Page 1

W

hite

HP Color LaserJet 3000, 3600, and

Paper

3800 Series Printer - Toner Cartridge

Shutters not closing/opening

Security Level: For HP and Channel Partner Internal Use

Date Written/Updated: September 19, 2006

Document Summary

Customers may experience trouble with shutters on the toner cartridges not opening or closing

Follow the troubleshooting steps below to determine the root cause

Issue Description:

The customer may experience issues with the toner cartridge shutters not opening or closing

when opening or closing the front door.

Solution or Workaround:

• Reseat all the cartridges

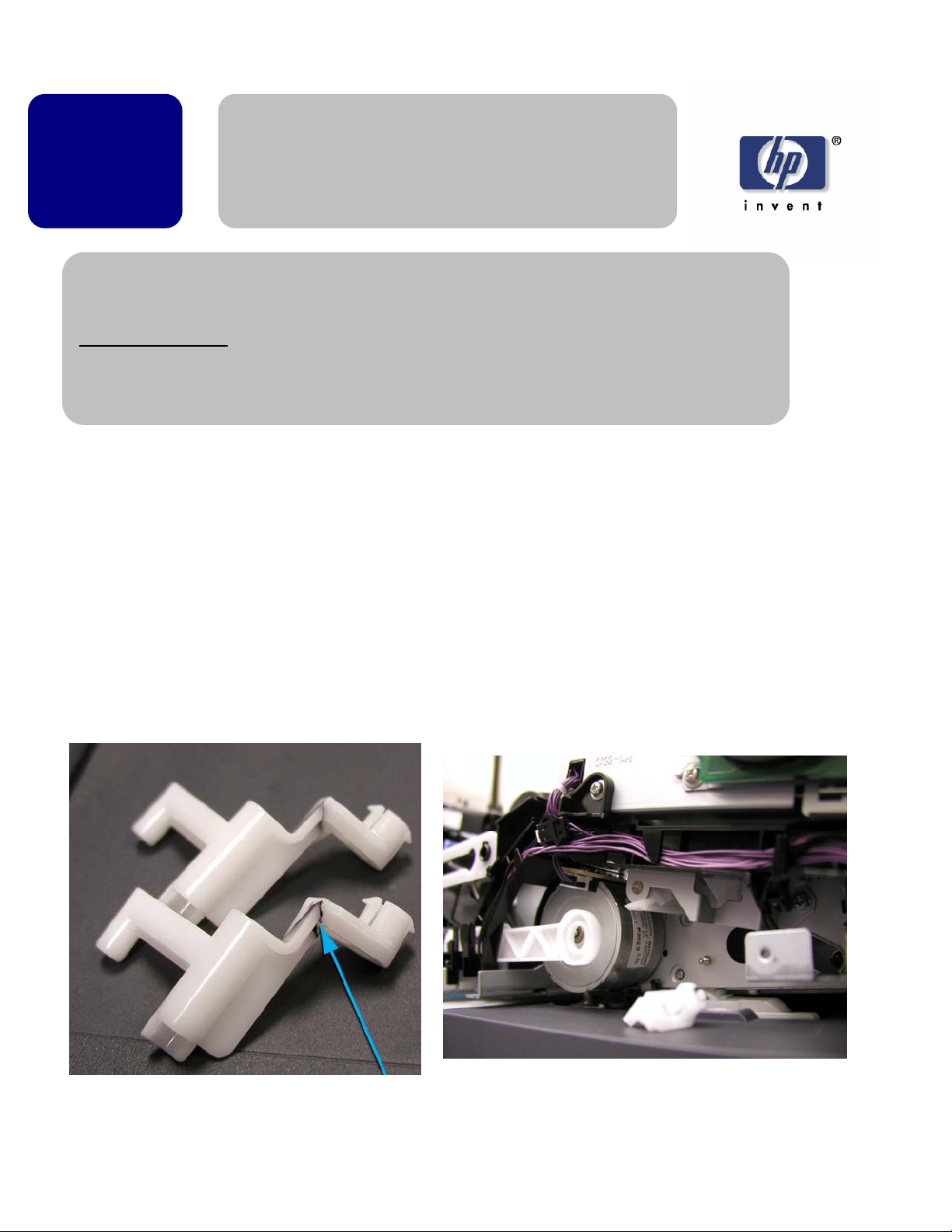

• Check for a broken part that controls the movement of the cartridge engagement arm, the cartridge

shutters, and the OPC drive. (See picture below – it outlines where the break occurs in the picture to the

left, and where this part is located for the picture on the right. The red arrows show where the part

should be.) You can easily check this without taking off the covers by reaching over to the white rod arm

on the right hand side of the ETB, and “wiggle” it. If it moves easily, then this part is broken. Replace

this part if broken (RC1-6645-000CN).

Page 1 of 18

Page 2

NOTE: If these break, this can also cause a 10.92.XX error.

In order to replace this part, please see the documentation below.

SERVICE ACTION

To Be Performed By: Service Technicians

1. Remove the toner cartridges and ETB.

2. Remove the upper cover (Page 80 in the Service Manual).

3. Remove the right cover (Page 87 in the service Manual).

4. For duplex models: Remove the wires to the duplex fan in the front cover. Simply follow

instructions 5 and 6 on page 77 – 78 in the service manual. This allows for easier removal of the

cable harnesses.

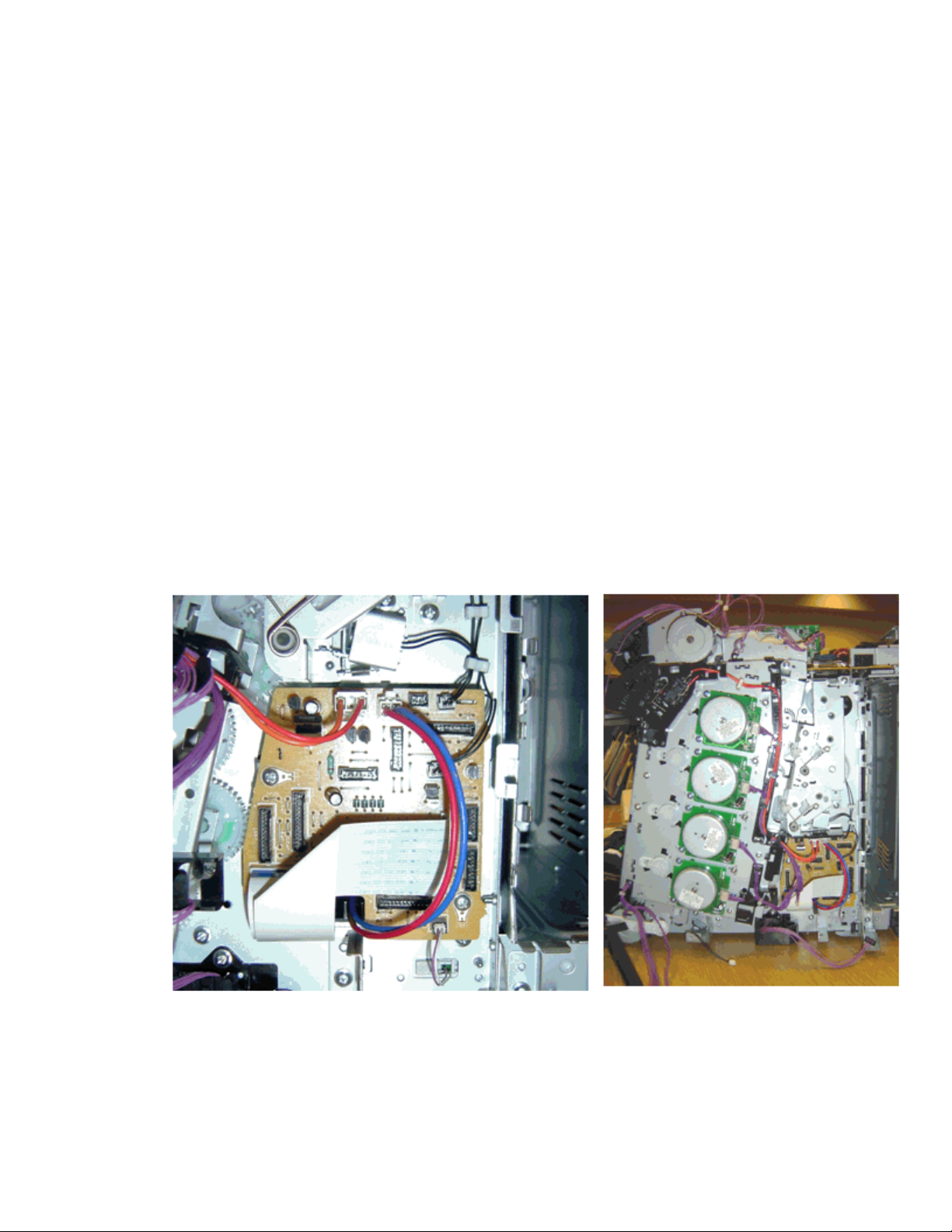

5. Unplug the following connectors from the driver PCA and remove the wires from the cable

harnesses: a. J209, b. J406, c. J404, d. J213, e. J207, f. J203, g. J402, h. J206, I. J410, j. J208.

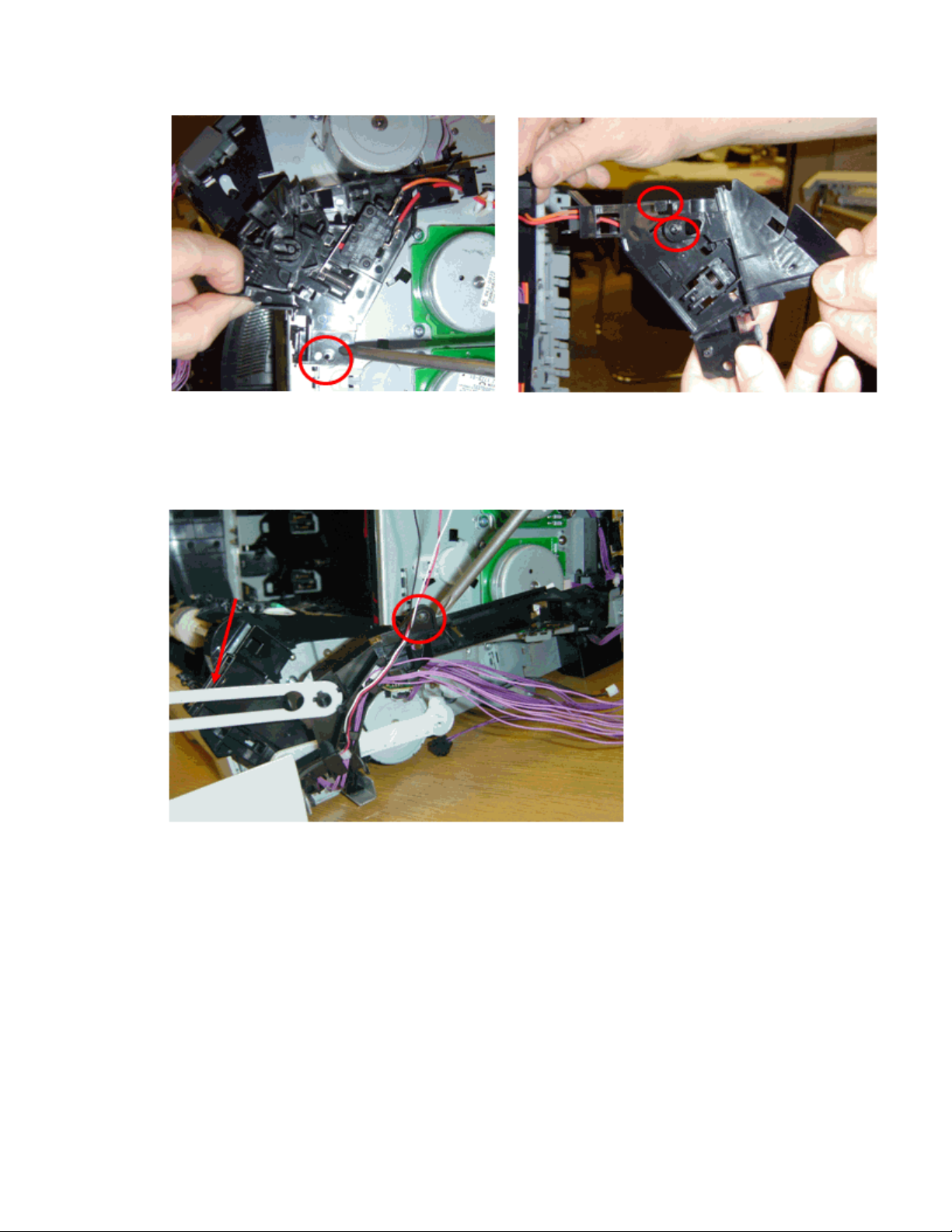

6. Remove the interlock switch assembly by removing the one screw attaching it to the chassis. Be

aware of the clip at the top and the alignment knob when removing the assembly.

Page 2 of 18

Page 3

7. Remove the bottom cable harness. There is one screw at the top to remove. Hint: when you

reinstall the guide, make sure that the rear locking tab is seated in the sheet-metal chassis. (See

page 120 - 121 in the service manual). It may be necessary to disconnect the white door latch

from the front door. (Notice the red arrow call-out).

8. Remove the main drive assembly (MDA). There are six screws attaching the MDA to the chassis.

Carefully note the locations of the screws to be removed.

CAUTION: Removing the incorrect screws could lead to opening up the MDA, requiring a uni t

replacement!

NOTE: Two gears may fall off, there are instructions in step 16 on how to align them during the

re-installation process.

Page 3 of 18

Page 4

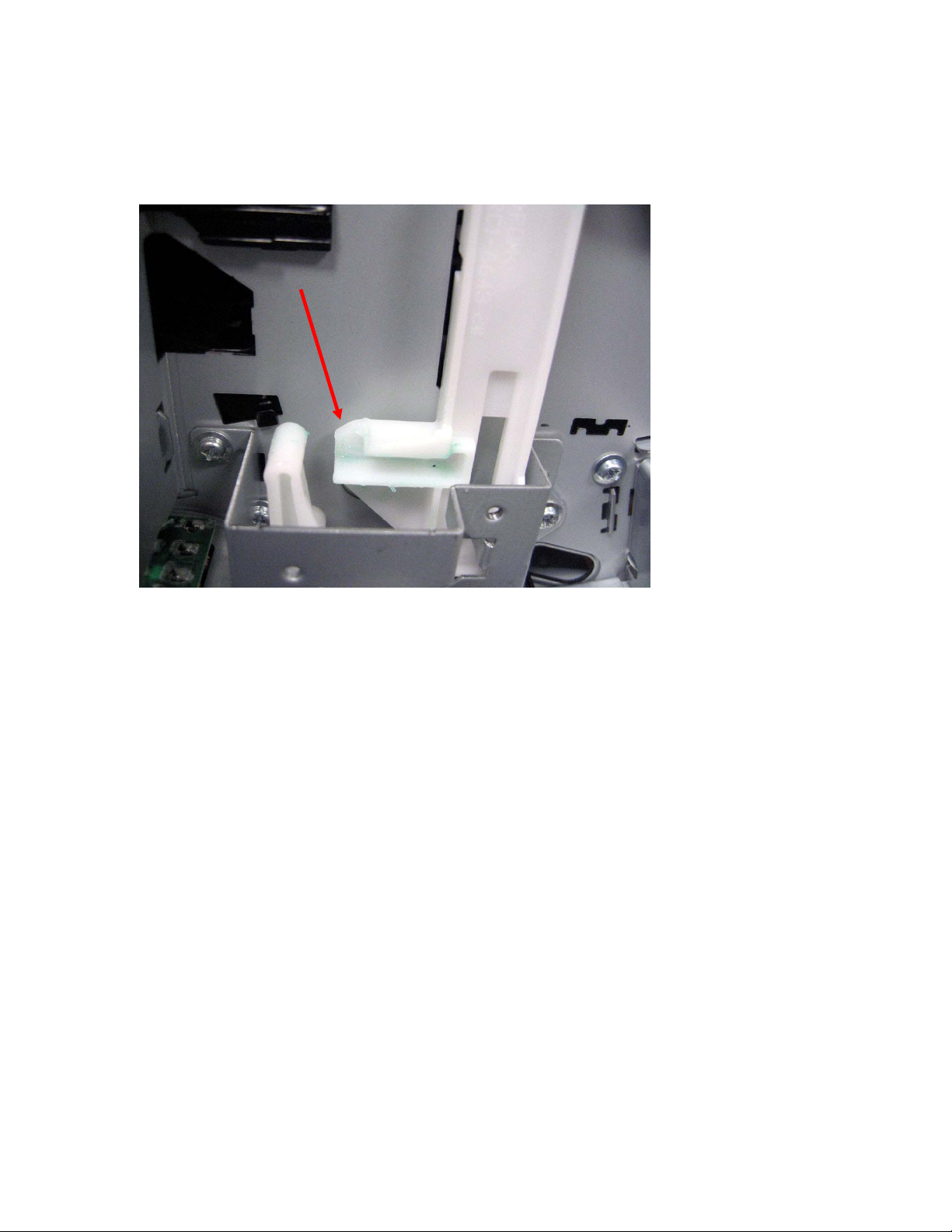

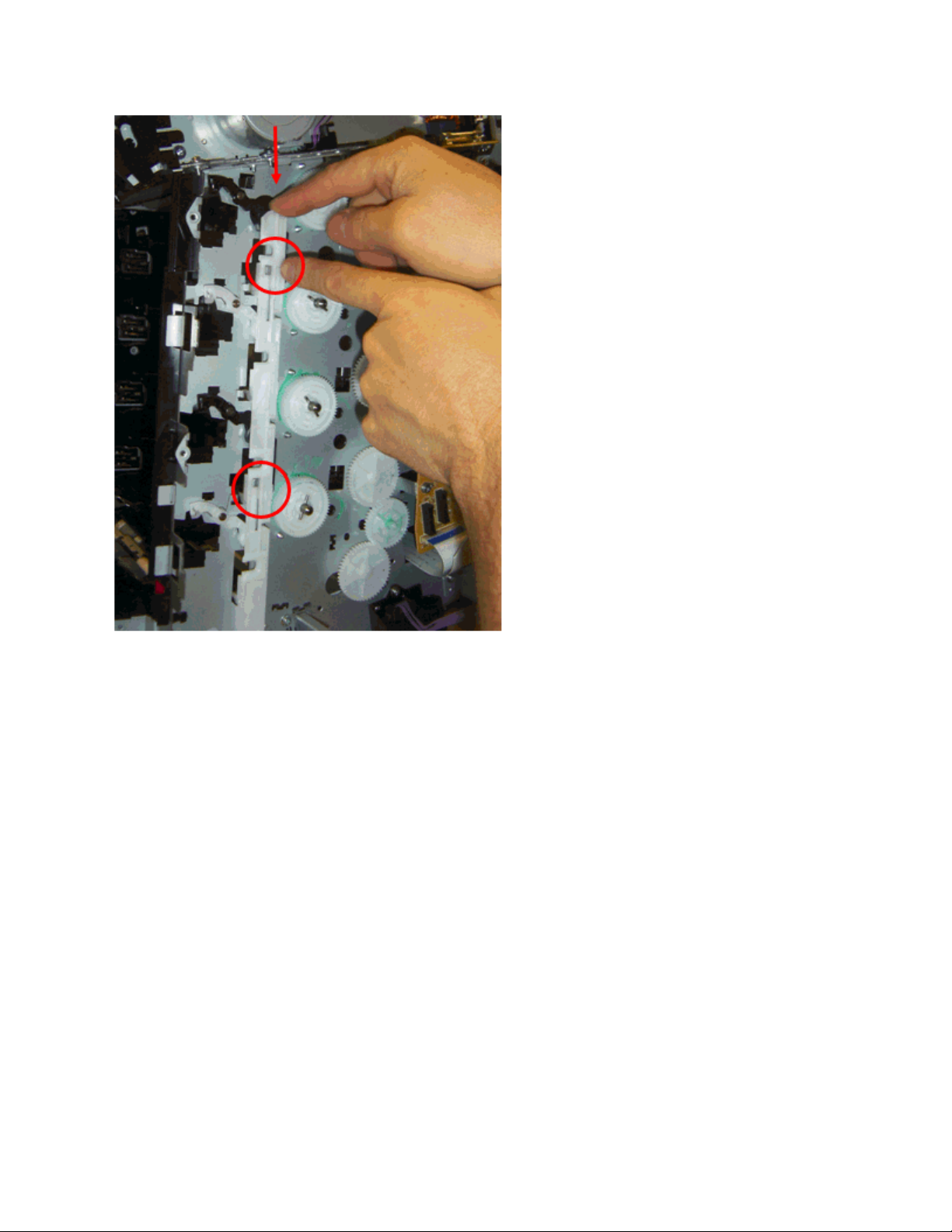

Remove the metal case by removing two screws. Remove the White Link Arm (see arrow in

figure below)

Page 4 of 18

Page 5

9. At this point, check to see if the white slide lever is broken. If the lever is broken (see picture

below), replace it with part number RC1-6643-000CN.

10. Remove the white slide lever by pushing down from the top to release it from the two tabs.

Carefully remove the lever by pulling out, be aware that four springs are attached to this lever and

the individual cartridge locks.

Page 5 of 18

Page 6

To reinstall and perform the correct timing for different parts, follow these

procedures:

11. Attach one end the four springs to the white slide lever and install the lever back into the

machine. (** Attach the other end of the spring in step 14.) Place the white slide lever so the two

metal tabs are in place (circled below), then adjust all the black cartridge locks to be “under” the

tabs on the white slide lever. Bend the top of the white slide lever out to put the top black

cartridge lock in place. Slide the white slide lever up when all the black cartridge locks are in

place.

Page 6 of 18

Page 7

12. The slide lever and cartridge locks should look like the picture below when all is in place.

13. Lock the white slide lever in place by installing the metal case and white plastic piece. Make sure

to insert the flange of the sheet metal in the slot on the sheet metal, and place the white shaft in

the while slide lever. Reconnect the white arm to put tension on the white slide lever.

Page 7 of 18

Page 8

14. Connect the four springs on the white slide lever to each of the individual cartridge locks (start

from the middle ones, it is easier that way). You will need needle-nosed pliers with pointed tips.

The spring on the top is attached; the one on the bottom is not attached. Move the ETB guide to

the up (vertical) position to help with removing and re-installing the Main Drive Assembly.

15. Make sure the gears are aligned properly before installing the main drive assembly. The four

large gears should be in an approximate line (see picture). The top two large gears have an oval

hole that aligns with a triangle stamped into the sheet metal. The two small gears to the right

(they may fall off when removing the MDA); align with the three large bottom gears. Notice the

two holes on each of the small gears align with the small holes of the large gears.

Page 8 of 18

Page 9

NOTE: If this procedure has been properly followed, in the back of the printer, you will see the 4

white cams that control the movement of developers (see figure below). On the top and bottom

shafts, you can see a black plastic part that has a flag associated with it. The top flag is for the

black cartridge, the bottom flag is for all the color cartridges. Also, note that the white cams are all

at different degrees of rotation. This reduces the force required to drive the motors when turning

the cams. Metal shafts should be oriented with the empty space downwards.

Page 9 of 18

Page 10

Page 10 of 18

Page 11

16. Prepare the MDA for installation. Two areas must be checked:

a. Make sure that all the white shafts are pushed to the right (clockwise) when the MDA is

oriented as shown below (See the blue arrows in the image below.). The shafts are

aligned correctly in the picture.

NOTE: It is important that the ETB guides are in the up position to make installation of

the MDA smooth.

Hint: Rotate the shaft all the way to the right side first (as far as possible) then push them

back a little to the left they will come to a hard stop. Leave them there. Look at the lines

marks on the metal frame of the MDA (yellow arrows).

Page 11 of 18

Page 12

b. Next, pay attention to the area marked with the two red arrows, enlarged in the picture

below. It is possible that during the handling of the MDA one or both of these two gears

can be mis-positioned by accident. If this happens, one or more of the color planes could

be missed during printing.

The gear on the right controls the black cartridge; it drives the larger gears to

right below it to the right.

The gear on the left controls all three of the color cartridges; it drives al the

remaining three larger gears, the one directly below it and the two to the left.

(Indicated by the dotted oval in the picture above).

Check if they are properly aligned as follows:

Both gears can be rotated either way to properly correct the MDA gears alignment. The

images above show how to verify if the gears are correctly aligned. The two holes from

larger gears should both be showing as illustrated by the red circles. (The large gears are

under the frame and driven by the smaller gears.)

Page 12 of 18

Page 13

17. With the above in alignment, install the main drive assembly. Start at the left side, inserting the

MDA into the metal slots and rotate it into position. Place a screw in the upper right corner of the

MDA to help keep it in place if the MDA doesn’t fit flush when first installing it. This gives access

with both hands to "jiggle" it into place.

Page 13 of 18

Page 14

18. Make sure the clips are pushed in and the MDA is seated properly.

19. At this point, reverse steps 7 on down. This will have the printer back up and running. Remember

to correctly thread the cables through the wire harnesses properly!

NOTE: The connector to the top cover is different between the simplex and duplex models. The

duplex has a larger connector, while the Simplex is much smaller.

If you experience the following issue after installing the new cartridge locks, here’s how to troubleshoot:

AISS Main Drive Ass'y (MDA) rework possible side-effects

Possible Failures After

Rework

Troubleshooting

13.01.00/13.02.00 Check connection 1 (see #1 in Figure 1)

Close Top Cover/ Close Front

Door

• Check connection 4 (see #4 in Figure 1)

• Check connection 3 (see #3 in Figure 1)

Insert or Close Tray 2 Check connection 2 (see #2 in Figure 1)

• 10.92.XX

Check the cartridge bottom lock (see #5 in Figure 2)

• Noise From Main Drive

Remove the MDA and check all the Gears Alignment and

Page 14 of 18

Page 15

AISS Main Drive Ass'y (MDA) rework possible side-effects

Possible Failures After

Rework

Assembly

• PQ-defect (i.e.: wrong

color, Missing color

pane, process CPR)

• 54.XX Error

59.C0 Error

Troubleshooting

correct as instructed. (for details, see steps 16 and 17

above and re-check the MDA alignment as shown in

Figure 3 below)

For noise specifically, check the Cartridge Drum Sensors

on the MDA (see Figure 4)

One of the two drive gears on the engine is NOT correctly

inserted. Remove MDA and re-align gears as instructed

(see step 16 above)

Page 15 of 18

Page 16

Figure 1: Troubleshooting connection checkpoints

Page 16 of 18

Page 17

Figure 2: Troubleshooting lock position

Figure 3: Troubleshooting gear alignment

Noise- Check the Main Drive Assembly to see that the cartridge drum sensor is correctly seated. See the

picture below for the proper orientation of the sensor. There are 4 of these (one per drum) on the MDA.

Page 17 of 18

Page 18

Figure 4: Troubleshooting cartridge drum sensor

Document Attributes

Product Models: CLJ3800 models, CLJ3600 models, CLJ3000 models

Product Numbers: Q5981A, Q5982A, Q5983A, Q5984A, Q5986A, Q5987A, Q5988A,

Q7533A, Q7534A, Q7535A, Q7536A

Page 18 of 18

Loading...

Loading...