For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Workshop

manual

chain saw model

181

www.mymowerparts.com

101 88 11-26

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Contents

1 ■ TechnicalData

2■ ServiceData

■ SpecialTools

3

4■ Fuelsystem

■ Electricsystem

5

■ Lubricatingsystem

6

7■ Cylinder,Piston

■ Crankcase,Crankshaft

8

■ Starter

9

—

—

.

3

5

7

11

17

1

23

_

33

10 w

11

■ SafetyEquipment

CentrifugalClutch—

www.mymowerparts.com

35

37

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Displacement

Bore

Stroke

Poweroutput

Ignitionsystem

Ignitionadvance

Air gap

Sparkplugtype

Electrodegap

80.7 cm3 (4.9 cu in)

52.0 mm (2.05”)

38.0 mm (1 .5”)

4.0 kW (5.5 hp) at 140 r/s (8.400 r/rein)

Make SEM type AM 7

25° before t.d.c. at 142 r/s (8.500 r/rein)

0.30 mm (0.01 2“)

Champion RCJ 7Y

0.5 mm (0.020”)

Technical Data ■

1

Handleheating

(181SG)

Carburetor

Fueltank volume

Oiltankvolume

Chain lubrication

Clutchdrum/sprocket

Weights

Weight sawbody incl. chain brake (empty)

Weight sawbody (empty) incl. chain brake and

18“ bar and chain

56 watts at 120 r/s (7.200 r/rein)

Diaphragm carburetor make Tillotson type HS 216

Basic setting:

H = 1.0

L = 1.0

0.85 Iitres (0.22 US gallon, 0.19 Imp gallon).

Fuel mixture 4% (1 :25)

With Husqvarna Twostroke Oil 2% (1 :50)

0.50 Iitres (0.13 US gallon, 0.11 Imp gallon)

Automatic. No supply during idling. Adjustable for 4 different delivery rates.

Recommended ~ositions:

Bar 18“;

Bar 20” and more: Pos. 3–4

Standard 7 teeth. Optional 8 teeth. 3/8” pitch.

6.8 kg

8.2 kg

Pos. 2

15.0 lb

18.1 lb

7.0 kg 15.4 lb

8.4 kg

18.5 lb

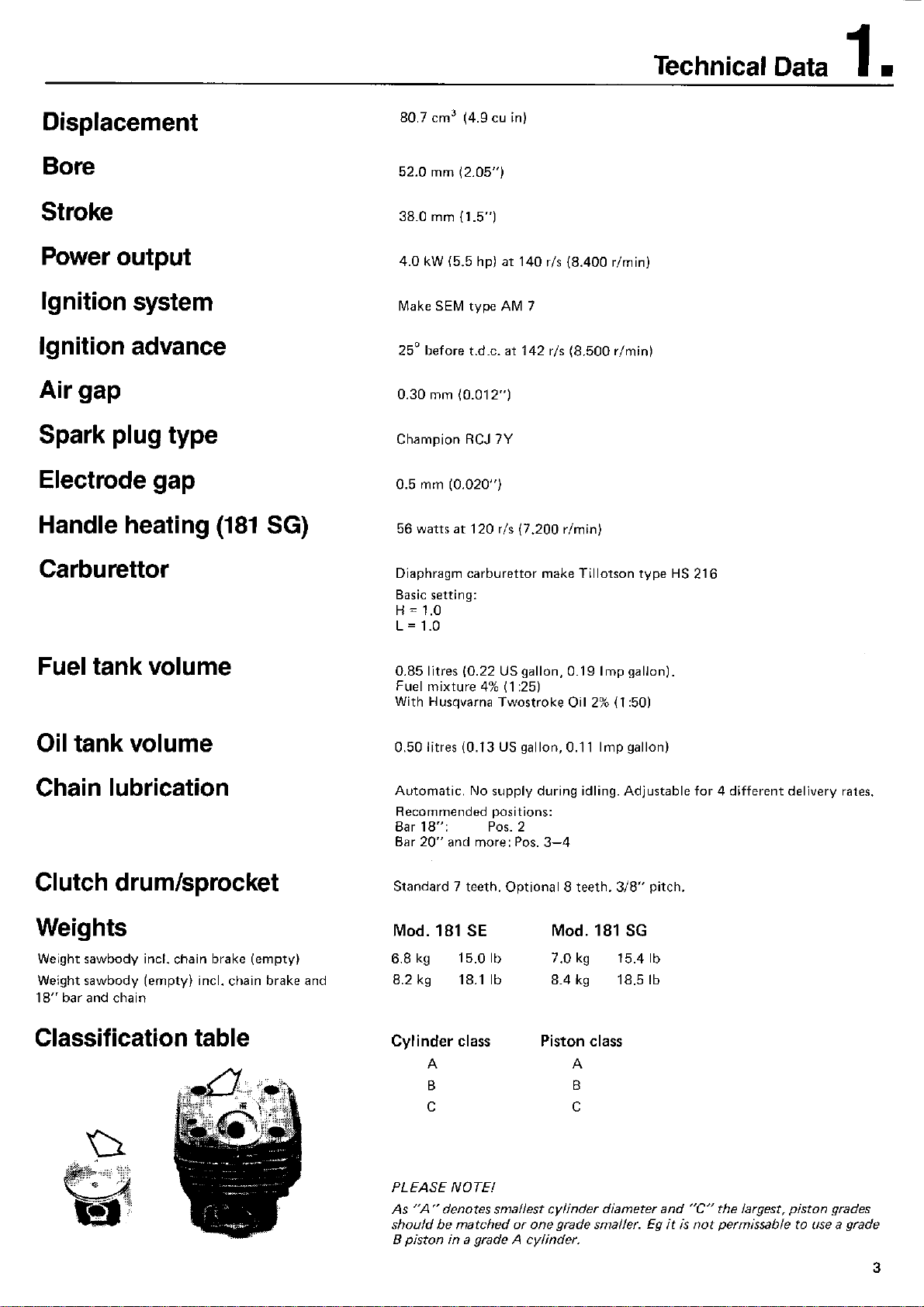

Classificationtable

C c

A

B

c

PLEASE NOTE!

As “A” denotes smallest cylinder diameter and “C’” the largest, piston grades

should be matched or one grade smaller. Eg it is not permissible to use a grade

B piston in a grade A cylinder.

P c

A

B

c

www.mymowerparts.com

3

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Service Data ■

CrankcaseAssy

v 0.04 MPa (0.4 kp/cm2, 5.7 psi)

l 0,01 MPa/1 min (0.1 kp/cm2, 1.4 psi per rein)

TOOIS: 5025037-01 Vacuum gauge

5025047-01 Cover plate, inlet port

5025081-01 Cover plate, exhaust port

P 0.08 MPa (0.8 kp/cm2, 11.4 psi)

l 0.02 MPa/30 sec (0.2 kp/cm2, 2,8 psi per 30 see)

TOOIS: 5025038-01 Pressure gauge

5025047-01 Cover plate, inlet port

5025081-01 Cover plate, exhaust port

2

Fueltank

PreSSUre: 0.05 MPa (0.5 kp/cm2, 7.

L No leakage permitted

: 5025038-01 Pressuregauge

I p

Starter

Make sure that it is possible to turn the pulley at least about 1/4 turn further

when the cord is pulled out completely.

Carburetor

p 0.03 MPa (0.3 kp/cm2, 4.3 psi)

L No leakage permitted

.

: 5025038-01 Pressuregauge

www.mymowerparts.com

5

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

—

Special Tools ■

5

Assembling pliers,

f

N

o

spark plug protector

5 4

5 3

5 3

Allen key

@p@

9

~:i: ‘[ “

@

- ,,,$*

@

5

Puller compl. with screw

5

Fitting tool compl. for

crankshaft and sealing ring

\

3

T

H

5

Ball bearing puller compl.

5

Stud fitting tool

5

Piston sto~

R

5 8

5

Socket spanner

5

Revolution counter

5

Holding bar compl.

/

.

www.mymowerparts.com

5

Vacuum gauge compl.

7

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

5 3

5 4

Allen screwdriver with ball

!

)

~..

R

a C,ampingdevice

5

Retouch paint, orange 1/8 I

5

..

d

Special Tools ■

5

SEM electric system tester

5

Air gap tool

5

Extractor sealing ring

3

A

b

&

5

Glue, adhesive

5

5

Loctite AA (normal locking power)

5

Loctite AAV (strong locking power)

%

Q

5

Puller for engineblock

5

Fitting drift, sealing ring

www.mymowerparts.com

9

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

2

■ Service Data

Chainbrake

.

When used with a 18“ guide bar the Swed-o-Matic should release at a load on

the bar tip of 12–17 kp (26–37 lb).

Replace the brake band as soon aswear has reduced its original thickness by

more than

band thickness.

25~0, i.e. at least 0,75 mm (0.03”) must be left of the original

Fueland oil

The twostroke engine is lubricated by oil mixed with petrol in various proportions depending on the type of oil used:

Ordinary twostroke oil

Husqvarna Twostroke oil

See also the mixing table below:

M t

1:25 (4% oil)

1:50 (2% oil)

Mixing table 2%

Litres Pints Litres

of oil

0.2 0.35 10

0.4 0.70 20

1.0 1.76 50

of oil of petrol Imp gallon US gallon of petrol Imp gallon USgallon

Petrol in

11.0 13.2 25

2,2

4.4

Petrol in

2.6 5

5.2 10

Litres

4%

Petrol in

1.1

2.2 2.6

5.5

Petrol in

1,3

6.6

www.mymowerparts.com

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

Fuelsystem I

4

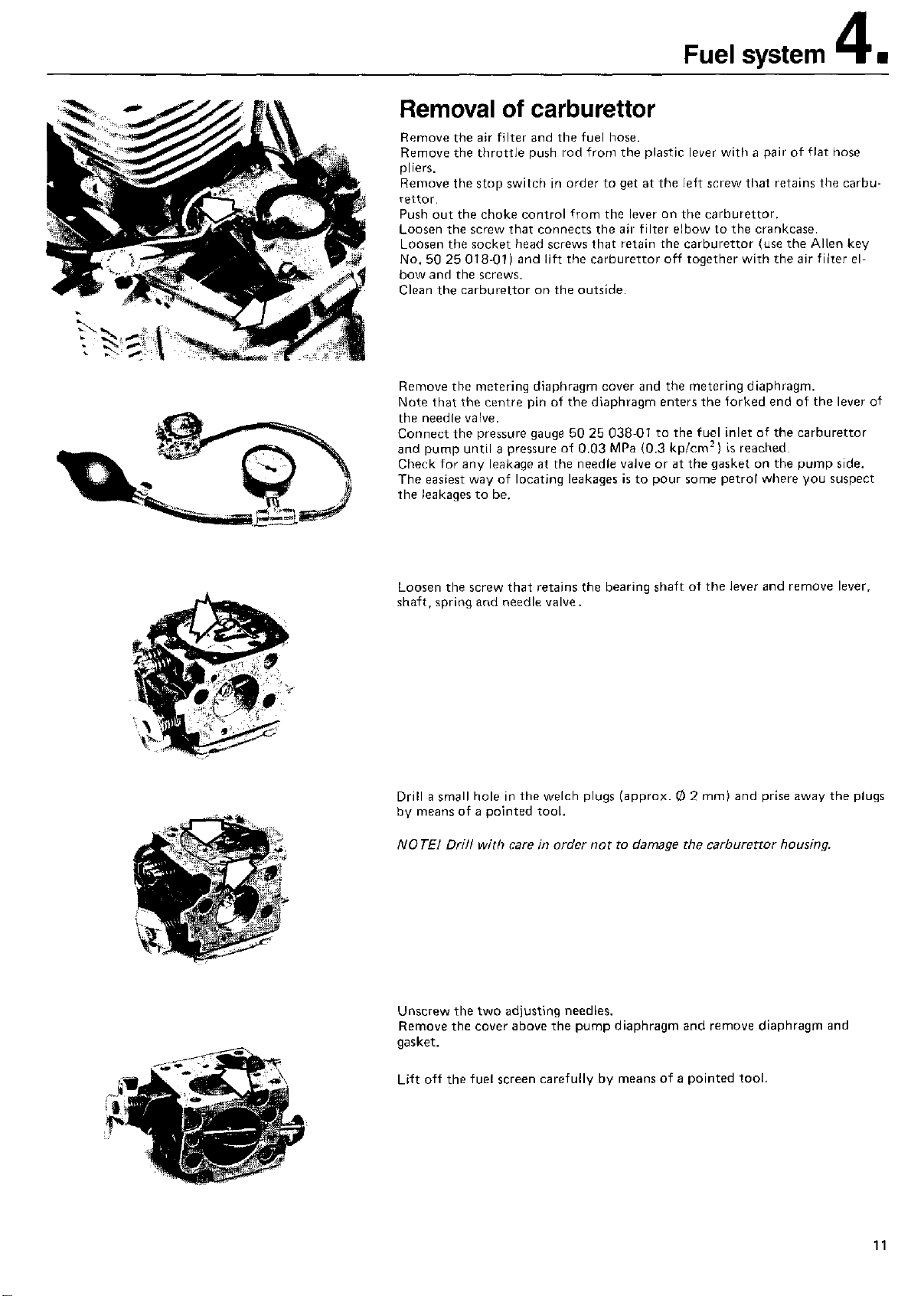

Removalof carburetor

Remove the air filter and the fuel hose.

Remove the throttle push rod from the plastic lever with a pair of flat hose

pliers.

Remove the stop switch in order to get at the left screw that retains the carburetor,

Push out the choke control from the lever on the carburetor.

Loosen the screw that connects the air filter elbow to the crankcase.

Loosen the socket head screwsthat retain the carburetor (use the Allen key

No. 502501 8-01) and lift the carburetor off together with the air filter elbow and the screws.

Clean the carburetor on the outside.

Remove the metering diaphragm cover and the metering diaphragm.

Note that the centre pin of the diaphragm enters the forked end of the lever of

the needle valve,

Connect the pressure gauge 5025038-01 to the fuel inlet of the carburetor

and pump until a pressureof 0.03 MPa (0.3 kp/cm2 ) is reached.

Check for any leakage at the needle valve or at the gasket on the pump side.

The easiest way of locating leakages is to pour some petrol where you suspect

the leakages to be.

Loosen the screw that retains the bearing shaft of the lever and remove lever,

shaft, spring and needle valve.

Drill a small hole in the welch plugs (approx. @ 2 mm) and prise away the plugs

by means of a pointed tool.

NOTE! Drill with care in order not to damage the carburetor housing.

Unscrew the two adjusting needles.

Remove the cover above the pump diaphragm and remove diaphragm and

gasket.

Lift off the fuel screen carefully by means of a pointed tool.

www.mymowerparts.com

11

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

■ Special Tools

3

5

Pressuregauge compl.

\

R

%

0

o:

o

*

5

Distance sleeve (57 mm)

5

Cover plate, inlet port

\

,--’

5

Cable clip pliers

5

Fitting sleeve for

sealing ring

5

U-spanner for vibration

damper

o

\

\

Q

‘,

&

T

5

Cover plate, exhaust port

o

/

5

’

Assembling pliers,

centrifugal clutch

5

Repair kit for elec-

tric cables

4

www.mymowerparts.com

5

Hook for fuel filter

For Husqvarna Parts Call 606-678-9623 or 606-561-4983

4Fuel system ■

When properly adjusted the lever of the needle valve shall be on a level with the

carburetor housing surrounding it.

If the lever is located too high, the carburetor will be very sensitive as regards

the adjustment of the adjusting needles,

A too low lever induces bad acceleration qualities.

Check that the lever can move freely.

Make a pressure test of the carburetor. Proceed as mentioned above,

Then mount gasket, metering diaphragm and cover.

NOTE!

Care should be taken to ensure that the centre pin of the diaphragm

enters the fork in the lever!

Install the adjusting needles and screw them out to the following basic posi-

tion: H = 1.0 turn open. L = 1.0 turn open.

Adjustmentof carburetor

B s

D

Before adjusting the carburetor, proceed as follows:

. Clean the air filter or, if necessary, replace it with a new one.

. Check the spark plug and its electrodes.

. Check that the fuel filter is not clogged.

Examine the fuel filter as follows:

Loosen the fuel hose from the carburetor and lay the chain saw on the clutch

side. Open the tank cap, If there is enough fuel in the tank, some of it now

ought to run out of the hose.

.....

‘%,.,

,.,

‘.

After having made the abovementioned checks you make a basic adjustment of

the carburetor needles, i.e. H = 1turn open and L = 1 turn open.

Start the chain saw and warm it

cut into a log.

A constant speed for 10–20 sec indicates not only a good high speed function

of the carburetor but also a good condition overall.

Should there be a sudden lean suPPly to the engine after approx. 10–20 sec

full throttle running (big speed increase), this would indicate some fault in the

fuel system.

The trouble may be caused by:

. Leakage in the pumping section of the carburetor.

. Crack in the insulating piece.

. Loose carburetor bolts.

. Incorrectly assembled or leaking gaskets.

. Tank breather valve inoperative.

. Fuel filter clogged.

u by applying full throttle and letting it

NOTE!

Too lean adjustment of the carburetor would cause a considerable loss

of power. Adjust the carburetor in order to obtain maximum power and

not maximum speed.

www.mymowerparts.com

13

Loading...

Loading...