Page 1

Pirani Gauge Display

PGD400

set

tinb14e1 (2009-07) 1

Operating Manual

Incl. EC Declaration of Conformity

Page 2

Product Identification

In all communications with INFICON, please specify the information on the product nameplate. For convenient reference copy

that information into the space provided below:

PGD400

100-240V 50/60Hz 30VA

P/N: S/N:

INFICON Instruments (Shanghai) Co.,Ltd.

Validity

This document applies to products with part number 398-800.

The part number (PN) can be taken from the product nameplate.

This document is based on firmware number F-1.01.

If your unit does not work as described in this document, please

check that it is equipped with the above firmware version

(→ 19).

We reserve the right to make technical changes without prior

notice.

All dimensions are indicated in mm.

2

Made in China

tinb14e1 (2009-07)

Page 3

Intended Use

The PGD400 is used together with an INFICON Pirani Standard

Gauge of the PSG5xx series for total pressure measurement. All

products must be operated in accordance with their respective

Operating Manuals.

Scope of Delivery

1× Pirani Gauge Display

1× Power cord

1× Operating Manual

tinb14e1 (2009-07) 3

Page 4

Contents

Product Identification 2

Validity 2

Intended Use 3

Scope of Delivery 3

1

Safety 6

1.1 Symbols Used 6

1.2 Personnel Qualifications 7

1.3 General Safety Instructions 7

1.4 Liability and Warranty 8

2 Technical Data 9

3 Installation 12

3.1 Installation in a Control Panel 12

3.2 Mains Power Connector 14

3.3 SENSOR Connector 15

3.4 OUTPUT Connector 16

4 Operation 18

4.1 Front Panel 18

4.2 Turning the PGD400 On and Off 19

4.3 Operating Modes 20

4.4 Measurement Mode 21

4.5 Parameter Mode 22

4.5.1 Parameters 24

5 Maintenance, Repair 26

6 Troubleshooting 27

7 Repair 29

8 Storage 29

9 Disposal 30

4

tinb14e1 (2009-07)

Page 5

Appendix 31

A: Default Parameters 31

B: Literature 31

EC Declaration of Conformity 32

For cross-references within this document, the symbol (→ XY)

is used, for cross-references to further documents, listed under

"Further Information", the symbol (→ [Z]).

tinb14e1 (2009-07) 5

Page 6

1 Safety

1.1 Symbols Used

DANGER

Information on preventing any kind of physical injury.

WARNING

Information on preventing extensive equipment and environmental damage.

Caution

Information on correct handling or use. Disregard can lead to

malfunctions or minor equipment damage.

Further symbols

The lamp/display is lit.

The lamp/display is dark.

set

Press the key (example: 'set' key).

Do not press any key

6

tinb14e1 (2009-07)

Page 7

1.2 Personnel Qualifications

Skilled personnel

All work described in this document may only be carried out by

persons who have suitable technical training and the necessary experience or who have been instructed by the end-user

of the product.

1.3 General Safety Instructions

Adhere to the applicable regulations and take the necessary

precautions for all work you are going to do and consider the

safety instructions in this document.

DANGER

DANGER: mains voltage

Contact with live parts is extremely hazardous

when any liquids penetrate into the unit.

Make sure no liquids penetrate into the equipment.

tinb14e1 (2009-07) 7

Page 8

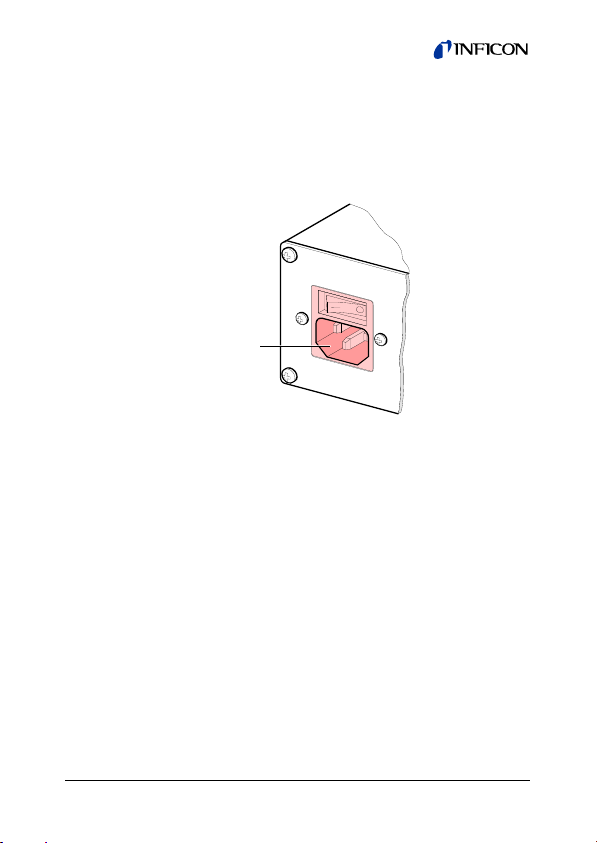

Disconnecting device

The disconnecting device must be readily identifiable and easily

reached by the user.

To disconnect the controller from mains, you must unplug the

mains cable.

Disconnecting device

acc. to EN 61010-1

Communicate the safety instructions to all other users.

1.4 Liability and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

• disregard the information in this document

• use the product in a non-conforming manner

• make any kind of interventions (modifications, alterations etc.)

on the product

• use the product with accessories not listed in the product

documentation.

8

tinb14e1 (2009-07)

Page 9

2 Technical Data

Mains specifications

Voltage 100 … 240 VAC

Frequency 50 … 60 Hz

Power consumption

Overvoltage category II

Protection class 1

Connection European appliance connector

Ambiance

Temperature

Storage

Operation

Relative humidity

Use indoors only

Pollution degree II

Degree of protection IP20 (EN 60529)

Compatible gauges

Number 1

Compatible types PSG500, PSG500-S,

Gauge connection

SENSOR connector RJ45 (FCC68), female

Operation

Front panel via 3 keys

≤30 VA

IEC 320 C14

–20 … +60 °C

+ 5 … +50 °C

≤80% up to +31 °C,

decreasing to 50% at +40 °C

max. altitude 2000 m NN

PSG502-S, PSG510-S,

PSG512-S

(pin assignment → 16)

tinb14e1 (2009-07) 9

Page 10

Measurement values

Measurement range

(air, O

, CO, N2)

2

Measurement error

Gain error

Offset error

-4

… 1000 mbar

5×10

(+1.9 … +10.0 VDC)

(→ [1])

≤0.02% FSr

≤0.05% FSr

Measurement rate 30 / s

Display rate 50 / s

Filter time constant 150 ms (f

Pressure units mbar, Pa, Torr

= 1 Hz)

g

Gauge supply

Voltage

+24 VDC ±5%

Current 750 mA

Power consumption 18 W

Fuse protection 900 mA with PTC element, self-

resetting after turning the

PGD400 off or disconnecting the

gauge

Switching function

Number 1

Reaction delay

≤10 ms if switching threshold

close to measurement value (for

larger differences consider filter

time constant).

-3

Adjustment range 1×10

Hysteresis

… 500 mbar

≥10% of measurement value

10

tinb14e1 (2009-07)

Page 11

Switching function relay

Contact type floating changeover contact

Load max. 60 VDC, 1 A (ohmic)

50 VAC, 5 A (ohmic)

Service life

Mechanic

Electric

Contact positions

8

cycles

10

5

cycles (at maximum load)

10

→ 17

OUTPUT connector 9-pole D-Sub, male

(pin assignment → 17)

Analog output

Number 1

Voltage range 0 … +10 V

Internal resistance

Measurement signal vs.

pressure

660 Ω

logarithmic, 1.286 V/decade

OUTPUT connector 9-pole D-Sub, male

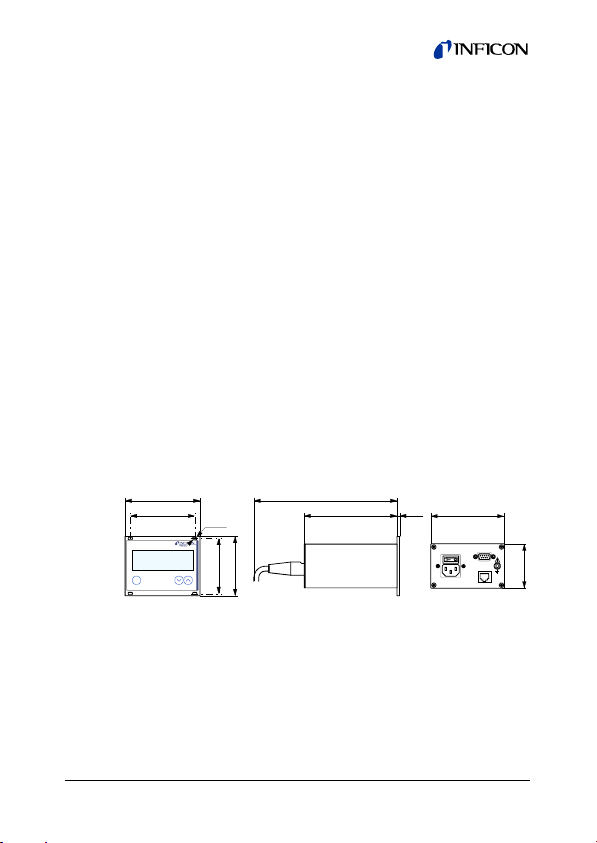

Dimensions [mm]

106.2

91.2

set

ø3

78

84

(pin assignment → 17)

212

131.5 3.5

104

OUTPUT

SENSOR

Use For incorporation into a control

panel

Weight 0.85 kg

62

tinb14e1 (2009-07) 11

Page 12

3 Installation

DANGER

DANGER: damaged product

Putting a damaged product into operation can be

extremely hazardous.

In case of visible damages, make sure the product

3.1 Installation in a Control Panel

The PGD400 is suited for incorporation into a control panel.

is not put into operation.

DANGER

DANGER: protection class of the control panel

If the product is installed in a rack, it is likely to

lower the protection class of the rack (protection

against foreign bodies and water) e.g. according to

the EN 60204-1 regulations for switching cabinets.

Take appropriate measures for the control panel to

meet the specifications of the protection class.

12

tinb14e1 (2009-07)

Page 13

For mounting the PGD400 into a control panel, the following cutout is required:

105

91.2

The admissible maximum

ambient temperature

→ 9) must not be

(

78

69

exceeded neither the air

circulation obstructed.

M3 or ø 3.5

For reducing the mechanical strain on the front panel, preferably

support the unit.

Slide the PGD400 into the cut-out of the control panel …

… and secure it with four M3 or equivalent screws.

tinb14e1 (2009-07) 13

Page 14

3.2 Mains Power Connector

DANGER

DANGER: line voltage

Incorrectly grounded products can be extremely

hazardous in the event of a fault.

Use only a 3-conductor power cable (3×1.5 mm

with protective ground. The power connector may

only be plugged into a socket with a protective

ground. The protection must not be nullified by an

extension cable without protective ground.

The unit is supplied with a 2 m power cord. If the mains cable is

not compatible with your system, use your own, suitable cable

with protective ground.

The socket must be fuseprotected with

10 A

max

Disconnecting device

acc. to EN 61010-1

If the unit is installed in a switch cabinet, the mains voltage

should be supplied and turned on via a central power distributor.

2

)

14

tinb14e1 (2009-07)

Page 15

Grounding

On the rear of the unit, there is a screw which can be used to

connect the unit to ground, e.g. using the grounding of the

pumping station.

Ground screw

3.3 SENSOR Connector

Connect the gauge to the SENSOR connector on the rear of the

unit. Use a screened 1:1 cable (electromagnetic compatibility).

Make sure the gauge is compatible (

DANGER

DANGER: protective low voltage

According to EN 61010, voltages exceeding

30 VAC or 60 VDC are hazardous.

tinb14e1 (2009-07) 15

Only connect a protective low voltage (SELV).

→ 9).

Page 16

Pin assignment SENSOR

Pin assignment of the

8-pole RJ45 appliance connector:

1

8

Pin Signal

4

Identification

1

Supply +24 VDC

2

Supply common GND

3

Signal input (Measurement signal+)

5

Signal common (Measurement signal–)

6

not connected

7

not connected

8

not connected

3.4 OUTPUT Connector

This connector allows to read the measurement signal and to

evaluate state of the floating switching function.

Connect the peripheral components to the OUTPUT

connector on the rear of the unit. Use a screened cable

(electromagnetic compatibility).

16

tinb14e1 (2009-07)

Page 17

DANGER

DANGER: protective low voltage

According to EN 61010, voltages exceeding

30 VAC or 60 VDC are hazardous.

Only connect a protective low voltage (SELV).

Pin assignment, Contact positions OUTPUT

Pin assignment of

5 1

the female 9-pole

D-Sub appliance

connector:

69

Pin Signal

1

Analog output 0 … +10 VDC

2

Chassis = GND

3

4

5

Pressure below

threshold

Pressure above

threshold or

power supply

turned off

9

not connected

8

not connected

not connected

6

not connected

7

tinb14e1 (2009-07) 17

Page 18

4 Operation

4.1 Front Panel

Measurement value in floating point or exponential

format or status messages

Warning/error

Switching function

status

Threshold

18

set

set

Operator keys

Pressure

unit

tinb14e1 (2009-07)

Page 19

4.2 Turning the PGD400 On and Off

Make sure the PGD400 is correctly installed and the specifications in the Technical Data are met.

Turning the PGD400 on

The power switch is on the rear of

the unit.

Turn the PGD400 on with the

power switch (or centrally, via a

switched power distributor, if the

unit is incorporated in a rack).

After power on, the PGD400 …

• automatically performs a self-test

• displays the firmware version F-1.01 for 3 s

• identifies if a gauge is connected

• activates the parameters that were in effect before the last

power off

• switches to the Measurement mode

Turning the PGD400 off

Turn the PGD400 off with the power switch (or centrally, via a

switched power distributor, if the unit is incorporated in a rack).

Wait at least 10 s before turning the PGD400 on again in

order for it to correctly initialize itself.

tinb14e1 (2009-07) 19

Page 20

4.3 Operating Modes

The PGD400 works in the following operating modes:

• Measurement mode

for displaying measurement values or status messages

→ 21)

(

• Parameter mode

for entering or displaying parameters (

→ 22)

20

tinb14e1 (2009-07)

Page 21

4.4 Measurement Mode

The Measurement mode is the standard operating mode of the

PGD400. Measurement values as well as status messages

(→ 27) are displayed in this mode.

Measurement mode

Measurement value

Status

>5 s

Power on

Parameter

mode

Pressure p

range

Measurement

tinb14e1 (2009-07) 21

Page 22

Getting to the Parameter mode

→ 22

4.5 Parameter Mode

The Parameter mode is used for displaying, editing and entering

parameter values.

Measurement

mode

Power on

>5 s

Parameter mode

Unit

Threshold

22

tinb14e1 (2009-07)

Page 23

Selecting a parameter

Ö The name of the parameter

Editing the parameter value

Ö Press key <1 s:

Ö Save the modificated parameter

e.g.:

Unit

is displayed as long as the key is

pressed or at least for 1 s.

Afterwards, the currently valid parameter value is displayed.

The value is increased / decreased

by 1 increment.

Press key >1 s:

The value is increased / decreased continuously.

value.

tinb14e1 (2009-07) 23

Page 24

4.5.1 Parameters

Switching threshold

The PGD400 has a switching function with one adjustable

threshold. The status of the switching function is displayed on

the front panel (

contact at the CONTROL connector (

Pressure pDisplay

→ 18) and can be evaluated via the floating

→ 16).

e

M

e

u

l

a

v

t

n

e

m

e

r

u

s

a

Hysteresis (10%

of threshold value)

Time t

24

4

3

2

function

Off On

Switching

e.g.:

4

3

2

4

3

2

Off

Value

The switching threshold defines the

pressure at which the switching function is activated when the pressure is

dropping.

(default)

tinb14e1 (2009-07)

Page 25

Pressure unit

Unit of measured values, thresholds etc.

Value

Ö mbar (default)

Ö Torr

Ö Pascal

tinb14e1 (2009-07) 25

Page 26

5 Maintenance, Repair

The product requires no maintenance.

Cleaning the PGD400

For cleaning the outside of the PGD400, a slightly moist cloth will

usually do. Do not use any aggressive or scouring cleaning

agents.

DANGER

DANGER: mains voltage

Contact with live parts is extremely hazardous

when any liquids penetrate into the unit.

Make sure no liquids penetrate into the equipment.

26

tinb14e1 (2009-07)

Page 27

6 Troubleshooting

Signalization of errors

Error messages

Possible cause and remedy / acknowledge-

ment

Interruption or instability in sensor line or

connector (Sensor error).

Possible cause and remedy / acknowledge-

ment

Pirani error (sensor defective).

Status messages

Ö Replace the sensor

Possible cause and remedy / acknowledge-

ment

0.5 V < measurement signal < 1.5 V

Ö Adjust the gauge (→ [1]).

10.3 V < measurement signal < 13.7 V

Ö Adjust the gauge (→ [1]).

tinb14e1 (2009-07) 27

Page 28

Technical support

If the problem persists after the message has been ack-

nowledged for several times and/or the gauge has been

exchanged, please contact your local INFICON service

center.

28

tinb14e1 (2009-07)

Page 29

7 Repair

Please contact your local INFICON service center.

INFICON assumes no liability and the warranty becomes null

and void if repair work is carried out by the end-user or third

parties.

8 Storage

Caution

Caution: electronic component

Inappropriate storage (static electricity, humidity

etc.) can damage electronic components.

Store the product in a bag or container. Observe

the corresponding specifications in the technical

data (

→ 9).

tinb14e1 (2009-07) 29

Page 30

9 Disposal

DANGER

DANGER: contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

N

Separating the components

After disassembling the product, separate its components according to the following criteria:

• Contaminated components

• Other components

30

when handling contaminated parts.

WARNING

WARNING: substances detrimental to the environment

Products or parts thereof (mechanical and electric

components, operating fluids etc.) can be detrimental to the environment.

Dispose of such substances in accordance with the

relevant local regulations.

Contaminated components (radioactive, toxic, caustic or biological hazard etc.) must be decontaminated in accordance

with the relevant national regulations, separated according to

their materials, and disposed of.

Such components must be separated according to their materials and recycled.

tinb14e1 (2009-07)

Page 31

Appendix

A: Default Parameters

Default User

-3

1.0

mbar

mbar

B: Literature

[1] www.inficon.com

Operating Manual

Pirani Standard Gauge

PSG500, PSG500-S, PSG502-S,

PSG510-S, PSG512-S

tina44e1

INFICON AG, LI–9496 Balzers, Liechtenstein

tinb14e1 (2009-07) 31

Page 32

EC Declaration of Conformity

We, INFICON, hereby declare that the equipment mentioned

below complies with the provisions of the Directive relating to

electrical equipment designed for use within certain voltage limits

2006/95/EC and the Directive relating to electromagnetic compatibility 2004/108/EC.

Pirani Gauge Display

PGD400

Standards

Harmonized and international/national standards and specifications:

• EN 61010-1:2001

measurement, control and laboratory use)

• EN 61326-1:2006

and laboratory use; general EMC requirements)

• EN 61326-2-2:2006

control and laboratory use; particular EMC requirements)

Signatures

INFICON AG, Balzers

6 July 2009 6 July 2009

(Safety requirements for electrical equipment for

(Electrical equipment for measurement, control

(Electrical equipment for measurement,

32

Dr. Urs Wälchli

Managing Director

Markus Truniger

Product Manager

tinb14e1 (2009-07)

Page 33

Notes

tinb14e1 (2009-07) 33

Page 34

Notes

34

tinb14e1 (2009-07)

Page 35

Notes

tinb14e1 (2009-07) 35

Page 36

LI–9496 Balzers

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

Original: English tinb14e1 (2009-07) reachus@inficon.com

t i nb14e1

www.inficon.com

Loading...

Loading...