Page 1

DESIGNJET L28500 printer series

User’s guide

Edition: 3rd edition

Page 2

© 2013 Hewlett-Packard Development

Company, L.P.

Legal notices

The information contained herein is subject to

change without notice.

The only warranties for HP Products and

services are set forth in the express warranty

statement accompanying such products and

services. Nothing herein should be construed

as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or

omissions contained herein.

Trademarks

Microsoft® and Windows® are U.S. registered

trademarks of Microsoft Corporation.

Page 3

Table of contents

1 Introduction .................................................................................................................................................. 1

Safety precautions ................................................................................................................................................. 1

The printer’s main features ................................................................................................................................... 4

The printer’s main components ............................................................................................................................ 5

The Embedded Web Server ................................................................................................................................... 9

Turn the printer on and off .................................................................................................................................. 11

Restart the printer ............................................................................................................................................... 11

2 Connectivity and software instructions ......................................................................................................... 13

Connection method ............................................................................................................................................. 13

Connect to a network .......................................................................................................................................... 13

3 Basic setup options ...................................................................................................................................... 15

Printer setup options ........................................................................................................................................... 15

Embedded Web Server setup options ................................................................................................................. 17

4 Handle the substrate ................................................................................................................................... 21

Overview .............................................................................................................................................................. 21

Porous substrates ............................................................................................................................................... 24

Load a roll onto the spindle ................................................................................................................................. 25

Load a roll into the printer (automatically) ......................................................................................................... 28

Load a roll into the printer (manually) ................................................................................................................ 31

Load a cut sheet into the printer ......................................................................................................................... 34

Unload a roll from the printer ............................................................................................................................. 35

The take-up reel .................................................................................................................................................. 35

The edge holders ................................................................................................................................................. 44

The loading accessory ......................................................................................................................................... 45

Double-sided printing .......................................................................................................................................... 49

View information about the substrate ................................................................................................................ 51

Substrate length tracking ................................................................................................................................... 51

Form feed and cut ................................................................................................................................................ 53

Store the substrate .............................................................................................................................................. 53

ENWW iii

Page 4

5 Substrate settings ....................................................................................................................................... 55

Download media presets ..................................................................................................................................... 55

Add a new substrate ............................................................................................................................................ 55

Faster printing ..................................................................................................................................................... 66

Color calibration .................................................................................................................................................. 66

Color profiles ....................................................................................................................................................... 67

Color reproduction tricks ..................................................................................................................................... 67

6 Retrieving usage information ....................................................................................................................... 69

Get accounting information ................................................................................................................................ 70

Check usage statistics ......................................................................................................................................... 70

Check usage statistics for a job ........................................................................................................................... 70

Request accounting data by E-mail .................................................................................................................... 70

7 The ink system ............................................................................................................................................ 73

Ink system components ...................................................................................................................................... 73

Order ink supplies ................................................................................................................................................ 77

8 Print options ............................................................................................................................................... 79

Printer states ....................................................................................................................................................... 79

Change margins ................................................................................................................................................... 79

Request the printer’s internal prints ................................................................................................................... 80

9 Accessories ................................................................................................................................................. 81

Order accessories ................................................................................................................................................ 81

10 Printer status ............................................................................................................................................ 83

Check printer status ............................................................................................................................................ 83

Check the status of the ink system ..................................................................................................................... 83

Check the status of the ink cartridges ................................................................................................................ 83

Check the status of a printhead .......................................................................................................................... 84

Check the file system .......................................................................................................................................... 84

Printer alerts ........................................................................................................................................................ 84

11 Firmware update ....................................................................................................................................... 87

12 Hardware maintenance .............................................................................................................................. 89

Ink system tips ..................................................................................................................................................... 89

Align the printheads ............................................................................................................................................ 89

Clean and lubricate the carriage rail ................................................................................................................... 90

Clean the electrical connections on a printhead ................................................................................................. 92

Clean the exterior of the printer .......................................................................................................................... 96

Clean the platen ................................................................................................................................................... 97

iv ENWW

Page 5

Clean (recover) the printheads ............................................................................................................................ 99

Clean the substrate-advance sensor window .................................................................................................. 100

Maintain the ink cartridges ................................................................................................................................ 100

Move or store the printer .................................................................................................................................. 101

Replace an ink cartridge .................................................................................................................................... 101

Replace the ink maintenance kit ....................................................................................................................... 105

Replace a printhead ........................................................................................................................................... 110

Replace the printhead cleaning kit ................................................................................................................... 116

Service maintenance ......................................................................................................................................... 121

13 Troubleshoot print-quality issues ............................................................................................................. 123

General printing advice ..................................................................................................................................... 123

Use the printhead status plot ........................................................................................................................... 123

Graininess .......................................................................................................................................................... 124

Horizontal banding ............................................................................................................................................ 125

Vertical banding ................................................................................................................................................. 127

The print is deformed into a curved shape ....................................................................................................... 128

Misaligned colors ............................................................................................................................................... 128

Color intensity varies ......................................................................................................................................... 128

Lack of sharpness .............................................................................................................................................. 129

Black areas look hazy ........................................................................................................................................ 129

Ink smears ......................................................................................................................................................... 130

Subtle stains or uneven appearance ................................................................................................................. 130

The ink smudges when touched, or looks oily .................................................................................................. 130

The dimensions of the print are wrong ............................................................................................................. 131

Tiling issues ....................................................................................................................................................... 131

14 Troubleshoot substrate issues .................................................................................................................. 133

The substrate cannot be loaded successfully .................................................................................................. 133

The substrate is mispositioned ......................................................................................................................... 134

The substrate has jammed ................................................................................................................................ 134

The substrate is deformed or wrinkled ............................................................................................................. 137

The substrate has shrunk or expanded ............................................................................................................ 137

The substrate has bow deformation ................................................................................................................. 138

The automatic cutter does not work ................................................................................................................. 139

Take-up reel substrate jam ............................................................................................................................... 139

Take-up reel does not wind .............................................................................................................................. 139

15 Troubleshoot ink-system issues ............................................................................................................... 141

Ink maintenance kit needs to be installed ........................................................................................................ 141

Cannot insert an ink cartridge ........................................................................................................................... 141

Cannot insert a printhead .................................................................................................................................. 141

Cannot insert the printhead cleaning cartridge ................................................................................................ 141

ENWW v

Page 6

Front panel recommends reseating or replacing a printhead .......................................................................... 141

Clean the printheads ......................................................................................................................................... 142

Align the printheads .......................................................................................................................................... 142

16 Troubleshoot other issues ........................................................................................................................ 145

The printer cannot get an IP address ................................................................................................................ 145

Cannot access the Embedded Web Server ........................................................................................................ 145

The printer is not printing ................................................................................................................................. 146

The software program slows down or stalls while generating the print job ................................................... 146

The printer seems slow ..................................................................................................................................... 146

Communication failures between computer and printer ................................................................................. 146

The platen rollers squeak ................................................................................................................................. 147

17 Front-panel error messages ..................................................................................................................... 149

Printer logs ........................................................................................................................................................ 151

18 When you need help ................................................................................................................................. 153

Introduction ....................................................................................................................................................... 153

Documentation .................................................................................................................................................. 153

Customer Self Repair ......................................................................................................................................... 153

HP Customer Care Centers ................................................................................................................................ 153

Service information ........................................................................................................................................... 154

19 Printer specifications ............................................................................................................................... 155

Functional specifications .................................................................................................................................. 155

Physical specifications ...................................................................................................................................... 157

Memory specifications ...................................................................................................................................... 157

Power specifications ......................................................................................................................................... 157

Environmental specifications ............................................................................................................................ 157

Acoustic specifications ...................................................................................................................................... 158

Appendix A Summary of common printing problems ....................................................................................... 159

Glossary ....................................................................................................................................................... 161

Index ........................................................................................................................................................... 165

vi ENWW

Page 7

1 Introduction

Safety precautions

Before using your printer, read the following safety precautions to make sure you use the equipment safely.

You are expected to have the appropriate technical training and experience necessary to be aware of hazards

to which you may be exposed in performing a task, and take appropriate measures to minimize the risks to

yourself and to other people.

General safety guidelines

●

There are no operator-serviceable parts inside the printer except those covered by HP's Customer Self

Repair program (see

service personnel.

http://www.hp.com/go/selfrepair/). Refer servicing of other parts to qualified

●

Turn off the printer and call your service representative in any of the following cases.

◦

The power cord or plug is damaged.

◦

Liquid has entered the printer.

◦

There is smoke or an unusual smell coming from the printer.

◦

The printer has been dropped or the drying or curing module has been damaged.

◦

The printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter) has been

repeatedly tripped.

◦

The printer is not operating normally.

●

Turn off the printer in either of the following cases.

◦

During a thunderstorm

◦

During a power failure

Electrical shock hazard

WARNING! The drying and curing modules operate at hazardous voltages capable of causing death or

serious personal injury.

Ensure that the power is disconnected from the branch circuit breaker of the PDU, and that the printer’s main

power switch is off, before servicing the printer.

To avoid the risk of electric shock:

●

Do not attempt to dismantle the drying and curing modules or the electrical control cabinet.

●

Do not remove or open any other closed system covers or plugs.

ENWW Safety precautions 1

Page 8

●

●

Heat hazard

The drying and curing subsystems of the printer operate at high temperatures and can cause burns if

touched. To avoid personal injury, take the following precautions.

●

●

Fire hazard

The drying and curing subsystems of the printer operate at high temperatures. Call your service

representative if the printer's built-in Residual Current Circuit Breaker (Ground Fault Circuit Interrupter) is

repeatedly tripped.

To avoid the risk of fire, take the following precautions.

●

●

Do not insert objects through slots in the printer.

Test the functionality of the Residual Current Circuit Breaker (RCCB) every 6 months.

Do not touch the internal enclosures of the printer's drying and curing modules. Even after opening the

window latch that disconnects drying and curing power, the internal surfaces could be hot.

Take special care when accessing the substrate path.

Use the power supply voltage specified on the nameplate.

An electrician is required for the setup and configuration of the building’s electrical system used to

power the printer, and for printer installation. Make sure that your electrician is appropriately certified

according to local regulations and supplied with all the information regarding the electrical

configuration.

●

The electrician should connect the power cord as specified in the Site preparation guide and Assembly

instructions. Three-phase lines are required, each protected by a branch circuit breaker. The power

cable is not provided with the printer.

●

Do not insert objects through slots in the printer.

●

Take care not to spill liquid on the printer.

●

Do not use aerosol products that contain flammable gases inside or around the printer.

●

Do not block or cover the openings in the printer body that are provided for ventilation.

●

Do not attempt to dismantle the drying or curing module, or the electrical control cabinet.

●

Ensure that the operating temperature of the substrate, as recommended by its manufacturer, is not

exceeded. If this information is not available from the manufacturer, be sure to use only substrates

suitable for operating temperatures of 125°C (257°F) or higher.

●

Do not load substrates with auto-ignition temperatures below 250°C (482°F). See note below.

NOTE: Test method based on EN ISO 6942:2002; Evaluation of materials and material assemblies when

exposed to a source of radiant heat, method B. The test conditions, to determine the temperature when the

substrate starts ignition (either flame or glow) were: Heat flux density: 30 kW/m², copper calorimeter, K type

thermocouple.

Mechanical hazard

The printer has moving parts that could cause injury. To avoid personal injury, take the following precautions

when working close to the printer.

●

Keep your clothing and all parts of your body away from the printer's moving parts.

●

Avoid wearing necklaces, bracelets, and other hanging objects.

2 Chapter 1 Introduction ENWW

Page 9

●

If your hair is long, try to secure it so that it will not fall into the printer.

●

Take care that sleeves or gloves do not get caught in the printer's moving parts.

●

Avoid standing close to the fans, which could cause injury and could also affect print quality (by

obstructing the air flow).

●

Do not touch gears or moving rolls during printing.

Heavy substrate hazard

Special care must be taken to avoid personal injury when handling heavy substrates.

●

Handling heavy substrate rolls may require more than one person. Care must be taken to avoid back

strain and/or injury.

●

Consider using a forklift, pallet truck, or other handling equipment.

●

When handling heavy substrate rolls, wear personal protective equipment including boots and gloves.

Ink handling

Your printer does not use solvent inks and does not have the traditional problems associated with them.

However, HP recommends that you wear gloves when handling ink system components.

Warnings and cautions

The following symbols are used in this manual to ensure the proper use of the printer and to prevent the

printer from being damaged. Follow the instructions marked with these symbols.

WARNING! Failure to follow the guidelines marked with this symbol could result in serious personal injury

or death.

CAUTION: Failure to follow the guidelines marked with this symbol could result in minor personal injury or

damage to the product.

Warning labels

Label Explanation

Risk of burns. Do not touch the internal enclosures of drying and

curing modules of the printer.

Risk of burns. Do not touch the drying enclosure of the printer.

Even after opening the window latch, which disconnects the

power to the drying and curing modules, the internal surfaces

could be hot.

Electric shock hazard. There are no operator-serviceable parts

inside the printer. Refer servicing to qualified service personnel.

ENWW Safety precautions 3

Page 10

Label Explanation

See installation instructions before connecting to the supply.

Ensure that the input voltage is within the printer's rated voltage

range, and select the correct printer 3-phase configuration.

Risk of trapped hands.

Risk of trapped fingers. Do not touch spindle gears while moving.

Do not put objects on top of the printer. Do not cover the top

fans.

The printer’s main features

Your printer is a color inkjet printer designed for printing high-quality images on flexible substrates from

0.584 m (23 in) to 2.64 m (104 in) wide. Some major features of the printer are shown below:

●

Printing speeds in draft mode of up to 70 m²/h (753 ft²/h).

●

Environmentally friendly, odorless, aqueous latex inks in six colors

●

No special ventilation required, no hazardous waste

●

775 ml ink cartridges

●

Print on a wide range of substrates—including most low-cost, uncoated, solvent-compatible substrates

●

A range of HP recyclable substrates is available

You are recommended to wear gloves when handling ink

cartridges, printhead cleaning cartridges, and the printhead

cleaning container.

●

Durable prints with outdoor display permanence up to three years unlaminated, five years laminated

●

Accurate and consistent color reproduction with automatic color calibration (built-in

spectrophotometer) for most substrates

To send print jobs to your printer, you will need Raster Image Processor (RIP) software, which should be run

on a separate computer. RIP software is available from various different companies; it is not provided with

the printer.

4 Chapter 1 Introduction ENWW

Page 11

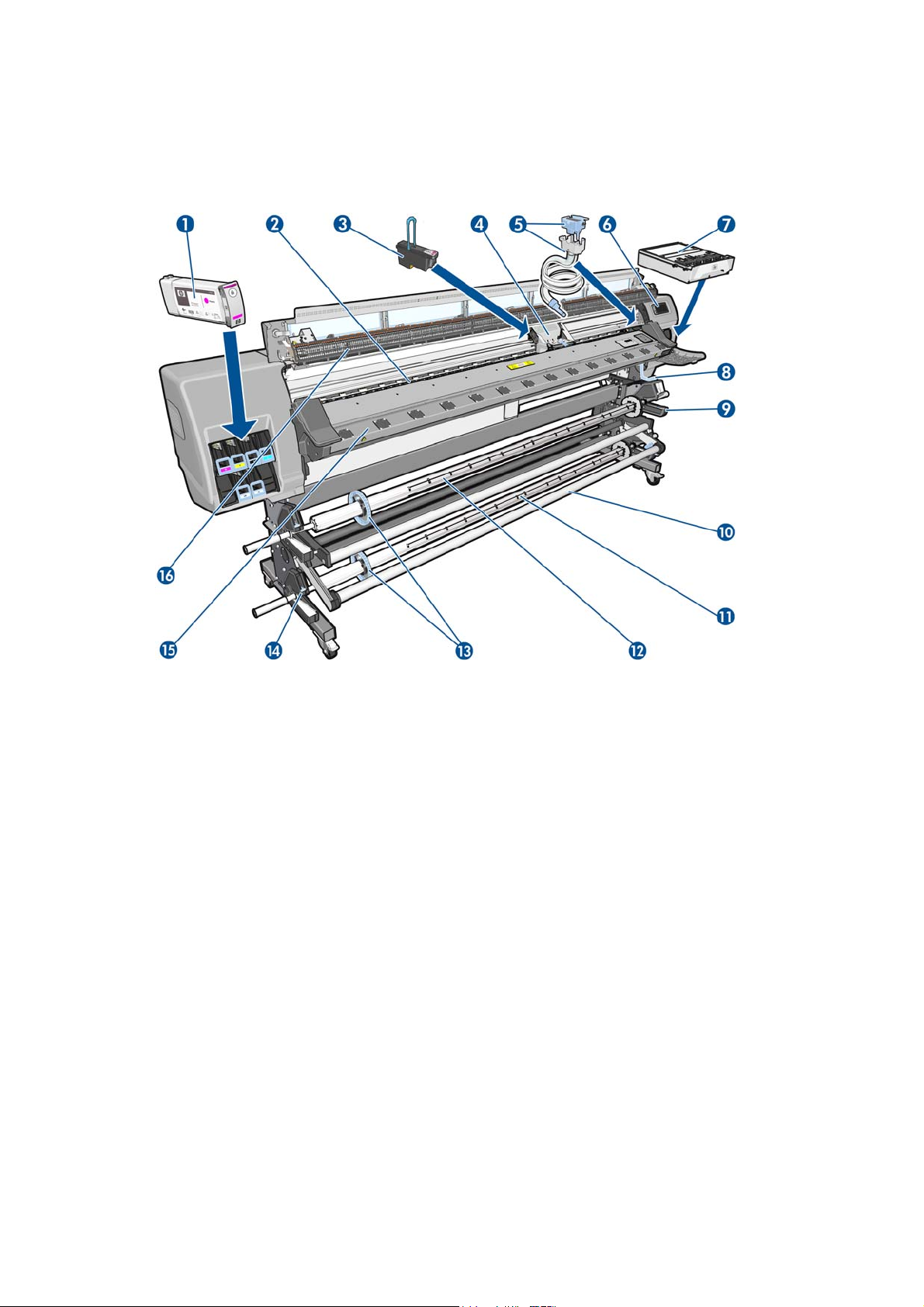

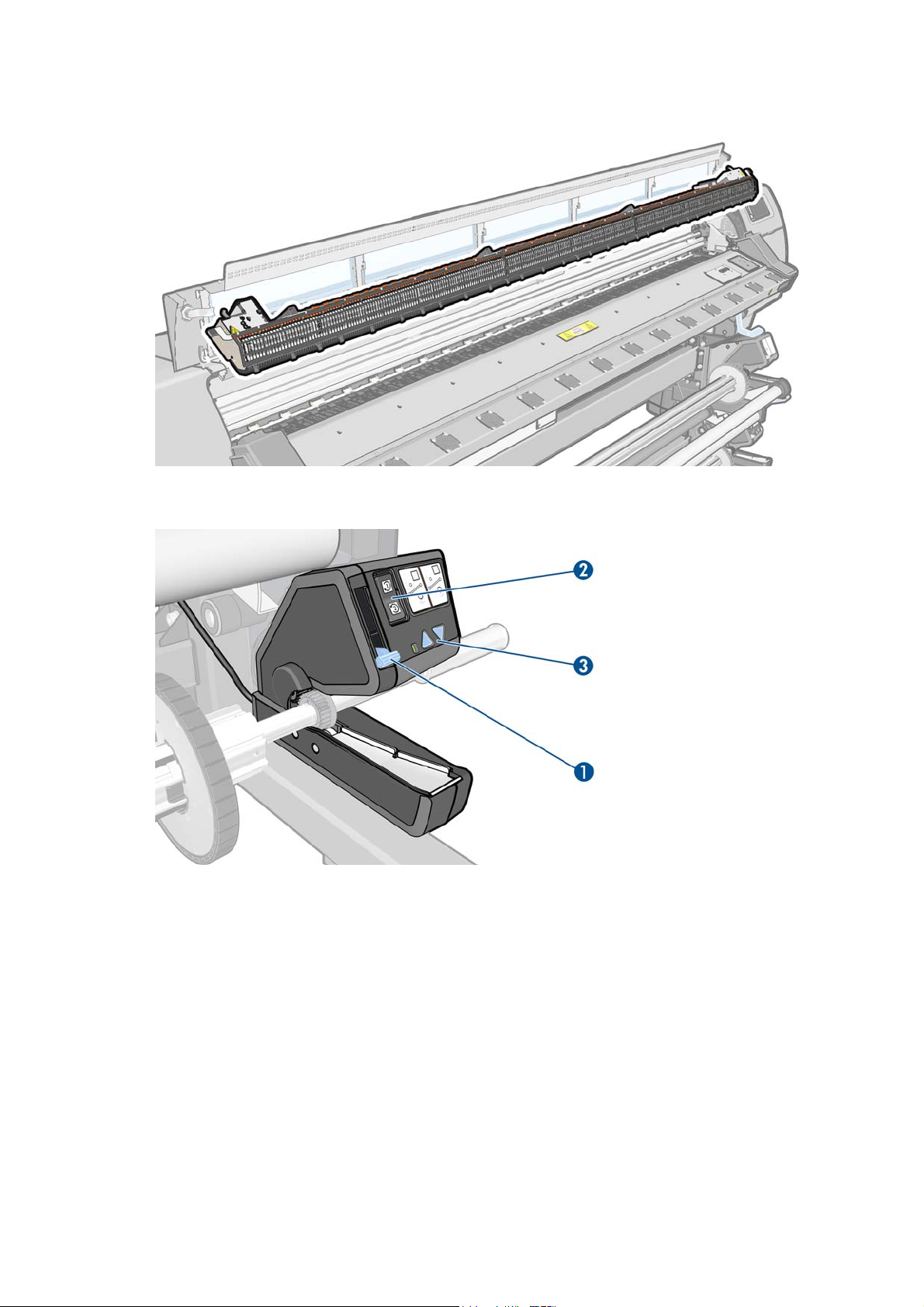

The printer’s main components

The following views of the printer illustrate its main components.

Front view

1. Ink cartridge

2. Platen

3. Printhead

4. Printhead carriage

5. Ink funnel and ink tube assembly

6. Front panel

7. Printhead cleaning cartridge

8. Substrate-adjustment lever

9. Take-up reel motor

10. Tension bar

11. Spindle

12. Take-up reel

13. Spindle stop

14. Spindle lock lever

15. Curing module

16. Drying module

ENWW The printer’s main components 5

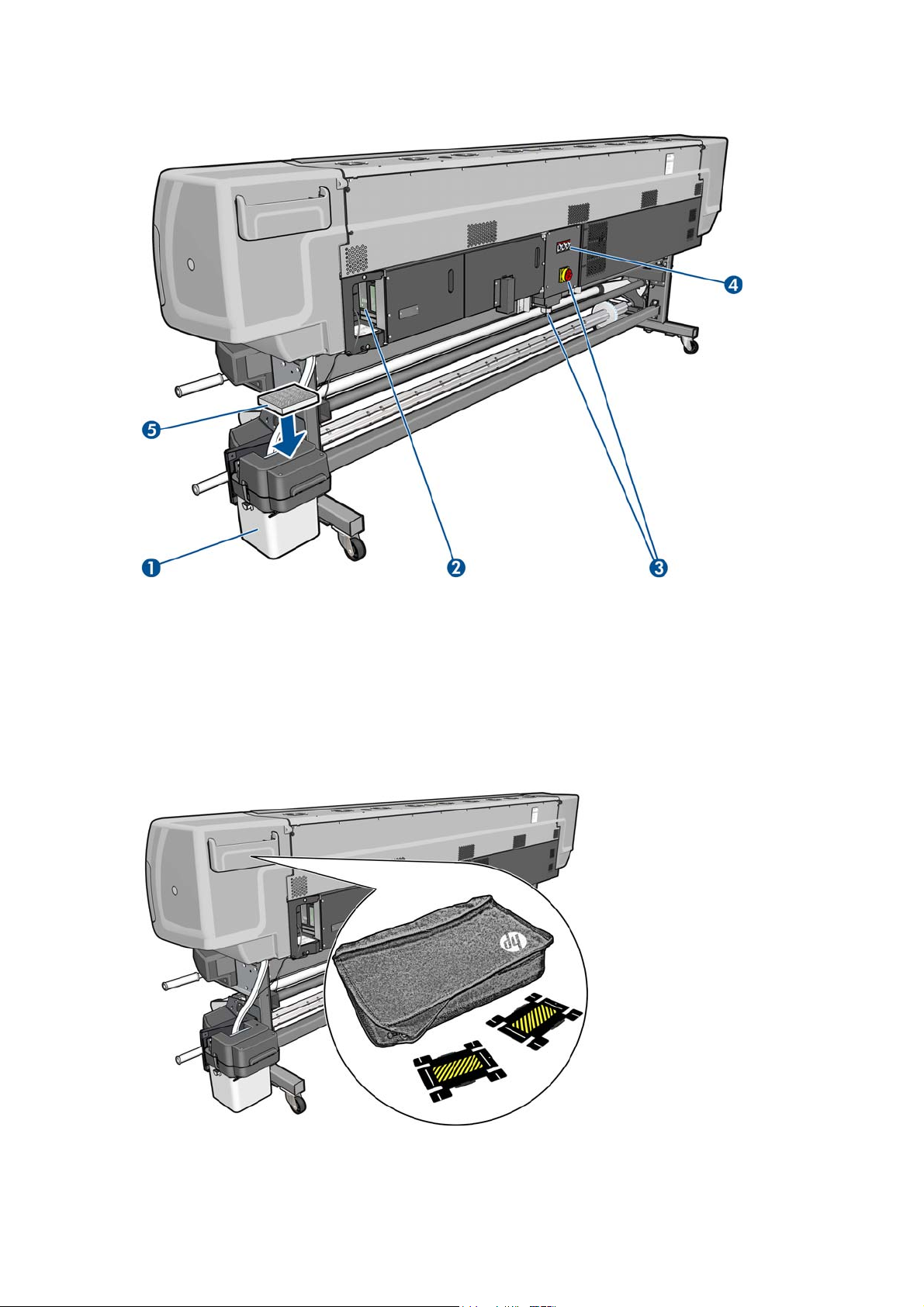

Page 12

Rear view

1. Printhead cleaning container

2. Sockets for communication cables and optional accessories

3. Power switch and power socket

4. Residual current circuit breakers for the heating components

5. Ink filter

Edge holders case

The case is normally attached to the rear of the printer, and contains the two edge holders when they are not

in use.

6 Chapter 1 Introduction ENWW

Page 13

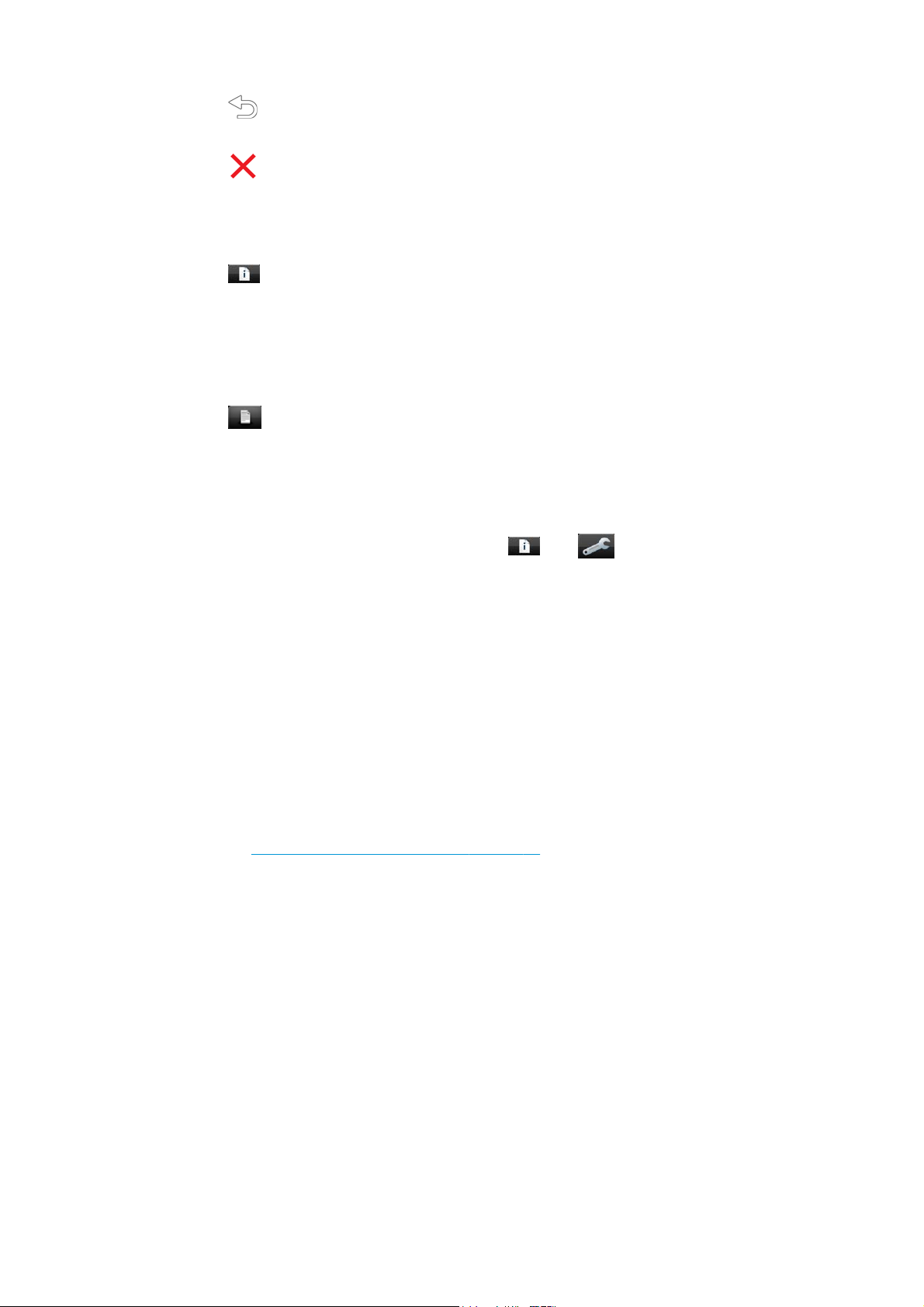

Drying enclosure

Take-up reel motor

1. Take-up reel lever

2. Winding-direction switch

3. Manual winding buttons

ENWW The printer’s main components 7

Page 14

Loading accessory

The loading accessory helps you to load some substrate types that are difficult to load without it. See The

loading accessory on page 45.

The front panel

Your printer's front panel is located at the front right of the printer. It has the following important functions:

●

Assists you in troubleshooting issues

●

Is used when performing certain physical operations, such as unloading substrate and maintaining the

printer

●

Displays information in brief about the status of the printer

●

Displays warning and error messages, when appropriate, along with audio alerts to call attention to a

warning or message

The front panel has a large central area to display dynamic information and icons. On the left and right sides

you can see up to six fixed icons at different times. Normally they are not all displayed at the same time.

Left and right fixed icons

●

Press

●

Press

to return to the home screen.

to view this User's guide on the front panel.

●

Press

●

Press

8 Chapter 1 Introduction ENWW

to go to the previous item.

to go to the next item.

Page 15

●

Press

screen.

to go back to the previous screen. This does not discard any changes made in the current

●

Press

Home screen dynamic icons

The following items are displayed only on the home screen.

●

Press

loading substrate or replacing ink supplies. A smaller warning icon appears if there are actions that

need to be performed.

●

To the right of the above button is a message showing the printer status or the most important current

alert. Press this message to see a list of all current alerts, with an icon indicating the severity of each

alert.

●

Press

●

Most of the central part of the screen is divided into four parts, summarizing the state of the ink

cartridges, the substrate, the printheads and printhead cleaning kit, and the network. For more

information on any of these, press that part of the screen.

If the printer is left idle for some time, it goes into sleep mode and switches off the front-panel display. To

change the time that elapses before sleep mode, press

Sleep mode wait time. You can set a time between 1 and 240 minutes.

The printer wakes from sleep mode and switches on the front-panel display whenever there is some external

interaction with it.

to cancel the current process.

to view information about printer status, change printer settings, or initiate actions such as

to view information about the job that is currently printing.

, then , then Setup > Front panel options >

Information about specific uses of the front panel can be found throughout this guide.

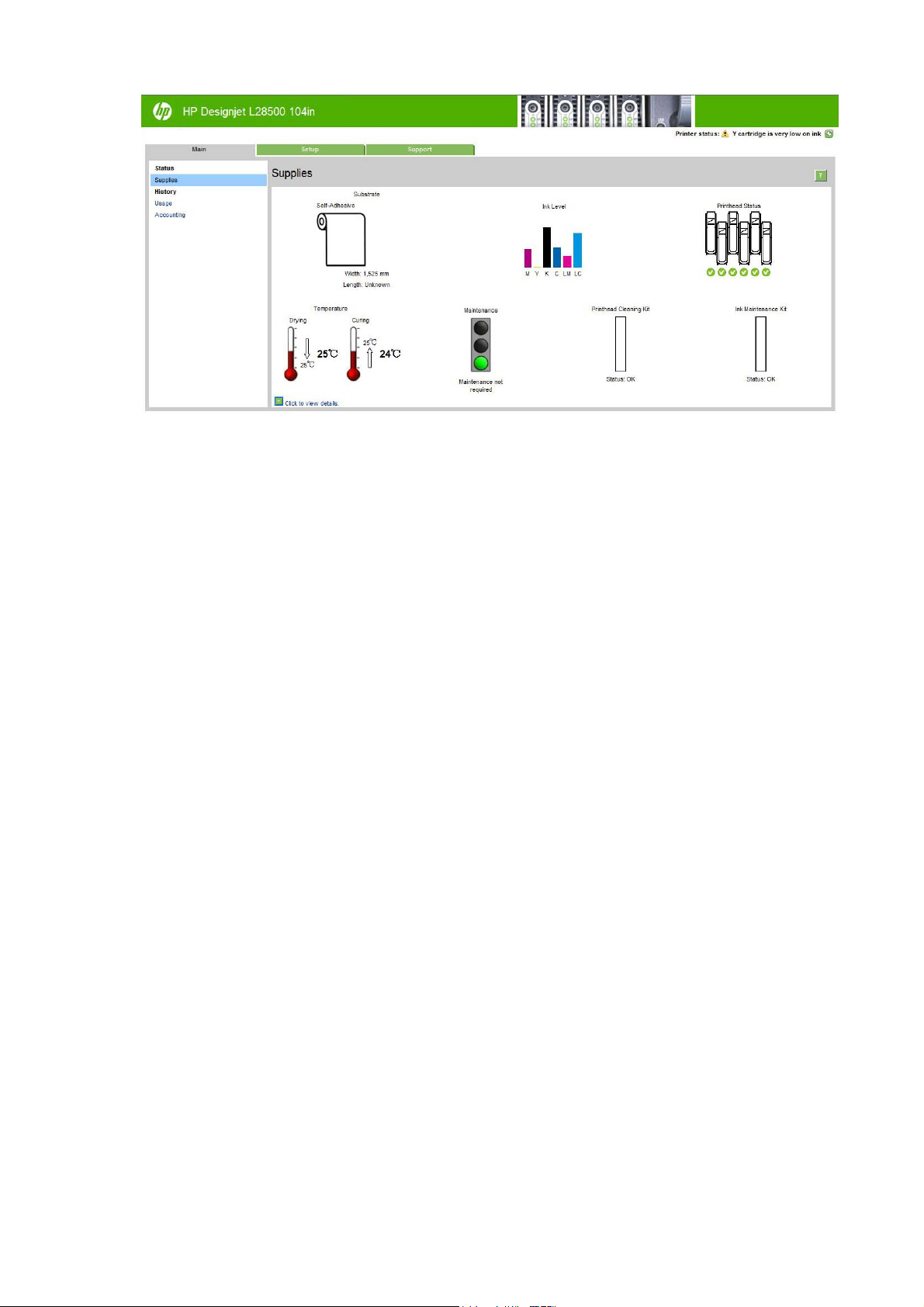

The Embedded Web Server

The Embedded Web Server is a Web server running inside the printer. You can use it to obtain printer

information, manage settings and presets, align printheads, upload new firmware and troubleshoot

problems. Service engineers can use it to retrieve internal information that helps to diagnose printer

problems.

You can access the Embedded Web Server remotely by using an ordinary Web browser running on any

computer. See

The Embedded Web Server window displays three separate tabs. Buttons near the top of each page provide

access to online help and supplies reordering.

Access the Embedded Web Server on page 17.

ENWW The Embedded Web Server 9

Page 16

Main tab

The Main tab provides information about the following items.

●

●

●

Setup tab

The Setup tab enables you to complete these tasks.

●

●

●

●

●

●

●

Substrate, ink, printhead and maintenance status

Temperatures of the drying and curing modules

Substrate and ink usage and accounting

Specify printer settings such as units of measurement and refresh date

Specify network and security settings

Set the date and time

Update firmware

Align printheads

Upload media presets

Sign up for the Customer Involvement Program and configure your participation

Support tab

The Support tab offers various kinds of help with your printer.

●

Browse helpful information from a variety of sources

●

Troubleshoot problems

●

Access HP Designjet links for technical support with your printer and accessories

●

Access service support pages that show current and historical data on the usage of your printer

10 Chapter 1 Introduction ENWW

Page 17

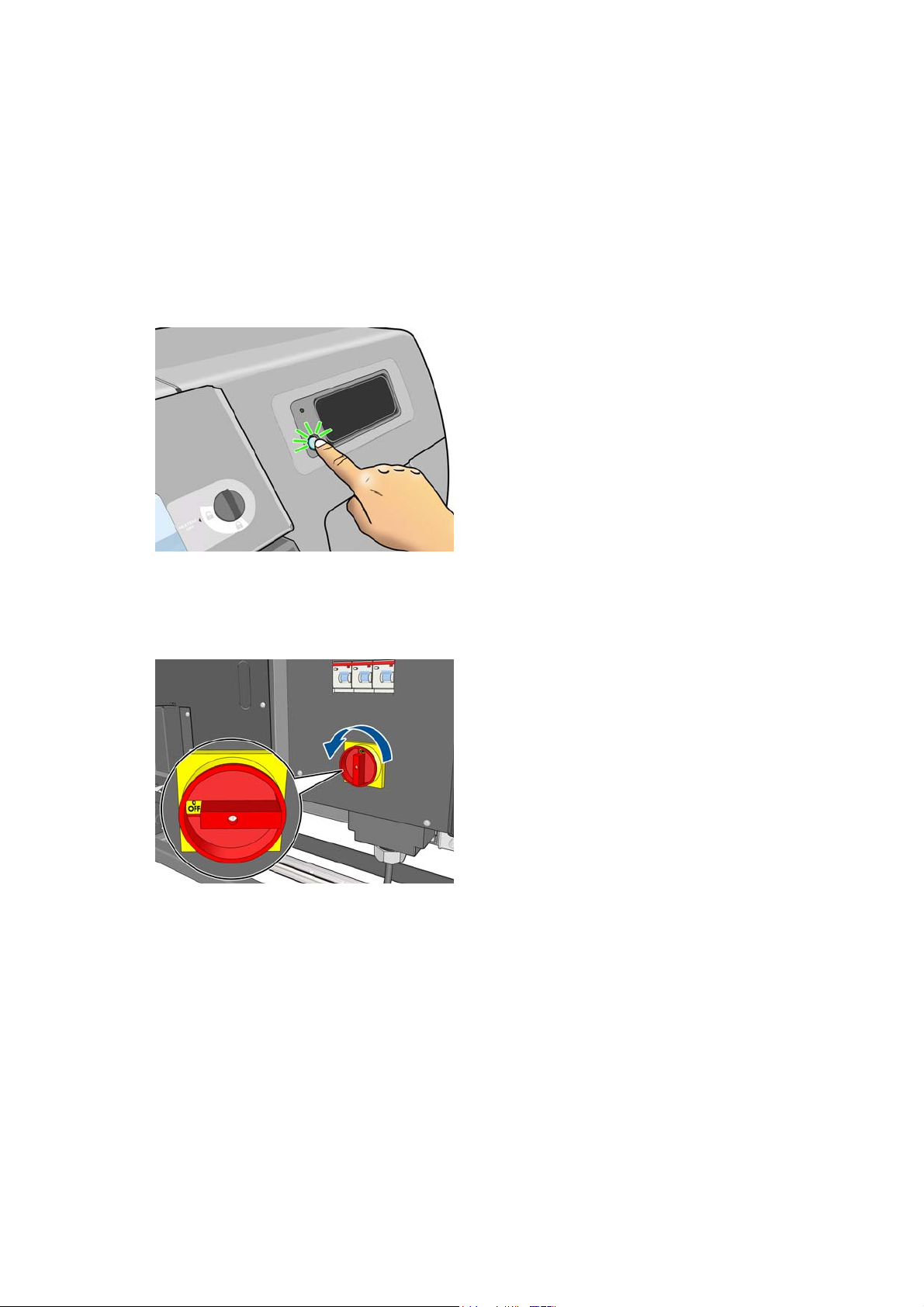

Turn the printer on and off

To turn on the printer, ensure that the residual current circuit breakers are in the up position and the power

switch at the rear of the printer is turned on. If the printer does not start automatically, press the Power

button on the front panel.

You can leave the printer on without wasting energy. Leaving it on improves response time. When the printer

has not been used for a certain period of time, it saves power by going into sleep mode. Any interaction with

the printer returns it to active mode, and it can resume printing immediately.

If you want to turn the printer on or off, the normal and recommended method is to use the Power button on

the front panel.

When you turn off the printer this way, the printheads are automatically stored with the printhead cleaning

cartridge, which prevents them from drying out.

However, if you plan to leave the printer turned off for a long period of time, you are recommended to turn it

off using the Power button, and then also turn off the power switch at the rear.

To turn it back on later, use the power switch at the rear. If the printer does not start automatically, press the

Power button on the front panel.

When the printer is turned on, it takes about 5 minutes to initialize itself.

Restart the printer

In some circumstances you may be advised to restart the printer. To do so, press the Power button on the

front panel to turn the printer off. Wait a few moments, then press the Power button again. This should

restart the printer.

If the printer fails to restart, try the following alternative procedure.

ENWW Turn the printer on and off 11

Page 18

1. Turn off the printer by using the power switch at the rear of the printer. Check that the residual current

circuit breakers are in the up position.

2. Wait for 10 seconds.

3. Turn on the printer by using the power switch.

4. Make sure that the Power light on the front panel illuminates. If it does not, use the Power button to

turn on the printer.

12 Chapter 1 Introduction ENWW

Page 19

2 Connectivity and software instructions

Connection method

Your printer can be connected in the following way.

Connection type Speed Maximum cable length Other factors

Gigabit Ethernet Fast; varies according to

NOTE: The speed of any network connection depends on all the components that are used in the network,

which can include network interface cards, hubs, routers, switches, and cables. If any one of these

components cannot operate at high speed, you will have a low-speed connection. The speed of your network

connection can also be affected by the total amount of traffic from other devices on the network.

Connect to a network

Before you begin, check your equipment:

●

The printer should be set up and turned on.

●

The Gigabit switch or router should be on and functioning correctly.

●

All computers on the network should be turned on and connected to the network.

●

The printer should be connected to the switch.

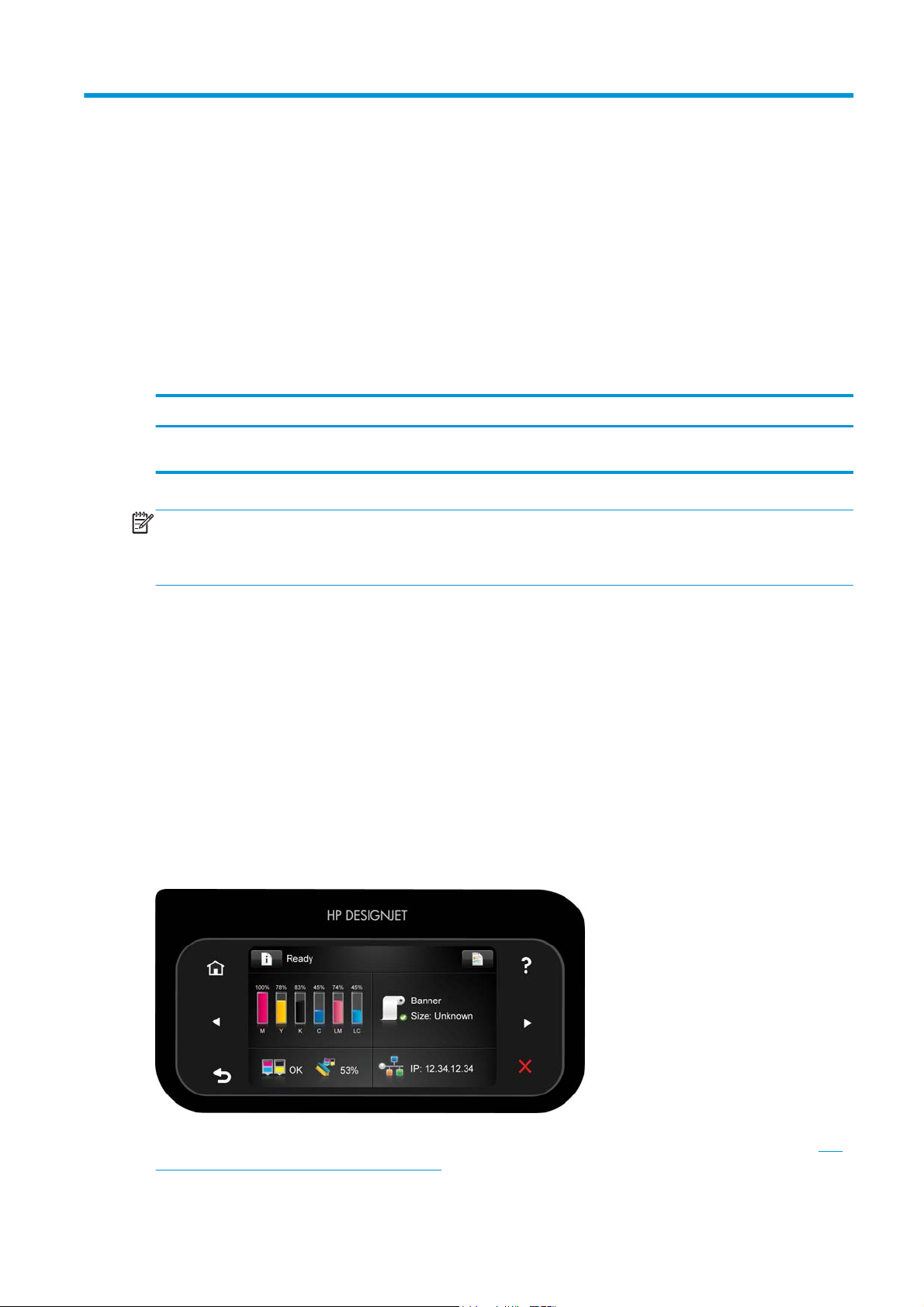

When the printer is connected to the network and turned on, you should see the printer's IP address appear

on the front panel (12.34.12.34 in this example). Make a note of the IP address: you can use it later to access

the Embedded Web Server.

network traffic

Long (100 m=328 ft) Requires extra equipment

(switches)

If you see this screen without the IP address, either the printer is not successfully connected to the network,

or your network has no DHCP server. In the latter case, you will have to set the IP address manually: see

printer cannot get an IP address on page 145.

ENWW Connection method 13

The

Page 20

Refer to the RIP instructions (not provided by HP) to install the software RIP.

14 Chapter 2 Connectivity and software instructions ENWW

Page 21

3 Basic setup options

Printer setup options

Change the language of the front panel

Two methods are available to change the language that is used for the front-panel menus and messages.

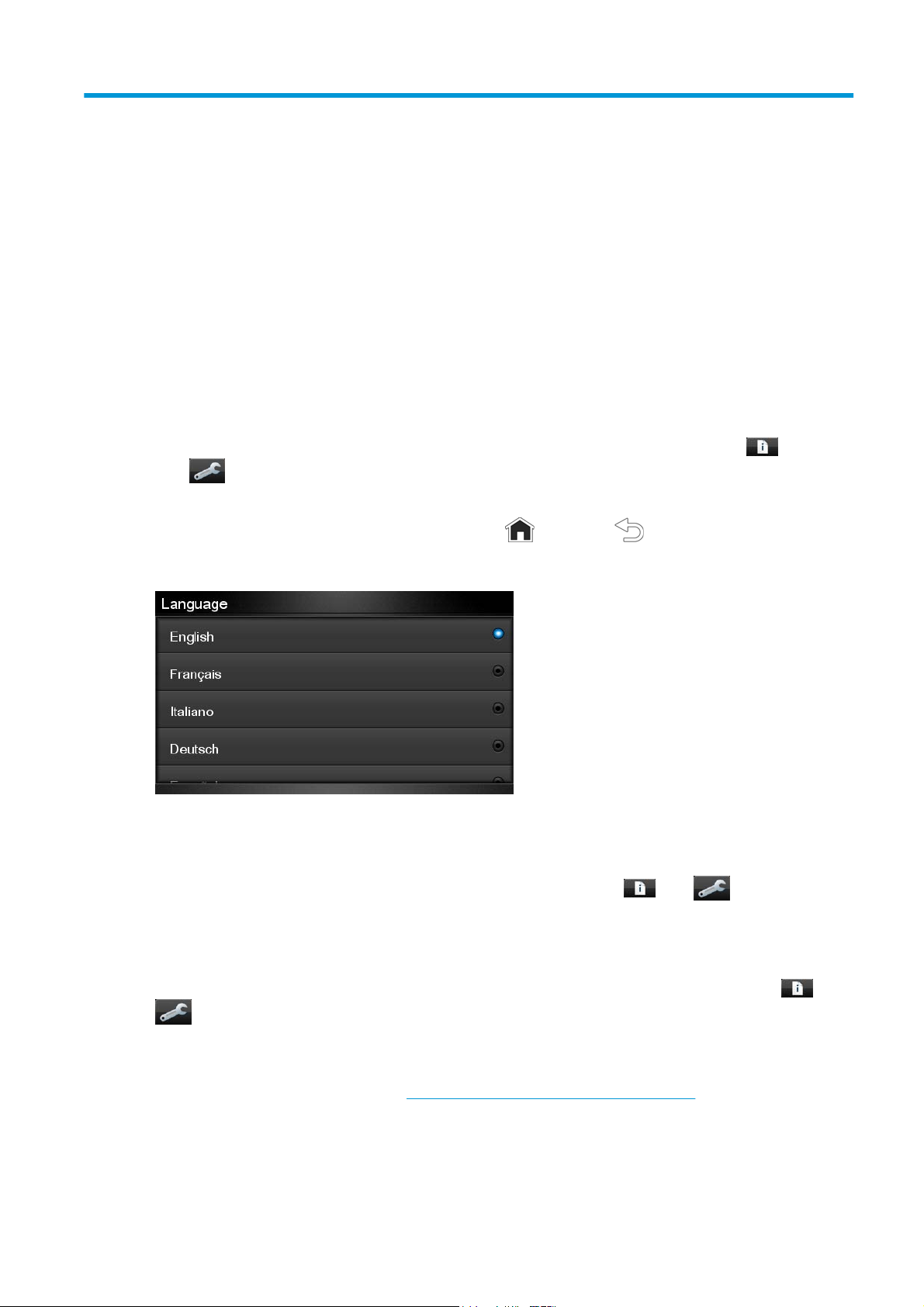

●

If you can understand the current front panel language, go to the front panel and press

, then Setup > Front panel options > Language.

●

If you cannot understand the current front panel language, start with the printer turned off. Turn it on.

As soon as icons appear on the front panel, press

Whichever method you used, the language selection menu should now appear on the front panel.

Highlight your preferred language, then press the OK button.

View or set the date and time

To view or set the printer's date and time, go to the front panel and press , then , then Setup >

Front panel options > Date and time options.

, then

followed by . The front panel blinks briefly.

Set altitude

If your printer is operating at a significant altitude above sea level, go to the front panel and press , then

, then Setup > Select altitude, to tell the printer its operating altitude.

Request e-mail notification of specific error conditions

1. In the Embedded Web Server (see Access the Embedded Web Server on page 17), go to the E-mail

server page on the Setup tab and ensure that the following fields are correctly filled in:

ENWW Printer setup options 15

Page 22

●

SMTP server. This is the IP address of the outgoing mail server (Simple Mail Transfer Protocol

[SMTP]) that processes all e-mail messages from the printer. If the mail server requires

authentication, e-mail notifications will not work.

●

Printer e-mail address. Each e-mail message that the printer sends must include a return

address. This address does not need to be a real, functional e-mail address, but it should be

unique, so that recipients of the message can identify the printer that sent it

2. Go to the Notification page, which is also on the Setup tab.

3. Click the New icon to request new notifications, or click the Edit icon to edit notifications that have

already been set up. Then specify the e-mail addresses to which notifications are sent, and select the

incidents that result in notification messages.

Change the warming duration

When there are no more jobs to print, or you want to pre-warm the printer (Prepare printing option in the

RIP), the printer´s drying and curing heaters remain on for the specified time and temperature in case

another job arrives or in case you need to avoid any print-quality problem that could be caused by an

incorrect temperature in the print zone. To choose the temperatures and how long you need the heaters to

continue working in this situation, go to the front panel and press

Substrate handling options > Warming temperature [45–55] ºC and/or Warm-up duration [5–120] min.

Change the sleep mode setting

, then , then Substrate >

If the printer is left turned on but unused for a certain period of time, it automatically goes into sleep mode to

save power. The default period of time it waits is 30 minutes. To change the time the printer waits before it

goes into sleep mode, go to the front panel and press

Sleep mode wait time. Enter in minutes the wait time that you want, then press OK.

Turn audio alerts on or off

To turn the printer's audio alerts on or off, go to the front panel and press , then , then Setup >

Front panel options > Enable audio alert or Disable audio alert. By default, audio alerts are enabled.

Change the front panel display brightness

To change the brightness of the front-panel display, press , then , then Setup > Front panel

options > Display brightness, then select a value by moving the scroll bar. Press OK to save the value.

Change the units of measurement

To change the units of measurement that appear on the front panel, press , then , then Setup >

Front panel options > Unit selection, then English or Metric.

The units of measurement can also be changed in the Embedded Web Server.

, then , then Setup > Front panel options >

Restore factory settings

To restore the printer settings to their original values as set in the factory, go to the front panel and press

, then , then Setup > Resets > Restore factory settings. This option restores all of the printer

settings except the Gigabit Ethernet settings.

16 Chapter 3 Basic setup options ENWW

Page 23

Embedded Web Server setup options

Access the Embedded Web Server

Use the Embedded Web Server to view printer information remotely through an ordinary Web browser

running on any computer.

The following browsers are known to be compatible with the Embedded Web Server:

●

Internet Explorer 6 and later for Windows

●

Safari 2 and later for Mac OS X

●

Mozilla Firefox 2 and later

●

Google Chrome 7

To use the Embedded Web Server on any computer, open your Web browser and type the printer's IP address

in the browser's address bar. The printer's IP address appears on the front panel's home screen (12.34.12.34

in this example):

If you follow these instructions but fail to open the Embedded Web Server, see Cannot access the Embedded

Web Server on page 145.

Change the language of the Embedded Web Server

The Embedded Web Server functions in the following languages: English, Portuguese, Spanish, Catalan,

French, Italian, German, Simplified Chinese, Traditional Chinese, Korean, and Japanese. It uses the language

that you specified in your Web browser options. If you specify a language that it cannot support, it functions

in English.

To change the language, change your Web browser's language setting. For example, in Internet Explorer

version 6, go to the Tools menu and select Internet Options > Languages. Make sure that the language you

want is at the top of the list in the dialog box.

To complete the change, close and reopen your Web browser.

Restrict access to the printer

From the Embedded Web Server, you can select Setup > Security to set an administrator password. Once set,

this password must be given in order to perform the following printer functions.

●

Change printer settings.

●

Update the firmware.

●

Change the printer's date and time.

●

Clear accounting information.

ENWW Embedded Web Server setup options 17

Page 24

For more information, see the Embedded Web Server's online help.

If you forget the administrator password, you can delete the current password from the front panel: press

, then , then Setup > Connectivity > Advanced > Embedded Web Server > Reset EWS password.

Join the Customer Involvement Program

Join the Customer Involvement Program (CIP) and help us create better products for you. The printer usage

data that we collect will help us determine how you use your printer, and which product features are the

most important to you. All data is collected and used in accordance with the HP Privacy Policy. There are no

mandatory surveys or follow-up emails. No personal contact information is collected. You can stop

participating at any time.

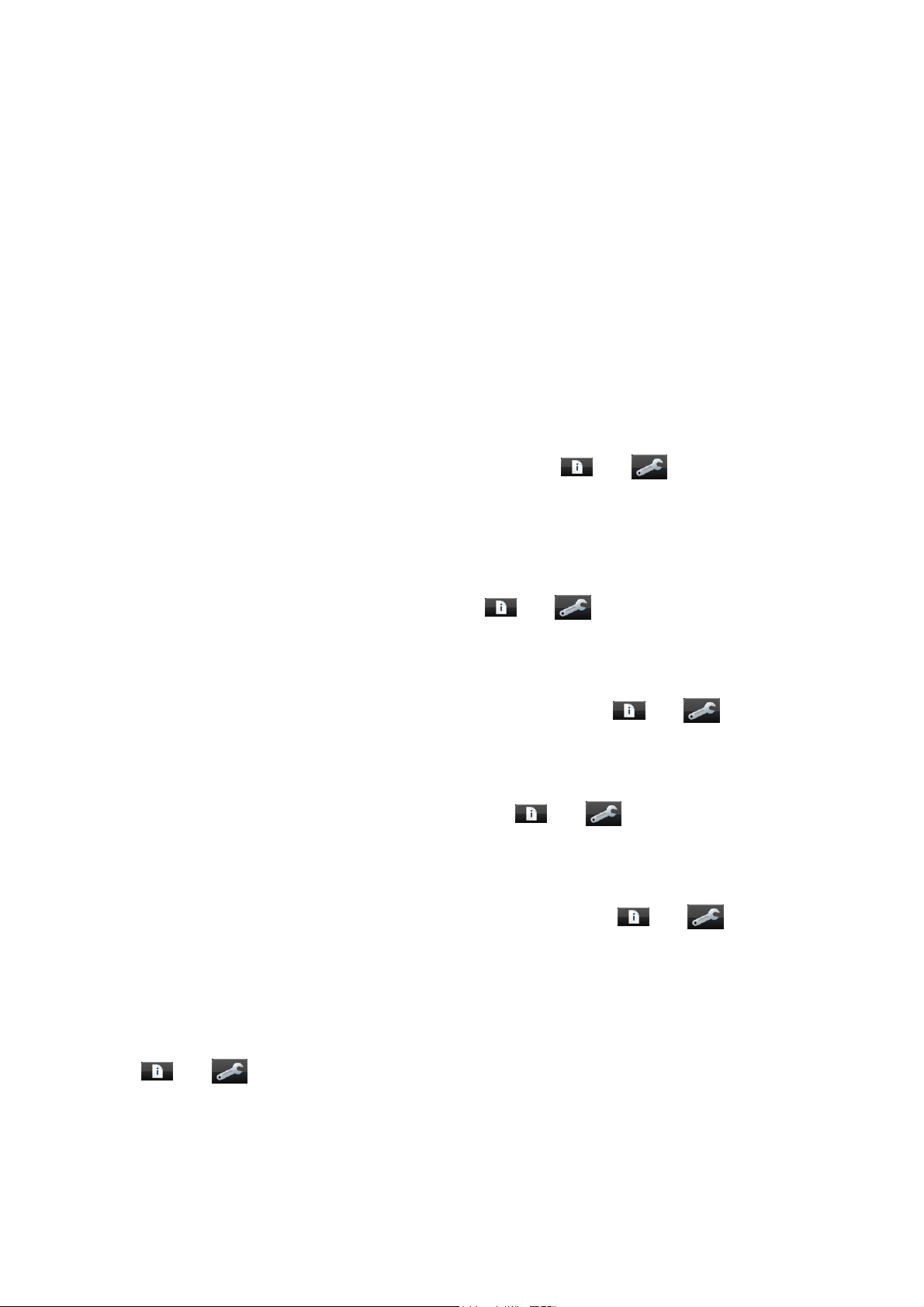

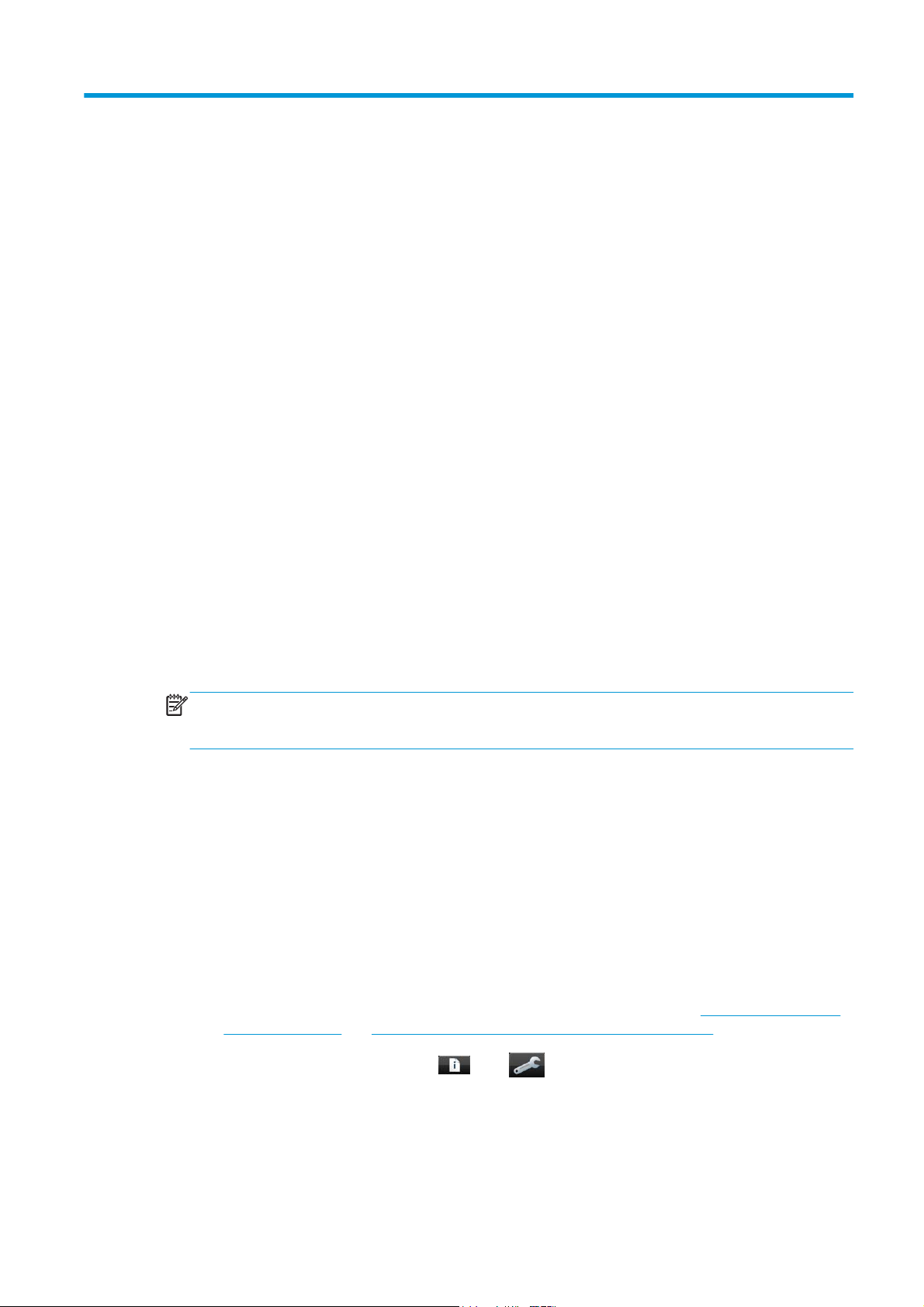

Customer Involvement Program participation is configured with the Embedded Web Server, in particular the

AutoSend page of the Setup tab, which looks like this.

To sign up for the CIP, perform the following configuration steps.

1. Check the Enable AutoSend box. This is the main control for the CIP program. If it is checked you may be

participating, depending on the rest of the configuration. If it is unchecked, you are not.

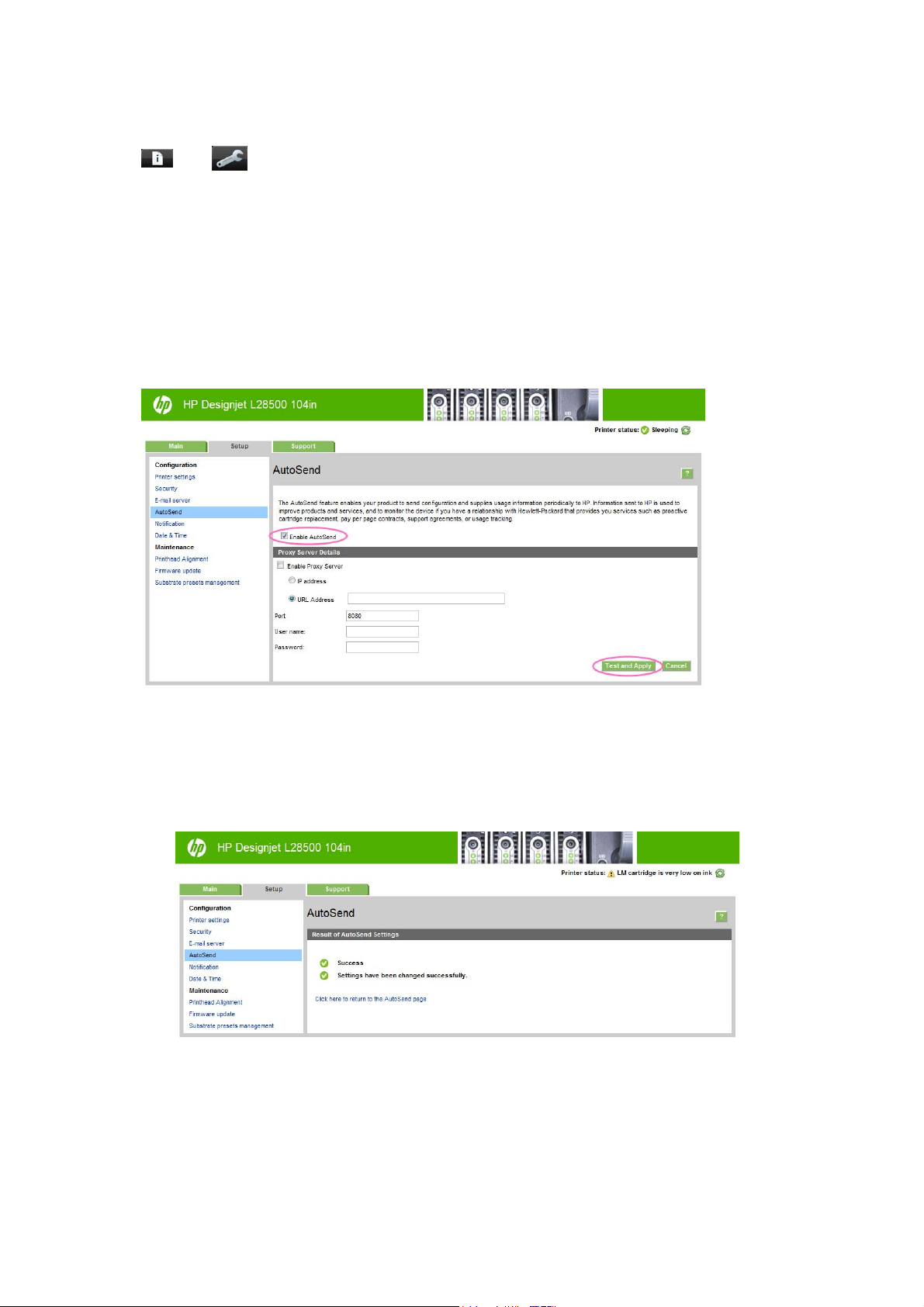

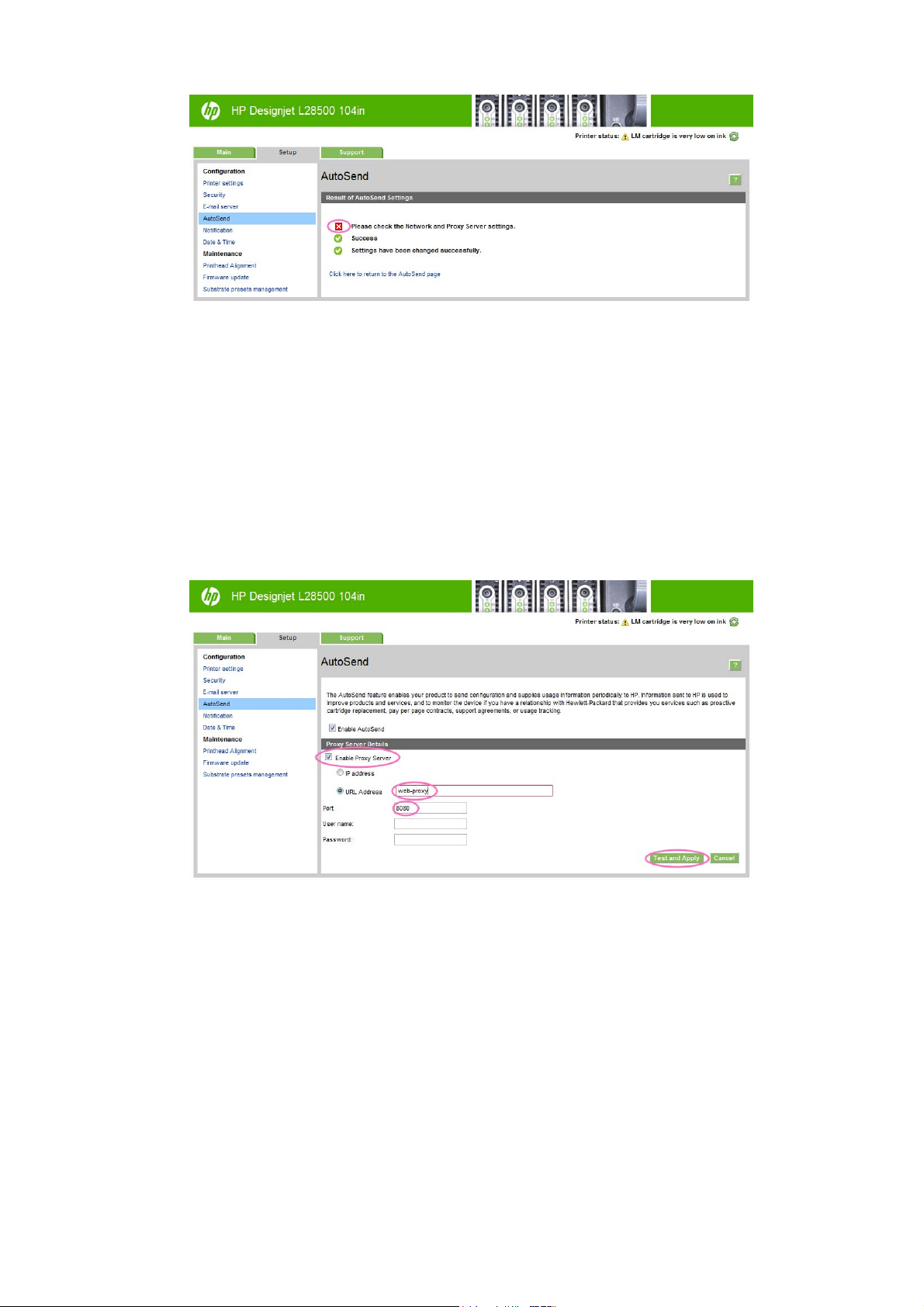

2. Click the Test and Apply button in the lower right corner of the screen. After a while you will see the

result of the test in a window like the following:

3. If the first message in the Result of AutoSend Settings window is Success and all items have a green

check mark in front of them, as shown above, then the configuration is complete. At this point you can

browse to another tab of the Embedded Web Server, or close your browser window.

If the message is anything else, for instance Partial Success, and there are red cross marks in front of

any items, then you may need to configure a proxy server: an ‘intermediary’ computer which sits in

between your printer and the Internet, and can ‘talk’ to both. The resulting window may look like this.

18 Chapter 3 Basic setup options ENWW

Page 25

Return to the AutoSend page, and perform the following steps:

a. Enable (check) the Enable Proxy Server box in the lower part of the window.

b. If you know the URL of your proxy server (for example, http://proxy.mycompany.com; ask your

network administrator or IT staff), select the URL Address button and enter the URL in the

corresponding box. If you know the IP address of your proxy server (for example, 192.0.0.1),

select the IP address button and enter the address into the corresponding boxes.

c. Enter the proxy port in the Port box; the value is site-specific, but usually it is port 80.

d. User name and password may be required for some proxy servers; if so, enter them into the

corresponding boxes. If you’re not sure, leave these fields empty.

For example, the AutoSend tab page might now look like this.

4. Click the Test and Apply button in the lower right corner of the screen. If the first message in the Result

of AutoSend Settings window is Success and all items have a green check mark in front of them, then

the configuration is complete. At this point you can browse to another tab of the Embedded Web Server,

or close your browser window. If any items have a red cross mark in front of them, you may have to

check and correct your proxy settings, as above.

ENWW Embedded Web Server setup options 19

Page 26

20 Chapter 3 Basic setup options ENWW

Page 27

4 Handle the substrate

Overview

You can print on a wide variety of printing materials, all of which are referred to in this guide as substrates.

Substrate tips

Choosing the correct substrate for your needs is an essential step in ensuring good print quality.

Here are some tips about substrate usage.

●

Allow all substrates to adapt to room conditions, out of the packaging, for 24 hours before using them

for printing.

●

Handle film and photo substrates by the edges, or wear cotton gloves. Skin oils can be transferred to

the substrate, leaving fingerprint marks.

●

Keep the substrate tightly wound on the roll throughout the loading and unloading procedures. To

make sure that the roll stays tightly wound, consider using tape to stick the leading edge of the roll to

the core just before removing the roll from the printer. You can keep the roll taped during storage. If the

roll starts to unwind, it can become difficult to handle.

NOTE: The use of tape to stick the leading edge of the roll to the core is especially important for heavy

substrates, because the inherent stiffness of the substrate can cause it to loosen and unwind from the

core.

●

Using the take-up reel with some substrates, such as textiles, may give the printer better control of the

substrate and is likely to improve print quality.

●

Print quality could be impaired if you use a substrate that is unsuitable for your image.

●

Make sure that the appropriate print-quality setting is selected in the RIP.

●

Whenever you load a roll, the front panel prompts you to specify the substrate family that you are

loading. For good print quality, it is essential to specify this correctly. Check that the substrate belongs

to the family named on the front panel, and check also that it matches the substrate profile in the RIP.

●

If the substrate family shown on the front panel does not correspond to the substrate that you have

loaded, take one of the following actions:

◦

Reload the roll into the printer and select the correct substrate family. See

printer on page 35 and Load a roll into the printer (automatically) on page 28.

◦

At the printer's front panel, press

, then , then Substrate > Change loaded substrate.

Unload a roll from the

ENWW Overview 21

Page 28

NOTE: Substrate advance calibration is not performed automatically when the substrate family

is changed from the front panel. To request the calibration manually, see

Adjust the substrate

advance on page 126.

●

For more substrate tips, see

the printer (manually) on page 31.

CAUTION: Removing the substrate from the printer manually without using the front panel could damage

the printer. Do this only when necessary to clear a substrate jam.

Supported substrate families

Substrate family Description

Self-Adhesive PVC films with adhesive on one side and a detachable liner. There are two main types classified by

Banner Usually a polyester mesh coated with PVC. There are also recyclable versions to cover the same

Textile Textiles are usually made of polyester or cotton yarns. Some open textiles come with a removable liner to

application purpose: calendered (for flat surfaces) and cast (for complex 3D curves). The film may have

different finishes: white, transparent, reflective, or perforated.

Examples: HP Air Release Adhesive Gloss Cast Vinyl, Avery MPI3000 (calendered), Avery MPI1005 (cast),

3M IJ-380 (cast)

applications (green banners). Banners have a wide range of grammage and can be grouped into frontlit,

backlit, and block-out categories.

Examples: HP Durable Frontlit Scrim Banner, Ultraflex Normandy Pro, Verseidag banners

prevent the ink from passing through the substrate. Very stiff textiles (such as canvases) should

preferably be loaded as “Low temp (incl. HP Photoreal)" substrate. The use of porous substrates without a

liner is not recommended.

Load a roll into the printer (automatically) on page 28 and Load a roll into

Film Usually a polyester film, although there are other materials. Select this family setting for substrates that

Synthetic Paper Substrates manufactured using synthetic resins, mainly extruded from polypropylene (PP). They have

Paper-Aqueous Light paper-based (cellulose) substrates with a coating compatible with water-based inks, or offset paper.

Paper-Solvent Paper-based (cellulose) substrates with a top coating compatible with solvent inks. Weight is usually

Low temp (incl. HP

Photoreal)

Mesh An open and resistant polyester mesh coated with PVC and mainly used for building wrap applications.

can resist temperatures over 95°C (200°F), otherwise load them as "Low temp (incl. HP Photoreal)"

substrate.

Example: Intelicoat SBL-7 Polyester Backlit Film

characteristics similar to those of plastic film, but their appearance and properties are similar to regular

paper made from wood pulp.

Example: Ilford Omnijet Dry Glossy Portable Display Film

These substrates are not compatible with solvent inks. Weight is usually around 100 g/m².

between 120 and 200 g/m².

Examples: HP Blue Back Billboard Paper, Intelicoat GPIOF140, blue back substrates

Substrates sensitive to high temperatures (PP, HDPE, PET thin films), and paper-based (cellulose)

substrates with top coating that have a high stiffness and grammage (200 g/m² or higher).

Example: HP Photorealistic Poster Paper

These substrates have a removable liner to prevent the ink from passing through the substrate.

Example: Ultraflex Stripmesh

The HP Media Finder is a tool that allows you to search for substrates (HP and third-party) that have been

tested and shown to be compatible with your printer. The tool allows searching by manufacturer brand,

substrate type, application or geographical availability. It can be found at

http://www.hp.com/go/

latexmediafinder/.

22 Chapter 4 Handle the substrate ENWW

Page 29

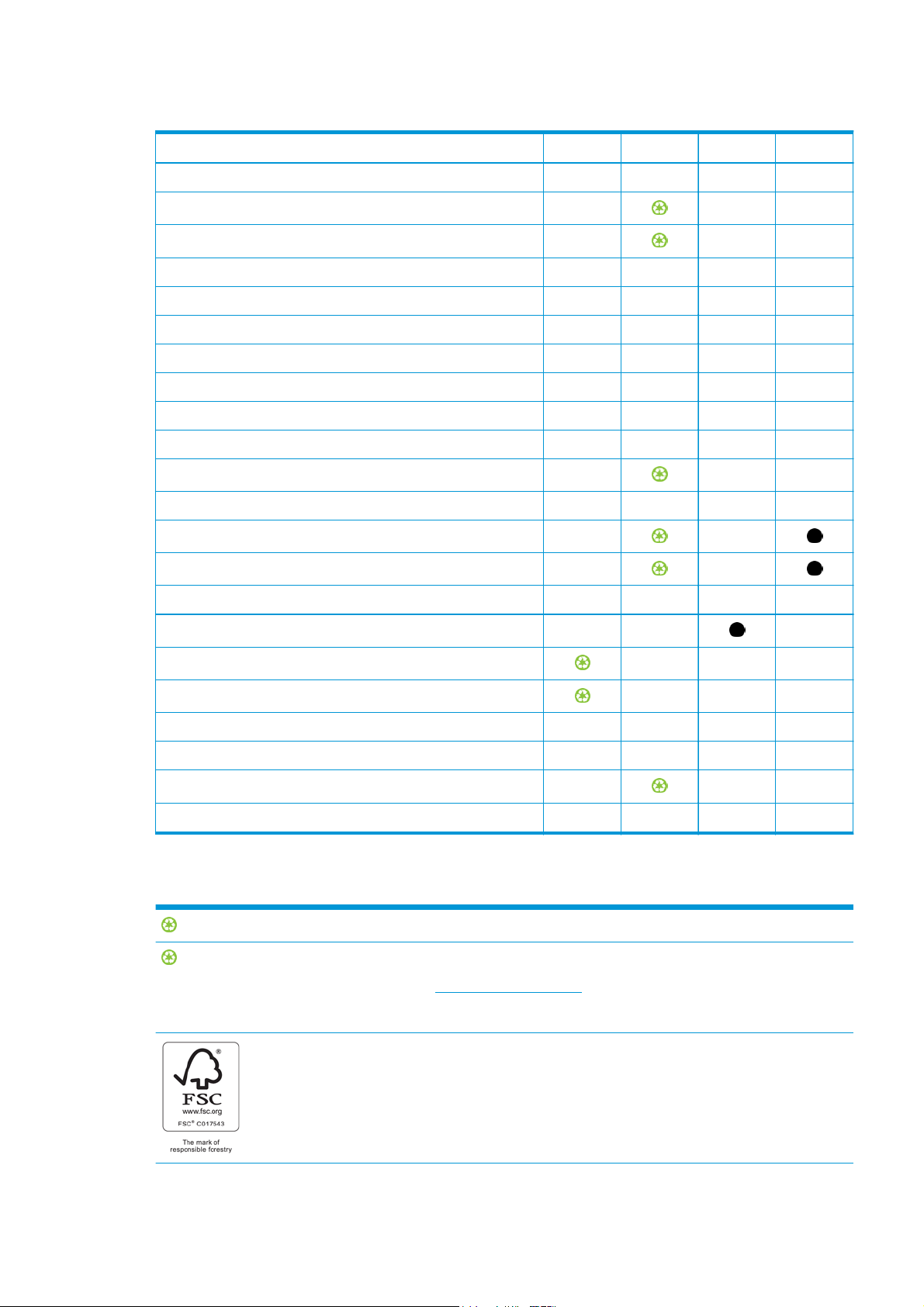

Supported HP substrates

Substrate Recycle Take Back FSC Oeko

Banners

HP HDPE Reinforced Banner

HP Double-sided HDPE Reinforced Banner

HP Durable Frontlit Scrim Banner

Self-adhesive materials

HP Air Release Adhesive Gloss Cast Vinyl

HP One-view Perforated Adhesive Window Vinyl

HP Permanent Gloss Adhesive Vinyl

HP Permanent Matte Adhesive Vinyl

Films

HP Backlit Polyester Film

Fabrics

HP Heavy Textile Banner

HP Light Textile Display Banner

Papers

HP PVC-free Wall Paper (Greenguard, AgBB)

HP White Satin Poster Paper

HP Photo-realistic Poster Paper

HP Blue Back Billboard Paper

Specialty materials

HP DuPont Tyvek Banner

HP Satin Canvas

Key

Recycle: Substrates that can be recycled through commonly available recycling programs.

TakeBack: HP offers the HP Large-format Media TakeBack program in North America and

Europe through which most HP recyclable substrates can be returned, availability varies. For

details, visit http://www.hp.com/recycle/. Aside from this program, recycling opportunities

for these products are currently only available in limited areas. Customers should consult

local recycling resources for recycling these products.

FSC-certified papers carry the Forest Stewardship Council (FSC) Mixed Sources label,

signifying that these substrates support the development of responsible forest management

worldwide. The wood comes from FSC-certified well-managed forests, company-controlled

sources and/or recycled material.

ENWW Overview 23

Page 30

Unprinted HP Heavy Textile Banner, HP Light Textile Display Banner and HP Wrinkle-free Flag

with Liner are Oeko-Tex-certified according to Oeko-Tex Standard 100, which is a globally

uniform testing and certification system for textile raw materials, intermediate and end

products at all stages of production. Tested for emissions of chemicals such as pesticides,

allergy-inducing dyestuffs or tin-organic compounds.

Greenguard HP PVC-free Wall Paper printed using HP Latex Inks is listed in the GREENGUARD product list

AgBB The Committee for Health-related Evaluation of Building Products, AgBB, establishes the

Porous substrates

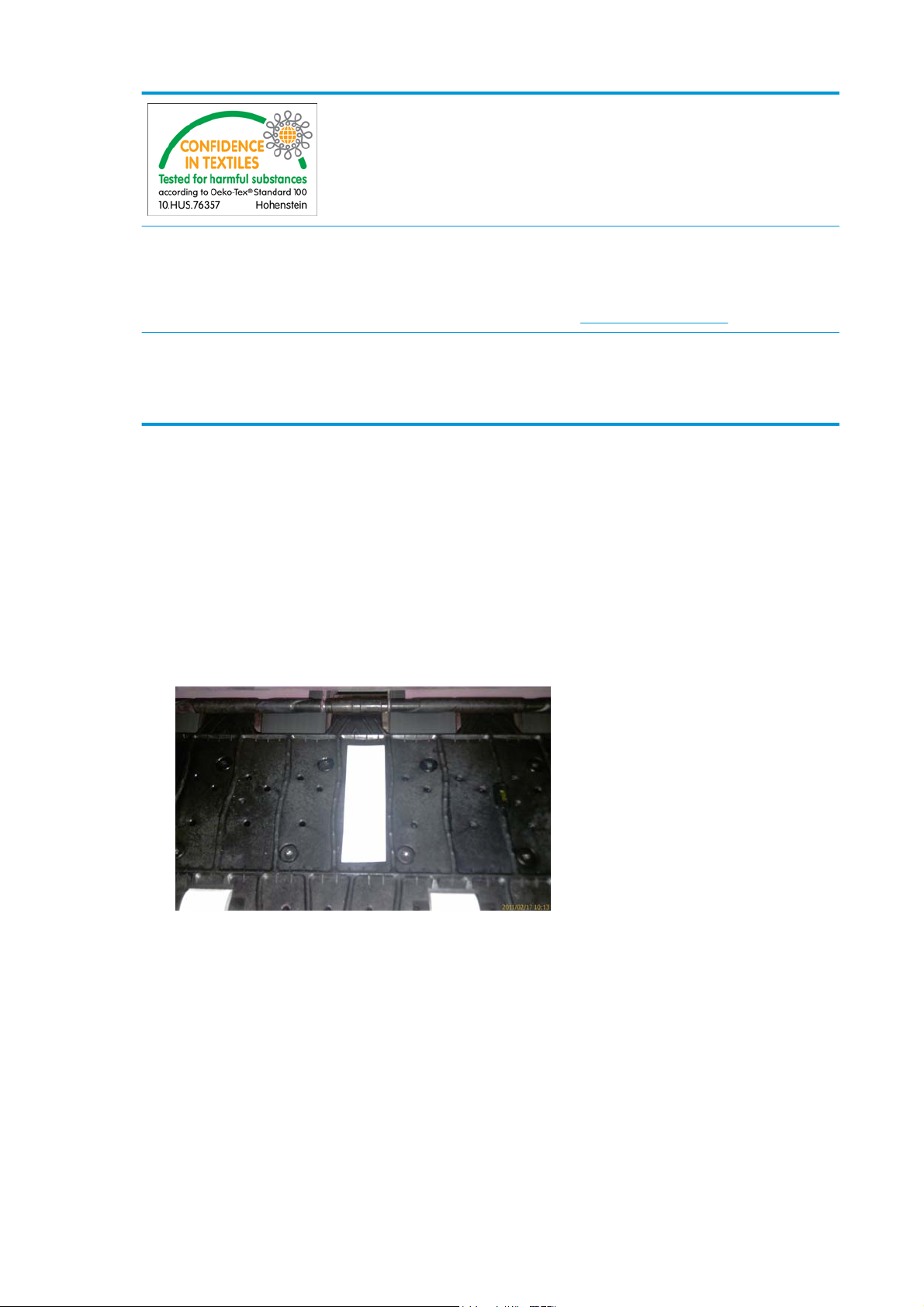

Substrates of limited porosity may be used with this printer, but very porous substrates could damage the

printer.

To check the porosity of your substrate, proceed as follows.

1. If the printer has any substrate loaded, unload it.

2. Cut a piece of self-adhesive vinyl white gloss 15 × 50 mm (0.6 × 2 in) in size.

3. Stick it to the platen as shown.

of low-emitting products and is tested to the GREENGUARD Children & Schools standard. The

print is neither GREENGUARD nor GREENGUARD Children & Schools Certified. The

GREENGUARD Environmental Institute is an American National Standards Institute (ANSI)

authorized standards developer that establishes acceptable indoor air standards for indoor

products, environments, and buildings. See

fundamentals for a uniform and reproducible health-related evaluation of building products

in Germany, including criteria for testing and an evaluation scheme for health-related

evaluation of volatile organic compound (VOC) emissions from building products used for

application indoors.

http://www.greenguard.org/.

4. Load the substrate that you want to check.

5. Open your RIP software.

6. Download the test file from inside the printer: http://printerIP/hp/device/webAccess/images/

Ink_trespassing_check.pdf, where printerIP is the IP address of your printer.

7. Print the test file using the number of passes and media preset that you intend to use in future with this

substrate (or a similar profile in terms of ink limit).

8. Unload the substrate.

24 Chapter 4 Handle the substrate ENWW

Page 31

9. Remove the strip of self-adhesive vinyl from the platen.

10. Look at the self-adhesive vinyl you have taken from the platen.

●

If the strip is completely white (has no ink on it), the tested substrate is non-porous and can be

used for printing as described in this guide.

●

If the strip is significantly non-white (as in the above example), the tested substrate is porous and

should not be used with this printer.

●

If the strip is lighter in color than PANTONE 427C, the tested substrate may be used for short print

runs.

NOTE: Printing on porous substrates can cause a decrease in print quality that would require a service

repair not covered by your warranty.

11. Clean the platen: see Clean the platen on page 97.

Load a roll onto the spindle

TIP: As an alternative to the description here, you can see an animation of this process in the front panel:

press

1. Make sure that the printer wheels are locked (the brake lever is pressed down) to prevent the printer

2. If the tension bar is in its upper position, lower it by lifting the lever.

, then , then Substrate > Substrate load > Learn how to load spindle.

from moving.

ENWW Load a roll onto the spindle 25

Page 32

3. Lift the spindle lock lever to disengage the spindle.

4. Remove the spindle from the printer.

CAUTION: Do not insert your fingers into the spindle supports.

The spindle has a stop at each end to keep the roll in position. Remove the blue stop at the left end to

mount a new roll (the stop at the other end can also be removed, if you wish). The stop slides along the

spindle to hold rolls of different widths.

5. Unlock the blue stop.

26 Chapter 4 Handle the substrate ENWW

Page 33

6. Remove the stop from the left end of the spindle.

7. Slide the spindle into the roll. If the roll is long and heavy, you may need two people to handle it.

8. The right stop of the spindle has two positions: one for rolls of the printer's maximum width, and

another for narrower rolls. Remember to use the second position for narrower rolls, which improves the

drying process and allows higher printing speeds.

ENWW Load a roll onto the spindle 27

Page 34

9. Put the blue stop on to the upper end of the spindle, and push it towards the end of the roll.

10. Lock the blue stop when it is in contact with the substrate.

11. Ease the spindle into the printer.

If you regularly use different substrates, you can change rolls more quickly if you pre-load rolls of different

substrates on different spindles. Extra spindles are available for purchase.

Load a roll into the printer (automatically)

To start this procedure, you need to have a roll loaded on the spindle. See Load a roll onto the spindle

on page 25.

The normal minimum substrate width is 23 inches (584 mm). To load substrates down to a minimum width of

10 inches (254 mm), go to the front panel and press

options > Enable narrow substrate. With this option, print quality is not guaranteed.

, then , then Substrate > Substrate handling

TIP: To load a roll of textile material, see The loading accessory on page 45.

28 Chapter 4 Handle the substrate ENWW

Page 35

TIP: When loading very thin or very thick substrates, or substrates with a tendency to curl, you should

follow the manual loading procedure to reduce the risk of substrate jams and printhead crashes; see

Load a

roll into the printer (manually) on page 31.

1.

At the printer's front panel, press

, then , then Substrate > Substrate load > Load roll.

2. Carefully insert the leading edge of the substrate above the black-ribbed roller, making sure the

substrate remains taut during the process. Avoid rewinding the substrate manually, unless the printer

asks you to do so.

WARNING! Take care not to touch the rubber wheels on the platen while loading substrate. These

wheels can rotate and trap skin, hair or clothing.

WARNING! Take care not to push your fingers inside the printer's substrate path.

The printer beeps when it detects and accepts the leading edge of the substrate.

3. The front panel may prompt you to remove the edge holders from the platen, if the printer believes

they are present (it may be wrong: it has no sensor to detect them).

ENWW Load a roll into the printer (automatically) 29

Page 36

4. Select the type of substrate you are loading.

NOTE: You should select the name of the particular substrate that you are using in your RIP software,

not in the front panel.

NOTE: The RIP substrate setting will overwrite the front panel setting.

5. You have the option of entering the length of substrate on the roll. If you choose to do so, the amount

of substrate that is subsequently used is then tracked. See

Substrate length tracking on page 51.

6. The printer checks the substrate in various ways and may ask you to correct problems with skew or

tension.

NOTE: You can specify the maximum permitted amount of skew at the front panel: press , then

, then Substrate > Substrate handling options > Max skew setting.

7. Wait until the substrate emerges from the printer, as shown below.

NOTE: If you have an unexpected problem at any stage of the substrate loading process, see The

substrate cannot be loaded successfully on page 133.

8. If you are loading transparent substrate without opaque borders, you are asked to enter the width of

the substrate and the distance of the right edge from the printer's side plate (as indicated by the ruler

on the front of the curing module).

30 Chapter 4 Handle the substrate ENWW

Page 37

9. If you have chosen double-sided printing, the front panel may ask a question about it at this point.

10. The printer calibrates the substrate advance.

11. The printer indicates that it is ready for printing.

Take care not to cover the top fans.

For instructions on how to use the take-up reel, see The take-up reel on page 35.

Load a roll into the printer (manually)

The manual loading process should be used in the following cases:

●

The substrate is unusually thin or unusually thick.

●

The substrate has ragged edges.

●

The substrate tends to curl at the edges.

●

The printing side of the substrate faces outwards.

In other cases, the automatic loading process is recommended: see

(automatically) on page 28.

To start this procedure, you need to have a roll loaded on the spindle. See

on page 25.

The normal minimum substrate width is 23 inches (584 mm). To load substrates down to a minimum width of

10 inches (254 mm), go to the front panel and press

options > Enable narrow substrate. With this option, print quality is not guaranteed.

TIP: To load a roll of textile material see The loading accessory on page 45.

, then , then Substrate > Substrate handling

Load a roll into the printer

Load a roll onto the spindle

ENWW Load a roll into the printer (manually) 31

Page 38

1.

At the printer's front panel, press

This step is optional: you can alternatively begin at step 2.

The front panel may prompt you to remove the edge holders from the platen, if the printer believes

they are present (it may be wrong: it has no sensor to detect them).

2. Lift the substrate-adjustment lever as far up as it will go.

, then , then Substrate > Substrate load > Manual load.

3. Carefully insert the leading edge of the substrate above the black-ribbed roller, making sure the

substrate remains taut during the process. Avoid rewinding the substrate manually, unless the printer

asks you to do so.

4. Continue to feed the substrate until it reaches the printing platen. Open the window to help pull the

substrate through.

WARNING! Do not touch the printer's drying enclosure. Even after you have opened the window latch,

which disconnects the power to the drying and curing modules, the internal surfaces could be hot.

TIP: If the substrate you are using tends to curl, keep feeding the substrate until the edge is out of the

printer. You are also recommended to use the take-up reel, or to disable the cutter from the front panel

if not using the take-up reel.

32 Chapter 4 Handle the substrate ENWW

Page 39

5. Pull down the substrate-adjustment lever as far as it will go.

6. Select the type of substrate you are loading.

NOTE: You should select the name of the particular substrate that you are using in your RIP software,

not in the front panel.

TIP: When loading very thin substrates, always select the substrate type as Banner to minimize the

vacuum pressure applied while loading; when loading very thick substrates, always select the substrate

type as HP Photorealistic to maximize the vacuum pressure. After loading and before printing, go to

the front panel and change to the correct type for the substrate you are loading: press

, then ,

then Substrate > Change loaded substrate.

TIP: When manually loading textile substrates that you intend to use with the take-up reel, before

selecting the substrate type it is a good idea to use the Move substrate option in theSubstrate menu to

advance the substrate beyond the point where it may jam in the printer. This avoids the possibility of a

substrate jam at this stage and also some other substrate issues; and it enables you to skip the normal

check for skew.

7. The printer checks the substrate in various ways and may ask you to correct problems with skew or

tension.

NOTE: You can specify the maximum permitted amount of skew at the front panel: press , then

, then Substrate > Substrate handling options > Max skew setting.

8. If you are loading transparent substrate without opaque borders, you are asked to enter the width of

the substrate and the distance of the right edge from the printer's side plate (as indicated by the ruler

on the front of the curing module).

9. If you have chosen double-sided printing, the front panel may ask a question about it at this point.

10. The printer calibrates the substrate advance.

ENWW Load a roll into the printer (manually) 33

Page 40

11. The printer indicates that it is ready for printing.

Take care not to cover the top fans.

Load a cut sheet into the printer

The printer is designed to be used with rolls of substrate. It is possible to load cut sheets into the printer, but

print quality cannot be guaranteed, and you may have some difficulty in avoiding skew.

●

The sheet should be at least 1067 mm (42 in) long.

●

Load the sheet by following the normal roll loading process (automatic or manual, depending on the

substrate).

●

During the loading process, the printer tries to detect the winding direction of the roll by turning the

spindle in both directions. When the substrate is not attached to the spindle, the following message

appears.

●

A cut sheet is likely to be loaded with excessive skew, and the printer may not be able to correct it

automatically. If the skew as measured by the printer exceeds 3 mm/m, you are recommended to stop

34 Chapter 4 Handle the substrate ENWW

Page 41

loading and try again. However, if the skew is tolerable, you can consider skipping the automatic skew

correction. To do so, when prompted, choose Continue with current skew.

Unload a roll from the printer

1. If you used the take-up reel during printing, unload the printed roll from the take-up reel. See Unload a

roll from the take-up reel on page 42.

2.

On the printer's front panel, press

3. If the printer has been tracking the length of the substrate, the front panel displays the remaining

length so that you can note it for future reference. See

Press OK to continue.

4. When the printer has rewound the roll, lift the spindle lock lever.

5. Remove the roll from the printer, pulling out the right end on the right side of the printer first. Do not

insert your fingers into the spindle supports during the removal process.

, then , then Substrate > Substrate unload > Unload roll.

Substrate length tracking on page 51.

The take-up reel

The take-up reel must be enabled and operated from the front panel. When the take-up reel is enabled, the

Take-up reel enabled message appears on the Substrate tab on the front panel. If the take-up reel is not

enabled and you would like to enable it, press

Yes to confirm, and follow the instructions on the front panel.

The tension bar

When in use, the take-up reel requires a dangling loop of substrate weighed down by the tension bar.

ENWW Unload a roll from the printer 35

, then , then Substrate > Enable take-up reel. Press

Page 42

The tension bar has a counterweight to increase output tension. It can be set in one of two positions (in or

out), depending on the substrate type.

With textile substrates only, it should be at the front.

Load a roll onto the take-up reel

1.

On the printer's front panel, press

36 Chapter 4 Handle the substrate ENWW

, then , then Substrate > Enable take-up reel.

Page 43

2. The front panel offers you the choice of loading the take-up reel immediately, or during printing.

If you decide to load the take-up reel during printing, familiarize yourself with the procedural steps.

Loading the take-up reel during printing requires you to complete the procedure while the printer is

feeding and printing substrate. Loading the take-up reel during printing saves approximately 1.5 m (4.9

ft) of substrate.

TIP: If you have already loaded the take-up reel, but the printer fails to recognize that it is loaded, you

can save some time by selecting Load it during printing.

TIP: You are recommended to keep the take-up reel winding-direction switch in the off position (see

Unload a roll from the take-up reel on page 42) to avoid unwanted movements when loading the

take-up reel while printing. Once you have the leading edge of the substrate attached to the core, and

the substrate is straight, switch the winding-direction switch to position 1 or 2, as you prefer. Setting 1

winds the substrate so that the printed image faces in, setting 2 winds the substrate so that the printed

image faces out.

The following steps assume that you have decided to load immediately. If you decide to load later,

during printing, you must complete the same operations without guidance from the front panel.

3. Ensure that the tension bar is in its raised position (up).

4. Unlock the take-up reel by lifting the two levers.

ENWW The take-up reel 37

Page 44

5. Remove the take-up reel.

6. Unlock the blue stop.

7. Remove the stop from the left end of the spindle.

8. Load the core onto the take-up reel. The core should be at least as wide as the substrate.

38 Chapter 4 Handle the substrate ENWW

Page 45

9. Replace the blue stop on the take-up reel. Slide it into contact with the core, then lock it.

10. Load the take-up reel into the printer by pushing firmly on both ends.

11. Use the Move substrate option in the front panel's Substrate menu to advance the substrate. Continue

advancing the substrate until it reaches the spindle.

ENWW The take-up reel 39

Page 46

12. Pass the substrate between the diverter and the tension bar.

13. Pull down the center of the substrate's leading edge to straighten the substrate. Do not attempt to pull

more substrate out of the printer.

NOTE: If you are loading the take-up reel during printing you do not need to pull the substrate taut.

Tape the substrate to the spindle core when an adequate length of substrate has fed from the printer

after printing begins.

14. Ensure that the right-hand edge of the substrate is aligned with the right-hand stop on the take-up reel.