Page 1

HP LaserJet M9059 MFP

Service Manual

Page 2

Page 3

HP LaserJet M9059 MFP

Service Manual

Page 4

Copyright and License

© 2009 Copyright Hewlett-Packard

Development Company, L.P.

Trademark Credits

®

Adobe

, Acrobat®, and PostScript® are

trademarks of Adobe Systems Incorporated.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CE800–90928

Edition 1, 06/2009

Java™ is a US trademark of Sun

Microsystems, Inc.

Microsoft®, Windows®, and Windows®XP

are U.S. registered trademarks of Microsoft

Corporation.

Windows Vista® is either a registered

trademark or trademark of Microsoft

Corporation in the United States and/or other

countries.

ENERGY STAR

®

logo

are U.S. registered marks of the United

®

and the ENERGY STAR

States Environmental Protection Agency.

Page 5

Table of contents

1 Product basics

Product introduction ............................................................................................................................. 2

Product features ................................................................................................................................... 3

Product walkaround .............................................................................................................................. 7

Output devices ..................................................................................................................................... 8

3,000-sheet stacker ............................................................................................................. 8

3,000-sheet stapler/stacker ................................................................................................. 8

Paper handling features ...................................................................................... 8

Stapling information ............................................................................................ 8

Multifunction finisher ............................................................................................................ 8

Paper handling features ...................................................................................... 8

Stapling information ............................................................................................ 9

Booklets .............................................................................................................. 9

8-bin mailbox ..................................................................................................................... 10

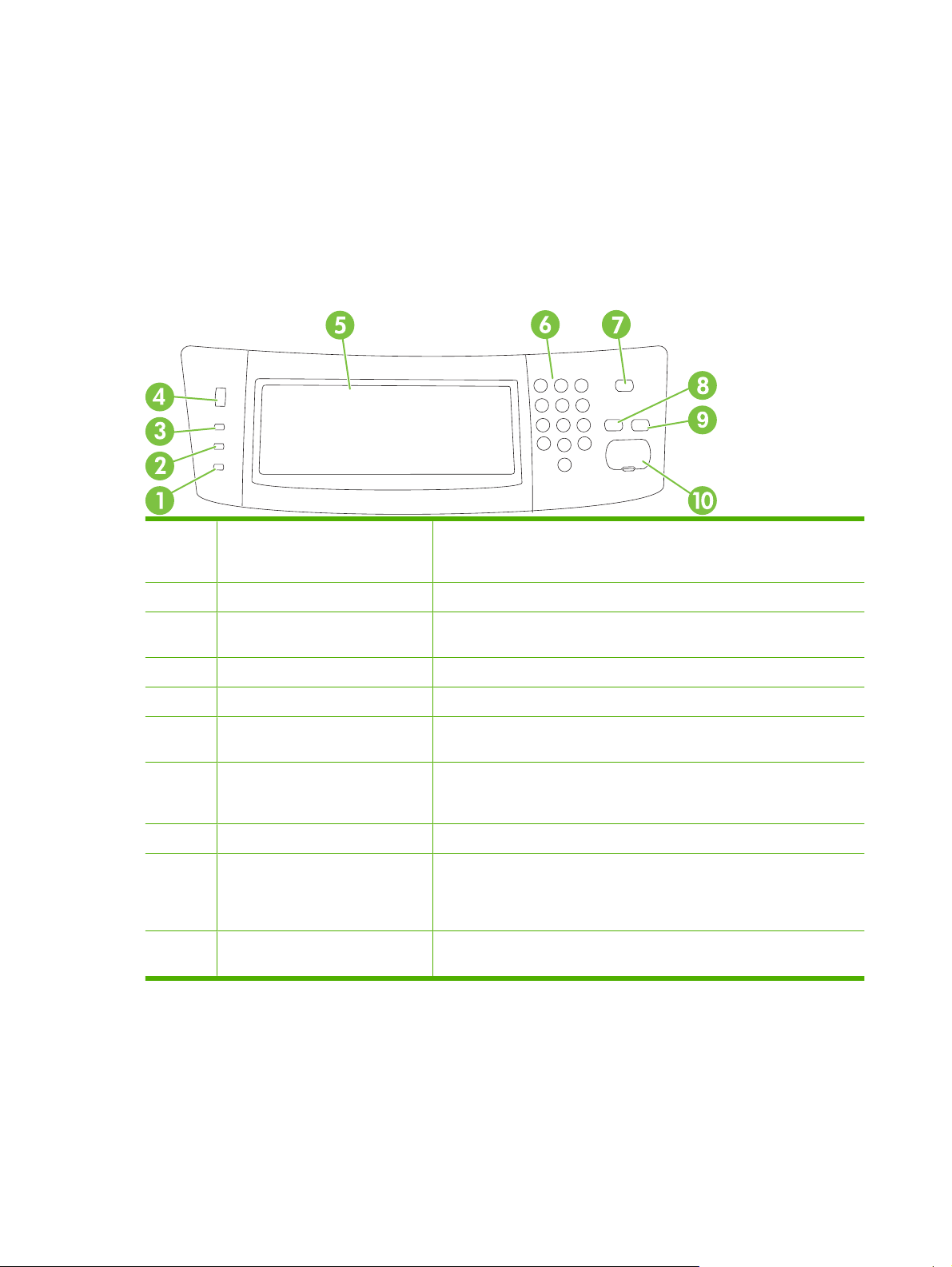

2 Control panel

Use the control panel ......................................................................................................................... 12

Use the Administration menu ............................................................................................................. 15

Control-panel layout ........................................................................................................... 12

Home screen ..................................................................................................................... 13

Buttons on the touchscreen ............................................................................................... 14

Control-panel help system ................................................................................................. 14

Navigate the Administration menu ..................................................................................... 15

Information menu ............................................................................................................... 16

Default Job Options menu ................................................................................................. 17

Default Options for Originals ............................................................................. 17

Default Copy Options ........................................................................................ 18

Default Fax Options .......................................................................................... 19

Default E-mail Options ...................................................................................... 20

Default Send to Folder Options ......................................................................... 21

Default Print Options ......................................................................................... 22

Time/Scheduling menu ...................................................................................................... 23

Management menu ............................................................................................................ 25

Initial Setup menu .............................................................................................................. 26

ENWW iii

Page 6

Device Behavior menu ....................................................................................................... 39

Print Quality menu ............................................................................................................. 43

Troubleshooting menu ....................................................................................................... 45

Resets menu ...................................................................................................................... 47

Service menu ..................................................................................................................... 47

3 Paper and print media

Understand paper and print media use .............................................................................................. 50

Supported paper and print media sizes .............................................................................................. 51

Custom paper sizes ............................................................................................................................ 52

Special paper or print media guidelines ............................................................................................. 53

Load paper and print media ............................................................................................................... 54

Load Tray 1 ........................................................................................................................ 54

Load Trays 2, 3, and 4 ....................................................................................................... 55

Configure trays ................................................................................................................................... 61

Configure a tray when loading media ................................................................................ 61

Configure a tray by using the Supplies Status button on the touchscreen ........................ 61

Select the media by source, type, or size .......................................................................... 61

Select the output bin ........................................................................................................................... 63

Select an output location ................................................................................................... 64

Networking and I/O ........................................................................................... 26

Fax Setup .......................................................................................................... 35

E-mail Setup ...................................................................................................... 38

Send Setup menu ............................................................................................. 38

Source ............................................................................................................... 62

Type and Size ................................................................................................... 62

Printing .............................................................................................................. 64

Copying ............................................................................................................. 64

4 Manage and maintain

Information pages ............................................................................................................................... 66

Embedded Web server ....................................................................................................................... 68

Open the embedded Web server by using a network connection ..................................... 68

Embedded Web server sections ........................................................................................ 69

Use HP Web Jetadmin software ........................................................................................................ 72

HP Printer Utility for Macintosh .......................................................................................................... 73

Open the HP Printer Utility ................................................................................................. 73

Print a cleaning page ......................................................................................................... 73

Print a configuration page .................................................................................................. 73

View supplies status .......................................................................................................... 73

Upload a file to the product ................................................................................................ 74

Update the firmware .......................................................................................................... 74

Activate the two-sided printing (duplexing) mode .............................................................. 74

iv ENWW

Page 7

Lock or unlock storage devices ......................................................................................... 74

Save or print stored jobs .................................................................................................... 75

Configure trays .................................................................................................................. 75

Change network settings ................................................................................................... 75

Open the embedded Web server ....................................................................................... 76

Set up e-mail alerts ............................................................................................................ 76

Security features ................................................................................................................................ 77

Secure the embedded Web server .................................................................................... 77

Secure Disk Erase ............................................................................................................. 77

Data affected ..................................................................................................... 77

Gain access to Secure Disk Erase .................................................................... 78

Additional Information ....................................................................................... 78

Security lock ...................................................................................................................... 78

Authentication .................................................................................................................... 78

Lock the control-panel menus ............................................................................................ 78

Set the real-time clock ........................................................................................................................ 80

Clean the product ............................................................................................................................... 81

Print a cleaning page ......................................................................................................... 81

Clean the product hardware .............................................................................................. 81

Clean the ADF delivery system ........................................................................................ 83

Configure alerts .................................................................................................................................. 88

Manage supplies ................................................................................................................................ 89

HP print cartridges ............................................................................................................. 89

Non-HP print cartridges ..................................................................................................... 89

Print cartridge authentication ............................................................................................. 89

HP fraud hotline ................................................................................................................. 89

Print cartridge storage ....................................................................................................... 89

Print cartridge life expectancy ............................................................................................ 90

Check the print cartridge life .............................................................................................. 90

Control panel ..................................................................................................... 90

Embedded Web server ..................................................................................... 90

HP Web Jetadmin ............................................................................................. 90

Printer maintenance kit ....................................................................................................................... 91

Manage memory ................................................................................................................................ 92

Determine memory requirements ...................................................................................... 92

Install memory ................................................................................................................... 92

Verify memory installation .................................................................................................. 95

Economy settings ............................................................................................................................... 96

Sleep and wake ................................................................................................................. 96

5 Theory of operation

Basic operation ................................................................................................................................... 98

Sequence of operation ....................................................................................................... 99

ENWW v

Page 8

Product start up sequence (turn on product) ................................................................... 102

Timing chart ..................................................................................................................... 103

Scanner subsystem ......................................................................................................... 103

Mechanical structure ....................................................................................... 103

Motors and fans .............................................................................................. 105

Basic block diagram ........................................................................................ 106

Basic system configuration ............................................................................. 107

Scanner unit systems ..................................................................... 107

Scan mode ..................................................................................... 108

Power supply assembly .................................................................. 108

Sleep mode .................................................................................... 109

Low-voltage power supply circuit .................................................... 110

Protective functions ........................................................................ 111

Scanner controller circuit ................................................................ 112

Flatbed operation ............................................................................................ 114

Flatbed document exposure control ............................................... 114

Flatbed optical drive control ............................................................ 114

Flatbed optical unit operation ......................................................... 115

Flatbed document size detection .................................................... 116

ADF operation ................................................................................................. 118

ADF document exposure control .................................................... 118

ADF document feed control ............................................................ 119

ADF document size detection ......................................................... 121

ADF feeder sensors ........................................................................ 122

ADF document skew detection ....................................................... 122

Scanned data flow ........................................................................................... 123

Copy processor ............................................................................................... 124

Scanning process control signals ................................................... 125

Typical scanning process flow ........................................................ 126

Engine control system ...................................................................................................................... 127

DC controller PCA ........................................................................................................... 128

High-voltage power supply circuit .................................................................................... 129

Low-voltage power supply ............................................................................................... 131

Fuser control circuit ......................................................................................................... 131

Formatter system ............................................................................................................................. 133

Formatter hardware ......................................................................................................... 133

Laser/scanner system ...................................................................................................................... 134

Image formation system ................................................................................................................... 135

The image formation process .......................................................................................... 135

Print cartridge .................................................................................................................. 136

Print cartridge design ...................................................................................... 137

No-shake toner ................................................................................................ 137

Cartridge memory ........................................................................................... 137

Toner seal ....................................................................................................... 137

vi ENWW

Page 9

Toner level detection ....................................................................................... 138

Pickup and feed system ................................................................................................................... 139

Media-size detection ........................................................................................................ 139

Media-level detection ....................................................................................................... 139

Multifeed prevention ........................................................................................................ 139

Transparency media detection ........................................................................................ 139

Fuser-wrapping jam detection ......................................................................................... 139

Jam detection .................................................................................................................. 140

Tray 1 ............................................................................................................................................... 145

Tray 1 driver PCA ............................................................................................................ 145

Tray 1 power supply ........................................................................................................ 145

Tray 1 sequence of operation .......................................................................................... 145

Tray 1 pickup and feed .................................................................................................... 146

Tray 1 jam detection ........................................................................................................ 146

Tray 4 ............................................................................................................................................... 147

Tray 4 driver PCA ............................................................................................................ 147

Tray 4 power supply ........................................................................................................ 147

Tray 4 sequence of operation .......................................................................................... 147

Tray 4 pickup and feed .................................................................................................... 148

Tray 4 media level and media size detection ................................................................... 148

Tray 4 jam detection ........................................................................................................ 148

6 Removal and replacement

Removal and replacement strategy .................................................................................................. 150

Repair notices .................................................................................................................................. 150

Electrostatic discharge ..................................................................................................................... 151

Required tools .................................................................................................................................. 151

Product orientation ........................................................................................................................... 152

Front and right side orientation ........................................................................................ 152

Back and left side orientation ........................................................................................... 153

Scanner assembly covers ................................................................................................................ 154

Control panel ................................................................................................................... 154

ADF feeder cover handle ................................................................................................. 157

ADF back cover ............................................................................................................... 157

ADF front cover ................................................................................................................ 159

Lower delivery roller cover ............................................................................................... 159

White board cover ............................................................................................................ 160

Copy processor/connect board ........................................................................................ 161

Reinstall the control panel ............................................................................... 155

ADF feeder cover ............................................................................................ 155

Reinstall the ADF feeder cover ....................................................................... 156

Reinstall the delivery roller cover .................................................................... 160

Reinstall the copy processor/connect board ................................................... 162

ENWW vii

Page 10

Flatbed rail cover ............................................................................................................. 162

Flatbed back cover .......................................................................................................... 162

Flatbed right cover ........................................................................................................... 164

Reinstall the flatbed right cover ....................................................................... 164

Flatbed left cover ............................................................................................................. 165

Flatbed upper front cover ................................................................................................. 166

Flatbed lower front cover ................................................................................................. 166

ADF base cover assembly ............................................................................................... 167

Reinstall the ADF base cover assembly ......................................................... 171

Scanner glass .................................................................................................................. 172

Reinstall the scanner glass ............................................................................. 173

Scan engine internal assemblies ...................................................................................................... 174

ADF and flatbed internal assemblies ............................................................................... 174

ADF main assembly ........................................................................................ 174

Reinstall the ADF main assembly ................................................... 179

ADF optical assembly ..................................................................................... 179

Reinstall the ADF optical assembly ................................................ 186

ADF shading filter ............................................................................................ 186

Flatbed optical unit .......................................................................................... 188

Reinstall the flatbed optical unit ...................................................... 190

Switch and solenoids ....................................................................................................... 191

ADF feeder cover detection switch ................................................................. 191

Weight solenoid ............................................................................................... 192

Shutter solenoid .............................................................................................. 192

Motors and fans ............................................................................................................... 193

Pickup motor ................................................................................................... 193

Reinstall the pickup motor .............................................................. 194

Delivery motor ................................................................................................. 194

Reinstall .......................................................................................... 195

Flatbed motor .................................................................................................. 195

Reinstall the flatbed motor .............................................................. 197

Power supply assembly .................................................................................. 197

Reinstall power supply assembly ................................................... 200

ADF fan assembly ........................................................................................... 200

Reinstall the ADF fan assembly ..................................................... 201

Flatbed fan assembly ...................................................................................... 201

Rollers and belts .............................................................................................................. 202

Pickup roller (D roller) ..................................................................................... 202

Pickup roller assembly .................................................................................... 202

Reinstall the pickup roller assembly ............................................... 203

Feed roller assembly ....................................................................................... 203

Lower registration roller assembly .................................................................. 204

Reinstall the lower registration assembly ....................................... 210

Lower delivery roller ........................................................................................ 210

viii ENWW

Page 11

Reinstall the lower delivery roller .................................................... 211

Upper delivery roller assembly ........................................................................ 211

Reinstall the upper delivery roller assembly ................................... 212

Separation belt assembly ................................................................................ 212

Reinstall the separation belt assembly ........................................... 215

Separation belts .............................................................................................. 215

Reinstall the separation belts ......................................................... 217

PCAs ................................................................................................................................ 217

ADF intermediate PCA .................................................................................... 217

ADF width detection sensor assembly ............................................................ 218

Reinstall the ADF width detection sensor assembly ....................... 218

Flatbed intermediate PCA ............................................................................... 219

Scanner controller board ................................................................................. 220

Intermediate PCA ............................................................................................ 222

Scan engine ..................................................................................................................... 223

Reinstall the scan engine ................................................................................ 227

Laser/scanner assembly .................................................................................................. 228

Delivery fan assembly ...................................................................................................... 229

Delivery motor .................................................................................................................. 231

Print engine covers ........................................................................................................................... 232

Front cover ....................................................................................................................... 232

Right door ........................................................................................................................ 233

Right lower cover ............................................................................................................. 234

Left upper cover ............................................................................................................... 23 4

Reinstall the left upper cover ........................................................................... 235

Left door and diverter ....................................................................................................... 236

Left back cover ................................................................................................................ 236

Back cover ....................................................................................................................... 237

Right and left rail covers .................................................................................................. 238

Front assemblies .............................................................................................................................. 239

Cartridge release lever .................................................................................................... 239

Print cartridge .................................................................................................................. 240

Reinstall the print cartridge ............................................................................. 241

Transfer-roller assembly .................................................................................................. 241

Reinstall the transfer-roller assembly .............................................................. 242

Tray 2 and Tray 3 (interchangeable) ............................................................................... 242

Rollers (pickup, feed, or separation) ................................................................................ 243

Fuser-jam-removal knob .................................................................................................. 243

Reinstall the fuser-jam-removal knob .............................................................. 244

Registration-jam-removal knob ........................................................................................ 244

Reinstall the registration-jam-removal knob .................................................... 245

Right assemblies .............................................................................................................................. 246

Tray 1 ............................................................................................................................... 246

Paper-input unit (PIU) ...................................................................................................... 247

ENWW ix

Page 12

Reinstall the paper-input unit .......................................................................... 250

Registration assembly ..................................................................................................... 250

Reinstall the registration assembly ................................................................. 251

Transfer-guide assembly ................................................................................................. 251

Reinstall the transfer-guide assembly ............................................................. 252

Left assemblies ................................................................................................................................ 253

Duplexer .......................................................................................................................... 253

Fuser assembly ............................................................................................................... 254

Back assemblies .............................................................................................................................. 256

Formatter ......................................................................................................................... 256

Low-voltage power supply ............................................................................................... 257

High-voltage power supply .............................................................................................. 259

DC controller .................................................................................................................... 260

Toner-sensor contact assembly ....................................................................................... 262

Reinstall the toner-sensor contact assembly .................................................. 263

Drum motor ...................................................................................................................... 263

Feed-drive assembly ....................................................................................................... 264

Reinstall the feed-drive assembly ................................................................... 265

Power-supply fan (fan 1) .................................................................................................. 265

Cartridge fan (fan 5) ......................................................................................................... 266

Reinstall the cartridge fan ............................................................................... 268

Controller fan (fan 2) ........................................................................................................ 268

Jetlink connector .............................................................................................................. 269

Duplexer connector holder assembly .............................................................................. 270

Fuser delivery-drive assembly ......................................................................................... 271

Reinstall the fuser delivery assembly .............................................................. 273

Tray 4 ............................................................................................................................................... 274

Orientation ....................................................................................................................... 274

Tray 4 left side cover ....................................................................................................... 274

Reinstall the Tray 4 left side cover .................................................................. 274

Tray 4 right side cover .................................................................................................... 275

Reinstall the Tray 4 right side cover ................................................................ 275

Tray 4 back covers .......................................................................................................... 276

Tray 4 center back cover ................................................................................. 276

Tray 4 right back cover .................................................................................... 276

Tray 4 left back cover ...................................................................................... 276

Tray 4 .............................................................................................................. 277

Tray 4 rollers (pickup, feed, and separation) ................................................................... 277

Reinstall the Tray 4 rollers .............................................................................. 278

Tray 4 registration assembly ............................................................................................ 278

Tray 4 drive motor ............................................................................................................ 279

Tray 4 drive assembly ...................................................................................................... 280

Tray 4 controller board ..................................................................................................... 281

Paper-size detection switch PCA .................................................................................... 282

x ENWW

Page 13

7 Solve problems

Troubleshooting process .................................................................................................................. 288

General troubleshooting information ................................................................................................ 290

Power-on checks .............................................................................................................................. 293

Malfunction troubleshooting ............................................................................................................. 294

Troubleshooting by using control-panel messages .......................................................................... 295

Control-panel error messages .......................................................................................................... 297

User- and service-level diagnostics .................................................................................................. 322

Service-level diagnostics .................................................................................................................. 326

Other diagnostics ............................................................................................................................. 330

Reinstall the paper-size switch PCA ............................................................... 283

Tray 4 power supply ........................................................................................................ 283

Tray 4 pickup assembly ................................................................................................... 284

Tray 4 paper-connecting unit ........................................................................................... 286

Preliminary operating checks ........................................................................................... 288

Installation environment .................................................................................. 288

Media checks .................................................................................................. 289

Scanner and ADF checks ............................................................................... 289

Abnormal noises are evident, such as grinding or chattering when the main motor is

turned on .......................................................................................................................... 290

Media does not feed from Tray X when printing from a software program; the paper-

path test is successful ...................................................................................................... 290

Media does not print from Tray 4 ..................................................................................... 290

The product stops printing and hangs on certain jobs ..................................................... 291

Envelopes are wrinkling ................................................................................................... 291

Fusing is poor .................................................................................................................. 291

The product feeds from an incorrect tray when different media is selected for the first

page of the job ................................................................................................................. 291

Event log page ................................................................................................................ 29 5

Print the event log ........................................................................................... 295

Interpret the event log ..................................................................................... 295

Sample event log ............................................................................................ 296

View the event log .......................................................................................... 296

Copy processor LEDs ...................................................................................................... 322

Troubleshooting menu ..................................................................................................... 323

Paper-path test ................................................................................................................ 324

Print a paper-path test ..................................................................................... 324

Service test ...................................................................................................................... 324

Perform a service test ..................................................................................... 324

Engine test ....................................................................................................................... 326

Service menu ................................................................................................................... 32 6

Boot-up key sequences ................................................................................................... 330

ENWW xi

Page 14

Low-level boot-up key sequence for selecting a language, performing a cold

reset, and enabling and disabling embedded LAN ......................................... 331

Medium-level boot-up key sequence for initializing disks ............................... 331

High-level boot-up key sequence for NVRAM initialization, manufacturing,

and skipping disk-load and calibration ............................................................ 331

Drum rotation functional check ........................................................................................ 332

Calibrations ...................................................................................................................... 332

Control panel touchscreen calibration ............................................................. 333

Simplified scanner and ADF calibration .......................................................... 333

ADF calibrations .............................................................................................. 336

Left side front calibration ................................................................ 336

Left side back calibration ................................................................ 338

Leading edge front calibration ........................................................ 339

Leading edge back calibration ........................................................ 340

ADF plain scaling calibration .......................................................... 340

ADF heavy scaling calibration ........................................................ 341

Glass calibrations ............................................................................................ 341

Left side glass calibration ............................................................... 341

Leading edge glass calibration ....................................................... 342

Glass scaling calibration ................................................................. 343

Plain motor speed calibration ......................................................... 343

Measurement and adjustment ......................................................................... 345

ADF unit height adjustment ............................................................ 345

ADF skew adjustment ..................................................................... 346

ADF width sensor adjustment ......................................................... 347

Weight solenoid stroke adjustment ................................................. 348

Tray 4 diagnostics ............................................................................................................................ 349

Motor test ........................................................................................................................ 349

Standalone running test ................................................................................................... 349

Sensor test ...................................................................................................................... 350

Light-pattern interpretation ............................................................................................... 350

Clear jams ........................................................................................................................................ 352

Jam locations ................................................................................................................... 352

ADF jams ......................................................................................................................... 353

Clear jams from the duplexer ........................................................................................... 354

Clear jams from the input-tray areas ............................................................................... 356

Clear jams from the output areas .................................................................................... 359

Solve repeated jams ........................................................................................................ 371

Image-formation troubleshooting ..................................................................................................... 372

Print image defects .......................................................................................................... 372

Print/stop test .................................................................................................. 373

Economode ..................................................................................................... 373

Skew ............................................................................................................... 374

Copy-image defects ......................................................................................................... 374

xii ENWW

Page 15

Scanner controller PCA ................................................................................... 376

Connector locations ........................................................................................ 378

Electrical structure ........................................................................................... 379

Wiring diagrams .............................................................................................. 380

Image-defect tables ......................................................................................................... 382

Repeating defect ruler ..................................................................................................... 390

Media troubleshooting ...................................................................................................................... 391

Determine the problem source ........................................................................................ 391

Isolate the paper path ...................................................................................................... 391

Try using the straightest paper path ................................................................ 391

Check the duplexing path ................................................................................ 391

Isolate the source of a jam .............................................................................. 391

Determine the location of a jam ...................................................................... 391

Determine whether the product is experiencing misfeeds or multifeed

jams ................................................................................................................. 391

Isolate a media brand ...................................................................................................... 392

Isolate a media type ......................................................................................................... 392

Communication troubleshooting ....................................................................................................... 393

Communications check .................................................................................................... 393

EIO troubleshooting ........................................................................................ 393

Jetdirect configuration ..................................................................................... 393

Embedded LAN troubleshooting ..................................................................... 393

Error codes ..................................................................................... 394

LAN diagnostics .............................................................................. 394

Wiring diagrams ............................................................................................................................... 398

8 Parts and diagrams

Order parts, accessories, and supplies ............................................................................................ 405

Supplies part numbers ..................................................................................................................... 406

Consumables, supplies, accessories, FRUs, and documents ......................................... 406

Common hardware .......................................................................................................... 409

Illustrations and parts lists ................................................................................................................ 410

Scanner assembly ............................................................................................................................ 412

Scanner engine covers and panels .................................................................................................. 414

Print engine covers and panels ........................................................................................................ 418

Flatbed scanner assembly ............................................................................................................... 420

Flatbed optical assembly .................................................................................................................. 426

ADF scanner assembly .................................................................................................................... 430

ADF paper pickup assembly ............................................................................................................ 434

ADF main assembly ......................................................................................................................... 440

ADF optical assembly ....................................................................................................................... 444

Scanner engine PCAs ...................................................................................................................... 446

Left door and diverter ....................................................................................................................... 448

Right cover assembly ....................................................................................................................... 450

ENWW xiii

Page 16

Print engine internal components ..................................................................................................... 452

Drum feed drive assembly ................................................................................................................ 460

Fuser delivery drive assembly .......................................................................................................... 462

Cartridge lifter assembly ................................................................................................................... 464

500-sheet trays (Tray 2 and Tray 3) ................................................................................................. 466

Paper input unit ................................................................................................................................ 468

Registration assembly ...................................................................................................................... 470

Transfer roller assembly ................................................................................................................... 472

Delivery assembly ............................................................................................................................ 474

PCA locations ................................................................................................................................... 476

Tray 4 main body .............................................................................................................................. 478

Tray 4 drive assembly ...................................................................................................................... 482

Tray 4 PCA location ......................................................................................................................... 484

Tray 1 assembly ............................................................................................................................... 486

Alphabetical parts list ....................................................................................................................... 488

Numerical parts list ........................................................................................................................... 512

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 538

Appendix B Specifications

Physical specifications ..................................................................................................................... 542

Considerations for "pre-flighting" a LaserJet .................................................................................... 543

Electrical specifications .................................................................................................................... 544

Acoustic emissions ........................................................................................................................... 545

Operating environment ..................................................................................................................... 545

Appendix C Regulatory information

FCC regulations ............................................................................................................................... 548

Declaration of conformity .................................................................................................................. 549

Certificate of volatility ....................................................................................................................... 550

Types of memory ............................................................................................................. 550

Volatile memory .............................................................................................. 550

Non-volatile memory ....................................................................................... 550

Hard-disk-drive memory .................................................................................. 550

Safety statements ............................................................................................................................. 551

Laser safety ..................................................................................................................... 551

Canadian DOC regulations .............................................................................................. 551

VCCI statement (Japan) .................................................................................................. 551

Power cord statement (Japan) ......................................................................................... 551

EMC statement (Korea) ................................................................................................... 551

EMI statement (Taiwan) ................................................................................................... 551

Laser statement for Finland ............................................................................................. 552

xiv ENWW

Page 17

Substances table (China) ................................................................................................ 553

Index ................................................................................................................................................................. 555

ENWW xv

Page 18

xvi ENWW

Page 19

1 Product basics

Product introduction

●

Product features

●

Product walkaround

●

Output devices

●

ENWW 1

Page 20

Product introduction

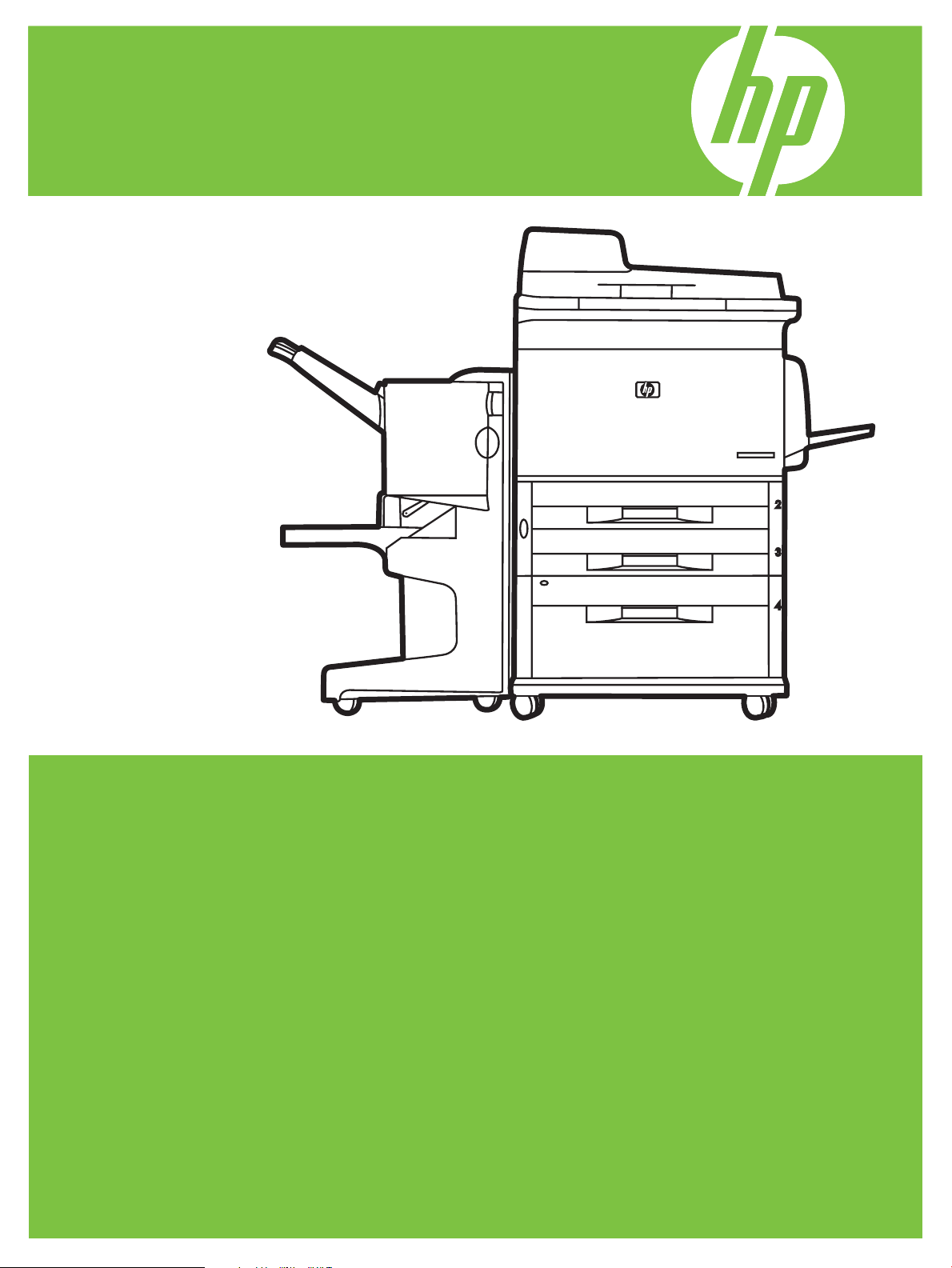

Figure 1-1 HP LaserJet M9059 MFP

The HP LaserJet M9059 MFP comes standard with the following items:

100-sheet multipurpose input tray (Tray 1)

●

Two 500-sheet input trays

●

One 2,000-sheet input tray

●

Automatic document feeder (ADF)

●

HP Jetdirect embedded print server for connecting to a 10/100/1000Base-TX network (Gigabit

●

support)

384 megabytes (MB) of random access memory (RAM)

●

Duplexer

●

Hard drive

●

2 Chapter 1 Product basics ENWW

Page 21

Product features

The HP LaserJet M9059 MFP is designed to be shared by a workgroup. The product is a standalone

copier that does not require connection to a computer. With the exception of network printing, you can

select all functions at the product control panel.

Functions

Two-sided copying and printing

●

Image modification

●

Color digital sending

●

Black-and-white printing and copying

●

Wide-format printing

●

Document finishing

●

Speed and throughput

40 ipm when scanning and printing on letter-size or ISO A4-size paper

●

25% to 400% scalability when using the scanner glass

●

25% to 200% scalability when using the automatic document feeder (ADF)

●

●

●

●

●

Resolution

●

●

●

Memory

●

●

User interface

●

Transmit Once, Raster Image Processing (RIP) ONCE technology

Eight-seconds to first page

Duty cycle of up to 300,000 images per month

533 megahertz (MHz) microprocessor

600 dots per inch (dpi) with Resolution Enhancement technology (REt)

FastRes 1200 provides 1200 dpi quality at full speed

Up to 256 levels of gray

384 megabytes (MB) of random-access memory (RAM), expandable to 512 MB by using industrystandard 100-pin double data rate dual inline memory modules (DDR DIMMs)

Memory Enhancement technology (MEt) that automatically compresses data to use RAM more

efficiently

Graphical display on control panel

Embedded Web server to gain access to support (for network-connected products)

●

ENWW Product features 3

Page 22

Language and fonts

HP Printer Command Language (PCL) 6

●

HP PCL 5e for compatibility

●

Printer Management Language

●

80 scalable TrueType typefaces

●

HP postscript level 3 emulation

●

Copying and sending

Modes for text, graphics, and mixed text and graphics formats

●

A job-interrupt feature (at copy boundaries)

●

Multiple pages per sheet

●

Operator attendance animations (for example, jam recovery)

●

The ability to copy books

●

E-mail compatibility

●

A sleep feature that saves energy

●

●

Print cartridge

●

●

●

Paper-handling

●

One-pass duplex scanning

No-shake cartridge design

Authentic HP print cartridge detection

Automatic seal-tab removal

Input

Tray 1 (multipurpose tray): A multipurpose tray for paper, transparencies, labels, and

◦

envelopes. Holds up to 100 sheets of paper or 10 envelopes.

Trays 2 and 3: Two 500-sheet trays. These trays automatically detect standard paper sizes

◦

up to 11 x 17/A3 and allow printing on custom-size paper.

Tray 4 (2000-sheet input tray): This tray automatically detects standard paper sizes up to

◦

11 x 17/A3 and allows printing on custom-size paper.

Automatic Document Feeder (ADF): Holds up to 100 sheets of Letter- or A4-size paper or

◦

50 sheets of 11 x 17- or A3-size paper.

Duplex printing: Provides two-sided printing (printing both sides of the paper).

◦

Output

●

4 Chapter 1 Product basics ENWW

Page 23

The product has the following optional output choices:

3000-sheet stacker: Stacks up to 3,000 sheets of paper.

◦

Upper bin (face up): Holds up to 100 sheets of paper.

Lower bin (face down): Holds up to 3,000 sheets of paper. The output bins are part of the

output device.

3000-sheet stapler/stacker: Provides multiposition stapling for up to 50 sheets of paper per

◦

job, or a maximum job height of 5 mm (0.2 in).

Upper bin (face up): Holds up to 100 sheets of paper.

Lower bin (face down): Holds up to 3,000 sheets of paper. The output bins are part of the

output device.

Multifunction finisher: Provides 1,000 sheets of stacking capacity, stapling for as many as

◦

50 sheets of paper per document, plus folding and saddle stitching of booklets that contain

up to 10 sheets of paper.

Upper bin (face up and face down): Holds up to 1,000 sheets of paper.

Lower booklet bin: Holds up to 50 booklets.

8-bin mailbox: A stacker, collator, or job separator that also provides eight mailbox bins that

◦

can be assigned to individual users or workgroups for easy identification and retrieval. The 8bin mailbox can stack up to 2,000 sheets of A4- or letter-size paper in all the bins.

Upper bin (face up): Holds up to 125 sheets of paper.

Bins 1 through 8 (face down): Each holds up to 250 sheets of paper.

Connectivity

Hi-Speed USB 2.0 connection

●

HP Jetdirect embedded print server.

●

Optional analog fax card

●

Optional HP Jetdirect EIO print server cards

●

HP Jetdirect 625n gigabit Ethernet internal print server

◦

Environmental features

To download the latest firmware, go to

●

onscreen instructions. To easily send firmware updates to multiple products, use the HP Web

Jetadmin software (go to

NOTE: HP Web Jetadmin 10.0 or later is required for full support of this product.

An internal hard disk can be used to store selected print jobs. It can support RIP ONCE technology

●

and can permanently store downloaded fonts and forms in the product. Many items on the hard

disk remain even when the product is turned off. Fonts on the hard disk are available to all users.

www.hp.com/go/ljm9059mfp_firmware and follow the

www.hp.com/go/webjetadmin).

An optional EIO hard disk accessory provides additional capacity for storing fonts and forms. The

●

product does not use the EIO hard disk accessory for tasks such as RIP ONCE and stored jobs.

ENWW Product features 5

Page 24

The product uses the internal hard disk for these tasks. Both disks can be write-protected through

software for additional security.

Security features

Secure Disk Erase

●

Security lock

●

Job retention

●

Front-panel authentication

●

6 Chapter 1 Product basics ENWW

Page 25

Product walkaround

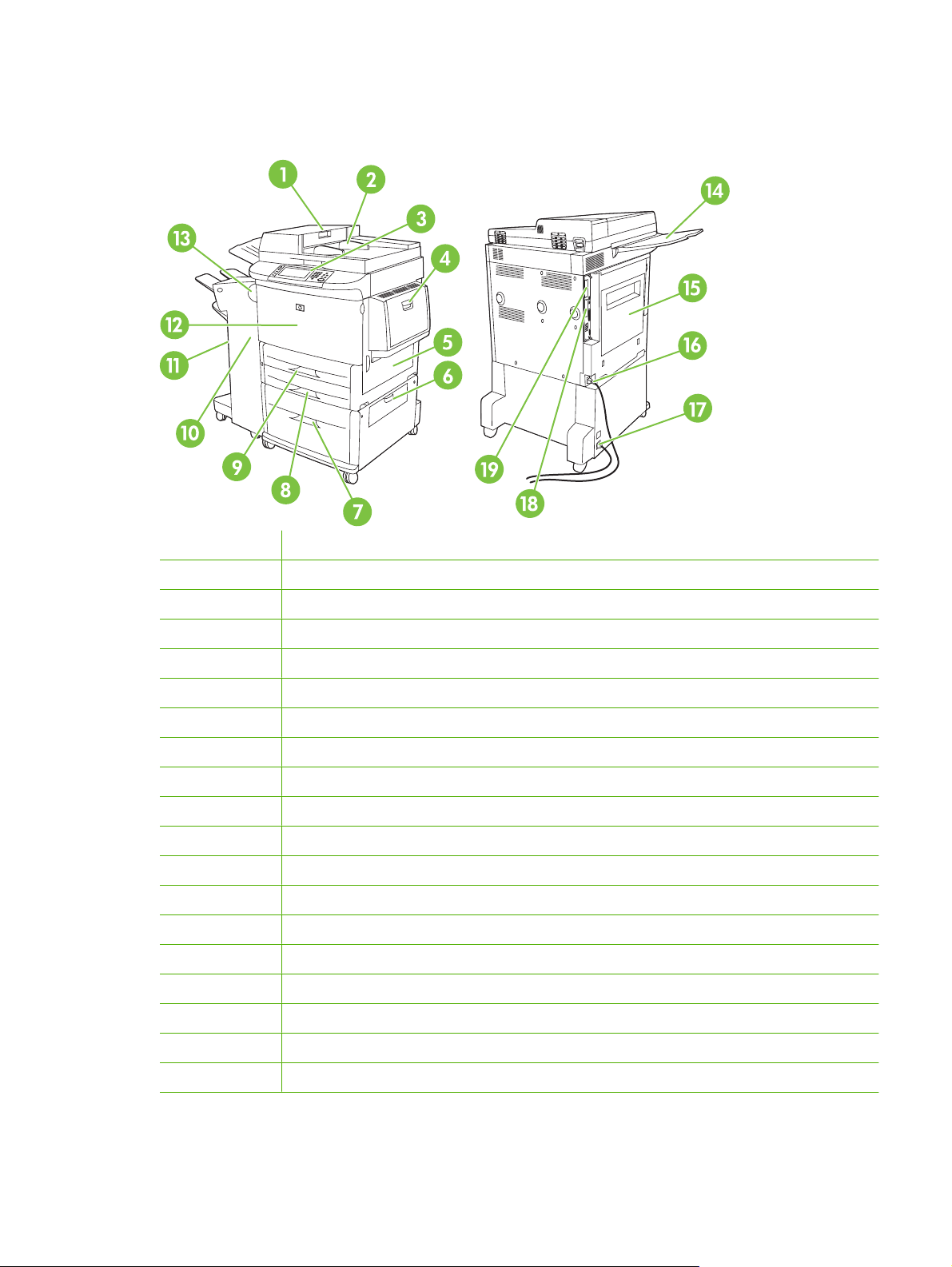

Figure 1-2 Product walkaround

1 Automatic document feeder cover

2 Automatic document feeder (ADF)

3 Control panel with touchscreen graphical display

4 Tray 1

5 Right door

6 Vertical transfer door

7 Tray 4

8 Tray 3

9 Tray 2

10 Left door (behind output device)

11 Output device

12 Front door

13 Duplex printing accessory (inside the product)

14 ADF output bin

15 Left door

16 Printer power cable

17 Tray 4 power cable

18 EIO slot 1

19 Copy processor EIO card

ENWW Product walkaround 7

Page 26

Output devices

The following optional finishing devices are available for this product: 3,000-sheet stacker, 3,000-sheet

stapler/stacker, multifunction finisher, and 8-bin mailbox.

3,000-sheet stacker

Stacks up to 3,000 sheets of A4- or letter-size paper

●

Stacks up to 1,500 sheets of A3- or ledger-size paper

●

Can offset jobs, or offset the first page of jobs

●

The lower bin (face-down bin) is the default bin for all output jobs.

3,000-sheet stapler/stacker

Paper handling features

Stacks up to 3,000 sheets A4- or letter-size paper

●

Stacks up to 1,500 sheets of A3- or ledger-size paper

●

Can offset jobs, or offset the first page of jobs

●

The upper bin (face-up bin) is the default bin for all output jobs.

Stapling information

The 3,000-sheet stapler/stacker can staple 2 to 50 pages of 75 g/m2 (20 lb) paper or equivalent 5 mm

(0.2 in). The pages must be 64 to 199 g/m

Heavier media might have a stapling limit of fewer than 50 pages.

●

If the job is only one sheet, or, if it is more than 50 sheets, it is printed and not stapled.

●

You can usually select the stapler in the software program or print driver, although some options might

be available only in the print driver. See the product user guide for more information.

If the stapler cannot be selected in the program or printer driver, it can be selected through the product

control panel. See the product user guide for instructions.

Multifunction finisher

Paper handling features

Stacks up to 1,000 sheets of A4 and letter paper or up to 500 sheets of A3 and 11 x 17 paper

●

Stacks up to 40 booklets of 5 sheets of A3 and ledger paper

●

Can offset jobs

●

Staples up to 50 sheets of paper per document of A4 and letter paper

●

2

(17 to 53 lb) of all sizes that the device supports.

Staples up to 25 sheets of paper per document A3 and ledger paper

●

8 Chapter 1 Product basics ENWW

Page 27

Folds single pages

●

Saddle-stitches and folds up to 40 booklets of 5 sheets stacked, or 20 booklets of 10 sheets stacked

●

Stapling information

Booklets

The finisher can staple 2 to 50 pages of 75 g/m2 (20 lb) A-4 or letter-size paper or up to 25 pages of A3

11 x 17 paper or equivalent to 5.5 mm (0.22 in). The pages must be 64 to 199 g/m

sizes supported by the device.

Consider these additional points:

The upper bin (stacker bin) can hold up to 1,000 sheets stacked (not stapled). The multifunction

●

finisher can deliver jobs face up or face down to the upper bin.

Heavier media might have a stapling limit of fewer than 50 pages.

●

If the job is only one sheet, or, if it is more than 50 sheets, it is printed and not stapled.

●

You can usually select the stapler in the software program or print driver, although some options might

be available only in the print driver. See the product user guide for more information.

If the stapler cannot be selected in the program or print driver, it can be selected through the product

control panel. See the product user guide for instructions.

You can gain access to the booklet feature in some software programs, such as desktop publishing

programs. See the user guide that came with your program for information about making booklets.

If you are using a program that does not support booklet making, you can create booklets by using the

HP print driver.

2

(17 to 53 lb) of all

NOTE: HP recommends that you use your program to prepare and preview your document for printing,

and then use the HP print driver to print and saddle stitch your booklet.

Use the following steps to create a booklet by using the print driver:

Prepare your booklet: Arrange the pages on a sheet (called booklet imposition) to create a booklet.

●

You can impose your booklet in your software program, or you can use the booklet-printing feature

in print driver.

Add a cover: Add a cover for the first page by selecting a different paper type that is the same size

●

as the rest of the booklet. The cover can be a weight different from the rest of the booklet.

Use saddle stitching: Paper must be fed into the product short edge first. The product prompts you

●

for rotated paper. The multifunction finisher staples the center of your booklet (called saddle

stitching). If your booklet contains only one sheet of paper, the multifunction finisher folds the sheet

but does not staple it. If the booklet contains more than one sheet of paper, the multifunction finisher

staples the sheets and then folds up to 10 sheets per booklet.

The booklet-printing feature of the multifunction finisher supports the saddle stitch and fold feature for

the following paper sizes:

A3

●

A4-Rotated (A4-R)*

●

Letter-Rotated (Letter-R)*

●

ENWW Output devices 9

Page 28

●

●

Legal

Ledger

See the HP Multifunction Finisher User Guide at

about making booklets.

* A4-R and Letter-R are A4- and letter-size paper that is rotated 90˚ in the source tray.

8-bin mailbox

Handles high-capacity output that increases the product output capacity to 2,000 sheets of

●

standard media

Uses the upper bin to provide 125 sheets of face-up stacking capacity

●

Delivers printed jobs face down to the eight face down bins, and each bin provides 250 sheets of

●

stacking capacity

Offers stacking options in different operational modes: mailbox, stacker, job separator, and sorter/

●

collator