For Husqvarna Parts Call 606-678-9623 or 606-561-4983

50, 50 Special, 51, and 55

Workshop Manual

531 03 00-76

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

This workshop manual is mainly intended for Husqvarna

50, 50 Special, 51, and 55 models, but certain chapters

can also be used for other models. The manual gives

information about how to repair the saw and how to use

special tools. In order to make sure that the saw will

function properly, always use Husqvarna original spare

parts and accessories.

The information, specifications and illustrations in this

manual are based on the information in effect at time of

printing. Any improvements or changes on these models

will be included in future manual revisions.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Page

2

3

4

5

6

7

Technical Specifications

Service Data

Service Tools

Safety Equipment

Rewind Starter

Ignition System

Centrifugal Clutch

2

3

3

4

12

15

22

8

9

10

12

13

Lubrication System, Oil Pump

Anti-Vibration System

Fuel System

Exhaust System

Cylinder & Piston

Crankcase & Crankshaft

26

30

32

47

46

51

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Engine

Displacement - cc (cu. in.)

Bore - mm (in.)

Stroke - mm (in.)

Max. power of speed - rpm

Idling speed - rpm

Clutch engagement speed - rpm

No load free speed - rpm

Ignition system - Electroiux

Air gap - mm (in.)

Spark plug - Champion

NGK

Electrode gap - mm (in.)

49 (3.0)

44(1 .73)

32(1 .26)

8400

2500

3700

12500

ET

0.3 (0.012)

RCJ7Y

BPMR6A

0.5 (0.020)

51 (3.1)

45(1 .77)

32(1 .26)

8400

2500

3700

12500

ET

0.3 (0.012)

RCJ7Y

BPMR6A

0.5 (0.020)

51 (3.1)

45(1 .77)

32(1 .26)

9000

2500

3700

12500

ET

0.3 (0.012)

RCJ7Y

BPMR6A

0.5 (0.020)

53 (3.2)

46(1 .81 )

32(1 .26)

9000

2500

3700

12500

ET

0.3 (0.012)

RCJ7Y

BPMR6A

0.5 (0.020)

Fuel and Lubrication System

Carburetor - Walbro

Fuel tank volume - Iitre (pint)

Oil tank volume - Iitre (pint)

Oil pump capacity at 6000 rpm

cc/rein. 7.0 7.0

Oil pump type

WA82 WA82

0.6 (1 .27)

0.3 (0.63) 0.3 (0.63) 0.3 (0.63)

Automatic Automatic

Bar and Chain

Bar length

cm

inch

Chain pitch

Chain speed

.325 m/see

3/8 m/see.

Drive link gauge - mm (in.)

Weight - kg (Ibs)

Weight with 38 cm (15 in.)

guide bar and chain - kg (Ibs)

37-45

15-18

.325

17.417t

****

1.5 (0.058)

5.2 (1 1.5)

6.2 (13.7)

WT170

0.6 (1 .27) 0.6 (1 .27)

7.0 7.0

Automatic Automatic

37-45

15-18

.325

17.417t

****

1.5 (0.058)

5.2 (1 1.5)

6.2 (13.7)

37-49

15-20

.325 or 3/8

17.417t

20.2/7t

1.5 (0.058)

5.2 (1 1.2)

6.2 (13.7)

WTl 70

0.6 (1 .27)

0.3 (0.63)

37-49

15-20

.325 or 3/8

17.417t

20.2/7t

1.5 (0.058)

5.2 (1 1.2)

6.2 (1 3.7)

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Service Data

& Service Tools

Service Data

Leakage Test

Crankcase/cylinder

Recommended pressure: 30 kPa (0.3 kp/cm2) (4 psi)

Maximum leakage: 20 kPa/30 sec. (0.2 kp/cm2)

(3

psi/30

see)

Service tools for test:

5025038-01

5049029-02

5025046-01

5025403-01

Pressure gauge

Intake/exhaust cover plate, 2 pieces

Sleeves, 2 pieces

Sleeves, 2 pieces

Leakage Test

Carburetor

Recommended pressure: 50 kPa (0.5 kp/cm2) (7.2 psi)

Maximum leakage: No leakage permitted

Service Tools

5025006-01

5025018-01

5025019-01

5025022-01

5025026-01

5025030-09

5025030-12

5025033-01

5025038-01

5025046-01

5025070-01

5025079-01

5025083-01

5025087-01

5025099-01

5025134-02

5025161-01

5025191-01

5025194-01

5027113-01

5027114-01

5049029-02

5049090-01

5052679-12

Assembling pliers, spark plug

Allen key, 4 mm

Allen key, 3 mm

Socket spanner, 8 mm

Puller, complete

Crankshaft installation device, Model 50 serial # 9250857 and up

Crankshaft installation device

Piston Stop

Pressure gauge

Sleeves, 2 pieces

Piston mounting set

Crankshaft seal installation tool

Hook for fuel filter

Allen screwdriver with ball

Worm wheel puller

Air gap gauge, ignition

Crankshaft removal tool

Air gap gauge, spark plug

Flywheel removal tool

Test plug

Tachometer

Intake/exhaust cover plates, 2 pieces

Puller, ball bearing

Flywheel removal tool, Model 50 serial # 9250857 and up

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

4

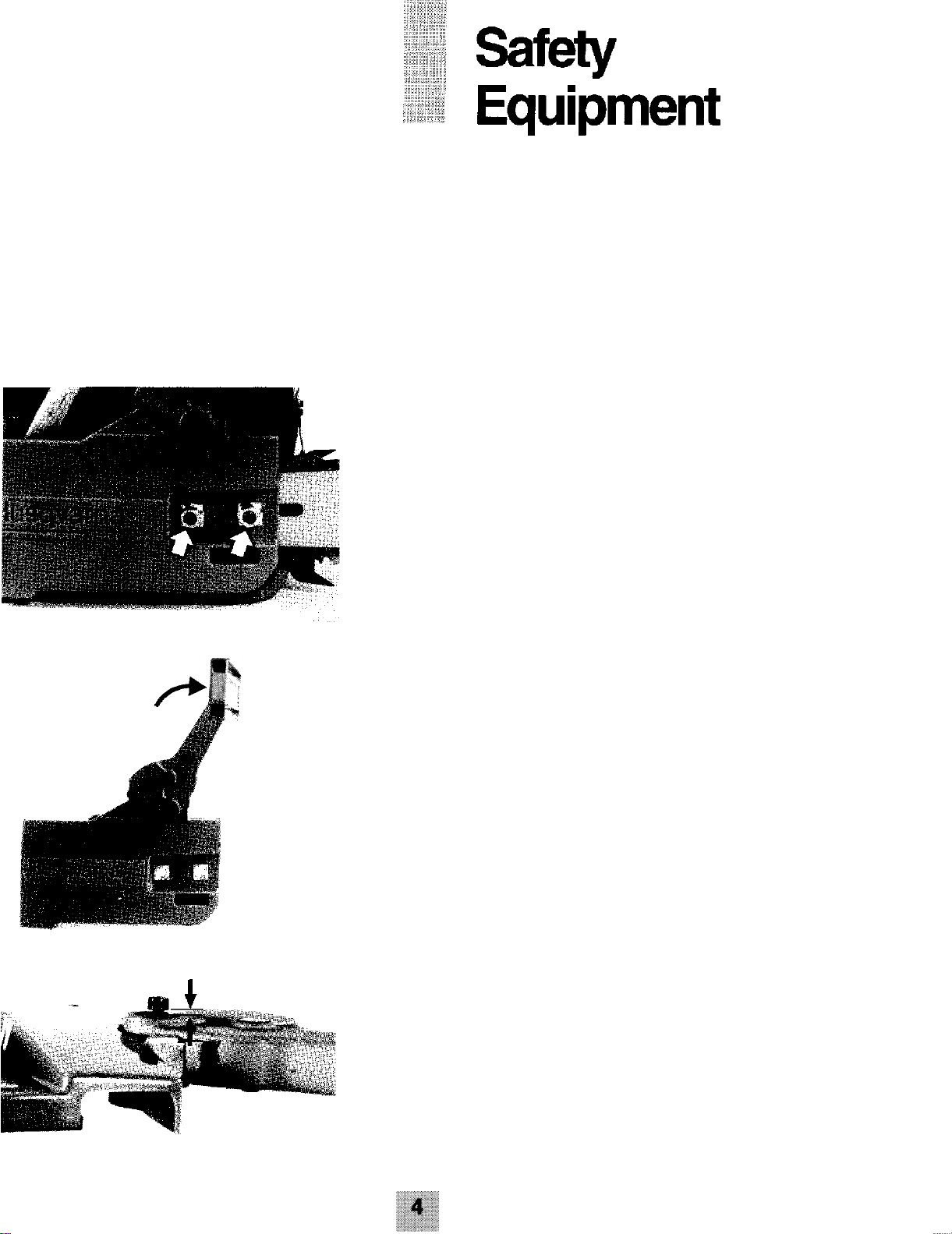

The chain brake system has a strong spring under

tension. This spring activates the chain brake band when

the chain brake is engaged. The spring is located under

a cover plate that must be removed during servicing.

Anytime the cover is removed and the spring is still under

tension it may dislodge without warning. Eye protection

must be worn during disassembly and reassembly of the

chain brake.

Chain Brake

Disassembly

Disengage chain brake. Remove clutch cover retaining

nuts and withdraw cover from the chain saw.

Clean chain brake and clutch cover assembly. Engage

the chain brake by moving the hand guard forward.

Remove hand guard retaining screw. Rethread screw

into pivot sleeve two turns. Press on screw head to drive

out pivot sleeve half on the opposite side.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Turn cover over. Using a suitable punch, drive out

remaining half of pivot sleeve. Separate hand guard from

cover.

Remove the five screws and lift off the cover plate.

CAUTION !

The spring is under tension.

Always wear safety goggles for eye protection.

Using the tip of a flat bladed screwdriver, carefully lift the

end of spring out of the cover.

Press out the pin which holds the linkage arm using a

suitable punch.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Turn the cover over and press out the brake bank

retaining pin with a punch.

Check the brake band for wear. Measure the thickness

of the band. The original thickness of the brake band is

0.80 mm (0.031 in.). The brake band must be exchanged

if the band is worn anywhere along its length to 0.65 mm

(0.026 in.) or less.

If the brake band needs to be exchanged, separate the

band from the linkage by removing the screw.

Assembly

Check all chain brake parts for wear or damage and

replace with new parts if necessary. Lubricate the linkage

and pivots with thin oil.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Assemble the brake band and knee link. Insert the roll

pin into the brake band so the open side of the pin is up

as shown in photo.

Insert the linkage and band assembly into the cover.

Secure the knee link to the cover with the retaining pin.

Slide the brake spring over the linkage spring post.

Using a flat bladed screwdriver, depress the spring, then

carefully press the spring end into the cover.

Install the cover plate.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Press the front hand guard into position. Install the pivot

sleeves and screw. Pull the hand guard back to

disengage the brake.

Mount the bar, chain and chain brake to the saw. Before

running the saw, check the brake function by moving the

hand guard forward until the brake engages. With the

brake engaged, it should not be possible to rotate the

saw chain around the guide bar. Pull the hand guard

back towards the front handle to disengage the brake.

Inertia Chain Brake Function

WARNING !

The engine must be stopped for the following test.

With the engine stopped, hold the chain saw with both

hands. With the chain saw horizontal, position the bar tip

approx. 35 cm (14 in.) above a tree stump or other firm

object such as a solid wood table.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

While holding onto the rear handle, release your grip

around the front handle. The chain saw will swing downward allowing the bar tip to contact the tree stump. When

the tip of the bar contacts the stump, the chain brake

should activate.

Manual Chain Brake Function

Place the saw on firm ground and start the engine. Hold

the handles with both hands and apply full throttle.

Activate the chain brake by turning your left wrist against

the hand guard. The saw chain should stop moving

immediately.

Throttle Trigger Lockout

Disassembly

Press out the pin.

On the 50 and 50 Special models, the throttle lockout

lever has a small tab midway on the left side. Insert a

small screwdriver between the lever and lever opening on

the left side so that the tab will clear the handle then

withdraw the lever out through the top.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Drive out the pin for the throttle trigger. Raise the throttle

trigger up into the handle and unhook the spring.

Assembly

Insert the spring down through the recess in the handle.

Hook the spring onto throttle trigger.

Align the pin hole in the trigger with the corresponding

hole in the handle and install the pin.

Insert the lockout lever making sure the end of the spring

fits within the lever.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

4

Align the pin holes and drive in the pin. After assembly

check throttle lockout function. It should not be possible

to move the throttle trigger (accelerate the saw) without

first depressing the lockout lever.

NOTE !

On 51 and 55 models, the fast idle system is integrated

into the choke system. When the choke knob is pulled,

the fast idle is engaged for starting purposes. When the

throttle trigger is depressed, the fast idle system

disengages allowing the engine to return to idle when the

trigger is released.

Chain Catcher

Check the chain catcher. If the chain catcher is missing

or damaged, install a new catcher.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

5

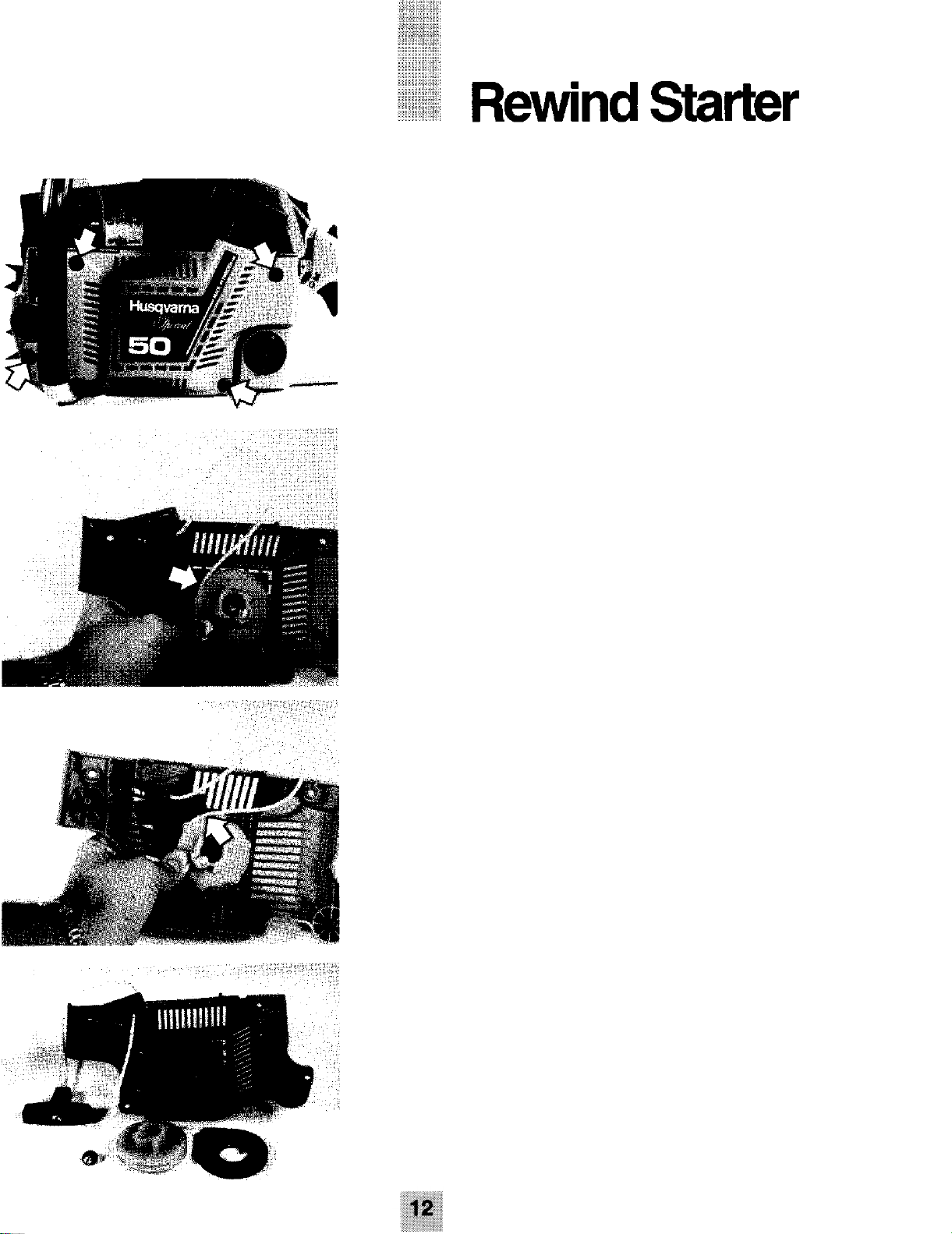

Disassembly

Remove the four starter housing retaining screws and

remove the starter assembly from the crankcase.

If the starter rope is still under tension from the rewind

spring, pull the starter grip out approximately 30 cm (12

inches) and hold starter pulley. Pull a loop of starter rope

up between pulley and housing. On 50 and 50 Special

models, engage rope in pulley notch. On 51 and 55

models, pull rope up between any notched section in

pulley.

Carefully and slowly release the pulley to allow the

rewind spring to unwind. Remove pulley retaining screw

from the starter post and remove the pulley. Carefully

withdraw the recoil spring cassette. Clean all parts

before assembly.

WARNING !

Be very careful when removing and installing the

rewind spring. The rewind

dislodged from the spring cassette causing injuries.

Wear safety goggles for eye protection.

www.mymowerparts.com

spring

can

become

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

5

Assembly

New starter rope length is 88 cm (34.5 inches). Tie a

knot in one end of the rope. Insert the other end through

the rope pulley first, then through the rope eyelet in the

housing and the starter grip.

Tie the rope at the starter grip end with a double loop

knot.

Install the new recoil spring cassette into the housing.

Lubricate the starter post with cold-resistant grease.

Wind 3 turns of the starter cord in a clockwise direction

onto the pulley. Install the rope pulley, washer and

retaining screw.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Pull the starter cord up into the pulley notch and rotate

the pulley clockwise two turns.

NOTE !

Check that the starter pulley can be turned at least

one half of a turn further when the starter cord is

pulled to the end of rope travel.

To install the starter assembly on crankcase, first pull the

starter grip out approximately 15 cm (6 in.) then position

the housing against the crankcase.

Release the grip so that the pulley engages the starter

pawls on the flywheel. Install and tighten the four starter

retaining screws.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

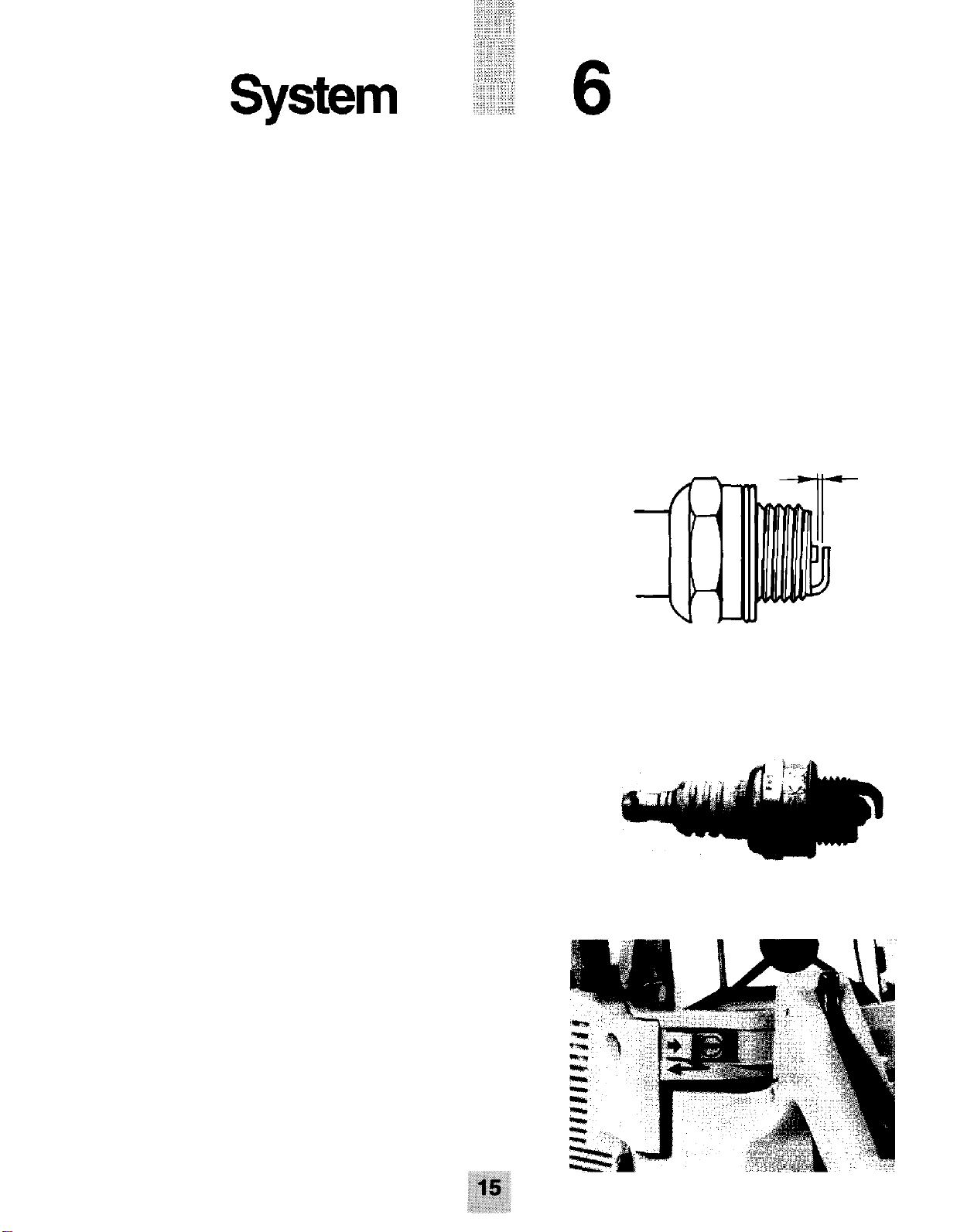

Ignition

Ignition System

These models are equipped with an electronic ignition

system. One of the characteristics of this system is that

the spark across the spark plug electrode gap has a

higher energy and shorter burning time (arc duration

time). When viewing the spark on a properly functioning

ignition system, the spark will appear to be weaker

compared to breaker point ignition systems due to the

shorter arc duration time.

Spark Plug

Champion RCJ7Y and NGK BPMR6A are the only spark

plugs that should be used. The spark plug should be

removed, cleaned and inspected at least once a week.

The spark plug electrode gap should be 0.5 mm

(0.020 in.).

If the electrodes are worn, install a new, properly gapped

spark plug.

Checking for Spark

Remove the spark plug. Move the ignition stop switch to

the “ON” position.

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Attach the high tension lead to the spark plug. Ground

the spark plug against the cylinder. With the-chain saw

secure from movement, pull the starter quickly while

watching for a spark across the spark plug electrode.

If no spark is evident, retest with a new spark plug or test

plug P/N 5027113-01.

If spark is still absent, disconnect the short circuit wire

from the stop switch. Check for spark again as

previously described. If spark occurs, the stop switch is

defective and should be replaced.

If no spark is evident, carefully inspect the full length of

the short circuit wire and the high tension lead to the

spark plug. Ensure that short circuit wire isn’t pinched or

grounded against any metal surface ( i.e., crankcase,

cylinder). Check the high tension lead connector at the

spark plug for a poor connection and the full length of the

lead for breakage or damaged insulation.

www.mymowerparts.com

Loading...

Loading...