Hellwig 7533 User Manual

559-734-7451 800-367-5480 FAX 559-734-7460

INSTALLATION INSTRUCTIONS

REAR STABILIZER BAR

Thank you for purchasing a quality Hellwig Product.

PLEASE READ THIS INSTRUCTION SHEET COMPLETELY BEFORE STARTING YOUR INSTALLATION

Maintenance and Inspection:

Your Hellwig Suspension Product is built to last. However, as with all vehicle systems, it requires routine

inspection. Inspect your Hellwig installation looking for secure hardware and tight fitting brackets and

bushings. If you do not perform this inspection, have your professional mechanic inspect as described.

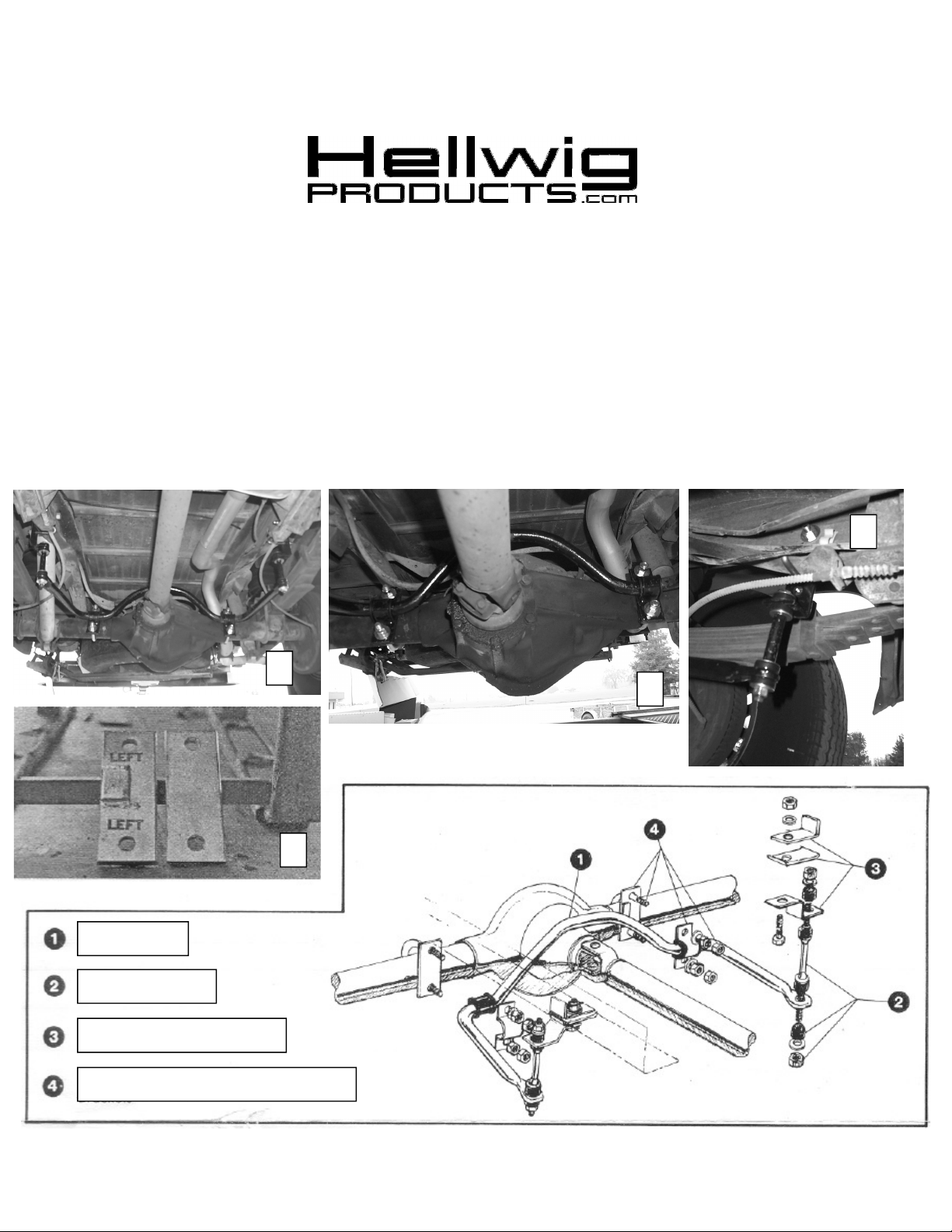

1

2

3

4

Anti-Sway Bar

End Link Assembly

Frame Pinch and Z-Brackets

U-Bolts, D-Bushings and Axle Brackets

( R-134 ) 11/28/2012

559-734-7451 800-367-5480 FAX 559-734-7460

SAFETY: BEFORE STARTING YOUR INSTALLATION, BE SURE TO SET PARKING BRAKE AND CHOCK TIRES.

NOTE: TO EASE INSTALLATION AND TO PROPERLY ADJUST THE BAR, THE WEIGHT OF THE VEHICLE MUST BE

ON THE SUSPENSION, AS IF DRIVING DOWN THE ROAD. DO NOT RAISE VEHICLE BY THE FRAME.

NOTE: THIS KIT MAY INCLUDE LOCK NUTS WHICH REQUIRES TIGHTENING WITH A WRENCH AFTER BEING

STARTED BY HAND.

TORQUE TABLE

BOLT SIZE: 3/8” = 20-30 ft. lbs. – 7/16” = 35-45 ft. lbs. – 1/2” = 50-70 ft. lbs. – 9/16” = 70-90 ft. lbs.-5/8”=120 ft. lbs.

1. Lubricate the insides and install D-shaped bushings around sway bar and position over top of axle as in

Photo 1.

2. Mount sway bar using U-bolts and plate components shown in Photo 2 and 3. Leave loose to allow for

adjustment later. NOTE: Photo 4 shows a plate marked left, looking from the back of the truck to the

front, install the left plate with the welded lug against axle tubing and plate extending over casting.

3. Install frame mounting bracket, as seen in illustration, in the proper location by raising the sway bar to

the frame to give you and approximate straight up and down installation of the cap screw assembly.

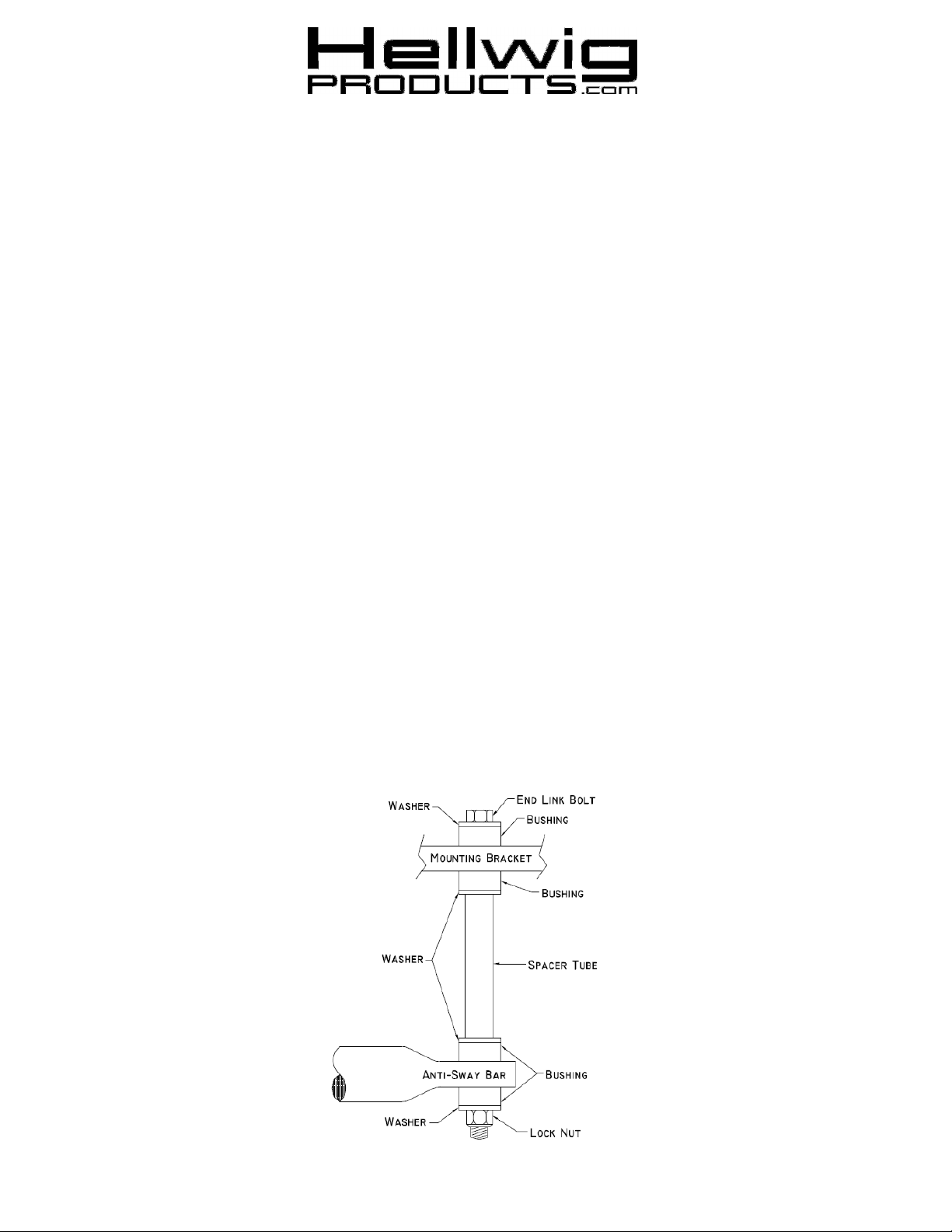

4. Install component parts as shown in the illustration. Assemble the end links as shown on the R-337

Form included.

5. When all component parts are installed rotate axle brackets, U-bolts, so that the long cap screw is in a

near to straight up and down position.

6. Bounce the vehicle and check for clearance on all undercarriage components. Be sure all nuts and bolts

are securely fastened and double nuts used where necessary or provided.

7. Recheck your installation, look for clearance between gas lines, exhaust pipes, brake lines, wiring, etc.

After one week of driving check your installation and periodically thereafter.

ATTENTION INSTALLER: BE SURE THE CUSTOMER RECEIVES THJIS INSTRUCTION

SHEET, ALL IMPORTANT NOTE CARDS, WARNING CARDS AND THE WARRANTY FORM.

( R-134 ) 11/28/2012

Loading...

Loading...