For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Brush Cutters, Trimmers,

Pruners, Hedge Trimmers

Workshop Manual

101 89 22-26

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Workshop Manual

Brush cutters, Trimmers,

Pruners, Hedge trimmers

List of Contents

General recommendations 2

1. Starter 3

2. Ignition system 21

3. Fuel system 31

4. Centrifugal clutch 61

5. Angle gear 83

6. Cylinder and piston 93

7. Crankshaft and Crankcase 115

8. Hydraulic unit 139

9. Cutting equipment 145

10. T ools 153

The Manual covers the models:

265

250

240/245

225 / 232 / 235 / 240 RBD

122

32

Mondo

235 P

225 H 60 / 225 H 75

www.mymowerparts.com

1

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

General recommendations

Bear in mind:

!

Do not start the engine without the clutch drum and

driveline fitted as the clutch can become detached and

cause severe personal injury .

!

Do not touch hot components, e.g. the muffler and clutch

before they have cooled sufficiently to avoid burns.

!

Avoid getting fuel or oil on your skin or in your mouth.

Use a barrier cream on your hands. This reduces the risk

of infection and makes dirt easier to wash away.

Long term contact with engine oil can represent a health

hazard.

!

Never start the engine indoors. Exhaust fumes are poisonous!

– Wipe up oil spills from the floor immediately to avoid

slipping.

– Do not use tools that are worn or fit badly, for example on

nuts and bolts.

+ Always work on a clean bench.

+ Always work logically to ensure all parts are fitted correctly

and that nuts and bolts are tightened.

+ Use the special tools where recommended to be able to

carry out the work correctly and efficiently.

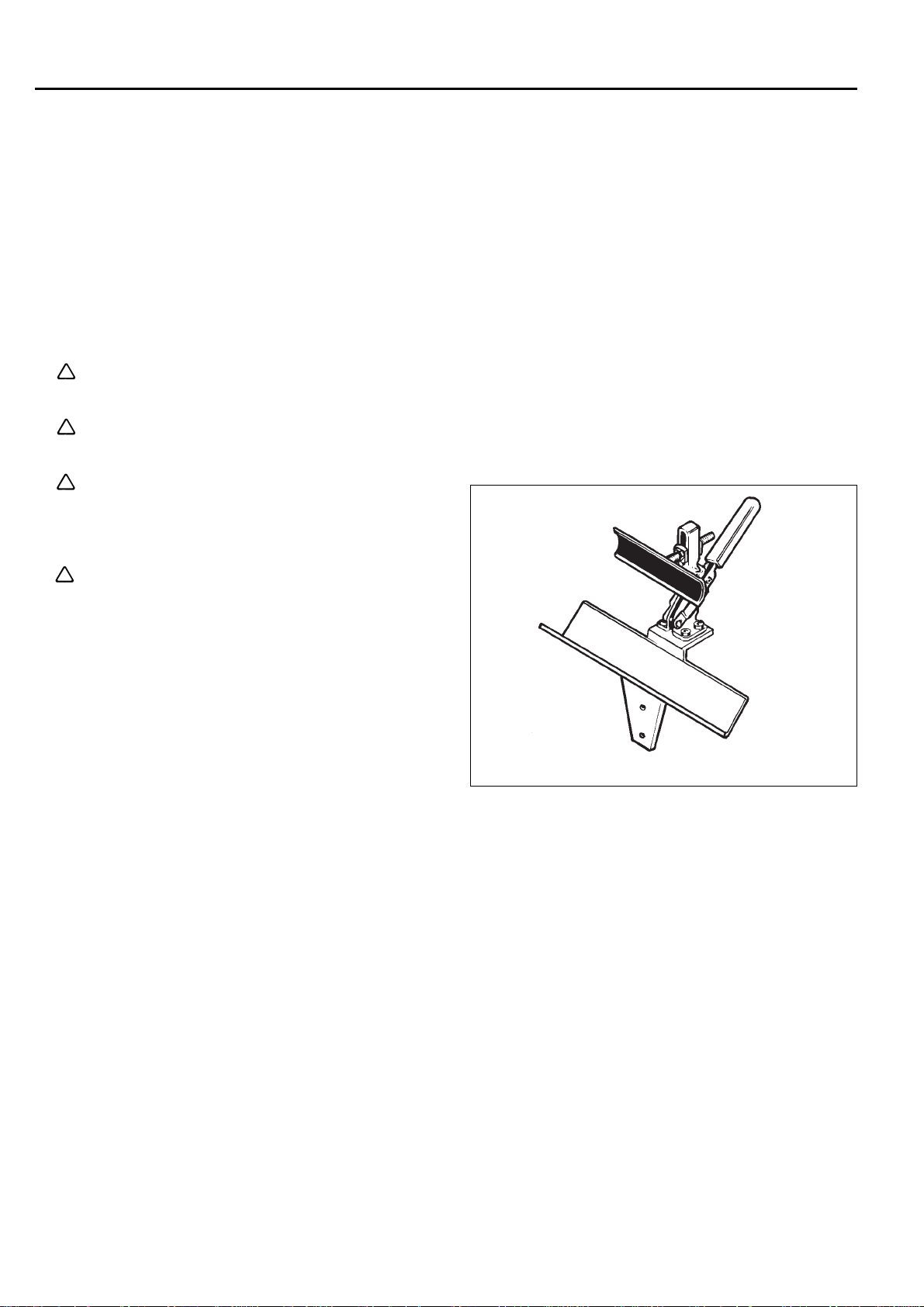

Special tools

Some of the work described in the Workshop Manual requires

special tools. In each section where this is necessary there is a

picture of the tool and an order number.

We recommend the use of special tools in order to avoid

expensive damage to parts in question and personal injury and

to provide an efficient repair procedure.

502 51 03-01

Fire risk

Handle fuel with respect as it is extremely inflammable.

Do not smoke and ensure there are no open flames or sparks

in the vicinity.

Make sure there is a working fire extinguisher close at hand.

Do not try to extinguish a petrol fire with water.

Poisonous fumes

When using cleaning agents read the instructions carefully.

Ensure there is good ventilation when handling petrol and

other volatile fluids.

The engine's exhaust fumes are poisonous. Test run the

engine outdoors.

2

Contact faces and gaskets

Ensure all surfaces are clean and free from gasket residue, etc.

When cleaning use a tool that will not damage the contact face.

Any scratches or unevenness should be removed using a flat

fine cut file.

Sealing rings

Always replace a sealing ring that has been dismantled. The

sensitive sealing lip can easily be damaged resulting in inferior

sealing capacity. Surfaces which the seal shall seal against

must also be completely undamaged. Lubricate the sealing lip

with grease before it is fitted and ensure that it is not damaged

e.g. by shoulders and splines on a shaft. Use tape or a conical

sleeve as protection. It is important that the sealing ring faces in

the right direction for it to act as it is intended.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

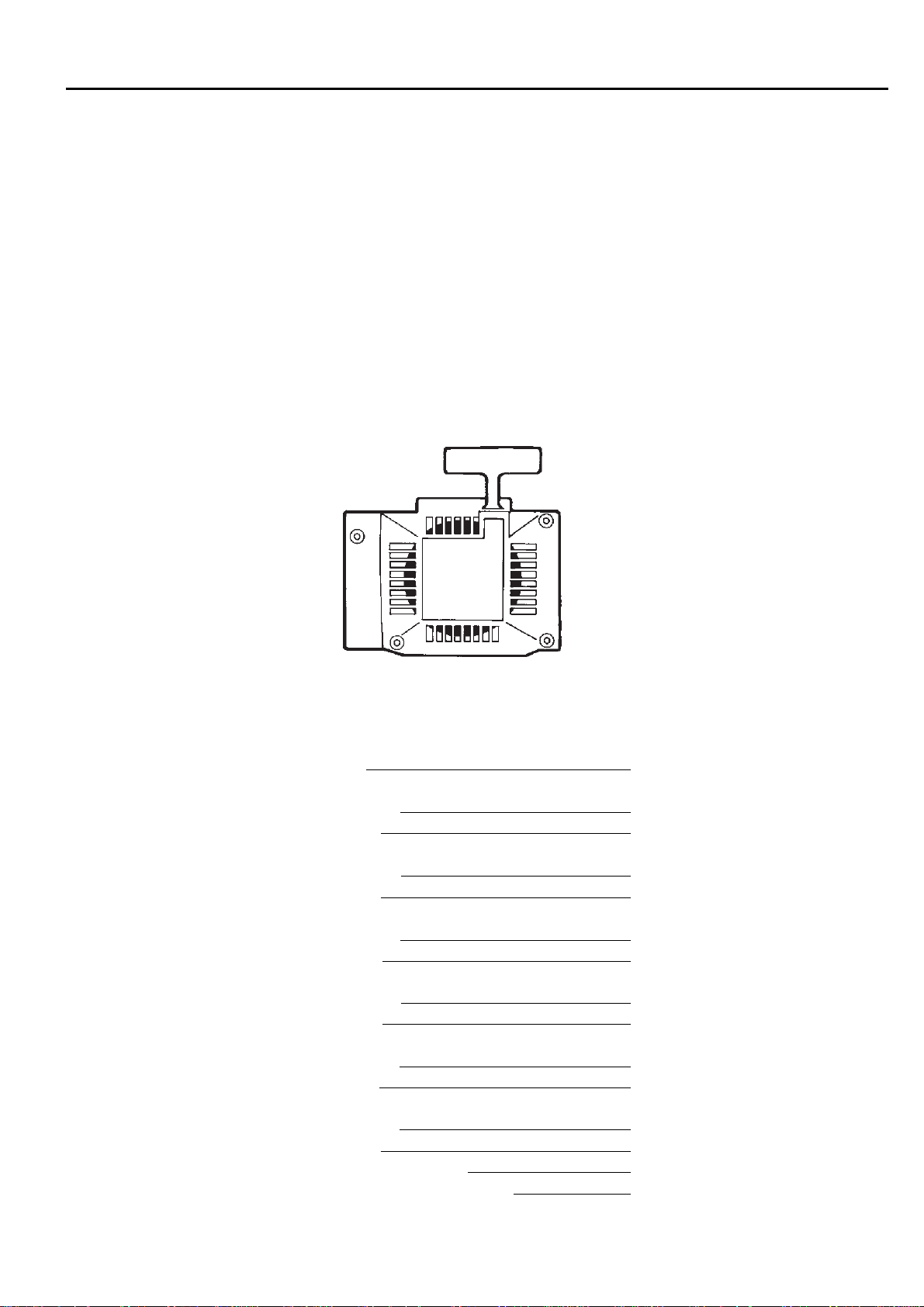

Starter

1.

Contents

Dismantling

General 4

Model 265

Dismantling 4

Assembly 5

Model 250

Dismantling 7

Assembly 8

Models 240/245

Dismantling 9

Assembly 10

Models 225, 232, 235, 240

Dismantling 11

Assembly 12

Model 122

Dismantling 13

Assembly 14

Models 32, Mondo

Dismantling 15

Assembly 17

Assembly, general 19

Replace the drive pawls 19

www.mymowerparts.com

3

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

!

WARNING!

Protective glasses should be worn when working on the starter to avoid injury to the eyes

if, for some reason, the return spring should fly out.

Dismantling

General

Dismantle the starter from the engine

body.

Dismantling

General

Remove all bolts and lift off the starter.

On some models the cylinder cover and

tank filler cap must be removed.

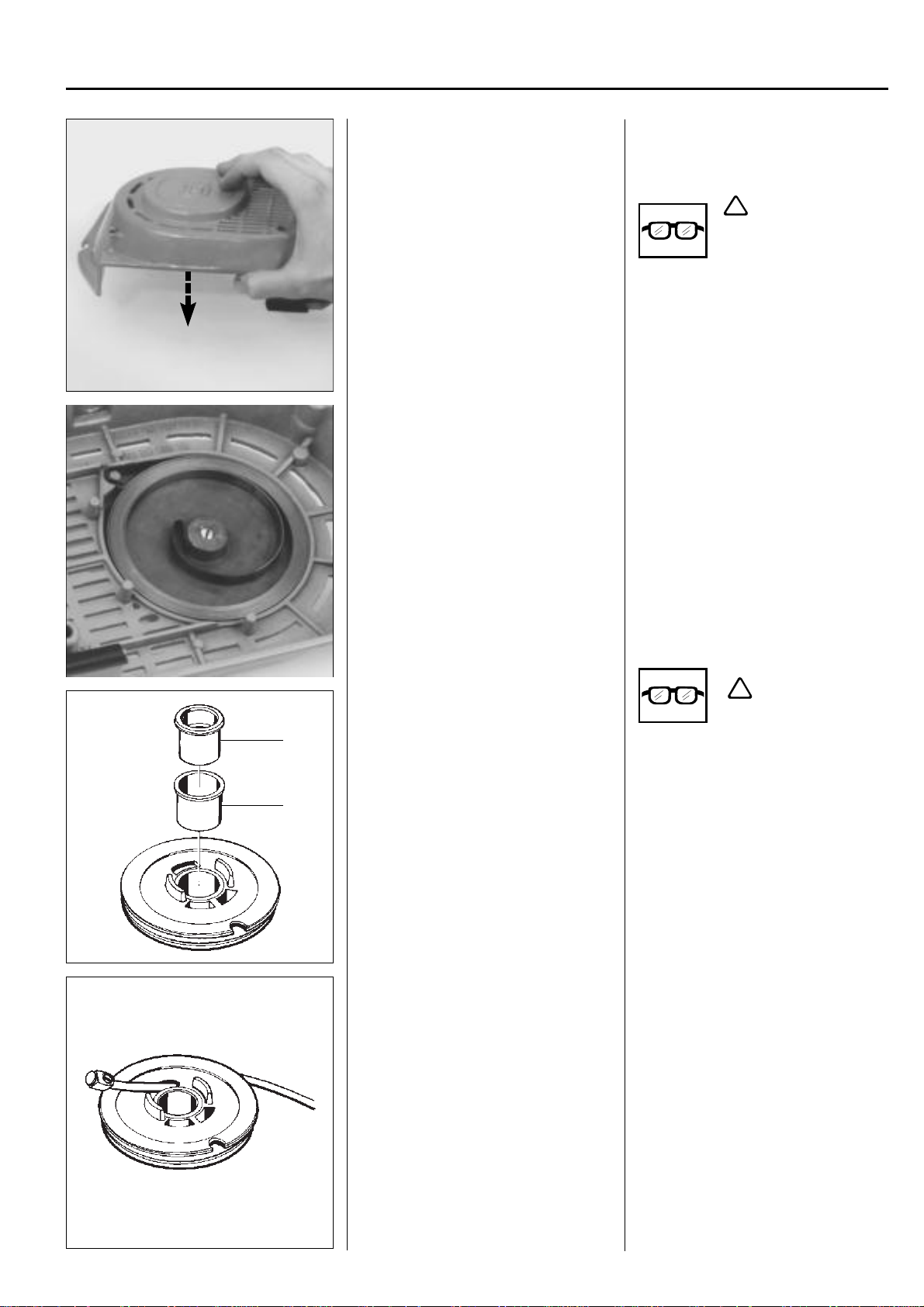

Model 265

Dismantling

Release the spring pressure.

Remove the screw and washer in the

centre of the starter pulley and bearing

sleeve.

Lift out the starter pulley.

Model 265

Dismantling

Release the spring pressure. Pull out the

starter cord approx. 30 cm.

Hold the starter pulley with your thumb

and place the cord in the cut-out on the

starter pulley rim.

Let the starter pulley slowly recoil.

NOTE!

Stop the spring with your thumb.

WARNING!

!

Take care not to injure your thumb

on the screw at the cord's fastening.

Remove the screw and washer in the

centre of the starter pulley and bearing

sleeve.

Lift out the starter pulley carefully so that

the spring does not follow and fly out.

!

WARNING!

Wear protective glasses. The return

spring can fly out and cause personal injury.

4

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

Remove the spring from the starter housing.

Assembly

Insert a new spring in the starter housing.

1

Remove the spring from the starter housing by knocking it against a bench with the

spring facing downwards.

!

WARNING!

Wear protective glasses.

Assembly

Fit a new return spring if necessary.

Let the spring retainer ring remain in

place.

1. Place the spring over its seating in the

starter housing

2. Push the spring into its right position

using your thumb and let the retainer

ring slide off the spring.

3. Lubricate the spring with a few drops

of oil.

NOTE!

Do not forget the Pertinax disc between

the spring and starter housing.

!

WARNING!

Wear protective glasses.

B

Check the starter pulley's bearing.

A

If necessary replace the sleeves (A) and

(B).

If necessary replace the starter cord.

Check the starter pulley's bearing. If it is

heavily worn the bearing sleeve (A) can

be replaced.

Cut out the sleeve and press in a new

sleeve.

If there is still too much play on the bearing a new metal sleeve (B) should also be

fitted.

If necessary replace the starter cord. Use

Husqvarna original pre-cut cord or cord

cut to the same length from a reel.

Thread the new cord through the hole in

the starter pulley as shown in the illustration and screw the plastic cube on the end

of the cord. Let it protrude approx. 3 mm

and melt it using a soldering iron to ensure a secure fastening is obtained.

www.mymowerparts.com

Tip!

The knot on the starter cord in the handle

can be difficult to undo. It is easier if you

place the knot on a hard surface and hit it

with a hammer.

5

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Wind the cord around the starter pulley

about 3 turns

pulley in the starter housing.

Fit the washer and screw that hold the

starter pulley.

B

clockwise

and position the

Wind the cord around the starter pulley

about 3 turns

pulley in the starter housing.

Check that the return spring grips the

starter pulley hub correctly.

Lubricate the bearing sleeve (B) with a

few drops of oil and insert the starter

pulley.

Fit the washer and screw.

Use Loctite on the screw.

clockwise

and position the

Fit the starter handle on the cord.

Tension the return spring.

Insert the cord through the cord guide in

the starter housing and anchor it in the

starter handle by tying a knot.

Fold down the free ends and pull the knot

fully into the starter handle.

To tension the return spring pull out the

starter cord fully and lift it into the cut-out

in the starter pulley.

Hold the pulley using your thumb then

tension the spring by turning the starter

pulley

clockwise

approx. 2 turns.

6

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Max

+ 1/2 r

Starter

Check the spring tension.

Model 250

Dismantling

Release the spring tension.

Remove the starter pulley.

1

Check the spring tension.

It should be possible to turn the starter

at least a further half turn

pulley

starter cord fully extended

Model 250

Dismantling

Release the spring tension in the same

way as described for model 265.

Remove the screw in the centre of the

starter pulley and lift out the pulley.

with the

.

Carefully remove the spring cassette so

that the spring does not fly out.

Check the starter pulley and starter housing for wear and damage.

Remove the screws and lift out the spring

cassette.

!

WARNING!

Wear protective glasses.

Despite the spring sitting in a cassette it

can still fly out when the cassette is pried

from the guide pin when inserting the

cord in the starter housing.

Check the following:

1. Wear on the drive pins on the starter

pulley.

If necessary replace the starter cord

as for 265RX and cord spec.

2. Nut in the nut pocket is in position and

the thread is undamaged.

3. Cord entry in the starter housing. If

worn the housing should be replaced.

www.mymowerparts.com

7

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Assembly

Fit a new spring cassette if necessary.

Fit the spring cassette in the starter housing.

Assembly

Lubricate the return spring with a few

drops of oil or a cold resistant grease.

Ensure the spring has been pressed down

to the bottom of the cassette especially at

the fastening points.

Press the spring cassette into the starter

housing and tighten the screws.

Check that the end of the spring is approx.

3 mm from the spindle to help assembly

of the starter pulley.

Lubricate the surface of the cassette with

oil or cold resistant grease.

Fit a new starter cord.

Fit the starter pulley.

Fit a new starter cord.

Tie a small knot on the cord and melt the

ends of the cord so that is does not fray .

Wind the cord approx. 3 turns

on the starter pulley.

wise

Tip!

First thread the cord straight through the

hole in the starter pulley and then back

again and out through the slot.

Lubricate the spindle in the starter housing with a few drops of oil and position the

starter pulley and tighten the screw.

Fit the starter handle as described for

model 265, but tie a double knot as the

cord is lighter.

anticlock-

8

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Max

Starter

Tension the return spring.

Check the spring tension.

1

To tension the return spring.

Wind the cord 2 turns

around the hub on the starter pulley and

pull out the starter handle until the cord is

extended.

Repeat the procedure once more.

NOTE!

With the starter cord fully extended it must

still be possible to turn the starter pulley

least a further half turn

anticlockwise

.

at

+ 1/2 r

Models 240/245

Dismantling

Release the spring.

Remove the starter pulley.

Lift out the spring cassette.

Models 240/245

Dismantling

Release the spring tension as described

for model 265.

Remove the screw and washer and lift out

the starter pulley.

!

WARNING!

Wear protective glasses.

The spring cassette sits freely in the starter

housing and can easily be lifted out to be

replaced.

www.mymowerparts.com

9

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Assembly

Check the starter housing for wear and

damage.

Fit the spring cassette.

Anchor the starter cord in the starter

pulley and wind it approx. 4 turns

wise

onto the pulley .

clock-

Assembly

Check the cord guide in the housing. If it

is worn the starter housing must be replaced.

Lubricate the spring with a few drops of oil

and position the spring cassette in the

starter housing.

Tie a small knot on the cord and seal the

ends by melting the cord ends, e.g. with a

soldering iron.

Anchor the starter cord in the starter

pulley and wind it about 4 turns

around the pulley.

Lubricate the bearing spindle with a few

drops of oil and fit the starter pulley in the

starter housing.

clockwise

Fit the starter pulley in the starter housing.

Fit the starter handle on the cord.

Position the washer and tighten the screw.

Fit the starter handle as described for

model 265, but tie a double knot as the

cord is lighter.

10

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Max

Starter

Tension the return spring.

Check the spring tension.

1

To tension the return spring

Wind the cord 2 turns clockwise around

hub on the starter pulley and pull out

the

the starter handle until the cord is fully

extended.

Repeat the procedure once more, but

only wind the cord 1 turn around the hub.

Check the spring tension.

NOTE!

With the starter cord fully extended it

must still be possible to turn the starter

pulley

at least a further half turn.

+ 1/2 r

Models 225, 232, 235, 240

Dismantling

Release the spring tension and dismantle the starter pulley.

Remove the spring cassette.

Models 225, 232, 235, 240

Dismantling

Release the spring tension as described

for model 265.

Remove the screw and washer and lift out

the starter pulley.

Remove the screw and lift out the spring

cassette from the starter housing.

!

WARNING!

Wear protective glasses.

www.mymowerparts.com

11

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Assembly

Check the starter housing for wear and

damage.

Fit a new spring cassette if necessary.

Fit a new starter cord. Specs as before.

Assembly

Check the cord entry.

If it is worn the starter housing must be

replaced.

Lubricate the return spring with a few

drops of oil and fit the cassette in the

starter housing.

NOTE!

The end of the spring should be 3–4 mm

from the spindle to help assembly of the

starter pulley.

Fit a new starter cord. Tie the smallest

knot possible on the cord and melt the

ends to stop it from fraying.

Wind the cord about 3 turns

on the starter pulley.

Position the starter pulley in the starter

housing and fit the washer and screw.

anticlockwise

Max

Fit the starter handle.

Tension the return spring.

Check the spring tension.

Fit the starter handle as described for

model 265.

Tension the return spring by winding the

starter cord 2 turns anticlockwise around

the

hub on the starter pulley.

Repeat the procedure once more, but

with the cord only wound once around the

hub.

NOTE!

With the starter cord fully extended it

must still be possible to turn the starter

pulley

at least a further half turn.

12

+ 1/2 r

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

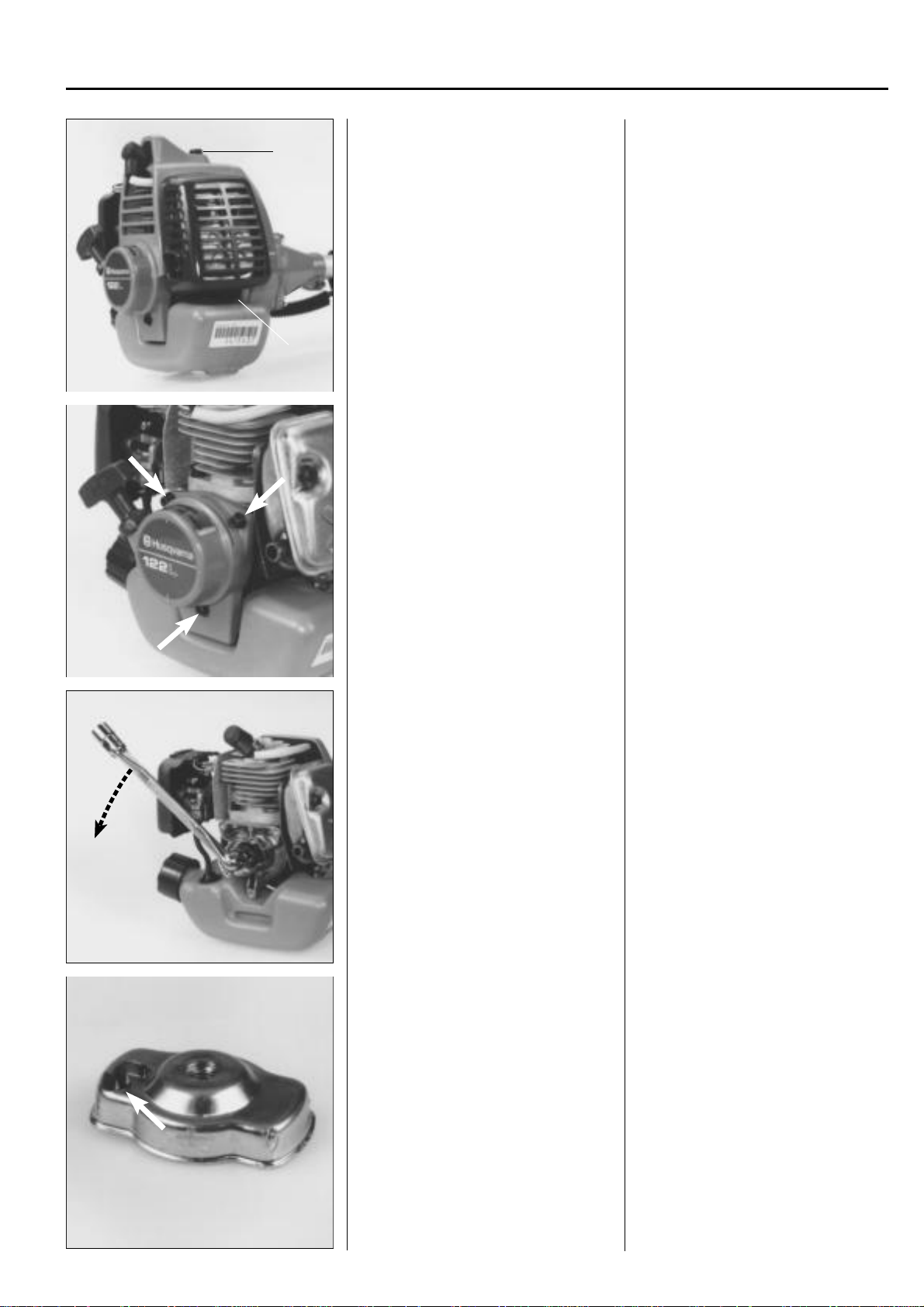

Model 122

2

1

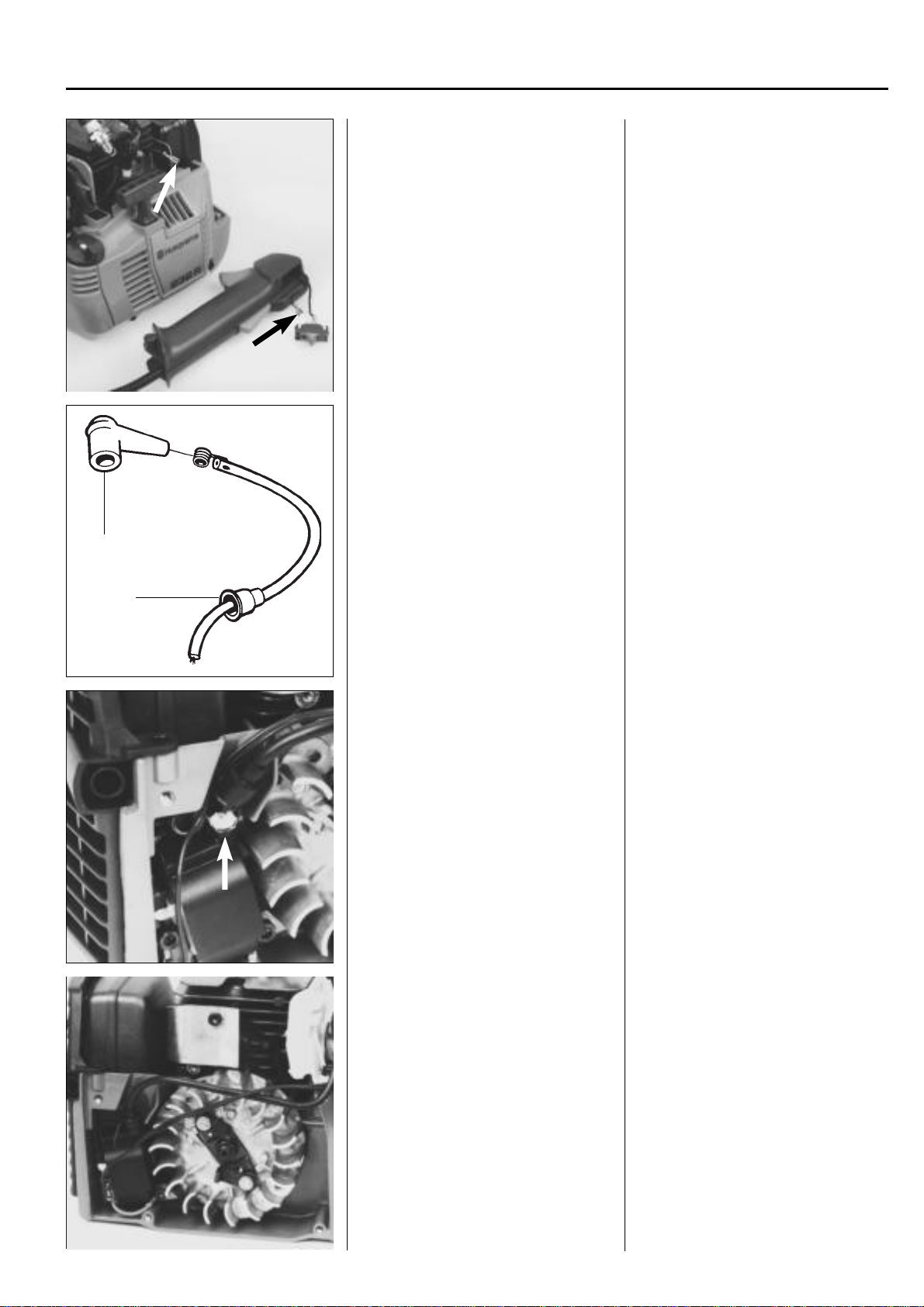

Dismantling

Remove the covers from the muffler and

cylinder.

Dismantle the starter from the engine

body.

Model 122

Dismantling

Y ou must first remove the covers over the

muffler and cylinder to be able to dismantle the starter.

Remove the screw (1), pull out the lower

edge of the cover and lift it off.

Remove the screw (2) and lift off the

cylinder cover.

Remove the screws and lift off the starter

from the engine body.

1

Remove the starter hub from the crankshaft.

Replace the drive dog if it is damaged or

worn.

Unscrew the hub from the crankshaft.

Use a hammer and punch to loosen the

hub if necessary.

NOTE!

The nut is brazed on the drive.

The drive dog and its spring can easily be

replaced if damaged or worn.

Squeeze together the drive dog's axle

stud with pliers when dismantling.

www.mymowerparts.com

13

!

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Release the spring tension and dismantle starter pulley.

Assembly

Fit a new return spring in the starter unit.

Release the spring tension as described

for model 265.

Remove the screw and washer and carefully lift out the starter pulley so that the

return spring does not fly out.

!

WARNING!

Wear protective glasses.

Assembly

Fit a new return spring in the starter unit.

Press the spring down correctly on the

fastener and lubricate with a few drops of

oil or cold resistant grease.

Ensure the ends of the spring are 2-3 mm

from the spindle.

Fit a new starter cord and position the

starter pulley in the starter housing. Cord

specs as before

Fit the starter handle.

Tension the return spring.

WARNING!

Wear protective glasses.

Fit a new starter cord. Tie the smallest

knot possible on the cord but leave free

an end of approx. 10 mm.

Press the free end into the cut-out in the

pulley hub reinforcement.

Wind the cord about 4 turns

(seen from the rear) on to starter pulley.

Position the starter pulley in the starter

housing and fit the washer and screw.

Fit the starter handle as described for

model 265, but tie a double knot on the

cord.

Lift up the starter cord from the cut-out

and wind it 2 turns

the

hub on the starter pulley . Pull out the

starter handle until the cord is fully extended.

Repeat the procedure once again.

anticlockwise

clockwise

around

14

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

+ 1/2 r

Max

Starter

Check the spring tension.

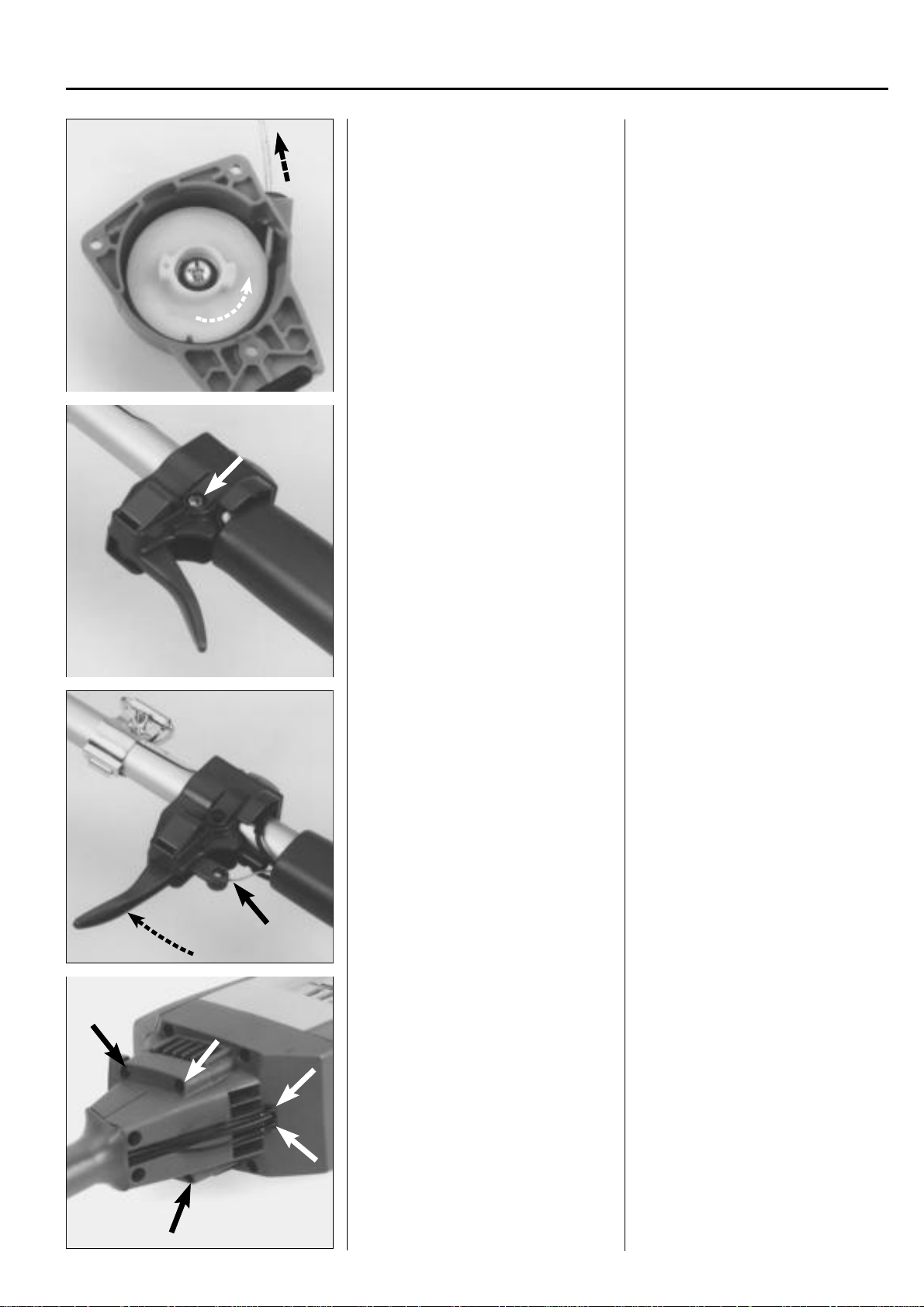

Models 32, Mondo

Dismantling

Remove the screws that hold the throttle

trigger.

1

NOTE!

With the starter cord fully extended it

must still be possible to turn the starter

pulley

at least a further half turn.

Fit the hub, starter and covers in the

reverse order set out for dismantling.

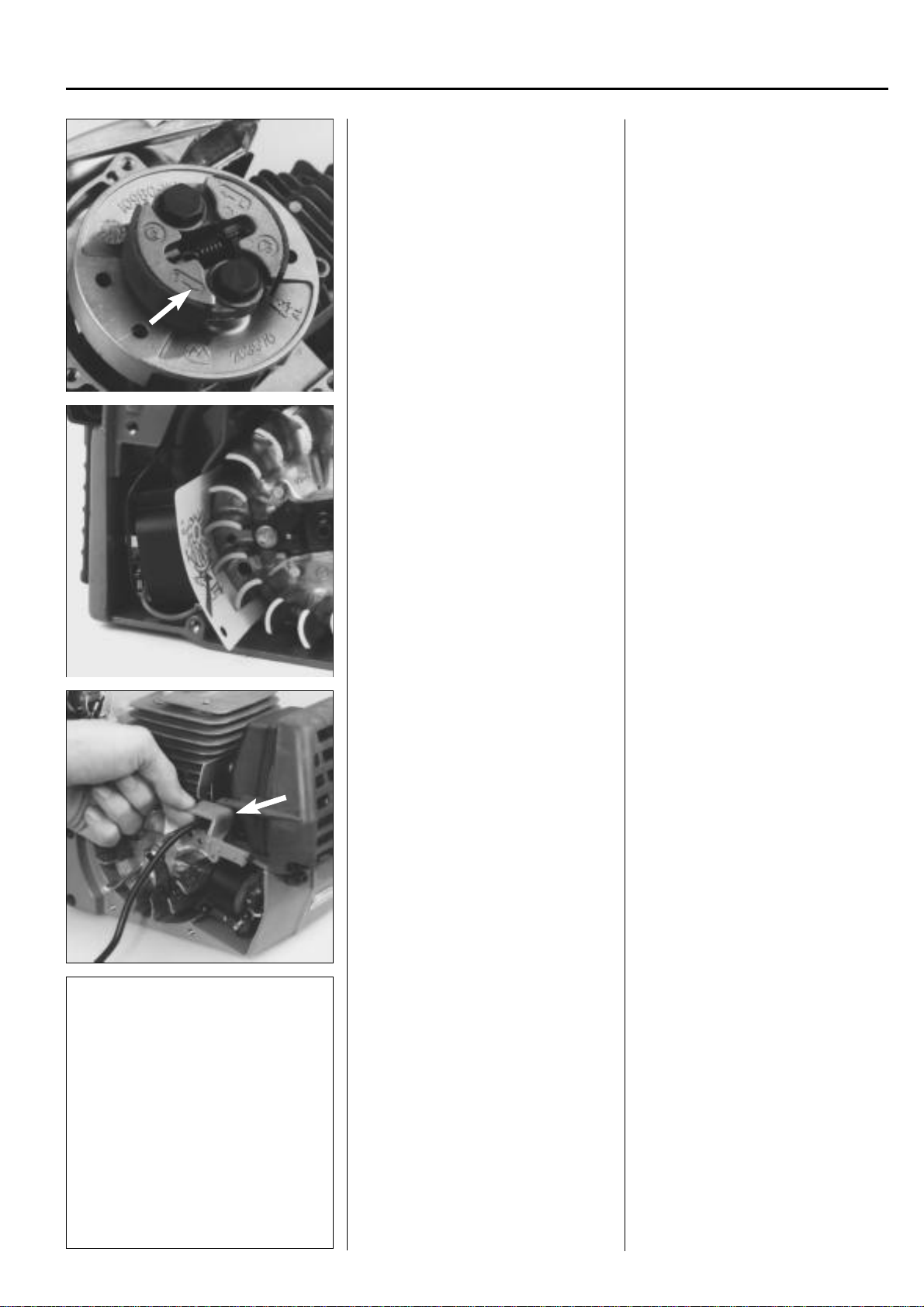

Models 32, Mondo

Dismantling

Remove the screws that hold the throttle

trigger and slide it along the shaft as far as

the throttle cable and electrical cables will

allow.

Lift out the throttle cable.

Disconnect the electrical cables.

Remove the shaft complete with handles.

Move the throttle trigger forward and lift

the throttle cable out of the trigger.

Disconnect the electrical cables from the

engine body, remove the 4 screws that

hold the shaft and handles on the starter

housing.

Lift off the shaft.

www.mymowerparts.com

15

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

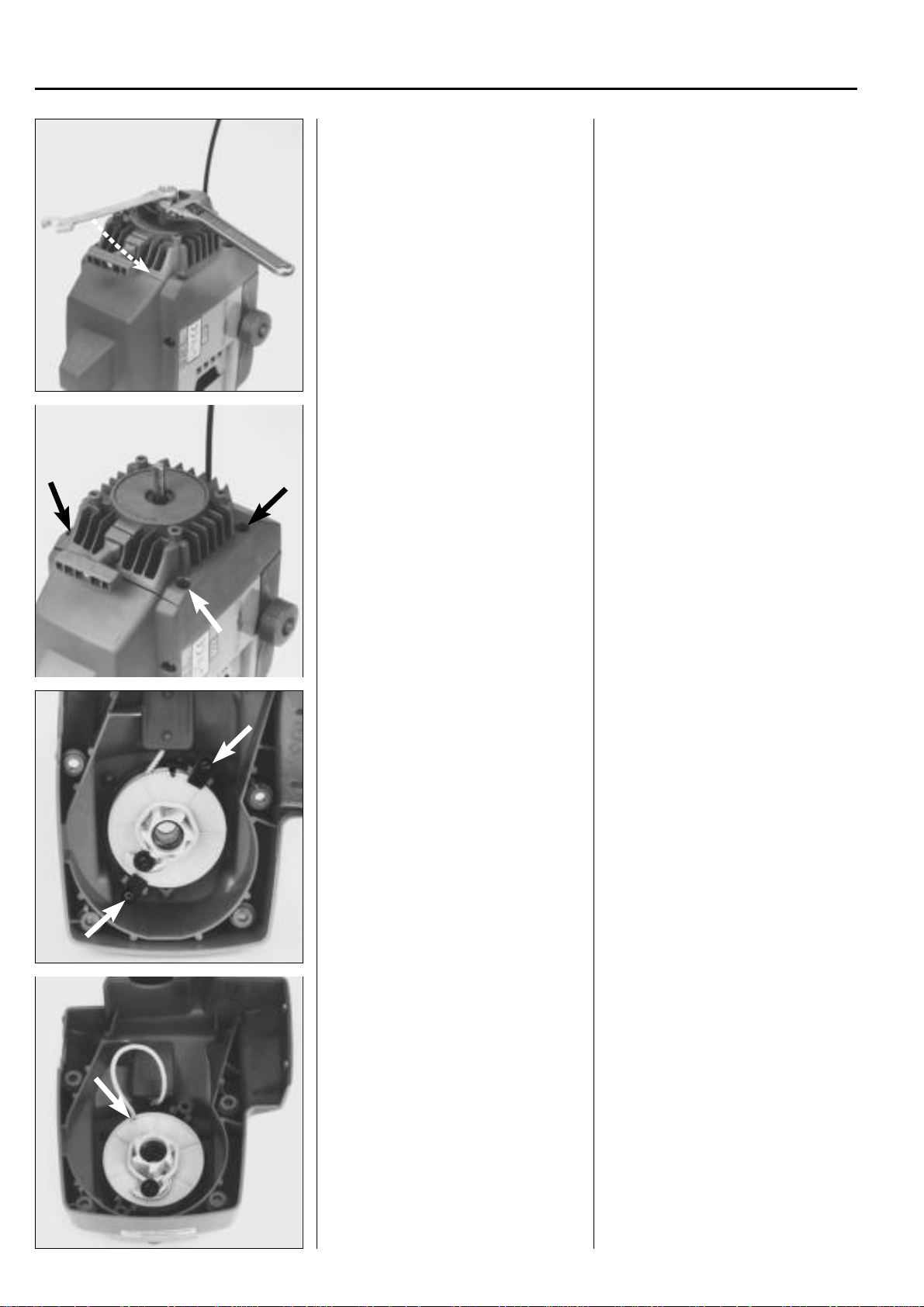

Dismantle the centrifugal clutch

Dismantle the starter.

Undo the nuts holding the centrifugal

clutch and lift off the clutch and the large

washer.

Remove the 4 screws and lift off the

starter.

Model Mondo

Also remove the screw by the spark plug.

Model 32

Pull out the electrical cables from the starter

housing using a pair of pliers.

Remove the two locking plates that hold

the starter pulley axially.

Release the spring tension.

Remove the two locking plates that hold

the starter pulley axially.

Release the spring tension.

Pull out the starter cord about 30 cm and

place the cord in the cut-out on the edge

of the starter pulley

16

www.mymowerparts.com

!

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

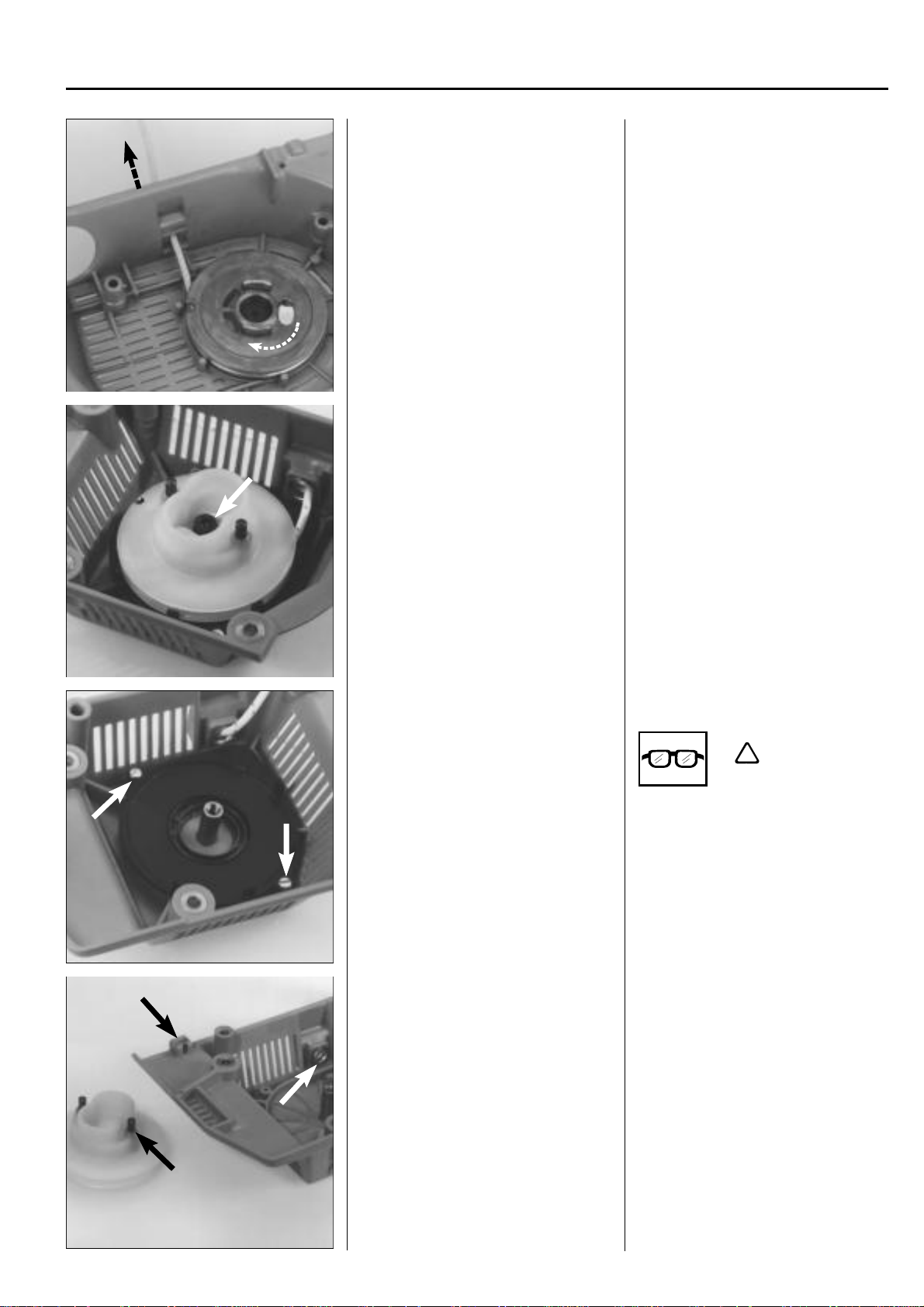

Starter

Let the starter pulley slowly rotate backwards.

Lift off the starter pulley.

Remove the return spring from the starter

housing.

1

Let the starter pulley slowly rotate backwards (anticlockwise) and then lift off the

pulley.

NOTE!

Stop the rotation using your thumb.

WARNING!

Take care so that your thumb is not

injured by the cord's fastening screw.

Exercise great care when removing the

starter spring.

The spring is tensioned inside a sheet

cassette, nevertheless it can still easily fly

out when dismantled.

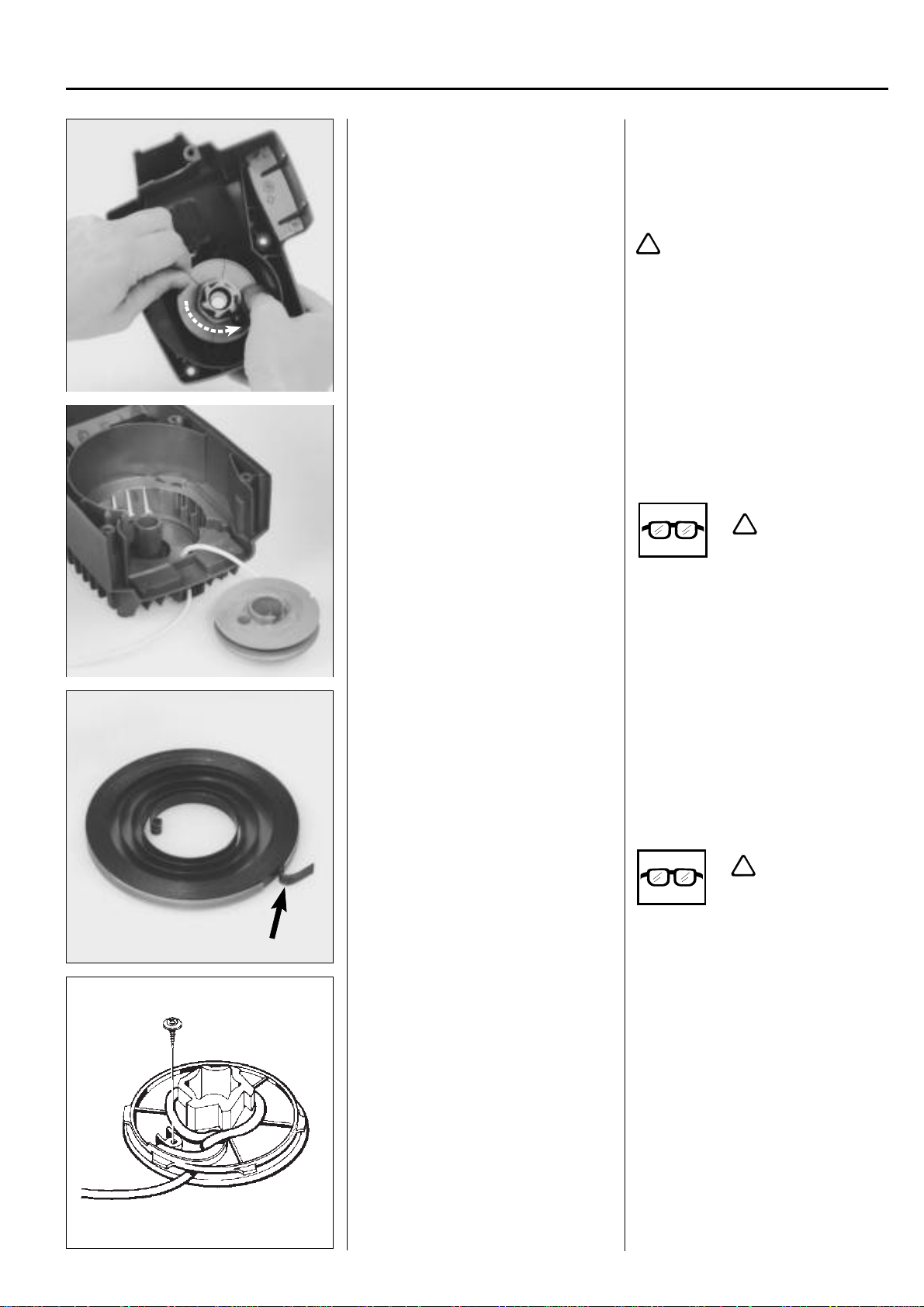

Assembly

Insert a new spring cassette in position in

the starter housing.

!

WARNING!

Wear protective glasses.

Assembly

Lubricate the return spring with a few

drops of oil and position the new spring

cassette in the starter housing.

If the spring, despite your being careful,

has flown out reposition it again in the

cassette with the end turned as shown in

the picture.

!

WARNING!

Wear protective glasses.

Replace the starter cord and attach it as

shown in the diagram.

www.mymowerparts.com

Attach the new starter cord to the starter

pulley and wind it about 3 turns

around the pulley.

clockwise

17

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

1

Starter

Fit the starter pulley.

Fit the starter handle.

Lubricate the pulley spindle with a few

drops of oil.

Ensure the end of the spring is about 2–

3 mm from the spindle and position the

starter pulley.

NOTE!

Do

not

tighten the locking plates that hold

the starter pulley axially.

Fit the starter handle as described for

model 265.

Tie a double knot on Mondo model.

Max

+1/2 r

Tension the return spring.

Repeat the spring tensioning and fit the

locking plates.

Tension the return spring.

● Pull out the cord approx. 30 cm and

stop the starter pulley with your thumb.

● Lift the cord up from one of the cut-

outs on the starter pulley.

● Wind the cord 2 turns

around the hub on the starter pulley.

● Pull out the starter cord fully.

Repeat the spring tensioning once more.

Ensure the starter pulley can still be turned

at least a further half turn

fully extended.

Tighten the locking plates that hold the

starter pulley axially.

NOTE!

Model 32 has a thin spacer under the

plates.

clockwise

with the cord

18

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Starter

Assembly , general

Assemble the starter following the reverse order set out for dismantling.

503 21 22-01

Replacing the drive dogs

See chapter 2 "Ignition system, flywheel".

1

Assembly , general

Assemble the starter.

Pull out the starter cord a little. Position

the starter. Release the starter cord and

ensure that the drive dogs grip in the

starter pulley.

Tighten the screws.

NOTE!

If the plastic threads in the crankcase

have, for some reason, been damaged it

is recommended to use an over dimensioned screw (no 503 21 22-01).

Replacing the drive dogs.

See chapter 2 "Ignition system, flywheel".

www.mymowerparts.com

19

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

20

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

2.

Contents

Checking the spark 22

Replacing the spark plug cover 24

Dismantling 25

Drive dogs 27

Assembly 28

www.mymowerparts.com

21

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

The engine is equipped with an electronic ignition

system with no moving parts. Consequently, a faulty

component cannot be repaired, but must be replaced

with a new one.

Checking the spark

Clean the electrodes and check the electrode gap.

The ignition spark in an electronic ignition system has a very short burn time and can be

judged to be weak and is at times difficult to see

when trouble shooting.

Checking the spark

Remove the spark plug and clean off any

carbon deposits using a wire brush.

Check the electrode gap, it should be 0.5

mm.

Adjust the gap to the correct size using

the side electrode.

If the electrodes are worn by more than

50% the spark plug should be replaced.

Check whether there is a spark when

attempting to start, if not test using spark

plug no. 502 71 13-01.

If the electrodes are worn by more than

50% the spark plug should be replaced.

An excessive spark gap can overload the

ignition module and risk short circuiting.

Ensure the stop switch is in the 'start'

position.

Earth the spark plug against the cylinder

and pull the starter handle sharply.

There should now be a spark between the

electrodes.

If there is no spark try using the test spark

plug no. 502 71 13-01.

If there is spark now the spark plug is

faulty.

Fit a new spark plug.

22

502 71 13-01

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

Fit a new spark plug.

If there is no spark disconnect the stop

switch.

Replace the switch if necessary.

Check the ignition lead's connections.

A

Fit a new spark plug.

If the procedure does not produce a spark

remove the short circuit cable from either

the ignition module or the stop switch.

If there is now a spark the stop switch is

faulty.

Replace the switch.

Still no spark?

Check the spark plug connections.

Pull back the rubber covers by the spark

plug (A) and the ignition module (B) and

check that the ignition cable is not damaged. Cut off a piece of the cable to give

a good connection if required.

2

B

Lubricate the cable ends with grease.

Check other cables and connections.

Lubricate the cable ends with a little grease

to facilitate assembly and to prevent dampness from entering the connections.

Still no spark?

Check other cables and connections for

bad contact (dirt corrosion, cable breaks

and damaged insulation).

www.mymowerparts.com

Tip!

Use an ohmmeter to check whether there

is a broken cable caused by crushing, for

example.

23

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

Check the air gap.

502 51 34-02

Adjust the air gap.

Still no spark?

Check the air gap between the flywheel's

magnet and the ignition module. The gap

should be 0.3 mm.

Use air gap gauge 502 51 34-02.

Model 122 should have a 0.38 mm gap.

Use air gap gauge 531 00 48-61

531 00 48-61 Mod. 122

Adjust the air gap to the right measurement.

● Loosen the screws.

● Insert the gauge and press the igni-

tion module against the flywheel.

● Tighten the screws and check the air

gap once again.

If there is still no spark the ignition system

should be replaced.

Changing the spark plug

cover

1. Push the ignition cable through the

spark plug cover.

2. Make a hole in the ignition cable for

the contact spiral.

502 50 06-01

3. Fit the contact spiral on the ignition

cable.

Changing the spark plug

cover

1. Lubricate the ignition cable using a

little grease and push it through the

spark plug cover.

2. Cut off a piece of the ignition cable

(about 5 mm) and make a hole in the

cable for the contact spiral using the

pliers no. 502 50 06-01.

3. Fit the contact spiral on the ignition

cable, taking care to form the wire

along the cable.

4. Pull the contact spiral into the spark

plug cover.

NOTE!

It is important that the point of the contact

spiral is positioned so that it's unable to

pierce the spark plug cover.

24

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

A

B

C

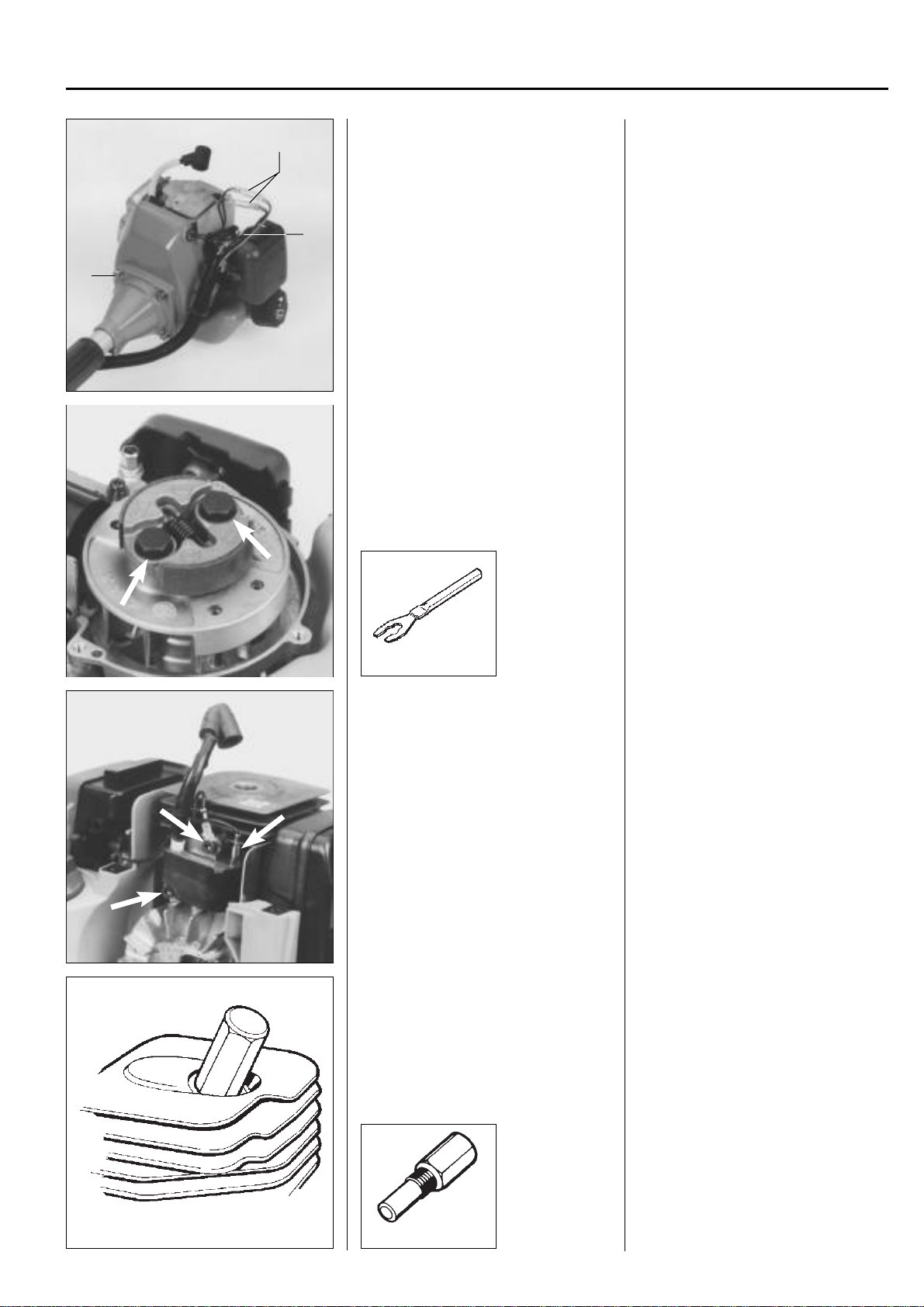

General

Remove all components necessary to

gain access to the flywheel and ignition

module.

Dismantle the fan cover and the centrifugal clutch.

531 00 48-62

Dismantling

Dismantling

General

Remove the cylinder cover, spark plug,

starter and air pipe support.

Model 32. Model Mondo

Remove the starter. See chap. 1 "Starter ."

Model 122

Pull apart the connector on the electrical

cables (A) and remove the throttle cable

from the carburettor lever (B).

Remove the screws (C) and lift off the

shaft.

Remove the screws and lift off the fan

cover.

Dismantle the centrifugal clutch by loosening the two bolts.

NOTE!

Hold the clutch carefully using a pipe grip

so that the soft clutch linings are not

damaged.

We recommend the use of tool no.

531 00 48-62.

Notice which way the clutch faces. The

"L"-markings on the clutch shoes face

outwards.

2

Dismantle the ignition module and loosen

other cable connections.

Fit the piston stop, no. 504 91 06-05 in the

spark plug hole.

Dismantle the ignition module by unscrewing the two bolts.

Loosen the other cable connections and

lift out the ignition module.

Fit the piston stop, no. 504 91 06-05 in the

spark plug hole.

Make sure the piston stop is screwed in

fully.

Carefully bring the piston into contact

with the stop before applying pressure on

the flywheel nut.

NOTE!

The piston stop cannot be used on model

122.

504 91 06-05

www.mymowerparts.com

25

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

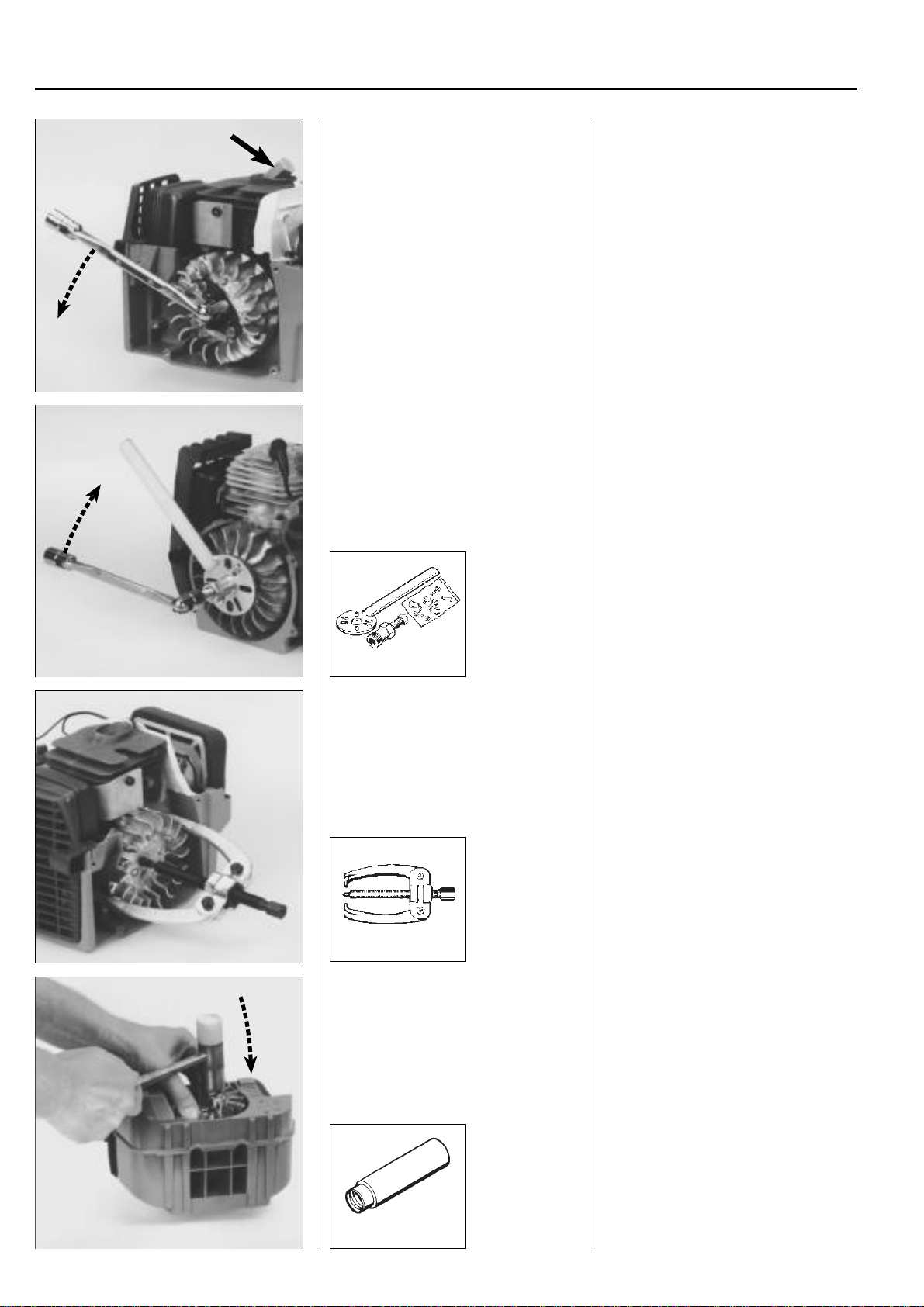

Model 240/245

Undo the flywheel nuts and the drive

pawls.

Dismantle the flywheel.

Model 265

Use the flywheel puller 502 51 49-01.

Model 240/245

Undo the flywheel nuts and the drive

pawls.

Remove the flywheel from the crankshaft.

Model 265

Fit the flywheel puller 502 51 49-01 on the

flywheel. Select suitable bolts and position the puller so that it pulls straight.

26

502 51 49-01

Model 240/245

Pull off the flywheel using the bearing

puller.

504 90 90-01

Model 225/232/235

Dismantle the flywheel by knocking with a

hammer.

502 51 94-01

Model 240/245

Pull off the flywheel using the bearing

puller no. 504 90 90-01.

NOTE!

The arms on the puller should be placed

by and opposite the magnet on the flywheel to avoid damaging it.

Is the flywheel really tight?

Lift up the engine body by holding the

puller and knock the puller screw a few

times with a hammer.

Model 225/232/235

Screw the nut on the axle to protect the

thread.

Unhook the springs and fold back the drive

dogs to give a little room for the hammer.

Grip the flywheel and lift up the engine

body.

Apply a few sharp blows with a hammer on

the flywheel nut until the flywheel frees

itself from the axel.

Tip!

Use the push bar to protect the tread at the

same time as it is easier to use the

hammer.

Do not screw the push bar completely up

to the flywheel – leave about 2 mm.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

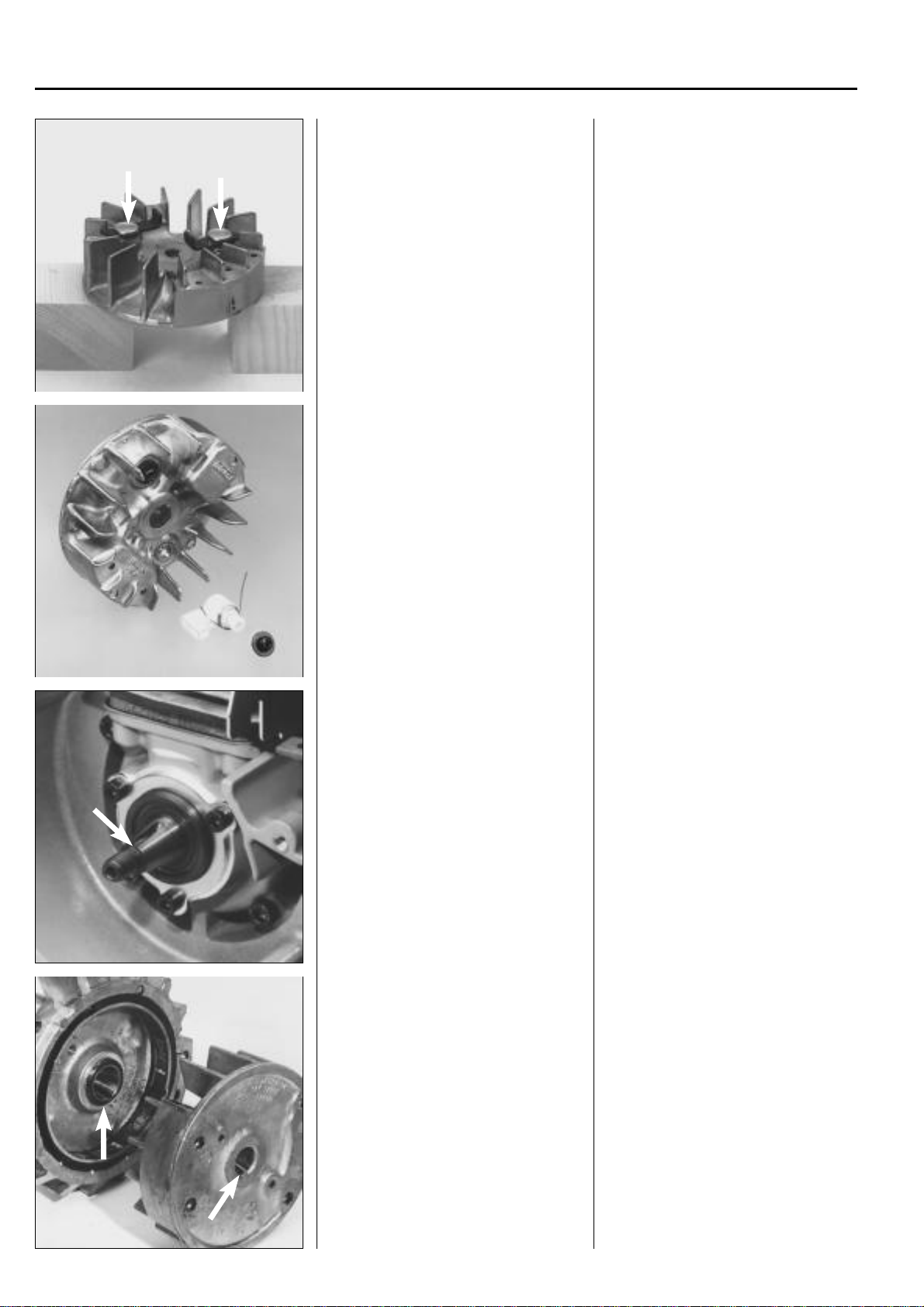

Drive pawls

Check the drive pawls with regard to wear

and cracking.

Replace damaged components.

Dismantle the locking clip. Turn the locking clip so that the opening

Drive pawls

Check the drive pawls with regard to wear

and cracking.

Replace damaged components.

The entire unit must replaced if the drive

dogs are fitted on a separate bridge.

aligns with the centre of the flywheel.

Use, e.g. punch no. 505 38 17-05 and

press off the clip.

2

505 38 17-05

Dismantle the drive pawls and the return

spring.

Unscrew the bearing pin.

Replace any damaged parts.

Press out the bearing studs using a suitable punch.

Dismantle the drive pawls and the return

spring.

Unscrew the bearing pin.

Replace any damaged parts.

Check that the drive pawls move easily.

NOTE!

The spring clip's opening should be turned

outwards between the fan fins.

Replace the drive pawls and springs as

follows if they are journalled on a stud

pressed into the flywheel:

Place the flywheel on support blocks and

press out the studs using a suitable punch.

www.mymowerparts.com

27

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

Ignition system

Replace damaged parts. Replace damaged parts.

Ensure the springs are not crushed when

the stud is pressed into the flywheel.

Check that the drive pawls move easily.

Model Mondo

The drive pawls can be dismantled once

the screws on the opposite side of the

flywheel have been removed.

Model Mondo

On these models the drive pawls are held

in place by screws, tightened from the

opposite side of the flywheel.

Dismantle the bolts and lift off the drive

pawls.

Assembly

Check that the keyway and key on the

crankshaft are not damaged.

Check that the keyway and cast key on

the flywheel are not damaged.

Fit the flywheel.

Assembly

Check that the keyway and key on the

crankshaft are not damaged.

Fit a new key if necessary and ensure it

sits correctly in the keyway .

NOTE!

If the crankshaft has two keyways it is the

keyway that is open all the way out to the

thread which is used if the flywheel has a

cast key.

Check that the keyway and cast key on

the flywheel are not damaged.

Fit the flywheel on the crankshaft and

check that key and keyway are correctly

aligned before the flywheel nut is tightened.

Tighten the nut to a torque of 25–35 Nm.

28

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Ignition system

Model 122

Turn the centrifugal clutch so that the "Lmarking on the clutch shoes is facing

outwards.

Fit the ignition module.

Adjust the air gap (0.3 mm).

Fit the other cables.

Fit the remaining components in the re-

verse order set out for dismantling.

2

Model 122

As the centrifugal clutch is fitted on the

flywheel it is important that it is positioned

so that the "L-marking" on the shoes

outwards.

faces

"L" means left rotation.

Fit the ignition module.

Adjust the air gap (0.3 mm).

Also see page 24.

Fit the other cables and ensure they sit

correctly in the cable channels, etc. so

that they cannot be damaged.

Fit the remaining components in the reverse order set out for dismantling.

Model 250

Do not forget to fit the heat guard for the

ignition cable.

Model 250

Fit the earth cable using the AMP connector on the ignition module before it is

screwed onto the crankcase.

NOTE!

Do not forget the plastic components that

protect the ignition cable from the radiant

heat from the muffler.

www.mymowerparts.com

29

Loading...

Loading...