Page 1

MENU

FOREWORD

This workshop manual has been prepared to provide information regarding repair procedures on Hino Trucks.

Applicable for HINO 238, 258LP, 268, 338 series, equipped with J08E-VB and J08E-VC engine

When making any repairs on your vehicle, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Driver’s / Owner’s Manual.

All information and specifications in this manual are based upon the latest product information available at the time of printing.

Hino Motors Sales U.S.A., Inc. reserves the right to make changes at any time without prior notice.

Please note that the publications below have also been prepared as relevant workshop manuals for the components and systems in these vehicles.

Manual Name Pub. No.

Chassis Workshop Manual S1-UNAE11A 2/2

J08E-VB, VC Engine Workshop Manual S5-UJ08E11A

S7-UNAE11A 1/3

Trouble Shooting Workshop Manual

S7-UNAE11A 2/3

S7-UNAE11A 3/3

Page 2

CHAPTER REFERENCES REGARDING THIS WORKSHOP MANUAL

Use this chart to the appropriate chapter numbers for servicing your particular vehicle.

MANUAL NO. S1-UNAE11A 1/2 (U.S.A.), S1-CNAE11A 1/2 (CANADA)

CHAPTER

GENERAL INTRODUCTION GN02-001

CLUTCH MAIN UNIT CL02-001 CL02-002

CLUTCH CONTROL CL03-001

TRANSMISSION MAIN UNIT TR02-001

AUTOMATIC TRANSMISSION

TRANSMISSION/TRANSFER CONTROL

PROPELLER SHAFT

DIFFERENTIAL CARRIER

BRAKE EQUIPMENT BR01-001 BR01-002

SERVICE BRAKE BR02-001 BR02-002

ABS (ANTI-LOCK BRAKE SYSTEM) BR03-001 BR03-002

EXHAUST BRAKE BR05-001

PARKING BRAKE BR07-001

MODELS HINO 238, 258LP, 268, 338, 358

Production Model

Code

TR04-001

TR06-001

NE8J, NF8J, NJ8J, NV8J

PP02-001

DF02-001

TR04-002

TR06-002

STEERING EQUIPMENT SR01-001

STEERING UNIT SR02-001

POWER STEERING SR03-001

FRONT AXLE AX02-001

REAR AXLE

WHEEL & TIRE AX04-001

SUSPENSION SU02-001

CHASSIS FRAME FC02-001

CAB CA02-001

ELECTRICAL EQUIPMENT EL01-001

ELECTRIC WIRE EL02-001

This manual does not contain items on half-tone dot meshing.

AX03-001

Page 3

INDEX: CHASSIS GROUP 1/4

GENERAL INTRODUCTION

CLUTCH EQUIPMENT

CLUTCH MAIN UNIT

WORKSHOP

MANUAL

CLUTCH CONTROL

TRANSMISSION EQUIPMENT

TRANSMISSION MAIN UNIT

TRANSFER MAIN UNIT

AUTOMATIC TRANSMISSION

PTO (POWER TAKE-OFF)

TRANSMISSION / TRANSFER CONTROL

PROPELLER SHAFT EQUIPMENT

PROPELLER SHAFT

DIFFERENTIAL EQUIPMENT

DIFFERENTIAL CARRIER

BRAKE EQUIPMENT

SERVICE BRAKE

ABS

Page 4

INDEX: CHASSIS GROUP 2/4

ES START (EASY & SMOOTH START) SYSTEM

EXHAUST BRAKE

RETARDER BRAKE

PARKING BRAKE

STEERING EQUIPMENT

STEERING UNIT

POWER STEERING

AXLE EQUIPMENT

FRONT AXLE

REAR AXLE

WHEEL & TIRE

SUSPENSION EQUIPMENT

SUSPENSION

CHASSIS EQUIPMENT

CHASSIS FRAME

COUPLER (5TH WHEEL)

PINTLE HOOK

Page 5

INDEX: CHASSIS GROUP 3/4

CAB EQUIPMENT

CAB

ELECTRICAL EQUIPMENT

ELECTRIC WIRE

HYBRID SYSTEM

Page 6

INDEX: CHASSIS GROUP 4/4

ENGINE CONTROL

FUEL CONTROL

BRAKE CONTROL

SUSPENSION CONTROL

CAB EQUIPMENT CONTROL

OTHERS

Page 7

GENERAL INTRODUCTION (CHASSIS) GN02–1

GN0 2

GENERAL INTRODUCTION (CHASSIS)

GENERAL INTRODUCTION.....................GN02-2

GENERAL PRECAUTIONS.............................GN02-2

IDENTIFICATION INFORMATION ...................GN02-5

HOW TO USE

THIS WORKSHOP MANUAL.........................GN02-12

PRECAUTIONS.............................................GN02-15

SEALANT ON THE TAPERED SCREW

FOR PIPING ..................................................GN02-18

NYLON TUBE REPLACEMENT METHOD ...GN02-19

METRIC INFORMATION ...............................GN02-21

SPECIFIED TORQUE

FOR STANDARD BOLTS AND NUTS ...........GN02-23

SPECIFIED TORQUE

FOR FLANGE BOLTS AND NUTS ................GN02-23

RECOMMENDED LUBRICANTS ..................GN02-25

VEHICLE LIFT

AND SUPPORT LOCATIONS........................GN02-27

INFORMATION DISPLAY ..............................GN02-29

SYMPTOM SIMULATION ..............................GN02-34

GLOSSARY ...................................................GN02-36

GLOSSARY OF SAE AND HINO TERMS.....GN02-39

GN02-001

Page 8

GENERAL INTRODUCTION (CHASSIS)GN02–2

GENERAL INTRODUCTION

GENERAL PRECAUTIONS

EN00Z00020100001

Some recommended and standard maintenance services for your vehicle are included in this section. When performing maintenance on your vehicle be careful not to get injured by improper work. Improper or incomplete work can cause a malfunction

of the vehicle which may result in personal injury and/or property damage. If you have any question about performing maintenance, please consult your Hino dealer.

WARNING

When working on your vehicle, observe the following general precautions to prevent death, personal injury and/or

property damage in addition to the particular DANGERS, WARNINGS, CAUTIONS and NOTICES in each chapter.

• Always wear safety glasses or goggles to protect your eyes.

• Remove rings, watches, ties, loose hanging jewelry and loose clothing before starting work on the vehicle.

• Bind long hair securely behind the head.

• When working on the vehicle, apply the parking brake firmly, place the gear shift lever in "Neutral" or "N" and

block the wheels.

• Always turn off the starter switch to stop the engine, unless the operation requires the engine running. Remov-

ing the key from the switch is recommended.

• To avoid serious burns, keep yourself away from hot metal parts such as the engine, exhaust manifold, radia-

tor, muffler, exhaust pipe and tail pipe.

• Do not smoke while working on the vehicle since fuel, and gas from battery are flammable.

• Take utmost care when working on the battery. It contains corrosive sulfuric acid.

• Large electric current flows through the battery cable and starter cable. Be careful not to cause a short which

can result in personal injury and/or property damage.

• Read carefully and observe the instructions specified on the jack before using it.

• Use safety stands to support the vehicle whenever you need to work under it. It is dangerous to work under a

vehicle supported only by a jack.

• If it is necessary to run the engine after the hood is raised (tilted), make sure that the parking brake is firmly

applied, the wheels are blocked, and the gear shift lever is positioned in "Neutral" before staring the engine.

• Run the engine only in a well-ventilated area to avoid inhalation of carbon monoxide.

• Keep yourself, your clothing and your tools away from moving parts such as the cooling fan and V-belts when

the engine is running.

• Be careful not to damage lines and hoses by stepping or holding your feet on them.

• Be careful not to leave any tool in the engine compartment. The tool may be hit by moving parts, which can

cause personal injury.

DEFINITION OF SAFETY TERMS

Indicates an extremely hazardous situation if proper procedures are not followed and could

result in death or serious injury.

Indicates a potential hazardous situation if proper procedures are not followed and could

result in death or serious injury.

Indicates a hazardous situation if proper procedures are not followed and could result in

serious injury or damage to parts/equipment.

Indicates the need to follow proper procedures and to pay attention to precautions so that

efficient service is provided.

Provides additional information to help you to perform the repair efficiently.

Page 9

GENERAL INTRODUCTION (CHASSIS) GN02–3

TOWING

• When being towed, always place the gear shift lever in "Neutral" and release the parking brake completely. In order to

protect the bumper, fit a protection bar against the lower edge of the bumper and put a wood block under the frame near

the No. 1 cross member when attaching the towing chain. Never lift or tow the vehicle if the chain is in direct contact with

the bumper.

1. Towing procedures

(1) Make sure that the propeller shaft of the vehicle to be towed is removed. When the differential gear or rear axle shaft is

defective, remove both right and left rear axle shafts, then cover the hub opening to prevent loss of axle lubricant and

entry of dirt or foreign matter.

(2) Use a heavy duty cable or rope when towing the vehicle. Fasten the cable securely to the towing hook on the frame.

(3) The angle of pulling direction of the cable fastened to the towing hook must not exceed 15 in horizontal and vertical

directions from the straight ahead, level direction. Avoid using the hook in a way that subjects it to jerk, as in towing a

vehicle trapped in a gutter.

(4) Keep the gear shift lever in Neutral.

(5) Make sure that the starter switch is kept in the "ON" position, if the engine is not running.

(6) Make sure that the engine of the towed vehicle is kept running. If the engine is off, no compressed air/ no vacuum will be

available for the brake. This is dangerous, as the brake system does not function if the engine is not running.

In addition, the power steering system will not function. The steering wheel, therefore, will become unusually hard to turn,

making it impossible to control the vehicle.

(7) Note that the engine brake and exhaust brake cannot be applied, if the propeller shaft is removed.

(8) Make a slow start to minimize shock. Towing speed should be less than 30 km/h {18 mile/h}.

2. If the engine of the towed vehicle is defective, make sure that the vehicle is towed only by a tow truck designed

for that purpose.

(1) Front end towing (with front wheels raised off the ground)

When towing from the front end with the front wheels raised off the ground, remove the rear axle shafts to protect the

transmission and differential gears from being damaged. The hub openings should be covered to prevent the loss of axle

lubricant or the entry of dirt or foreign matter. The above-mentioned precautions should be observed for vehicles

equipped with either manual or automatic transmission, and for even short distance towing. After being towed, check and

refill the rear axle housing with lubricant if necessary.

(2) Rear end towing

When being towed with the rear wheels raised off the ground, fasten and secure the steering wheel in a straight-ahead

position.

CLEAN AIR ACT

1. Heavy-duty engine rebuilding practices.

§ 86.004-40

• The provisions of this section are applicable to heavy-duty engines subject to model year 2004 or later standards and are

applicable to the process of engine rebuilding (or rebuilding a portion of an engine or engine system). The process of

engine rebuilding generally includes disassembly, replacement of multiple parts due to wear, and reassembly, and also

may include the removal of the engine from the vehicle and other acts associated with rebuilding an engine. Any deviation

from the provisions contained in this section is a prohibited act under section 203(a) (3) of the Clean Air Act (42 U.S.C.

7522(a) (3)).

(1) When rebuilding an engine, portions of an engine, or an engine system, there must be a reasonable technical basis for

knowing that the resultant engine is equivalent, from an emissions standpoint, to a certified configuration (i.e., tolerances,

calibrations, specifications) and the model year(s) of the resulting engine configuration must be identified. A reasonable

basis would exist if:

a. Parts installed, whether the parts are new, used, or rebuilt, are such that a person familiar with the design and func-

tion of motor vehicle engines would reasonably believe that the parts perform the same function with respect to emissions control as the original parts; and

b. Any parameter adjustment or design element change is made only:

In accordance with the original engine manufacturer's instructions; or

Where data or other reasonable technical basis exists that such parameter adjustment or design element change,

when performed on the engine or similar engines, is not expected to adversely affect in-use emissions.

(2) When an engine is being rebuilt and remains installed or is reinstalled in the same vehicle, it must be rebuilt to a configu-

ration of the same or later model year as the original engine. When an engine is being replaced, the replacement engine

must be an engine of (or rebuilt to) a configuration of the same or later model year as the original engine.

Page 10

GENERAL INTRODUCTION (CHASSIS)GN02–4

(3) At time of rebuild, emissions-related codes or signals from on-board monitoring systems may not be erased or reset with-

out diagnosing and responding appropriately to the diagnostic codes, regardless of whether the systems are installed to

satisfy requirements in § 86.004-25 or for other reasons and regardless of form or interface. Diagnostic systems must be

free of all such codes when the rebuilt engine is returned to service. Such signals may not be rendered inoperative during

the rebuilding process.

(4) When conducting a rebuild without removing the engine from the vehicle, or during the installation of a rebuilt engine, all

critical emissions-related components listed in § 86.004-25(2) not otherwise addressed by paragraphs (1) through (3) of

this section must be checked and cleaned, adjusted, repaired, or replaced as necessary, following manufacturer recommended practices.

(5) Records shall be kept by parties conducting activities included in paragraphs (1) through (4) of this section. The records

shall include at minimum the mileage and/or hours at time of rebuild, a listing of work performed on the engine and emissions-related control components including a listing of parts and components used, engine parameter adjustments, emissions-related codes or signals responded to and reset, and work performed under paragraph (4) of this section.

a. Parties may keep records in whatever format or system they choose as long as the records are understandable to an

EPA enforcement officer or can be otherwise provided to an EPA enforcement officer in an understandable format

when requested.

b. Parties are not required to keep records of information that is not reasonably available through normal business prac-

tices including information on activities not conducted by themselves or information that they cannot reasonably

access.

c. Parties may keep records of their rebuilding practices for an engine family rather than on each individual engine

rebuilt in cases where those rebuild practices are followed routinely.

d. Records must be kept for a minimum of two years after the engine is rebuilt.

2. Maintenance instructions.

§ 86.010-38

(1) For each new diesel-fueled engine subject to the standards prescribed in § 86.007-11, as applicable, the manufacturer

shall furnish or cause to be furnished to the ultimate purchaser a statement that

"This engine must be operated only with ultra low-sulfur diesel fuel (meeting EPA specifications for highway diesel fuel, including a 15 ppm sulfur cap)."

Page 11

GENERAL INTRODUCTION (CHASSIS) GN02–5

VIN

label

IDENTIFICATION INFORMATION

EN00Z00020200001

1. VEHICLE IDENTIFICATION NUMBER

• VEHICLE IDENTIFICATION NUMBER (VIN) is comprised of 17 digits and letters. The VIN label is affixed to the left pillar

of the cab.

These numbers are used for identification purposes when you have a vehicle registered or inspected. Please quote these

numbers when ordering spare parts or reporting technical matter to receive prompt service attention.

• The following is an explanation of the items that are listed on the VIN label.

Page 12

GENERAL INTRODUCTION (CHASSIS)GN02–6

(1) VIN

See VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE on the following page.

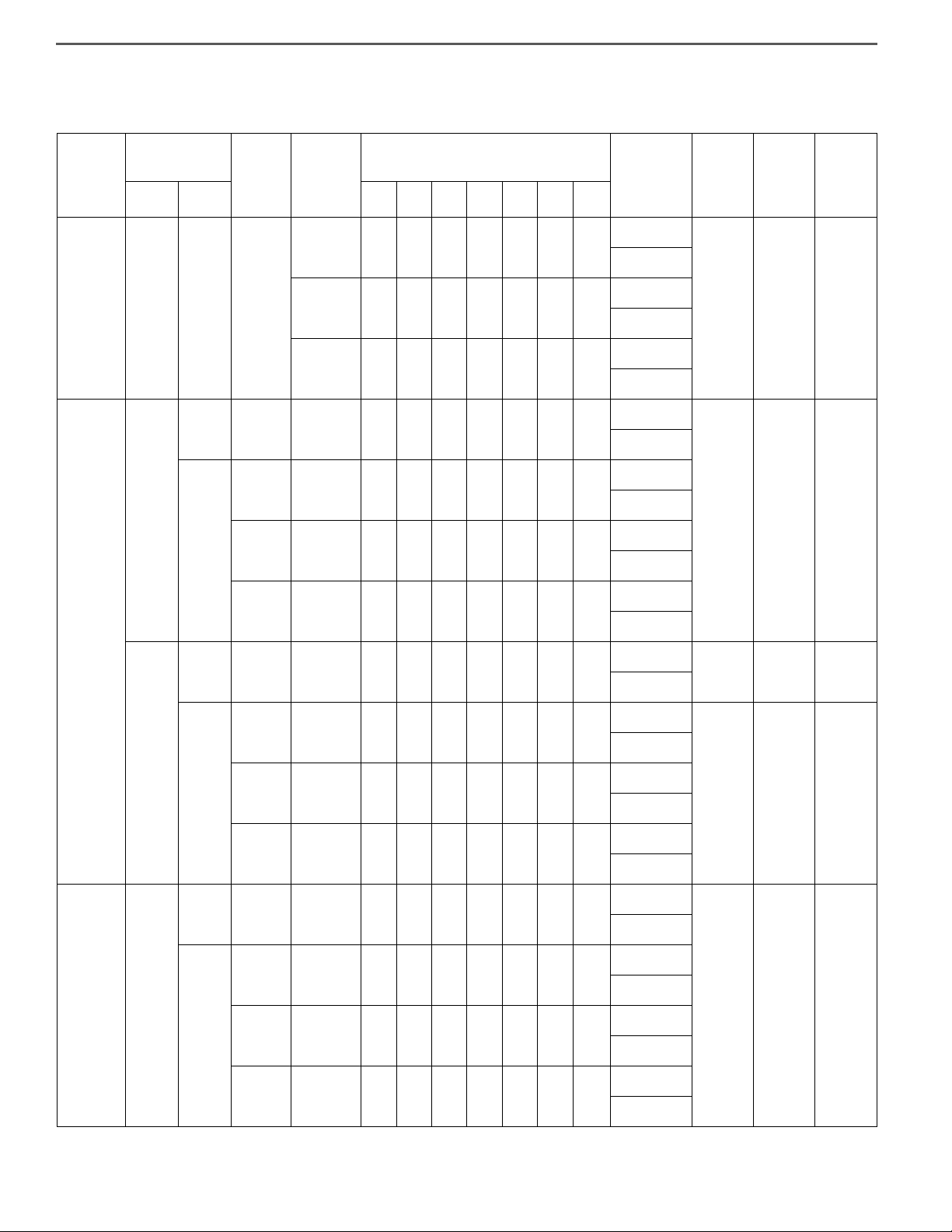

(2) P.S. (PRODUCTION SERIES) AND VEHICLE COMPONENTS

MODEL

(CLASS)

HINO238

(6)

HINO258

(6)

PRODUC-

TION CODE

MODEL SERIES

CLUTCH

NE8J HBC -

GBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

NE8J

HBC

JBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

SIZE

TRANS-

MIS-

SION

SERIES

TRANSMISSION RATIO REAR

1st 2nd 3rd 4th 5th 6th Rev.

2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

AXLE

SERIES

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

SERVICE

BRAKE

PARK-

ING

BRAKE

SUSPEN-

SION

HDLor

A

HDLor

A

FWA

HINO268

(6)

NJ8J

NE8J

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

KBC

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

GBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

HBC

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

FWLor

A

HDLor

A

Page 13

GENERAL INTRODUCTION (CHASSIS) GN02–7

MODEL

(CLASS)

HINO268

(6)

PRODUC-

TION CODE

MODEL SERIES

JBC 350mm FS5406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

NJ8J

KBC

NBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

PBC

CLUTCH

SIZE

TRANS-

MIS-

SION

SERIES

TRANSMISSION RATIO REAR

1st 2nd 3rd 4th 5th 6th Rev.

- 2200HS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

- 2200RDS 3.10 1.81 1.41 1.00 0.71 0.61 4.49

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

AXLE

SERIES

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS17-145

RS19-145

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

SER-

VICE

BRAKE

PARK-

ING

BRAKE

FW

SUSPEN-

SION

L

or

A

HINO268

(7)

HINO338

(7)

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

NV8J

TBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

SBC

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

DBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63 RS21-145

NF8J

EBC - 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09 RS21-145

NV8J NBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

FWLor

HD

or

FW

A

L

A

Page 14

GENERAL INTRODUCTION (CHASSIS)GN02–8

MODEL

(CLASS)

HINO338

(7)

PRODUC-

TION CODE

MODEL SERIES

PBC

NV8J

TBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63

SBC

CLUTCH

SIZE

TRANS-

MIS-

SION

SERIES

TRANSMISSION RATIO REAR

1st 2nd 3rd 4th 5th 6th Rev.

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

- 2500RDS 3.51 1.90 1.44 1.00 0.74 0.64 5.09

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00

AXLE

SERIES

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

RS21-145

RS23-160

SERVICE

BRAKE

PARK-

ING

BRAKE

FWLor

SUSPEN-

SION

A

NBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63 RS23-160

PBC

HINO358

(8)

NH8J

TBC 350mm FS6406 9.01 5.27 3.22 2.04 1.36 1.00 8.63 RS23-160

SBC

CODE SERVICE BRAKE

H: Hydraulic

F: Full air

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03 RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00 RS23-160

- 3000RDS 3.49 1.86 1.41 1.00 0.75 0.65 5.03 RS23-160

- 3500RDS 4.59 2.25 1.54 1.00 0.75 0.65 5.00 RS23-160

PARKING BRAKE CONTROL CODE

D: ACTING ON DIFFERENTIAL

W: ACTING ON REAR WHEEL

FWLor

A

FWLor

A

SUSPENSION

L: LEAF

A: AIR

Page 15

GENERAL INTRODUCTION (CHASSIS) GN02–9

HINO VEHICLE IDENTIFICATION NUMBER (VIN) STRUCTURE FOR U.S.A. and CANADA (2015MY)

WMI VDS CD VIS

12 3 4 56 78 9 10111213141516

5P V NJ 8 J T 4 F4S10 0 0

17

1

MANUFACTURER TYPE

MAKE, MODEL

LINE & CAB/BODY TYPE,

SERIES, BRAKE SYSTEM

MODEL YEAR

ASSEMBLY PLANT

ENGINE MODEL

WHEEL BASE

CHECK DIGIT

MODIFICATION

SEQUENTIAL NUMBER

CODE

JHA

JHB

TRUCK

INCOMPLETE VEHICLE

TYPEMANUFACTURER

HINO MOTORS, LTD.

HINO MOTORS, LTD.

5PV INCOMPLETE VEHICLE

HINO MOTORS

MANUFACTURING

U.S.A., INC.

2AY INCOMPLETE VEHICLE

HINO MOTORS

CANADA, LTD.

CODE

P

CODE

2023

YEARYEAR

R 2024

S 2025

T 2026L 2020

M 2021

N 2022

H 2017

J 2018

K 2019

F 2015

G 2016

CODE

8J

J08E-VC

MODEL

7.6 LITERS, DIESEL 220HP

J08E-VB 7.6 LITERS, DIESEL 260HP

DESCRIPTIONMANUFACTURER

HINO MOTORS, LTD.

CODE

G 3,861

LENGTH

NE - NV

mm in.

J

4,445L4,750M5,207N5,385P5,512R5,969T6,426V6,883

152

175

187

205

212

217

235

253

271

CODE

S

DESCRIPTION

A NEW LETTER

T WILL BE ALLOTTED

U AT EVERY MAJOR

...

MODIFICATION

Z

CODE

1

ASSEMBLY PLANT

HINO MOTORS, LTD.

HINO PLANT IN JAPAN

3 Canada Plant

4 W.V Plant

MODEL

CODE

MAKE

NF

HYDRAULIC

LINE & CAB/BODY TYPE

INCOMPLETE VEHICLE

Intended GVWR and Vehicle Class

and Class

BRAKE

SYSTEMS

NV

FULL AIR

FULL AIR

INCOMPLETE VEHICLE

INCOMPLETE VEHICLE

INCOMPLETE VEHICLE

INCOMPLETE VEHICLE

NJ

10434 kg. - 11793 kg or less

[23,001 - 26,000 (lbs.)] (CLASS 6)

13609 kg. - 14968 kg or less

[30,001 - 33,000 (lbs.)] (CLASS 7)

13609 kg. - 14968 kg or less

[30,001 - 33,000 (lbs.)] (CLASS 7)

14969 kg - 15875 kg or less

[33,001 - 35,000 (lbs.) ] (CLASS 8)

NE

HINO

HINO

NHHINO

HINO

HINO

8846 kg. - 11793 kg or less

[19,501 - 26,000 (lbs.)] (CLASS 6)

HYDRAULIC

FULL AIR

SHTS00Z000200007

Page 16

GENERAL INTRODUCTION (CHASSIS)GN02–10

VEHICLE NOISE EMISSION CONTROL INFORMATION

THIS VEHICLE CONFORMS TO U.S. EPA REGULATIONS FOR NOISE

EMISSION APPLICABLE TO MEDIUM AND HEAVY TRUCKS.

THE FOLLOWING ACTS OR THE CAUSING THEREOF BY ANY PERSON ARE

PROHIBITED BY THE NOISE CONTROL ACT OF 1972.

(A)THE REMOVAL OR RENDERING INOPERATIVE. OTHER THAN FOR

PURPOSES OF MAINTENANCE, REPAIR, OR REPLACEMENT, OF ANY

NOISE CONTROL DEVICE OR ELEMENT OF DESIGN (LISTED IN THE

OWNER' S MANUAL) INCORPORATED INTO THIS VEHICLE IN

COMPLIANCE WITH THE NOISE CONTROL ACT.

(B)THE USE OF THIS VEHICLE AFTER SUCH DEVICE OR ELEMENT OF

DESIGN HAS BEEN REMOVED OR RENDERED INOPERATIVE.

MFD BY:HINO MOTORS, LTD. DATE OF MANUFACTURE 03/2009

For all models

SHTS00Z000200010

SHTS00Z000200011

SHTS00Z000200012

SHTS00Z000200013-C

2. VEHICLE NOISE EMISSION CONTROL INFORMATION

• The Vehicle Noise Emission Control Information is affixed to the side

of the left door. The name of manufacturer, production year and

month, and noise emission applicable to medium and heavy trucks in

conformity with U.S. EPA Regulations are displayed.

3. ENGINE SERIAL NUMBERS.

• Please quote these numbers when ordering spare parts or reporting

technical matter to receive prompt service attention.

The engine serial number is engraved on the engine cylinder block.

4. CHASSIS SERIAL NUMBER

• Chassis serial number is engraved on the left side frame near the

front wheel.

5. CLEAN IDLE CERTIFIED LABEL FOR U.S.

• Make sure that the following clean engine idling certified label is

affixed to the outside of the left door.

By the CARB below, the label must be affixed there to prove that the

new vehicle with diesel engine manufactured from Jan., 2008 conforms to this low.

CARB § 1956.8. Exhaust Emission Standard and Test Procedure

(a) (b) Heavy-Duty Diesel Engine Idling Requirements

Page 17

GENERAL INTRODUCTION (CHASSIS) GN02–11

GN02-13-1-0

For example

GN02-13-1-1

VIN

label

Vehicle emission

control information

6. VEHICLE EMISSION CONTROL INFORMATION

• The Vehicle Emission Control Information is affixed to the side of the

left door. The name of manufacturer, production year and month, and

emission applicable to medium and heavy trucks in conformity with

U.S. EPA Regulations are displayed.

Page 18

GENERAL INTRODUCTION (CHASSIS)GN02–12

HOW TO USE THIS WORKSHOP MANUAL

EN00Z00020200002

This workshop manual is designed as a guide for servicing the vehicle.

An INDEX is provided on the first page of each chapter.

TROUBLESHOOTING is dealt with in each chapter.

When beginning operations, refer to the TROUBLESHOOTING section for

a guide to appropriate diagnosis.

SPECIAL TOOL is dealt with in each chapter.

When ordering a special tool, confirm the part number with the applicable

parts catalog.

• RERAIR PROCEDURES

Repair procedures when self-explanatory, such as simple installation

and removal of parts, have been omitted. Illustrations, such as the

one below, have been provided to make such simple procedures

clear. Only essential procedures requiring specific directions have

been dealt with explicitly.

Page 19

GENERAL INTRODUCTION (CHASSIS) GN02–13

SHTS00Z000200014

MAIN CYLINDER

EXAMPLE:

1 Clevis 8 Return spring

2 Lock nut 9 Body

3 Push rod 10 Hose joint

4 Boot 11 O-ring

5 Retainer ring 12 Soft washer

6 Thrust washer 13 Bolt

7Piston

Tightening torque Unit: Nm {kgfcm, lbfft}

A 2.5-4.4 {25-45, 1.8-3.2}

In some cases, illustrations may be of parts which differ in some nonessential way from the parts found on your particular vehicle. In such cases, the

principle or procedure being illustrated applies regardless of such nonessential differences.

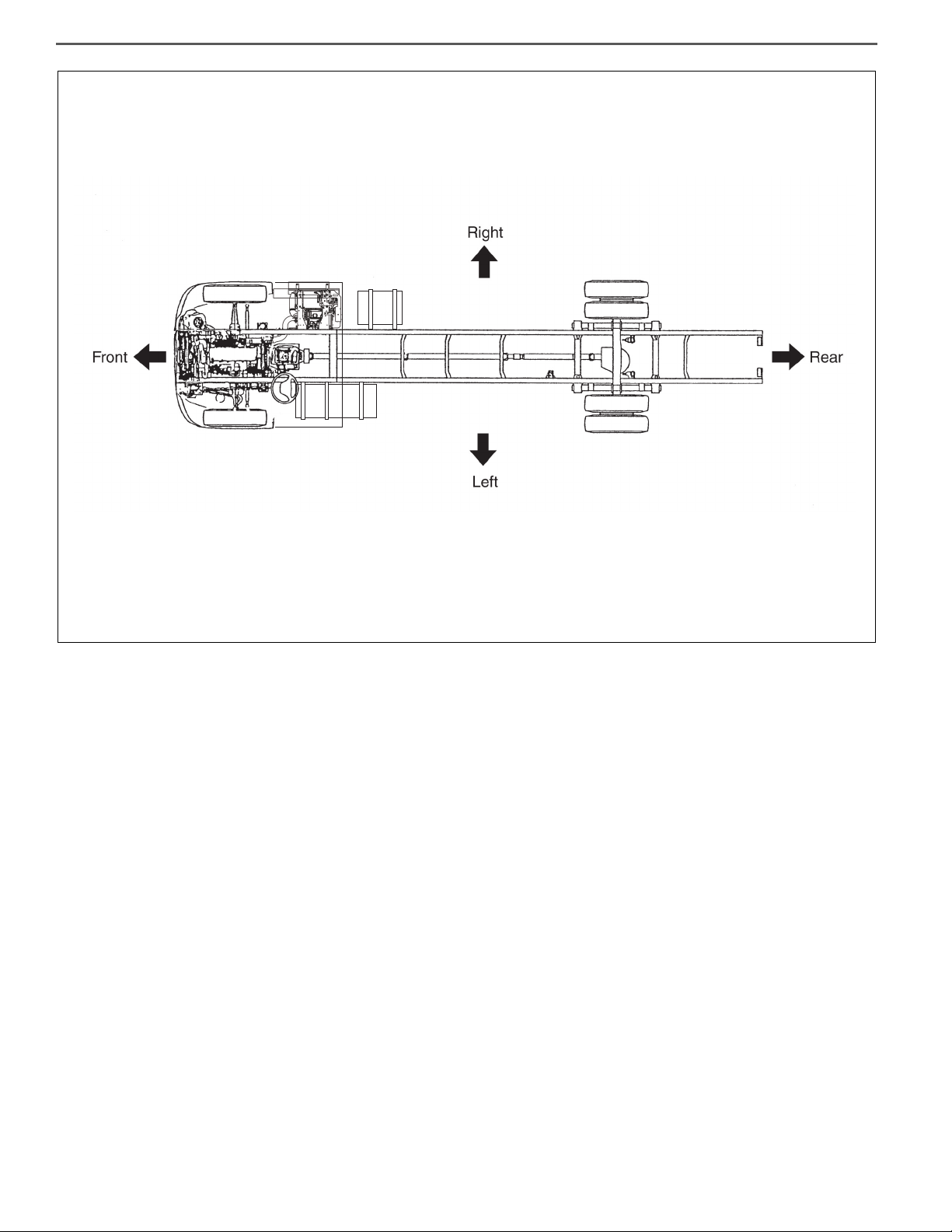

• DEFINITION OF TERMS

Definition of vehicle right and left.

Right and left refers to the left and right sides of the vehicle as seen

while looking down the center line from the rear towards the front.

Page 20

GENERAL INTRODUCTION (CHASSIS)GN02–14

SHTS00Z000200015C

Page 21

GENERAL INTRODUCTION (CHASSIS) GN02–15

! WARNING

Loosen

saph00z000200008

Incorrect

saph00z000200009

Incorrect

Incorrect

Incorrect

saph00z000200010

PRECAUTIONS

EN00Z0002C100001

PRECAUTIONS FOR ELECTRICAL SYSTEM

1. REMOVING THE BATTERY CABLE

• Be sure to wait for at least ten minutes after the starter key is

turned to "LOCK" position before you disconnect the battery terminals from the battery, as the vehicle data is recorded on ECU

and DCU starts working for the exhaust gas after treatment after

the starter key is turned to "LOCK" position. Otherwise, the vehicle data will not be recorded on ECU properly and DCU will not

complete working properly, which may result in the malfunction

of DPR system and DEF-SCR system.

• The MIL (malfunction indicator light) may come on when the

starter key is turned to "ON" position again, even if you wait for

at least ten minutes before disconnecting the battery terminals

from the battery after the starter key is turned to "LOCK" position. In this case, use HINO DX Ⅱ to clear the DTC (P204F and

P068A), to turn off the MIL and to conduct DPR regeneration

manually.

(1) Before electrical system work, remove the cable from the minus termi-

nal of the battery in order to avoid burning caused by short-circuiting.

(2) To remove the battery cable, fully release the nut to avoid damage to

the battery terminal. Never twist the terminal.

2. HANDLING OF ELECTRONIC PARTS

(1) Never give an impact to electronic parts of a computer or relay.

(2) Keep electronic parts away from high temperatures and humidity.

(3) Never splash water onto electronic parts in washing the vehicle.

(4) Do not remove the harness connector, electric component box, and

cover except for repair and inspection.

If removal is necessary, pay attention that water and foreign matters

do not attach or enter to the connector, terminals, electric component

box, and cover.

In restoration, make sure there is no attachment or entry of water and

foreign matters and mount them properly, because it causes degradation of waterproof function.

3. HANDLING OF WIRE HARNESS

(1) Perform marking on a clamp and a clip and secure then in original

position so that the wire harness will not interfere with the end and

acute angle section of the body and a bolt.

(2) To attach a part, take care not to bite the wire harness.

Page 22

GENERAL INTRODUCTION (CHASSIS)GN02–16

! WARNING

! WARNING

Incorrect

Incorrect

Correct

saph00z000200011

4. HANDLING OF CONNECTOR

(1) To remove a connector, hold the connector (indicated by an arrow in

the figure) to pull it out. Never pull the harness.

(2) To remove a connector with lock, release the lock then pull it out.

(3) To connect a connector with lock, insert it until it clicks.

(4) To insert a test lead into the connector, insert it from behind the con-

nector.

(5) In case it is difficult to insert a test lead from behind the connector,

prepare a harness for inspection and perform inspection.

5. INSTALLATION OF BATTERY DISCONNECT SWITCH

• Installation of the battery disconnect switch on the power supply

circuit for the dosing control unit of DEF-SCR (DCU) may dam-

age or result in the malfunction of DEF-SCR system.

• Be sure to read and follow the procedures and instructions on

the service bulletin before the installation of the battery discon-

nect switch.

6. HANDLING OF BATTERY DISCONNECT SWITCH

• Wait for at least one minute before using the battery disconnect

switch after the starter key is turned to "LOCK" position.

Otherwise, the vehicle data will not be recorded on ECU properly,

which may result in the malfunction of DPR system.

Page 23

GENERAL INTRODUCTION (CHASSIS) GN02–17

saph00z000200012

PRECAUTIONS FOR ELECTRIC WELDING

1. PRECAUTION FOR ELECTRIC WELDING

Electrical components such as the alternator and tachograph are

directly connected to the battery and one end is earthed to the

chassis frame. Under these conditions, welding current will flow

back along the earth circuit if electric welding is carried out and

damage may be caused to the alternator, tachograph, electrical

components, etc. Consequently, the following precautions are

always to be taken during welding.

(1) Disconnect the earth terminal of the battery at the frame fitment and

earth the welding equipment securely to the frame itself. (Do not fit the

welding equipment earth to such things as the tire rims, brake pipes

or fuel pipes and leaf spring, etc.)

a. Turn the starter switch off.

b. Disconnect the negative terminal of the battery.

c. Earth welding equipment securely, near to the area to be welded.

d. Put back battery negative ground as original condition.

e. Finally check the functioning of all instruments.

Alternator

etc.

ARC welding

machine

Computer

Battery

Disconnect the ground terminal for

battery at the connecting point on the

frame and disconnect the ground for

computer as well.

Chassis frame Chassis frame

Connect the ground of the ARC welding

machine near the place on the frame to be

welded but not connect it to plated parts such

as fuel pipes, brake pipes and leaf spring.

(2) In order to prevent damage to ancillary equipment components from

sparks during welding, take steps such as putting fire-resistant covers

over things like the engine, meters, steering wheel, hoses, tubes, leaf

spring and tires.

Page 24

GENERAL INTRODUCTION (CHASSIS)GN02–18

! WARNING

SHTS00Z000200021

SHTS00Z000200022

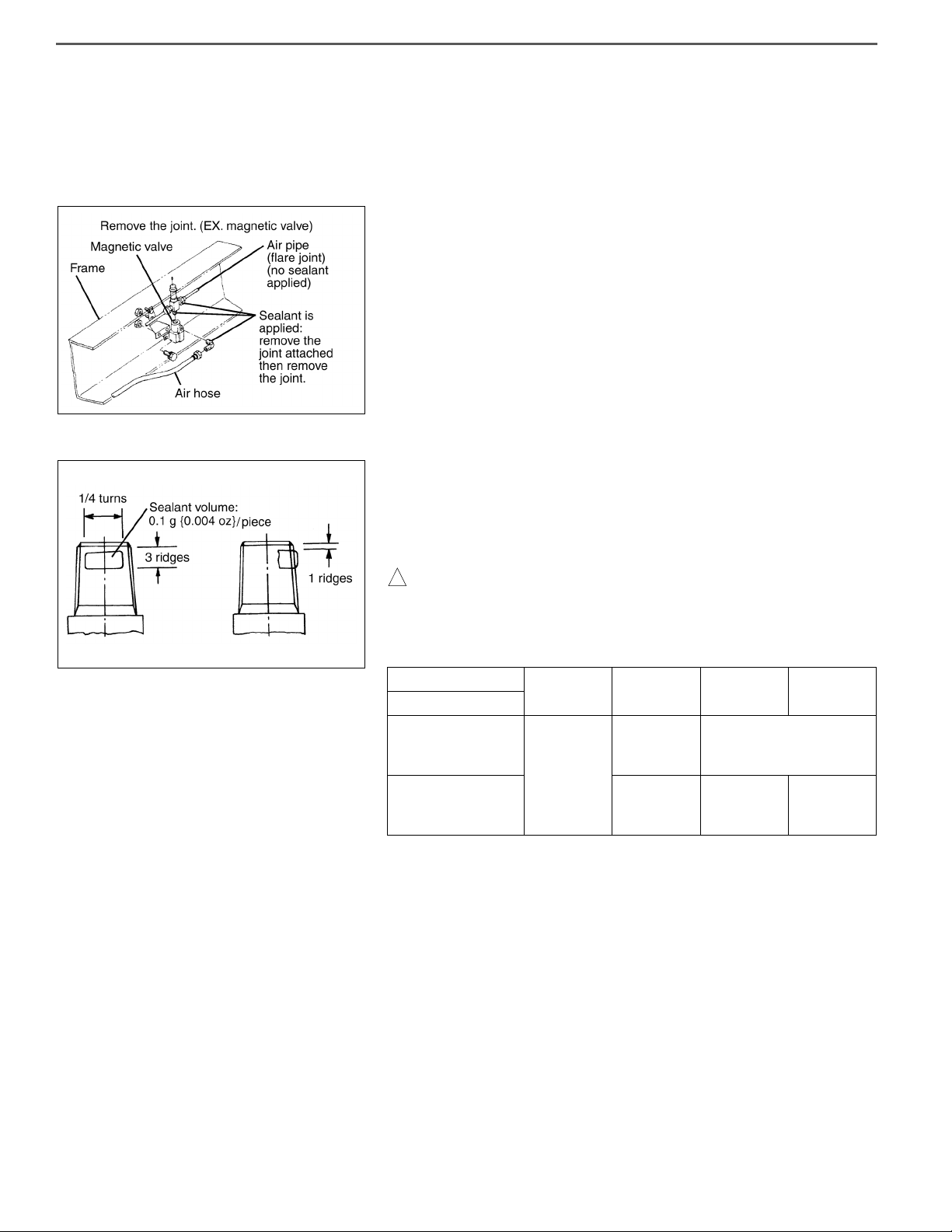

SEALANT ON THE TAPERED SCREW FOR PIPING

EN00Z00020200003

To the tapered thread of the air pipe joint is applied the sealant "LOC-TITE

#575". Follow the procedure below to remove/attach the piping.

1. REMOVAL

(1) The sealant (LOCTITE #575) has a high sealing capability. The return

torque of taper joint is about 1.5 times as high as the initial tightening

torque. To remove the joint, use a longer wrench.

(2) For replacement of joint in a place with poor workability, remove the

auxiliaries with the joint attached then remove the joint.

2. ATTACHING

(1) To apply sealant (LOCTITE #575), use waste and thinner to wipe the

dirt off the sealing section, directly apply the sealant by a quarter turn

(three ridges) starting from the second ridge from the tip, then assemble in accordance with the tightening torque table below.

Wipe dirt off the mating part (female screw) before tightening it.

In case the sealant has entered your eye or attached to your skin,

wash it away in running water.

Tightening torque of tapered joint Unit: Nm {kgfcm, lbfft}

Screw diameter

Material

1/8 1/4 3/8 1/2

4910

Steel

Aluminum, brass

205

{20050,

14.43.6}

{500100,

36.27.2}

255

{25050,

18.13.6}

6415 {650150, 4710}

345

{35050,

25.33.6}

445

{45050,

32.53.6}

(2) To replace vulcanized tape with sealant, remove the tape before-

hand, same as (1).

NOTICE

Take special care not to let dirt and foreign matters enter the piping.

(3) In the event of air leakage after sealant is applied and piping attached,

retightening cannot check the air leakage. Follow the steps (1) and (2)

to reassemble the piping.

Page 25

GENERAL INTRODUCTION (CHASSIS) GN02–19

One-touch joint

Caulking joint

SHTS00Z000200023

Insertion length

Nylon tube

SHTS00Z000200024

SHTS00Z000200025

Less than 5˚

SHTS00Z000200026

NYLON TUBE REPLACEMENT METHOD

EN00Z00020200004

NYLON TUBE REPLACEMENT METHOD

• In this vehicle, nylon tubes are used for all the air tubes except those

on the charge line and the rear axle, the tubing for the wheel power

signal, a portion of the accessory system tubing, and for the unloader

tubing, and it is also used in joints, depending on the connection conditions of the two types of joints; one-touch joints and caulking joints.

NOTICE

Since the function and quality of nylon tubes and joints are guaranteed as tube and joint sets, the use of parts other than Hino Genuine

Parts must be avoided.

1. ONE-TOUCH JOINT NYLON TUBE INSERTION LENGTH

DIAMETER

(Outside diameter x inside diam-

eter)

1/4 in. 14-19 {0.55-0.75}

3/8 in. 18-23 {0.71-0.91}

1/2 in. 21-26 {0.83-1.02}

INSERTION LENGTH

mm {in.}

2. REMOVAL OF A ONE-TOUCH JOINT

(1) Make sure there is no dirt or grease stuck to the connector end. If the

end is dirty, clean it thoroughly by air blowing or other means.

(2) Using the special tool for removing the nylon tube to push the connec-

tor end, pull off the nylon tube with your hand in one stroke, without

stopping partway, pulling the tube in the connector axial direction.

SST:

Puller (S0942-11490)

INSTALLATION OF A ONE-TOUCH JOINT AND CAULKING JOINT

• Make sure the joint interior is free of dirt grease. If the interior is dirty,

clean it thoroughly by air blowing or other means.

• Cut off the tube end where the tube surface is scarred by the joint

pinch marks, and make sure that the part of the tube inserted into the

joint has no surface damage. If the tube is damaged, cut off the damaged part (provided that the tube length is more than sufficient).

NOTICE

Use the special nylon tube cutter when cutting the nylon tube, and cut

the tube so that the angle of the cut end to the axial center is 85-95.

1. INSTALLATION OF A ONE-TOUCH JOINT

Page 26

GENERAL INTRODUCTION (CHASSIS)GN02–20

Aligning marks

SHTS00Z000200027

•

Before inserting the tube, mark the insertion length on the tube with a

white-out pen or similar implement, in accordance with the dimensions, "ONE-TOUCH JOINT NYLON TUBE INSERTION LENGTH."

Then insert the tube firmly in place as far as the marked point.

2. INSTALLATION OF A CAULKING JOINT

• Press in the tube so that it does not move (will not come out), and

tighten the sleeve nut with the tightening tool to the torque shown in

the following table.

3. NYLON TUBE NUT TIGHTENING TORQUE

Unit: Nm {kgfcm, lbfft}

NUT DIAMETERS TIGHTENING TORQUE

1/4 in. 20-26 {200-270, 15-19}

3.8 in. 35-45 {350-460, 26-33}

1/2 in. 50-60 {500-610, 37-44}

NOTICE

Nuts must be tightened to 5- 35C.

4. ASSEMBLING THE CAULKING JOINT (AFTER THE TUBE HAS

FIRST BEEN REMOVED FROM THE JOINT AND THEN REINSTALLED IN THE SAME PLACE)

(1) Make aligning marks on the connector and union to mark their posi-

tions before loosening the nut.

(2) When re-assembling the joint, tighten the nut until the pre-disassem-

bly position (position of aligning marks) is reached, and then tighten

the nut 60 more.

(3) Always check air leakage after assembling the joint. If air is leaking

from the joint, continue tightening the sleeve nut until the leak stops.

(4) If the air leak does not stop, replace the tube, sleeve, and insert with

new parts. If the air leak still continues, replace the nut and connector

/ union.

NOTICE

• During repair or other work, make sure the temperature limit of

the nylon tube is within -40-90C, especially during paint drying

work.

• During boring, welding, sanding, and other work, protect nylon

tubes from tools, cuts, heat sources, and sparks, or remove the

nylon tubes beforehand.

• Do not attach a welding equipment clamp near the nylon tube.

• Do not pour battery fluid or other acidic fluid on the nylon tube.

• Do not bend the nylon tube beyond the nylon tube bending

radius R values shown in the following table. Also, do not use

the remaining portion of a tube that has broken due to overbending.

OUTSIDE DIAMETER OF

TUBE

MINIMUM BENDING RADIUS DURING

HANDLING: R mm {in.}

1/2 in. 30 {1.18}

3/8 in. 65 {2.56}

1/2 in. 70 {2.76}

Page 27

GENERAL INTRODUCTION (CHASSIS) GN02–21

Metric system

M12-1.75 25

DT L

P

7

T

L

D

7

9

D- Nominal Diameter P- Property Class

(millimeters) (bolt strength)

L- Length (millimeters) T- Thread Pitch (thread

width crest to crest

millimeters)

Metric Bolts P Identification class numbers correspond to bolt strength. Increasing numbers represent increasing strength.

Nomenclature for bolts

Bolt strength identification

Bolt

SHTS00Z000200028

METRIC INFORMATION

EN00Z00021200001

METRIC FASTENERS

1. Most threaded fasteners on the Hino trucks series are metric.

Be careful not to mix them up with threaded fasteners using the

inch system.

Mismatched or incorrect bolts, nuts and screws can cause damage or malfunction, resulting in personal injury and/or property

damage.

2. When bolts, nuts and screws are removed from the vehicle, they

should be kept for reuse whenever possible.

If they are not re-usable, parts that are equivalent to the original

parts in dimensions, strength, and thread pitch must be

selected.

3. Most original bolts are marked with identification numbers indicating the strength of the bolts. The markings are shown below.

4. When replacing bolts, be careful to use bolts with the same

markings as the original bolts.

Page 28

GENERAL INTRODUCTION (CHASSIS)GN02–22

DECIMAL AND METRIC EQUIVALENTS

Fractions Decimal In. Metric mm. Fractions Decimal In. Metric mm.

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 17/32 0.53125 13.494

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.09375 2.381 19/32 0.59375 15.081

7/64 0.109375 2.778 39/64 0.609375 15.478

1/8 0.125 3.175 5/8 0.625 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.763 11/16 0.6875 17.463

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.250 6.35 3/4 0.750 19.05

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.54 51/64 0.796875 20.241

5/16 0.3125 7.938 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.375 9.525 7/8 0.875 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.113 15/16 0.9375 23.813

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.500 12.7 1 1.00 25.4

Page 29

GENERAL INTRODUCTION (CHASSIS) GN02–23

No Mark

7

q

SPECIFIED TORQUE FOR STANDARD BOLTS AND NUTS

Class 4T 7T 9T

Representation

Diameter

M6

M8 11.5-16.5 {114-172, 8.3-12.4}

M10

M12

M14

M16

{976-1,464, 70.6-105.8}

4.4-6.6

{45-67, 3.3-4.8}

22.0-32.0

{221-331, 16.0-23.9}

38.5-57.5

{392-588, 28.4-42.5}

62.0-92.0

{629-943, 45.5-68.1}

96.0-144.0

{976-1,464, 70.6-105.8}

{1,552-2,328, 112.3-168.3}

7.2-10.8

{74-110, 5.4-7.9}

18.0-26.0

{179-269, 13.0-19.4}

34.5-51.5

{351-527, 25.4-38.1}

61.0-91.0

{621-931, 44.9-67.3}

96.0-144.0

152.0-228.0

{816-1,224, 59.0-88.5}

{1,304-1,956, 94.3-141.4}

{2,040-3,060, 147.5-221.2}

EN00Z00023200001

Unit: Nm {kgfcm, lbfft.}

9.5-13.5

{94-140, 6.8-10.1}

23.5-34.5

{237-355, 17.2-25.6}

46.0-68.0

{466-698, 33.7-50.4}

80.0-120.0

128.0-192.0

200.0-300.0

M18

M20

M22

M24

132.0-198.0

{1,344-2,016, 97.2-145.7}

188.0-282.0

{1,920-2,880, 138.8-208.2}

256.0-384.0

{2,616-3,924, 189.2-283.7}

324.0-486.0

{3,304-4,956, 238.9-358.3}

{2,120-3,180, 153.3-229.9}

{3,024-4,536, 218.7-327.9}

{4,120-6,180, 297.9-446.8}

{5,220-7,840, 377.5-566.8}

208.0-312.0

296.0-444.0

405.0-605.0

515.0-765.0

SPECIFIED TORQUE FOR FLANGE BOLTS AND NUTS

Diameter

M8

M10

M12

Class

{184-265, 13.3-19.2}

{421-631, 30.5-45.6}

{744-1,116, 53.8-80.7}

7T 9T 12T Shape

18.0-26.0

41.5-61.5

{560-840, 40.5-60.7}

73.0-109.0

{979-1,469, 70.8-106.2}

——

55.0-82.0

96.0-114.0

—

—

276.0-414.0

{2,816-4,224, 203.6-305.4}

392.0-588.0

{4,000-6,000, 289.3-433.8}

540.0-800.0

{5,470-8,210, 395.5-593.6}

680.0-1,010.0

{6,900-10,340, 499.0-747.6}

EN00Z0002C100002

Unit: Nm {kgfcm, lbfft.}

M14 — —

86.0-142.0

{877-1,448, 63.4-104.7}

Page 30

GENERAL INTRODUCTION (CHASSIS)GN02–24

With new flange (w/o grooves)

Unit: Nm {kgfcm, lbfft.}

Diameter

Class

M8

M10

M12

M14 —

{221-411, 16.0-29.7}

{250-464, 18.1-33.6}

{450-835, 32.5-60.4}

8.8T 10.9T Shape

21.7-40.3

24.5-45.5

44.1-81.9

27.3-50.7

{278-517, 20.1-37.4}

32.7-60.3

{333-615, 24.1-44.5}

57.4-106.6

{585-1087, 42.3-78.6}

91-169

{928-1723, 67.1-124.6}

104-156*

{106-1590, 76.7-115.1}

Page 31

GENERAL INTRODUCTION (CHASSIS) GN02–25

RECOMMENDED LUBRICANTS

EN00Z0002H600001

No. LUBRICANTS POSITONS VISCOSITY RECOMENDATIONS (SAE)

Engine oil

A.P.I.: CJ-4

1

JASO: DH-2

ACEA: E–6, E-9

No. LUBRICANTS POSITONS ATMOSPHERIC TEMP. S.A.E. No

Heavy duty engine oil

MIL-L-2104D, API-CD, or Cat

TO-4

2

Automotive gear oil API-MT-1

Mobil Delvac Synthetic

Transmission Fluid 50,

Shell SPIRAX GSX SAE 50,

EATON Roadranger SAE 50,

3

EATON Approved Synthetic

Transmission oil,

or equivalent (See Eaton

Lubrication Manual for detail)

Automatic transmission fluid;

TES 389-approved fluid

4

Automatic transmission fluid;

TES 295-approved fluid

Axle lubricant

Non- Extended Drain Lubricants

(Petroleum with EP Additives)

(A.P.I. GL-5) (MIL-PRF-2105E

and SAE J2360)

5

Axle lubricant

Extended Drain Lubricants

(Petroleum with EP Additives)

(A.P.I. GL-5) (MIL-PRF-2105E

and SAE J2360)

Cylinder Block

EATON Fuller

FS-5406A,FS-6406A

EATON Fuller

FS-5406A, FS-6406A

Allison 2200HS, 2200RDS,

2500RDS, 3000RDS,

3500RDS

Allison 2200HS, 2200RDS,

2500RDS, 3000RDS,

3500RDS

Rear axle

Above 10F (–12C) 50

Above 10F (–12C) 40

Below 10F (–12C) 30

Above 10F (–12C) 80W-90

Below 10F (–12C) 75W

All 50

——

Above 10F (–12C) 85W/140

Above –15F (–26C) 80W/140

Above –15F (–26C) 80W/90

Above –40F (–40C) 75W/90

From –40F (–40C) to –35F (2C) 75W

Above –40F (–40C) 75W/140

Above –15F (–26C) 80W/90

Above –15F (–26C) 80W/90

Above –40F (–40C) 75W/140

Above –40F (–40C) 75W/90

Page 32

GENERAL INTRODUCTION (CHASSIS)GN02–26

No. LUBRICANTS POSITONS

6 POWER STEERING FLUID (ATF DEXRON 2 or 3) Integral Power Steering Gear

7 BRAKE AND CLUTCH FLUID (DOT-3) or (DOT-4) Brake & Clutch

WHEEL BEARING GREASE

8

(MIL-G-10924B/18709A) (N.L.G.I.'s No.2 LITHIUMSOAP)

HEAT RESISTANCE GREASE

9

(MIL-G-22615/23549/21164) (N.L.G.I.'s No.2 or No.3)

10 SPECIAL GREASE (KLUBER GLKO) B-Frame Disc Brake (Guide buss, Caliper body, Piston)

11 STARTER GREASE (N.L.G.I.'s No.2 LITHIUM-SOAP)

12 BEARING GREASE (N.L.G.I.'s No.2 LITHIUM-SOAP)

CHASSIS GREASE (MIL-G-17740) (N.L.G.I.'s No.1

13

CALCIUM or LITHIUM-SOAP)

14 LONG LIFE COOLANT Engine, Radiator

15 Mobil Synthetic 75W-90 Front Wheel Hub (Oil Lubricated Bearings)

Propeller Shaft Universal Joint and Slip Joint

Clutch Disc Hub Spline

T/M Main Drive Shaft Spline

Q-Plus Brake (Retainer Clip, Anchor Pin, Roller (Journal only), Camshaft, Automatic Slack Adjuster, Clevis

Pin) Parking Brake (Camshaft, Anchor Pin, Shoe web)

Bushing, Clutch, Drive Shaft, Pinion Shaft Lever &

Reduction Gear

Clutch Release Sleeve

Clutch Release Shaft

Alternator Bearing

Starter Bearing

Chassis Grease Fitting

No. LUBRICANTS POSITONS SHEEL MOBIL EXXON

LITHIUM BASE DISULFIDE

16

MOLYBDENUM GREASE

Drag Link & Tie

Rod Ball Joint

Retinax AM

Mobil Grease

Special

Beacon Q2

Page 33

GENERAL INTRODUCTION (CHASSIS) GN02–27

VEHICLE LIFT AND SUPPORT LOCATIONS

EN00Z0002A200001

1. NOTICE ABOUT VEHICLE CONDITION WHEN JACKING UP

(1) As a rule, vehicle must be in an unloaded condition and never jack up

or lift up the vehicle with things of heavy weight.

(2) If removing any things of heavy weight like the engine and transmis-

sion, the center of gravity of the vehicle moves. Therefore, place a balance weight so as to keep it from rolling, or hold the jacking support

location using the transmission jack.

2. NOTICE FOR USING 4 POST LIFT

(1) Follow the instruction manual for a safety operation.

(2) Do not damage tires or wheels with a free wheel beam.

(3) Using a wheel stopper, fix the vehicle.

3. NOTICE FOR USING JACK AND SAFETY STAND

(1) Work in a flat place using a wheel stopper all the time.

(2) Support the specified location with a jack and safety stand accurately.

(3) Do not work or leave the vehicle supported only by a jack. Be sure to

support the vehicle together with a safety stand.

(4) Be careful and accurate in jacking up and down the vehicle.

(5) Care must be taken when jacking up and supporting the vehicle. Be

sure to lift and support the vehicle at the proper locations.

• Cancel the parking brake on a level place and shift the transmission in

Neutral.

• When jacking up the front wheels of the vehicle at first place stoppers

behind the rear wheels.

• When jacking up the rear wheels of the vehicle at first place stoppers

behind the front wheels.

• When either the front or rear wheels only should be jacked up, set

safety stands and place stoppers in front and behind the other wheels

on the ground.

• After the vehicle is jacked up, be sure to support it on the safety

stands. It is extremely dangerous to perform any work on a vehicle

raised on a jack alone, even for a small job that can be finished

quickly.

Page 34

GENERAL INTRODUCTION (CHASSIS)GN02–28

Front Rear

Leaf suspension

Air suspension

Air spring

Front

Rear

Center of front axle beam

Center of rear axle housing

Garage jack position

Safety stand

If necessary, remove the front bumper.

Support position

Oil jack position

SHTS00Z000200034

Page 35

GENERAL INTRODUCTION (CHASSIS) GN02–29

Information display control switch

Information display

SHTS00Z000200035C

MODE

SELECT

SET/RESET

SHTS00Z000200036

INFORMATION DISPLAY

EN00Z0002A200002

1. INFORMATION DISPLAY ITEMS

• Information display shows following items.

(1) Ordinary display

Trip meter, voltage, date, fuel consumption, average speed and

engine or vehicle maintenance information etc.

(2) Warning display

The warning display is automatically displayed and shows messages.

NOTICE

• When turn the key to "ON" position, display shows last message.

But in case of device operating, the warning display is prior to

ordinary display.

2. INFORMATION DISPLAY CONTROL SWITCH

• The following information is shown with the key turned on. Each time

you push the "MODE" button, the displayed information is changed.

NOTICE

• Diagram on the next page shows the operation method of the

information display.

• If you push and hold "SET/RESET" button, as the display case,

data may be reset.

• Press the "MODE" button more than 1 second to release the

warning information.

Page 36

GENERAL INTRODUCTION (CHASSIS)GN02–30

Push and hold

for at least 1sec.

Push down "MODE " button

The system remembers last display at each function.

Push button "SET/RESET" at the same time

Push up "SELECT " button

Other : Those displays are broken in automatically

Secondary

Setting

Maintenance

Self check

Self check

Normal display item

Operation menu Control menu

Secondary

Setting

Maintenance

Returns to last display automatically

Fuel consumption monitor

Trip data

Operation time

DPR

Water temperature

Voltage meter

Setting cannot be made while driving.

Push and hold

for at least 1sec.

(Starter key ON)

Interruption display

Water temp

Voltage

DPR

Current

Average

Main menu

Clock

Language

Units

Display

Conversion rate

Engine oil

T/M oil

Diff oil

Coolant

Fuel filter

Belt

DPR

Tu rb o

Starter

Alternator

Radiator

Battery

Air dryer

Customize 1

Customize 2

Customize 3

SHTS00Z000200037

Page 37

GENERAL INTRODUCTION (CHASSIS) GN02–31

3. WARNING DISPLAY

(1) Warning display

Display Warning Display remarks

Engine control system has malfunction. This is

important and must be addressed immediately.

DPR cleaner needs to be manually regenerated.

NOTICE

• The display shows DPR MANUAL REGENERATE REQUIRED with

the buzzer sound when DPR cleaner needs to be manually regen-

erated.

(2) Information display

Display Display remarks

Appears when idling is stopped due to emergency.

DPR regenerate on time.

DPR remaining for few minute.

DPR regenerate completed.

DPR regeneration interrupted, push DPR button to resume.

NOTICE

• The DPR system automatically regenerates when the quantity of

soot collected in the DPR cleaner exceeds a specific quantity.

This prevents an abnormal accumulation of soot and keeps the

DPR cleaner in good condition. Use of high-performance catalyst

and an electronically controlled common rail fuel injection sys-

tem has made it possible to burn (regenerate) the soot while

driving.

Page 38

GENERAL INTRODUCTION (CHASSIS)GN02–32

SHTS00Z000200044

599999

599000

Disable

SHTS00Z000200049

4. SELF DIAGNOSIS SYSTEM

If the vehicle has fault, display shows the trouble.

(1) Select to "Self check" and push "SET/RESET" button.

(2) Select to "System check" and push "SET/RESET" button, display

shows "No fault" in case of no trouble. If it has trouble, display shows

fault item.

(3) If display shows trouble warning, Immediately get the vehicle checked

and repaired at an authorized Hino dealer.

(4) In case of "Engine malfunction" displayed, push and hold "SELECT"

button for more than 1 sec. until the display shows trouble code.

Push "SELECT" button, display shows another trouble codes, if there

are.

(5) Push and hold "SELECT" button for longer than 1 sec. to display the

"Inactive".

(6) Trouble code display

Initial Display Remarks

It has no trouble.

It has trouble.

Yellow background.

It has trouble code, now.

Get the vehicle checked and repaired.

It had trouble code, previously.

5. RESETTING PROCEDURE

EX.Differential oil change period

(1) Scroll up and select "Maintenance" and push "SET/RESET" button.

(2) Scroll up and select the preferred setting item and push "SET/

RESET" button.

(3) Push and hold "SET/RESET" button for longer than 1 sec.

NOTICE

• In the case of the other item on trouble code, data may be reset

as the same procedure.

• But, especially in the case of "DPR", push and hold "MODE" and

"SET/RESET" button at the same time for more than 20sec. to

reset. (Following to the low, use only at an authorized Hino

dealer.)

Page 39

GENERAL INTRODUCTION (CHASSIS) GN02–33

6. AVAILABLE SETTING ITEMS

• Engine oil

• T/M oil

• Diff oil

• Coolant

• Fuel filter

• Belt

• DPR

• Tu rbo

• Starter

• Alternator

• Radiator

• Battery

• Air dryer

• Customize1

• Customize2

• Customize3

Page 40

GENERAL INTRODUCTION (CHASSIS)GN02–34

Vibrate slightly

Vibrate

slightly

Shake slightly

SHTS00Z000200050

SYMPTOM SIMULATION

EN00Z0002A200003

HINT

The most difficult case in troubleshooting is when no problem symptoms occur. In such a case, a thorough problem analysis must be carried out. A simulation of the same or similar conditions and

environment in which the problem occurred in the customer's vehicle

should be carried out. No matter how much skill or experience a technician has, troubleshooting without confirming the problem symptoms will lead to important repairs being overlooked and mistakes or

delays.

For example:

With a problem that only occurs when the engine is cold or as a result

of vibration caused by the road during driving, the problem can never

be determined if the symptoms are being checked on a stationary

vehicle or a vehicle with a warmed-up engine. Vibration, heat or water

penetration (moisture) is difficult to reproduce. The symptom simulation tests below are effective substitutes for the conditions and can

be applied on a stationary vehicle. Important points in the symptom

simulation test: In the symptom simulation test, the problem symptoms as well as the problem area or parts must be confirmed. First,

narrow down the possible problem circuits according to the symptoms. Then, connect the tester and carry out the symptom simulation

test, judging whether the circuit being tested is defective or normal.

Also, confirm the problem symptoms at the same time. Refer to the

problem symptoms table for each system to narrow down the possible causes.

1. VIBRATION METHOD: When malfunction seems to occur as a

result of vibration.

(1) PART AND SENSOR

Apply slight vibration with a finger to the part of the sensor suspected

to be the cause of the problem, and check whether or not the malfunc-

tion occurs.

NOTICE

Applying strong vibration to relays may open relays

(2) CONNECTORS

Slightly shake the connector vertically and horizontally.

(3) WIRE HARNESS

Slightly shake the wire harness vertically and horizontally.

HINT

The connector joint and fulcrum of the vibration are the major areas

that should be checked thoroughly.

2. HEAT METHOD: When a malfunction seems to occur when the

area in question is heated.

(1) Heat the component that is the possible cause of the malfunction with

a hair dryer or similar device. Check if the malfunction occurs.

NOTICE

• Do not heat to more than 60C (140F). Exceeding this tempera-

ture may damage components.

• Do not apply heat directly to the parts in the ECU.

Page 41

GENERAL INTRODUCTION (CHASSIS) GN02–35

SHTS00Z000200051

3. WATER SPRINKLING METHOD: When a malfunction seems to

occur on a rainy day or in high-humidity.

(1) Sprinkle water onto the vehicle and check if the malfunction occurs.

NOTICE

• Never sprinkle water directly into the engine compartment. Indi-

rectly change the temperature and humidity by spraying water

onto the front of the radiator.

• Never apply water directly onto the electronic components.

HINT

If the vehicle has or had a water leakage problem, the leakage may

have damaged the ECU or connections. Look for evidence of corrosion or short circuits. Proceed with caution during water tests.

4. HIGH ELECTRICAL LOAD METHOD: When a malfunction seems

to occur when electrical load is excessive.

(1) Turn on the heater blower, headlight, rear window defogger and all

other electrical loads. Check if the malfunction reoccurs.

Page 42

GENERAL INTRODUCTION (CHASSIS)GN02–36

GLOSSARY

DEFINITION OF ABBREVIATION IN THIS MANUAL

LIST OF ABBREVIATION

SAE

ABBREVIATIONS

A/C Air conditioner

ABS Anti-lock Brake System

ACC Accessory

AMT Automated Manual Type

ATC After Turbo catalyst

ATF Automatic Transmission Fluid

CA Crank Angle

CAN Controller Area Network

CD-ROM Compact Disc Read Only Memory

CPU Central Processing Unit

dB Decibel

DC Direct Current

D-CAT Diesel-Clean Advanced Technology System

DC motor Direct Current Motor

SAE TERMS

DCU Dosing Control Unit

DEF Diesel Exhaust Fluid

DPR Diesel Particulate active Reduction System

DSS Driving Support System

ECU Electronic Control Unit

EEPROM Electronically Erasable and Programmable Read Only Memory

EGR Exhaust Gas Recirculation

ELR Emergency Locking Retractor

ENG Engine

ES START Easy and Smooth start system

F/A Front axle

FCCB Fuel Control Cylinder Balance

FCV Fuel Cutoff Valve

FF Shift Feather touch & Finger shift

FL Fusible link

Fr Front

FRP Fiber Reinforces Plastic

Page 43

GENERAL INTRODUCTION (CHASSIS) GN02–37

SAE

ABBREVIATIONS

FUP Front Underrun Protector

GND Ground

GVW Gross Vehicle Weight

Hi High

HINO DX Ⅱ Hino Diagnostic eXplorer Ⅱ

HVAC Heating, Ventilating and Air-Conditioning unit

I.S.C. Idle Speed Control

IC Integrated Circuits

ID Identification

IPD Intelligent Power Device

IS Idle Stop

ISO International Organization for Standardization

JIS Japanese Industrial Standards

LED Light Emitting Diode

SAE TERMS

LEV Low Emission Vehicle

LH Left Hand

LLC Long Life Coolant

Lo Low

MAX Maximum

MIN Minimum

MS evaporator Multi-rank and Super slim structure evaporator

No Number

NOx Nitrogen Oxide

NMR No load Maximum Revolution

OHC Over Head Camshaft

PC Personal Computer

PCD Pitch Circle Diameter

PCS Pre-Crash Safety

PCV Pump Control Valve

PCV valve Positive Crankcase Ventilation valve

PM Particulate Matter

PPG Glass-fiber-reinforced Polypropylene

PPm Parts Per Million

PS pump Power Steering Pump

Page 44

GENERAL INTRODUCTION (CHASSIS)GN02–38

SAE

ABBREVIATIONS

PVD Physical Vapor Deposit

PWR Power

QE code Quick Response Code

R/A Rear axle

RH Right Hand

SCR Selective Catalytic Reduction

SW Switch

T/M Transmission

SAE TERMS

Page 45

GENERAL INTRODUCTION (CHASSIS) GN02–39

GLOSSARY OF SAE AND HINO TERMS

EN00Z00020200005

This glossary lists all SAE-J2403 terms and abbreviations used in this manual in compliance with SAE recommendation, as

well as their HINO equivalents.

SAE

ABBREVIATIONS

A/T AUTOMATIC TRANSMISSION Automatic transmission

AAT AMBIENT AIR TEMPERATURE Ambient Air Temperature

ACL AIR CLEANER Air cleaner

ACL Element ACL (Air Cleaner) Element Air Cleaner element

ACL Element AIR CLEANER Element Air Cleaner element

ACL Housing AIR CLEANER Housing Air cleaner body assembly

ACL Housing Cover AIR CLEANER Housing Cover Air Cleaner Housing Cover

AFTDEF

AFTDEFDU

AFTDOC

AFTERTREATMENT DIESEL EXHAUST

FLUID

AFTERTREATMENT DIESEL EXHAUST

FLUID DOSING UNIT

AFTERTREATMENT DIESEL OXIDATION

CATALYST

SAE TERMS

DEF

DCU

DOC (Diesel Oxidation Catalyst)

HINO TERMS

( )--ABBREVIATIONS

AFTDOS AFTERTREATMENT DOSER AFTDOS DEF injector

AFTDPF

AFTDPFDP

AFTEGT

AP ACCELERATOR PEDAL Accelerator pedal

AP Sensor ACCELERATOR PEDAL Sensor Accelerator Pedal Position Sensor

APP ACCELERATOR PEDAL POSITION Accelerator Pedal Position

CAC CHARGE AIR COOLER Intercooler

CPP Switch CLUTCH PEDAL POSITION Switch Clutch Switch

DCC DIAGNOSTIC CONNECTOR, Cab Diagnosis connector

DCU DIAGNOSTIC CONNECTOR, Underhood Diagnosis connector

DRIVER DRIVER driver

DTC DIAGNOSTIC TROUBLE CODE Diagnosis Trouble Code

DTM Switch DIAGNOSTIC TEST MODE Switch Diagnosis switch

AFTERTREATMENT DIESEL PARTICULATE

FILTER

Aftertreatment Diesel Particulate Filter Differential Pressure

AFTERTREATMENT EXHAUST GAS TEMPERATURE

DPR filter

DPR differential pressure

Exhaust gas temperature

EBP EXHAUST BACK PRESSURE Backpressure

EBP EXHAUST BACK PRESSURE Exhaust backpressure

EBP Sensor EXHAUST BACK PRESSURE Sensor Back Pressure Sensor

Page 46

GENERAL INTRODUCTION (CHASSIS)GN02–40

SAE

ABBREVIATIONS

EBPR Valve

EC ENGINE CONTROL Engine control

ECT ENGINE COOLANT TEMPERATURE Coolant Temperature

ECT ENGINE COOLANT TEMPERATURE Water Temperature

EFT ENGINE FUEL TEMPERATURE Fuel temperature

EFT Sensor ENGINE FUEL TEMPERATURE Sensor Fuel temperature sensor

EGR EXHAUST GAS RECIRCULATION EGR

EGR Valve EXHAUST GAS RECIRCULATION Valve EGR valve

EGRT

EGRT Sensor

EGT EXHAUST GAS TEMPERATURE Exhaust gas temperature

EI ELECTRONIC IGNITION Ignition coil

EXHAUST BACK PRESSURE REGULATOR

Val ve

EXHAUST GAS RECIRCULATION TEMPERAT UR E

EXHAUST GAS RECIRCULATION TEMPERATURE Sensor

SAE TERMS

Exhaust control valve

EGR temperature

EGR exit temperature sensor

HINO TERMS

( )--ABBREVIATIONS

EOP ENGINE OIL PRESSURE Oil Pressure

EOT ENGINE OIL TEMPERATURE Oil Temperature

FP FUEL PUMP Fuel pump

FUEL PRESSURE Sensor FUEL PRESSURE Sensor Fuel Pressure sensor

GLOW PLUG GLOW PLUG Glow plug

GND GROUND GROUND

IA INTAKE AIR Air Intake

IA System INTAKE AIR System Air Intake System

IAT INTAKE AIR TEMPERATURE Intake temperature

IAT Sensor INTAKE AIR TEMPERATURE Sensor Intake temperature sensor

IDLE IDLE idle

IMAT INTAKE MANIFOLD AIR TEMPERATURE Intake manifold Air temperature sensor

IMAT INTAKE MANIFOLD TEMPERATURE Intake manifold temperature sensor

INJ INJECTOR Injector

MAF Sensor MASS AIR FLOW Sensor Air flow sensor

MIL MALFUNCTION INDICATOR LIGHT MIL (Malfunction Indicator Light)

OSS Sensor OUTPUT SHAFT SPEED Sensor Output Speed Sensor

OSS Sensor OUTPUT SHAFT SPEED Sensor Speed Sensor

PC Solenoid Valve PRESSURE CONTROL Solenoid Valve Solenoid control valves

PCV POS CRANKCASE VENTILATION PCV (Positive Crankcase Vent)

PCV Valve POS CRANKCASE VENTILATION Valve PCV (Positive Crankcase Vent) Valve

Page 47

GENERAL INTRODUCTION (CHASSIS) GN02–41

SAE

ABBREVIATIONS

PCV Valve POS CRANKCASE VENTILATION Valve PCV Valve

PCV Valve POSITIVE CRANKCASE VENT Valve PCV Valve

PNP PARK/NEUTRAL POSITION Neutral position

PNP Switch PARK/NEUTRAL POSITION Switch Neutral switch

RFP RAIL FUEL PRESSURE Common rail Pressure

RFP Sensor RAIL FUEL PRESSURE Sensor Common rail pressure sensor

SPARK PLUG SPARK PLUG Spark plug

SRI SERVICE REMINDER INDICATOR Check engine

ST SCAN TOOL Diagnostic tool

TC TURBOCHARGER Turbocharger

TCC TORQUE CONVERTER CLUTCH Torque Converter

TP Sensor THROTTLE POSITION Sensor Throttle Sensor

TSS Sensor TURBINE SHAFT SPEED Sensor Turbine Speed Sensor

VAF Sensor VOLUME AIR FLOW Sensor Air flow sensor

SAE TERMS

HINO TERMS

( )--ABBREVIATIONS

VLS VEHICLE LIMITING SPEED Speed Limiter Upper Limit

VSS VEHICLE SPEED SENSOR Vehicle Speed sensor

Page 48

CLUTCH MAIN UNIT (EATON 1401) CL02–1

CL02

CLUTCH MAIN UNIT (EATON 1401)

CLUTCH ASSEMBLY

(EATON SAS1401).................................... CL02-2

DATA AND SPECIFICATIONS..........................CL02-2

DESCRIPTION .................................................CL02-2

TROUBLESHOOTING......................................CL02-3

SPECIAL TOOL................................................CL02-5

COMPONENT LOCATOR.................................CL02-6

OVERHAUL ......................................................CL02-7

CLUTCH ASSEMBLY

(EATON SOLO1401) ............................... CL02-14

DATA AND SPECIFICATIONS........................CL02-14

COMPONENT LOCATOR...............................CL02-14

OVERHAUL ....................................................CL02-15

INSPECTION AND REPAIR ...........................CL02-22

CL02-001

Page 49

CLUTCH MAIN UNIT (EATON 1401)CL02–2

1

2

SHTS02Z020200001

CLUTCH ASSEMBLY (EATON SAS1401)

DATA AND SPECIFICATIONS

EN02Z0202I200001

CLUTCH FACING Unit: mm {in.}

Material Sintered metal (Ceramic metal)

Type Dry single plate with damper spring

Inside diameter 222 {8.8}

Outside diameter 350 {13.8}

Thickness 11.5 {0.45}

DESCRIPTION

EN02Z0202C100001

1 Clutch disc 2 Clutch cover

Page 50

CLUTCH MAIN UNIT (EATON 1401) CL02–3

TROUBLESHOOTING

Symptom Possible cause Remedy/Prevention

Clutch dragging. Clutch disc distorted or warped. Replace clutch disc.

Transmission input shaft worn. Replace input shaft and check clutch

hub for excessive wear. If worn,

replace disc. Check flywheel housing

alignment.

Excessive clutch control parts wear. Replace control parts.

Clutch control parts not functioning

properly.

Improper clutch control adjustment. Adjust clutch control.

Clutch disc assembly too thick. Replace clutch disc.

Clutch slipping. Release lever and release bearing

clearance incorrectly adjusted.

Clutch disc facing gummed with oil or

grease.

Release bearing worn. Replace bearing.

Clutch pedal free-play incorrectly

adjusted.

Compression spring weak. Replace cover assembly.

Clutch facing worn. Replace disc assembly.

Failing to remove plate from the clutch

pressure plate assembly.

Driver riding clutch pedal. Do not ride the clutch pedal.

Vehicle vibrates when starting. Improper engine idling. Adjust idling.

Clutch control incorrectly adjusted. Adjust clutch control

Clutch disc facing gummed with oil or

grease.

Glazed flywheel friction surface. Deglaze flywheel surface with coarse

Clutch disc distorted or warped. Replace disc.

Improper clutch cover tightening. Tighten bolts.

Flywheel housing misalignment. Replace flywheel housing.

Abnormal noise in transmission. Malfunction of engine. Tune up engine.

Improper clutch disc used. Replace proper clutch disc.

Trouble in transmission. Check transmission.

The engine idle speed is low. Increase the idle speed.

Replace control parts.

Adjust clearance.

Replace disc assembly.

Adjust free-play.

Remove plate.

Replace disc assembly.

emery cloth, stroking parallel to

machining lines.

EN02Z0202F300001

Page 51

CLUTCH MAIN UNIT (EATON 1401)CL02–4

Symptom Possible cause Remedy/Prevention

Noisy clutch. Release bearing worn or dried. Replace release bearing.

Pilot bearing worn or dried. Replace pilot bearing.

Clutch disc distorted or warped. Replace clutch disc.

Flywheel housing misalignment. Replace flywheel housing.

Transmission input shaft or clutch disc

spline worn.

Insufficient lubrication of pedal and its

accessories.

Insufficient lubrication of release shaft

and release bearing hub.

Transmission input shaft retainer

rusted or soiled.

Clutch pedal free-play incorrectly

adjusted.

Clutch pedal cannot be depressed. Clutch control incorrectly adjusted. Adjust clutch control.

Insufficient lubricant release shaft and

release bearing hub.

Change in clutch pedal give. Air trapped in clutch fluid. Bleed air.

Clean and lubricate or replace.

Lubricate.

Lubricate.

Clean or replace if rusted.

Adjust free-Play.

Lubricate.

Page 52

CLUTCH MAIN UNIT (EATON 1401) CL02–5

SPECIAL TOOL

Prior to starting a clutch overhaul, it is necessary to have these special tools.

Illustration Part number Tool name Remarks

S0965-01970

S0942-01442 SLIDING HAMMER

CLUTCH PILOT BEARING

PULLER

EN02Z0202K100001

S0966-21410 CLUTCH ALIGNING ARBOR

S0940-91200 CRANKING TOOL

Page 53

CLUTCH MAIN UNIT (EATON 1401)CL02–6

SHTS02Z020200006

COMPONENT LOCATOR

EN02Z0202D100001

1 Clutch cover 3 Adjusting screw

2Clutch disc 4Bolt

Tightening torque Unit: Nm {kgfcm, lbfft}

A 50-64 {510-655, 37-47}

Page 54

CLUTCH MAIN UNIT (EATON 1401) CL02–7

1.Remove the

transmission

SHTS02Z020200007

SHTS02Z020200008

SHTS02Z020200009

A.

Check cross-shafts

and bushings

SHTS02Z020200010

OVERHAUL

EN02Z0202H200001

IMPORTANT POINT - DISMOUNTING

1. REMOVE THE TRANSMISSION, SUPPORTING ITS WEIGHT TO

PREVENT DAMAGE TO THE BEARING AND DISCS.

2. INSTALL TWO WOODEN SPACERS 1"-1-1/2" THICK BETWEEN

RELEASE BEARING AND COVER ASSEMBLY.

3. REMOVE THE CLUTCH FROM THE FLYWHEEL.

IMPORTANT POINT - INSPECTION AND REPLACEMENT

1. REPLACE THE PILOT BEARING.

(1) Remove the pilot bearing.

SST:

Pilot Bearing Puller (S0965-01970)

Sliding Hammer (S0942-01442)

(2) Using a suitable tapping rod, install the pilot bearing.

NOTICE

After installing the pilot bearing, ensure that it rotates smoothly.

2. CHECK THE FOLLOWING ITEMS FOR WEAR REPLACE ANY

WORN COMPONENTS:

(1) Cross-shafts and bushings

NOTICE

Excessive wear at these points can cause a side loading condition.

Also, inspect the remaining pivot points of the linkage for excessive

wear.

Page 55

CLUTCH MAIN UNIT (EATON 1401)CL02–8

B.

Check release yoke

fingers

SHTS02Z020200011

D.

Check splines on the

input shaft

SHTS02Z020200012

E.

Check smooth

area of input

shaft for wear /

roughness

SAPH02Z080200001

(2) Release yoke fingers

(3) Splines on the input shaft

NOTICE

Any wear on the splines will prevent the newly installed driven discs

from sliding freely, thus causing poor release (clutch drag). Select a

disc out of the new installation and slide it full length on the transmission splines. This will detect a twisted input shaft. Replace input shaft

if disc does not freely slide.

(4) Smooth area of input shaft

(5) Mating surfaces

NOTICE

Inspect the mating surfaces of both the transmission bell housing and

the flywheel housing. Any appreciable wear on either housing will

cause misalignment. Most wear will occur between the 3 and 8 o'clock

positions.

Replace housings if worn.

Page 56

CLUTCH MAIN UNIT (EATON 1401) CL02–9

! CAUTION

1.

Insert 2 guide studs

Guide studs