Page 1

HP Color LaserJet CP3525 Series Printer

Service Manual

Theory of operation

Removal and replacement

Solve problems

Parts list

www.hp.com/support/cljcp3525

Page 2

Page 3

HP Color LaserJet CP3525 Series Printers

Service Manual

Page 4

Copyright and License

© 2008 Copyright Hewlett-Packard

Development Company, L.P.

Trademark Credits

®

, Acrobat®, and PostScript® are

Adobe

trademarks of Adobe Systems Incorporated.

Reproduction, adaptation, or translation

without prior written permission is prohibited,

except as allowed under the copyright laws.

The information contained herein is subject

to change without notice.

The only warranties for HP products and

services are set forth in the express warranty

statements accompanying such products

and services. Nothing herein should be

construed as constituting an additional

warranty. HP shall not be liable for technical

or editorial errors or omissions contained

herein.

Part number: CC468-90963

Edition 1, 10/2008

Corel® is a trademark or registered

trademark of Corel Corporation or Corel

Corporation Limited.

Intel® Core™ is a trademark of Intel

Corporation in the U.S. and other countries.

Java™ is a US trademark of Sun

Microsystems, Inc.

Microsoft®, Windows®, and Windows®XP

are U.S. registered trademarks of Microsoft

Corporation.

Windows Vista® is either a registered

trademark or trademark of Microsoft

Corporation in the United States and/or other

countries.

PANTONE® is Pantone, Inc's checkstandard trademark for color.

®

is a registered trademark of The Open

UNIX

Group.

ENERGY STAR and the ENERGY STAR

mark are registered U.S. marks.

Page 5

Table of contents

1 Product basics

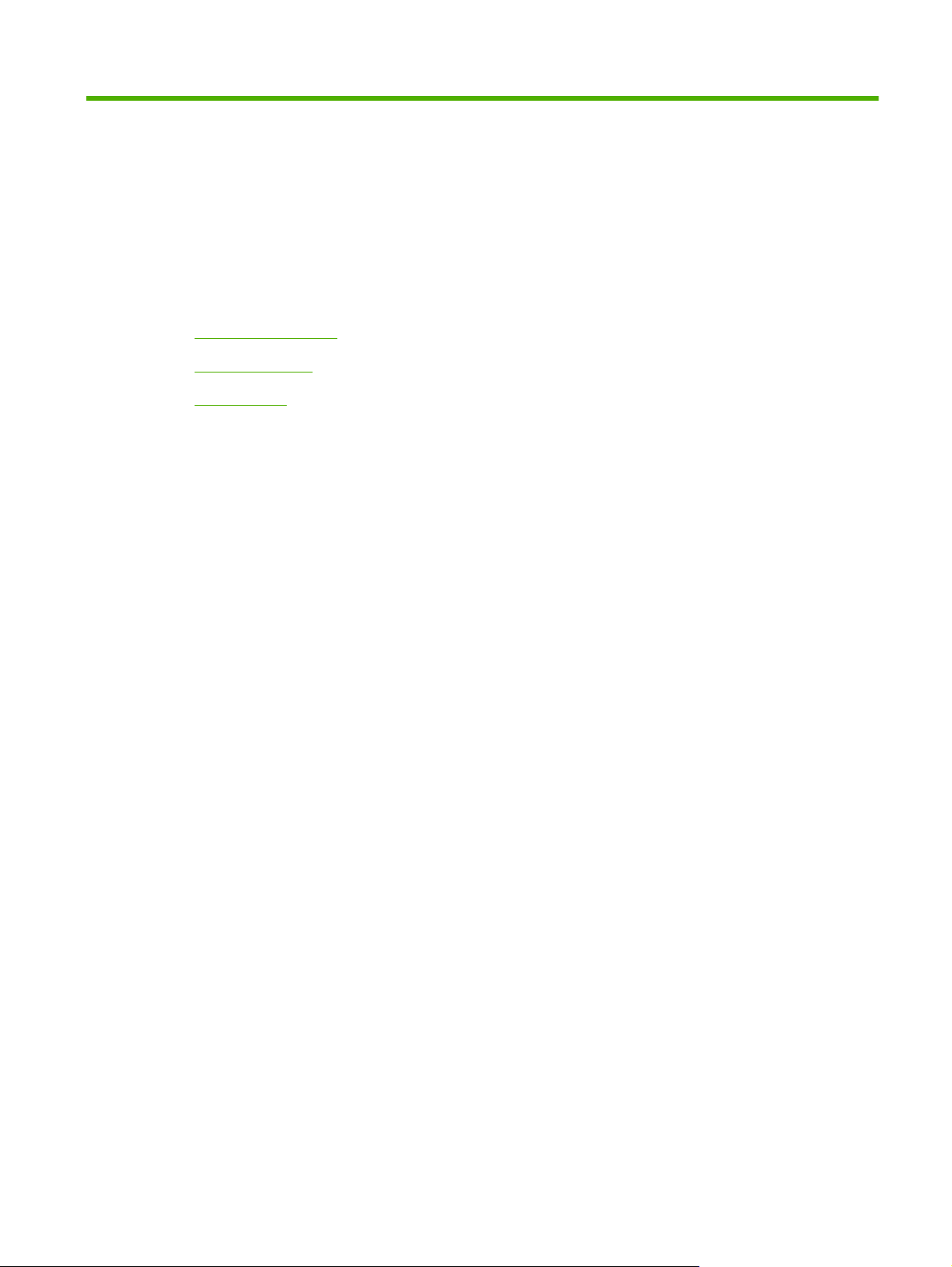

Product comparison ............................................................................................................................. 2

Product features ................................................................................................................................... 3

Product view ......................................................................................................................................... 6

Front view ............................................................................................................................ 6

Back view ............................................................................................................................. 7

Interface ports ...................................................................................................................... 8

Serial number and model number location .......................................................................... 8

2 Control panel

Use the control panel ......................................................................................................................... 10

Control-panel layout ........................................................................................................... 10

Interpreting control panel indicator lights ........................................................................... 11

Control panel menus .......................................................................................................................... 12

Use the menus ................................................................................................................... 12

Menu hierarchy ................................................................................................................................... 13

Show Me How menu .......................................................................................................................... 14

Retrieve job menu .............................................................................................................................. 15

Information menu ............................................................................................................................... 17

Paper handling menu ......................................................................................................................... 18

Configure device menu ...................................................................................................................... 19

Printing menu ..................................................................................................................... 19

PCL sub-menu .................................................................................................. 20

Print Quality menu ............................................................................................................. 22

System setup menu ........................................................................................................... 25

I/O menu ............................................................................................................................ 32

Resets menu ...................................................................................................................... 39

Diagnostics menu ............................................................................................................................... 40

Service menu ..................................................................................................................................... 42

3 Paper and print media

Supported paper and print media sizes .............................................................................................. 44

Custom paper sizes ............................................................................................................................ 46

Supported paper and print media types ............................................................................................. 47

ENWW iii

Page 6

Tray and bin capacity ......................................................................................................................... 48

Special paper or print media guidelines ............................................................................................. 49

Load trays ........................................................................................................................................... 50

Paper orientation for loading trays ..................................................................................... 50

Tray 1 ................................................................................................................ 50

Tray 2 or optional Tray 3 ................................................................................... 52

Load Tray 1 ........................................................................................................................ 53

Print envelopes ................................................................................................. 55

Load Tray 2 ........................................................................................................................ 55

Load the optional 500-sheet paper and heavy media tray (Tray 3) ................................... 57

Load standard-sized paper into Tray 3 ............................................................ 57

Load custom-size paper into Tray 3 .................................................................. 59

Load 4 x 6 inch (10 x 15 cm) size paper into Tray 3 ......................................... 61

Configure trays ................................................................................................................................... 65

Configure a tray when loading paper ................................................................................. 65

Configure a tray to match print job settings ....................................................................... 65

Configure a tray by using the Paper Handling menu ......................................................... 66

Automatic overhead transparency sensing (auto sense mode) ......................................... 66

Auto-sense settings ........................................................................................... 66

Select the media by source, type, or size .......................................................................... 67

Source ............................................................................................................... 67

Type and Size ................................................................................................... 67

4 Manage and maintain the product

Information pages ............................................................................................................................... 70

HP Easy Printer Care ......................................................................................................................... 71

Open the HP Easy Printer Care software .......................................................................... 71

HP Easy Printer Care software sections ............................................................................ 71

Embedded Web server ....................................................................................................................... 74

Open the embedded Web server by using a network connection ..................................... 74

Embedded Web server sections ........................................................................................ 75

Use HP Web Jetadmin software ........................................................................................................ 77

Security features ................................................................................................................................ 78

Secure the embedded Web server .................................................................................... 78

Secure Disk Erase (optional EIO hard drive) ..................................................................... 78

Data affected ..................................................................................................... 78

Additional Information ....................................................................................... 79

Job storage ....................................................................................................... 79

HP Encrypted High Performance Hard Disks .................................................................... 79

Lock the control-panel menus ............................................................................................ 79

Lock the formatter cage ..................................................................................................... 80

Manage supplies ................................................................................................................................ 81

Print-cartridge storage ....................................................................................................... 81

iv ENWW

Page 7

HP policy on non-HP print cartridges ................................................................................. 81

HP fraud hotline and Web site ........................................................................................... 81

Replace supplies ............................................................................................................... 81

Supplies life ....................................................................................................... 81

Locate supplies ................................................................................................. 81

Supply replacement guidelines ......................................................................... 82

Change print cartridges ..................................................................................... 83

Change the toner collection unit ........................................................................ 86

Install memory ................................................................................................... 89

Install DDR2 memory DIMMs ........................................................... 89

Enable memory for Windows ............................................................ 92

Install an HP Jetdirect or EIO print server card or EIO hard disk ..... 92

Clean the product ............................................................................................................................... 96

Clean the exterior .............................................................................................................. 96

Clean spilled toner ............................................................................................................. 96

Clean the fuser .................................................................................................................. 96

Product updates ................................................................................................................................. 97

Determine the current firmware version ............................................................................. 97

Download new firmware from the HP Web site ................................................................. 97

Transfer the new firmware to the product .......................................................................... 97

Use the HP Easy Firmware Upgrade utility to update the firmware .................. 97

Use FTP to upload the firmware through a browser ......................................... 98

Use FTP to upgrade the firmware on a network connection ............................. 99

Use HP Web Jetadmin to upgrade the firmware ............................................... 99

Use Microsoft Windows commands to upgrade the firmware ......................... 100

Upgrade the HP Jetdirect firmware .................................................................................. 100

5 Theory of operation

Basic operation ................................................................................................................................. 104

Sequence of operation ..................................................................................................... 104

Engine-control system ...................................................................................................................... 106

DC controller .................................................................................................................... 107

Solenoids ........................................................................................................ 107

Clutches .......................................................................................................... 108

Switches .......................................................................................................... 108

Sensors ........................................................................................................... 109

Motors and fans .............................................................................................. 109

High-voltage power supply .............................................................................................. 111

Low-voltage power supply ............................................................................................... 113

Overcurrent/overvoltage protection ................................................................. 114

Safety .............................................................................................................. 114

Voltage detection ............................................................................................ 114

Sleep (powersave) mode ................................................................................ 114

ENWW v

Page 8

Low-voltage power supply failure .................................................................... 114

Fuser (fixing) control ........................................................................................................ 115

Fuser (fixing) temperature-control circuit ........................................................ 116

Fuser (fixing) over-temperature protection ...................................................... 116

Fuser (fixing)-failure detection ......................................................................... 117

Laser/scanner system ...................................................................................................................... 119

Image-formation system ................................................................................................................... 121

Image-formation process ................................................................................................. 122

Step 1: Pre-exposure ...................................................................................... 123

Step 2: Primary charging ................................................................................. 123

Step 3: Laser-beam exposure ......................................................................... 124

Step 4: Development ....................................................................................... 124

Step 5: Primary transfer .................................................................................. 124

Step 6: Secondary transfer ............................................................................. 125

Step 7: Separation .......................................................................................... 126

Step 8: Fusing ................................................................................................. 126

Step 9: ITB cleaning ........................................................................................ 127

Step 10: Drum cleaning ................................................................................... 127

Print cartridge .................................................................................................................. 127

Developing-roller engagement and disengagement ........................................................ 129

Intermediate transfer belt (ITB) unit ................................................................................. 130

Primary-transfer-roller engagement and disengagement ................................ 131

ITB cleaning .................................................................................................... 132

Calibration ........................................................................................................................ 133

Color-misregistration control ........................................................................... 134

Image-stabilization control .............................................................................. 135

Pickup, feed, and delivery system .................................................................................................... 136

Pickup-and-feed unit ........................................................................................................ 139

Cassette pickup ............................................................................................... 139

Cassette-presence detection .......................................................... 141

Cassette lift operation ..................................................................... 141

Cassette paper-presence detection ................................................ 142

Multifeed prevention ....................................................................... 143

Multipurpose tray pickup ................................................................................. 144

Paper feed ....................................................................................................... 145

Skew-feed prevention ..................................................................... 146

OHT detection ................................................................................ 146

Fusing and delivery unit ................................................................................................... 147

Loop control .................................................................................................... 147

Pressure-roller pressurization control ............................................................. 148

Duplexing unit (HP Color LaserJet CP3525dn and HP Color LaserJet CP3525x

only) ................................................................................................................................. 150

Duplexing reverse and feed control ................................................................ 151

Duplex pickup operation .................................................................................. 151

vi ENWW

Page 9

Jam detection ................................................................................................................................... 152

Optional paper feeder ....................................................................................................................... 154

Paper-feeder pickup and feed operation ......................................................................... 156

Paper-size detection and cassette-presence detection ................................................... 156

Paper-feeder cassette lift operation ................................................................................. 158

Paper-feeder presence detection .................................................................................... 159

Paper-feeder multiple feed prevention ............................................................................. 160

Paper feeder jam detection .............................................................................................. 161

6 Removal and replacement

Introduction ....................................................................................................................................... 164

Removal and replacement strategy ................................................................................................. 164

Electrostatic discharge ..................................................................................................................... 164

Required tools ................................................................................................................................. 165

Before performing service ................................................................................................................ 165

After performing service ................................................................................................................... 166

Post-service test ............................................................................................................................... 166

Print-quality test ............................................................................................................... 166

DC controller connector locations .................................................................................................... 167

Parts removal order .......................................................................................................................... 168

Customer self repair (CSR) components ......................................................................................... 170

Print cartridges ................................................................................................................. 170

Duplex-reverse guide ....................................................................................................... 172

Toner-collection unit ........................................................................................................ 173

Formatter PCA ................................................................................................................. 175

Memory DIMM ................................................................................................................. 176

Tray cassette ................................................................................................................... 178

Fuser ............................................................................................................................... 179

Pickup roller (Tray 2) ....................................................................................................... 180

Pickup and feed rollers (Tray 3) ....................................................................................... 182

Separation roller (Tray 2) ................................................................................................. 183

Secondary transfer roller ................................................................................................. 184

Secondary transfer assembly .......................................................................................... 186

Intermediate transfer belt (ITB) ........................................................................................ 188

Right door (optional paper feeder) ................................................................................... 190

External panels, covers, and doors .................................................................................................. 192

Identification and location ................................................................................................ 192

Front-door assembly ........................................................................................................ 193

Right-door assembly ........................................................................................................ 194

Remove the memory DIMM ............................................................................ 176

Enable memory for Windows .......................................................... 177

Reinstall the transfer roller .............................................................................. 185

Reinstall the secondary transfer assembly ..................................................... 187

ENWW vii

Page 10

Right-rear cover ............................................................................................................... 198

Left cover ......................................................................................................................... 200

Control-panel assembly ................................................................................................... 203

Right-front cover .............................................................................................................. 205

Remove the right-front cover ........................................................................... 205

Reinstall the power button .............................................................. 207

Front-top cover ................................................................................................................ 208

Remove the front-top cover ............................................................................. 208

Rear cover and upper-rear cover ..................................................................................... 209

Remove the rear cover and upper-rear cover ................................................. 209

Rear-top cover ................................................................................................................. 211

Remove the rear-top cover ............................................................................. 211

Internal assemblies .......................................................................................................................... 213

Pickup roller (Tray 1) ....................................................................................................... 213

Delivery fan, cartridge fan, and environmental sensor .................................................... 215

Remove the delivery fan, cartridge fan, and environmental sensor ................ 215

Toner-collection sensor .................................................................................................. 220

Remove the toner-collection sensor ................................................................ 220

Residual-toner-feed motor ............................................................................................... 222

Remove the residual-toner-feed motor ........................................................... 222

Reinstall the residual-toner collection door ..................................... 226

Registration density (RD) sensor assembly ..................................................................... 227

Remove the RD sensor assembly ................................................................... 227

Power-supply fan and fan duct ........................................................................................ 230

Remove the power-supply fan and fan duct .................................................... 230

Registration assembly ..................................................................................................... 233

Remove the registration assembly .................................................................. 233

Interconnect board (ICB) ................................................................................................. 238

Remove the ICB .............................................................................................. 238

DC controller PCA and tray ............................................................................................. 240

Remove the DC controller PCA ...................................................................... 240

Low-voltage power supply ............................................................................................... 243

Remove the low-voltage power supply ........................................................... 243

High-voltage power supply lower (HVPS-D) .................................................................... 248

Remove the high-voltage power supply lower ................................................ 248

Reinstall the high-voltage power supply lower ............................... 250

Developing-disengagement motor ................................................................................... 251

Remove the developing-disengagement motor .............................................. 251

Pickup motor .................................................................................................................... 253

Remove the pickup motor ............................................................................... 253

Lifter-drive assembly ........................................................................................................ 254

Remove the lifter-drive assembly .................................................................... 254

Cassette-pickup drive assembly ...................................................................................... 256

Remove the cassette-pickup drive assembly .................................................. 256

viii ENWW

Page 11

Reinstall the cassette-pickup drive assembly ................................. 261

Cassette-pickup assembly ............................................................................................... 263

Remove the cassette-pickup assembly ........................................................... 263

Laser/scanner assembly (Y/M) ........................................................................................ 265

Remove the laser/scanner assembly (Y/M) .................................................... 265

Laser/scanner assembly (C/Bk) ....................................................................................... 272

Remove the laser/scanner assembly (C/Bk) ................................................... 273

Reinstall the protective glass cleaner (PGC) actuators .................. 276

High-voltage power supply upper (HVPS-T) .................................................................... 279

Remove the high-voltage power supply upper ................................................ 279

Reinstall the high-voltage power supply upper ............................... 282

Drum motor 1 ................................................................................................................... 2 83

Remove the drum motor 1 .............................................................................. 283

Drum motor 2 or drum motor 3 ........................................................................................ 284

Remove the drum motor 2 or drum motor 3 .................................................... 284

Fuser motor ..................................................................................................................... 285

Remove the fuser motor .................................................................................. 286

Main-drive assembly ........................................................................................................ 287

Remove the main-drive assembly ................................................................... 288

Reinstall the main-drive assembly .................................................. 292

Fuser-drive assembly ...................................................................................................... 298

Remove the fuser-drive assembly ................................................................... 299

Reinstall the fuser-drive assembly .................................................. 302

Delivery assembly ............................................................................................................ 303

Remove the delivery assembly ....................................................................... 304

Reinstall the delivery assembly ...................................................... 307

Duplex-drive assembly .................................................................................................... 308

Remove the duplex-drive assembly ................................................................ 309

Optional paper feeder assembly (Tray 3) ......................................................................................... 310

Drawer connector ........................................................................................................... 310

7 Solve problems

Solve problems checklist .................................................................................................................. 312

Menu map ........................................................................................................................................ 314

Troubleshooting process .................................................................................................................. 315

Determine the problem source ........................................................................................ 315

Pre-troubleshooting checklist .......................................................................... 315

Troubleshooting flowchart ............................................................................... 316

Power subsystem ............................................................................................................ 317

Power-on checks ............................................................................................. 317

Power-on troubleshooting overview ............................................... 317

Tools for troubleshooting .................................................................................................................. 319

Individual component diagnostics .................................................................................... 319

ENWW ix

Page 12

LED diagnostics .............................................................................................. 319

Understand lights on the formatter ................................................. 319

Engine diagnostics .......................................................................................... 320

Diagnostics menu ........................................................................... 320

Diagnostics mode ........................................................................... 321

Diagnostics that put the engine into the special diagnostics

mode ............................................................................................... 321

Defeating interlocks ........................................................................ 321

Disable cartridge check .................................................................. 323

Engine-test button .......................................................................... 323

Paper-path test ................................................................................................ 324

Manual sensor test (special-mode test) .......................................................... 325

A TOP (top of page) sensor ............................................................ 325

B and C loop sensors ..................................................................... 326

D fuser (fixing) delivery sensor ....................................................... 327

E duplex re-pickup sensor .............................................................. 328

F output bin full sensor ................................................................... 328

H fuser (fixing) pressure-release sensor ....................................... 329

I primary transfer-roller disengagement sensor .............................. 330

K right and front door interlock switches ......................................... 332

Manual sensor test 2 (special-mode test) ....................................................... 334

L Tray 1 media present sensor ...................................................... 334

M Tray 2 paper out sensor ............................................................. 335

N Tray 2 closed sensor ................................................................... 336

O Tray 2 stack-surface sensor ...................................................... 336

P optional Tray 3-empty sensor ...................................................... 337

Q optional Tray 3 media-feed sensor (Q) ....................................... 338

R optional Tray 3 stack-surface sensor (R) .................................... 338

S, T, and U optional Tray 3 media-size sensors ............................ 339

Paper-path sensors test .................................................................................. 340

Print/stop test .................................................................................................. 340

Component tests ............................................................................................. 341

Component test (special-mode test) ............................................... 341

Diagrams ......................................................................................................................... 343

Formatter PCA ................................................................................................ 343

Location of connectors .................................................................................... 344

DC controller PCA .......................................................................... 344

Paper feeder driver PCA ................................................................ 345

PCAs, motors, fans, switches, solenoids, and clutches .................................. 345

Base product .................................................................................. 346

1 x 500 paper feeder ...................................................................... 352

Sensors ........................................................................................................... 353

General timing chart ........................................................................................ 355

Circuit diagrams .............................................................................................. 355

x ENWW

Page 13

Print-quality troubleshooting tools .................................................................................... 358

Repetitive defects ruler ................................................................................... 358

Calibrate the product ....................................................................................... 359

Internal print-quality test pages ........................................................................................ 359

Print-quality-troubleshooting pages ................................................................. 359

Diagnostics page ............................................................................................. 362

Cleaning page ................................................................................................. 363

Configuration page .......................................................................................... 364

Configuration page ......................................................................... 364

HP embedded Jetdirect page ......................................................... 366

Embedded protocol page ............................................................... 367

Finding important information on the configuration pages .............. 368

Color-band test ................................................................................................ 368

Control-panel messages table .......................................................................................................... 369

Event log messages ......................................................................................................................... 395

Print an event log ............................................................................................................. 39 5

Show an event log ........................................................................................................... 395

Sample event log ............................................................................................................. 396

Clear the event log ........................................................................................................... 396

Event log message table ................................................................................................. 397

Clear paper jams .............................................................................................................................. 404

Common causes of jams ................................................................................................. 404

Jam locations ................................................................................................................... 405

Clear jams ........................................................................................................................ 405

Clear jams in the right door ............................................................................. 406

Clear jams in the output bin area .................................................................... 410

Clear jams in Tray 1 ........................................................................................ 411

Clear jams in Tray 2 ........................................................................................ 413

Clear jams in the optional 500-sheet paper and heavy media tray

(Tray 3) ............................................................................................................ 414

Clear jams in the lower right door (Tray 3) ...................................................... 414

Jam causes and solutions ............................................................................... 415

Jams in the output bin .................................................................... 415

Jams in the fuser and transfer area ................................................ 416

Jams in the duplex area (HP Color LaserJet CP3525dn and HP

Color LaserJet CP3525x only) ........................................................ 419

Jams in Tray 1, Tray 2 and internal paper path .............................. 421

Jams in Tray 3 ................................................................................ 423

Change jam recovery ....................................................................................................... 424

Solve paper-handling problems ........................................................................................................ 425

Product feeds multiple sheets .......................................................................................... 425

Product feeds incorrect page size ................................................................................... 425

Product pulls from incorrect tray ...................................................................................... 425

Paper does not feed automatically .................................................................................. 426

ENWW xi

Page 14

Paper does not feed from Tray 2 or 3 .............................................................................. 426

Transparencies or glossy paper will not feed .................................................................. 427

Envelopes jam or will not feed in the product .................................................................. 427

Output is curled or wrinkled ............................................................................................. 428

Product will not duplex or duplexes incorrectly ................................................................ 428

Use manual print modes .................................................................................................................. 430

Solve image-quality problems .......................................................................................................... 432

Image defects table ......................................................................................................... 432

Solve performance problems ........................................................................................................... 438

Solve connectivity problems ............................................................................................................. 439

Solve direct-connect problems ........................................................................................ 439

Solve network problems .................................................................................................. 439

Service mode functions .................................................................................................................... 441

Service menu ................................................................................................................... 441

Product resets .................................................................................................................. 442

Restore factory-set defaults ............................................................................ 442

Hard disk initialization (optional) ..................................................................... 443

NVRAM initialization ........................................................................................ 443

Product cold reset .......................................................................................... 443

8 Parts and diagrams

Order parts, accessories, and supplies ............................................................................................ 446

Part numbers .................................................................................................................................... 447

Accessories ..................................................................................................................... 447

Print cartridges and toner collection unit .......................................................................... 447

Memory ............................................................................................................................ 447

Cables and interfaces ...................................................................................................... 448

Customer self repair (CSR) parts .................................................................................... 448

Maintenance kits .............................................................................................................. 450

Screws .............................................................................................................................................. 451

How to use the parts lists and diagrams .......................................................................................... 452

External covers, panels, and doors .................................................................................................. 454

.......................................................................................................................................... 454

Right door assembly ......................................................................................................................... 456

Internal components ......................................................................................................................... 458

Internal components (1 of 5) ............................................................................................ 458

Internal components (2 of 5) ............................................................................................ 460

Internal components (3 of 5) ............................................................................................ 462

Internal components (4 of 5) ............................................................................................ 464

Internal components (5 of 5) ............................................................................................ 466

Cassette ........................................................................................................................... 468

Cassette paper pickup assembly ..................................................................................... 470

MP paper pickup assembly .............................................................................................. 472

xii ENWW

Page 15

Registration assembly ..................................................................................................... 474

Secondary transfer assembly .......................................................................................... 476

Delivery assembly ............................................................................................................ 478

Fusing (fixing) assembly ................................................................................................. 480

PCAs ................................................................................................................................ 484

Assessories ...................................................................................................................................... 486

1 x 500 paper feeder ........................................................................................................ 486

1 x 500 paper feeder ........................................................................................................ 487

Paper feeder main body .................................................................................................. 489

Cassette ........................................................................................................................... 491

Alphabetical parts list ....................................................................................................................... 493

Numerical parts list ........................................................................................................................... 500

Appendix A Service and support

Hewlett-Packard limited warranty statement .................................................................................... 508

HP's Premium Protection Warranty: LaserJet print cartridge limited warranty statement ................ 509

HP Color LaserJet Fuser Kit Limited Warranty Statement ............................................................... 510

End User License Agreement .......................................................................................................... 511

Customer self-repair warranty service .............................................................................................. 513

Customer support ............................................................................................................................. 514

Appendix B Product specifications

Physical specifications ..................................................................................................................... 516

Performance specifications .............................................................................................................. 516

Electrical specifications .................................................................................................................... 516

Acoustic specifications ..................................................................................................................... 517

Environmental specifications ............................................................................................................ 517

Paper and print media specifications ............................................................................................... 517

Skew specifications .......................................................................................................................... 517

Appendix C Regulatory information

FCC regulations ............................................................................................................................... 520

Declaration of Conformity ................................................................................................................. 521

Certificate of volatility ....................................................................................................................... 522

Safety statements ............................................................................................................................. 523

Laser safety ..................................................................................................................... 523

Canadian DOC regulations .............................................................................................. 523

VCCI statement (Japan) .................................................................................................. 523

Power cord statement (Japan) ......................................................................................... 523

EMC statement (Korea) ................................................................................................... 523

Laser statement for Finland ............................................................................................. 523

Substances Table (China) ............................................................................................... 524

ENWW xiii

Page 16

Index ................................................................................................................................................................. 525

xiv ENWW

Page 17

List of tables

Table 2-1 Embedded Jetdirect and EIO <X> Jetdirect menus ......................................................................... 32

Table 3-1 Supported paper and print media sizes ........................................................................................... 44

Table 5-1 Sequence of operation ................................................................................................................... 105

Table 5-2 Solenoids ....................................................................................................................................... 107

Table 5-3 Switches ......................................................................................................................................... 108

Table 5-4 Sensors .......................................................................................................................................... 109

Table 5-5 Motors ............................................................................................................................................ 110

Table 5-6 Fans ............................................................................................................................................... 111

Table 5-7 High-voltage power supply circuits ................................................................................................. 112

Table 5-8 Converted DC voltages .................................................................................................................. 113

Table 5-9 Fuser (fixing) components .............................................................................................................. 115

Table 5-10 Primary-transfer-roller engagement states ................................................................................... 131

Table 5-11 Image-stabilization controls .......................................................................................................... 135

Table 5-12 Switches and sensors for the pickup, feed, and delivery system ................................................. 136

Table 5-13 Motors and solenoids for the pickup, feed, and delivery system ................................................. 137

Table 5-14 Jams that the product detects ...................................................................................................... 152

Table 5-15 Electrical components for the paper feeder ................................................................................. 155

Table 6-1 DC controller connectors ................................................................................................................ 167

Table 7-1 Pre-troubleshooting checklist ......................................................................................................... 315

Table 7-2 Troubleshooting flowchart .............................................................................................................. 316

Table 7-3 Manual sensor diagnostic tests ...................................................................................................... 325

Table 7-4 Manual sensor test 2 diagnostic tests ............................................................................................ 334

Table 7-5 Paper-path sensors diagnostic tests .............................................................................................. 340

Table 7-6 Component test details .................................................................................................................. 341

Table 7-7 Formatter PCA ............................................................................................................................... 343

Table 7-8 DC controller connectors ................................................................................................................ 344

Table 7-9 Paper feeder driver PCA connectors ............................................................................................. 345

Table 7-10 PCAs, motors, fans, switches, solenoids, and clutches ............................................................... 350

Table 7-11 Sensors ........................................................................................................................................ 353

Table 7-12 Important information on the configuration pages ........................................................................ 368

Table 7-13 Control-panel messages .............................................................................................................. 369

Table 7-14 Causes and solutions for delivery delay jam ................................................................................ 415

Table 7-15 Causes and solutions for fuser delivery delay jams ..................................................................... 416

Table 7-16 Causes and solutions for wrapping jams ..................................................................................... 416

ENWW xv

Page 18

Table 7-17 Causes and solutions for fuser delivery stationary jams .............................................................. 416

Table 7-18 Causes and solutions for residual media jams ............................................................................ 417

Table 7-19 Causes and solutions for pickup delay jams 2 ............................................................................. 418

Table 7-20 Causes and solutions for pickup stationary jams ......................................................................... 419

Table 7-21 Causes and solutions for duplexing reverse jams ...................................................................... 419

Table 7-22 Causes and solutions for duplex repick jams .............................................................................. 420

Table 7-23 Causes and solutions for residual media jams ............................................................................ 420

Table 7-24 Causes and solutions for pickup delay jam 1: tray pickup ........................................................... 421

Table 7-25 Causes and solutions for pickup stationary jams ......................................................................... 422

Table 7-26 Causes and solutions for pickup delay jam 1; MP tray pickup ..................................................... 422

Table 7-27 Causes and solutions for pickup delay and pickup stationary jams ............................................. 423

Table 7-28 MP modes under the ADJUST PAPER TYPES sub menu .......................................................... 430

Table 7-29 MP modes under the OPTIMIZE submenu .................................................................................. 431

Table 8-1 Common fasteners ........................................................................................................................ 451

Table 8-2 External covers, panels, and doors; .............................................................................................. 455

Table 8-3 Right door assembly ...................................................................................................................... 457

Table 8-4 Internal components (1 of 5) .......................................................................................................... 459

Table 8-5 Internal components (2 of 5) .......................................................................................................... 461

Table 8-6 Internal components (3 of 5) .......................................................................................................... 463

Table 8-7 Internal components (4 of 5) .......................................................................................................... 465

Table 8-8 Internal components (5 of 5) .......................................................................................................... 467

Table 8-9 Cassette ......................................................................................................................................... 469

Table 8-10 Cassette paper pickup assembly ................................................................................................. 471

Table 8-11 MP paper pickup assembly .......................................................................................................... 473

Table 8-12 Registration assembly .................................................................................................................. 475

Table 8-13 Secondary Transfer assembly ..................................................................................................... 477

Table 8-14 Delivery assembly ........................................................................................................................ 479

Table 8-15 Fusing assembly .......................................................................................................................... 483

Table 8-16 PCAs ............................................................................................................................................ 485

Table 8-17 1 x 500 paper feeder .................................................................................................................... 488

Table 8-18 Paper feeder main body ............................................................................................................... 490

Table 8-19 Cassette ....................................................................................................................................... 492

Table 8-20 Alphabetical parts list ................................................................................................................... 493

Table 8-21 Numerical parts list ....................................................................................................................... 500

Table B-1 Product dimensions ....................................................................................................................... 516

Table B-2 Product dimensions, with all doors and trays fully opened ............................................................ 516

Table B-3 Power requirements ....................................................................................................................... 516

Table B-4 Power consumption (average, in watts) ........................................................................................ 517

Table B-5 HP Color LaserJet CP3525 Series ................................................................................................ 517

Table B-6 Media registration and image placement accuracy ....................................................................... 517

xvi ENWW

Page 19

List of figures

Figure 4-1 Slot for the security cable ................................................................................................................ 80

Figure 4-2 Supply item locations ...................................................................................................................... 82

Figure 5-1 Relationship between the main product systems ......................................................................... 104

Figure 5-2 Engine-control system .................................................................................................................. 106

Figure 5-3 DC controller block diagram .......................................................................................................... 107

Figure 5-4 High-voltage power supply circuits ............................................................................................... 111

Figure 5-5 Low-voltage power-supply circuit .................................................................................................. 113

Figure 5-6 Fuser (fixing) components ............................................................................................................ 115

Figure 5-7 Fuser temperature-control circuit .................................................................................................. 116

Figure 5-8 Laser/scanner system ................................................................................................................... 119

Figure 5-9 Image-formation system ............................................................................................................... 121

Figure 5-10 Image-formation process ............................................................................................................ 122

Figure 5-11 Pre-exposure .............................................................................................................................. 123

Figure 5-12 Primary charging ......................................................................................................................... 123

Figure 5-13 Laser-beam exposure ................................................................................................................. 124

Figure 5-14 Development ............................................................................................................................... 124

Figure 5-15 Primary transfer .......................................................................................................................... 125

Figure 5-16 Secondary transfer ...................................................................................................................... 125

Figure 5-17 Separation ................................................................................................................................... 126

Figure 5-18 Fusing ......................................................................................................................................... 126

Figure 5-19 ITB cleaning ................................................................................................................................ 127

Figure 5-20 Drum cleaning ............................................................................................................................. 127

Figure 5-21 Print-cartridge system ................................................................................................................. 128

Figure 5-22 Developing-roller engagement and disengagement control ....................................................... 129

Figure 5-23 ITB unit ........................................................................................................................................ 130

Figure 5-24 Three states of primary-transfer-roller engagement and disengagement ................................... 132

Figure 5-25 ITB cleaning process .................................................................................................................. 133

Figure 5-26 Toner patterns for calibration ...................................................................................................... 134

Figure 5-27 Switches and sensors for the pickup, feed, and delivery system ............................................... 136

Figure 5-28 Motors and solenoids for the pickup, feed, and delivery system ................................................ 137

Figure 5-29 Three main units of the pickup, feed, and delivery system ......................................................... 138

Figure 5-30 .................................................................................................................................................... 139

Figure 5-31 Cassette-pickup mechanism ....................................................................................................... 140

Figure 5-32 Cassette presence sensor .......................................................................................................... 141

ENWW xvii

Page 20

Figure 5-33 Cassette lift mechanism .............................................................................................................. 142

Figure 5-34 Paper-level-detection mechanism .............................................................................................. 143

Figure 5-35 Multifeed prevention .................................................................................................................... 143

Figure 5-36 Multipurpose tray pickup mechanism .......................................................................................... 144

Figure 5-37 Paper-feed mechanism ............................................................................................................... 145

Figure 5-38 Skew-feed prevention ................................................................................................................. 146

Figure 5-39 Fuser and delivery unit ................................................................................................................ 147

Figure 5-40 Loop-control mechanism ............................................................................................................. 148

Figure 5-41 Pressure-roller pressurization control ......................................................................................... 149

Figure 5-42 Duplexing unit ............................................................................................................................. 150

Figure 5-43 Jam detection sensors ................................................................................................................ 152

Figure 5-44 Optional paper feeder ................................................................................................................. 154

Figure 5-45 Signals for the paper feeder ....................................................................................................... 155

Figure 5-46 Paper-feeder pickup and feed operation .................................................................................... 156

Figure 5-47 Paper size detection ................................................................................................................... 157

Figure 5-48 Paper-feeder cassette lift ........................................................................................................... 159

Figure 5-49 Paper-feeder multiple feed prevention ........................................................................................ 160

Figure 5-50 Jam detection .............................................................................................................................. 161

Figure 6-1 Phillips and pozidrive screwdriver comparison ............................................................................. 165

Figure 6-2 DC controller connector locations ................................................................................................. 167

Figure 6-3 Parts removal order (1 of 2) .......................................................................................................... 168

Figure 6-4 Parts removal order (2 of 2) .......................................................................................................... 169

Figure 6-5 Remove the print cartridge (1 of 2) ............................................................................................... 170

Figure 6-6 Remove the print cartridge (2 of 2) ............................................................................................... 171

Figure 6-7 Remove the duplex-reverse guide (1 of 2) ................................................................................... 172

Figure 6-8 Remove the duplex-reverse guide (2 of 2) ................................................................................... 172

Figure 6-9 Remove the toner-collection unit (1 of 4) ...................................................................................... 173

Figure 6-10 Remove the toner-collection unit (2 of 4) .................................................................................... 173

Figure 6-11 Remove the toner-collection unit (3 of 4) .................................................................................... 174