HP PageWide Enterprise Color 765, PageWide Enterprise Color 780, PageWide Enterprise Color 785 Troubleshooting Manual

Page 1

HP PageWide Enterprise Color 765 and MFP

780/785

HP PageWide Managed Color E75160 and

MFP E77650/P77660

Troubleshooting Manual

Page 2

Copyright and License

Trademark Credits

© Copyright 2017 HP Development Company,

L.P.

Reproduction, adaptation, or translation without

prior written permission is prohibited, except as

allowed under the copyright laws.

The information contained herein is subject to

change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products and

services. Nothing herein should be construed as

constituting an additional warranty. HP shall not

be liable for technical or editorial errors or

omissions contained herein.

Edition 1, 9/2017

Microsoft®, Windows®, Windows® XP, and

Windows Vista® are U.S. registered trademarks

of Microsoft Corporation.

Adobe®, Acrobat®, and PostScript® are

trademarks of Adobe Systems Incorporated.

UNIX® is a registered trademark of The Open

Group.

Page 3

Conventions used in this guide

TIP: Helpful hints or shortcuts.

NOTE: Information that explains a concept or how to complete a task.

Reinstallation tip: Reinstallation helpful hints, shortcuts, or considerations.

IMPORTANT: Information that help the user to avoid potential printer error conditions.

CAUTION: Procedures that the user must follow to avoid losing data or damaging the printer.

WARNING! Procedures that the user must follow to avoid personal injury, catastrophic loss of data, or extensive

damage to the printer.

ENWW iii

Page 4

iv Conventions used in this guide ENWW

Page 5

For additional service and support information

HP service personnel, go to one of the following Web-based Interactive Search Engines (WISE) sites:

AMS

●

https://support.hp.com/wise/home/ams-en

●

https://support.hp.com/wise/home/ams-es

●

https://support.hp.com/wise/home/ams-pt

APJ

●

https://support.hp.com/wise/home/apj-en

●

https://support.hp.com/wise/home/apj-ja

●

https://support.hp.com/wise/home/apj-ko

●

https://support.hp.com/wise/home/apj-zh-Hans

●

https://support.hp.com/wise/home/apj-zh-Hant

EMEA

●

https://support.hp.com/wise/home/emea-en

Channel partners, go to HP Channel Services Network (CSN) at www.hp.com/partners/csn .

At these locations, nd information on the following topics:

●

Install and congure

●

Printer specications

●

Up-to-date control panel message (CPMD) troubleshooting

●

Solutions for printer issues and emerging issues

●

Remove and replace part instructions and videos

●

Service advisories

●

Warranty and regulatory information

Channel partners, access training materials in the HP University and Partner Learning Center at

https://content.ext.hp.com/sites/LMS/HPU.page.

To access HP PartSurfer information from any mobile device, go to http://partsurfermobile.hp.com/ or scan the

Quick Response (QR) code below.

ENWW v

Page 6

vi For additional service and support information ENWW

Page 7

Table of contents

1 Theory of operation .................................................................................................................................................................................. 1

Basic operation ......................................................................................................................................................................... 2

Function structure ............................................................................................................................................... 2

Operation sequence ............................................................................................................................................ 4

System control .......................................................................................................................................................................... 6

................................................................................................................................................................................. 6

Formatter and data path .................................................................................................................................... 6

Engine control ...................................................................................................................................................... 8

Pen interface (I/F) .............................................................................................................................................. 10

Power supply ...................................................................................................................................................... 11

AC control module ............................................................................................................................................. 11

Cabling system ....................................................................................................................................................................... 13

Flat Flexible Cables ........................................................................................................................................... 13

FFC routing .......................................................................................................................................................... 16

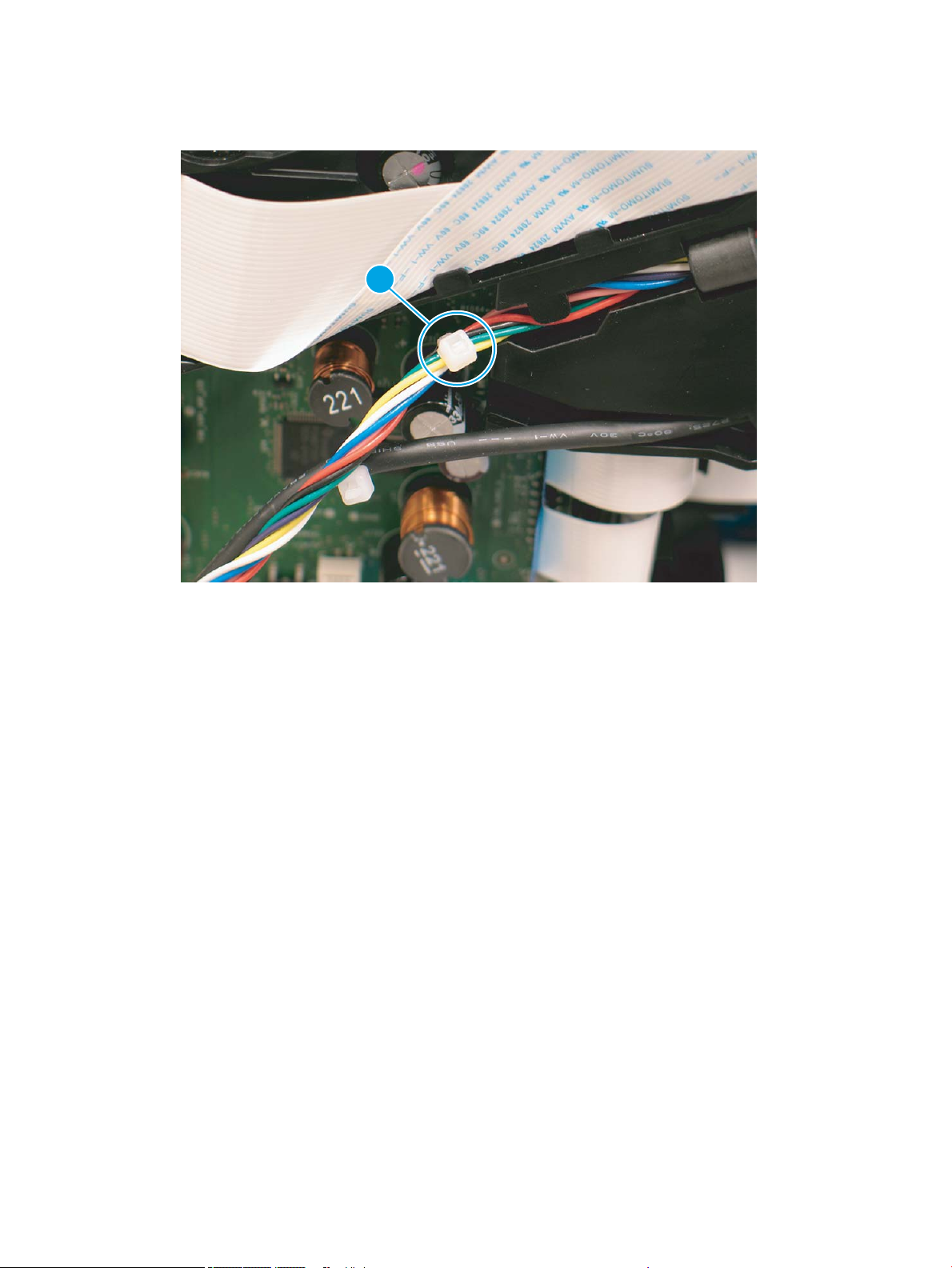

Discrete cables ................................................................................................................................................... 19

Ground wires ...................................................................................................................................................... 20

Connectors .......................................................................................................................................................... 21

Ferrites ................................................................................................................................................................ 23

Cable management ........................................................................................................................................... 23

Print subsystem ..................................................................................................................................................................... 25

Printhead ............................................................................................................................................................ 25

Printhead air management system ................................................................................................................ 26

Printhead lift ....................................................................................................................................................... 26

Print cartridges .................................................................................................................................................. 26

Optical scan carriage ......................................................................................................................................... 26

Print system operational states ...................................................................................................................... 26

Paper-handling system ......................................................................................................................................................... 29

Printer sensors ................................................................................................................................................... 29

High Capacity Input (HCI) sensors ................................................................................................................... 30

3x550 tray sensors ........................................................................................................................................... 31

1x550 tray sensors ........................................................................................................................................... 32

Inline nisher sensors ....................................................................................................................................... 33

ENWW vii

Page 8

Printer motors/solenoids ................................................................................................................................. 34

High capacity input (HCI) motors/solenoids .................................................................................................. 35

3x550 tray motors/solenoids .......................................................................................................................... 36

1x550 tray motors/solenoids .......................................................................................................................... 37

Inline nisher motors ........................................................................................................................................ 38

Printer printing system ..................................................................................................................................... 39

Input trays ........................................................................................................................................................... 40

Paper path zones ............................................................................................................................................... 43

Jam detection ..................................................................................................................................................... 45

Servicing system .................................................................................................................................................................... 48

Printhead wiper .................................................................................................................................................. 48

Service uid and aerosol management systems ............................................................................................................. 49

Airow system ........................................................................................................................................................................ 51

Function .............................................................................................................................................................. 51

Heating ................................................................................................................................................................ 51

Airow ................................................................................................................................................................. 51

Modes .................................................................................................................................................................. 51

Components ....................................................................................................................................................... 52

Document feeder system ..................................................................................................................................................... 53

Document feed system .................................................................................................................................... 53

Sensors in the document feeder .................................................................................................................... 53

Document feeder paper path .......................................................................................................................... 54

Document feeder simplex operation ............................................................................................................. 55

Document feeder e-duplex operation ........................................................................................................... 56

Deskew operation ............................................................................................................................................. 57

Document feeder hinges .................................................................................................................................. 57

Scanning and image capture system (780/785) .............................................................................................................. 59

Fax functions and operation ................................................................................................................................................. 60

Computer and network security features ..................................................................................................... 60

PSTN operation .................................................................................................................................................. 60

The fax subsystem ............................................................................................................................................ 60

Fax card in the fax subsystem ......................................................................................................................... 60

Fax page storage in ash memory ................................................................................................................. 62

Output accessories ................................................................................................................................................................ 63

Inline nisher ...................................................................................................................................................... 64

2 Solve problems ....................................................................................................................................................................................... 91

Problem-solving checklist .................................................................................................................................................... 92

Step 1: Check that the printer power is on .................................................................................................... 92

Step 2: Check the control panel for error messages ................................................................................... 92

Step 3: Test print functionality ........................................................................................................................ 93

viii ENWW

Page 9

Step 4: Test copy functionality (MFP models only) ...................................................................................... 93

Step 5: Test the fax sending functionality (785f/785zs/785z+) ............................................................... 94

Step 6: Test the fax receiving functionality (fax models only) ................................................................... 94

Step 7: Try sending a print job from a computer ......................................................................................... 94

Step 8: Test the Plug and Print USB Drive printing functionality ............................................................... 94

Factors that aect printer performance ........................................................................................................ 94

Troubleshooting process ...................................................................................................................................................... 96

Determine the problem source ....................................................................................................................... 96

Power subsystem .............................................................................................................................................. 98

Tools for troubleshooting ................................................................................................................................................... 129

Print the conguration and printhead information pages ........................................................................ 129

Event log messages ........................................................................................................................................ 132

Tools for troubleshooting: Individual component diagnostics ................................................................ 133

Diagrams .......................................................................................................................................................... 146

Print-quality troubleshooting tools .............................................................................................................. 159

Control panel menus ...................................................................................................................................... 168

Control panel message document (CPMD) ................................................................................................. 243

Print quality troubleshooting guide .................................................................................................................................. 244

Printer pre-checks .......................................................................................................................................... 244

Printer specic image defects ....................................................................................................................... 258

Solve copy/scan problems (780/785) .............................................................................................................................. 297

Solve copy problems (780/785 models only) ............................................................................................ 297

Solve scan problems (780/785 models only) ............................................................................................ 302

Solve paper jam or feed problems ................................................................................................................................... 308

Printer does not pick up paper or misfeeds ................................................................................................ 308

Clear paper jams ............................................................................................................................................. 310

Solve performance problems ............................................................................................................................................ 340

Factors aecting print performance ............................................................................................................ 340

The printer does not print or it prints slowly .............................................................................................. 341

The printer prints slowly ................................................................................................................................ 342

Solve connectivity problems .............................................................................................................................................. 343

Solve USB connection problems ................................................................................................................... 343

Solve wired network problems ..................................................................................................................... 343

Service mode functions ...................................................................................................................................................... 345

Service menu ................................................................................................................................................... 345

Printer resets ................................................................................................................................................... 354

Format Disk and Partial Clean functions ..................................................................................................... 356

Firmware upgrades ............................................................................................................................................................. 359

Determine the installed revision of rmware ............................................................................................. 359

Perform a rmware upgrade ........................................................................................................................ 361

Solve fax problems .............................................................................................................................................................. 365

ENWW ix

Page 10

Solve email problems ......................................................................................................................................................... 366

Appendix A Printer specications ......................................................................................................................................................... 367

Printer dimensions and weight ......................................................................................................................................... 368

Printer space requirements ............................................................................................................................................... 369

Power consumption, electrical specications, and acoustic emissions ...................................................................... 369

Operating-environment range .......................................................................................................................................... 370

Certicate of Volatility ......................................................................................................................................................... 371

Index ........................................................................................................................................................................................................... 415

x ENWW

Page 11

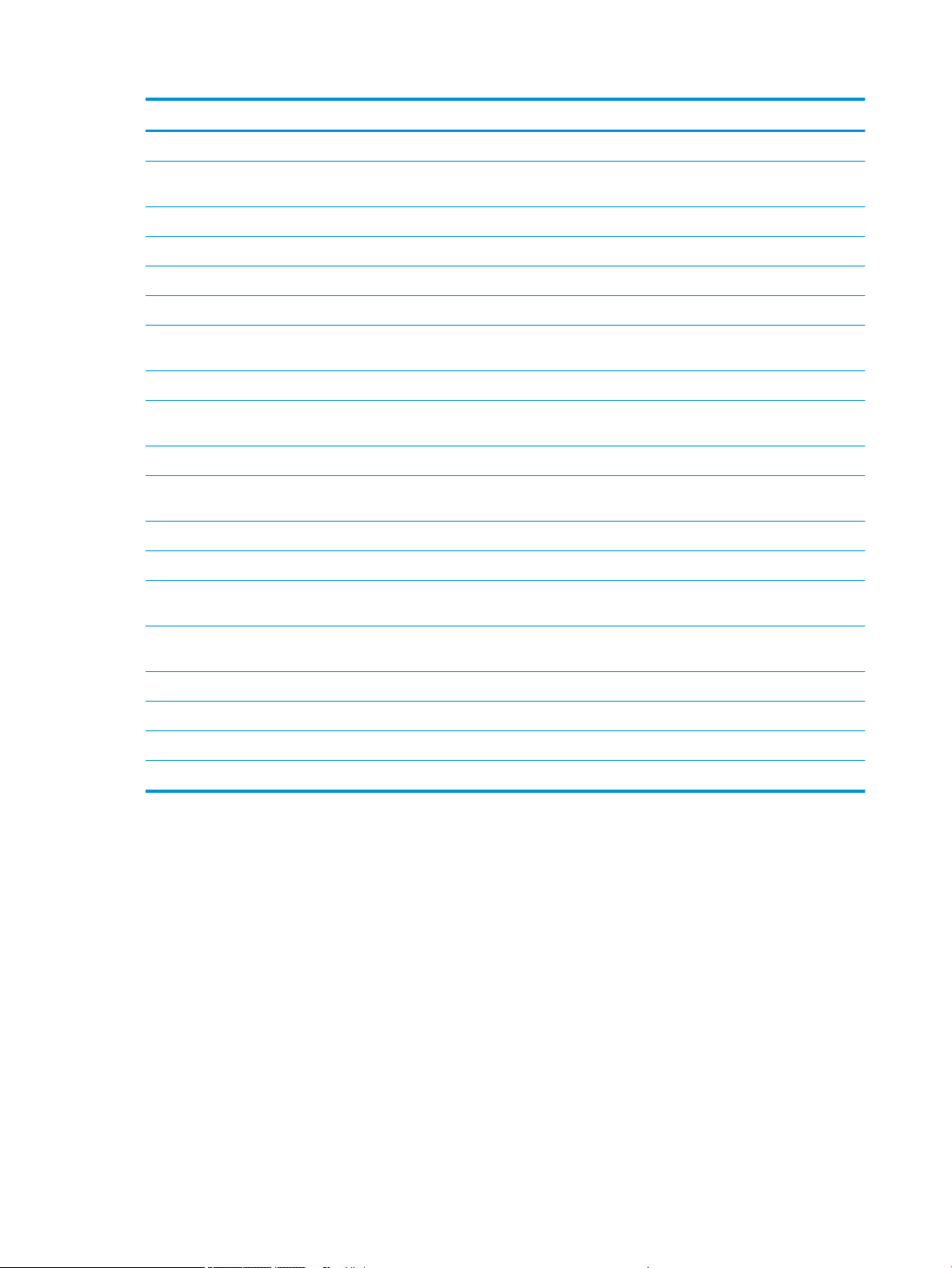

List of tables

Table 1-1 Operation sequence ................................................................................................................................................................ 4

Table 1-2 Printbar components ............................................................................................................................................................ 25

Table 1-3 Service Fluid and Aerosol Management System Components ...................................................................................... 50

Table 1-4 Document feeder sensors ................................................................................................................................................... 54

Table 1-5 Document feeder paper path .............................................................................................................................................. 54

Table 2-1 Troubleshooting owchart .................................................................................................................................................. 97

Table 2-2 MPCA LEDs ........................................................................................................................................................................... 100

Table 2-3 MPCA LED sequence at printer power on ....................................................................................................................... 100

Table 2-4 MPCA LEDs ........................................................................................................................................................................... 133

Table 2-5 MPCA LED sequence at printer power on ....................................................................................................................... 134

Table 2-6 ACCM LEDs ........................................................................................................................................................................... 135

Table 2-7 ACCMA LED sequence at printer power on ..................................................................................................................... 135

Table 2-8 Heartbeat LED, product initialization ............................................................................................................................... 136

Table 2-9 Heartbeat LED, product operational ................................................................................................................................ 139

Table 2-10 Reports menu ................................................................................................................................................................... 169

Table 2-11 Settings menu ................................................................................................................................................................... 171

Table 2-12 Copy menu (MFP only) ..................................................................................................................................................... 197

Table 2-13 Scan menu (780/785) ..................................................................................................................................................... 203

Table 2-14 Fax menu (fax models only) ........................................................................................................................................... 231

Table 2-15 Print Options menu .......................................................................................................................................................... 235

Table 2-16 Supplies menu .................................................................................................................................................................. 236

Table 2-17 Trays menu ........................................................................................................................................................................ 237

Table 2-18 Backup/Restore menu ..................................................................................................................................................... 238

Table 2-19 Calibrate/Cleaning menu ................................................................................................................................................. 238

Table 2-20 Troubleshooting menu .................................................................................................................................................... 240

Table 2-21 Printhead health score .................................................................................................................................................... 251

Table 2-22 Solve performance problems ......................................................................................................................................... 340

Table 2-23 Service menu .................................................................................................................................................................... 345

Table A-1 Dimensions for printer base model (SFP; all) ................................................................................................................. 368

Table A-2 Dimensions for base models (780dn, 785f; MFP) ......................................................................................................... 368

Table A-3 Dimensions for 785zs (MFP) ............................................................................................................................................. 368

Table A-4 Dimensions for the 1x550-sheet paper feeder ............................................................................................................. 368

ENWW xi

Page 12

Table A-5 Dimensions for the 1x550-sheet paper feeder with stand ......................................................................................... 369

Table A-6 Dimensions for the 3x550-sheet paper feeder with stand ......................................................................................... 369

Table A-7 Dimensions for the 4,000-sheet HCI with stand ........................................................................................................... 369

Table A-8 Operating-environment specications ............................................................................................................................ 370

xii ENWW

Page 13

List of gures

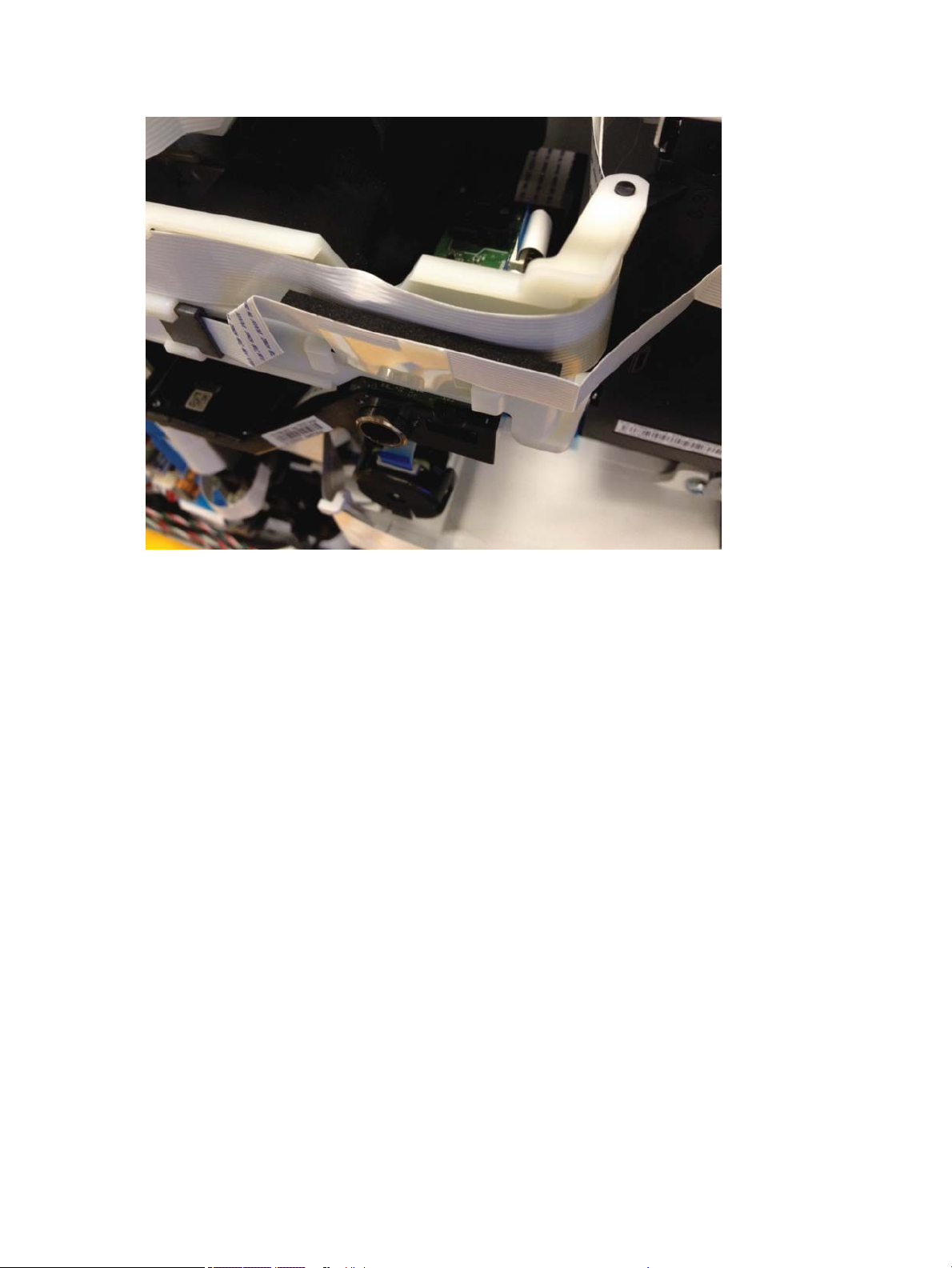

Figure 1-3 FFC insertion line ................................................................................................................................................................. 13

Figure 1-4 FFC support tape ................................................................................................................................................................. 14

Figure 1-5 FFC label ................................................................................................................................................................................ 14

Figure 1-6 FFC wing feature .................................................................................................................................................................. 15

Figure 1-7 ZIF connector ........................................................................................................................................................................ 15

Figure 1-8 FFC hook arm retainers ...................................................................................................................................................... 16

Figure 1-9 FFC pill bump retainers ....................................................................................................................................................... 17

Figure 1-10 FFC die-cut retainers ........................................................................................................................................................ 18

Figure 1-11 FFC double-sided tape retainer ...................................................................................................................................... 18

Figure 1-12 Discrete cable ferrite ........................................................................................................................................................ 19

Figure 1-13 Discrete cable tie-wraps .................................................................................................................................................. 20

Figure 1-14 Ground wires ...................................................................................................................................................................... 21

Figure 1-16 FFC wing feature ............................................................................................................................................................... 22

Figure 1-17 ZIF connector ..................................................................................................................................................................... 23

Figure 1-18 FFC spacing ........................................................................................................................................................................ 24

Figure 1-19 Printhead components ..................................................................................................................................................... 25

Figure 1-20 Print engine sensors ......................................................................................................................................................... 29

Figure 1-21 HCI sensors ........................................................................................................................................................................ 30

Figure 1-22 3x550 Tray sensors .......................................................................................................................................................... 31

Figure 1-23 1x550 tray sensors ........................................................................................................................................................... 32

Figure 1-24 Inline nisher sensors ....................................................................................................................................................... 33

Figure 1-25 HCI motors/solenoids ....................................................................................................................................................... 35

Figure 1-26 3x550 tray motors/solenoids ......................................................................................................................................... 36

Figure 1-27 1x550 tray motors/solenoids ......................................................................................................................................... 37

Figure 1-28 Inline nisher motors ........................................................................................................................................................ 38

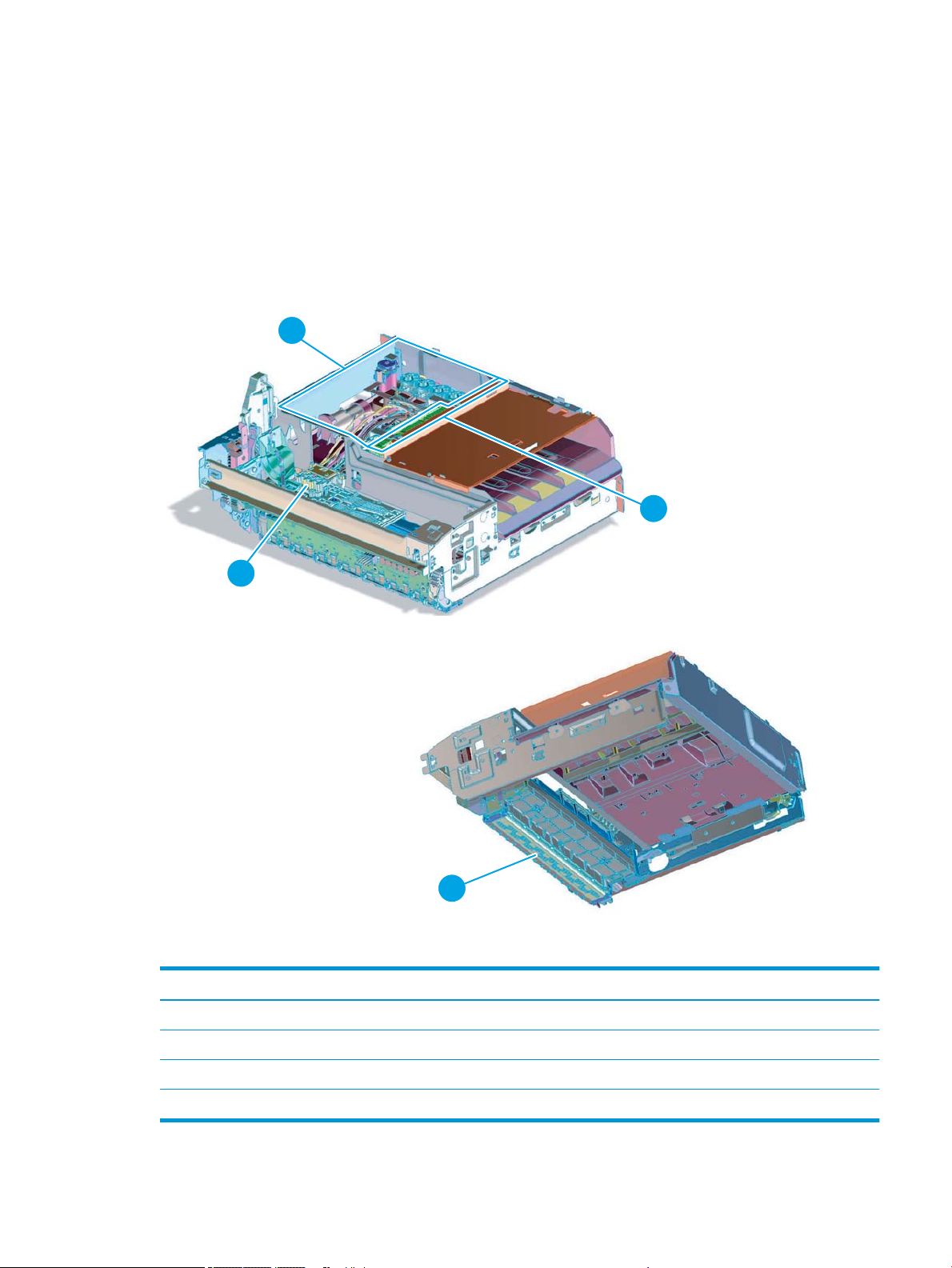

Figure 1-29 Printer printing system .................................................................................................................................................... 39

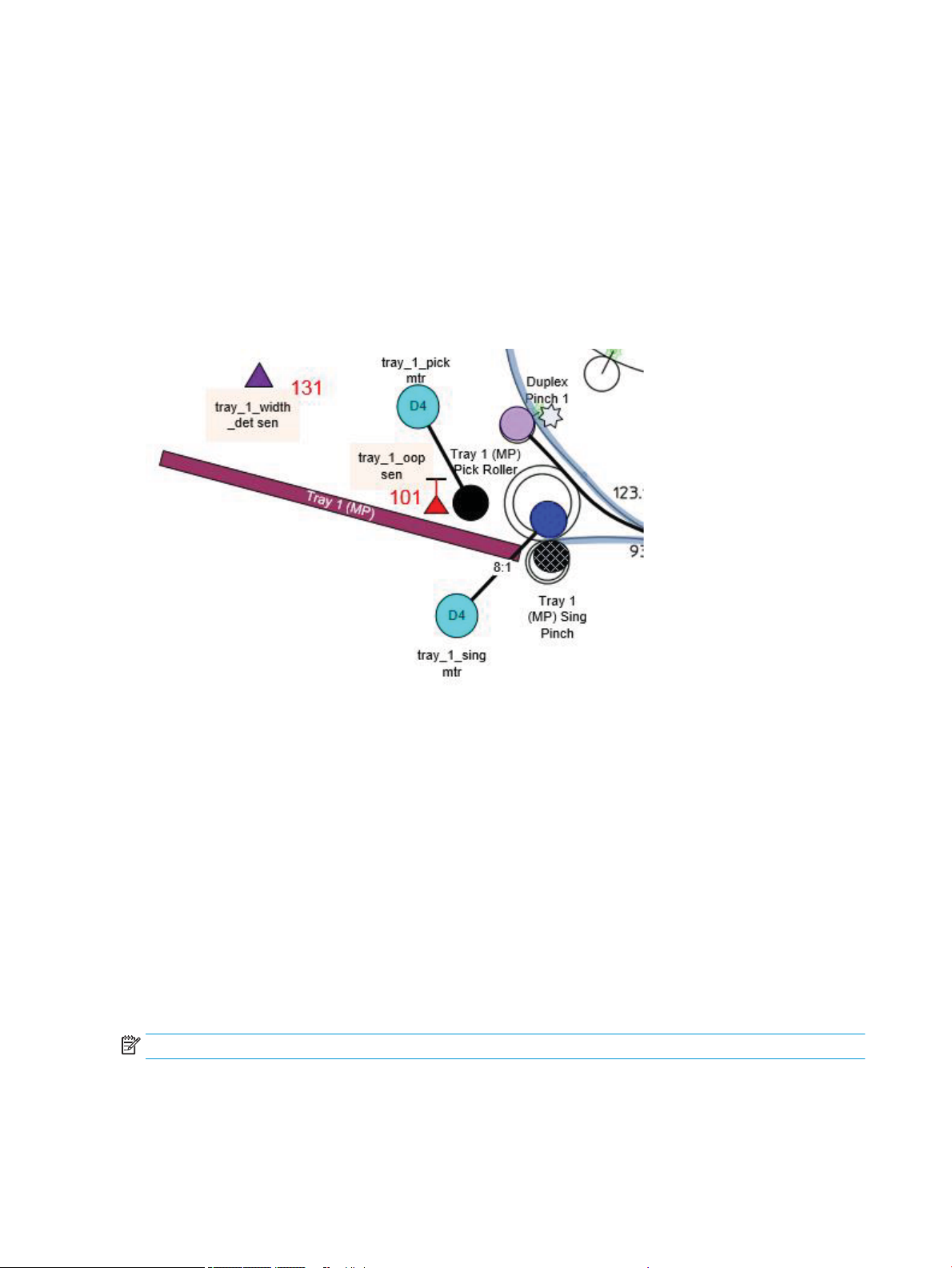

Figure 1-30 Tray 1 pick and separation system ................................................................................................................................ 40

Figure 1-31 Service uid and aerosol management system .......................................................................................................... 50

Figure 1-32 Airow system components ........................................................................................................................................... 52

Figure 1-33 Document feeder sensors ............................................................................................................................................... 54

Figure 1-34 Document feeder paper path .......................................................................................................................................... 54

Figure 1-35 Deskew operation ............................................................................................................................................................. 57

ENWW xiii

Page 14

Figure 1-36 Document feeder open (book mode) ............................................................................................................................ 58

Figure 1-37 Document feeder open (60º to 80º) .............................................................................................................................. 58

Figure 1-38 FFC insertion line ............................................................................................................................................................... 67

Figure 1-39 FFC support tape ............................................................................................................................................................... 68

Figure 1-40 FFC label ............................................................................................................................................................................. 68

Figure 1-41 FFC hook arm retainers .................................................................................................................................................... 69

Figure 1-42 FFC pill bump retainers .................................................................................................................................................... 70

Figure 1-43 FFC die-cut retainers ........................................................................................................................................................ 71

Figure 1-44 FFC double-sided tape retainer ...................................................................................................................................... 71

Figure 1-45 Discrete cable ferrite ........................................................................................................................................................ 72

Figure 1-46 Discrete cable tie-wraps .................................................................................................................................................. 73

Figure 1-47 Connectors ......................................................................................................................................................................... 74

Figure 1-48 FFC spacing ........................................................................................................................................................................ 75

Figure 1-49 Inline nisher control diagram (front) ............................................................................................................................ 76

Figure 1-50 Inline nisher sensor control diagram (front) ............................................................................................................... 77

Figure 1-51 Inline nisher motor control diagram (front) ................................................................................................................ 78

Figure 1-52 Inline nisher sensor diagram (1 of 2) ........................................................................................................................... 79

Figure 1-53 Inline nisher sensor diagram (2 of 2) ........................................................................................................................... 80

Figure 1-54 Inline nisher motor diagram .......................................................................................................................................... 81

Figure 1-55 Inline nisher stapler control diagram ........................................................................................................................... 82

Figure 1-56 Inline nisher stapler sensor diagram ........................................................................................................................... 83

Figure 1-57 Inline nisher stapler motor control diagram ............................................................................................................... 84

Figure 2-1 MPCA LEDs ......................................................................................................................................................................... 100

Figure 2-2 Formatter heartbeat LED ................................................................................................................................................. 101

Figure 2-3 Diagnostic-tests access button (765 printers) ............................................................................................................. 104

Figure 2-4 Diagnostic-tests access button (780/785 printers) .................................................................................................... 104

Figure 2-5 Press the diagnostics-access button (780/785 printers) ........................................................................................... 105

Figure 2-6 Control panel version A yellow screen ........................................................................................................................... 105

Figure 2-7 Exit the diagnostic mode ................................................................................................................................................. 107

Figure 2-8 Open the Pre-boot menu ................................................................................................................................................. 108

Figure 2-9 Pre-boot menu .................................................................................................................................................................. 109

Figure 2-10 Access the administration menu .................................................................................................................................. 110

Figure 2-11 Access the diagnostics menu ........................................................................................................................................ 110

Figure 2-12 Open the screen test ...................................................................................................................................................... 111

Figure 2-13 Blue vertical gradient screen ........................................................................................................................................ 111

Figure 2-14 Open the touch test ........................................................................................................................................................ 115

Figure 2-15 Touch the white grid ....................................................................................................................................................... 115

Figure 2-16 Verify the mark ............................................................................................................................................................... 116

Figure 2-17 Open the softkey test .................................................................................................................................................... 117

Figure 2-18 Select Home .................................................................................................................................................................... 117

Figure 2-19 Successful test ................................................................................................................................................................ 118

xiv ENWW

Page 15

Figure 2-20 Open the backlight test .................................................................................................................................................. 119

Figure 2-21 Open the sound test ....................................................................................................................................................... 120

Figure 2-22 Open the keyboard test ................................................................................................................................................. 121

Figure 2-23 Open the sound test ....................................................................................................................................................... 122

Figure 2-24 Touchscreen blank, white, or dim (no image) ............................................................................................................ 124

Figure 2-25 Touchscreen has an unresponsive zone ..................................................................................................................... 125

Figure 2-26 No control panel sound .................................................................................................................................................. 126

Figure 2-27 Home key is unresponsive ............................................................................................................................................ 127

Figure 2-28 Hardware integration pocket (HIP) is not functioning (control panel functional) ................................................ 128

Figure 2-29 Conguration page ......................................................................................................................................................... 129

Figure 2-30 Printhead information page .......................................................................................................................................... 131

Figure 2-31 MPCA LEDs ....................................................................................................................................................................... 133

Figure 2-32 ACCM LEDs ....................................................................................................................................................................... 135

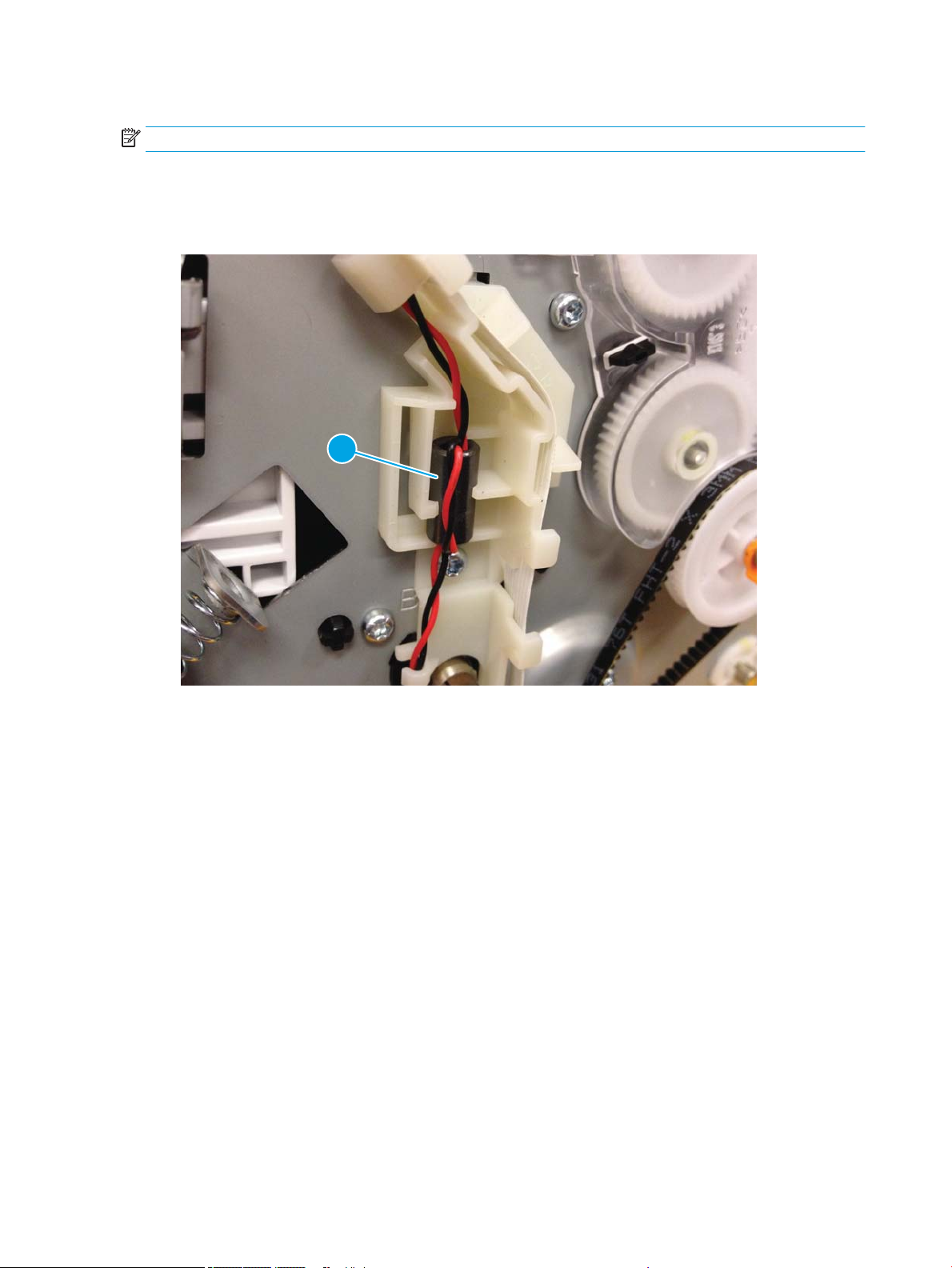

Figure 2-33 Defeating interlocks (cartridge door) .......................................................................................................................... 141

Figure 2-34 Defeating interlocks (left door) .................................................................................................................................... 142

Figure 2-35 Defeating interlocks (right door) .................................................................................................................................. 142

Figure 2-36 Plug/jack locations (external printer) .......................................................................................................................... 146

Figure 2-37 Print engine sensors ...................................................................................................................................................... 148

Figure 2-38 HCI sensors ...................................................................................................................................................................... 149

Figure 2-39 3x550 tray sensors ........................................................................................................................................................ 150

Figure 2-40 1x550 tray sensors ........................................................................................................................................................ 151

Figure 2-41 Inline nisher sensors .................................................................................................................................................... 152

Figure 2-42 Printer motors/solenoids .............................................................................................................................................. 153

Figure 2-43 HCI motors/solenoids ..................................................................................................................................................... 154

Figure 2-44 3x550 tray motors/solenoids ....................................................................................................................................... 155

Figure 2-45 1x550 tray motors/solenoids ....................................................................................................................................... 156

Figure 2-46 Inline nisher motors ..................................................................................................................................................... 157

Figure 2-47 Printer printing system .................................................................................................................................................. 158

Figure 2-50 Ink smear/redeposit ....................................................................................................................................................... 255

Figure 2-51 Print Quality Report page .............................................................................................................................................. 260

Figure 2-52 Print Head Diagnostic Page ........................................................................................................................................... 262

Figure 2-53 Printhead Details page .................................................................................................................................................. 264

Figure 2-67 Paper jam locations (765) ............................................................................................................................................. 310

Figure 2-68 Paper jam locations (780/785) .................................................................................................................................... 312

Figure 2-69 Open the Pre-boot menu .............................................................................................................................................. 355

Figure 2-70 Open the Pre-boot menu .............................................................................................................................................. 357

Figure 2-71 Open the Pre-boot menu .............................................................................................................................................. 358

Figure 2-72 Determine the installed revision of rmware ............................................................................................................ 360

Figure 2-73 Open the Pre-boot menu .............................................................................................................................................. 363

Figure A-1 Certicate of Volatility (750dn; 1 of 3) ........................................................................................................................... 371

Figure A-2 Certicate of Volatility (750dn; 2 of 3) ........................................................................................................................... 372

ENWW xv

Page 16

Figure A-3 Certicate of Volatility (750dn; 3 of 3) ........................................................................................................................... 373

Figure A-4 Certicate of Volatility (750dw; 1 of 4) .......................................................................................................................... 374

Figure A-5 Certicate of Volatility (750dw; 2 of 4) .......................................................................................................................... 375

Figure A-6 Certicate of Volatility (750dw; 3 of 4) .......................................................................................................................... 376

Figure A-7 Certicate of Volatility (750dw; 4 of 4) .......................................................................................................................... 377

Figure A-8 Certicate of Volatility (772dn; 1 of 3) ........................................................................................................................... 378

Figure A-9 Certicate of Volatility (772dn; 2 of 3) ........................................................................................................................... 379

Figure A-10 Certicate of Volatility (772dn; 3 of 3) ........................................................................................................................ 380

Figure A-11 Certicate of Volatility (772dw; 1 of 4) ........................................................................................................................ 381

Figure A-12 Certicate of Volatility (772dw; 2 of 4) ........................................................................................................................ 382

Figure A-13 Certicate of Volatility (772dw; 3 of 4) ........................................................................................................................ 383

Figure A-14 Certicate of Volatility (772dw; 4 of 4) ........................................................................................................................ 384

Figure A-15 Certicate of Volatility (777z; 1 of 4) ........................................................................................................................... 385

Figure A-16 Certicate of Volatility (777z; 2 of 4) ........................................................................................................................... 386

Figure A-17 Certicate of Volatility (777z; 3 of 4) ........................................................................................................................... 387

Figure A-18 Certicate of Volatility (777z; 4 of 4) ........................................................................................................................... 388

Figure A-19 Certicate of Volatility (75050dn; 1 of 3) .................................................................................................................... 389

Figure A-20 Certicate of Volatility (75050dn; 2 of 3) .................................................................................................................... 390

Figure A-21 Certicate of Volatility (75050dn; 3 of 3) .................................................................................................................... 391

Figure A-22 Certicate of Volatility (75050dw; 1 of 4) ................................................................................................................... 392

Figure A-23 Certicate of Volatility (75050dw; 2 of 4) ................................................................................................................... 393

Figure A-24 Certicate of Volatility (75050dw; 3 of 4) ................................................................................................................... 394

Figure A-25 Certicate of Volatility (75050dw; 4 of 4) ................................................................................................................... 395

Figure A-26 Certicate of Volatility (77740dn; 1 of 3) .................................................................................................................... 396

Figure A-27 Certicate of Volatility (77740dn; 2 of 3) .................................................................................................................... 397

Figure A-28 Certicate of Volatility (77740dn; 3 of 3) .................................................................................................................... 398

Figure A-29 Certicate of Volatility (77740dw; 1 of 4) ................................................................................................................... 399

Figure A-30 Certicate of Volatility (77740dw; 2 of 4) ................................................................................................................... 400

Figure A-31 Certicate of Volatility (77740dw; 3 of 4) ................................................................................................................... 401

Figure A-32 Certicate of Volatility (77740dw; 4 of 4) ................................................................................................................... 402

Figure A-33 Certicate of Volatility (77740z; 1 of 4) ...................................................................................................................... 403

Figure A-34 Certicate of Volatility (77740z; 2 of 4) ...................................................................................................................... 404

Figure A-35 Certicate of Volatility (77740z; 3 of 4) ...................................................................................................................... 405

Figure A-36 Certicate of Volatility (77740z; 4 of 4) ...................................................................................................................... 406

Figure A-37 Certicate of Volatility (77750z; 1 of 4) ...................................................................................................................... 407

Figure A-38 Certicate of Volatility (77750z; 2 of 4) ...................................................................................................................... 408

Figure A-39 Certicate of Volatility (77750z; 3 of 4) ...................................................................................................................... 409

Figure A-40 Certicate of Volatility (77750z; 4 of 4) ...................................................................................................................... 410

Figure A-41 Certicate of Volatility (77760z; 1 of 4) ...................................................................................................................... 411

Figure A-42 Certicate of Volatility (77760z; 2 of 4) ...................................................................................................................... 412

Figure A-43 Certicate of Volatility (77760z; 3 of 4) ...................................................................................................................... 413

xvi ENWW

Page 17

Figure A-44 Certicate of Volatility (77760z; 4 of 4) ...................................................................................................................... 414

ENWW xvii

Page 18

xviii ENWW

Page 19

1 Theory of operation

●

Basic operation

●

System control

●

Cabling system

●

Print subsystem

●

Paper-handling system

●

Servicing system

●

Service uid and aerosol management systems

●

Airow system

●

Document feeder system

●

Scanning and image capture system (780/785)

●

Fax functions and operation

●

Output accessories

ENWW 1

Page 20

Airflow Assembly

Printhead Lift

Motor

Printhea d

Wiper Mo tor

N

S

Air Pump

Fluid Pump

Vent Soleno id

Air Pump

Motor

Fluid Pump Motor

Drop Detect

Carriage Motor

Image Sensor

Carriage Motor

Fluid Level Sensors

Acumen

Printhead Lift

Sensor

Printhead Lift

Encoder

Aerosol Fan

Motor

Airflow Fan

Motor

Airflow Heater

Airflow Ass embl y

Thermistor

F

Sheet 500 Tray 3

500 Sheet Tray 2

Duplex

Pinch 1

Duplex

Pinch 2

Output

Pinch 1

Ejection

Pinch 1

Output

Pinch 2

Tray 1

Separation

Pinch

Outpu t

Pinch 3

Duplex

Pinch 3

Duplex

Pinch 4

Duplex

Pinch 5

Left Vertical

Pinch 2

Tray 2 Pick

Roller

Tray 3 Pick

Roller

Printhead Assembly

Legend

Pinch roller

Motor

Star Wheel

Media Path

Retard Roller

Switch/Hall

Effect Sensor

Fan/Digital Tach

F

Other Sensors

Torque Coupling

12.13 mm Dia

16.17 mm Dia

PTO connection

150 LPI, 1200 Line

Digital Encoder

Opto Sensor

Solenoid

N

S

Reflective REDI

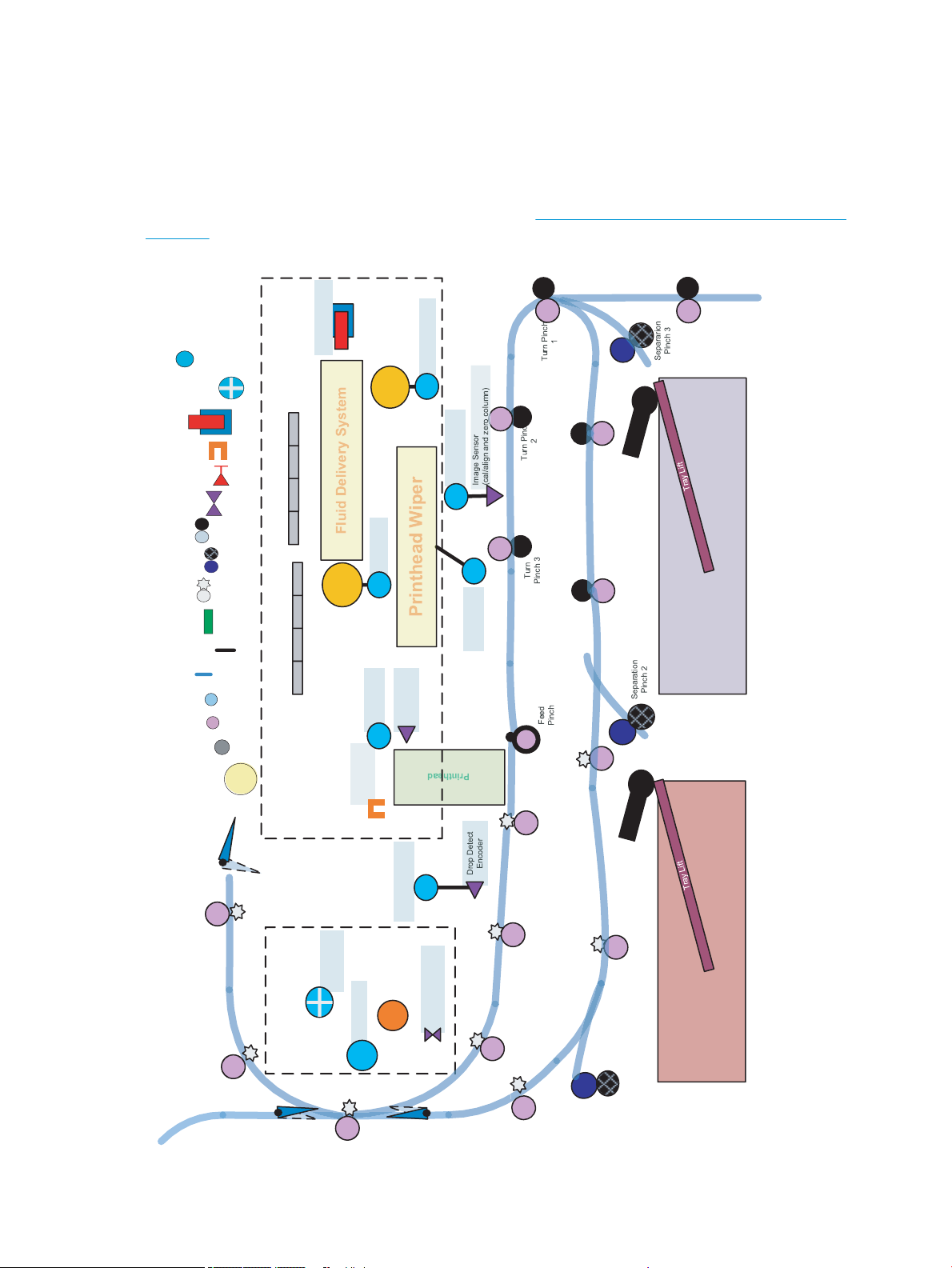

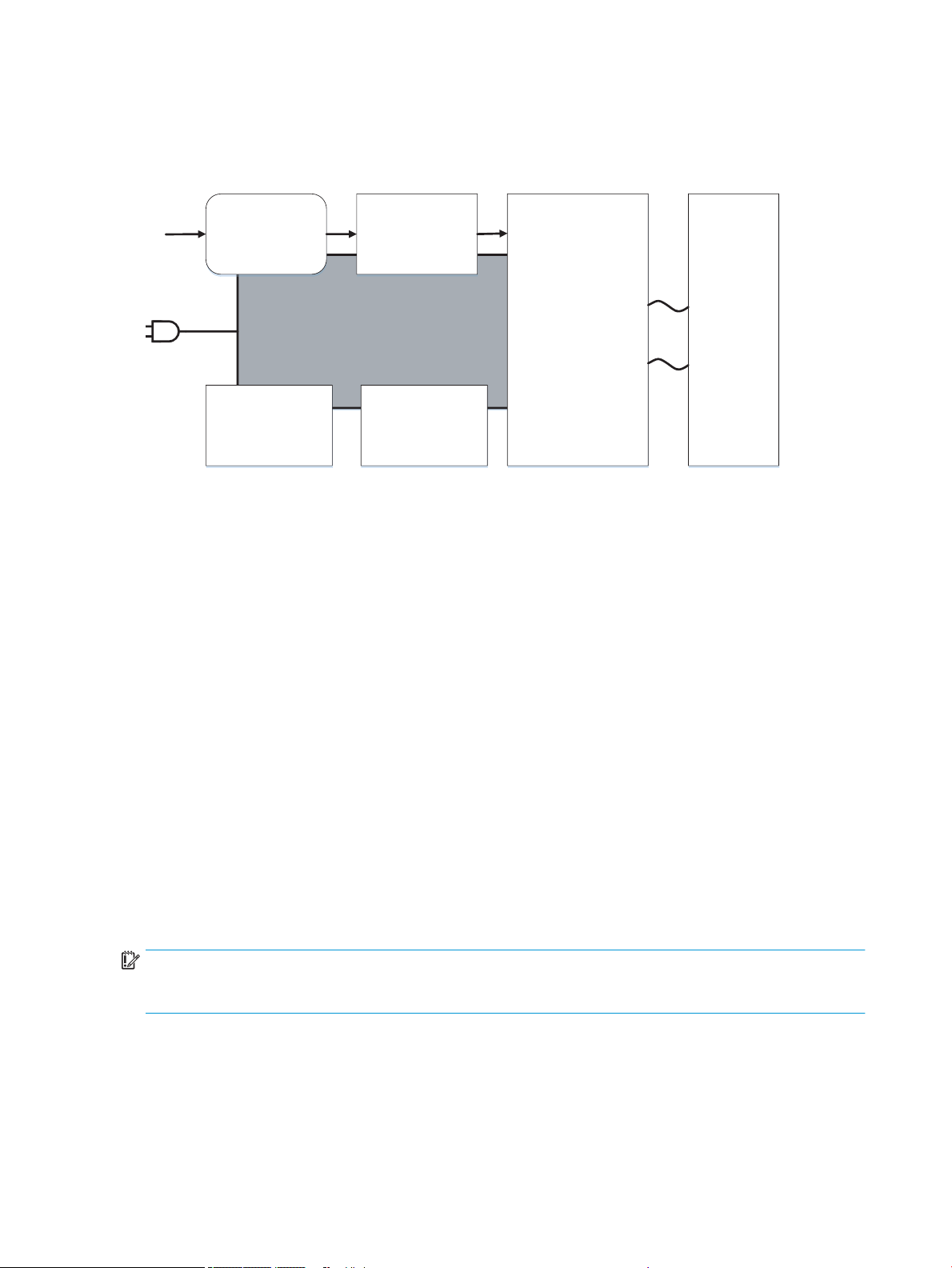

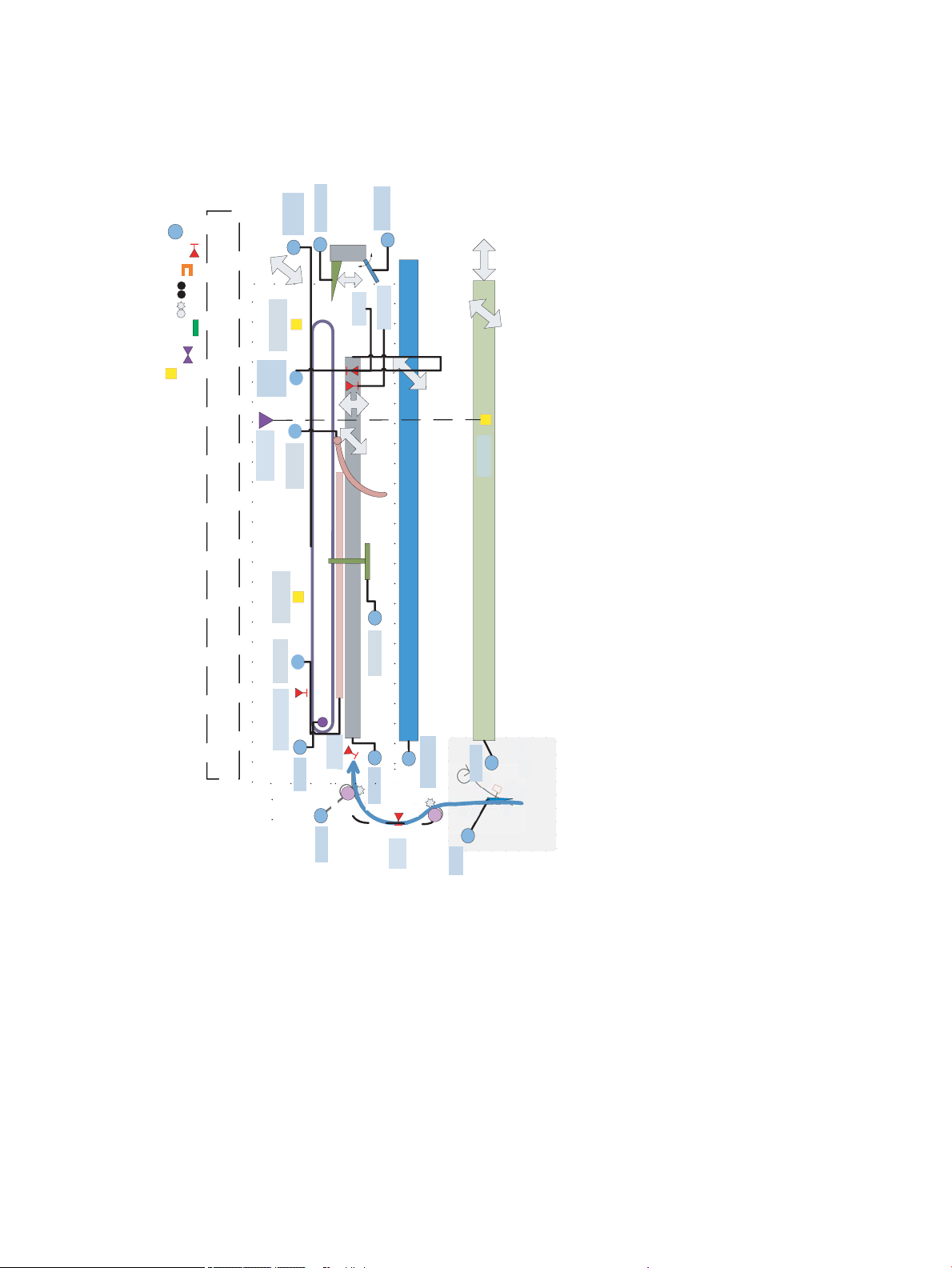

Basic operation

Function structure

HP recommends printing the following document (on A3 size paper) for troubleshooting reference. It is available

on the HP Web-based Interactive Search Engines (WISE). See HP Web-based Interactive Search Engines (WISE)

on page 3.

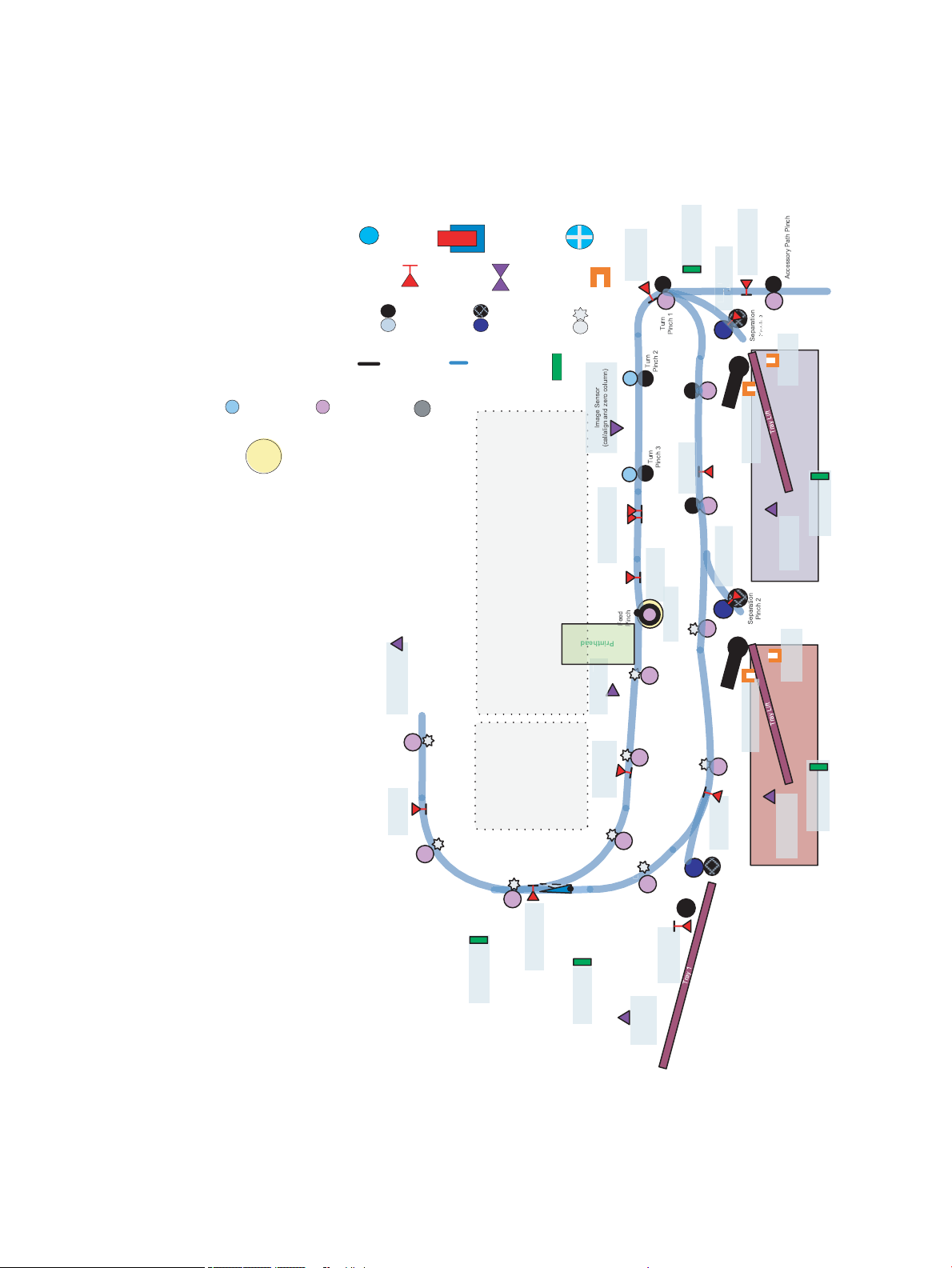

Figure 1-1 Printer printing system

2 Chapter 1 Theory of operation ENWW

Page 21

HP Web-based Interactive Search Engines (WISE)

The printer print system document is available on the HP Web-based Interactive Search Engines (WISE). Go to

the appropriate Web site (listed below), and then search information by printer name.

NOTE: Make sure that this document is printed on A3 size paper.

AMS

●

https://support.hp.com/wise/home/ams-en

●

https://support.hp.com/wise/home/ams-es

●

https://support.hp.com/wise/home/ams-pt

APJ

●

https://support.hp.com/wise/home/apj-en

●

https://support.hp.com/wise/home/apj-ja

●

https://support.hp.com/wise/home/apj-ko

●

https://support.hp.com/wise/home/apj-zh-Hans

●

https://support.hp.com/wise/home/apj-zh-Hant

EMEA

●

https://support.hp.com/wise/home/emea-en

ENWW Basic operation 3

Page 22

Operation sequence

The engine-control system on the main printed circuit board MPCA controls the operational sequences. The

following table describes the durations and the operations for each period of a print operation from when the

printer is turned on to when the motors stop rotating.

Table 1-1 Operation sequence

Period Duration Purpose

Initial startup and

calibrations

Servicing operations Performed just before the

Print preparation From the time the printer

When the printer is set up for the

rst time from the factory.

NOTE: Startup is disabled if the

temperature is 5°C (41°F) or

lower. The recommend

temperature range for this

function is 15°C (59°F) to 40°C

(104°F).

printhead enters the capped

state after printing, when leaving

the capped state after a print job

is initiated, or during printer idle

times when a print job is not

impacted.

receives a print command until

paper enters the print zone.

This one-time setup process gets the printer ready to print for the rst

time.

●

Fluid replacement—The printer ushes the shipping and

handling uid out of the printhead and replaces it with ink. No

pages are printed.

●

Pen energy calibration (TTOE)—No pages are printed.

●

Die alignment—The printer aligns the 14 die on the printhead

active face, and then prints and internally analyzes one page.

●

Die density leveling—The printer measures and compensates

for the drop variation, and then prints and internally analyzes

multiple pages.

Servicing maintains print quality by removing debris and excess ink.

Nozzle presence detection is employed to replace missing nozzles.

●

Nozzle presence detection—The optical scan carriage detects

and disables inoperable nozzles, and replaces them with

operable nozzles.

●

Printhead servicing—The web wipe on the printhead wiper

moves under the printhead to clean the active face and res the

nozzles into the ink collection unit to clear clogged or blocked

nozzles.

Prepares the printer for a print job.

●

The printhead leaves the capping state as the printhead wiper

moves away from the printhead.

●

If needed, some servicing occurs.

●

The printhead lowers to the printing position. The media type

and printing mode determine the print zone height.

●

The printer picks paper from one of the input trays.

●

Every page from Tray 1 is measured for edge detection. For Tray

2/3 and optional Trays 3, 4 and 5, the printer performs media

edge detection after printing the rst sheet. The last sheet of

each job is also measured for edge detection if at least ve

sheets have been printed.

●

The printer monitors environmental conditions. The printer can

slow the print speed if conditions are signicantly dierent from

a normal oce environment (23°C (73.4°F), 50% relative

humidity).

●

The formatter PCA processes print data and transmits the data

to the printhead.

4 Chapter 1 Theory of operation ENWW

Page 23

Table 1-1 Operation sequence (continued)

Period Duration Purpose

Printing From the start of media pick in

the designated input tray until

the last sheet is delivered to the

designated output bin.

End of print job Performed after the print job is

completed, and continues until

the next job is initiated.

Processes the print job.

●

The page is picked from the designated tray and travels through

the media path to the print zone.

●

As the page passes under the printhead, the printhead applies

ink to the page.

●

The page then enters the airow assembly area where heated

air might be applied to reduce the moisture content of the page.

●

For Simplex print jobs, the page then proceeds to the output bin

(face-down).

●

For Duplex print jobs, the page then advances until the trailing

edge of the media moves past the left side vertical path sensor.

The page then reverses direction and proceeds down through

the duplex path and underneath the left duplexer (service uid

container). Then the page turns upward, and re-enters the print

zone.

Ink is then applied to the second side of the page by the

printhead.

●

The process continues until all the pages of the print job are

completed. The process might be interrupted by occasional

printhead servicing events if the job includes many pages.

This period puts the printer in a state where it’s ready for the next

print job.

●

After a short dwell interval, the printhead will be allowed to cap.

Standby The printer is sitting idle, waiting

for the next print job to be

initiated.

●

If needed, servicing or nozzle presence detection occurs, but

these events are interruptible if another job is initiated.

●

The printhead moves to the capping position.

●

The printhead wiper moves to cap the printhead.

This period is intended to conserve energy while the printer is sitting

idle. Certain functions might be disabled to save power, and then

restarted when needed. The printer has two standby modes:

●

Idle mode—The printhead is capped and the printer is ready to

immediately start a new job

●

Sleep 1 mode—After the printer is inactive for about 10 minutes

(a setting that can be adjusted from the control panel or the

Embedded Web Server), the control panel turns o and the

power LED blinks to indicate the unit is in Sleep mode. When in

Sleep mode, the printer must wake up and go to idle mode

before all printer functions are available. The printer is designed

to wake up from Sleep mode based on certain interactions with

the printer, such as touching the control panel or opening a

paper tray.

●

Sleep 2 mode-After the printer is inactive for a longer period of

time (typically 2 hours), the engine controller powers down to

minimize power consumptions. This setting can be adjusted

from the control panel.

ENWW Basic operation 5

Page 24

System control

Power supply

FormaƩer

I/O, PDL, UI Control

Datapath

ASIC + memory

Pen I/F

Pen energy control

Pen voltage sequencing

Signal integrity

Ink-short protecƟon

Ink pumps

Printhead interconnects

Ink supply

Engine control

Motor + sensor drive

Printhead

56,000 nozzles

I/O

AC control

module

Airflow system

The system control coordinates all the other systems, according to commands from the MPCA.

Figure 1-2 System control

●

MPCA

●

Data path

●

Engine control

●

Pen interface

●

Power supply

●

AC control module

MPCA digital ASIC

The MPCA digital ASIC contains dual ARM CPUs (one at 512 MB and one at 600MHz) that execute rmware code

that provides high-level device control. The digital ASIC uses a standard PCle interface to pass data to the

formatter ASIC.

MPCA analog ASIC

The MPCA ASIC generates the system voltage for the MPCA, formatter drives the scanner and ADF motors,

manages the real-time clock, and drives the fax speaker.

Formatter and data path

IMPORTANT: Do not simultaneously install a replacement trusted platform module (TPM), hard disk drive (HDD

MFP), eMMC (SFP) and formatter PCA. Remove and install each part separately, making sure to turn the printer

power on between installations. Failure to do so results in an unusable printer.

The formatter controller ASIC controls the input/output (I/O) control, the user interface, and the rendering of

page description language les into printer-specic commands.

6 Chapter 1 Theory of operation ENWW

Page 25

Input/output (I/O) control

The printers support 10/100/1000 Ethernet, 802.11 wireless and NFC (some 765 and 780/785 models), a rear

USB host port, a rear USB device port, a walk-up USB host port, and analog fax port (some 780/785 models).

The formatter PCA controls the USB device and USB host. The optional dual USB host port accessory is also

connected to the formatter after user installation.

Wireless and NFC I/O are provided via a separate radio module.

User interface

The printers contain either a 4.3-in (765 models) or an 8-in (780/785 models) color graphics display. For

wireless models, there is an icon on the control panel to denote that the wireless feature is enabled. The printers

include a walk-up USB host port for connection to thumb drives.

Formatter digital ASIC

The formatter digital ASIC has dual ARM CPUs (1.2 GHz) that execute rmware code that provides high-level

device control. The digital ASIC uses a standard PCle interface to pass data to the engine control ASIC. The

formatter rmware is located on either a 320 GB hard-disk drive (HDD) on 780/785 models, or an embedded 8

GHz MultiMedia Card (eMMC) or optional HDD on 765 models.

Additionally, the formatter digital ASIC manages the real-time clock, interfaces to the mass storage controller

ASIC, provides control of USB ports, and interfaces with the Ethernet LAN ASIC and fax module.

Formatter Ethernet ASIC

The formatter Ethernet ASIC connects to the formatter digital ASIC with a PCIe interface to transmit and receive

network packets.

Formatter mass storage ASIC

The formatter mass storage ASIC bridges between the formatter digital ASIC (via PCIe interface) and the mass

storage device (via SATA interface). The 780/785 models use a rotating media HDD, while the 765 models use

eMMC an optional HDD is available.

Formatter memory

Formatter memory is installed on-board and there is support for additional DIMM memory installation. The size

of the memory on the formatter is 1.5 GB for 765 models and 2.5-3.0 GB for 780/785 models. An optional 1GB

DIMM is available as a customer accessory.

Real-time clock

The real-time clock (RTC) allows the fax module to time-stamp outgoing faxes. It also determines the elapsed

time between printhead and ISS calibration events. The RTC uses a separate device connected to the formatter

digital ASIC, along with a crystal and a battery.

Late point dierentiation conguration (LPDC)

Allows the channel partner to congure the speed to the printer depending on the customer’s order. LPDC

conguration is stored on the Trusted Platform Module (TPM). There are three methods to program the speed to

the printer.

ENWW System control 7

Page 26

●

Automatic

●

O line

●

Manual

Engine control

The engine controller digital ASIC receives high-level commands from the MPCA, and it then provides low-level

control to the print mechanism. In particular, the engine controller digital ASIC and its rmware control motors,

system sensors, and the printhead. The engine controller analog ASICs integrate motor drivers, voltage

regulators, sensor interfaces, and supervisory circuits.

Engine controller digital ASIC

The engine controller digital ASIC has a high-performance 480 MHz ARM CPU and DSP co-processors that

execute rmware code to provide low-level engine control. It also drives a FPGA which then creates the

printhead 15 high-speed LVDS transmission signals. The signals are routed from the engine PCA to the printhead

via two large FFC cables. The engine controller digital ASIC receives pre-rendered data from the MPCA digital

ASIC over a standard PCle interface.

When a printer enters Sleep mode, many functions of the printer go into a low-power mode. If a print job is

received while the printer is in Sleep mode, the printer will take a short period of time to "wake up". This can take

up to 15 seconds, which will delay the rst page out (FPO) time accordingly.

Engine controller analog ASICs

The engine uses six analog ASICs to generate the system voltages for the engine, drive the engine motors,

control various engine sensors, and monitor printhead power delivery for correct operation.

The engine contains 24 motors, 3 solenoids and 2 fans:

NOTE: The air ow fan is created using a DC motor.

Certain models might have fewer motors, depending upon the exact conguration of the paper trays.

Motors

●

Tray 1 pick motor

●

Tray 2 lift motor

●

Tray 3 lift motor

●

Tray 1 separation motor

●

Tray 2 separation motor

●

Tray 3 separation motor

●

Duplex diverter motor

●

Duplex entry motor

●

Duplex exit motor

●

Finisher diverter motor

●

Vertical motor

8 Chapter 1 Theory of operation ENWW

Page 27

Solenoids

●

Deskew motor (front)

●

Deskew turn motor (back)

●

Scanning carriage motor

●

Stack control motor

●

Printhead wiper motor

●

Eject motor

●

Drop detect carriage motor

●

Print zone feed motor

●

Ink pump motor

●

Ink prime motor

●

Air ow fan motor (for the air ow fan)

●

Printhead lift motor

●

Tray 2 pick solenoid (E-clutch)

●

Tray 3 pick solenoid (E-clutch)

●

Ink prime vent solenoid

Fans

●

Airow fan

Aerosol fan

Most motors are DC motors with encoder feedback, to provide precision servo control. These motors are driven

directly by one of the engine analog ASICs.

The printer uses many sensors to track the media as it travels through the paper path. Most of these are optical

reective edge detection interrupter (REDI) sensors, which are used in conjunction with mirrors to sense the

presence or absence of paper in the paper path. These are carefully aligned and calibrated at the factory, so care

must be taken when servicing these sensors. See the remove and Replace chapter of the Repair manual for

more details.

Other printed circuit assemblies

In addition to hosting the system ASICs, the engine printed circuit assembly (PCA) incorporates many of the

circuits required to interface with sensors and other sub-system components. In some cases, this circuitry is

located on a smaller remote PCAs (SLBs) to optimize cable interconnects. The following table lists the various

PCAs in the base mechanism engine/MPCA.

IMPORTANT: Do not simultaneously install a replacement trusted platform module (TPM), hard disk drive (HDD

MFP), eMMC (SFP) and formatter PCA. Remove and install each part separately, making sure to turn the printer

power on between installations. Failure to do so results in an unusable printer.

ENWW System control 9

Page 28

Name Description/Function Name Description/Function

Left door PCA Distribution Main bin full sensor PCA Main bin paper out sensor

Printhead lift encoder PCA Printhead lift Heat zone temperature

thermistor PCA

Feed motor encoder PCA Feed motor Contact size detect PCA Paper length/width detect

Left front upper PCA Distribution SIM PCA SHAID and distribution

Air ow assembly PCA Air ow assembly TT dashboard PCA Tabletop control panel interface

Center rear lower PCA Distribution HE1 PCA Hall eect sensor

Left rear lower PCA Distribution Button on/o PCA Base mechanism on/o

AC control module PCA AC control for air ow assembly Power button interface PCA Base mechanism on/o button

Printhead registration sensor

PCA

Main logic PCA MPCA and engine Power button PCA Base mechanism on/o button