étendant tel

un delta, de l'orifice de l'entonnoir au palais (fig. 3a).

Les prothèses du bas requièrent l'aménagement de

2 canaux reliant chacun l'entonnoir à l'une des parties

postérieures (fig 3b).

En cas de prothèses squelettées, chacune des selles doit

recevoir un canal d'injection côté lingual, à moins que l'on

®

Page 17

ne préfère les relier par un canal circulaire (lignes

9

8

7

6

5

4

15

14

12

13

11

10

pointillées) (fig 3c).

Mettre en place des canaux en cire rose avant la réali sation de

la contre-coulée ou fraiser après l'ébouillantage et avant

l'isolation.

– les canaux d'injection doivent avoir un diamètre de

3–5 mm

– toujours choisir le chemin le plus court

– ne pas détériorer les rebords de plâtre le long de

l'entonnoir d'injection ; ils sont nécessaires à

l'étanchéité postérieure.

Mise en moufle – partie supérieure

Après avoir isolé à l'aide de vaseline ou de Separating

Fluid d'Ivoclar Vivadent, positionner la partie supérieure du

moufle. Préparer le plâtre et le verser, sans bulles, jusqu'à

ce que les faces triturantes ou les bords libres des incisives

soient légèrement couverts.

Afin de faciliter le démouflage, déposer une feuille de

papier qui servira de couche de séparation (humecter

la feuille de papier).

Remplir le moufle à ras bord, mettre le couvercle et presser à la

main jusqu'à la butée.

Ne pas fermer le moufle à l'aide d'une presse.

Ebouillantage

Immerger le moufle pendant 6 minutes dans l'eau très

chaude. Eliminer la cire, puis bien ébouillanter. Laisser

ensuite refroidir les deux parties du moufle à tempéra ture

ambiante. Eliminer le plâtre résiduel de l'entonnoir, du

cylindre et de l'épaulement.

Isolation

Isoler 2 fois avec le Separating Fluid Ivoclar Vivadent les

surfaces de plâtre sèches. L'utilisation d'un pulvérisateur

est également possible. Eviter la formation de poche d'air

par ex. dans les sillons vestibulaires ou les espaces interdentaires. Ne pas rincer la couche isolante à l'eau.

Préparation de la cartouche

Contenu de la cartouche :

20 g de polymère, 30 ml de monomère

a) retirer le contenant de monomère de la cartouche puis

ouvrir la cartouche en tournant l'embout au point de

fragilité.

b) verser le monomère dans la cartouche.

c) Avant le mélange replacer le réservoir vide dans la cartouche.

Procéder au mélange immédiatement après avoir ajouté

le monomère (5 minutes dans le Cap Vibrator)

d) introduire la cartouche dans le Cap Vibrator, placer

l'élastique de sécurité et mélanger 5 minutes.

Une boule de résine SR Ivocap en résulte. Si après 5 minutes de

mélange, aucune boule ne se forme, mélanger à nouveau

30 secondes. Si la formation de boule est inexistante, cela

n'influence en aucun cas la qualité du matériau.

Ne pas mélanger plus de 7 minutes car le matériau chauffe

après le mélange et le risque d'une polymérisation prématurée

augmente.

e) ôter le réservoir de monomère vide, par ex. avec de l'air

comprimé, et à l'aide du poussoir avancer le matériau en

effectuant des mouvements de bascule. Laisser échapper

l'air en ouvrant le bouchon.

Aucune poche d'air ne doit subsister entre matériau

et piston. Le matériau malaxé se conserve au

réfrigérateur pendant 5 jours. Le ramener à

température ambiante avant son utilisation.

Mise en bride du moufle

Placer le cylindre isolant muni de l'entonnoir dans la partie

inférieure du moufle. Assembler ensuite soigneusement les

deux parties du moufle. Veiller à la bonne assise du

couvercle du moufle.

Placer alors le moufle dans la bride jusqu'à la butée. Introduire

la bride dans la presse hydraulique et élever la pression à

3 tonnes (ce qui correspond à une pression hydraulique de

80 bar) pour les presses en usage dans les laboratoires

dentaires. Pousser en même temps vers la droite le levier de

verrouillage situé sur la bride. Décomprimer et sortir l'ensemble

moufle et bride de la presse.

Mise en place de la cartouche SR Ivocap

Enlever le bouchon de la cartouche et introduire la

cartouche dans le moufle jusqu'à l'arrêt.

Mise en place du cylindre d'injection

Sortir entièrement le piston du cylindre d'injection par ex.

en tirant sur la tige, le robinet d'arrêt d'air comprimé étant

ouvert.

Adapter le cylindre sur le moufle, tirer la bride de sécurité (A4)

et enfoncer le piston dans la cartouche jusqu'à ce que le levier

soit bien positionné par rapport au moufle. Ensuite tirer la bride

de sécurité vers le bas jusqu'à ce qu'elle s'enclenche.

Mise en place du cylindre d'injection

Injection

Mettre l'ensemble sous une pression de 6 bar, le robinet

d'arrêt d'air comprimé étant fermé, puis ouvrir lentement

celui-ci. Le piston descend et presse le matériau SR Ivocap.

– en cas d'utilisation d'une cartouche déjà entamée

ou malaxée depuis plus longtemps, porter le délai à

10 minutes

– avant son utilisation, le matériau doit être à

température ambiante

– si lors de l'injection, la marque rouge sur la tige du

piston devient visible, c'est que la cartouche est

vide. Celle-ci doit être remplacée par une nouvelle

cartouche.

Mise en place du cylindre d'injection

Polymérisation

Placer l'ensemble SR Ivocap dans un bac à polyméri saiton

approprié. La surface de l'eau doit être couverte de billes

plastiques afin d'éviter une perte inutile de chaleur du

13

Page 18

bain (isolation). Veiller à ce que les billes ne se posent pas

191817

16

sous la bride au moment de l'immersion de l'ensemble.

– la température doit être réglée de manière à ce que l'eau

soit en ébullition pendant toute la durée de polymérisation

– le niveau d'eau doit atteindre le repère rouge imprimé sur

la bride et être maintenu pendant toute la durée de

polymérisation

– le délai de polymérisation, à compter du début de l'é-

bullition, est exactement de 35 minutes

– ne pas interrompre la cuisson par immersion d'un second

moufle

– teneur en monomère résiduel selon ISO 20795-1 < 2.2% .

Pour maintenir la teneur en monomère résiduel en-dessous

de 1%, le délai de polymérisation dans l'eau bouillante doit

être de 90 minutes. Cela conduit à un durcissement du

matériau dans la capsule.

Conséquences d'un niveau d'eau incorrect

– Niveau au-dessus du repère rouge

– la résine polymérise dans la cartouche, un apport de

résine pendant la polymérisation devient impossible

– perte du matériau resté dans la cartouche

– Niveau en-dessous du repère rouge

– polymérisation en partie incomplète des parties

postérieures, A ou rétromolaires.

Mise en place du cylindre d'injection

Refroidissement

Au terme de la polymérisation de 35 minutes, retirer

l'ensemble de l'eau en ébullition et le plonger directement

dans l'eau froide.

Pendant les 20 premières minutes, l'air comprimé et la

pression de la bride doivent être conservés.

Après 20 minutes, on peut retirer le cylindre. La bride et le

moufle doivent rester encore pendant 10 minutes dans l'eau

froide.

Délai de refroidissement total: 30 minutes.

Le robinet d'arrêt sur le cylindre permet de maintenir la

pression d'injection pendant le refroidissement indépendamment de l'alimentation en air comprimé. Il en résulte

une plus grande mobilité car le bac de refroidissement ne

doit plus se trouver à proximité de l'alimentation en air

comprimé.

Mise en place du cylindre d'injection

Démouflage

Remettre la bride sous la presse, mettre la pression à

3 tonnes, repousser le cliquet d'arrêt vers la gauche (B1),

décompresser. Retirer le moufle du cylindre.

Procédure recommandée

– enlever les deux couvercles en plastique. Placer le moufle

sous la presse avec la partie étroite vers l'avant. Poser une

pièce appropriée (cylindre) entre le plateau de presse et le

moufle, de manière à ce que celui-ci ne soit pas touché.

Ensuite, fermer la presse sous une légère pression

(photo 19).

– coïncer un tournevis large dans la rainure située près du

guide d'assemblage et soulever la partie supérieure vers le

haut (photo 19).

– retourner le moufle et répéter l'opération. Le plâtre peut

être retiré sans problème du moufle et sans recourir à la

force (par ex. marteau)

– retirer le reste du plâtre comme à l'accoutumée

– procéder aux opérations de finition et de polissage

habituelles

– des appareils de démouflage peuvent être utilisés pour cet

usage

Réparations

Toutes les teintes Ivocap sont également disponibles en version

autopolymérisante. Pour ce qui concerne les réparations, on

recommande d'utiliser les résines autopolymérisantes Ivoclar

Vivadent. Les modes d'emploi de ces matériaux donnent en

détail la méthode de réparation.Veuillez respecter les modes

d'emploi correspondants de chaque appareil

Recommandations de stockage

– Conserver le matériau à l'abri de la chaleur et de la lumière

et dans un lieu bien ventilé

– non malaxé : température de stockage (2–28°C /

36–82°F)

– une fois malaxé: max. 5 jours au frais à 8°C/46°F

et à l'abri de la lumière

– Si le matériau est conservé au réfrigérateur, sortir la capsule

1 heure avant son utilisation pour qu'elle soit à température

ambiante

– Ne plus utiliser les produits après la date de péremption

– Ne pas mettre à la portée des enfants.

Classification selon ISO 20795-1

Type 1, classe 1

Date de réalisation du présent mode d’emploi

11/2010

Production

Ivoclar Vivadent AG, FL-9494 Schaan / Liechtenstein

Cet appareil est destiné à un usage dans le domaine dentaire et doit être utilisé conformément

au mode d'emploi. Les dommages résultant du non-respect de ces prescriptions ou d'une

utilisation à d'autres fins que celles indiquées n'engagent pas la responsabilité du fabricant.

L'utilisateur est tenu de vérifier sous sa propre responsabilité l'appropriation de l'appareil à

l'utilisation prévue et ce d'autant plus si celle-ci n'est pas citée dans le mode d'emploi.

14

Page 19

Schéma d'installation

15

Page 20

Plan d'installation

Refroidissement dans l’eau froid – min 30 mn

dont 20 mn sous pression

16

Page 21

Italiano

1

Istruzioni d’uso

Descrizione prodotto

Il sistema SR Ivocap è un metodo ad iniezione specificatamente

ideato per compensare retrazioni da polimerizzazione.

Attraverso una fase guidata a pressione/calore è possibile

compensare la retrazione dell'acrilato durante la polimerizzazione per mezzo di un flusso continuo di materiale.

Quindi il sistema ad iniezione SR Ivocap garantisce risultati di

qualità con ottime caratteristiche fisiche.

Composizione

SR Ivocap High Impact

Polvere:

polimetilmetacrilato, copolimero, perossido di benzoile, pigmenti

Liquido:

metilmetacrilato, dimetacrilato (reticolante), copolimero

SR Ivocap Clear

Polvere:

polimetilmetacrilato, perossido di benzoile

Liquido:

metilmetacrilato, dimetacrilato (reeticolante)

Elenco particolari

SR Ivocap System

A) Iniettore "ID2"

A1 = manometro

A2 = pistone di pressione

A3 = montante

A4 = staffa di sicurezza

B) Staffa di tenuta

B1 = leva di arresto

B2 = anello di spinta con leva

B3 = disco di spinta

C) muffola

C1 = controstampo

C2 = stampo

C3 = coperchio della muffola

C4 = centracapsule

D) spingicapsula

E) Mantenitore di spazio

F) imbuto

G) timer

Indicazioni

SR Ivocap High Impact, SR Ivocap Clear

– Protesi totali

– Protesi parziali

– Ribasature

– Piani di riabilitazione

– Lavori ortodontici

Controindicazioni

– Contatto di materiale non polimerizzato in campo intra -

orale!

– In caso di allergia nota ad uno dei componenti

Avvertenza importante

– Non umettare il alcun caso i denti con il monomero

SR Ivocap, poiché ció comporterebbe un peggioramento del

legame con i denti!

– Bagnare accuratamente i modelli prima della messa in

muffola

– Isolare accuratemente stampo e controstampo prima della

messa in muffola

– I canali di alimentazione devono presentare un diametro di

3–5 mm

– Detergere ed isolare accuratamente le superfici in gesso

– Attenersi scrupolosamente ai tempi di polimerizzazione e di

raffreddamento

– Non conservare il materiale giá miscelato per piú di 5 gior-

ni, perché il monomero portrebbe evaporare

– Il contatto del materiale per protesi polimerizzato con

solventi o con monomero puó determinare decolorazioni

bianche

– Nel caso in cui non si possa rinunciare allisolamento dei

colletti dei denti nel procedimento SR Ivocap, si consiglia

l'uso del seguente prodotto: Sil-Tech

Vivadent). Altri prodotti possono causare reazioni negative

del materiale per protesi.

Avvertenze di pericolo

– Il monomero contiene metilmetacrilato.(MMA)

– MMA é facilmente infiammabile, punto dinfiammabilitá

+10 ºC / 50 ºF

– MMA é irritante per gli occhi, gli organi respiratori e la

pelle

– Possibile sensibilizzazione da contatto cutaneo.

– Evitare il contatto con monomero e con materiale non

indurito. I tradizionali guanti non forniscono protezione

dalla sensibilizzazione verso i metacrilati.

– Evitare il contatto prolungato o ripetuto con monomero e

con materiale non polimerizzato

– Non inalare i vapori

– Tenere lontano da fonti infiammabili – non fumare

– Impedire il versamento di monomero nella canalizzazione

– Prendere provvedimenti contro cariche elettrostatiche

®

Super (Ivoclar

Istruzioni duso

Messa in muffola - stampo

Inserire nella muffola il mantenitore di spazio (1) o

utilizzare direttamente il contenitore termico della capsula

e l'imbuto, miscelare del gesso duro di Classe III e mettere

in muffola il modello bagnato. Eliminare le eccedenze di

gesso dal contenitore termico (2) e dalle superfici della

muffola.

17

Page 22

Inserimento dell'imbuto

3

4

5

6

7

8

2

9

10

111213

14

Dopo l'indurimento del gesso, togliere il mantenitore di

spazio e sostituirlo con il contenitore termico della capsula

(3) e l'imbuto (4).

Canali di alimentazione

Nelle protesi totali superiori è sufficiente un canale di alimentazione che decorre a forma di delta dalla punta dell'imbuto al palato (fig. 3a). Le protesi inferiori necessitano

sempre di due canali che decorrono fino alle estremità

distali della protesi (fig. 3b). Nelle protesi parziali con

selle, ogni singola sella viene alimentata da un canale

all'estremità distale oppure da un canale ad anello (linea

tratteggiata) (fig. 3c).

I canali possono essere eseguiti prima della preparazione del

controstampo in cera rosa oppure fresati nel gesso dopo

l'eliminazione della cera.

• I canali di alimentazione devono avere un diametro

di 3–5 mm

• scegliere il percorso più breve

• i bordi del gesso lungo l'imbuto non devono essere

danneggiati, poichè servono a garantire una perfetta chiusura

Messa in muffola – controstampo

Dopo aver isolato il gesso con schiuma di sapone o con

Separating Fluid Ivoclar Vivadent, adagiare il controstampo

sullo stampo. Miscelare il gesso di Classe III e, senza provocare bolle, colarlo in prossimità dei denti fino a leggera

copertura delle parti incisali ed occlusali degli stessi.

Per facilitare lo smuffolaggio inserire un foglio di carta

per separazione inumidito.

Riempire la muffola fino al bordo e chiudere manualmente con

il coperchio premendo con la mano fino all’arresto.

Non chiudere la muffola con la pressa!

Eliminazione della cera

Preriscaldare la muffola per almeno 5 minuti in acqua

molto calda e quindi eliminare accuratamente la cera.

Quindi lasciare raffreddare a temperatura ambiente.

Eliminare residui di gesso dall'imbuto, dai bordi della

muffola e dal contenitore termico.

Isolamento

Isolare le superfici in gesso ancora umide con due strati di

Separating Fluid Ivoclar. E' possibile anche l'utilizzo di una

pistola a spruzzo per isolanti. Evitare la formazione di

accumuli, p.e. nella piega palatina o negli spazi interdentali. Non sciacquare l'isolante con acqua.

Preparazione della capsula

Contenuto della capsula: polimero 20 g, monomero 30 ml

a) Togliere il contenitore di monomero dalla capsula ed

aprirlo, girando la parte terminale predisposta alla rottura.

b) Versare il monomero.

c) Reinserire il contenitore vuoto del monomero nella capsula

prima della miscelazione.

18

Iniziare la miscelazione immediatamente dopo

l'aggiunta di monomero (5 minuti in Cap Vibrator).

d) Inserire la capsula nel Cap Vibrator, applicare la gomma

di sicurezza e miscelare per 5 minuti.

In tal modo si forma una sfera di materiale SR Ivocap miscelato.

Se dopo la miscelazione di 5 minuti non si é formata la sfera é

possibile prolungare la miscelazione di ulteriori 30 secondi. La

mancata formazione di una sfera omogenea non influisce in

alcun modo sulla qualitá del materiale per protesi.

Non miscelare per un tempo superiore a 7 min., perché altrimenti la resina, in seguito all'attrito all'interno della capsula, si

surriscalda eccessivamente aumentando il pericolo di una polimerizzazione precoce.

e) Prelevare il contenitore vuoto del monomero, applicare

la capsula sullo stantuffo e spingere il materiale verso l'alto. Lasciare defluire l'aria dal coperchio aperto.

Fra materiale e stantuffo non deve esserci presenza

d'aria. Capsule vibrate possono essere conservate in

luogo fresco e oscuro (frigorifero) fino a 5 giorni.

Prima dell'uso riportare a temperatura ambiente.

Introduzione della muffola nella staffa di

tenuta

Congiungere accuratamente le due parti della muffola;

fare attenzione che i coperchi siano posti correttamente e

far scivolare la muffola verticalmente nella staffa, fino

all'arresto.

Poggiare la staffa, con la parte bloccante rivolta verso l'alto, nel

centro della pressa idraulica. Caricare 3 tonnellate (corrisponde

a 80 bar di pressione idraulica) e contemporaneamente

spostare verso destra la leva di chiusura a (B1). Quindi eliminare la pressione dalla pressa e togliere la staffa con la muffola.

Introduzione della capsula SR Ivocap

Togliere il tappo della capsula ed inserirla fino all'arresto

nell'apposito contenitore situato nella muffola.

Applicazione dell'iniettore

Estrarre il pistone dell'iniettore fino a fine corsa p.e.

tirando il pistone manualmente con la valvola dell'aria

aperta. Applicare l'iniettore sulla muffola.

Sollevare la staffa di sicurezza (A4) e spingere il pistone nella

capsula finchè le braccia dell'iniettore siano in posizione corretta.

Infine portare la staffa di sicurezza (A4) fino all'arresto.

Iniezione

Collegare l'iniettore SR Ivocap, con leva dell'aria compressa

chiusa, alla fonte di aria compressa (6 bar). Aprire lentamente la leva di pressione aria. Lo stantuffo si abbassa

premendo il materiale SR Ivocap nello spazio della muffola.

– Nel caso si utilizzi una capsula per la seconda volta

o nel caso in cui la capsula sia stata miscelata

diverso tempo prima, l'iniezione deve avvenire per

un tempo più lungo (10 minuti).

– Prima dell'uso, portare il materiale a temperatura

ambiente.

Page 23

19

18

– Se durante l'iniezione di una capsula sul perno

15

16

17

dello stantuffo appare la linea rossa, è necessario

miscelare una nuova capsula sostituendola a quella

vuota.

Polimerizzazione

Immergere l'attrezzatura SR Ivocap in un'idonea vasca di

polimerizzazione. Ricoprire la superficie della vasca con

palline in plastica per evitare un'inutile perdita termica

(isolamento). Fare attenzione che durante l'introduzione

dell'attrezzatura non rimangano delle palline sotto la staffa.

– La temperatura dell'acqua della vasca deve essere regolata

in modo tale che l'acqua bolla durante l'intero processo di

polimerizzazione.

– Il livello dell'acqua deve raggiungere esattamente la linea

rossa sita sulla staffa mantenedolo per tutta la polimerizzazione.

– Il tempo di polimerizzazione, a partire da quando l'acqua

bolle, deve essere esattamente di 35 minuti.

– Non interrompere il processo di polime ri zzazione

aggiungendo in seguito altre muffole.

– Contenuto di monomero residuo secondo ISO 20795-1

<2,2%. Per ridurre il contenuto di monomero residuo al di

sotto dell1% deve essere esguita una polimeri zzazione in

acqua bollente per 90 minuti. Ció porta d un indurimento

del materiale residuo nella capsula.

Conseguenze sulla polimerizzazione di un livello

d'acqua non corretto

– Sopra la demarcazione rossa

– Il contenuto della capsula polimerizza rendendo

impossibile un costante afflusso durante la polime ri zzazione

– Spreco di materiale in seguito a polimerizzazione

dell'eventuale materiale residuo.

– Sotto la demarcazione rossa:

– Parti parzialmente non polimerizzate delle zone palatali,

limiti di chiusura posteriori e parti retromolari.

Raffreddamento

Al termine della polimerizzazione di 35 minuti, prelevare

dalla vasca l'attrezzatura SR Ivocap e raffreddarla

direttamente in acqua fredda.

Per i primi 20 minuti la pressione della staffa e

dell'iniettore deve rimanere inalterata.

Dopo 20 minuti si può togliere l'iniettore. La staffa con la

muffola deve però assolutamente rimanere in acqua fredda per

ulteriori 10 minuti.

Tempo totale di raffreddamento: 30 minuti.

Il rubinetto di chiusura sull'iniettore permette, indipendentemente dall'afflusso di aria compressa, di mantenere

inalterata la pressione di iniezione durante la fase di

raffreddamento. Ciò permette una migliore mobilità

dell'impianto stesso, in quanto il lavandino o vasca per il

raffreddamento non devono più trovarsi in prossimità

dell'aria compressa.

Smuffolaggio

Rimettere la staffa sotto la pressa e caricare con

3 tonnellate. Aprire la leva di chiusura (B1) spingendo

verso sinistra. Togliere la pressione. Prelevare la muffola

dalla staffa di tenuta.

Procedimento consigliato

– Togliere i due coperchi in plastica; introdurre la muffola,

con la parte stretta in avanti, sotto la pressa. Appoggiare

quindi una parte intermedia fra gesso e piatto della pressa

in modo che non tocchino i bordi metallici della muffola. A

tale scopo si può utilizzare il centracapsule (contenitore

termico). Quindi caricare con leggera pressione. (fig. 19)

– Introdurre un cacciavite largo nella fessura accanto al perno

guida ed alzare la parte superiore della muffola (fig. 19)

– Quindi togliere la muffola dalla pressa, capovolgere e

procedere nuovamente come sopra. Il rivestimento in gesso

può ora essere tolto facilmente e senza esercitare sollecita-

zioni (p.e. martello) sulla muffola.

– L'ulteriore eliminazione del gesso avviene come di consueto.

– Rifinitura e lucidatura come d'uso.

– A tale scopo si possono utilizzare anche apparecchi per

smuffolaggio.

Riparazioni

Tutti i colori SR Ivocap sono disponibili anche per le resine per

palati a freddo Ivoclar Vivadent. Per le riparazioni si consigliano

le resine a freddo Ivoclar Vivadent. Le istruzioni duso di questi

materiali forniscono informazioni dettagliate sulle procedure di

riparazione. Si prega di attenersi alle istruzioni duso dei singoli

apparecchi.

Note per la conservazione

– Conservare il monomero in luogo fresco, scuro e ben

arieggiato

– non miscelato: temperatura di conservazione 2–28 ºC

– miscelato: max. 5 giorni, in luogo asciutto e protetto da

luce a 8 ºC

– In caso di conservazione in frigorifero prelevare la capsula

unora prima delluso e portarla a temperatura ambiente.

– Non utilizzare i prodotti dopo la data di scadenza.

– Tenere fuori dalla portata di bambini.

Classificazione secondo ISO 20795-1

Tipo 1, classe 1

Stesura delle istruzioni d’uso: 11/2010

Produttore

Ivoclar Vivadent AG, FL-9494 Schaan / Liechtenstein

Il materiale è stato realizzato per l'impiego nel campo dentale e deve essere utilizzato secondo

le istruzioni d'uso. Il produttore non si assume alcuna responsabilità per danni derivanti da

diverso o inadeguato utilizzo. L'utente è tenuto a controllare personalmente l'idoneità del prodotto per gli impieghi da lui previsti soprattutto, se questi impieghi non sono riportati nelle

istruzioni d'uso.

19

Page 24

Schema di utilizzo

20

Page 25

Piano di installazione

21

Page 26

Español

3

2

1

Instrucciones de Uso

Descripción del producto

SR Ivocap es un sistema de inyección especialmente

desarrollado que controla la contracción de polimeri zación

mediante calor / presión del acrílico durante la polimerización,

gracias a la inyección continuada de material.

El sistema de inyección SR Ivocap permite así obtener prótesis

de calidad con extraordinarias propiedades físicas.

Composición

SR Ivocap High Impact

Polvo:

Polimetilmetacrilato, Copolímero, Peróxido de benzoilo,

Pigmentos

Líquido:

Metilmetacrilato, Dimetacrilato (reticulante), Copolímero

SR Ivocap Clear

Polvo:

Polimetilmetacrilato, Peróxido de dibenzoilo

Líquido:

Metilmetacrilato, Dimetacrilato (reticulante)

Despiece

SR Ivocap System

A) Inyector "ID2"

A1 = Manómetro

A2 = Pistón

A3 = Agarres del inyector

A4 = Brida de seguridad

B) Brida

B1 = Uñeta

B2 = Anillo de presión con mango

B3 = Placa de presión

C) Mufla

C1 = Parte inferior mufla

C2 = Parte superior mufla

C3 = Tapa de la mufla

C4 = Guía de centrado

D) Embolo de inyección

E) Patrón de revestimiento

F) Embudo

G) Temporizador

Indicaciones

SR Ivocap High Impact, SR Ivocap Clear

– Prótesis total

– Prótesis parcial

– Rebases

– Trabajos ortodónticos

– Férulas

22

Contraindicaciones

– El contacto de material sin polimerizar con la cavidad oral

– En caso de alergia conocida a alguno de sus componentes

Notas importantes

– En modo alguno humectar los dientes con monómero

SR Ivocap, ya que ello provoca una insuficiente adhesión a

los mismos

– Humedecer bien los modelos antes del enmuflado

– Antes del enmuflado aplicar separador en la parte interna

de las muflas

– Los canales de inyección deberán tener un diámetro de

3–5 mm.

– Limpiar a fondo y aislar las superficies de yeso.

– Respetar con exactitud los tiempos de polimerización y

enfriamiento.

– El contacto de agentes disolventes o monómero, con el

material de prótesis polimerizado, puede provocar

decoloraciones blancas.

– En caso de ser imprescindible aislar los cuellos de los dien-

tes con el sistema SR Ivocap, se recomienda utilizar el

siguiente producto: Sil-Tech

de otros productos puede provocar reacciones negativas del

material de prótesis

Advertencias

– El monómero contiene metilmetacrilato (MMA)

– MMA es fácilmente inflamable – punto de inflamación

+ 10º C

– MMA sin polimerizar irrita los ojos, las vías respiratorias y la

piel

– Es posible una sensibilización por contacto con la piel

– Evitar el contacto de la piel con el monómero y con

material sin polimerizar. Los guantes clínicos comerciales no

proveen de protección al efecto de sensibilización de los

metacrilatos

– No inhalar los vapores

– Mantener alejado de fuentes inflamables – no fumar

– No verter el monómero en la canalización

– Tomar medidas contra cargas electroestáticas

®

Super (Ivoclar Vivadent). El uso

Instrucciones de uso

Enmuflado – mitad inferior

Colocar los patrones de enmuflado (1) en la mufla,

mezclar el yeso duro y enmuflar el modelo humedecido.

Eliminar el sobrante de yeso del aislante térmico (2) y de

las partes de la mufla.

Colocación del embudo

Retirar el patrón una vez fraguado el yeso y colocar en su

lugar la guía de enmuflado (3) con embudo (4).

Canales de inyección

En prótesis completas superiores basta con colocar un

único canal de inyección en forma de delta desde el extremo del embudo al paladar (fig. 3a). En prótesis completas

inferiores deben aplicarse siempre dos canales de inyección

hacia los extremos posteriores de la prótesis (fig. 3b). En

Page 27

el caso de esqueléticos con sillas individuales debe colo-

9

876

5

4

14

13

12

11

10

carse un canal en el extremo distal o un canal circular

(línea punteada) en cada silla (fig. 3c).

Colocar los canales de cera rosa antes de la preparación de la

contramufla. Si los canales de inyección se hacen después del

escaldado y antes del aislamiento, deben realizarse con fresa.

– Los canales de inyección deben tener un diámetro

de 3–5 mm.

– Elegir el recorrido más corto.

– No dañar los bordes de yeso a lo largo del embudo

de inyección; éstos hermetizan posteriormente el

hombro de la mufla.

Enmuflado – mitad superior

Colocar la mitad superior de la mufla tras el aislamiento

con vaselina o con Separating Fluid de Ivoclar Vivadent.

Mezclar el yeso y rellenar la contramufla hasta que las

superficies incisales y las caras masticatorias de los dientes

queden ligeramente cubiertas.

Para facilitar el desenmu flado, se coloca un folio de

papel que actúa como capa separadora (humedecer el

folio de papel).

A continuación llenar la mufla hasta el borde, colocar la tapa y

presionar con la mano hasta el tope.

¡No cerrar la mufla con prensa!

Escaldado

Precalentar la mufla al menos durante 5 minutos en agua

muy caliente. Eliminar la cera y escaldar bien. A continuación, dejar enfriar ambas mitades de la mufla a temperatura ambiente. Eliminar los restos de yeso del embudo,

borde de la mufla y aislante térmico.

Aislamiento

Las superficies de yeso todavía húmedas se aíslan dos

veces con Separating Fluid de Ivoclar Vivadent.También

puede utilizarse una pistola pulverizadora con separador.

Evitar la formación de charcos p..ej. en el fondo de saco o

en los espacios interdentales. No eliminar la capa de

separador con agua.

Preparación de las cápsulas

Contenido de la cápsula:

20 gr. polímero, 30 ml. monómero

a) Extraer el recipiente de monómero de la cápsula y abrir

por la zona de rotura girando el extremo.

b) Verter el monómero dentro de la cápsula.

c) Antes de la mezcla, volver a colocar el recipiente de

monómero en la cápsula.

Inmediatamente después de añadir el monómero iniciar

la mezcla (5 minutos en el Cap-Vibrator)

d) Colocar la cápsula en el Cap-Vibrator, fijar la cápsula

con la cinta de goma y mezclar durante 5 minutos.

Durante la mezcla se forma una bola de material de prótesis

SR Ivocap. Si después de una correcta mezcla de 5 minutos no

se ha formado una bola, puede prolongarse la mezcla durante

otros 30 segundos. En caso de no formarse una bola de

material, no influyen en modo alguno en la calidad del

material de prótesis.

No mezclar durante más de 7 minutos, ya que la resina se

calienta durante la mezcla, incrementando así el riesgo de una

polimerización prematura.

e) Retirar el recipiente de monómero vacío, p.ej. con aire

comprimido, colocar la cápsula sobre el émbolo y

empujar el material hacia arriba con ligeros movimientos

basculantes. Eliminar el aire por la tapa abierta.

No puede quedar aire entre el material y el émbolo.

Las cápsulas mezcladas pueden almacenarse hasta 5

días en lugar refrigerado y oscuro. Antes de volver a

utilizar, dejar a temperatura ambiente.

Fijación de la mufla

Colocar la guía de centrado con embudo en la mitad

inferior de la mufla. A continuación, unir con cuidado

ambas mitades de la mufla y procurar que la tapa de la

misma esté correctamente asentada.

Seguidamente introducir la mufla en la brida hasta el tope.

Colocar la brida con la mufla en una prensa hidráulica dental y

cargar con 3 toneladas (en prensas dentales corresponde a

80 bar de presión). Al mismo tiempo, girar la uñeta (B1) de la

brida hacia la derecha. Eliminar el aire comprimido y extraer la

brida con la mufla de la prensa.

Colocación de la cápsula SR Ivocap

Retirar la tapa de la cápsula e introducir la cápsula hasta

el tope en la mufla.

Colocación del inyector

Extraer totalmente el pistón del inyector, p.ej. tirando de la

barra del pistón con la llave de paso del aire comprimido

abierta.

Colocar el inyector SR Ivocap sobre la mufla, levantar la brida

de seguridad (A4), introducir el pistón en la cápsula hasta que

los agarres del inyector encajen correctamente en la mufla. A

continuación bajar la brida de seguridad hasta que encaje.

Inyección

Conectar el inyector de presión con la llave de aire comprimido cerrada a la instalación de aire (6 bar).

Abrir lentamente la llave de paso del aire comprimido.

El pistón desciende e inyecta el material SR Ivocap en el

modelo.

– Si se utiliza una segunda vez material sobrante

SR Ivocap o éste fue mezclado hace tiempo, debe

prolongarse el tiempo de inyección 10 minutos

– Templar el material sobrante a temperatura

ambiente antes de su uso

– Si durante el proceso de inyección aparece la marca

roja en el pistón, es que la cápsula está vacía.

Mezclar una cápsula nueva y reemplazar la vacía.

23

Page 28

Polimerización

181817

16

15

Colocar la unidad SR-Ivocap en una bañera de polimerización adecuada. La superficie del agua debe cubrirse con

bolas flotantes de plástico para evitar una pérdida

innecesaria de calor del baño de agua (aislamiento).

Procurar que no quede ninguna bola de plástico debajo

de la brida.

– Graduar la temperatura del agua de tal manera que esté

hirviendo durante todo el proceso de polimerización

– El nivel del agua debe llegar hasta la marca roja de la

brida, pero durante toda la polimerización no debe sobre-

pasar ésta

– El tiempo de polimerización una vez que ha empezado a

hervir es exactamente de 35 minutos

– No interrumpir el proceso de cocción por la introducción

posterior de otras muflas

– Monómero residual según ISO 20795-1 <2,2%. Para que el

monómero residual sea inferior al 1% debe polimerizarse

con agua hirviendo durante 90 minutos. Esto provoca una

polimerización del material sobrante de la cápsula

Consecuencias por un nivel de agua incorrecto

durante la polimerización

– Por encima de la marca roja:

– Polimeriza el material de la cápsula; se hace imposible

una inyección continuada durante la polimerización

– Pérdida de material por polimerización del posible

material sobrante.

– Por debajo de la marca roja:

– Zonas del paladar, línea de Post Dam o zonas

retromolares parcialmente sin polimerizar

Enfriamiento

La unidad SR Ivocap se extrae del agua hirviendo una vez

transcurridos los 35 minutos de polimerización y se enfría

directamente en agua fría.

Durante los primeros 20 minutos, la presión de la brida

y la de inyección debe ser constante.

A los 20 minutos se puede retirar el inyector. Sin embargo, la

brida con la mufla deben permanecer otros diez minutos en

agua fría.

Tiempo total de enfriamiento: 30 minutos.

Una llave de paso en el inyector permite mantener la presión de inyección durante el enfriamiento, independientemente del suministro de aire comprimido. Ello se traduce

en una mayor movilidad, ya que la bañera de enfriamiento

no tiene que estar necesariamente cerca de la conexión de

aire comprimido.

Desenmuflado

Colocar la brida en la prensa y volver a cargar con

3 toneladas. Desplazar la uñeta (B1) hacia la izquierda y

eliminar la presión. Retirar la mufla de la brida.

Procedimiento recomendado:

– Retirar ambas tapas de plástico de la mufla. Colocar la

mufla con la parte más delgada hacia delante en la prensa.

Colocar una plantilla adecuada entre el yeso y el plato de

la prensa de tal forma que no toque directamente la mufla.

Cargar a continuación con presión mínima (fig. 19)

– Introducir un destornillador ancho en la ranura al lado de la

espiga guía y levantar la mitad superior de la mufla (fig.

19)

– Retirar la mufla de la prensa, girar la misma y volver a

repetir el proceso. El yeso se puede eliminar de la mufla sin

problemas y sin necesidad de ejercer fuerza (p.e.: martillo)

– La eliminación del yeso se hace de forma habitual

– Acabado y pulido como de costumbre

– También pueden utilizarse aparatos para desenmuflar

Reparaciones

Para realizar reparaciones se recomiendan las resinas autopolimerizables Ivoclar Vivadent, las cuales están disponibles en

todos los colores SR Ivocap. Las instrucciones de uso de dichos

materiales de Ivoclar Vivadent, explican detalladamente los

métodos de reparación. Rogamos observen las instrucciones de

uso de cada uno de los aparatos.

Condiciones de almacenamiento

– Conservar el material en un lugar fresco, oscuro y bien

ventilado

– Sin mezclar: A temperatura ambiente (2–28ºC /

36–82ºF)

– Mezclado: Máx. 5 días en lugar fresco y protegido de la

luz a 8ºC / 46ºF

– En caso de almacenamiento en frigorífico, sacar la cápsula

una hora antes de su utilización para que alcance la tempe-

ratura ambiente

– No utilizar el producto una vez caducado

– Mantener fuera del alcance de los niños

Clasificación según ISO 20795-1

Tipo I, classe 1

Fecha de elaboración de estas Instrucciones de

uso: 11/2010

Fabricante

Ivoclar Vivadent AG, FL-9494 Schaan / Liechtenstein

El material ha sido fabricado para uso dental y debe manipularse según instrucciones de uso. El

fabricante no se hace responsable de los daños ocasionados por otros usos o una manipulación

indebida. Además, el usuario está obligado a comprobar, bajo su propia responsabilidad, antes

de su uso si el material es apto para los fines previstos, sobre todo si éstos no figuran en las

instrucciones de uso.

24

Page 29

Esquema de utilización

Inyector de presión

Aire compri

mido 6 bar

Cápsula

Soporte mural para

4 inyectores de presión

(sobre pedido)

Introducir en

baño de agua fría

Nivel de agua

Inyección 5 minutos

Polimerización – 35 minutos en

agua hirviendo

Enfriamiento en baño de agua fría –

mínimo 30 minutos de ellos 20 minutos con

presión de inyección

Soportes

Mufla

Marca roja

25

Page 30

Plano de instalación

Acoplamiento

Presión del aire 6 bar

Prensa hidráulica,

3t u 80 bar

Cap Vibrator

Bañera de

Nivel del baño de agua

polimerización

Salida de agua

Entrada agua

Agua fría

caliente

Manguera flexible de presión

(200 cm largo)

6 bar de

presión

Soporte mural para

inyectores

26

Temporizador

Page 31

Português

321

Instruções de Uso

Descrição

O Sistema SR Ivocap é uma técnica de injeção especificamente

desenvolvida para compensar a contração de polimerização.

Esta forma de polimerização, com calor/pressão, possibilita que

a contração do acrilato, ocorrida durante a polimerização, seja

compensada pela constante injeção de material.

Além disto, a técnica de injeção SR Ivocap permite a confecção

de produtos de alta qualidade, com excelentes propriedades

físicas.

Composição

SR Ivocap High Impact, SR Ivocap Clear

Pó:

Polymethyl methacrylate, Co-polymer, Benzoyl peroxide,

Pigmentos

Líquido:

Methyl methacrylate, Dimethacrylate (cross-linking agent),

Co-polymer

SR Ivocap Clear

Pó:

Polymethyl methacrylate, Dibenzoyl peroxide

Líquido:

Methyl methacrylate, Dimethacrylate (cross-linking agent)

Lista de partes

SR Ivocap System

A) Aparelho de injeção "ID2”

A1 = Manômetro

A2 = Pistão de extrusão

A3 = Haste da morsa

A4 = Presilha de segurança

B) Prensa de polimerização

B1 = Lingüeta da alavanca de empuxo

B2 = Anel de pressão com alavanca

B3 = Placa de prensagem

C) Mufla

C1 = Metade inferior da mufla

C2 = Metade superior da mufla

C3 = Tampa da mufla

C4 = Funil de injeção

D) Êmbolo da cápsula

E) Auxiliar de inclusão

F) Funil

G) Timer

Indicação

SR Ivocap High Impact, SR Ivocap Clear

– Próteses totais.

– Próteses parciais.

– Placas bases e reembasamentos.

– Placas de mordida e registros de articulação.

Contra-indicação

– Contato intra-oral direto com o material não polimerizado.

– Quando existir comprovada alergia a qualquer um dos seus

componentes.

Importante

– Não umectar os dentes com o monômero SR Ivocap, por-

que isto debilita a ligação do material com os dentes.

– Embeber completamente os modelos, antes da inclusão.

– Isolar completamente as superfícies internas da mufla,

antes da inclusão.

– Os canais de injeção devem possuir 3–5 mm de diâmetro.

– Limpar e isolar completamente as superfícies de gesso.

– Observar, de modo rigoroso, os tempos de polimerização e

de esfriamento.

– Não conservar o material misturado por mais de cinco dias,

porque o monômero pode evaporar.

– O contato de solventes ou do monômero com o material de

base de prótese pode causar descoloração branca.

– Entretanto, se as áreas cervicais têm de ser isoladas quan-

do o procedimento SR Ivocap está sendo empregado,

Ivoclar Vivadent recomenda o uso do Sil-Tech

Outros produtos podem causar reações desfavoráveis no

material de base de prótese.

Advertências

– O monômero contém metilmetacrilato.

– MMA é altamente irritante e inflamável (ponto de

inflamação: 10ºC/50°F).

– O monômero pode irritar olhos, pele e órgãos respiratórios.

– Contato com a pele pode resultar em sensibilização.

– Evitar o contato da pele com o monômero ou com o

material não polimerizado. Luvas médicas comerciais não

promovem proteção contra o efeito de sensibilização dos

metacrilatos.

– Não inalar os gases.

– Manter o material distante de fontes de calor – não fumar.

– Não descartar o monômero em sistemas de drenagem.