Page 1

T

he TREK 180 battery-powered, inverter-based

wire welder is the first professional system on

the market for MIG welding “off the power grid.”

No matter where your hobby or job takes you, the

TREK delivers heavy-duty weld power to fabricate or

repair 24 ga. up to 1/4 in. mild steel in a single pass.

Powered by two internal, premium high-performance,

sealed lead-acid batteries, the high-purity energy

storage technology enables the TREK to be charged

complete in about 90 minutes and quickly recharged

in about 20 minutes. The unit delivers approx. 100

inches of weld bead when fully charged (using .030

diameter flux-cored wire on 1/8 in. mild steel.)

The integrated charging system is powered by a

standard 115 volt household receptacle. The machine

can operate while plugged in or completely cordless.

The TREK delivers 180 amps (approx. 12% duty cycle)

on 115 volt standard power… a weld output which,

until TREK, has been limited to 230 volt welders.

The TREK 180 can be charged inside a vehicle using

an automotive power inverter (400 continuous watt

minimum/charging times increase slightly.) The weld

output is regulated to provide consistent welding

voltage regardless of battery level. The unit is setup

for both self-shielded flux-cored and solid gasshielded wires from .024 to the .035 diameter. A

removable storage bag provides cable management

of standard MIG gun, work cable, clamp and

removable power cord. Impact-resistant case

provides strength and durability, protecting the

internal components and welding wire.

TREK™180

Battery-Powered MIG Welding Package

245164

Nov. 2010

Features Benefits

Includes:

Pouch for storage of MIG gun and work lead during

transportation

Comfortable 10 ft. H100L4-10 MIG torch

10 ft. work lead with clamp

2 premium high-performance sealed lead-acid

batteries

Spare .030 in. (0.8 mm) contact tips

Sample spool of .030 in. (0.8 mm) self-shielded

flux cored welding wire

Weld set-up and information chart

Removable power/recharging cord with plug

Owner’s Manual with parts lists, installation,

operation, maintenance and MIG welding guidelines

#500539

Inverter arc control technology for a smooth and stable arc.

Provides positive feed with adjustable tension. Easy access for threading wire.

Disables the welder when the battery runs low to protect the life of the battery.

Scans the available input charging power to compensate line draw for low capacity devices such as

small automotive inverters.

Provides a broader operating window for each wire with quick and easy adjustment for different materials

and thicknesses.

Quick and easy polarity change access for solid or tubular wire.

Easy to change from one wire size to another .023/.025 in. (0.6 mm) or .030–.035 in. (0.8–0.9 mm).

Diagnostic lights for quick information on the temperature, charging and battery status.

Thin plate pure lead (TPPL) technology allows for fast recharge (only 20 minutes).

Protects unit against current overload.

Protects power circuitry against thermal overload to ensure reliability.

Protects wire feed system from overload, no fuses to change or circuit breaker buttons to press.

Five-year warranty on transformers, stabilizers and generators; three years on electronics (drive motors,

rectifiers); and one year on guns (MIG and plasma torches).

Excellent arc performance

Proven built-in wire feeder with

quick-release tension lever

Low battery shutdown

“AutoPower

™

” technology

Infinite voltage and wire control

Convenient polarity changeover

Quick-change, dual-groove drive roll

LED indicators

High-performance sealed

lead batteries

Short circuit protection

Self-resetting thermal overload

protection

Self-resetting motor protection

Hobart’s 5/3/1 Industrial Warranty

Page 2

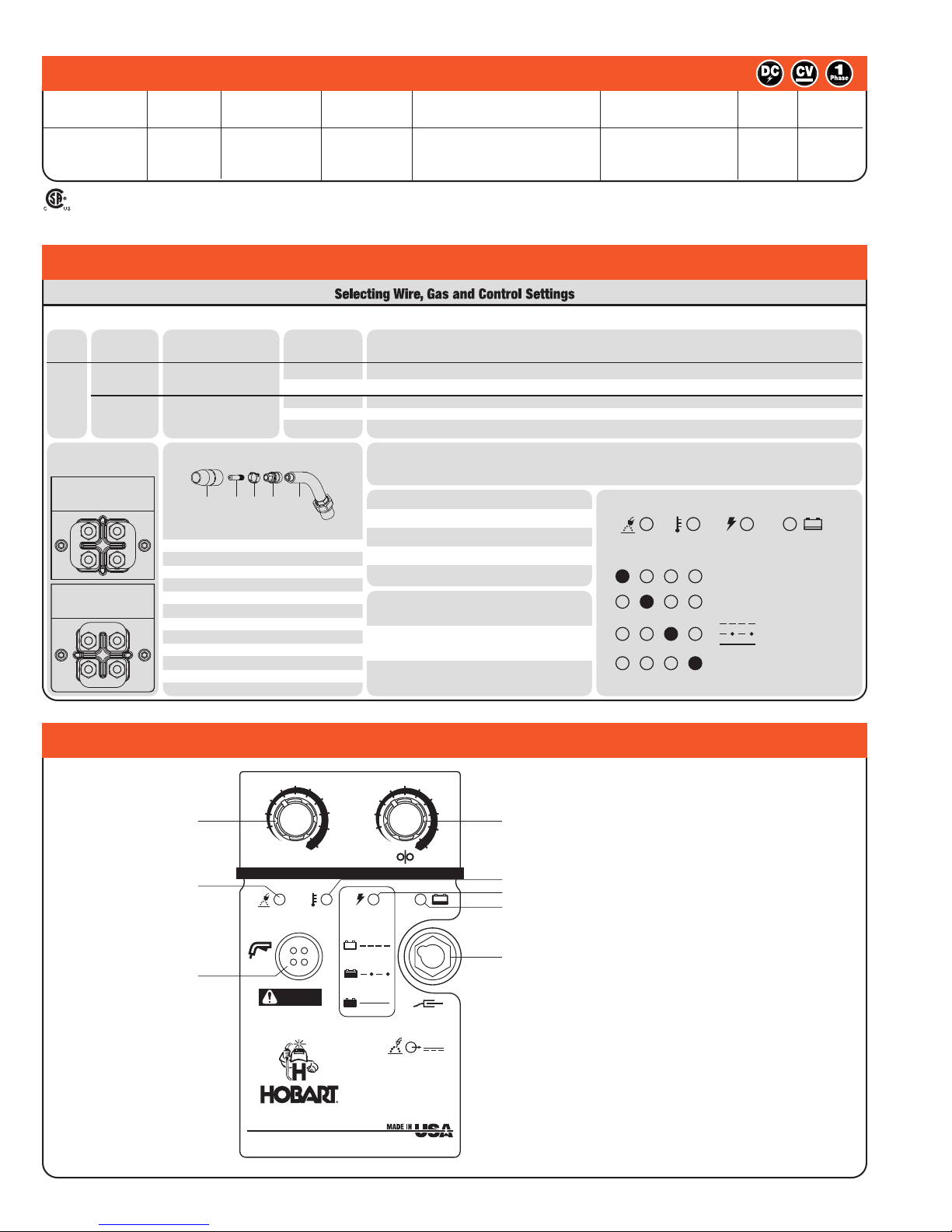

Control Panel

C25 Gas Mixture

75% Ar / 25% CO

2

Produces Less Spatter

Better Appearance

No Shielding Gas Required

Good for Windy or

Outdoor Applications

Flux Core

E71T-GS

(DCEN)

Solid Wire

ER70S-6

(DCEP)

Steel

Welding Gun Consumables

169715

226190

Stock No.

170470

169716

242831

194011

194010

000068

087299

000067

.500” orf flush

Flux Cored

A) Nozzles

C) Retaining Ring

D) Contact Tip Adaptor

Liners

.030” / .035”

.023” / .025”

E) Head Tube

.035” ( 0.9mm )

B) Tips

.023” ( 0.6mm )

.030” ( 0.8mm )

A

B C D E

LED Status

See Owner’s Manual for Other LED Combinations

READY LOW BATTERYOVER TEMP CHARGING

STATUS

Unit is charged, ready to weld

Batteries Charging

Batteries 80% Charged

Batteries Fully Charged

Low Battery, plug in welder to charge

Over Temp has occurred, stop welding

and allow unit to cool down

Changing

Polarity

DCEN

Electrode Negative

For Flux Cored Wire

DCEP

Electrode Positive

For Solid Wire

Drive Rolls

V – Groove

.024” - .030” / .035”

( 0.6mm - 0.8mm / 0.9mm )

237338

VK – Groove

.030” / .035” - .045”

( 0.8mm / 0.9mm - 1.2mm )

202926

Dual Grooved

Groove

Wire

Size

Stock

No.

See Owner’s Manual

Match drive roll groove to diameter of wire being used.

Settings are approximate. Adjust as required. Thicker materials can be

welded using proper technique, joint preparation and multiple passes.

Recommended Voltage and Wire Speed Settings for Thickness of Metal Being Welded

Number on Left is Voltage Setting / Number on Right is Wire Feed Setting

Diameter

of Wire

Being Used

Suggested

Shielding Gases

20–30 cfh Flow Rate

Wire Type,

and

Polarity Setting

Material

Being

Welded

24 gauge

.024 inch

( 0.6 mm )

22 gauge

.030 inch

( 0.8 mm )

20 gauge

.036 inch

( 0.9 mm )

18 gauge

.048 inch

( 1.2 mm )

16 gauge

.060 inch

( 1.5 mm )

14 gauge

.075 inch

( 1.9 mm )

12 gauge

.105 inch

( 2.7 mm )

1/8 inch

( 3.2 mm )

3/16 inch

( 4.8 mm )

1/4 inch

( 6.4 mm )

5/16 inch

( 7.9 mm )

.030” ( 0.8 mm ) — — — 1 / 0 2 / 5 3 / 10 5 / 30 6 / 40 8 / 70 10 / 100 —

.024” ( 0.6 mm )

0 / 20 0 / 30 2 / 40 4 / 40 7 / 60 8 / 80 10 / 100 10 / 100 — — —

.030” ( 0.8 mm ) — 0 / 10 1 / 10 2 / 20 3 / 30 3 / 40 5 / 50 7 / 50 10 / 60 10 / 60 —

.035” ( 0.9 mm ) — — — — 3 / 10 5 / 20 6 / 25 7 / 30 9 / 35 10 / 40 —

• Set Tension Knob Setting to 3 at start. Adjust tension per instructions in the manual.

• Wire Speed listed is a starting value only. Wire speed setting can be fine-tuned while welding. Wire speed

also depends on other variables such as stick out, travel speed, weld angle, cleanliness of metal, etc.

232680-A

.035” ( 0.9 mm )

— — — — — — — 5 / 20 8 / 40 10 / 50 10 / 60

For Maximum Battery Life, Unit Should Be

Plugged In When Not In Use

Battery Must Be Recharged After Each Use.

USE ONLY FACTORY AUTHORIZED BATTERIES

Stock No. 232612

TREK 180 Welding Guide

2

Rated Output

120 A, 17 VDC at

20% Duty Cycle

Max. Open

Circuit Voltage

30 V

Current

Range

25–180 A

Dimensions

H: 13-5/16 in. (338 mm)

W: 17 in. (433 mm)

D: 7-7/8 in. (200 mm)

Wire Feed

Speed Range

40–400 IPM

Net

Weight

51.87 lb.

(23.5 kg)

Shipping

Weight

61 lb.

(27.7 kg)

Amps Input at Rated Load, 60 Hz

115 V KVA KW

12* 1.38 0.75

*

Auto Power™ technology will adjust as low as 3.5 A based on input power available.

Specifications

(SUBJECT TO CHANGE WITHOUT NOTICE.)

V

1

2

3

4

5

6

7

8

9

10

10

20

30

40

50

60

70

80

90

100

READY LOW BATTERYOVER TEMP CHARGING

STATUS

TRIGGER

WORK

CHARGING

80% CHARGED

100% CHARGED

TREK TM 180

BATTERY POWERED WIRE FEED WELDER

25-180 AMP OUTPUT

WARNING

• UNPLUG TRIGGER

BEFORE TRANSPORTING

OR STORING.

VOLTAGE WIRE FEED

VOLTS

AMPS

DUTY CYCLE

MAX OCV

AMP RANGE

17

120

20%

30

25-180

RATED WELD OUTPUT

1

3

7

4

5

6

2

8

1. Voltage Control

2. Welder Ready Light

3. Trigger Receptacle

4. Wire Speed Control

5. Over Temperature Light

6. Charging Status Light

7. Battery Status Light

8. Work Lead Receptacle

Certified by Canadian Standards Association to both Canadian and U.S. Standards.

Page 3

Performance Data

Accessories

3

DUTY CYCLE CHART

(WHILE OPERATING CONNECTED TO A 115V SUPPLY)

0

20

40

60

80

100

120

140

160

180

200

0 10 20 30 40 50 60 70 80 90 100

% DUTY CYCLE

DC AMPERES

TREK 180 VA CURVES

0

5

10

15

20

25

30

0 20 40 60 80 100 120 140 160 180 200

DC AMPERES

DC VOLTS

Minimum

Maximum

WELD TIME WHILE OPERATING FROM BATTERIES ONLY

1

2

3

4

5

10

20

30

100

0 20 40 60 80 100 120 140 160 180 200

DC AMPERES

WELD TIME (MINUTES)

20 Ga. 18 Ga. 16 Ga. 1/8" 3/16" 1/4"

H100L4-10 Replacement MIG Torch

#243864

For .030–.035 in. (0.8–0.9 mm) wire.

Includes 10 ft. (3 m) cable.

Drive Rolls

Dual-Groove, V-Smooth #237338

For .023/.025 in. (0.6 mm) and .030 –.035 in.

(0.8–0.9 mm) wire.

Dual-Groove, V-Knurled #202926

For .030–.035 in. (0.8–0.9 mm) and .045 in.

(1.2 mm) flux-cored wire.

Contact Tips

(See chart on back page.)

MIG Nozzle

(See chart on back page.)

Protects tip adapter and

focuses gas coverage.

Gasless Flux-cored

Nozzle

(See chart on back page.)

For use with self-shielding

flux-cored wires. Improves

visibility, eases access in

tight corners, protects tip adapter/gas diffuser

from spatter and from shorting to the work piece.

For use with H9, H10, M10, and M15 torches.

Tip Adapter

(See chart on back page.)

Replacement Liners

(See chart on back page.)

Page 4

Hobart Welders An Illinois Tool Works Company hobartwelders.com

Hobart Welding Products Service 800-332-3281 Sales 800-626-9420

Litho in USA

Item Hobart Package Part #* Miller Package Part #**

Contact Tips

.023/.025 in. (0.6 mm) #770174 (5 per package) #087 299 (10 per package)

.030 in. (0.8 mm) #770177 (5 per package) #000 067 (10 per package)

.035 in. (0.9 mm) #770180 (5 per package) #000 068 (10 per package)

MIG Nozzle (Standard) #770404 #169 715

Gasless Flux Cored Nozzle #770487 #226 190

Tip Adapter #770402 #169 716

Replacement Liners

.023/.025 in. (0.6 mm) #196139 #194 010

.030/.035 in. (0.8/0.9 mm) #196139 #194 011

.035/.045 in. (0.9/1.2 mm) #196140 #194 012

*Available at farm and tool supply retailers. **Available at Hobart/Miller welding distributors.

Consumables

Loading...

Loading...