Page 1

HP Enterprise Modular Library E-Series

User Guide

HP Part Number: AH876-96010

Published: December 2012

Edition: 8th

Page 2

© Copyright 2005, 2012 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

1 Library overview.........................................................................................7

Available configurations............................................................................................................7

Parts of the library..................................................................................................................10

Base module..........................................................................................................................11

Expansion modules.................................................................................................................13

Tape drive expansion module..............................................................................................14

Card cage expansion module.............................................................................................14

Capacity expansion module................................................................................................15

Controller cards......................................................................................................................15

Library robotics controller....................................................................................................16

Interface Manager card......................................................................................................16

Interface controller ............................................................................................................18

Ports on the e2400-FC 2Gb interface controller.................................................................18

Ports on the e2400-FC 4Gb interface controller.................................................................18

Changing the master controller (SIPP master).....................................................................19

Functional description..............................................................................................................19

Load ports and magazines......................................................................................................20

Tape drives............................................................................................................................21

Switch for the internal network..................................................................................................21

Operator control panel............................................................................................................22

Numbering............................................................................................................................22

Command View TL..................................................................................................................26

Library and Tape Tools............................................................................................................27

2 Using the library......................................................................................28

Powering on the library...........................................................................................................28

Powering off the library...........................................................................................................29

Center-door interlock...............................................................................................................29

Performing an inventory...........................................................................................................29

Attaching barcode labels to tape cartridges...............................................................................29

Setting the write-protect switch..................................................................................................31

Inserting tape cartridges into the load port.................................................................................31

Using the OCP.......................................................................................................................32

OCP icons........................................................................................................................32

Home screen.....................................................................................................................33

OCP tabs and status bar.....................................................................................................33

Timeouts...........................................................................................................................34

OCP functions...................................................................................................................35

Status screen.....................................................................................................................37

Configuration screen..........................................................................................................39

Operations screen..............................................................................................................40

Support screen..................................................................................................................42

Controls and indicators...........................................................................................................42

Library robotics controller....................................................................................................42

Interface Manager card......................................................................................................43

e2400-FC 2Gb interface controller.......................................................................................44

e2400-FC 4Gb interface controller.......................................................................................44

LTO tape drives..................................................................................................................45

Switch for the internal network.............................................................................................46

Library main power switch...................................................................................................47

Power supply in the base module or tape drive expansion module............................................48

Power supply in the card cage expansion module..................................................................48

Contents 3

Page 4

Power distribution unit.........................................................................................................49

3 Troubleshooting and event reporting...........................................................50

Periodic and routine maintenance.............................................................................................50

Maintaining tape cartridges................................................................................................50

Cleaning Ultrium tape drives...............................................................................................51

Diagnostic support tools..........................................................................................................51

Troubleshooting......................................................................................................................51

Startup problems...............................................................................................................53

OCP problems...................................................................................................................55

Robotics problems..............................................................................................................55

Operating problems...........................................................................................................57

Tape drive problems...........................................................................................................57

Interface Manager card problems........................................................................................58

Interface controller problems...............................................................................................61

LED indicators...............................................................................................................61

Basic troubleshooting.....................................................................................................61

Examining FC port connection...................................................................................62

Examining the interface controller configuration............................................................62

Examining devices....................................................................................................62

Examining the host configuration................................................................................62

Examining HBA device driver information....................................................................62

Examining serial port configuration.............................................................................62

4 Removing and replacing parts....................................................................64

Interface Manager card...........................................................................................................64

Required tools...................................................................................................................64

Interface Manager card 342213-001 or 393531-001..............................................................64

Removing the Interface Manager card 342213-001 or 393531-001......................................64

Replacing the Interface Manager card 342213-001 or 393531-001......................................66

Interface Manager card 480240-001...................................................................................67

Removing the Interface Manager card480240-001............................................................67

Replacing the Interface Manager card 480240-001..........................................................68

Power supply in the base module or tape drive expansion module................................................69

Required tools...................................................................................................................69

Removing a power supply from the base module or tape drive expansion module......................69

Replacing a power supply in the base module or tape drive expansion module..........................70

Power supply in the card cage expansion module ......................................................................70

Required tools...................................................................................................................71

Removing a power supply from the card cage expansion module ............................................71

Replacing a power supply in the card cage expansion module ...............................................71

LTO2 or LTO3 tape drive..........................................................................................................72

Required tools...................................................................................................................72

Removing an LTO2 or LTO3 tape drive..................................................................................72

Replacing an LTO2 or LTO3 tape drive..................................................................................72

LTO4 and later tape drives.......................................................................................................73

Load port magazine...............................................................................................................75

Removing a load port magazine..........................................................................................75

Replacing a load port magazine..........................................................................................75

5 Moving the library....................................................................................77

Selecting an installation location...............................................................................................77

Preparing the library for a short move.......................................................................................77

Preparing the library for long-distance relocation........................................................................77

Repacking the library..............................................................................................................78

Preparing the library for operation............................................................................................79

4 Contents

Page 5

6 Support and other resources......................................................................80

Contacting HP........................................................................................................................80

Related information.................................................................................................................80

Related documentation.......................................................................................................80

HP websites......................................................................................................................80

HP tape cartridges........................................................................................................81

Product warranties.........................................................................................................81

Subscription services......................................................................................................81

Typographic conventions.........................................................................................................81

Updated regulatory compliance and recycling notices.................................................................82

7 Documentation feedback...........................................................................83

A Specifications and characteristics...............................................................84

Library component specifications..............................................................................................84

Library environmental specifications..........................................................................................85

Acoustics...............................................................................................................................86

Ultrium tape drive comparisons.................................................................................................86

B Regulatory statements................................................................................87

Federal Communications Commission notice..............................................................................87

FCC rating label................................................................................................................87

Class A equipment........................................................................................................87

Class B equipment........................................................................................................87

Declaration of Conformity for products marked with the FCC logo, United States only.................87

Modification.....................................................................................................................88

Cables.............................................................................................................................88

Canadian notice (Avis Canadien).............................................................................................88

Class A equipment.............................................................................................................88

Class B equipment.............................................................................................................88

European Union notice............................................................................................................88

Japanese notices....................................................................................................................88

Japanese VCCI-A notice......................................................................................................88

Japanese VCCI-B notice......................................................................................................89

Japanese power cord statement...........................................................................................89

Korean notices.......................................................................................................................89

Class A equipment.............................................................................................................89

Class B equipment.............................................................................................................89

Taiwanese notices...................................................................................................................89

BSMI Class A notice...........................................................................................................89

Taiwan battery recycle statement..........................................................................................90

Turkish recycling notice............................................................................................................90

Laser compliance notices.........................................................................................................91

English laser notice............................................................................................................91

Dutch laser notice..............................................................................................................91

French laser notice.............................................................................................................91

German laser notice...........................................................................................................92

Italian laser notice..............................................................................................................92

Japanese laser notice.........................................................................................................92

Spanish laser notice...........................................................................................................93

Recycling notices....................................................................................................................93

English recycling notice......................................................................................................93

Bulgarian recycling notice...................................................................................................94

Czech recycling notice........................................................................................................94

Danish recycling notice.......................................................................................................94

Dutch recycling notice.........................................................................................................94

Contents 5

Page 6

Estonian recycling notice.....................................................................................................95

Finnish recycling notice.......................................................................................................95

French recycling notice.......................................................................................................95

German recycling notice.....................................................................................................95

Greek recycling notice........................................................................................................96

Hungarian recycling notice.................................................................................................96

Italian recycling notice........................................................................................................96

Latvian recycling notice.......................................................................................................96

Lithuanian recycling notice..................................................................................................97

Polish recycling notice.........................................................................................................97

Portuguese recycling notice.................................................................................................97

Romanian recycling notice..................................................................................................97

Slovak recycling notice.......................................................................................................98

Spanish recycling notice.....................................................................................................98

Swedish recycling notice.....................................................................................................98

Battery replacement notices.....................................................................................................98

Dutch battery notice...........................................................................................................98

French battery notice..........................................................................................................99

German battery notice........................................................................................................99

Italian battery notice........................................................................................................100

Japanese battery notice....................................................................................................100

Spanish battery notice......................................................................................................101

C Ordering HP tape cartridges and barcode label packs...............................102

Where to buy tape cartridges and barcode labels....................................................................102

Part numbers for tape cartridges and barcode labels.................................................................102

D Installing a redundant PDU......................................................................104

PDU components..................................................................................................................104

Leakage current....................................................................................................................104

Redundancy.........................................................................................................................104

Power rating........................................................................................................................104

Placement of redundant PDU components................................................................................105

Installation of redundant PDU components...............................................................................105

Glossary..................................................................................................106

Index.......................................................................................................109

6 Contents

Page 7

1 Library overview

The HP Enterprise Modular Library (EML) E-Series Tape Libraries provide performance, reliability

and investment protection for your data protection needs. With up to 16 HP LTO tape drives, the

EML E-Series boasts native throughput of over 6.9 TB/hr. Based on the HP Extended Tape Library

Architecture (ETLA), controllers help to ensure that rogue I/O requests do not interrupt the backup

or recovery job in progress. Additionally, the hardware itself is very reliable, designed for 24x7

environments. Investment protection is achieved through the addition of expansion modules, the

EML E-Series library scales within the library footprint to 16 drives and 442 slots for maximum

performance, or 8 drives and 505 slots for maximum capacity.

The EML E-Series Tape Libraries contain the following features:

• Scalable capacity from 71 slots to 505 slots

• Scalable performance up to 16 Ultrium tape drives with 442 slots

• Interface controllers protect tape drives from SAN events

• Remote management via Command View for Tape Libraries software or the command line

interface

• Easy to use touch screen graphical user interface

• User configurable load ports with removable magazines

• Certified under the HP Enterprise Backup Solution (EBS)

• Factory and field rack configurations

• 2,000,000 mean swaps between failure

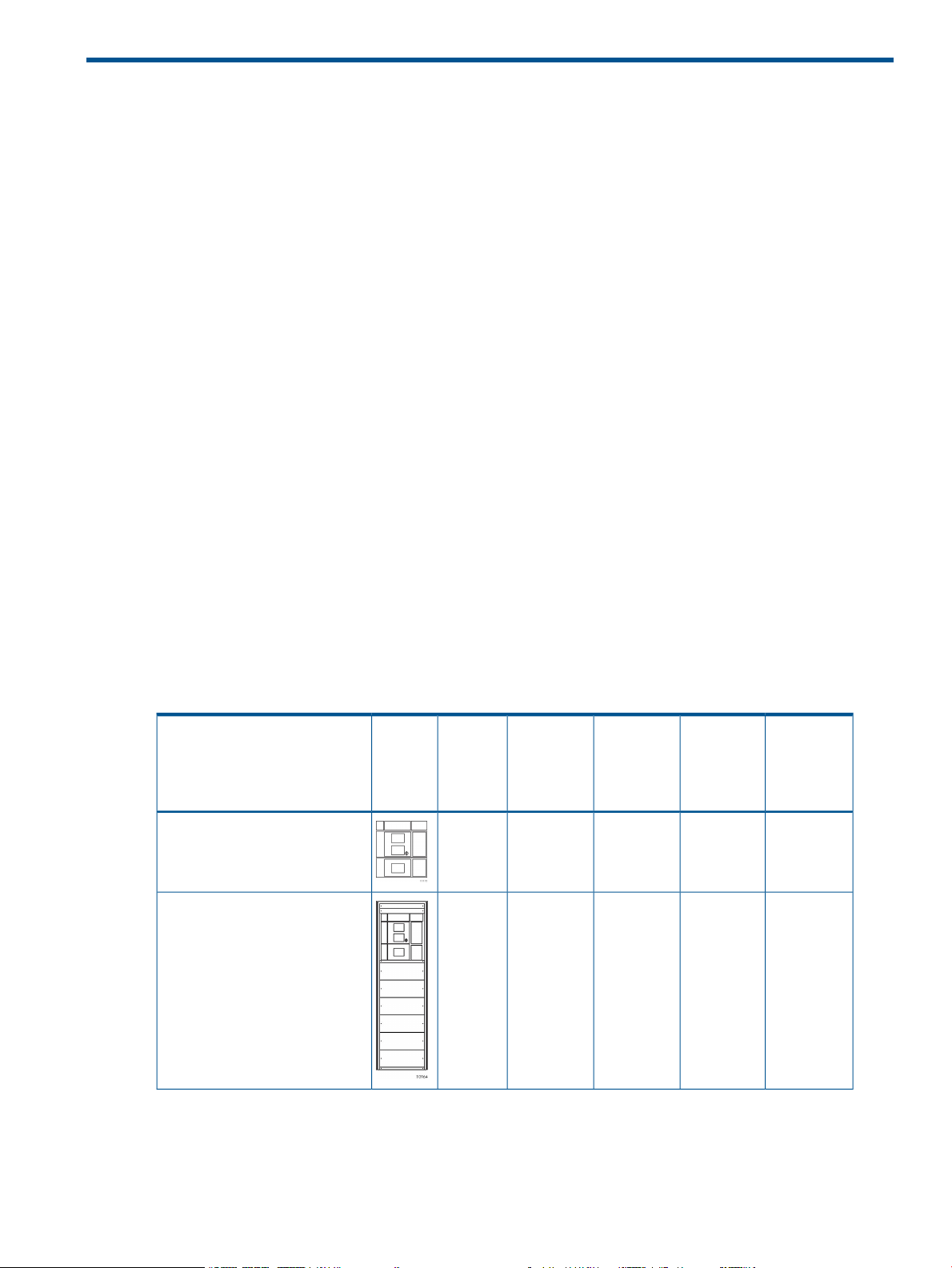

Available configurations

You can order the library in the following configurations.

Table 1 EML configurations

racked

IllustrationConfiguration

Height in

“U”

Maximum

slots

available

Configurable

load port

slots (in

multiples of

5)

Configurable

reserved

slots

Number of

possible

tape drives

1–400–5711271e1 base modulefield racked

1–40–90–510312103e1 base modulefactory

Available configurations 7

Page 8

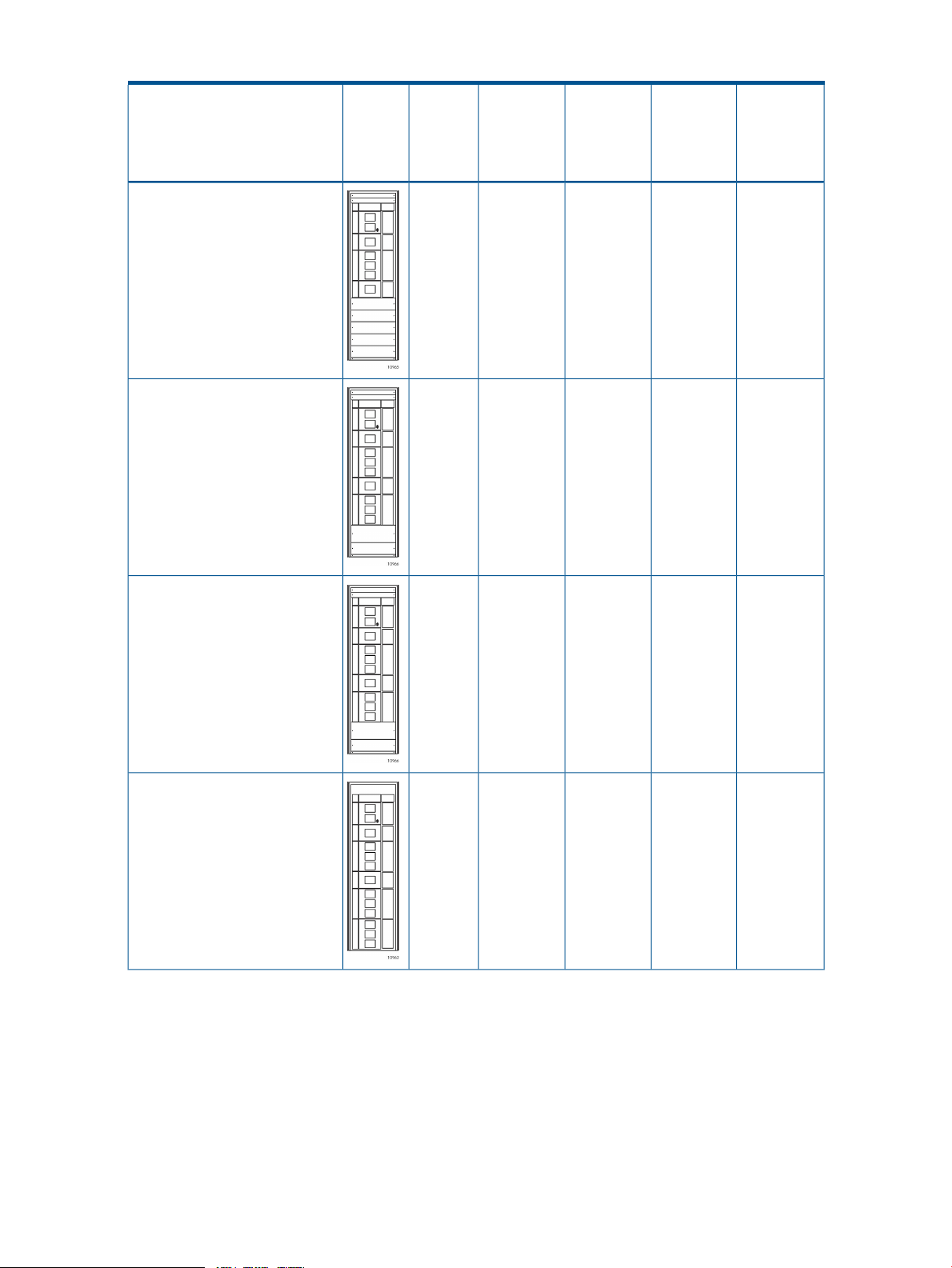

Table 1 EML configurations (continued)

expansion module1 card cage

expansion modulefactory racked

expansion modules1 card cage

expansion modulefactory racked

IllustrationConfiguration

Height in

“U”

Maximum

slots

available

Configurable

load port

slots (in

multiples of

5)

Configurable

reserved

slots

Number of

possible

tape drives

1–80–90–1524524245e1 base module1 tape drive

1–120–90–2534832348e1 base module2 tape drive

expansion module1 card cage

expansion module1 capacity

expansion modulefactory racked

expansion modules1 card cage

expansion modulefactory racked

1–80–90–2537532375e1 base module1 tape drive

1–160–90–3544240442e1 base module3 tape drive

8 Library overview

Page 9

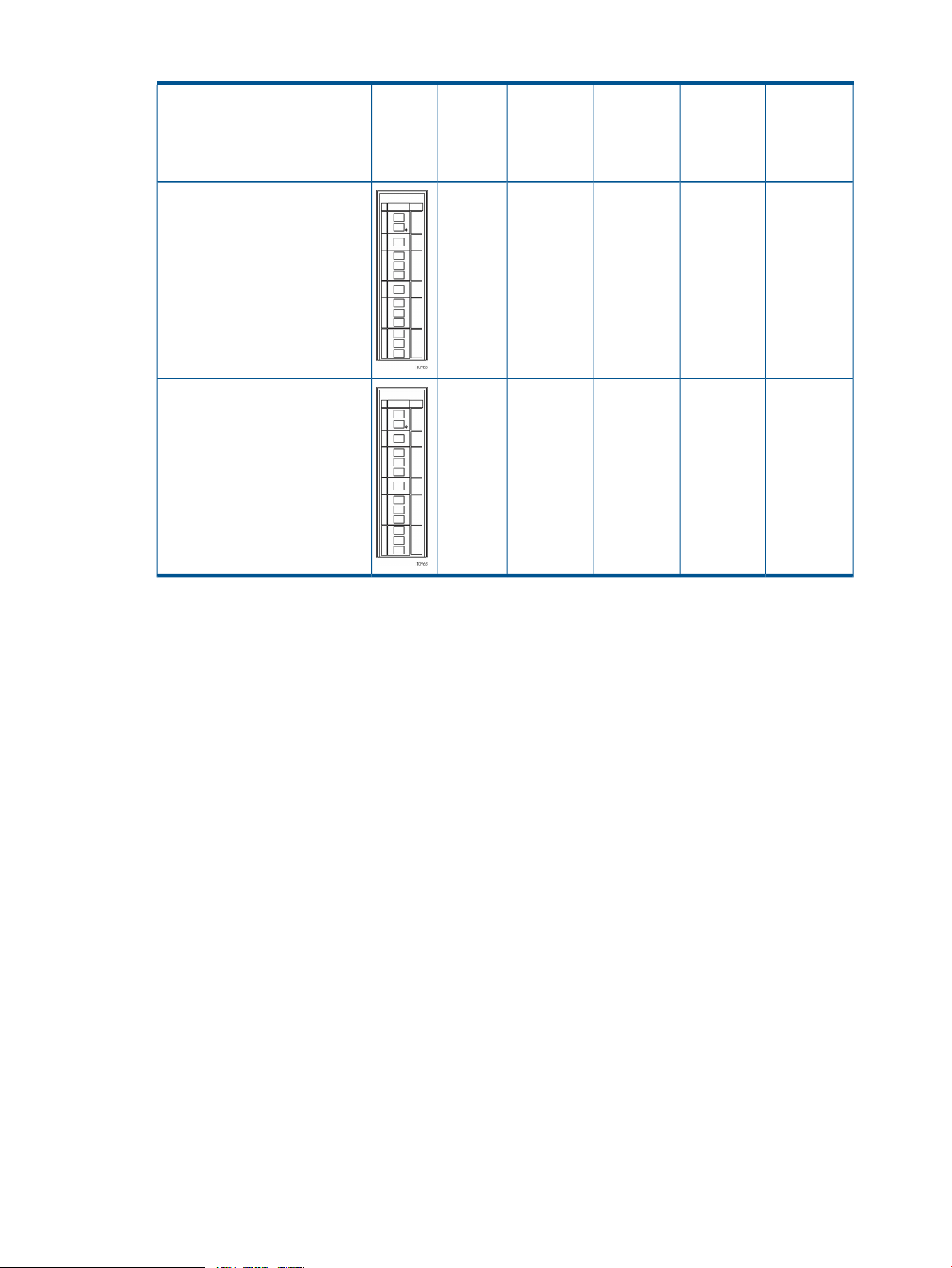

Table 1 EML configurations (continued)

expansion modules1 card cage

expansion module1 capacity

expansion modulefactory racked

expansion module1 card cage

expansion module2 capacity

expansion modulesfactory racked

IllustrationConfiguration

Height in

“U”

Maximum

slots

available

Configurable

load port

slots (in

multiples of

5)

Configurable

reserved

slots

Number of

possible

tape drives

1–120–90–3546940469e1 base module2 tape drive

1–80–90–3550540505e1 base module1 tape drive

Available configurations 9

Page 10

Parts of the library

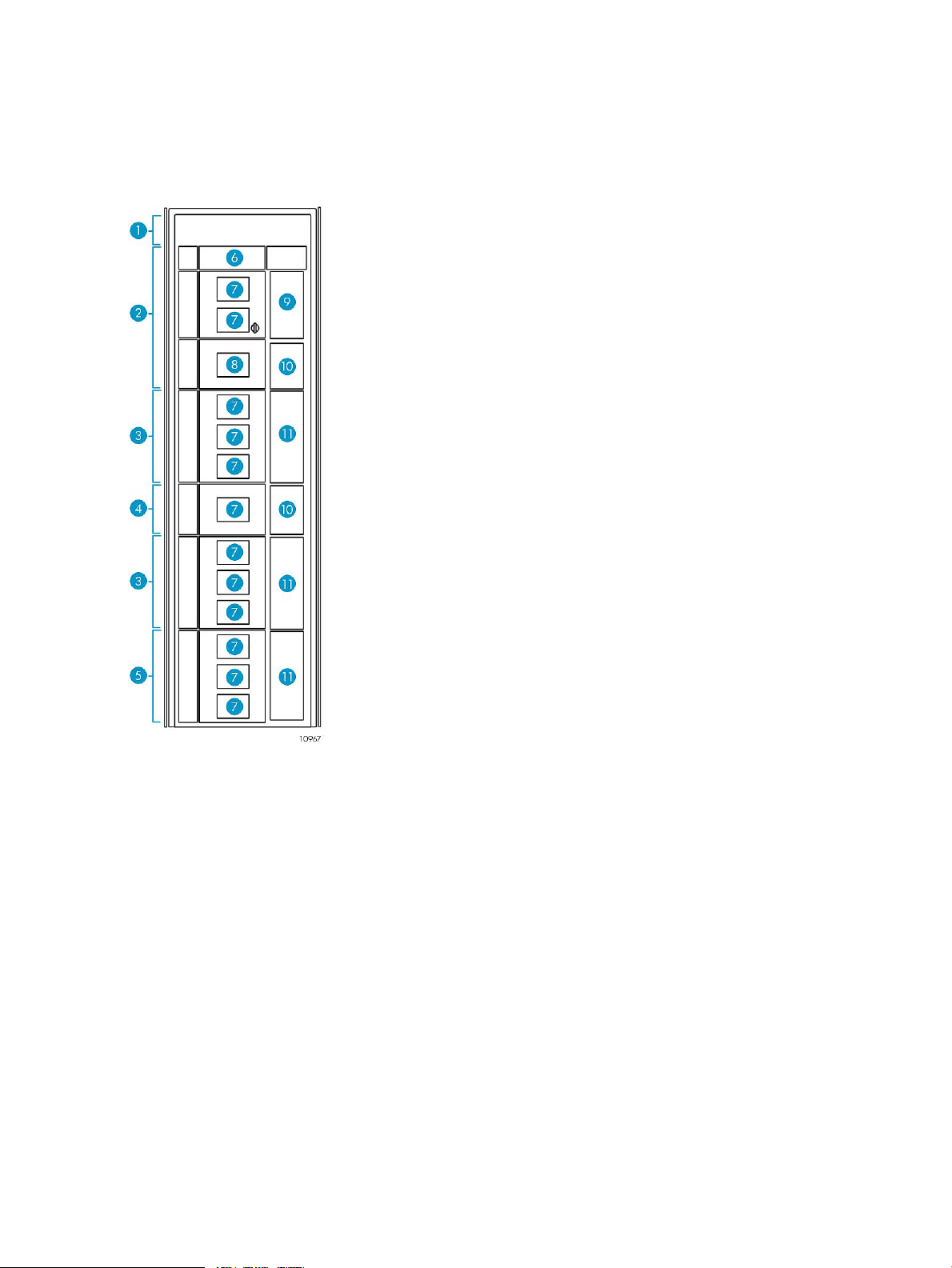

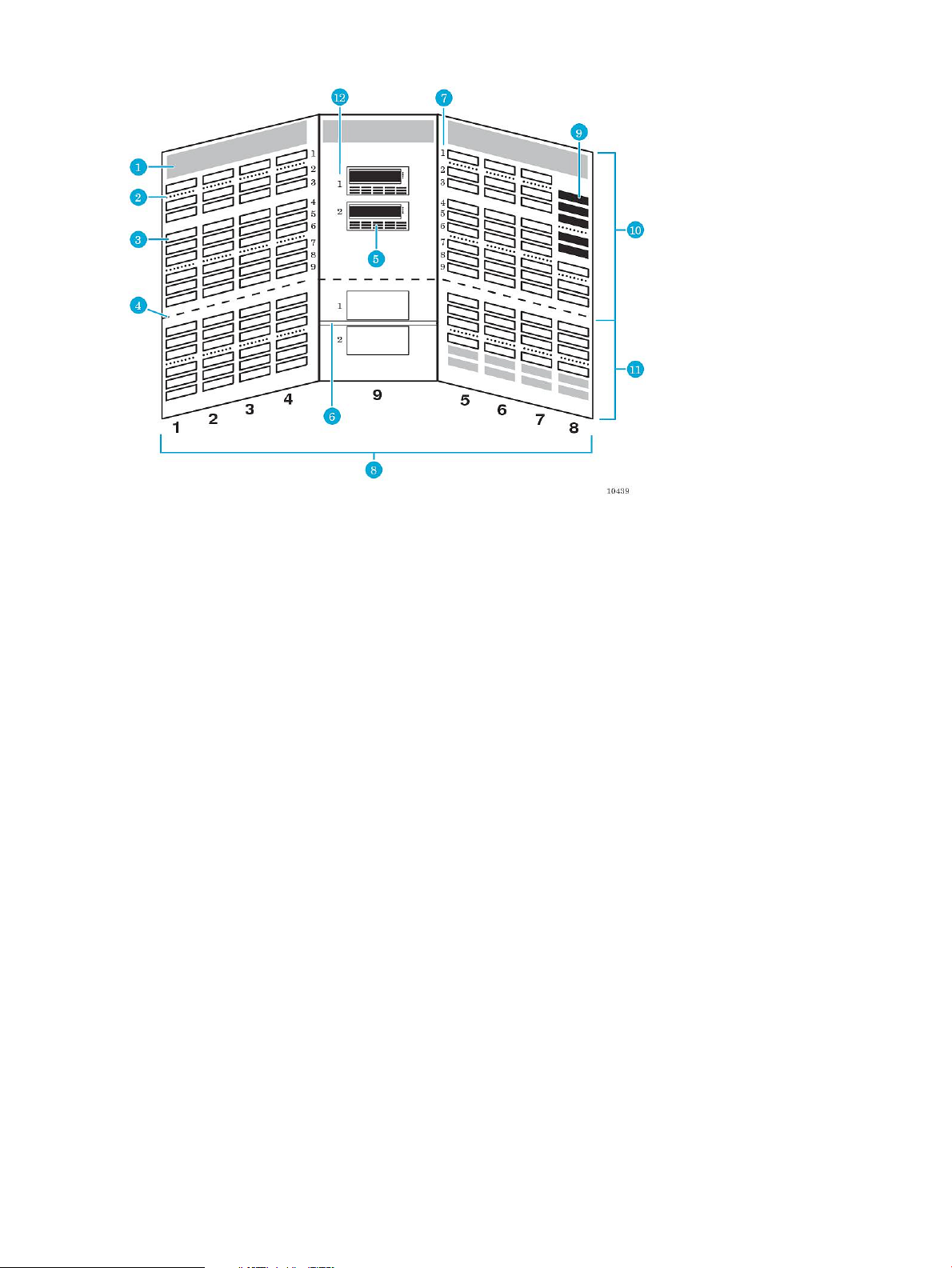

The following figures show the parts of a 469e library. See (page 7).

Figure 1 Front view of the library

tape drives, this space contains the switch for the internal

network.

11. 10-Cartridge load ports

10 Library overview

2. Base module1. Reserved space. If your library contains LTO4 or later

4. Card cage expansion module3. Tape drive expansion module

6. Robotics unit5. Capacity expansion module

8. Operator control panel (OCP)7. Viewing windows

10. 4U blank covers9. 5-Cartridge load port

Page 11

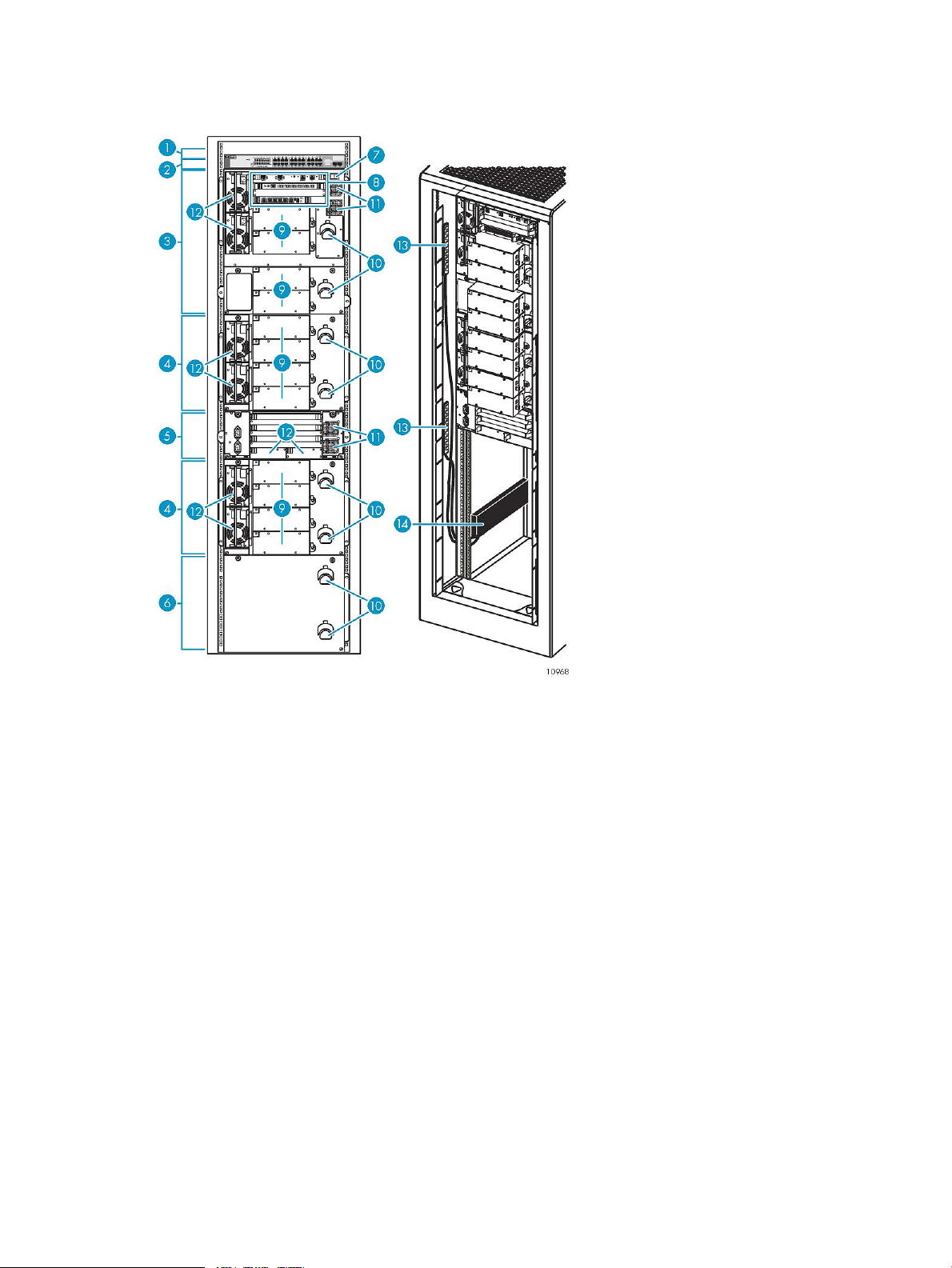

Figure 2 Rear view of the library

1. Reserved space

7. Main power switch

Base module

The 12U base module (see (page 10) and (page 11)) resides at the top of the library below the

2U reserved space or the switch for the internal network.

In the EML 71e, the base module contains a total of 71 LTO slots. Five slots within a load port are

configurable as either import/export slots or storage slots. No reserved slots are available.

In all other EML configurations, the base module contains a total of 103 LTO slots. Five slots are

configurable as either import/export slots or storage slots within a load port through the use of a

removable magazine. You can configure 9 slots as reserved. A common use for reserved slots is

for holding cleaning cartridges. The number of usable permanent slots depends on whether it is

the bottom module in the library because the library floor is always attached to the bottom module

2. Switch for the internal network (in libraries with LTO4 or

later tape drives only)

4. Tape drive expansion module3. Base module

6. Capacity expansion module5. Card cage expansion module

8. Base module card cage (e2400-FC 2Gb interface

controller shown)

10. Cable management features9. Tape drives (LTO3 tape drives shown)

12. Power supplies11. Fans

14. Power distribution unit (PDU)13. Power strips

Base module 11

Page 12

and the floor limits the distance that the robot can travel. If the library floor is attached to the base

module, the bottom two rows (containing 16 slots) cannot be used.

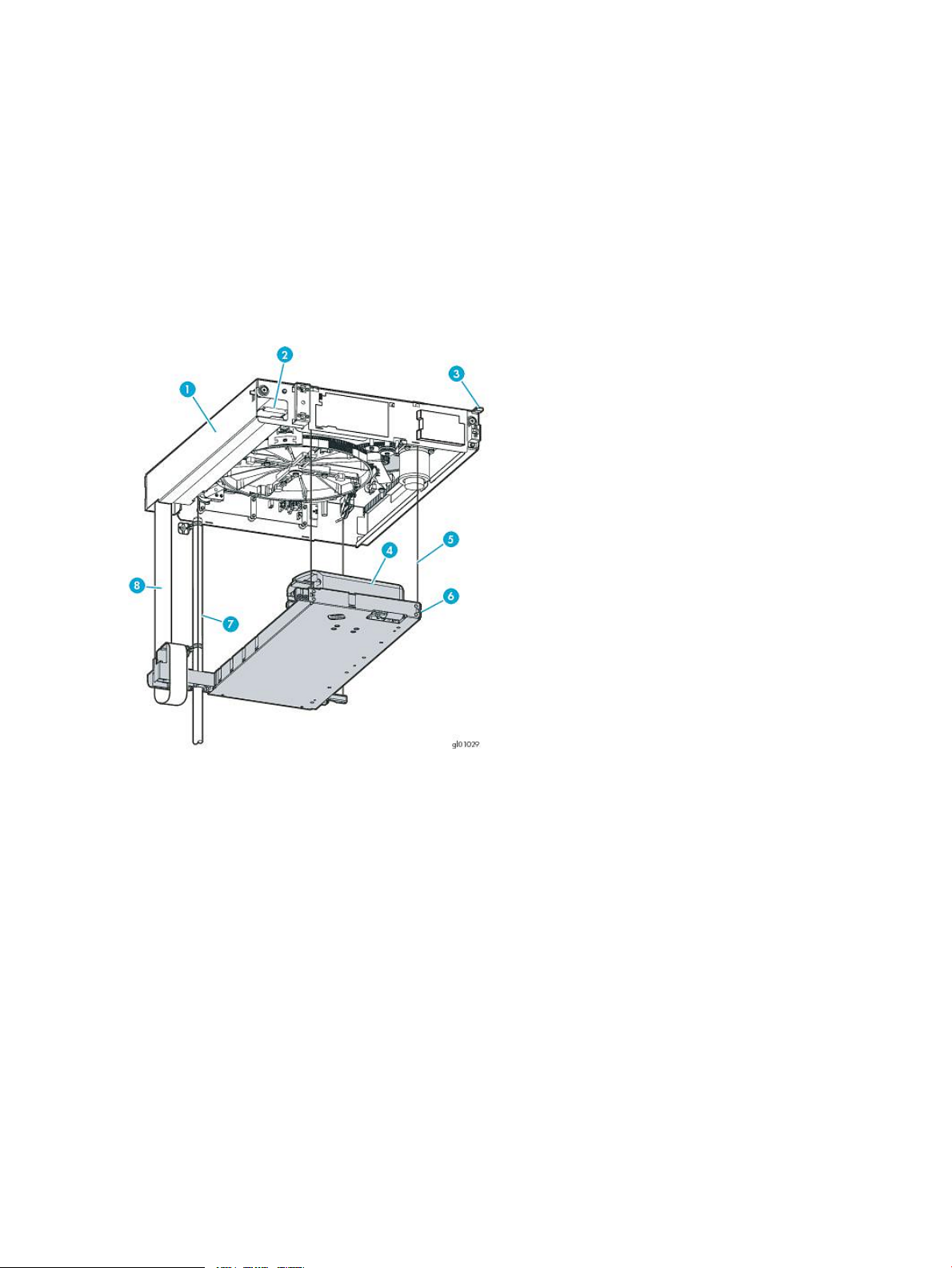

The robotics unit is located at the top of the base module. When fully retracted (or parked), the

robot is fully contained within a 2U space. For safety reasons, the robot is parked before the center

door can be opened.

Within the robot, a lift table assembly contains a motor, pulleys, and cables to move the table up

and down to a specific level in the library. The picker assembly moves front and back, and

side-to-side along the table. A barcode scanner, attached to the bottom of the picker assembly,

scans targets on rack components for alignment, as well as barcode labels on tape cartridges, if

they are present. The picker has fingers that remove and insert tape cartridges among storage

slots, tape drives, or load ports.

Figure 3 Robotics unit

The base module has two windows on the front for viewing the robotic motion inside the library.

A load port door is located to the right front (see (page 10)) where a 5-cartridge magazine can

be loaded with tape cartridges for insertion into or removal from the library. The load ports are

mechanical devices that enable you to import and export tape cartridges to and from the library

through removable magazines, or act as additional library storage slots. These two functions for

a load port cannot be mixed; you must either designate an entire load port to be import/export

slots or storage slots. The base module contains a load port capable of using one 5-cartridge

magazine. An operator control panel (OCP) is located at the bottom front of the base module.

The base module contains an autoranging power supply (a redundant power supply is optional),

card cage, cable management features, and space for mounting up to four LTO-technology tape

drives on the back.

12 Library overview

2. Lift-flex retraction handle1. Robotics unit

4. Robot picker3. Ratchet tool

6. Table assembly5. Lift suspension cable

8. Lift-flex cable7. Lift pole

Page 13

The card cage in the base module (see (page 13)) provides six cPCI slots for the following:

• Library robotics controller (see (page 16)) A single slot, 6U-wide cPCI board having Ethernet

ports and an RS-232 port. One Ethernet port connects this controller to the Interface Manager

card.

• Interface Manager card (see (page 16)) A single slot, 4U-wide cPCI board having six Ethernet

ports. This board contains 128MB of dynamic random access memory (DRAM) plus a 256MB

CompactFlash memory card, both in their own sockets. A 2U-wide adapter panel next to the

4U-wide Interface Manager card enables it to fit in the lowest 6U-wide card cage slot.

• Interface controller A cPCI board, having two FC ports for connecting to the SAN, along with

four FC ports for connecting up to four HP LTO2 or LTO3 tape drives. LTO4 and later tape

drives do not connect to the interface controller; instead, they connect directly to the SAN.

The interface controller is available in two speeds. The e2400-FC 2Gb interface controller

has an FC speed of 2 Gbps, is 6U wide, and uses a single slot (see (page 18)). The e2400-FC

4Gb interface controller has an FC speed of 4 Gbps, is 4U wide, and uses two slots (see

(page 18)).

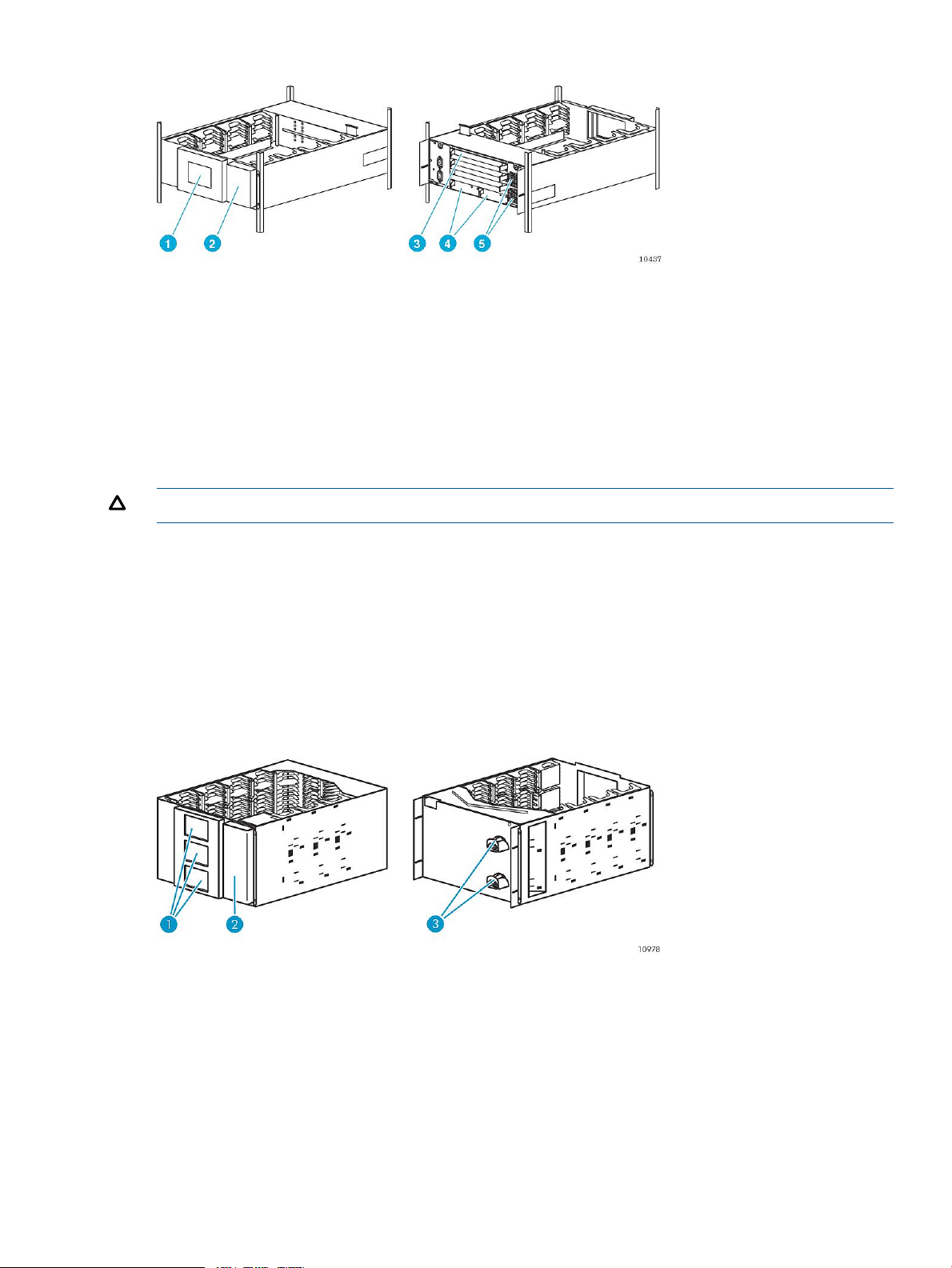

Figure 4 Base module card cage (LTO3 tape drives shown)

shown)

5. Adapter panel

The cable management feature is a spool, mounted near the tape drives, that enables LAN and

FC cables to be dressed and routed away from hot plug or hot swap components.

Expansion modules

Three expansion modules are available to increase library capacity beyond that provided by the

base module. These expansions modules are:

• Tape drive expansion module

• Card cage expansion module

• Capacity expansion module

IMPORTANT: If you are adding expansion modules to an EML 71e, you must purchase a capacity

upgrade license for Command View TL (part number AH063A). This license upgrades your base

module from 71 slots to 103 slots. You must also make sure that your rack has side panels and

doors installed to comply with regulatory requirements.

2. Interface Manager card1. Base module card cage

4. Library robotics controller3. Interface controller (e2400-FC 2Gb interface controller

Expansion modules 13

Page 14

Tape drive expansion module

The tape drive expansion module is an 8U chassis containing 94 LTO slots (84 permanent and

10 configurable). The number of usable permanent slots depends on whether it is the bottom module

in the library because the library floor is always attached to the bottom module and the floor limits

the distance that the robot can travel. If the library floor is attached to the tape drive expansion

module, the bottom row (containing seven slots) cannot be used.

CAUTION: Never operate the library with the floor removed. The robot can be damaged.

The tape drive expansion module has three windows on the front for viewing the robotic motion

inside the library. To the right is a 10-cartridge configurable load port that holds two 5-cartridge

magazines.

On the back, the module contains one primary power supply with a slot provided for another

optional redundant power supply. Up to four Ultrium tape drives can be installed in the tape drive

expansion module. Cable management features are provided for cable routing and dressing.

Figure 5 Tape drive expansion module

5. Cable management features

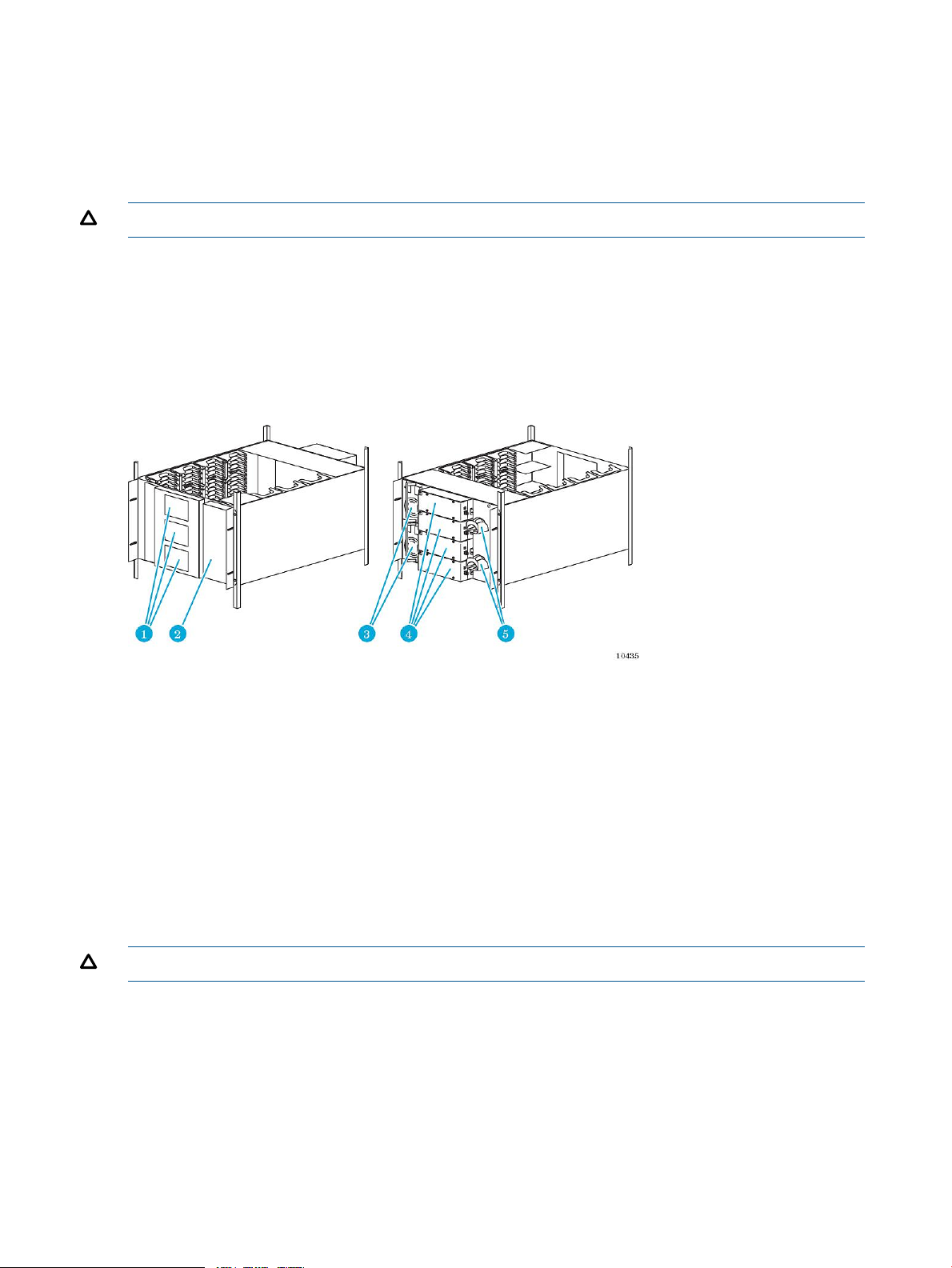

Card cage expansion module

The card cage expansion module is a 4U chassis that contains 48 permanent LTO slots and space

for additional interface controllers. This module must be located directly below the top 8U tape

drive expansion module. The number of usable permanent slots depends on whether it is the bottom

module in the library because the library floor is always attached to the bottom module and the

floor limits the distance that the robot can travel. If the library floor is attached to the card cage

expansion module, the last two rows (containing 16 slots) cannot be used.

CAUTION: Never operate the library with the floor removed. The robot can be damaged.

The front of the card cage expansion module has one window for viewing robotic motion inside

the library. On the back, six PCI card slots are available for additional interface controllers to

expand the library tape drive capacity. One interface controller is added for every four additional

LTO2 or LTO3 tape drives. LTO4 and later tape drives do not connect to an interface controller;

instead, they connect directly to the SAN. Two power supplies are located at the bottom of the

card cage, and two cooling fans are on the right.

2. 10-Cartridge load port1. Viewing windows

4. Tape drives (LTO3 tape drives shown)3. Power supplies (optional redundant power supply shown)

14 Library overview

Page 15

Figure 6 Card cage expansion module

5. Fans

Capacity expansion module

The capacity expansion module is an 8U chassis containing 120 LTO slots (110 permanent and

10 configurable). If the library floor is attached to the capacity expansion module, the bottom row

containing 10 slots is blocked and cannot be used.

CAUTION: Never operate the library with the floor removed. The robot can be damaged.

2. 4U blank cover1. Viewing window

4. Power supplies3. Card slots

If the capacity expansion module is placed below the base module or a tape drive expansion

module, six slots at the top of the back wall cannot be used because the tape drives in the module

above it prevent the robot from reaching these slots.

On the front of the capacity expansion module are three windows for viewing the robotic motion

inside the library. To the right is a 10-cartridge configurable load port that holds two 5-cartridge

magazines.

On the back of the capacity expansion module are cable management features for cable routing

and dressing.

Figure 7 Capacity expansion module

2. 10-Cartridge load port1. Viewing windows

3. Cable management features

Controller cards

This section explains the function of the three major cards that control the library. These cards are:

• Library robotics controller

• Interface Manager card

• Interface controller

Controller cards 15

Page 16

Library robotics controller

The library robotics controller contains firmware to control the robot, communicate with the Interface

Manager card, manage the library servo and vision control, and monitor the door and load port

sensor status.

Robot commands are sent from hosts in the SAN to an interface controller, which directs them over

an internal Ethernet network to the library robotics controller. The library robotics controller translates

these commands into movements to be performed by the robot.

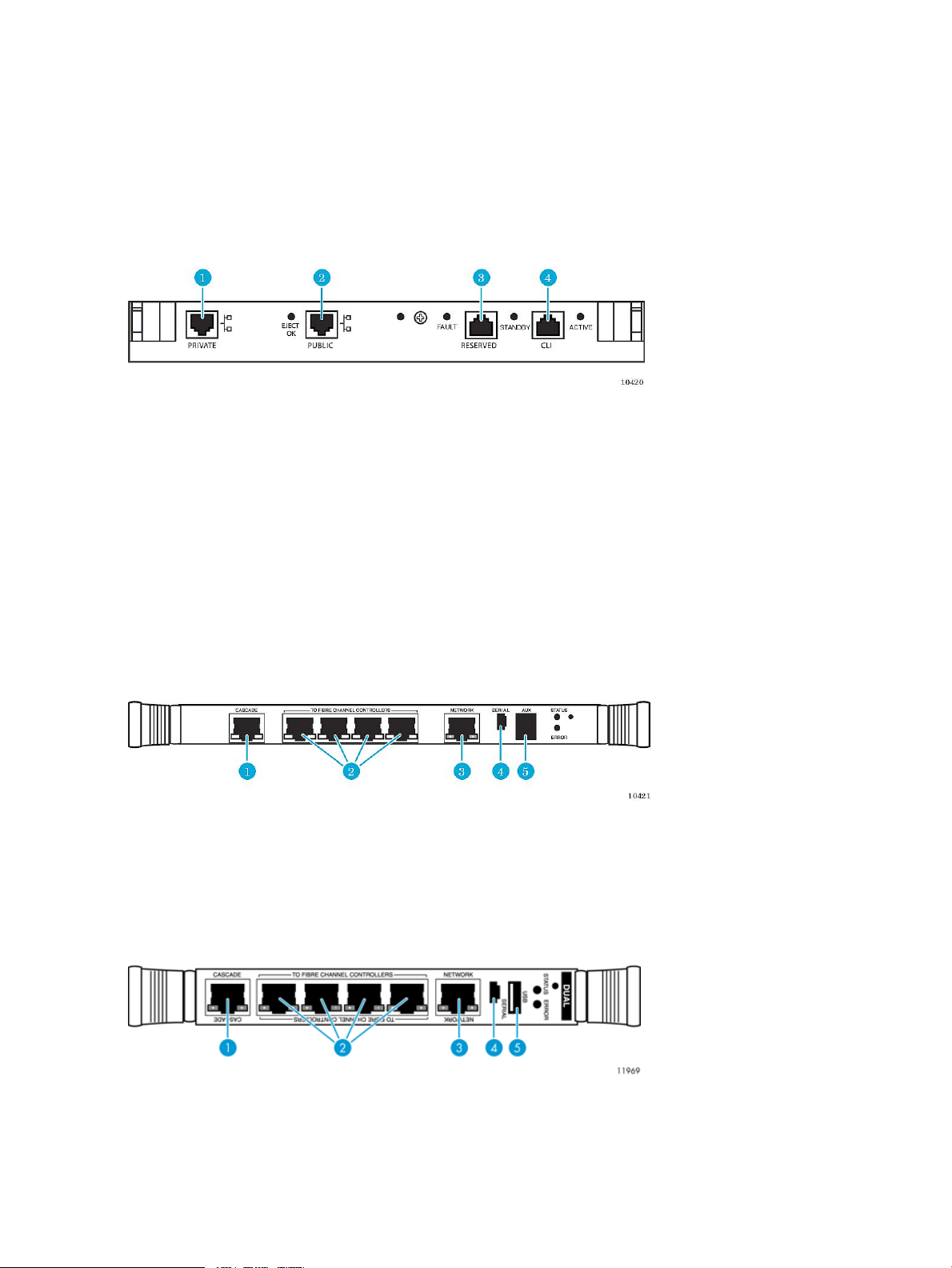

Figure 8 Ports on the library robotics controller

1. Private Ethernet port (not used)

Interface Manager card

The Interface Manager card is an HP proprietary management card designed to consolidate and

simplify the management of multiple interface controllers installed in the library. It also provides

SAN-related diagnostics and management for library components, including the interface controllers,

tape drives, and robotics. The Interface Manager card, in conjunction with HP Command View TL

software, provides remote management of the library by using a serial, Telnet, or Web-based

graphical user interface (GUI).

Figure 9 Ports on the Interface Manager card 342213–001 or 393531–001

controller)

5. Auxiliary RJ-11 serial connector (not used)

2. Public Ethernet port (connection to Interface Manager

card)

4. CLI port (RS-232–HP services only)3. Reserved port (not used)

2. Private Ethernet ports to interface controllers1. Cascade Ethernet port (connection to library robotics

4. Serial port3. Network Ethernet port (to management station)

Figure 10 Ports on the Interface Manager card 480240-001

controller)

5. USB port

16 Library overview

2. Private Ethernet ports to interface controllers1. Cascade Ethernet port (connection to library robotics

4. Serial port3. Network Ethernet port (to management station)

Page 17

The Interface Manager card communicates with the management station over the LAN. The

management station is a Microsoft Windows-based PC (server) that hosts the Command View TL

software. Ideally, the management station should have a static IP address, and be dedicated for

use with the Interface Manager card and Command View TL software.

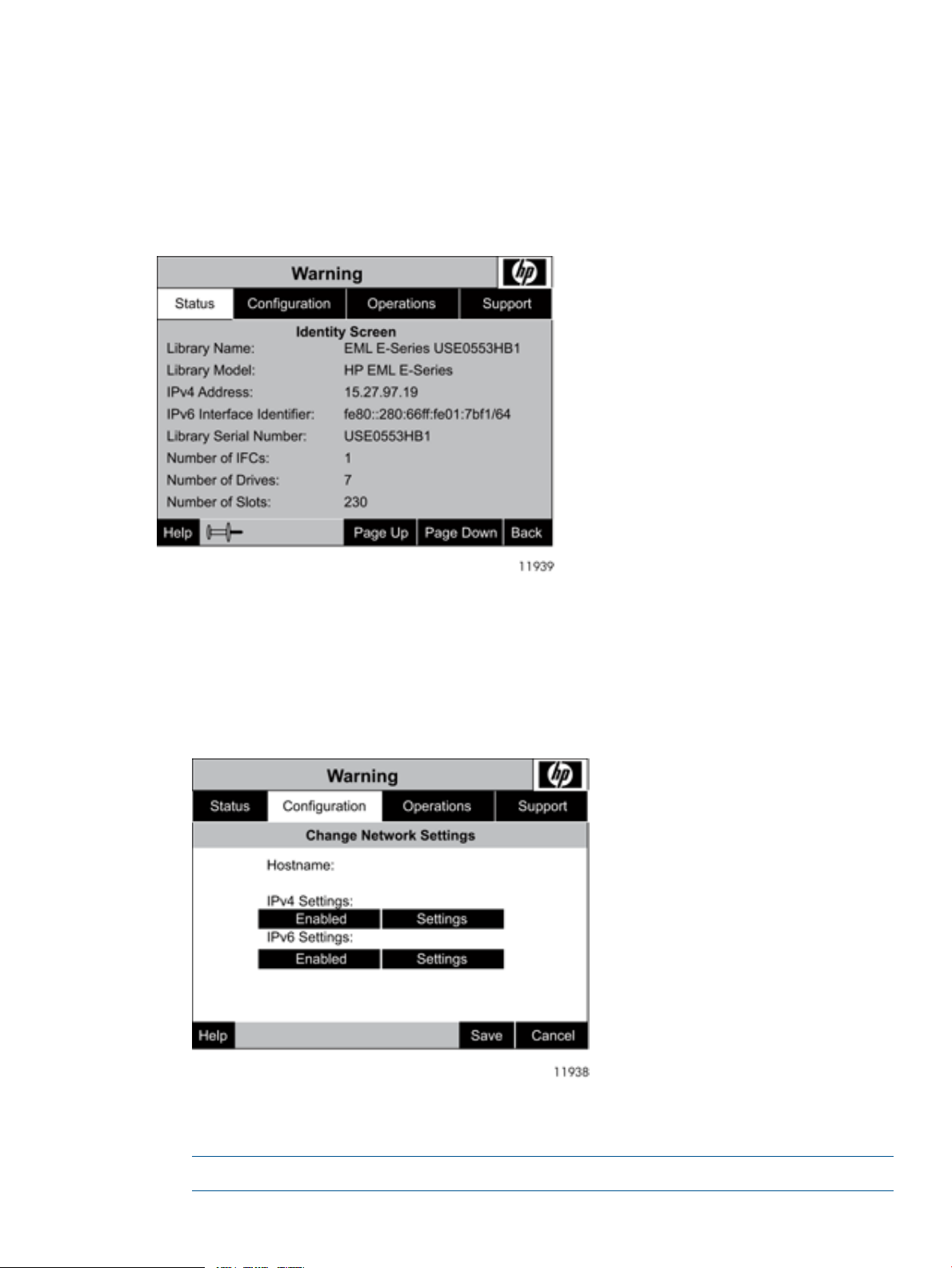

IP connections on the EML can be IPv4 or IPv6 format. The library can be configured to use one

or both formats, but can not operate if neither protocol is enabled. View the IP connections on the

Identity Screen (from the Home screen select Status, then Identity Screen).

Figure 11 Viewing IP connections from the Identity Screen

Enable or disable the protocols from the Change Network Settings screen, then view and save the

settings from that same screen.

To view and change the settings for either IPv4 or IPv6:

1. From the Home screen, select Configuration.

2. From the Library Configuration menu select Change Network Settings.

Figure 12 Viewing the Change Network Settings screen

3. To enable or disable IPv4 or IPv6, touch the appropriate Enable or Disable button.

4. To view or change the settings, touch the appropriate Settings button.

NOTE: Some settings are read-only.

Controller cards 17

Page 18

5. To save any changes to the network settings, select the Save button at the bottom, right of the

OCP.

Any client machine on the LAN can communicate with the Interface Manager card either through

the GUI or through a command line interface (CLI). At a higher level, multiple libraries, each

containing an Interface Manager card, can be connected to a single management station. Each

Interface Manager card can communicate with only one management station, but the management

station can communicate with multiple Interface Manager cards.

After being configured, the Interface Manager card is used to configure the interface controllers

based on knowledge of the library and SAN. As robotics commands are received from the interface

controllers, the Interface Manager card acts as a switch to relay these commands to the library

robotics controller. The Interface Manager card contains on-board Flash memory to provide a

persistent history of the library and storage network health.

Interface controller

The interface controller is an HP proprietary card that provides FC connectivity for LTO2 and LTO3

tape drives and robotics in the SAN. Commands, data, and status information are transferred to

and from this controller, from hosts, the robot, and the LTO2 and LTO3 tape drives. One interface

controller can manage up to four LTO2 or LTO3 tape drives.

LTO4 and later tape drives do not connect to an interface controller; instead, they connect directly

to the SAN. Libraries that contain only LTO4 or later tape drives still need one interface controller

which is used to direct commands to the robot. The interface controller is available in two speeds:

2 Gbps and 4 Gbps.

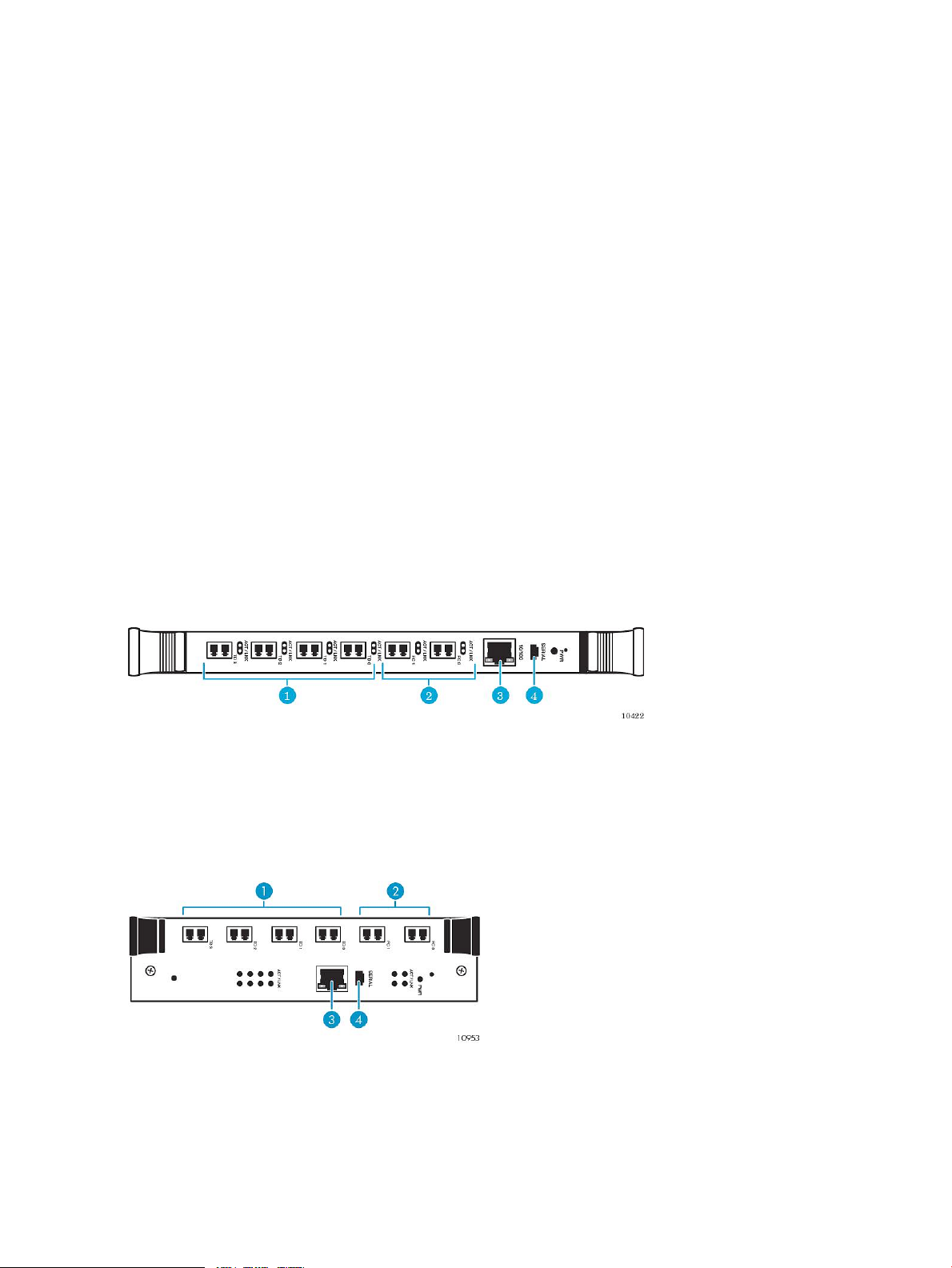

Ports on the e2400-FC 2Gb interface controller

Figure 13 Ports on the e2400-FC 2Gb interface controller

Ports on the e2400-FC 4Gb interface controller

Figure 14 Ports on the e2400-FC 4Gb interface controller

2. FC ports to hosts1. FC ports to LTO2 and LTO3 tape drives

4. Serial port3. Ethernet port (connection to Interface Manager card)

18 Library overview

2. FC ports to hosts1. FC ports to LTO2 and LTO3 tape drives

4. Serial port3. Ethernet port (connection to Interface Manager card)

Page 19

Changing the master controller (SIPP master)

One interface controller is assigned by the Interface Manager card as the master controller the

SIPP master. Only the SIPP master is designated to send commands to the library robotics controller.

If multiple interface controllers are present, Command View TL software, through the Cabling View,

can be used to determine which one is acting as the SIPP master. Changing the SIPP master requires

a service-level password and command using the CLI (Telnet or serial). The commands are:

SERVICE L&TTPASSWORD

SET IPCONNECTION INTERFACE MASTER X

, if the IM firmware is i182 or lower

SERVICE L&TTPASSWORD

SET IPCONNECTION MASTER X

, if the IM firmware is I200 or higher

where L&TTPASSWORD is the Library and Tape Tools (L&TT) password and X is the interface

controller number. Obtain the password from the web site L&TT web siteby calling HP Support to

get a 2–day ltt service password. Find the interface controller number by using the SHOW

INTERFACE INFO ALL CLI command.

If the master interface controller (designated SIPP master) is replaced, the Hardware Replacement

wizard sets up the SIPP master. If the master interface controller (designated SIPP master) is moved

to another interface controller in the library, perform the following manual service steps:

1. Remove all partitions.

2. Remove all host maps.

3. Log in to the CLI and obtain service-level access.

4. Use the SET IPCONNECTION MASTER X command to make a particular interface controller

the SIPP master. Currently, the Interface Manager card does not automatically failover an

interface controller, even if the previous SIPP master is missing.

5. Reconfigure maps and partitions.

Functional description

The library receives commands and data throughout the SAN from hosts running applications from

approved independent software vendors (ISVs). Host bus adapters (HBAs) in servers send this traffic

over FC links, usually through FC switches. For LTO4 and later tape drives, the traffic goes directly

to the tape drive; but for LTO2 and LTO3 tape drives, the traffic first goes through an interface

controller. One interface controller can connect up to four LTO2 or LTO3 tape drives. For all

libraries, regardless of whether they contain LTO2 and LTO3 or LTO4 and later tape drives, at

least one interface controller is required to pass tape cartridge changer (robotics) commands to

the Interface Manager card over a private network. The Interface Manager card passes these SCSI

commands on to the library robotics controller over the private network, taking advantage of the

error handling and retry capabilities of TCP/IP.

Functional description 19

Page 20

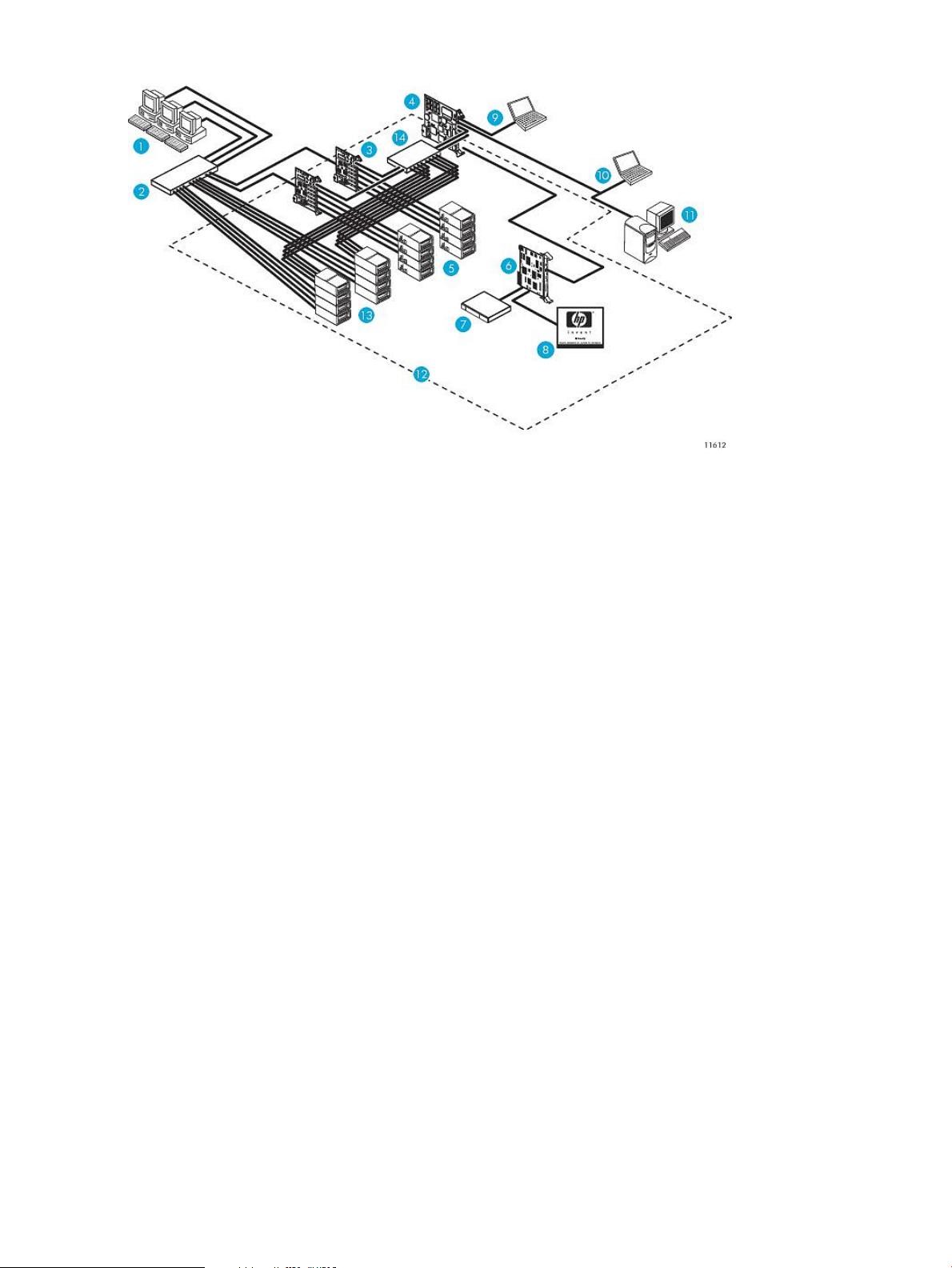

Figure 15 Library network

2. FC Switch (SAN)1. Hosts

4. Interface Manager card3. Interface controller

6. Library robotics controller5. LTO2 or LTO3 tape drives

8. OCP7. Robot

10. Telnet connection9. Serial connection

12. Library boundary11. Management station

14. Switch for the internal network13. LTO4 and later tape drives

In addition to receiving traffic from the interface controllers, the Interface Manager card receives

command and diagnostic requests over an Ethernet connection from three other possible sources.

The majority of requests come from a management station where Command View TL software

resides. The other two sources are through a Telnet session or a serial interface. The Interface

Manager card works in the background to manage library functions. It configures the interface

controllers to direct commands from host systems to the appropriate LTO2 or LTO3 tape drive or

to the library robotics controller.

The library robotics controller receives commands over an internal private network and from the

OCP. It manages robotics movement, monitors the door and load port sensor status, and stores

library information in volatile memory.

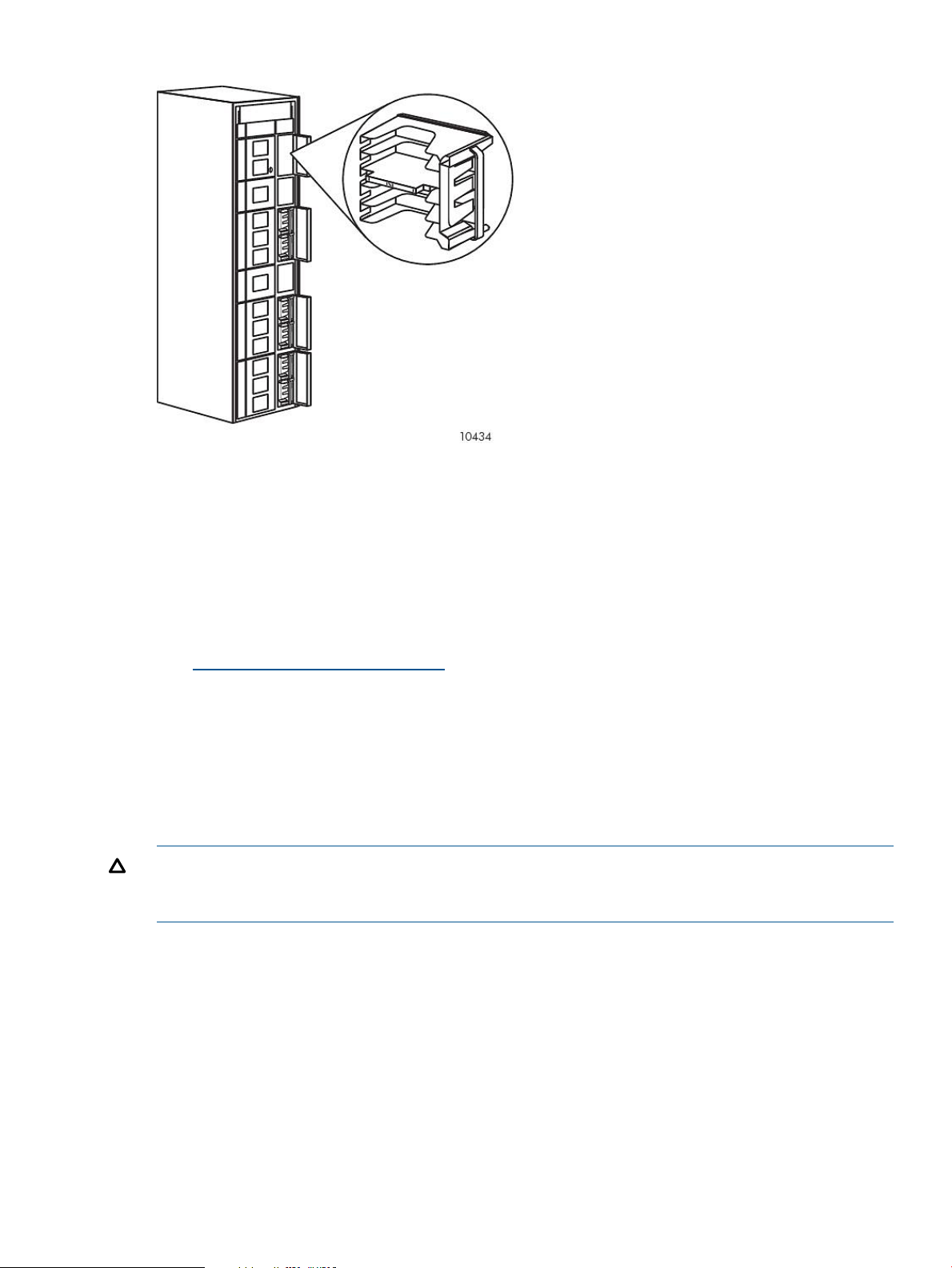

Load ports and magazines

The load ports are mechanical devices on the front of the library that enable you to import and

export tape cartridges to and from the library through removable magazines, or act as additional

library storage slots. These two functions for a load port cannot be mixed; you must either designate

an entire load port to be import/export slots or storage slots. The base module contains a load

port capable of using one 5-cartridge magazine. The 8U expansion modules contain load ports

capable of using two 5-cartridge magazines each.

20 Library overview

Page 21

Figure 16 Library load ports on 40U configuration

Tape drives

The Ultrium tape drive is a high performance streaming tape drive that uses LTO technology. The

library can use Ultrium 460 (LTO 2), Ultrium 960 (LTO 3), Ultrium 1840 (LTO4), Ultrium 3280

(LTO5) and Ultrium 6650 (LTO6) tape drives.

The Ultrium 960 and later include support for both rewriteable and Write-Once, Read-Many

(WORM) tape cartridges. WORM tape cartridges provide an enhanced level of data security

against alteration of data because you cannot erase or overwrite them. To check whether your

backup or archive software application supports WORM tape cartridges, see the following web

site: http://www.hp.com/go/connect.

For optimum performance, always use a tape cartridge that matches the specifications of your

tape drive. You can find comparisons between the Ultrium tape drives in (page 86).

Tape cartridges and cleaning cartridges are specifically formatted for use with Ultrium drives. To

order Ultrium tape cartridges, see “Ordering HP tape cartridges and barcode label packs” (page

102).

Switch for the internal network

CAUTION: Do not connect this switch to your local LAN. It is for internal library use only.

Connecting this switch to the LAN could cause library components to perform incorrectly or report

failures.

The 24-port Ethernet switch provides a private management network to connect the Interface

Manager card to the LTO4 or later tape drives. You must install one switch in each library that

contains LTO4 or later tape drives.

Tape drives 21

Page 22

Figure 17 Ports on the switch for the internal network

1. 10/100Base-TX RJ-45 ports

Operator control panel

The OCP displays library status information and enables you to access the library menus with a

touch screen. Use these menus to view and change the library settings, move tape cartridges,

obtain status information, or run diagnostic tests. Functions provided by the OCP are:

• Robotic and tape drive firmware revision reporting

• Library configuration

• Library and tape drive serial number reporting

• Critical component status report

• Critical component failure notification

• Ability to move tapes to and from any location

• Ability to configure barcode label length and justification reporting to the front panel and to

the host

• Access to error information

• Adjust screen contrast

Figure 18 Location of the OCP

Numbering

All of the tape cartridge slots and tape drives in a library are numbered with a coordinate system.

You might see these numbers in your application software or in error or diagnostic messages. Error

22 Library overview

Page 23

messages often include a slot location in the format MRC x,y,z. This identifies a module (x), row

(y), and column (z) location.

Each module has a different number of available slots, but a common numbering scheme for

identifying the slot location.

The library numbers the LTO slots using the following scheme:

• In general, the library numbers the slots one module at a time, starting with the top module.

For slot numbering purposes, the 12U base module is considered to be two modules: an 8U

base module and a 4U base module.

• Within each module, column numbering starts with 1 at the left column as viewed from the

front of the library.

• Within each module, row numbering starts with 1 at the top row.

• Any reserved slots, located in the first column of the 8U base module, and taking up as many

as nine slots, are not included in the numbering scheme. A common use for reserved slots is

for holding cleaning cartridges.

NOTE: Reserved slots are not available on the EML 71e.

• If the load port slots are configured as import/export slots, they are skipped and not counted

in the numbering of storage slots. If the load port slots are instead configured as storage slots,

they are counted in the numbering scheme.

NOTE: Reconfiguring the load port slots for either import/export or storage changes the slot

numbering in any lower modules the next time you perform an inventory.

• Some slots are not available in the bottom module in the library because the floor limits the

distance that the robot can travel.

CAUTION: Never operate the library with the floor removed. The robot can be damaged.

The slot numbering for various modules are shown on the following pages:

• Base module of the EML 71e ((page 24))

• Base module of all other configurations ((page 25))

• Tape drive expansion module ((page 25))

• Card cage expansion module ((page 26))

• Capacity expansion module ((page 26))

Numbering 23

Page 24

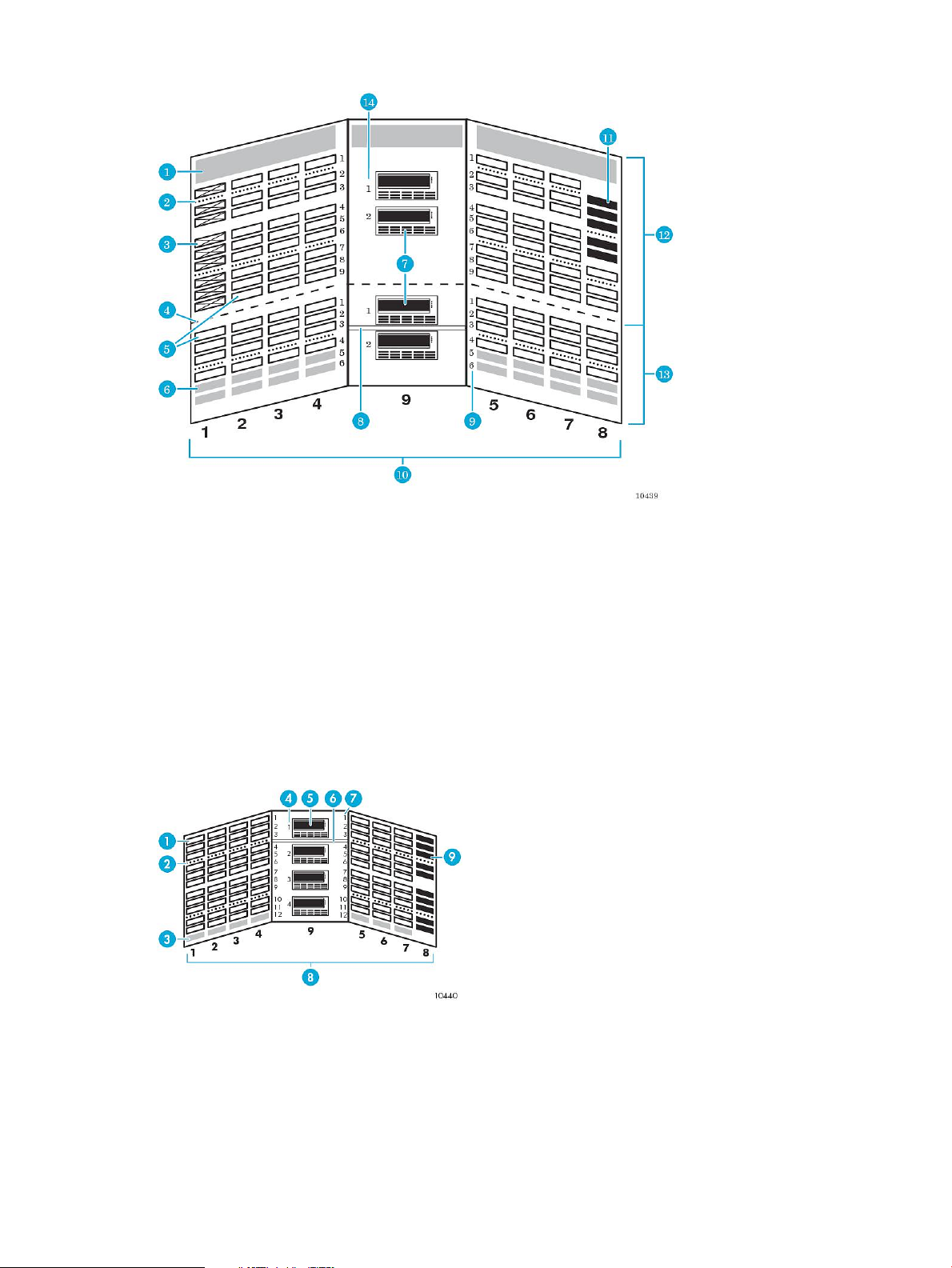

Figure 19 Slot numbering in the base module for the EML 71e

3. Slots available for data cartridges

2. Array targets for the barcode scanner1. Robot park zone

4. Software demarcation between upper and lower modules

for slot counting purposes

6. Expansion identification label5. Tape drives

8. Column numbering7. Row numbering

10. 8U base module9. Load port slots

12. Tape drive numbering11. 4U base module

24 Library overview

Page 25

Figure 20 Slot numbering in the base module for all other EML configurations

2. Array targets for the barcode scanner1. Robot park zone

3. Reserved slots-can be used for cleaning cartridges or

data cartridges

5. Slots available for data cartridges

4. Software demarcation between upper and lower modules

for slot counting purposes

6. Slots unavailable for use when the library floor is installed

in this module

8. Expansion identification label7. Tape drives

10. Column numbering9. Row numbering

12. 8U base module11. Load port slots

14. Tape drive numbering13. 4U base module

Figure 21 Slot numbering in the tape drive expansion module

in this module

9. Load port slots

2. Array targets1. Slots available for data cartridges

4. Tape drive numbering3. Slots unavailable for use when the library floor is installed

6. Expansion identification label5. Tape drives

8. Column numbering7. Row numbering

Numbering 25

Page 26

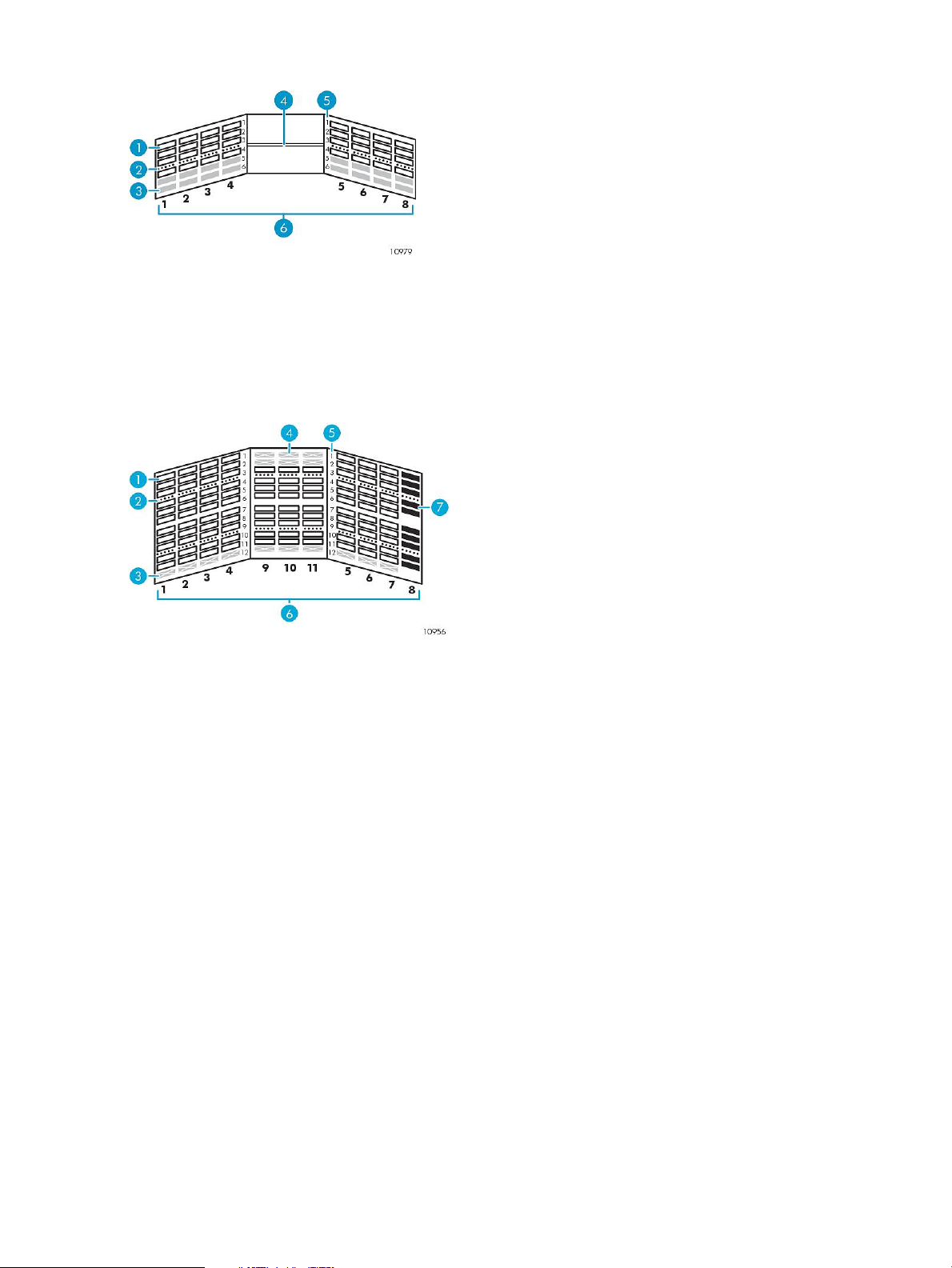

Figure 22 Slot numbering in the card cage expansion module

2. Array targets1. Slots available for data cartridges

4. Expansion identification label3. Slots unavailable for use when the library floor is installed

in this module

6. Column numbering5. Row numbering

Figure 23 Slot numbering in the capacity expansion module

3. Slots unavailable for use when the library floor is installed

in this module

7. Load port slots

Command View TL

Command View TL provides a browser-based GUI for remote management and monitoring of the

Interface Manager card through a LAN. Command View TL is the preferred method for controlling

the Interface Manager card. In conjunction with the Interface Manager card, Command View TL

provides the following:

• Configuration and management of the Interface Manager card and FC interface controllers

• Management of the entire library system

• Hardware inventory and identity information

• Status information for connected hardware

• Error reporting and comprehensive error logs

• Firmware management

• License management

2. Array targets1. Slots available for data cartridges

4. Slots unavailable for use when a base module or tape

drive expansion module is above this module

6. Column numbering5. Row numbering

Command View TL is installed on a management station and communicates with the Interface

Manager card through the LAN. The management station processes information from the Interface

Manager card and serves up the Command View TL GUI. You can access Command View TL from

26 Library overview

Page 27

the management station directly, or through any client on the LAN using a browser-based GUI.

Multiple Command View TL clients can be simultaneously open across the LAN, and multiple

libraries can be managed through the Command View TL software.

See the Command View TL documentation at http://www.hp.com/support/cvtl for prerequisites,

installation, and operating instructions.

IMPORTANT: If you are upgrading an EML 71e, you must purchase a capacity upgrade license

for Command View TL (part number AH063A). This license upgrades your base module from 71

slots to 103 slots.

Library and Tape Tools

Library and Tape Tools (L&TT) is a collection of storage hardware management and diagnostic

tools assembled into a single, convenient program. L&TT offers a GUI or command screen interface

(CSI), enabling you to perform the following functions with the library:

• Installation check Guides you through a basic installation check of the library. The software

helps you choose an appropriate HBA, making sure that the device is detected by the system,

and verifying key device functionality.

• Device identification Identifies the storage products connected to the system, along with key

information on product configuration and status.

• Troubleshooting tests Provides various tests to verify product functionality or to isolate product

issues. Tests include device self-tests, read/write tests on tape drives, exerciser tests for

autoloaders and libraries, and specific device utilities.

• Support ticket generation If you experience a problem with a storage product, L&TT can

generate a support ticket that includes essential information for troubleshooting the problem.

• Automatic notification of Web updates If a connection to the Internet is present and Web

updates are enabled in the tool preferences, L&TT automatically informs you of the following

updates, if available, each time the program is started:

◦ New versions of L&TT

◦ New firmware files for connected devices

◦ New device-specific functionality (such as new or updated tests) for connected devices

For more information on L&TT, go to the web site http://www.hp.com/support/tapetools.

Library and Tape Tools 27

Page 28

2 Using the library

This chapter describes operating procedures for the library.

Powering on the library

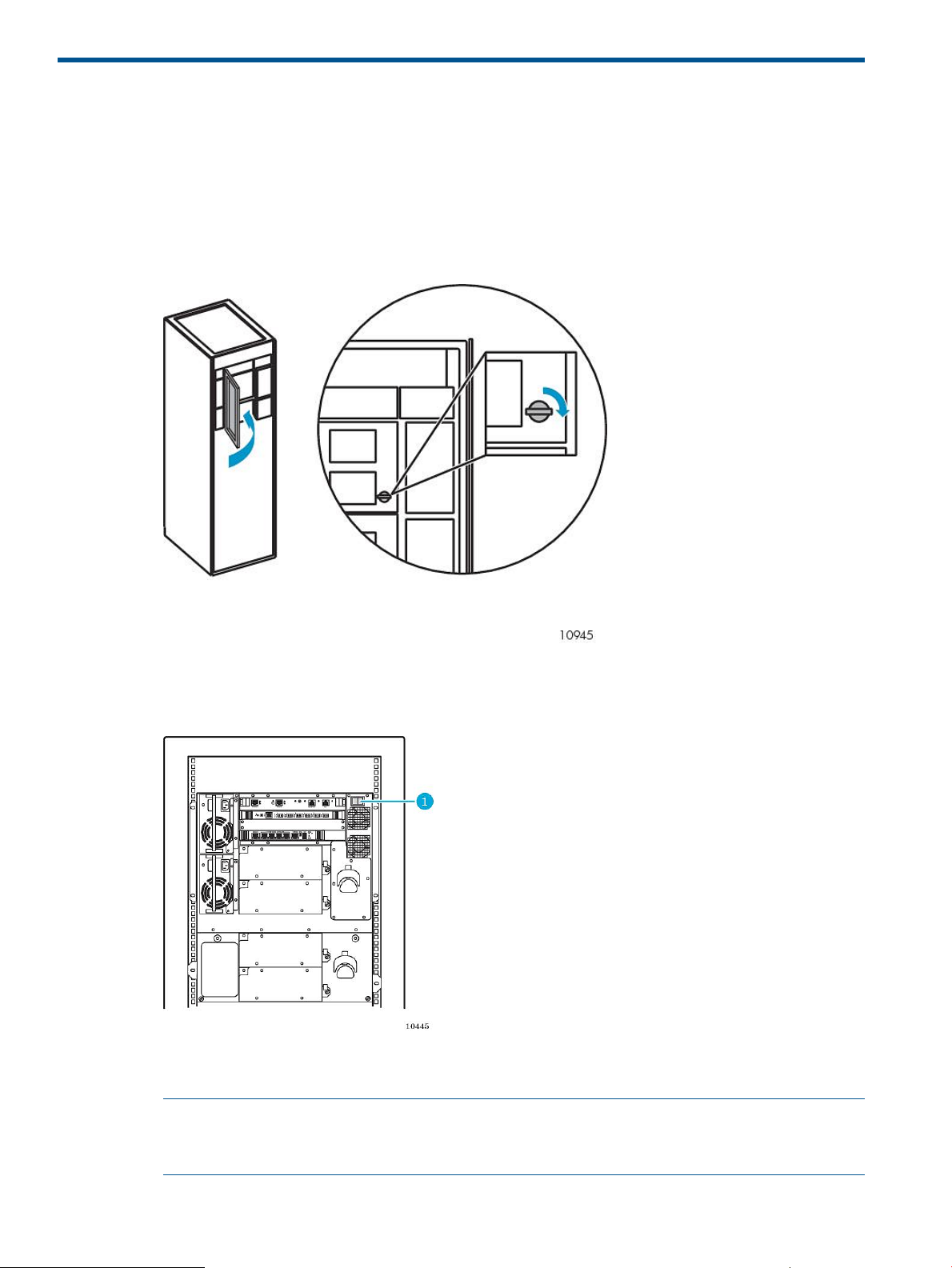

1. Close the center door of the library and turn the center-door knob one-quarter turn clockwise

to lock it.

Figure 24 Closing the center door

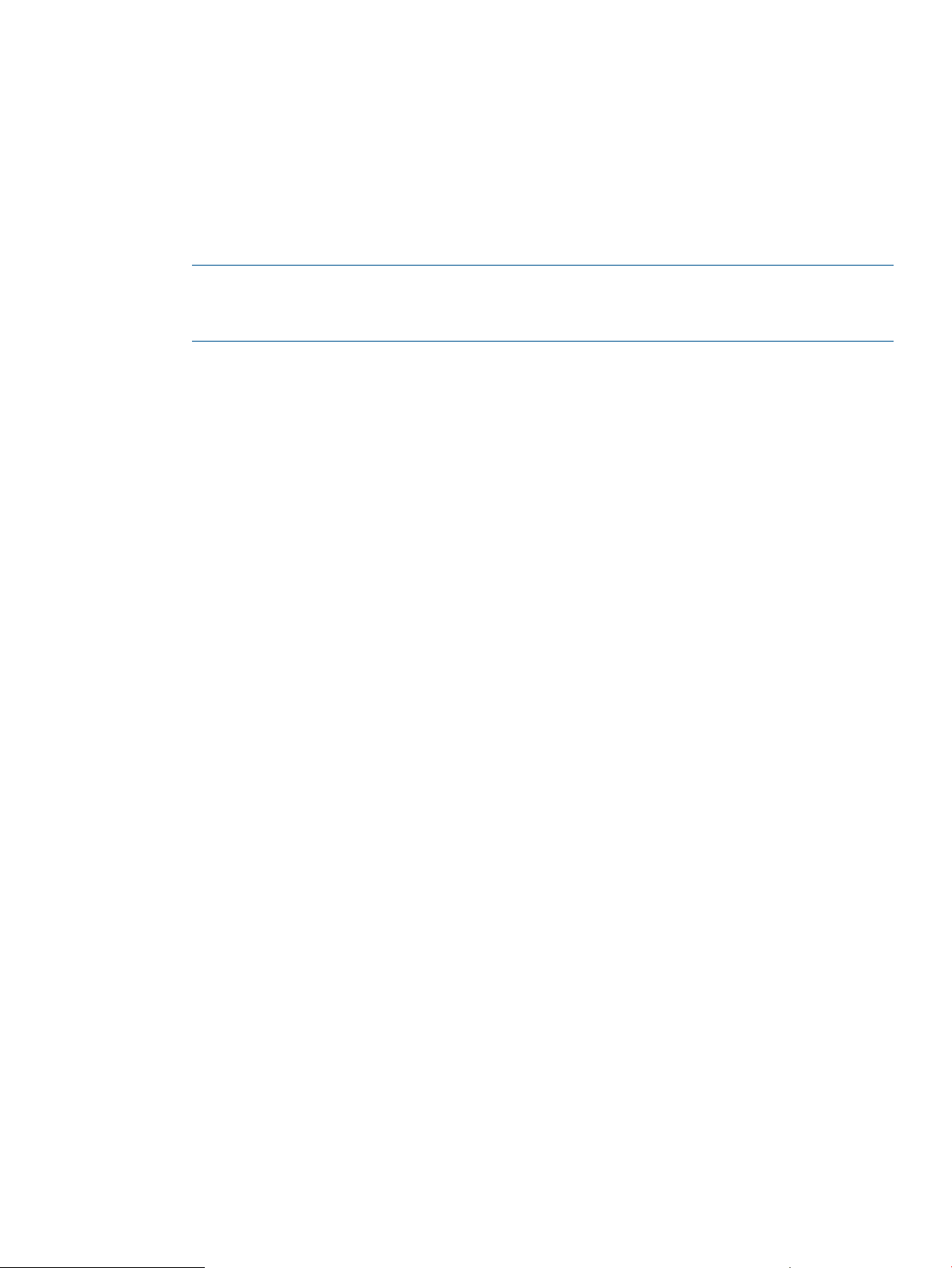

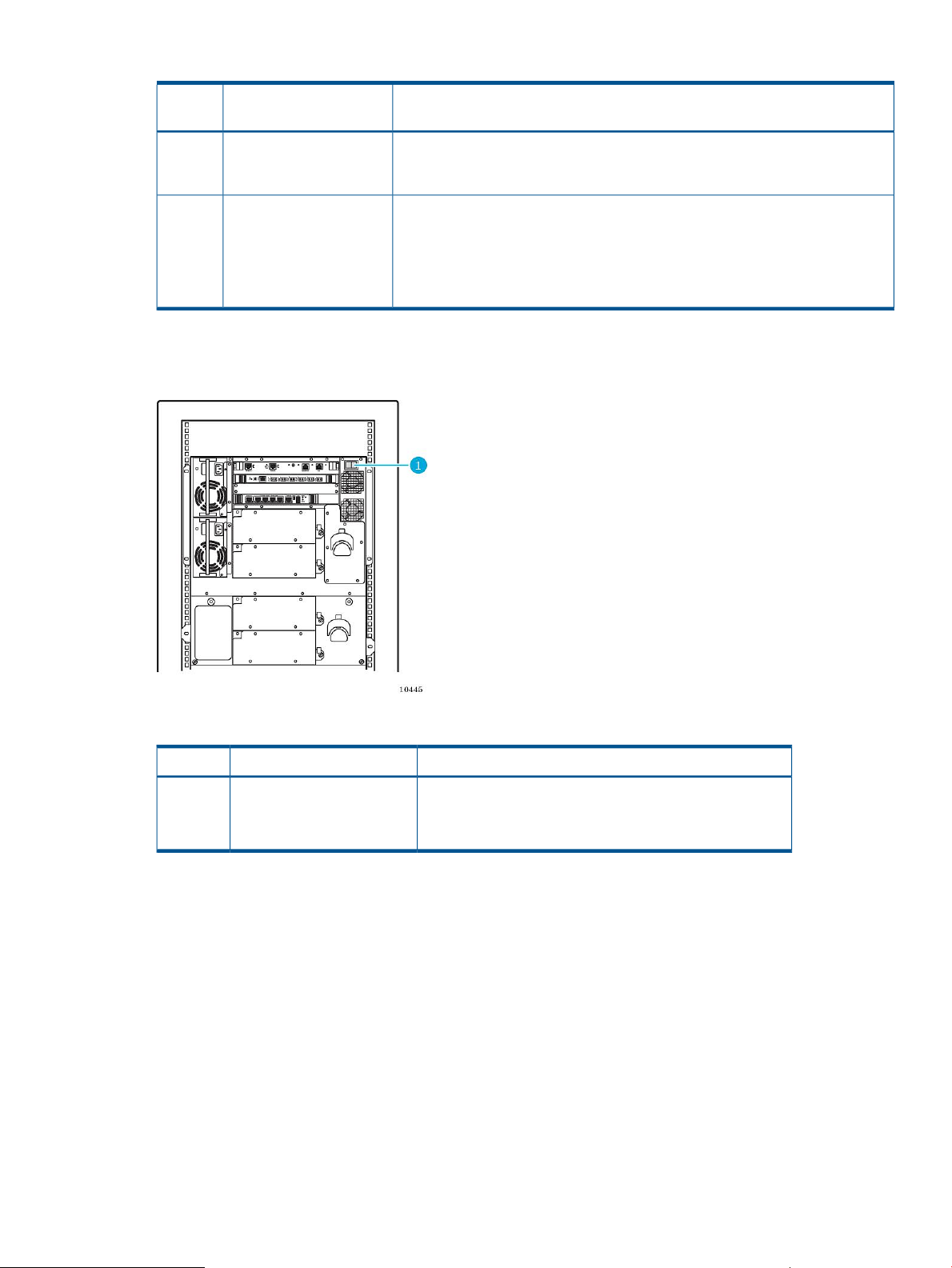

2. At the back of the library, press the library main power switch to the I (On) position.

Figure 25 Library main power switch control

1. Library main power switch

NOTE: The following step applies only when the library is powered on for the first time or

when a new interface controller is installed. This step is necessary to put the interface controller

into managed mode.

28 Using the library

Page 29

3. If this is the first time the library has been powered on after delivery, or if a new interface

controller was installed, configure the interface controller so that it is recognized by the Interface

Manager card. Do one of the following:

• If your library has an e2400-FC 2Gb interface controller, wait approximately two minutes,

and turn off the main power switch. Wait several seconds and then turn on the power

switch again.

• If your library has an e2400-FC 4Gb interface controller, reset the interface controller

twice. To reset the interface controller, insert a paper clip into the reset hole. After resetting

the interface controller, wait three minutes, then reset it again.

NOTE: A 71e library requires approximately 15 minutes to initialize. All other library models

require up to an hour to initialize and do an inventory. Nothing appears on the OCP for the

first few minutes of this process.

Powering off the library

1. Use your backup software to stop all library activity and make sure the picker is empty.

2. On the OCP, select the Operations→Unlock Door command to park the robot.

3. After the robot is parked, press the main power switch ((page 28)) to the O (Off) position.

Center-door interlock

The center door on the front of the library cannot be opened until a password-protected command

to unlock the center door is selected on the OCP. This command parks the robot, and actuates a

lever that enables you to open the center door. Even if the unit is powered off, the robot must be

parked before you can open the center door. If the robot is not parked prior to removing power,

you cannot readily open the center door.

Performing an inventory

The library does an inventory at three different times:

• When you turn on the power to the library

• When you reboot the library (Operations→Reboot Library)

• When you open and close the center door of the library (Operations→Unlock Door )

During the inventory:

• The library robotics controller applies voltage to the motors (picker, reach, wrist, and lift drive)

to obtain range of motion for each motor.

• The range of motion of the robot is tested.

• The targets and labels are read for calibration purposes.

• The barcode scanner looks at each slot to see if it contains a tape. The library robotics controller

stores this information. You must configure the library to use or not use barcode labels

(Configuration→Library Configuration→Configure Inventory Mode). If barcode labels are not

used, the inventory time may take as long as an hour, and a tape cartridge in a slot is only

known to the library as being full.

Attaching barcode labels to tape cartridges

Attaching barcode labels enables the library and application software to identify the tape cartridge

quickly, thereby speeding up inventory time. When a barcode label is not used, the library simply

designates that tape slot as being full. Even though the library functions without barcode labels,

Powering off the library 29

Page 30

HP recommends that you use them on your tape cartridges. Your host software can use barcode

labels to track the following information:

• Date of format or initialization

• Media pool of tape

• Data residing on the tape

• Age of the backup

• Errors encountered while using the tape (to determine if the tape is faulty)

CAUTION: Handle tape cartridges with care. Do not drop or mishandle them, or place them

near sources of electromagnetic interference. Rough handling can damage the tape cartridge

making it unusable and potentially hazardous to the tape drives.

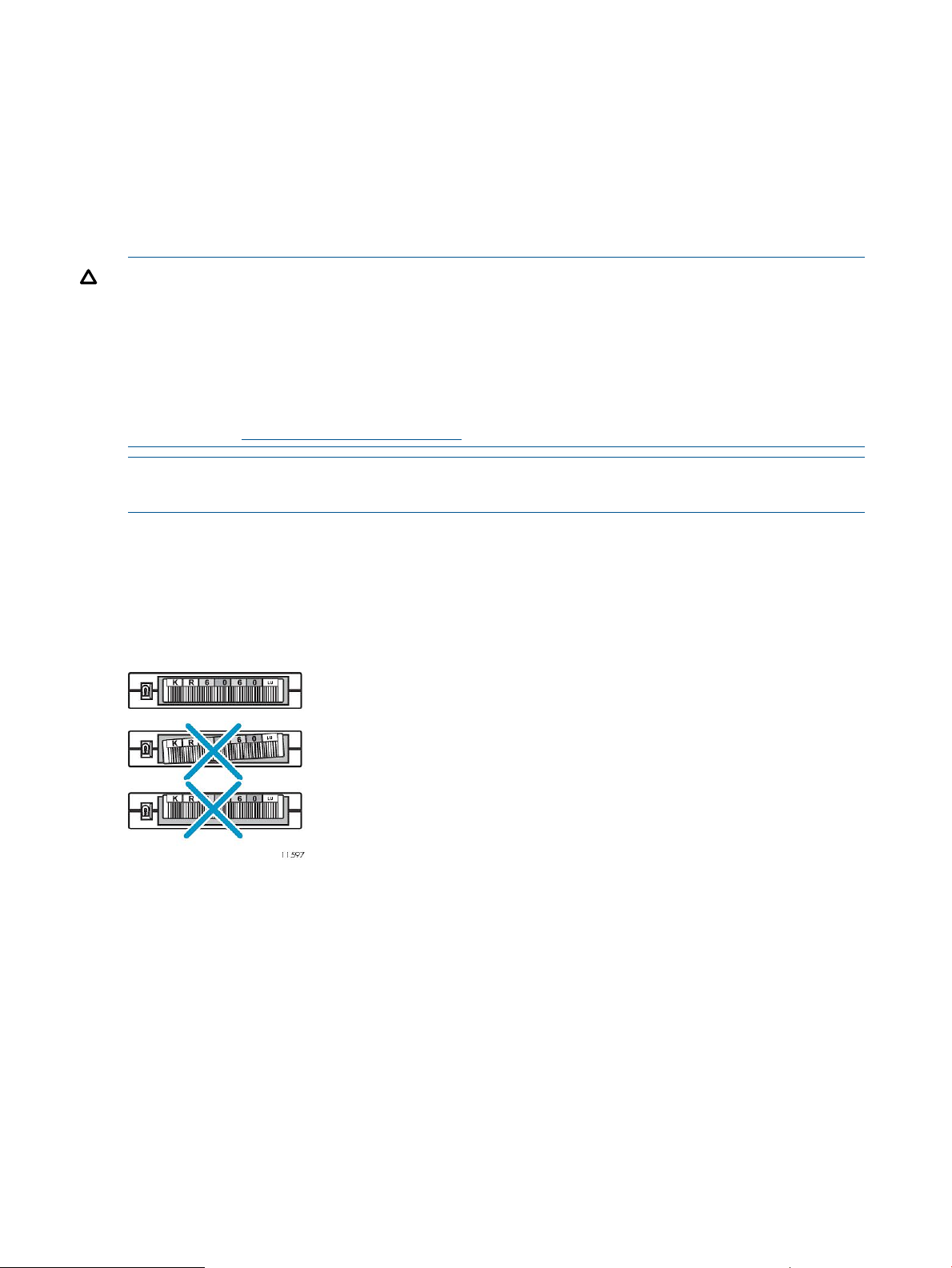

CAUTION: The misuse of barcode technology can result in backup and restore failures. To ensure

that your barcodes meet HP's quality standards, always purchase them from an approved supplier

and never print barcode labels yourself. For more information, see the order form provided with

the library, as well as the Barcode Label Requirements, Compatibility and Usage white paper

available from http://www.hp.com/support.

NOTE: For information on ordering tape cartridges and barcode labels, see “Ordering HP tape

cartridges and barcode label packs” (page 102).

Ultrium tape cartridges have a recessed area located on the face of the tape cartridge next to the

write-protect switch. Use this area for attaching the adhesive-backed barcode label. Only apply

labels onto the tape cartridge in this designated area. For successful operation of your tape library,

place the barcode label entirely within the recessed area, making sure that no part of the label

extends outside.

Figure 26 Proper barcode label placement

Position the barcode label as shown in the following figure, with the alphanumeric portion facing

the hub side of the tape cartridge (LTO2) or numeric portion away from the hub (LTO3 and later).

Never apply multiple labels onto a tape cartridge, because extra labels can cause the tape cartridge

to jam inside a tape drive.

Always use the proper barcode labels for your tape drive technology. An L2 (Ultrium 460), L3

(Ultrium 960), L4 (Ultrium 1840), or L5 (Ultrium 3280), L6 (Ultrium 6650) identifier is located at

the end of the 8-character Ultrium barcode labels on data cartridges. The universal LTO cleaning

cartridges have a CLN and L1 identifier on the label.

30 Using the library

Page 31

Figure 27 Attaching an Ultrium barcode label

Setting the write-protect switch

Each tape cartridge has a sliding write-protect switch. This switch determines whether new data

can be written to the tape cartridge (write-enabled) or whether data on the tape cartridge is

protected from being erased or overwritten (write-protected).

By moving the switch to the left, the tape cartridge is write-enabled. By moving the switch to the

right, the tape cartridge is write-protected.

Figure 28 Write-protecting Ultrium tape cartridges

2. Write-protected1. Write-enabled

4. Barcode label3. Write-protect switch

5. Insertion arrow

Inserting tape cartridges into the load port

Inserting tapes through the center door of the library should only be done when bulk loading. At

all other times, load tape cartridges into the library through the load port. Not using the load port

stops all robotic activity and tape movement, and requires a complete library inventory before

operations can resume. When using the load port, tape cartridges are inserted into 5-cartridge

magazines, which are placed into either the 5-cartridge load port or a 10-cartridge load port. To

use a load port:

1. Attach a barcode label to each tape cartridge (see (page 29)).

2. Write-protect or write-enable each tape cartridge as appropriate (see (page 31)).

3. On the OCP, select Operations→Unlock Load Ports. If the load ports are password protected

and you are prompted to enter the password, use the keypad that appears on the OCP to

enter the password, then press the Enter key on the touchscreen. All load port doors open.

Setting the write-protect switch 31

Page 32

4. Grab the handle on the magazine and pull it out of the library.

CAUTION: Guard plates prevent access to the inside of the library when a load port

magazine is removed. These doors will move back out of the way when a magazine is

reinserted. You should not attempt to otherwise move these guards, nor gain access to the

library through the load ports.

5. Insert the tape cartridges into any available slots in the magazine.

CAUTION: Excessive force when inserting a magazine can cause a tape cartridge to unseat

and extend into the path of the robot.

6. Align the magazine with the track on the load port door and gently slide the magazine through

the spring door and fully into the load port.

7. Close the load port door.

8. After all load port doors are closed, the library does an inventory of the load ports.

Figure 29 Inserting a magazine into the load port

Using the OCP

The OCP is an LCD screen located on the front of the library that is operated by touch. The icons,

text, and tabs on the OCP enable you to obtain information about the library, execute library

commands, and test library functions.

OCP icons

The following table displays icons that can appear on the OCP.

Table 2 OCP icons

32 Using the library

DescriptionIcon

Critical error—A component failure has made the library inoperable.

Warning—A component failure has degraded library activity, but the library

is still operable.

Ready—The library is online and ready for operation.

Thumbtack out—The screen is eligible to be selected for display after a period

of inactivity.

Page 33

Table 2 OCP icons (continued)

Home screen

The first screen that appears after library initialization is the Home screen. After the library status

is determined (ready, warning, or error), that status appears on the Home screen, and you can

touch the screen to access other functional and operational screens.

Figure 30 Home screen

DescriptionIcon

Thumbtack in—The screen has been selected for display after a period of

inactivity. Only one screen at a time can be thumbtacked.

Item selection—The item can be selected from a menu list.

Password required—A password is required to access this feature.

Password entered—The correct password has been entered. The command is

available.

OCP tabs and status bar

After touching the Home screen, the menu screen appears. All menu screens contain a status bar

to the left of an HP logo, two rows of tabs, and an area for detailed screen information in the

center.

Using the OCP 33

Page 34

Figure 31 Menu screen

The status bar is a quick indicator of library health. The bar is green when the library is functioning

normally, yellow during a warning condition, and red during an error condition. Touching the

status bar takes you to the Health Summary screen.

The detailed functions of the four top-level menu tabs (Status, Configuration, Operations, and

Support) are discussed later. Selecting any of these four tabs takes you to menu items under that

screen category.

Five navigation tabs can be displayed at the bottom of the screen. The thumbtacked (in or out) tab

was discussed in (page 33). The remaining tabs are:

Timeouts

• Help Displays help text for features appearing on that screen.

• Page Up Scrolls text to a previous page when text is longer than a page in size.

• Page Down Scrolls text to the following page when text is longer than a page in size.

• Back Moves you one level up in the menu tree. All screens except the Home, test status, error

message, and keypad screens have this tab at the lower, right corner. Returning to the Home

screen removes all password privileges previously granted through the OCP.

The library enters a timeout state after five minutes of inactivity. In this state:

• The OCP backlight turns off.

• Password privileges are removed on all screens granted access.

• The OCP returns to either the Home screen or a thumbtacked screen, if one is designated. If

a thumbtacked screen consists of more than one page, the pages cycle every five seconds.

Touching a screen in a timeout state turns on the backlight. Subsequent touches after the backlight

is lit perform the requested command.

The following are special timeout cases:

• When a service password is entered, the length of time to enter a timeout state changes from

5 minutes to 30 minutes. If the OCP is touched during the 30-minute period, the library reverts

to a normal 5-minute period before a timeout.

• If a warning condition occurs while the library is timed-out, the backlight comes on for 30

minutes. If the OCP is touched during this 30-minute period, the library reverts to a normal

5-minute period before a timeout. Otherwise, the library re-enters a normal timeout state after

30 minutes.

• If an error condition occurs while the library is timed-out, the backlight comes on for 60 minutes.

If the OCP is touched during this 60-minute period, the library reverts to a normal 5-minute

34 Using the library

Page 35

period before a timeout. Otherwise, the library re-enters a normal timeout state after 60

minutes.

For certain functions, the timeout feature is disabled and re-enabled when the function completes.

This occurs:

• During an operation and until the operation completes. For example, the OCP does not time

out while a tape drive cleaning operation is in progress but waits for the operation to complete

before starting the 5-minute timeout counter.

• While displaying the results of any test operation. Select the Cancel or OK button to return to

the test menu screen.

• When displaying an error report or menu after an error. The screen is treated as temporarily

thumbtacked, which clears the password protected screens after the normal timeout period,

but displays the screen until it is acknowledged.

• When success or failure messages appear for an operation. The screen is temporarily

thumbtacked, clearing the password protected screens after the normal timeout period, but

the screen remains until acknowledged.

OCP functions

The OCP enables you to perform various functions on the library. Table 3 (page 36) provides a

list of the OCP functions available from the Home screen.

Using the OCP 35

Page 36

Table 3 OCP components

Options to view or selectTab

Identity ScreenStatus

Health Summary >

• Library and Robotics >

Library Status◦

◦ Robotics Status

◦ Power Supply Status > (power supplies 1–6)

• Load Ports > (load ports 1–4)

• Drives > (drives 1–16)

• Interface Controllers > (interface controllers 1–4)

• Interface Manager

Component Status >

• Library and robotics Status >

Library Status◦

◦ Robotics Status

◦ Drive Odometers

◦ Load Port Door Status

◦ Library Sensors > (modules 1–4)

• Individual Drive Status

• All Drive Summary

• Interface Controller Status > (interface controllers 1–4)

• Interface Manager Status

Event Log Type Selection

View Library Inventory

Library Configurations >Configuration

• Change Password

◦ Load Port Access Password Option

• Configure Load Ports

• Change Network Settings

• Configure Barcode Reporting Formats >

◦ Format for front panel reporting

36 Using the library

◦ Format for host reporting

• Configure Reserve Slots

• Configure Inventory Mode

Adjust Screen Contrast

Unlock Load PortsOperations

Unlock Door

Page 37

Table 3 OCP components (continued)

Options to view or selectTab

Reboot Library

Media Operations >

• Move Tape

• Clean Drive

Run Admin Tests >

• Operator Control Panel >

Align Touch Screen◦

◦ Panel Colors

◦ Panel Pixel Test

◦ Panel Firmware Version

◦ Turn Backlight Off

• Inventory Library

• Run Demo

• Run Self Test

• Slot Test

• Drive Load/Unload Test

• Force Rewind Unload Test

• Recalibrate Library

Status screen

The Status screen provides access to the current state of every library component.

Power supplies, load ports, tape drives, and interface controllers are all numbered from top to

bottom in the rack. However, power supplies are numbered by slot, so if a slot is not filled with a

power supply, the slot still receives a number. For example, the top power supply slot in the rack

is power supply 1. The power supply slot under that is power supply number 2. If a power supply

is on the same level horizontally (like those in the card cage expansion module), the one to the

right (facing the back of the rack) has the next highest number. If a component is removed, the

numbering does not change until you reboot the library. After a reboot, the library rediscovers all

components and reassigns numbers from top to bottom.

HP Support InfoSupport

Service Menu >

Contact Information

Display Library Time

Using the OCP 37

Page 38

Figure 32 OCP Status screen

Table 4 Status screen functions

DescriptionFunction

Identity Screen

Health Summary

Contains basic configuration information. The library name, IPv4 address,

and IPv6 Interface Identifier are obtained from Command View TL. Other

information comes from the robot firmware.

The number of interface controllers and tape drives installed in the library

are listed, as well as the total number of available storage slots. For

example, load port slots configured as storage slots are counted in the