Hino FR1E, FS1E, FY1E, SH1E, SS1E Service Manual

...

■■■■■■■■

1 MENU

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Vehicles.

Applicable for FR1E, FS1E, FY1E, SH1E, SS1E and ZS1E series, equipped with E13C engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owner’s Manual.

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors reserves the right to make changes at any time without prior notice.

This manual is divided into 9 sections with a thumb index for each section at the edge of the pages.

Please note that the publications below have also been prepared as relevant service manuals for the components and systems in this vehicles.

Manual Name Pub. No.

Chassis Workshop Manual S1-YFSE16A 1/3

Chassis Workshop Manual S1-YFSE16A 3/3

E13C Engine Workshop Manual S5-YE13E01A

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

CHAPTER

GENERAL INTRODUCTION GN02-001

CLUTCH MAIN UNIT CL02-001 CL02-002 CL02-003 CL02-004

CLUTCH CONTROL CL03-001 CL03-002 CL03-003 CL03-004

TRANSMISSION MAIN UNIT TR02-001 TR02-002 TR02-003 TR02-004

P.T.O. (POWER TAKE-OFF) TR05-001 TR05-002 TR05-003

TRANSMISSION/TRANSFER CONTROL TR06-001

PROPELLER SHAFT PP02-001 PP02-002 PP02-003

DIFFERENTIAL EQUIPMENT DF01-001

DIFFERENTIAL CARRIER DF02-001 DF02-002 DF02-003 DF02-004 DF02-005

BRAKE EQUIPMENT BR01-001

SERVICE BRAKE BR02-001

ABS (ANTI-LOCK BRAKE SYSTEM) BR03-001

MANUAL NO. S1-YFSE16A 2/3

MODELS FR1E, FS1E, FY1E, SH1E, SS1E, ZS1E

ES START (EASY & SMOOTH START) SYSTEM BR04-001

STEERING EQUIPMENT SR01-001

STEERING UNIT SR02-001

POWER STEERING SR03-001

FRONT AXLE AX02-001 AX02-002

REAR AXLE AX03-001 AX03-002

WHEEL & TIRE AX04-001

SUSPENSION SU02-001 SU02-002 SU02-003 SU02-004

CHASSIS FRAME FC02-001

COUPLER (5TH WHEEL) FC03-001

PINTLE HOOK FC04-001

CAB CA02-001

ELECTRICAL EQUIPMENT EL01-001

ELECTRIC WIRE EL02-001

BRAKE CONTROL DN03-001 DN03-002

SUSPENSION CONTROL DN04-001

OTHERS DN06-001

This manual does not contain items on half-tone dot meshing.

INDEX: CHASSIS GROUP 1/4

GENERAL INTRODUCTION

CLUTCH EQUIPMENT

CLUTCH MAIN UNIT

WORKSHOP

MANUAL

CLUTCH CONTROL

TRANSMISSION EQUIPMENT

TRANSMISSION MAIN UNIT

TRANSFER MAIN UNIT

AUTOMATIC TRANSMISSION

P.T.O. (POWER TAKE-OFF)

TRANSMISSION / TRANSFER CONTROL

PROPELLER SHAFT EQUIPMENT

All rights reserved. This manual may not be

reproduced or copied in whole in part, without the written consent of Hino Motors, Ltd.

PROPELLER SHAFT

DIFFERENTIAL EQUIPMENT

DIFFERENTIAL CARRIER

BRAKE EQUIPMENT

SERVICE BRAKE

ABS (ANTI-LOCK BRAKE SYSTEM)

ES START (EASY & SMOOTH START) SYSTEM

This manual does not contain items on half-tone dot meshing.

INDEX: CHASSIS GROUP 2/4

EXHAUST BRAKE

RETARDER BRAKE

PARKING BRAKE

STEERING EQUIPMENT

STEERING UNIT

POWER STEERING

AXLE EQUIPMENT

FRONT AXLE

REAR AXLE

WHEEL & TIRE

SUSPENSION EQUIPMENT

SUSPENSION

CHASSIS EQUIPMENT

CHASSIS FRAME

COUPLER (5TH WHEEL)

PINTLE HOOK

CAB EQUIPMENT

CAB

This manual does not contain items on half-tone dot meshing.

INDEX: CHASSIS GROUP 3/4

ELECTRICAL EQUIPMENT

ELECTRIC WIRE

This manual does not contain items on half-tone dot meshing.

INDEX: CHASSIS GROUP 4/4

ENGINE CONTROL

FUEL CONTROL

BRAKE CONTROL

SUSPENSION CONTROL

CAB EQUIPMENT CONTROL

OTHERS

This manual does not contain items on half-tone dot meshing.

BRAKE EQUIPMENT BR01–1

BR01

BRAKE EQUIPMENT

SERVICE BRAKE ASSEMBLY.................BR01-2

DESCRIPTION ................................................ BR01-2

DIAGRAM ........................................................ BR01-3

TROUBLESHOOTING................................... BR01-41

BR01-001

BRAKE EQUIPMENTBR01–2

SERVICE BRAKE ASSEMBLY

DESCRIPTION

EN0680201C100001

Type of service brake Drum-shoe type wheel brake activated by compressed air.

Air charging system Air charging is from piston type air compressor and air flow is directed and con-

trolled by a pressure regulator, the necessary valves, and lines as required.

Pressure sensor and air pressure warning switch are used for indicating the

pressure level in the system.

Service brake control system Two independent lines for front and rear wheels with air flow controlled by a

brake valve, and each line comprises a group of valve and brake chambers

(one/ wheel).

Stop lamp switch is used to operate the stop lamps.

Spring brake control system Single line for all spring brake chambers.

The line comprises a control valve which controls air flow, the other necessary

valve and spring brake chambers.

A stop lamp switch is used to turn on the stop lamps.

A parking brake switch is used to turn off the warning buzzer and to turn on the

parking brake warning lamp.

Wheel brake Drum brake with internally expanding, leading-trailing shoes are operated by

slack adjuster and cam shaft or expander in all wheels.

NOTICE

See "DIAGRAM" of the following page the component parts

(Valves, Switches, etc.) used in easy system.

BRAKE EQUIPMENT BR01–3

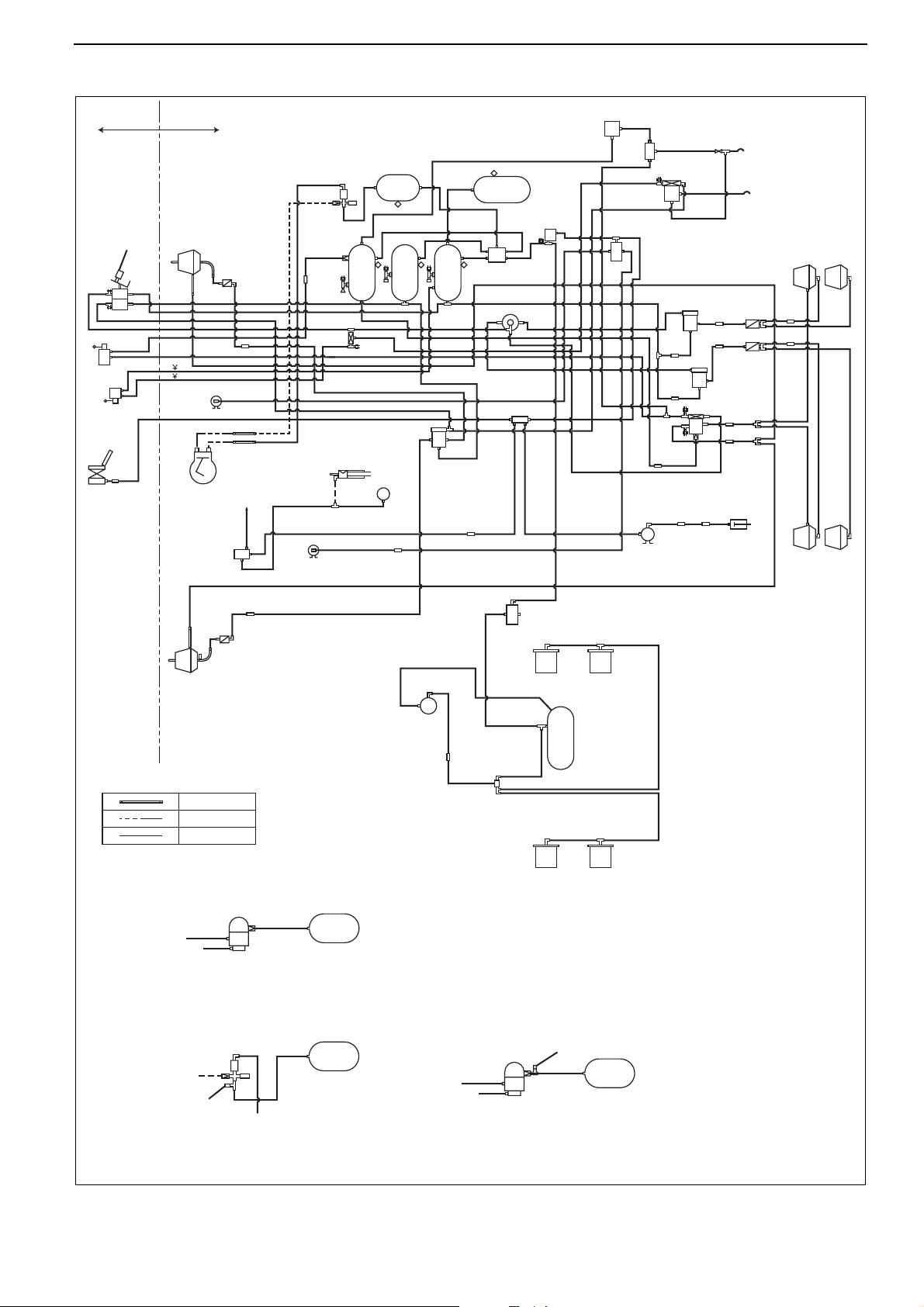

DIAGRAM

EN0680201J100001

MODELS: FS (DUMP, MIXER AND CARGO TRUCK), ZS (DUMP AND CARGO TRUCK)

(For GENERAL COUNTRIES, CHILE, CHINA, G.C.C. COUNTRIES, HONG KONG, IRELAND,

SOUTH AFRICA, TAIWAN)

Q1

3

26L

26L

A5

A6

A7

R

A4

4

F

26L

5

E3

D1

C3

9

19

H1

H3

H2

20

20

6

E5

E4

13

E6

21

P3

E7

P4

P9P13

Q4Q3

18

F21

F51

P5

32

32

14

15

P6

F11P3

7

17

24

2

A/D

CHASSIS

CAB

8

11

R

F

C1

E1

C2

E2

P1

P2

S1

P15

D3

32

D40

P14

H20

27

A3

B1

C0

A2

B2

1

16

23

12

P18

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

TRANSMISSION

25

L1

28

D60

32

D8

21

CHASSIS

19

X5

H12 H11

H41 H4

H22

H5

22

21

H21

P8

14

D6

H7

22

X4

21

L1

25

21

H7

X3

X2

25

23

X1

H41

H6

H5

16 12

F16P6

15

WITH MZ12 TRANSMISSION

(IF SO EQUIPPED)

12

H9

H5

21

22

H7

21

WITH HX07 TRANSMISSION

(IF SO EQUIPPED)

WITH ZF TRANSMISSION

(IF SO EQUIPPED)

21

W1 W2

25

W3 W4W31

WITH INER-AXLE DIFFERENTIAL LOCK

(IF SO EQUIPPED)

SHTS068020100001

26

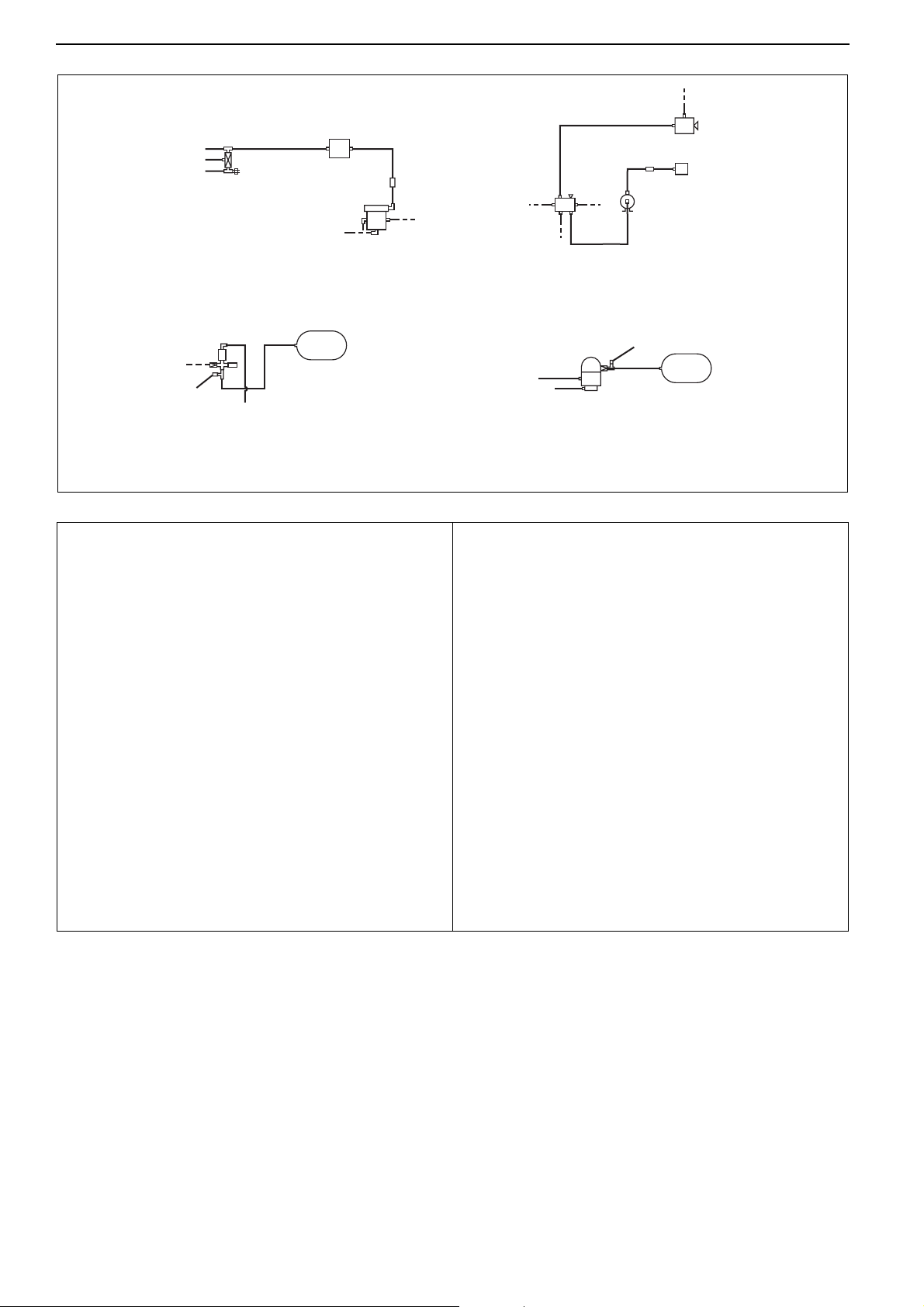

BRAKE EQUIPMENTBR01–4

(

)

(

)

E3

B1

10

A3

A4

3

29

13

E31

E4

21

WITHOUT AIR DRYER

(IF SO EQUIPPED)

H5

J2J1J4

21

J5

30

25

21

WITH TRANSMISSION P.T.O.

(WITH HX07 AND MZ12 TRANSMISSION)

(IF SO EQUIPPED)

10

H50

E3E50E2

33

A3

31

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

H5

J2J1J4

21

30

25

21

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

B1

A4

2

3

A/D

A3

B1

31

A4

3

WITH ES START

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

IF SO EQUIPPED

WITH TIRE INFLATOR

(WITH AIR DRYER)

IF SO EQUIPPED

SHTS068020100002

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Spring brake chamber-Front 28 Cab suspension-Rear

12 Power shift 29 Load sensing valve (If so equipped)

13 Release valve-Rear brake 30 Transmission P.T.O. (If so equipped)

14 Spring brake chamber-Rear 31 Tire inflator (If so equipped)

15 Brake chamber 32 ABS control valve (If so equipped)

16 Splitter valve 33 ES start control valve (If so equipped)

17 Spring brake control valve

MODEL: FS (For AUSTRALIA)

CHASSIS

CAB

B1

A3

8

7

17

35

24

11

D3

R

F

E2

P1

S1

P15

C1

E1

C2

P2

1

2

32

D20

D40

H20

27

A2

B2

1

L1

21

D60

D30

P18

32

D8

11

P0

16

H7

28

BRAKE EQUIPMENT BR01–5

3

10

22

26L

A4

A8

R

F

26L

26L26L

4

E3

C3

D1

9

23

H10H5

H41 H4

H22 H21

D6

R7

R5

19

Z8

33

Z2

34

E5

E12

E15

E13

E16 E14

P4

Q1

Q4

W2 W3 W4

Z6

Z4

Z9

13

E5

13

Z3

A9

A5

A6

26L

R

5

19

A7

5

H11

6

P22

H3H2

20

12

C7

21

W1

25

R1

P17

EMERGENCY

SERVICE

15

14

F20F1

F21

32

F3

F11

32

P6

18

P51

P5

P9

E7

F6

F16

P8

26

14

15

20

R13

31 31

R6

R1

R2

RUBBER HOSE

STEEL PIPE

NYLON TUBE

2

A/D

A3

B1

A4

WITH AIR DRYER

B1

10

A3

A4

36

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

R4

30

R2

26L

29

R3

R1

R10

R20 R17

R2

25

31 31

3

36

2

A/D

3

A3

B1

A4

3

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

SHTS068020100003

BRAKE EQUIPMENTBR01–6

1 Air compressor 19 Reducing valve

2 Air dryer (If so equipped) 20 Protection valve

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Clutch booster

5 Air tank-Rear brake 23 Range valve

6 Protection valve 24 Air suspension seat

7 Brake valve 25 Magnetic valve

8 Stop lamp switch 26 Inter-axle differential lock control cylinder

9 Relay valve-Front brake 27 Cab suspension-Front

10 Pressure regulator 28 Cab suspension-Rear

11 Spring brake chamber-Front 29 Air tank-Air suspension

12 Quick release valve 30 Leveling valve

13 Release valve-Rear brake 31 Air spring

14 Spring brake chamber-Rear 32 ABS control valve

15 Brake chamber 33 Cut valve

16 Air tank-Spring brake and trailer brake 34 Trailer control valve

17 Spring brake control valve 35 Trailer hand brake valve

18 Relay valve-Spring brake 36 Tire inflator (If so equipped)

BRAKE EQUIPMENT BR01–7

MODEL: FS (CARGO TRUCK) (For HONG KONG, IRELAND, TAIWAN)

Q1

7

17

24

CHASSIS

CAB

11

D3

8

R

F

C1

E1

C2

E2

P1

P2

S1

12

D40

H20

27

B1

10

A3

A2

B2

C0

3

A5A4

26L

4

f

26L

A6

R

26L

5

D1

1

L1

11

D8

RUBBER HOSE

STEEL PIPE

NYLON TUBE

21

28

D60

12

H41

H22

H4

H21

D6

R5

R9

R16

25

20

19

H1

6

A7

H3

H2

14

15

20

P11

F11

F3

P6

9

C3

E3

E5

21

Q3

R1

P10

E4

13

F1

F4

P4P3

P9

Q4

12

E6

12

E7

P5

18

P12

F21F2

F7

F12

F5 F51

P51

14

F8

F13

F16

F6

P8

15

20

R13

R1

R2

31 31

R4

R2

29

26L

29

26L

R3

R10

R20 R17

21

R1

H7

22

X4

L1

25

X3

X2

25

23

X1

H41

H6

H5

31 32

31

31 31

23

32

R2

TRANSMISSION CHASSIS

X5

H12 H11

25

WITH ZF TRANSMISSION WITH MZ12 TRANSMISSION

H9

21

2

H5

H7

21

22

A/D

A3

B1

A4

3

WITH HX07 TRANSMISSION WITH AIR DRYER

(IF SO EQUIPPED)

19

H5

22

21

SHTS068020100004

21

H7

BRAKE EQUIPMENTBR01–8

H5

J2J1J4

21

30

25

21

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

E3

33

13

WITH LOADSENSING VALVE

(IF SO EQUIPPED)

E31

H5

J2J1J4

21

J5

30

25

21

WITH TRANSMISSION P.T.O.

(WITH HX07, MZ12 TRANSMISSION)

(IF SO EQUIPPED)

21

E4

H50

E3E50E2

16

WITH ES START

(IF SO EQUIPPED)

B1

10

A3

A4

34

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

2

3

A/D

A3

B1

A4

3

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

34

21

W1 W2

25

W3 W4W31

26

WITH INTER-AXLE DIFFERENTIAL LOCK

(MODEL: FS)

SHTS068020100005

BRAKE EQUIPMENT BR01–9

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Brake chamber 28 Cab suspension-Rear

12 ABS control valve (If so equipped) 29 Air tank-Air suspension

13 Relay valve-Rear 30 Transmission P.T.O.

14 Spring brake chamber-Rear, Frontward 31 Splitter valve

15 Spring brake chamber-Rear, Rearward 32 Power shift

16 ES start control valve (If so equipped) 33 Load sensing valve

17 Spring brake control valve 34 Tire inflator (If so equipped)

MODEL: FS (For NEW ZEALAND)

(

)

(

)

Y

BRAKE EQUIPMENTBR01–10

17

12

7

24

F2

F21

F7

F12

F5 F51

P51

14

14

19

33

P6

P8

Z8

Z4

Z6

EMERGENC

15

F8

F13

15

SERVICE

F11F3

F16F6

Z3

CHASSIS

CAB

10

3

11

P15

D3

D20

C1

E1

C2

E2

P1

P2

㩯1

㩯2

H20

8

R

F

P21

S1

27

D40

32

A3

B1

C0

A2

B2

1

26L

F

4

26L

22

A9

A5A4

A6

R

5

26L

E3

23

H5 H10

11

P18

L1

D30

D8

32

28

D40

21

H41

H22

H4

H21

P17

5

P10

16

F

A8

26L

Q3

Z2

C7

P22

E4

13

F1

F4

P4P3

P9

Q4

R2

32

E6

E7

32

P5

18

26LR

19

H1

6

9

D1

C3

H3

H2

20

E5

21

R1

20

R13

R2

R1

31 31

RUBBER HOSE

STEEL PIPE

NYLON TUBE

R3

30

26L

29

R10

R20 R17

R1

R2

31 31

21

W1 W2

25

W3 W4W31

26

2

A/D

A3

B1

WITH INTER-AXLE DIFFERENTIAL LOCK WITH AIR DRYER

(IF SO EQUIPPED)

B1

10

A3

34

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

IF SO EQUIPPED

A4

2

3

A/D

A3

B1

WITH TIRE INFLATOR

(WITH AIR DRYER)

IF SO EQUIPPED

A4

3

34

A4

3

SHTS068020100006

BRAKE EQUIPMENT BR01–11

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Spring brake chamber-Front 28 Cab suspension-Rear

12 Trailer hand brake valve 29 Air tank-Air suspension

13 Release valve-Rear brake 30 Leveling valve

14 Spring brake chamber-Rear 31 Air spring

15 Brake chamber 32 ABS control valve

16 Air tank-Spring brake and trailer brake 33 Trailer control valve

17 Spring brake control valve 34 Tire inflator (If so equipped)

BRAKE EQUIPMENTBR01–12

MODEL: FS (FULL TRACTOR) (For GENERAL COUNTRIES, CHILE, G.C.C. COUNTRIES)

7

17

24

CHASSIS

CAB

11

D3

8

R

F

D20

P15

P14

C1

E1

C2

E2

P1

P2

H20

27

S1

1

L1

B1

10

A3

A2

B2

C0

3

A4 A5

26L

4

F

R

26L

26L

D1

19

A6

5

A7

H1

A8

6

9

C3

21

H3

H2

26L

15

Q3

14

20

E4E3

F21

F3

F11

13

E6

F51

E7

P6

18

P5

P8

F16

P10

E5

P4P3

P9

Q4

21

16

14

F6

15

P18

11

D30

H41

28

D60

D8

H22

P17

RUBBER HOSE

STEEL PIPE

NYLON TUBE

H4

H21

D6

34

CAB

CHASSIS

>1

>2

19

Z8

33

Z3

16

26L

5

R

26L

Z2

P22

P4

C7

9

WITH TRAILER CONTROL

(IF SO EQUIPPED)

Z6

35

18

H7

22

EMERGENCY

X4

21

L1

25

Z4

Z9

SERVICE

X3

X2

25

23

X1

H41

H6

H5

29 30

WITH ZF TRANSMISSION

SHTS068020100007

BRAKE EQUIPMENT BR01–13

H5

J2J1J4

21

31

25

21

WITH TRANSMISSION P.T.O.

(WITH ZF TRANSMISSION)

(IF SO EQUIPPED)

H5

J2J1J4

31

25

21

WITH TRANSMISSION P.T.O.

(WITH MZ12 TRANSMISSION)

(IF SO EQUIPPED)

21

25

CHASSIS

19

X5

H12 H11

H5

21

H7

22

TRANSMISSION

29

23

30

21

WITH MZ12 TRANSMISSION

12

E3

J5

E31

E4

13

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

2

A/D

A3

B1

A4

WITH AIR DRYER

3

10

A3

32

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

21

W1 W2

25

W3 W4W31

WITH INTER-AXLE DIFFERENTIAL LOCK

26

B1

A4

3

2

A/D

A3

B1

32

A4

3

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

SHTS068020100008

BRAKE EQUIPMENTBR01–14

1 Air compressor 19 Reducing valve

2 Air dryer (If so equipped) 20 Protection valve

3 Air tank-Water separator 21 Multi joint

4 Air tank-Front brake 22 Clutch booster

5 Air tank-Rear brake 23 Range valve

6 Protection valve 24 Air suspension seat

7 Brake valve 25 Magnetic valve

8 Stop lamp switch 26 Inter-axle differential lock control cylinder

9 Relay valve-Front brake 27 Cab suspension-Front

10 Pressure regulator 28 Cab suspension-Rear

11 Spring brake chamber-Front 29 Splitter valve

12 Load sensing valve (If so equipped) 30 Power shift

13 Release valve-Rear brake 31 Transmission P.T.O. (If so equipped)

14 Spring brake chamber-Rear 32 Tire inflator (If so equipped)

15 Brake chamber 33 Cut valve (If so equipped)

16 Air tank-Spring brake and trailer brake 34 Trailer hand brake valve (If so equipped)

17 Spring brake control valve 35 Trailer control valve (If so equipped)

18 Relay valve-Spring brake

BRAKE EQUIPMENT BR01–15

MODEL: FS (FULL TRACTOR) (For SOUTH AFRICA)

19

7

17

24

26L

Z3

F

Q3

P11

13

F1

E6

F4

P5

18

A15

CHASSIS

CAB

2

A/D

A3

8

11

D3

R

F

P1

P21

C1

E1

C2

E2

P2

D40

H20

27

B1

C0

A2

B2

1

H7

22

X4

L1

X3

X2

25 25

21

28

D60

23

X1

3

A4

26L

F

26L

4

D1

C3

9

29

H6

H5

H41 H4

H22

H21

D6

26L

19

A5

A6

A7

R

5

H1

A8

6

E5

E3

H3

H2

20

21

30

P10

16

Z2

C7

P22

E4

P4P3

P9

Q4

Z8

Z4

Z6

EMERGENCY

12

14

P6

F21

F51

P51

P8

15

F8

F13

14 15

SERVICE

F11F3

F16F6

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

A3

B1

10

A4

3

WITHOUT AIR DRYER

21

W1 W2

25

W3 W4W31

26

WITH INTER-AXLE DIFFERENTIAL LOCK

SHTS068020100009

BRAKE EQUIPMENTBR01–16

E3

31

13

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

B1

10

A3

A4

3

33

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

E31

H5

J2J1J4

E4

25

21

WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

33

2

A/D

A3

B1

A4

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

21

32

3

SHTS068020100010

1 Air compressor 18 Relay valve-Spring brake

2 Air dryer (If so equipped) 19 Reducing valve

3 Air tank-Water separator 20 Protection valve

4 Air tank-Front brake 21 Multi joint

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Range valve

7 Brake valve 24 Air suspension seat

8 Stop lamp switch 25 Magnetic valve

9 Relay valve-Front brake 26 Inter-axle differential lock control cylinder

10 Pressure regulator 27 Cab suspension-Front

11 Brake chamber-Front 28 Cab suspension-Rear

12 Trailer control valve 29 Splitter valve

13 Release valve-Rear brake 30 Power shift

14 Spring brake chamber-Rear 31 Load sensing valve

15 Spring brake chamber-Rearward 32 Transmission P.T.O.

16 Air tank-Spring brake and trailer brake 33 Tire inflator

17 Spring brake control valve

BRAKE EQUIPMENT BR01–17

MODEL: FY (For GENERAL COUNTRIES, NEW ZEALAND)

16

35

31

Z3

CHASSIS

CAB

34

3

22

26L

26L

4

F

11

8

7

R

F

P21

C1

E1

C2

E2

P1

P2

㩯1

㩯2

S1

27

H20

12

P15

D5

P14

A3

B1

C0

A2

B2

D3

D2

26L

A9

A5A4

A6

5

R

E3

C3

19

1

H5 H10

L1

19

11

RUBBER HOSE

STEEL PIPE

NYLON TUBE

D7

12

P18

28

H41

H22

D10D8

P17

H4

H21

D9

5

26LR

18

H1

6

H3

H2

26

9

10

P10

25

F

A8

26L

Q3

Z2

C7

P22

E4

F4

P4P3

P9

Q4

10

13

F21F1

E6

F51

E7

P51

P5

17

26

R13

R2

R1

R2

32 32

23

26L

18

26

14 15

F23

F53

P6

P8

14

Z8

Z4

Z6

EMERGENCY

21

15

SERVICE

F11F3

F16F6

19

W1 W2

20

W3 W4W31

WITH INTER-AXLE DIFFERENTIAL LOCK

33

E3

E31

E4

13

WITH LOAD SENSING VALVE

24

29

A/D

A3

B1

A4

2

WITH AIR DRYER

(IF SO EQUIPPED)

B1

34

A3

A4

30

WITH TIRE INFLATOR

(WITHOUT AIR DRYER)

(IF SO EQUIPPED)

3

3

R3

R1

32 32

R10

R20 R17

R2

30

A/D

A3

B1

2

WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

3

A4

SHTS068020100011

BRAKE EQUIPMENTBR01–18

1 Air compressor 19 Multi joint

2 Air dryer (If so equipped) 20 Magnetic valve

3 Air tank-Water separator 21 Trailer control valve (If so equipped)

4 Air tank-Front brake 22 Clutch booster

5 Air tank-Rear brake 23 Air tank-Air suspension (If so equipped)

6 Protection valve 24 Leveling valve (If so equipped)

7 Brake valve 25 Air tank-Spring brake and trailer brake

(If so equipped)

8 Stop lamp switch 26 Protection valve

9 Relay valve-Front brake 27 Cab suspension-Front

10 ABS control valve 28 Cab suspension-Rear

11 Brake chamber-Front 29 Inter-axle differential lock control cylinder

12 Spring brake chamber-Front 30 Tire inflator (If so equipped)

13 Relay valve-Rear brake 31 Air suspension seat (If so equipped)

14 Spring brake chamber-Rear 32 Air spring (If so equipped)

15 Brake chamber-Rear 33 Load sensing valve (If so equipped)

16 Spring brake control valve 34 Pressure regulator

17 Relay valve-Spring brake 35 Trailer hand brake valve (If so equipped)

18 Reducing valve

BRAKE EQUIPMENT BR01–19

6

MODEL: FY (For CHINA, HONG KONG)

CHASSIS

16

31

CAB

8

7

R

F

11

C1

E1

C2

E2

P1

P2

H20

12

D3

P15

D2

27

2

A/D

A3R

B1

D5

A3

A2

B2

1

24

L1

22

H41

19

11

28

P18

12

H22 H21

D7

D10D8

3

A4

26L

4

F

C0

26L

C3

H5

H7

P17

D9

Q1

25

18

A9

H3

H2

26L

A5

5

R

A7

H1A6

6

Q3

P14

D4

9

19

H9

26

E3 E4

E5

P3

P13

5

26LR

15

14

F11F3

13

P51

F23

F53

P6

P8

F1

F6

E6

E7

F21F1

F51

P5

17

F4

P4

P9

Q4

19

14

H4

15

RUBBER HOSE

STEEL PIPE

NYLON TUBE

19

W1 W2

20

W3 W4W31

29

WITH INTER-AXLE DIFFERENTIAL LOCK

23

21

24

TRANSMISSION

CHASSIS

18

X5

H12 H11

20

WITH MZ12 TRANSMISSION

H5

22

SHTS068020100012

19

H7

BRAKE EQUIPMENTBR01–20

)

(

)

3

B1

10

A3

A4

19

H50

A/D

E3E50E2

A3

B1

2

34

WITHOUT AIR DRYER WITH ES START WITH TIRE INFLATOR

(WITH AIR DRYER)

(IF SO EQUIPPED)

E3

WITH LOAD SENSING VALVE

(IF SO EQUIPPED)

33

13

E31

32

19

J5

30

H5

E4

J2J1J4

19

B1

10

A3

20

WITH TRANSMISSION P.T.O.

(IF SO EQUIPPED)

WITH TIRE INFLATOR

(WITHOUT AIR DRYER

IF SO EQUIPPED

30

3

A4

3

A4

SHTS068020100013

1 Air compressor 18 Reducing valve

2 Air dryer (If so equipped) 19 Multi joint

3 Air tank-Water separator 20 Magnetic valve

4 Air tank-Front brake 21 Range valve (If so equipped)

5 Air tank-Rear brake 22 Clutch booster

6 Protection valve 23 Splitter valve (If so equipped)

7 Brake valve 24 Power shift

8 Stop lamp switch 25 Protection valve

9 Relay valve-Front brake 26 Protection valve

10 Pressure regulator (If so equipped) 27 Cab suspension-Front

11 Brake chamber-Front 28 Cab suspension-Rear

12 Spring brake chamber-Front 29 Inter-axle differential lock control cylinder

13 Relay valve-Rear brake 30 Tire inflator (If so equipped)

14 Spring brake chamber-Rear 31 Air suspension seat (If so equipped)

15 Brake chamber-Rear 32 Transmission P.T.O. (If so equipped)

16 Spring brake control valve 33 Load sensing valve (If so equipped)

17 Relay valve-Spring brake 34 ES start control valve (If so equipped)

Loading...

Loading...