Page 1

GETINGE 9100-SERIES

TECHNICAL MANUAL

6001341502

Page 2

Page 3

Contents

PREFACE...................................................................................................................... 5

SAFETY PRECAUTIONS................................................................................................ 6

Important................................................................................................................ 6

Isolator switch......................................................................................................... 6

In an emergency..................................................................................................... 7

Make sure that the assembly and installation is carried out:.................................... 7

When the work is complete, check that................................................................... 7

Product liability........................................................................................................ 7

Attention symbols................................................................................................... 8

INTRODUCTION............................................................................................................ 9

Area of application.................................................................................................. 9

General Description................................................................................................. 9

Washer-disinfector options and selections.............................................................. 9

Performance Characteristics................................................................................. 12

CONTROL PANEL....................................................................................................... 19

OP30 panel........................................................................................................... 19

Display panel rules................................................................................................ 23

OP10 panel......................................................................................................... 107

ALARM MANAGEMENT............................................................................................. 108

Error indicators................................................................................................... 108

Acknowledging an alarm..................................................................................... 109

PREVENTIVE MAINTENANCE.................................................................................... 121

General............................................................................................................... 121

Function check................................................................................................... 122

Loading of System Program and Application Program........................................ 123

Load the back up in the "Flash Prom" to the PACS............................................. 125

Changing of operating language.......................................................................... 125

Cold and warm start of PACS 3500.................................................................... 126

Softstart.............................................................................................................. 127

Adjusting analog input......................................................................................... 129

Pressure transmitter for DISCHARGE PRESSURE (0-2.5 bar)............................. 134

Temperature sensors.......................................................................................... 135

Pressure differential transmitter for drying unit (0-10 mbar).................................. 135

DOSING..................................................................................................................... 136

Replacing a hose in the dosing pump................................................................. 136

Hose selection.................................................................................................... 137

Setting detergent and rinse-aid quantities........................................................... 138

Flow monitoring.................................................................................................. 139

Starting up.......................................................................................................... 139

DOORS...................................................................................................................... 140

Door switches, position and operation................................................................ 140

Adjusting the pressure stabilizer.......................................................................... 141

Adjusting the limit switch..................................................................................... 142

Adjusting safety line breaker................................................................................ 147

Overheating protection (only on electrically heated washer-disinfectors).............. 148

Page 3 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 4

Dryer (electrically heated).................................................................................... 149

Printer (optional).................................................................................................. 150

LIST OF COMPONENTS............................................................................................ 152

Detergent system................................................................................................ 156

Water system, steam heated............................................................................... 157

Electric heating................................................................................................... 158

Drying system, electrically heated........................................................................ 159

Booster tank, steam heated................................................................................ 160

GLOSSARY............................................................................................................... 162

ADDRESSES............................................................................................................. 163

Page 4 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 5

PREFACE

This manual is intended for users of products from Getinge Disinfection AB.

The user manual describes the design and operation of the machine and the maintenance for which the

user is responsible. The installation manual describes the machine's installation. The technical manual

describes necessary information for operators and maintenance personnel. The information in the manual

must be complied with to ensure safe and error-free operation.

Read the manual before use.

Users must read through the manual before using the machine for the first time, as well as familiarizing

themselves with the operation of the machine and its safety instructions. Operators and maintenance

personnel must have completed training through Getinge Academy.

The information in this manual describes the machine as dispatched from Getinge Disinfection AB. There

may be differences due to customization for customers or countries.

The machine is accompanied by the following documentation:

• User manual

• Installation manual

• Declaration of conformity

The following documentation is supplied on CD:

• User manual

• Installation manual

• Electrical diagrams

• Program sheets

The following documentation shall be provided by the sales company to the end-user on request:

• Technical manual

• Spare parts list

Getinge Disinfection AB reserves the right to change the specification and design without prior notice.

The information in this manual was up-to-date on the date that the manual was issued.

© Copyright

The content of this manual must not be copied, in

whole or in part, without written consent from

Getinge Disinfection AB.

Page 5 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 6

SAFETY PRECAUTIONS

This machine has a number of built-in safety devices.

To avoid injury, it is highly important not to bypass these safety devices.

If the equipment is used in a manner not specified by the manufacturer this can impair the safety

equipment on the machine.

Operators and maintenance personnel must undergo safety training for the machine. All personnel who

handle chemicals for washing and disinfection must understand the washing process, possible health

hazards and ways of detecting leaks of toxic chemicals.

Operators and maintenance personnel must undergo regular training in the operation and maintenance of

the equipment. There must be a documented list of personnel who have been trained to use the

machine. Trained personal must be tested to verify the training program.

Important

• Take care when handling the chemical agents used in the machine. Read the instructions on

the pack or contact the manufacturer before using the machine for instructions about:

o

if the agent comes into contact with the operator’s eyes or skin or if the vapors are

breathed in, etc.

o

for storage of packs and sorting of empty packs

o

use personal safety equipment such as safety goggles, protective gloves, etc.

• The machine must be connected in accordance with the instructions given in the installation

manual.

• The machine may only be used by adults.

• Installation and servicing may only be done by personnel trained for this machine.

• Never bypass door safety switches.

• Leaks in the system caused by worn seals in the door, for example, must be repaired

immediately.

• Before any welding is done, all cables connected to the control system via connectors and

sockets must be disconnected.

• Before doing any servicing or maintenance work on the machine, isolate it from the electric

power supply and drain all tanks.

• Do not wash down or hose down the machine with water.

• Take care when using corrosive substances.

• Observe safety measures for steam and hot water.

• The machine must not be operated with cladding plates, roof and plinths removed. Doing this

puts at risk the safety and functioning of the machine.

• The electrical cabinet may only be opened by authorized and trained personnel.

• Spare parts may only be obtained from Getinge sales companies.

Isolator switch

The machine must be preceded by a lockable switch for the electric power supply. The switch must be

easily accessible on a wall close to the machine. The installation must conform to and be marked in

accordance with local regulations.

Page 6 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 7

In an emergency

• Press the emergency stop.

• Switch off the main power switch.

• Close shutoff valves in the water and any steam supply lines.

Make sure that the assembly and installation is carried out:

• by qualified personnel.

• in accordance with current local regulations and rules.

To avoid the risk of back injury, this equipment should be assembled and installed

by at least two people.

When the work is complete, check that

• all parts have been installed according to the installation manual.

• all screws have been properly tightened

• there are no sharp edges on any parts that may come into contact with people

• all hoses, pipes and connections are intact and free from defects

• all the functions of the machine are working properly. Adjust if necessary.

• make sure that no electrical wires or hoses are touching any hot surfaces

• check electrical connections both inside the electrical cabinet and to elements

Carry out an Installation Qualification, an Operating Qualification, and a Performance Qualification

according to ISO 15883 before putting the machine into service.

Incorrect use may result in damage to objects and personal injury.

Product liability

Any modification or incorrect use of the equipment without the approval of Getinge Disinfection AB

negates Getinge Disinfection AB’s product liability.

This product was manufactured by:

GETINGE DISINFECTION AB

Ljungadalsgatan 11, Box 1505

SE-351 15 Växjö, Sweden

Page 7 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 8

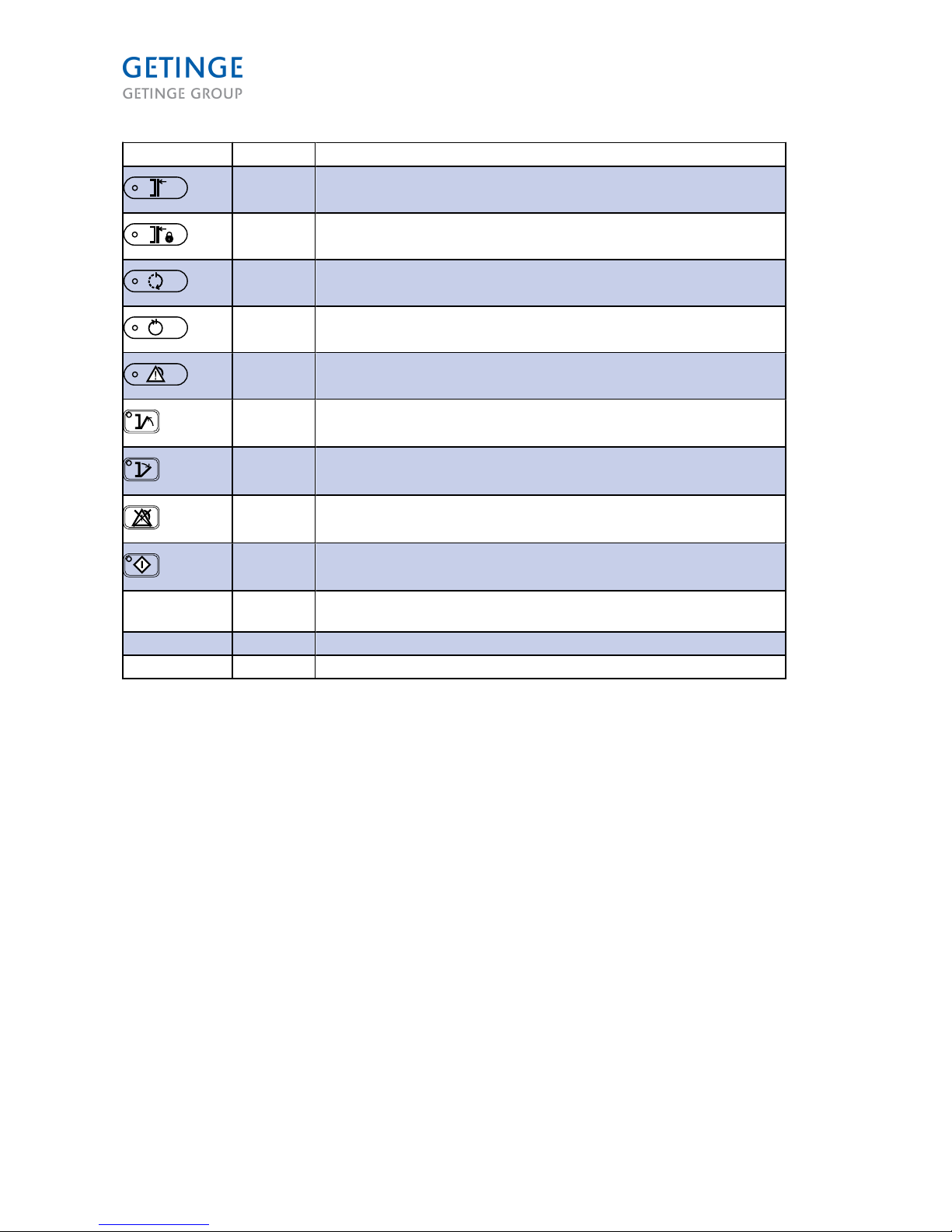

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that we use the following

special symbols to draw attention to them. The symbols and designs used are:

Risk of injuries or machine damage.

ESD-sensitive equipment.

Live components.

Page 8 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 9

INTRODUCTION

Area of application

Getinge's washer-disinfector in the 9100 series is used in medical services for washing, disinfecting at

intermediate level (A0 = 600 as standard) and drying. The washer-disinfector is used at hospitals to wash,

disinfect and dry items such as carts, containers and equipment (wash basins, bowls and similar items in

stainless steel).

Getinge's washer-disinfector in the 9100 series is used in life science for washing, disinfecting at

intermediate level (A0 = 600 as standard) and drying. The washer-disinfectors are used by animal testing

companies to wash, disinfect and dry items such as transport trolleys, racks, cages and rack equipment.

The containers should be loaded correctly on loading equipment recommended by Getinge Disinfection

AB. The customer is responsible for Installation Qualification, Operating Qualification and Performance

Qualification being performed according to EN ISO 15883 before product usage.

Incorrect use can result in damage to objects and personal injuries.

General Description

The Getinge 9100-series washer-disinfectors are large capacity, jet spray washers for mechanical

washing, intermediate level (A0 value = 600 as standard) thermal disinfection and drying of moisture and

temperature stable hospital carts, sterilization containers, material handling carts, stands and utensils.

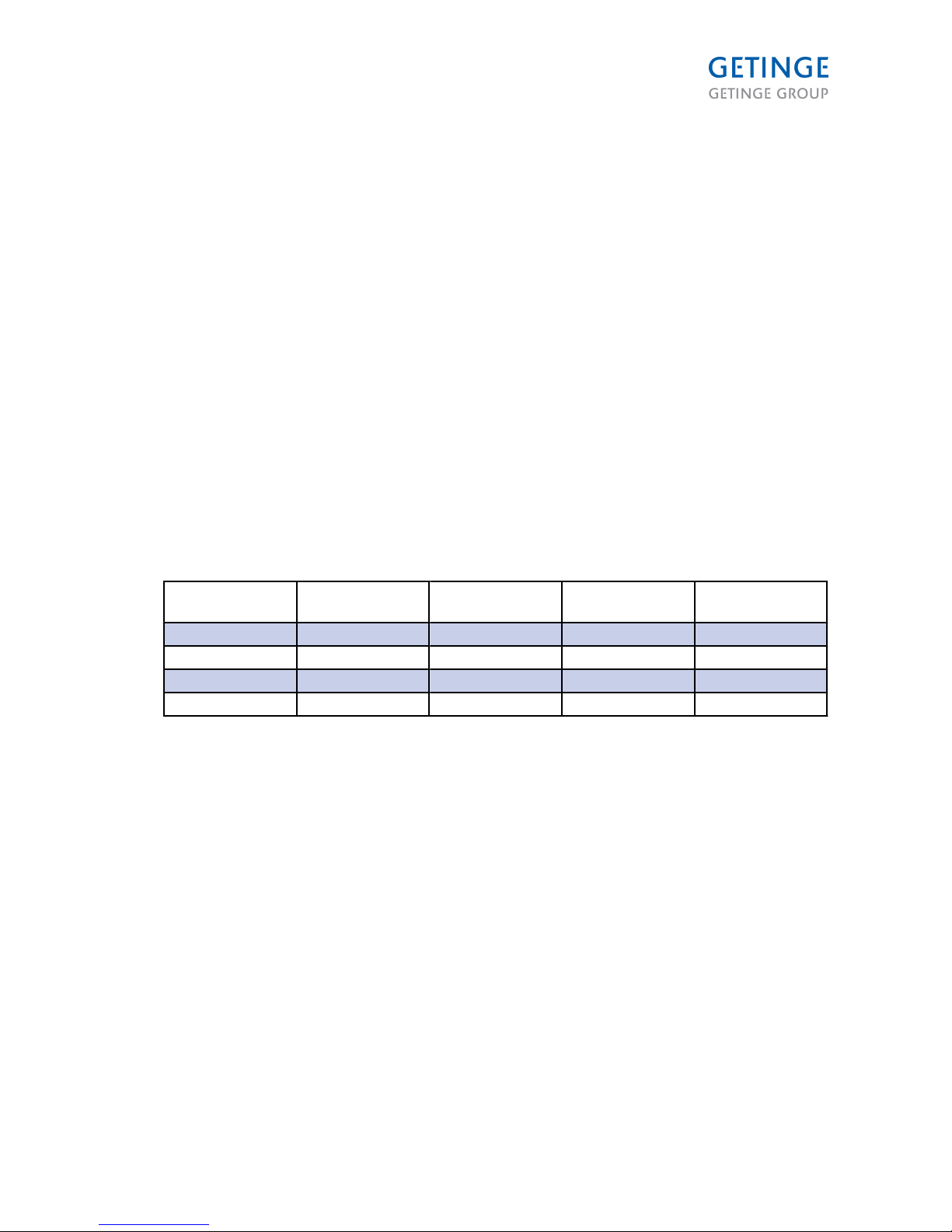

The washer-disinfector comes in four different sizes: the 9120, 9125, 9128 and 9122 models.

Model

Door Width Door High Chamber Length /

Load Length

9120 960 (38”) 2000 (80”) 2000 (80”) Health Care (HC)

9125 960 (38”) 2000 (80”) 2500 (98”) Health Care (HC)

9128 960 (38”) 2000 (80”) 2850 (112”) Health Care (HC)

9122 1170 (46”) 2200 (86”) 2200 (86”) Life Science (LS)

Washer-disinfector options and selections

The 9100-series washer-disinfector may be equipped according to the following options and accessories.

Floor Mount or Pit Mount

For a floor-mounted washer-disinfector, ramps are required to access the washer-disinfector. The inner

floor of a pit-mounted washer-disinfector is at the same level as the area's floor.

Horizontal or Inclined Sliding Door

As standard, the door opens horizontally, straight to the side. An inclined sliding door is required if the

unit is mounted in a pit with a width of 1900-2400 mm. The sliding doors open toward the service area.

Right Side or Left Side Service Area

Provide access to components such as plumbing, valves, pumps, tanks, electrical cabinet, etc. The

location of service area on your washer can be located left or right hand.

One or two doors

One door for loading/unloading on the same side, or two doors - one for loading on soiled side and one

for unloading on clean side.

Page 9 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 10

Steam or electric heating

The heating elements for water, drying and the booster tank are heated with the building's steam or

electricity.

Connection for treated water

Connection for treated water in addition to hot and cold water, which are standard.

Dosing pumps for detergent

The washer-disinfector comes as standard with two dosing pumps for detergent for process chemicals,

but a third and fourth can also be installed. This allows the chemical disinfection of e.g. heat-sensitive

objects. All dosing pumps for detergents have flow-regulation.

Water-saving tanks

One or two water-saving tanks can be installed in the service area.

Docking for wash cart

A docking mechanism in the floor to dock wash carts equipped with spray arms.

Booster tank

Tank for the preheated water to be used in the process.

Automatic flushing system for valve rack

The spray system to be used with special carts equipped with this type of spray system.

Cooling system for waste water

Cooling system to adjust the temperature of the waste water that comes from the machine.

Neutralization system for waste water

Neutralization system for adjusting the pH value for the waste water that comes from the machine.

Comes in two versions, time control or pH monitoring.

Conductivity control, final rinse

Conductivity control for the final rinse.

Conductivity control, dosing

Conductivity control for dosage of detergent

Trolley Tilt

The Chamber floor can be tilted in the washing phase so that the water on the items can drip off and the

items can dry faster.

Printer, option 1

Thermal printer that provides a printout of activities in the washer-disinfector during the process at a

preset time.

Printer, option 2

Laser printer

Page 10 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 11

Flow sensor with kalrez seal

Flow sensor with kalrez seal for highly concentrated detergent.

Front panels for service area

Cover plates to conceal the service area. The cover plates have a door for easy access to the space.

Installation kit

• Manometer, stop valve and filter for water and steam connection.

• Air bleeding kit with drainage hose.

Instrument wash

Instrument wash is a program for the washer-disinfector that cleans, disinfects and dries soiled, heavy

surgical instruments. To use this program, you need a wash cart that is suitable for these type of objects.

Ramp

Washers-disinfectors that are floor-mounted come with a split or whole ramp.

NetCom

Netcom connection

Page 11 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 12

Performance Characteristics

Programming may only be done by authorized personnel.

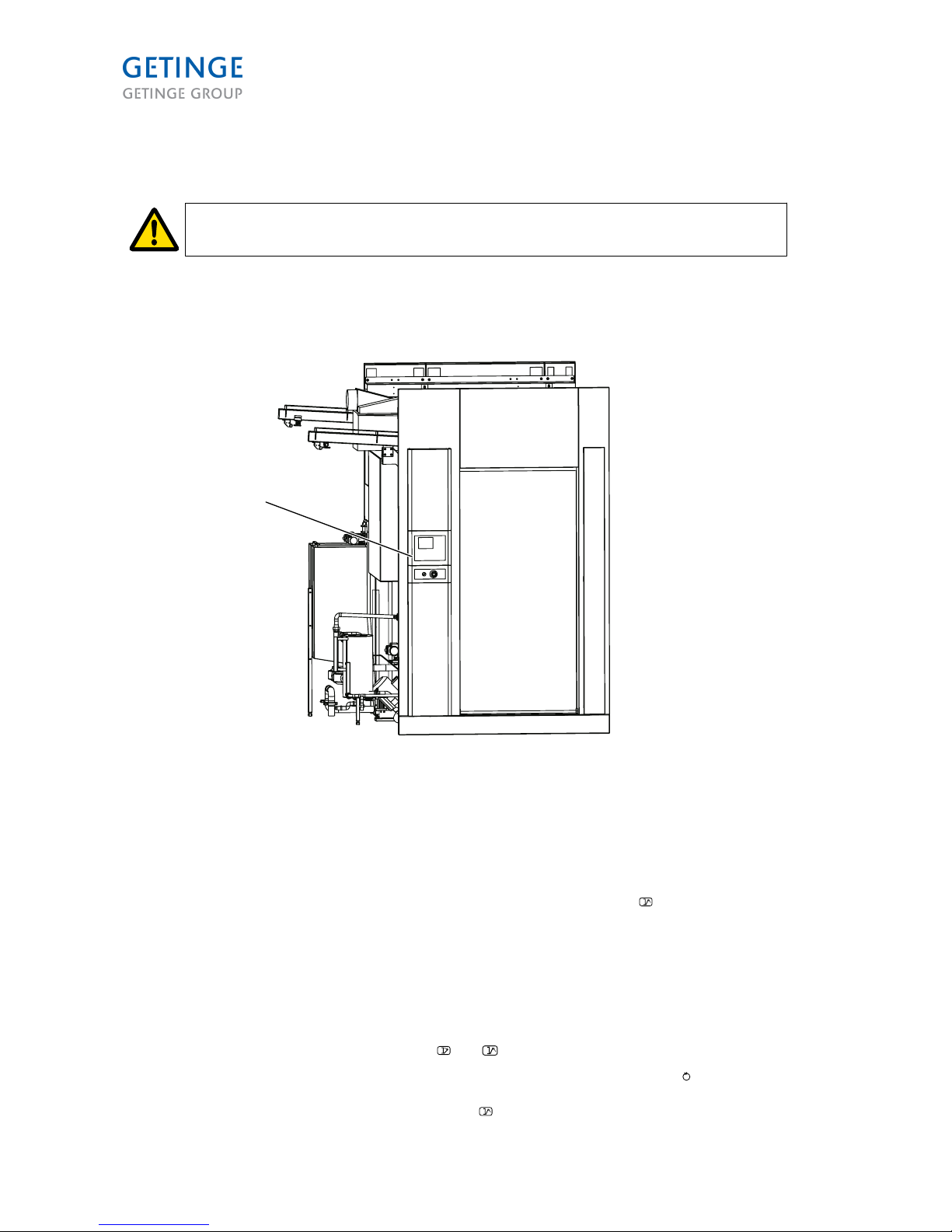

Door operation

The washer-disinfector has one or two doors. Two doors give an ”airlock” function between the soiled

and clean side of the machine. The doors are horizontal sliding doors.

1

001718

1. Control panel

The doors are motorized. As a safety measure, the operator must hold down the open or close button

during the entire opening or closing sequence. If the button is released during the sequence, the door

stops immediately (on a machine with two doors, the door on the clean side can be opened by pressing

the button once).

Machines with two doors have an interlock system so that only one door can be opened at a time. This

means that the door on the clean side must be closed and locked with the button before the door on

the soiled side can be opened.

Where the door meets the floor, there is a threshold which lowers automatically when the door opens and

closes the gap between the chamber floor and the installation floor that is created when the door opens.

This function facilitates loading and unloading of the chamber. When the button is pressed, the closing

sequence is as follows: the threshold comes out, the door closes, the door locks. When the button is

pressed, the opening sequence is as follows: door is unlocked, door opens, the threshold is retracted.

The door must be closed and locked before the start button indicates that the machine is ready. In

standby mode, the door can open and close with and respectively.

When the program is ready, a green lamp comes on, indicating that the process is ready (on both sides

if the machine has two doors). When the items have been unloaded from a machine with two doors, the

door on the clean side must be closed using the button before the door on the soiled side can be

opened.

Page 12 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 13

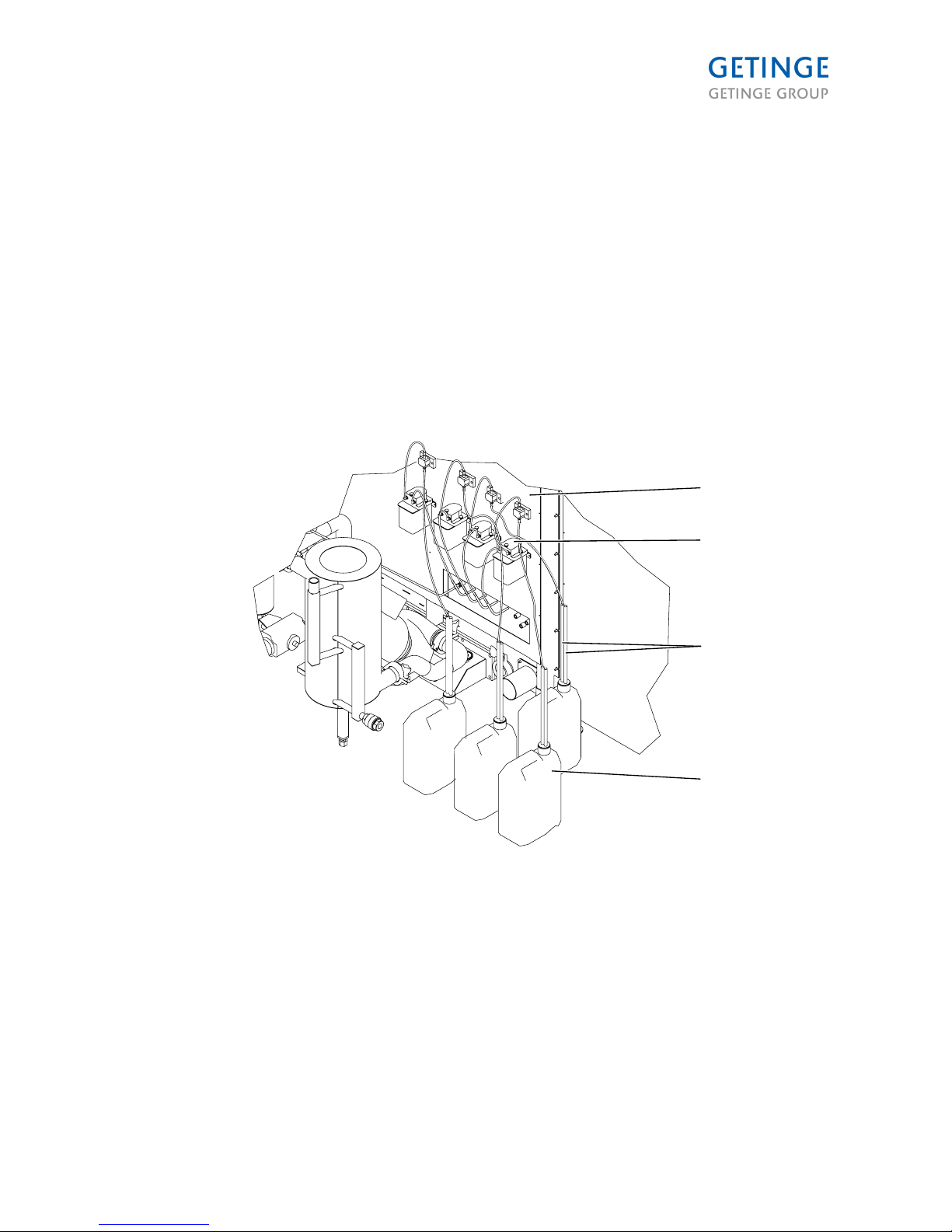

Dosing system

In standard form, the machine has two dosing systems. The dosing amount can be set individually for

each program.

The machine cannot be started if detergent level is to low in one of the detergent holders.

If the detergent bottle is empty, no ready-to-start signal is given. If, with the machine in this mode, the

start button is pressed, the display shows ”DET X LOW LEVEL” (X= 1,2).

You can also install a third or a fourth dosing system.

The machine is equipped with flow monitoring, which is linked to the monitoring system. If the flow of

detergent is too low, this is indicated via an alarm on the display.

4

001719

3

2

1

1. Flowmeter for dosing

2. Dosing pumps

3. Level sensor, detergent

4. Container for detergent/rinsing agent

Page 13 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 14

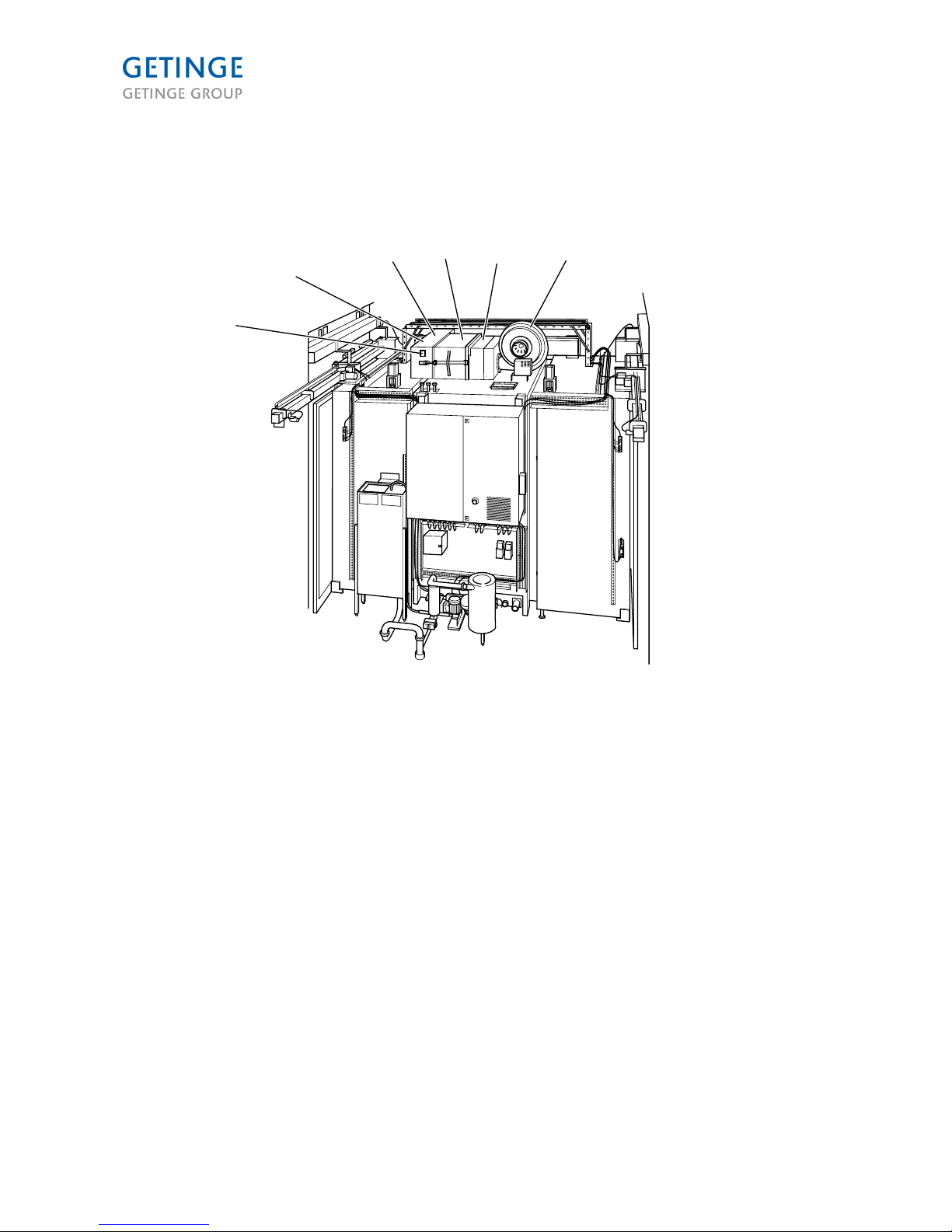

Drying

The machine is fitted by default with a drying system, which includes a fan, heating element, filter, heat

exchanger and air duct, temperature sensor and a pressure differential sensor.

1

2

3 4 5 6

001790

1. Sensor for pressure differential

2. Temperature sensor

3. Air duct

4. Filter

5. Heating element

6. Fan

Page 14 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 15

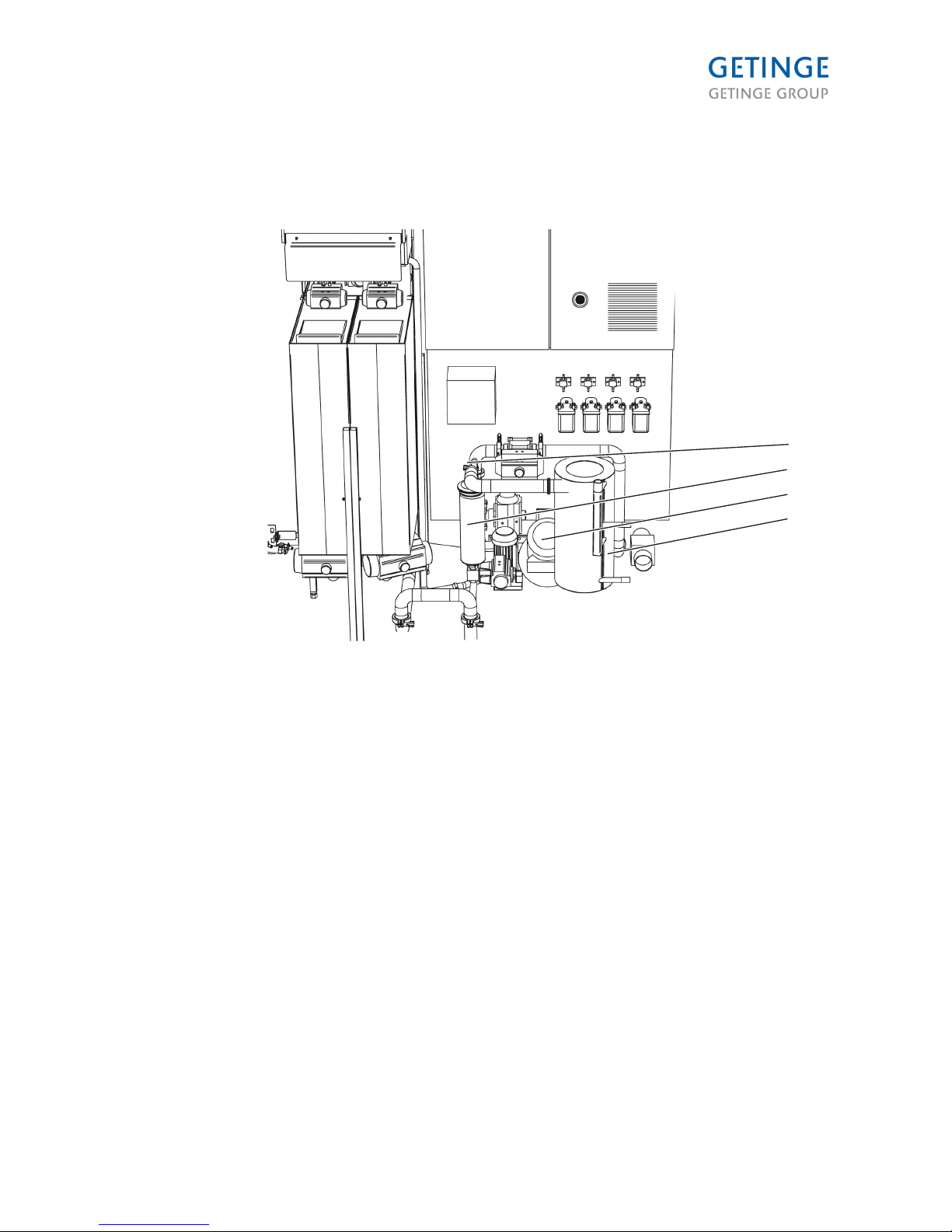

Circulation system

The machine is fitted by default with the following circulation system:

4

1

2

3

1

971

0

00

1. Pressure sensor

2. Filter

3. Circulation Pump

4. Heater

A docking system for docking the wash cart can be added as an option. There are two pressure sensors

in the "monitoring" option, one of which is connected to the main system and one to the monitoring

system.

Page 15 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 16

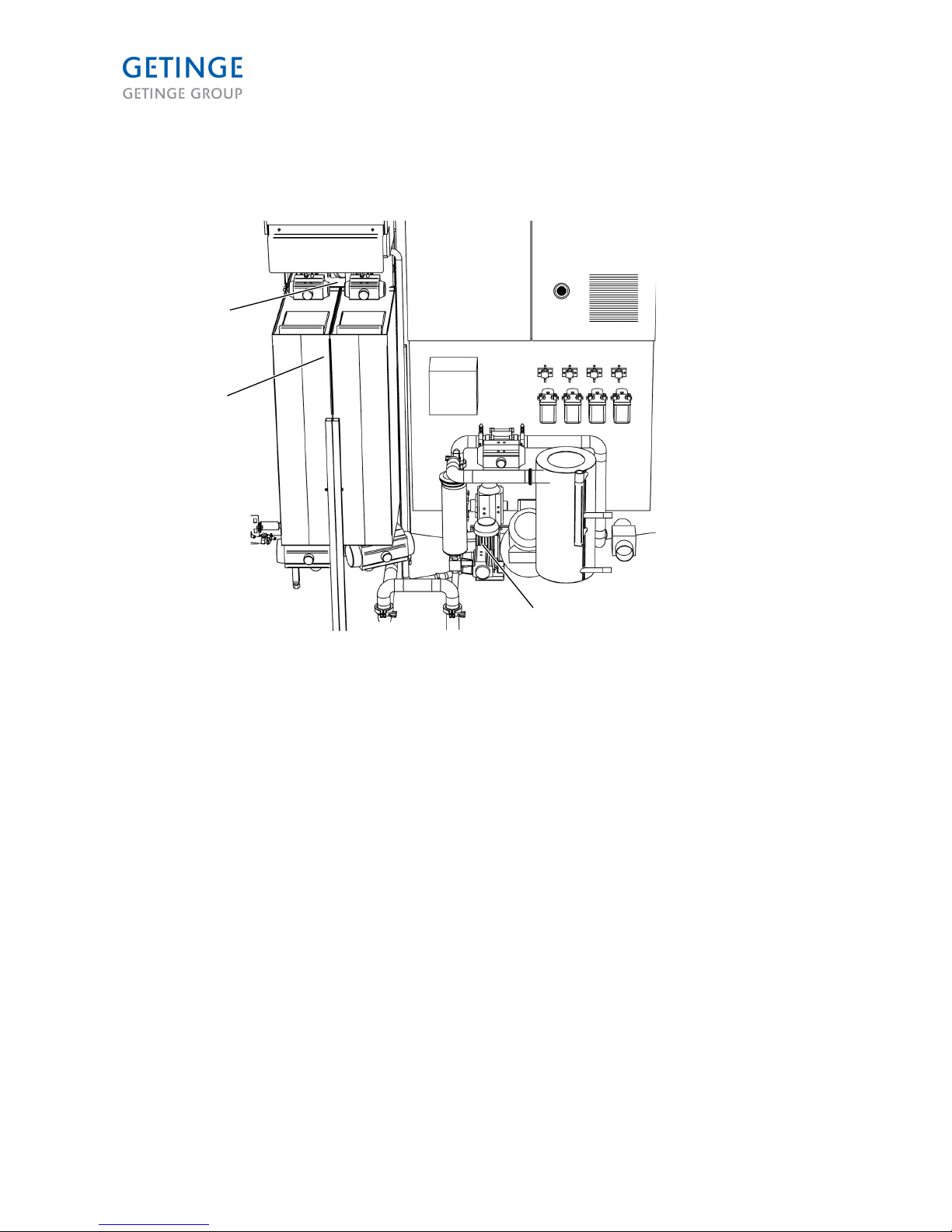

Tanks

The machine is fitted as standard with the following tank system:

1

2

3

001792

1. Waste tank

2. Storage tanks

3. Draining pump

One or two saving tanks can be added as an option. Waste water cooling is also an available option. This

includes a temperature sensor and a valve for cooling water.

Page 16 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 17

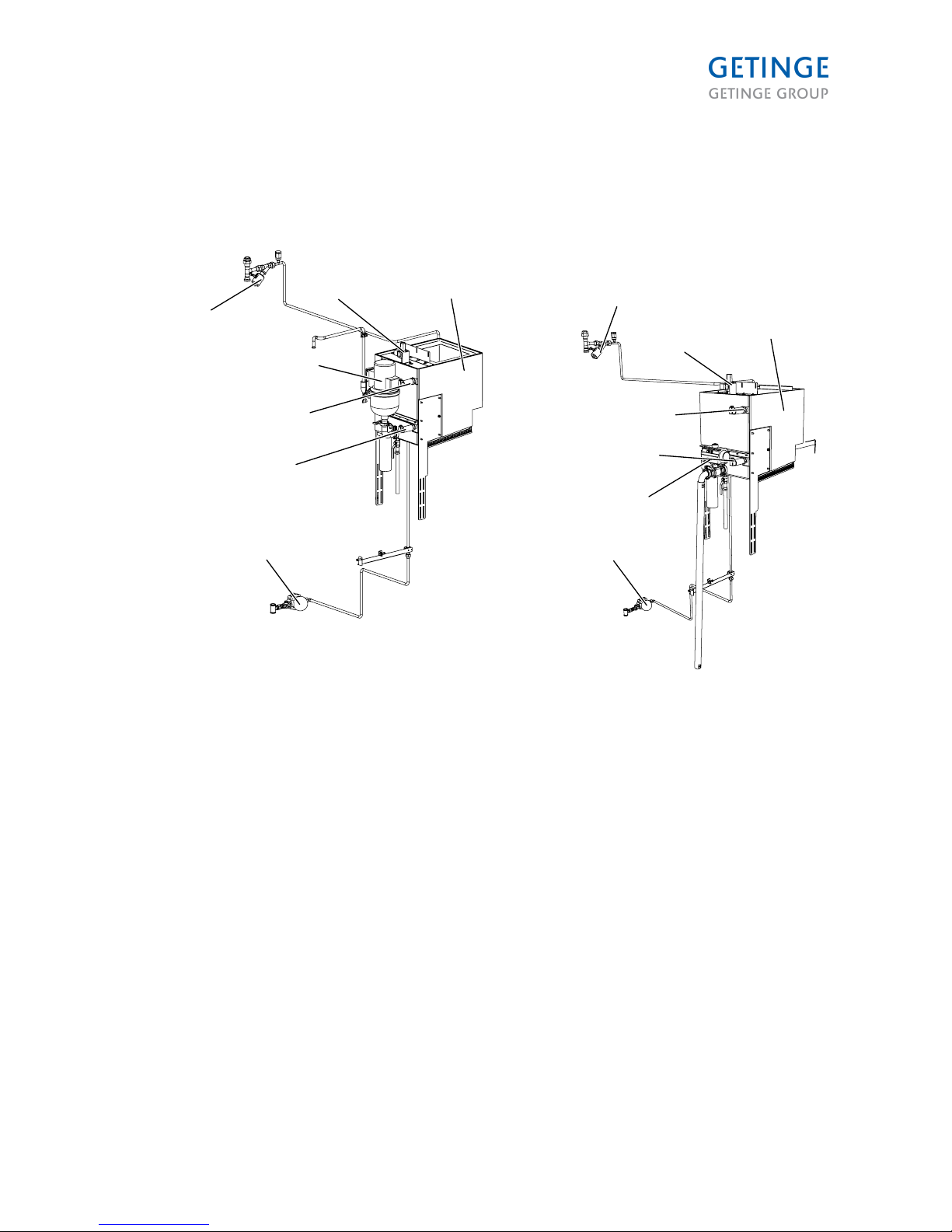

Booster tank

The machine can be equipped with an extra tank for using preheated water in the process.

The following equipment is included:

6

6

1

1

3

3

2

2

5

5

4

7

8

8

001793

1. Steam valve

2. Filling valve

3. Booster tank

4. Auxiliary pump

5. Level switch, high

6. Level switch, low

7. Booster valve

8. Condensate drain

Page 17 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 18

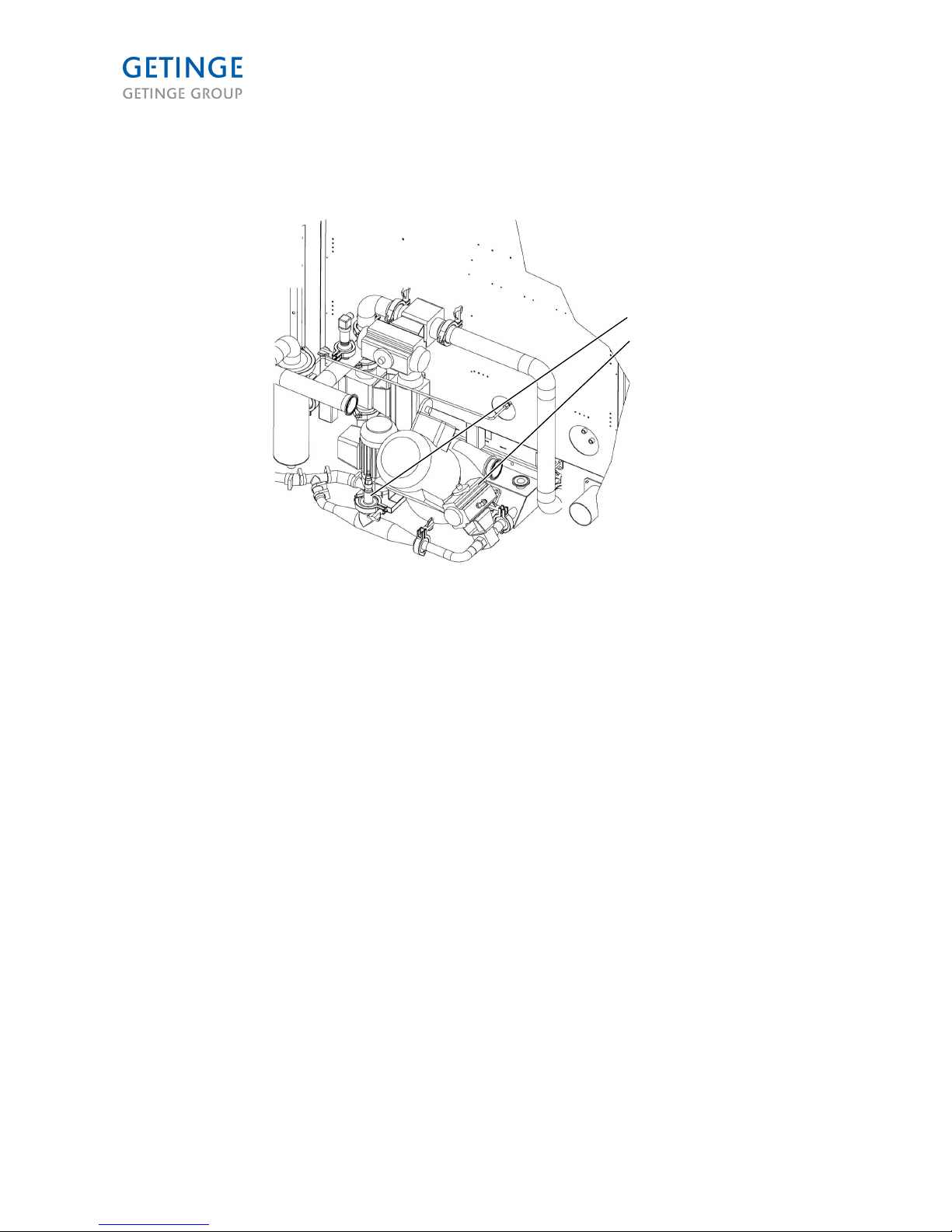

Neutralization system for waste water

The machine can be equipped with a neutralization system for waste water that includes:

2

001794

1

1. pH measuring system

2. Valve

Page 18 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 19

CONTROL PANEL

OP30 panel

Layout

OP30 is a color graphical display with a 320 W x 240 H pixel resolution mounted in a panel with a

number of buttons and LEDs.

000547

Page 19 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 20

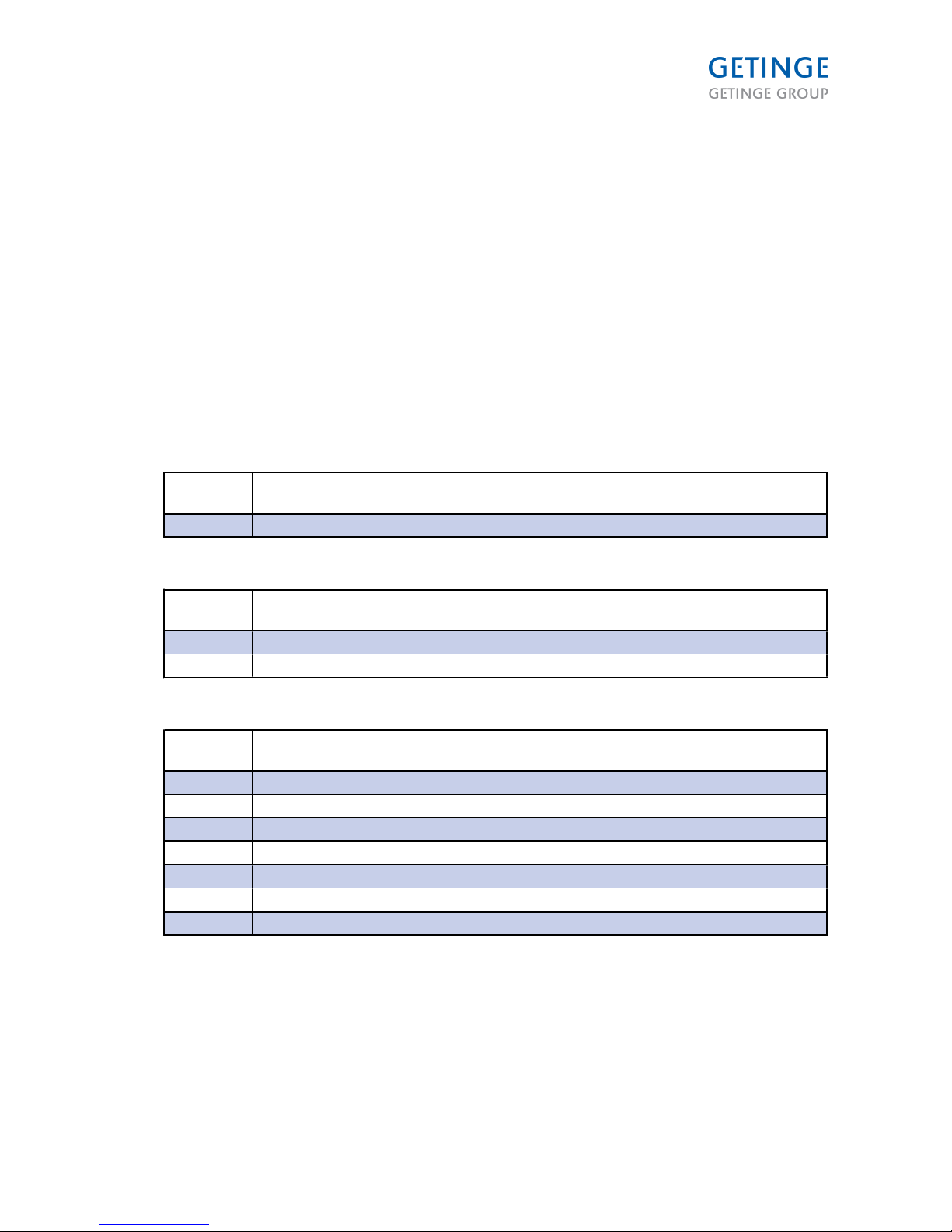

Position Type Explanation

Indication The doors are closed

Indication The doors are closed and locked

Indication Process running

Indication Process completed without errors

Indication Defective process

Button / ind Close door

Button / ind Open door

Key Acknowledge and reset the alarm

Button / ind Cycle start

5 buttons under

the display

Key Function buttons different functions for different displays

4 direction Key Arrow buttons for scrolling up/down in the menus

Enter Key Confirmation

Page 20 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 21

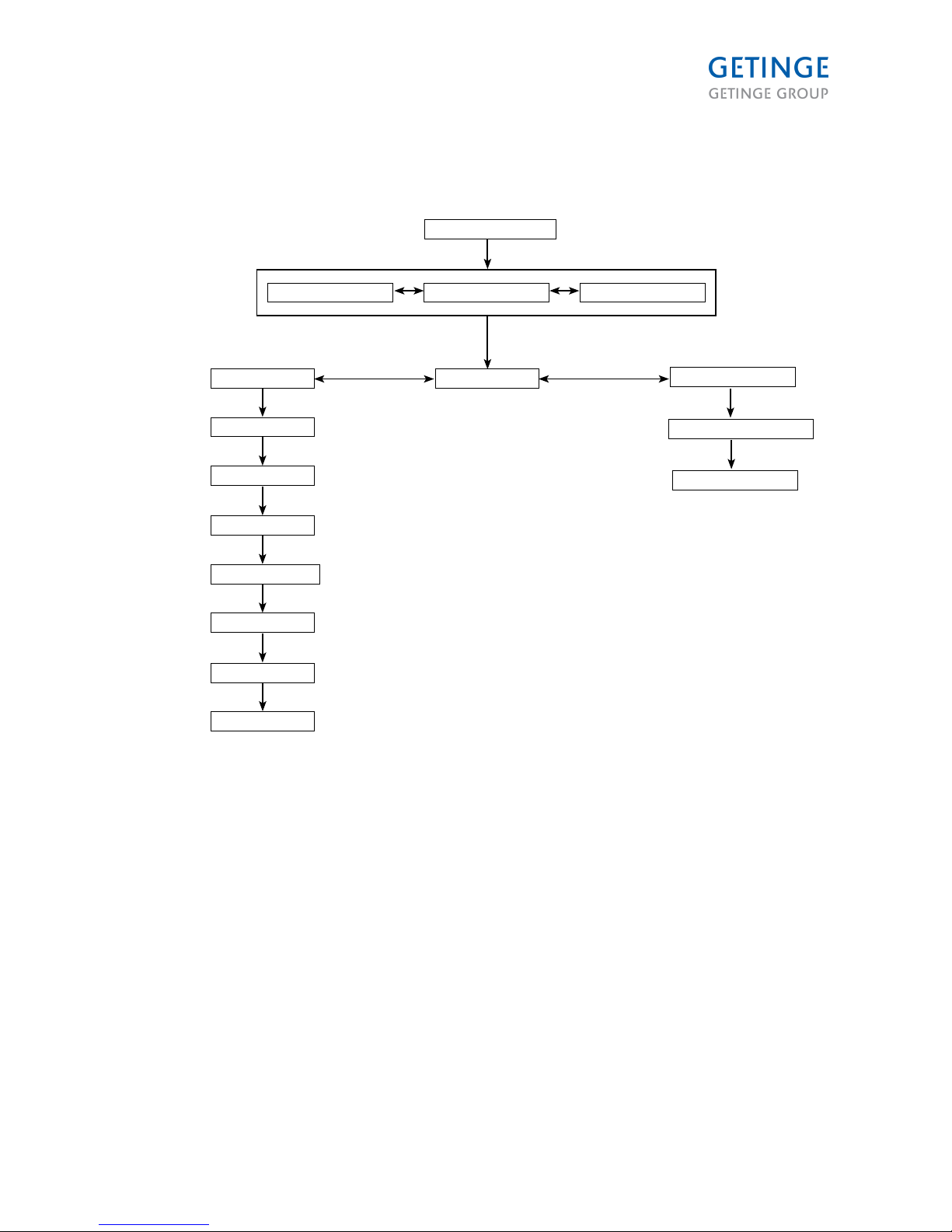

Menu tree

001720

COLDSTART DISPLAY

DETAILS PLOT GRAPH BAR GRAPH

SETUP SELECT CYCLE

DETAILS

PLOT GRAPH

VIEW PARAMTERS

QUICK EDIT PARAMETER*

SYSTEM**

BAR GRAPH

PRINT LAST CYCLE

SELECT PACS

ABOUT

1.1 1.2 1.3

2.1 2.2

2.1.6

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

2.1.7

2.3.1

EDIT POPUP

2.3.2

2.3

Process display

* Requires principal operator’s password

** Requires service personnel password

Page 21 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 22

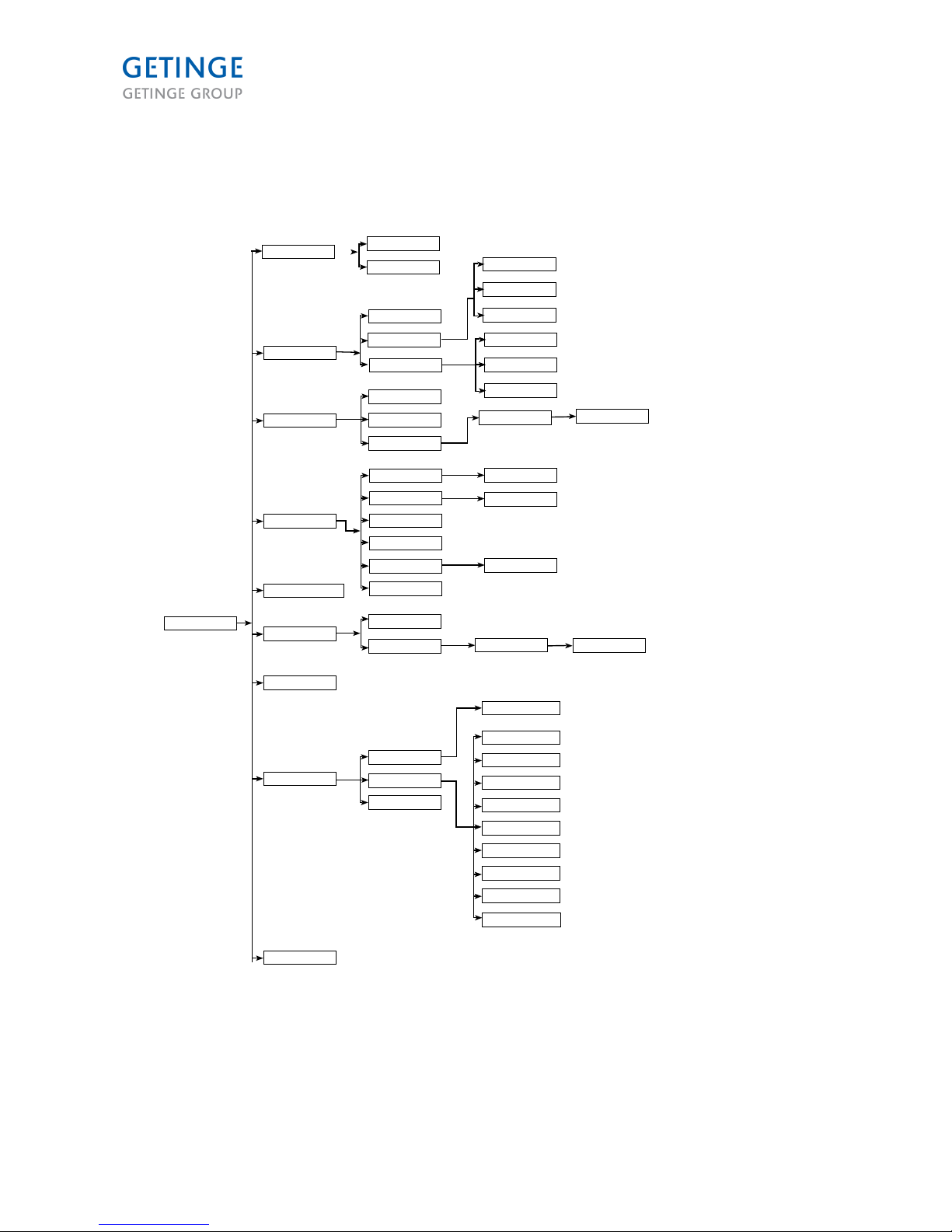

SYSTEM MENU

2.1.6

686000

CALIBRATION

DOCUMENTATION

CONFIGURATION

SYSTEM SETUP

PASSWORDS

DIPSWITCHES

SERVICE

SAVE RAM TO FLASH

EXTE. PARAMETERS

LANGUAGE & DATE UNITS

PANEL SETUP

EDIT CYCLES

PARAMETE R SELECT.

MACHINE NAME

EDIT PARAMETERS

NAME

ADD/DELETE

DIAGNOSTICS

PACS ADDRESS

ERROR LOG

ERROR LOG POPUP

ANALOG OUTPUT

TEST

ANALOG

INPUT

2.1.6.2

AUT. CALIB.

2.1.6.2.2

2.1.6.3

2.1.8.3.1

2.1.8.3.2

2.1.8.3.3

TYPE

2.1.8.3.3.1

2.1.6.4.1.1

2.1.6.4.2

2.1.6.4.2.1

2.1.6.4

2.1.6.4.1

2.1.6.4.3

2.1.6.4.3

2.1.6.4.4

2.1.6.4.5

2.1.6.4.4.1

2.1.6.5

2.1.6.6

2.1.6.6.1

2.1.6.6.2

PASSWORD

2.1.6.6.2.1.1

2.1.6.7

2.1.6.8

2.1.6.8.1

2.1.6.8.1.1

2.1.6.8.2

2.1.6.8.2.1

2.1.6.8.2.2

2.1.6.8.2.3

2.1.6.8.2.4

2.1.6.8.2.5

2.1.6.8.2.6

2.1.6.8.2.7

2.1.6.8.2.8

2.1.6.8.2.9

2.1.6.9

TIME SETTINGS

CALENDER

ALARM CLOCK

2.1.6.1

2.1.6.1.1

2.1.6.1.2

MANUAL CALIBRATION

2.1.6.2.1

DOSE MONITOR SELEC

2.1.6.2.3

FACTOR

2.1.6.2.3.1

2.1.6.2.3.2

2.1.6.2.3.3

MEASURD VOLUME

DESIRED VOLUME

PRINT CYCLE

ITEM

2.1.8.3.3.1.1

ACCESS AREAS

2.1.6.6.2.1

TEST

TEST PRINTER

2.1.6.8.3

2.1.6.2.2.1

2.1.6.2.2.2

2.1.6.2.2.3

HI

LO

PRT

TEST

DIGITAL

INPUT

TEST DIGITAL

OUTPUT

TEST USER FLAG

TEST SYSTEM FLAG

TEST LED AND BUZZER

TEST PULSE COUNTER

MACHINE NAME ENTRY

CYCLE NAME ENTRY

PRINTER

PRINTER LOG VALUES

Page 22 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 23

Display panel rules

Scope

This set of common rules or practices will apply specifically to the LCD display to be used on the OP30. It

is the objective of this section of the user interface to create a common method for selecting and editing

fields, saving data, etc. The goal is to ensure that all screens and functions used on the OP30 panel

operate in a logical and consistent manner. In those cases where there are exceptions to the rules, these

are specific to certain screens and are highlighted with comments on the screen.

General rules

1. The four (4) arrow buttons on the OP30 panel have a repeat function. If you press the button,

the button's function will be repeated 3-5 times per second until the button is released. The

repeat function starts after 0.5-1.0 sec.

2. The ¼ VGA screen will be refreshed 2 times per second.

3. When scrolling in a list, the highlighted field is inverted and displayed in a different color than the

original. The colors are determined by CS.

4. When a character is flashing (during editing), it switches between the normal and inverted

mode.

Softkey buttons

1. There are five (5) program buttons along the bottom of the LCD screen. The buttons use a small

(8x10 pixel) font and have two rows with up to seven (7) characters. The buttons are centered

and have (1) or two (2) pixel buttons in 3D.

2. The buttons are displayed in the same place. For example, if the HOME function is active in a

screen, it will always be displayed in location No. 2.

3. From the main processing screen, which is standard, use the buttons to move to the display

menus and select a function.

Fixed buttons

1. There are five (5) fixed function buttons on the OP30 panel. The fixed buttons are four (4) cursor

direction buttons (up, down, left and right) and the ENTER button.

2. Even if they are not specifically associated with the display being used on the OP30 panel, there

are several fixed buttons for various functions.

Page 23 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 24

Panel operation

1. The display is normally made up of various screens with additional function options, screens

where data can be displayed or screens with adjustable fields where data can be entered or

modified.

2. The arrow buttons can be used to scroll (up, down, right or left) through all of the various

selectable fields on the screen.

3. When you select something by going into a field, the highlighting is inverted to indicate that the

field is selected.

4. If there are more list items than there is room for in the screen, only the first ten items are

displayed along with a scroll bar to the right of the list box.

5. Use the up and down keys to scroll through the list. If the cursor is in the last field in a list, and

there are more fields below, you can go up one (1) row on the screen using the down arrow

button. The same rule applies when going in the opposite direction.

6. All selectable submenus and options work as a circular list, which means that when you press

the down button after highlighting the last item, the cursor moves to the first item in the list. The

circular dropdown list works the same way regardless of how many items there are.

7. The HOME button is always in the number 2 location, and takes you to the main menu and logs

the user out.

8. Scrollable fields may contain a maximum of 120 lines.

9. System messages on the panel, e.g. “System occupied” etc. are displayed in pop-up screens.

Screen modes

A screen has up to three different modes:

1. READ mode – displaying values

2. EDIT mode – editing values

3. SAVE mode – saving values

Page 24 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 25

Field editing

• When the screen is in Read move, the Enter button activates the Edit mode so that you can edit

the highlighted field.

• Use the cursor buttons to edit the field.

• When the button is in Edit mode, the Enter button activates the Save mode.

• Use the cursor buttons to select another field.

• When the screen is in Save mode, the Enter button activates the Edit mode so that you can edit

the highlighted field.

• The SAVE button saves the value in PACS and changes the screen mode to Read.

1. Editing numeric fields - The first character will blink while the remaining are displayed inverted.

You can change the blinking character with the up and down buttons. Press the left or right

arrow buttons to select the next character to the left or right and make it editable. Press the

right arrow button on the character at the far right to move the cursor to the far left. The same

applies for the character on the far left. Once you press ENTER after editing a numeric field, the

system checks to make sure that the value is within the allowable range.

2. Activating field editing - All characters in the field will blink. Press the up or down buttons to

activate the field value for the previous or next field value in the list. If the field is the last value in

the list, you can display the first value in the list by pressing the down button. The same applies

to the first value in the list, if you press the up button.

3. Editing alphanumeric fields – A keyboard appears in a pop-up screen above the active screen.

The pop-up keyboard is not transparent. A cursor displays where the field value is. Field value

will be empty. The first key on the keyboard is highlighted. Use the cursor buttons to move to

the desired character. Press the ENTER button to insert the selected character in the field. Use

the cursor buttons and the ENTER button to enter the remaining characters in the field. The

keyboard supports both upper and lower case characters. Then use the "CAPS LOCK" button

on the keyboard to switch between upper and lower case. Press the OK button to close the

screen and return to the previous screen and insert the selected character in the selected field.

OK and Cancel buttons

Use the OK button in Read mode to go to the previous screen. No dialog box "Confirm cancel"?

The CANCEL function is always in button location 1 and is defined as follows:

a. Read mode – go to previous screen. No dialog box "Confirm cancel"?

b. Edit mode, no pop-up screen – resets the field to the original value and activates Save mode.

Edit mode, pop-up screen – restores the field to its original value, returns to previous screen

and activates Save mode.

c. Save mode – opens "Confirm cancel"? (if activated), resets all fields on the screen to their

original values and returns to the previous screen

1. If the flag in the panel setup menu for confirming SAVE/CANCEL is set to Yes, the "Confirm

save?" question appears when you select SAVE, so that you have to choose YES or NO. Select

YES to continue and save the values in the screen. Select NO to return to the screen.

2. If the flag in the panel setup menu to confirm SAVE/CANCEL is set to Yes, and if any value on

the screen has been modified, the question “Confirm Cancel ?” will be displayed when you

push CANCEL, allowing the user to select YES or NO. YES will continue and cancel. Select NO

to return to the screen.

Page 25 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 26

Panel communication

Panel boot sequence

1. When the control panel starts, the previous PACS system (saved in the control panel's memory)

is connected.

2. Try the next PACS address in the list, if a connection cannot be established (saved in the

control panel's memory).

3. If it is not possible to establish a connection with any of the defined PACS addresses in the list

or if there isn't a list (new panel), you will need to search through all addresses (01-99) until a

connection is established. Stop searching when the first address is found. Add the new PACS

address to the list.

4. When the connection is established with a different PACS than the previous one, go to the

menu "Select PACS" (2.1.5) and select the PACS that was found.

5. The default settings for the panel are saved in the PACS RAM memory and downloaded to the

panel during startup. Default settings are programmed with CS 1000.

Communication error

If a communications error occurs, a message will be displayed on the screen, “COMMUNICATION

ERROR”, while the panel will try to establish a communication with the PACS. The panel will try

communicating with PACS until the connection can be established.

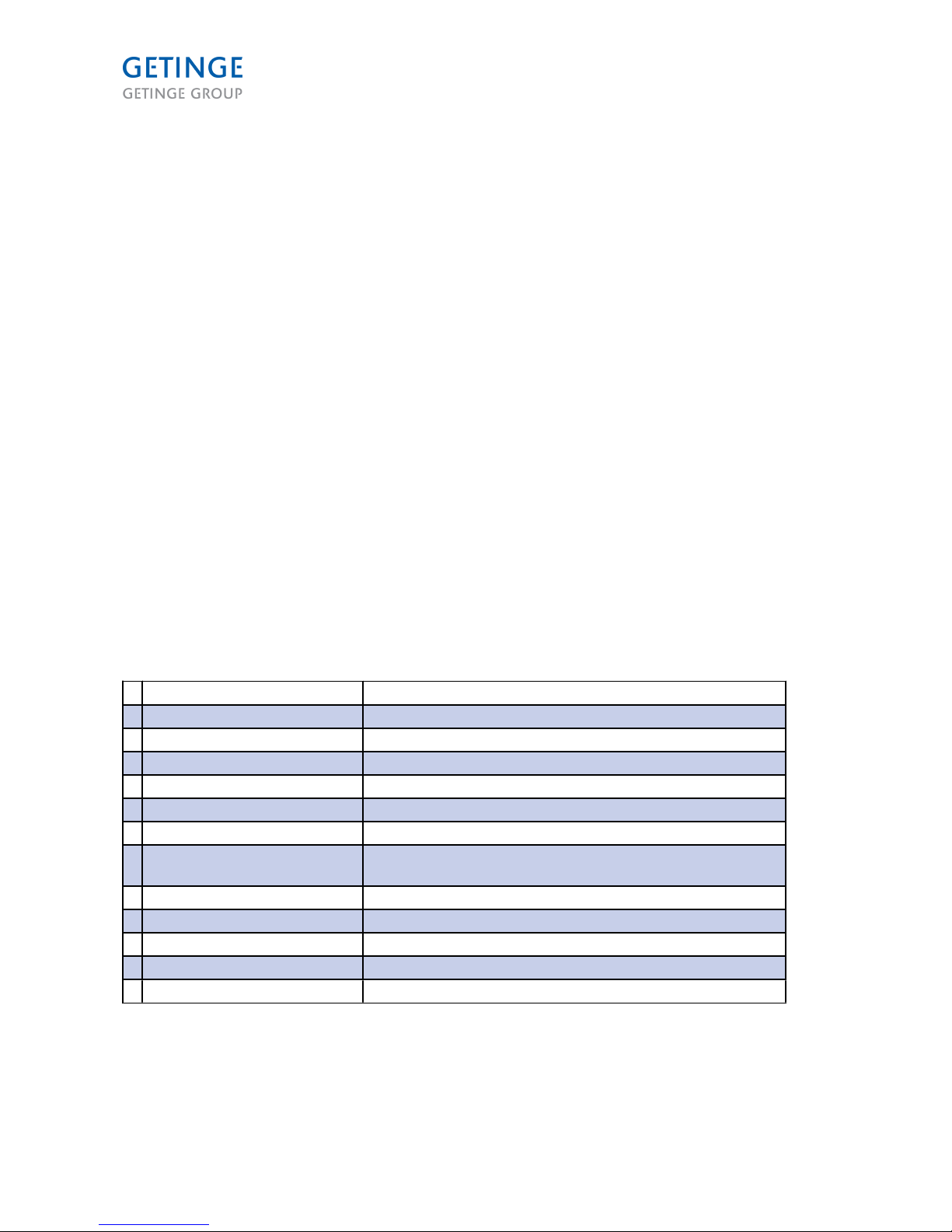

User access and passwords

Access areas

The menu tree on OP30 is divided into several access areas. Each area is allowing access to various

screens. The areas are:

Access area:

Access rights to:

A Parameter Settings Parameter screen (2.3) and all submenus

B Time Settings Time settings (2.1.6.1) and all submenus

C Calibration Calibration screen (2.1.6.2) and all submenus

D Boolean Password 1 Used for Boolean password, initiated from Boolean code

E Service Service screen (2.1.6.8) and all submenus.

F DIP switch The DIP switch screen (2.1.6.7) and all submenus

G Non Process Critical

Configuration

Configuration screen (2.1.6.4) and all sub-screens

The Save RAM to Flash screen (2.1.6.9) and all submenus

H Process Critical Configuration System settings screen (2.1.6.5)

I Boolean Code Does not apply to this panel

J Password Setup Password screen (2.1.6.6) and all submenus

K Document Document screen (2.1.6.3) and all submenus

L Boolean Password 2 Used for Boolean password, initiated from Boolean code

After accessing the system menu (2.1.6) and entering the password, the user will only see sub-menus to

(2.1.6) that the user has access to. Other menus will be hidden. When logged in the user can freely move

around in the menu tree. However leaving the system menu by using CANCEL or HOME will log out user.

Next time user tries to access the system menu, the password question will show again. If a user tries to

access an area that does not belong to the users access rights, a message “No Access” will be

displayed.

Page 26 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 27

Password system in the standard 9100-Series machine of Getinge Disinfection AB

Password

Users are defined in screen (2.1.6.6). In screen (2.1.6.6.1) users will be entered with a name, a password

and areas the user has access to (A through L). Passwords may be numerical or alphanumerical. The

password must have a minimum of 3 characters and a maximum of 6 characters. Upper case or lower

case letters do not matter.

Different users may not have the same password. This shall be checked when entering a new password.

The authorization groups are as following:

• Operator (no password requested for start).

• Main operator

• Supervisor

• Service

Operator

Access

code:

Access rights to:

- No authorization to access areas A through L

Main operator

Access

code:

Access rights to:

A Authorization to modify the program, adjustable parameters (A parameters).

D Authorization to acknowledge alarms and start password protected programs.

Supervisor

Access

code:

Access rights to:

A Authorization to modify the program, adjustable parameters (A parameters).

B Authorization to modify time settings

C Authorization to use calibration function.

D Authorization to acknowledge alarms and start password protected programs.

G Authorization to modify the non-process-critical configuration, extended parameters

J Authorization to define new users and change passwords.

K Authorization to the documentation system.

Page 27 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 28

Service

Access

code:

Access rights to:

A Authorization to modify the program, adjustable parameters (A parameters).

B Authorization to modify time settings

C Authorization to use calibration function.

D Authorization to acknowledge alarms and start password protected programs.

E Authorization to service menu.

F Authorization to change dipswitches.

G Authorization to modify the non-process-critical configuration, extended parameters

H Authorization to modify the process-critical configuration, system setup.

I Authorization to change Boolean codes.

J Authorization to define new users and change passwords.

K Authorization to the documentation system.

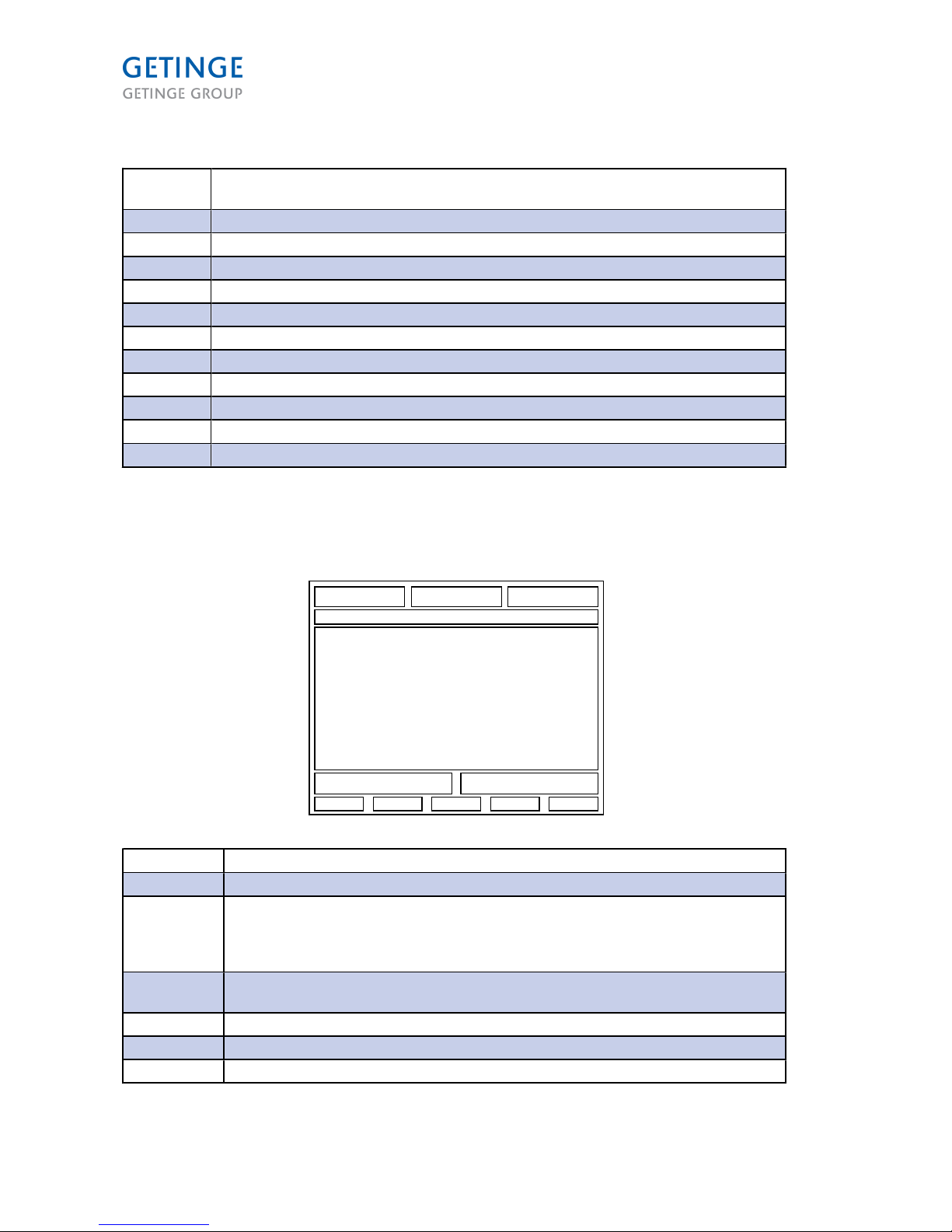

Screen Layout

Button:

1 2 3

4

5

6 7

8 9 10 11 12

000555

Section

Description

Section 1-3: Process value or Parameter value

Section 4: Cycle number and name + Phase name and sub number

This field is also linked to the Process Ready LED in terms of colors. If the process is

normal with no errors, a green light appears. If errors it is displayed red. If a test process,

it blinks with the same function as above.

Section 5: Main screen for text values, bar graphs, trend curves, parameter input data, test

functions, messages, system messages, etc.

Section 6: Alarm messages (tripping)

Section 7: Information and system messages (Non-critical)

Section 8-12: Softkey buttons

Page 28 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 29

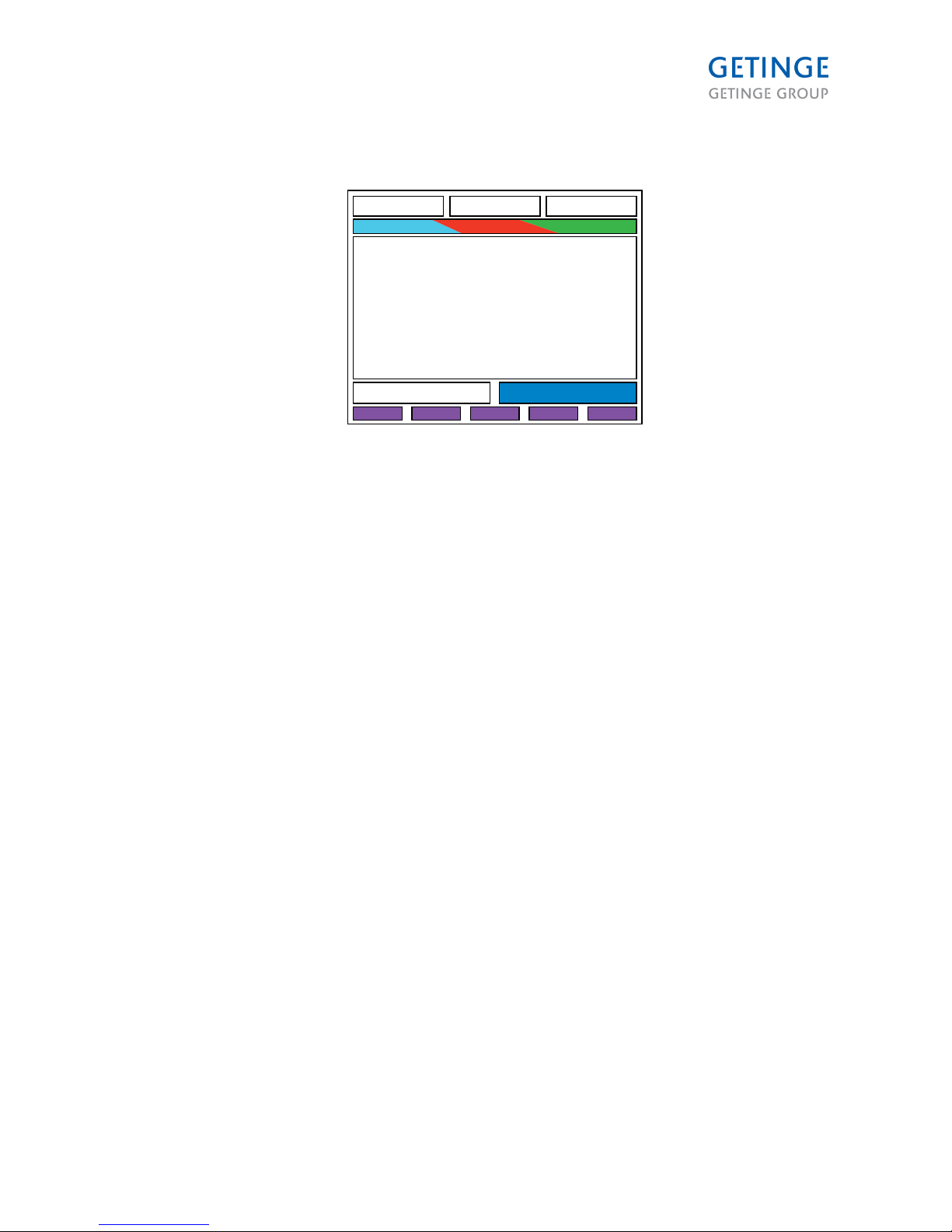

Colors:

000556

1 2 3

4

5

6 7

8 9 10 11 12

Section 4 If the phase is in progress, the area showing the current phase, is displayed in light blue.

• If there is an alarm when a normal sterilization process is running, the area is displayed in red. *

• If there is an alarm when a test process is running, the area will blink in red. *

• After normal sterilization process is completed, the area is displayed in green. *

• After a test process is completed, the area is blinking in green. *

* Those functions are linked to the LEDs on the panel and can be programmed with the application

software.

Button description

The following buttons/keys are panel controlled:

• 5 program buttons

• 4 cursor buttons

• 1 ENTER button

Following buttons/keys are program-controlled:

• 1 acknowledge alarm key

• 1 door open

• 1 door close

• 1 start

LED description

Following LEDs are program-controlled:

• Start Available

• Door(s) Closed

• Door(s) Locked

• In Progress

• Process Error

• Process Complete

• Door Open Available

• Door Close Available

Page 29 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 30

Buzzer

The buzzer in the control panel is program-controlled.

Cold Start Screen (0.1)

This screen is displayed when the OP30 panel is cold started. It will show while the panel boots up and

starts up communication with the PACS, before the Main Process Screen comes on. As this screen is

showing, all LEDs on the panel will be lit for test.

PACS 3500

000546

Panel screen

Process screen

When the washer-disinfector has started up, the Cold Start Screen is replaced by either screen 1.1, 1.2

or 1.3. If no active selection is made, screen 1.1 appears after start-up.

Screens (1.1), (1.2) and (1.3) display the values for the process.

These screens contain the "MENU", "SELECT PROGRAM" and "EDIT VALUES" buttons, which brings up

other screens.

Page 30 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 31

Details (1.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT

00:12:24

01 STANDBY

00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

SETUP

SELECT

CYCLE

PARA-

METERS

CHAMBER TEMP

17,2 C

INDEPENDENT TEMP

38,1 C

DISCHARGE PRESS

0.000 BAR

DRYER TEMP

22,6 C

DRY FILTER DIFF PR

BOOSTER TEMP

2,03 mBar

21,3 C

1

32

11

7

12

13

6

5

4

8

9

10

14

15

1. WASH1 TEMP SP

2. WASH1 TIME

3. DRYER TEMP

4. PARAMETERS

5. SELECT CYCLE

6. SETUP

7. A34 I/O FAULT

8. BOOSTER TEMP

9. DRY FILTER DIFF PR

10. DRYER TEMP

11. DISCHARGE PRESS

12. INDEPENDENT TEMP

13. CHAMBER TEMP

14. STANDBY

15. HC SHORT

Page 31 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 32

Plotgraph (1.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

SET UP

SELECT

CYCLE

PARA-

METERS

DISCHARGE PRESS

WASH1 TEMP SP

BAR

C

000714

1

32

8

7

9

10

6

5

4

11

12

1. WASH1 TEMP SP.

2. WASH1 TIME

3. DRYER TEMP

4. PARAMETERS

5. SELECT CYCLE

6. SETUP

7. A34 I/O FAULT

8. GRAPH

9. WASH1 TEMP SP

10. DISCHARGE PRESS

11. STANDBY

12. HC SHORT

Page 32 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 33

Bar graph (1.3)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

SET UP

PARA-

METERS

CHAMBER TEMP

DISCHARGE PRESS

38,1 °C 0.000 BAR

00:19

TIME REMAINING

000715

SELECT

CYCLE

1

32

9

10

8

7

6

11

12

4

5

1. WASH1 TEMP SP

2. WASH1 TIME

3. DRYER TEMP

4. DISCHARGE PRESS

5. TIME REMAINING

6. PARAMETERS

7. SELECT CYCLE

8. SETUP

9. A34 I/O FAULT

10. CHAMBER TEMP

11. STANDBY

12. HC SHORT

Page 33 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 34

Menus (2.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

DETAILS

PLOTGRAPH

BAR GRAPH

SYSTEM MENU

ABOUT

317

000

17.2 C

17.6 C

0.000 BAR

22.6 C

0.06 mBAR

21.3 C

PRINT LAST CYCLE

SELECT PACS

7

2

8

9

1

3

4

5

6

1. CANCEL

2. A34 I/O FAULT

3. ABOUT

4. SYSTEM MENU

5. SELECT PACS

6. PRINT LAST CYCLE

7. BAR GRAPH

8. PLOTGRAPH

9. DETAILS

Menus of popup list boxes. A scroll list is displayed if there are more selections available than

what is visible. The previous screen can still be seen behind the list.

CANCEL opens the Main Process Screen

DETAILS make screen (1.1) into the Main Process Screen.

PLOT GRAPH makes screen (1.2) into the Main Process Screen.

BAR GRAPH makes screen (1.3) into the Main Process Screen.

PRINT LAST CYCLE is only available during set-up

SELECT PACS is only displayed if the system has more than one PACS.

SYSTEM MENU requires a password to modify settings in PACS.

DEVICE INFO opens the device info screen.

Page 34 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 35

Details (2.1.1)

DETAILS is selected by highlighting the text in the display using the cursor buttons. When the DETAILS

text is highlighted, press ENTER. When DETAILS is selected, screen (1.1) becomes the process screen

while you go up one level in the menu tree and end up in the process screen.

49,1 C

WASH1 TEMP SP

P1 HC SHORT

00:12:24

01 STANDBY

00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

SETUP

SELECT

CYCLE

PARA-

METERS

CHAMBER TEMP

17,2 C

INDEPENDENT TEMP

38,1 C

DISCHARGE PRESS

0.000 BAR

DRYER TEMP

22,6 C

DRY FILTER DIFF PR

BOOSTER TEMP

2,03 mBar

21,3 C

1

32

11

7

12

13

6

5

4

8

9

10

14

15

1. WASH1 TEMP SP

2. WASH1 TIME

3. DRYER TEMP

4. PARAMETERS

5. SELECT CYCLE

6. SETUP

7. A34 I/O FAULT

8. BOOSTER TEMP.

9. DRY FILTER DIFF PR

10. DRYER TEMP

11. DISCHARGE PRESS

12. INDEPENDENT TEMP

13. CHAMBER TEMP

14. STANDBY

15. HC SHORT

Page 35 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 36

Plotgraph (2.1.2)

When PLOT GRAPH is selected, the screen (1.2) becomes the process screen, while you go up one level

in the menu tree and end up in the process screen.

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

SET UP

SELECT

CYCLE

PARA-

METERS

DISCHARGE PRESS

WASH1 TEMP SP

BAR

C

000714

1

32

8

7

9

10

6

5

4

11

12

1. WASH1 TEMP SP.

2. WASH1 TIME

3. DRYER TEMP

4. PARAMETERS

5. SELECT CYCLE

6. SETUP

7. A34 I/O FAULT

8. GRAPH

9. WASH1 TEMP SP

10. DISCHARGE PRESS

11. STANDBY

12. HC SHORT

Page 36 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 37

Bar graph (2.1.3)

When BAR GRAPH is selected, screen (1.3) becomes the process screen, while you go up one level in

the menu tree and end up in the process screen.

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

SET UP

PARA-

METERS

CHAMBER TEMP

DISCHARGE PRESS

38,1 °C 0.000 BAR

00:19

TIME REMAINING

000715

SELECT

CYCLE

1

32

9

10

8

7

6

11

12

4

5

1. WASH1 TEMP SP

2. WASH1 TIME

3. DRYER TEMP

4. DISCHARGE PRESS

5. TIME REMAINING

6. PARAMETERS

7. SELECT CYCLE

8. SETUP

9. A34 I/O FAULT

10. CHAMBER TEMP

11. STANDBY

12. HC SHORT

Page 37 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 38

Print last cycle menu (2.1.4)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

PLOTGRAPH

BAR GRAPH

SYSTEM MENU

SELECT PACS

ABOUT

000716

DETAILS

17.2 C

17.6 C

0.000 BAR

22.6 C

0.06 mBAR

21.3 C

PRINT LAST CYCLE

1

2

1. CANCEL

2. PRINT LAST CYCLE

PRINT LAST CYCLE is only shown in standby mode.

The menu item brings you to the CONFIRM PRINT screen (2.1.4.1).

CANCEL returns to default screen.

Page 38 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 39

Confirm Print last cycle (2.1.4.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME NO

YES

PRINT LAST CYCLE

000717

3

2

1

4

5

1. YES

2. NO

3. HOME

4. CANCEL

5. PRINT LAST CYCLE

CANCEL reverts to the process screen.

NO opens the previous screen (2.1.4)

YES prints last cycle and opens previous menu (2.1.4)

Page 39 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 40

Select PACS (2.1.5)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

WASHER

SUPERVISOR

000718

2

3

1

1. CANCEL

2. WASHER

3. SELECT PACS

CANCEL reverts to default process screen.

ENTER button saves the PACS ID in the panel memory and start communication to the selected PACS.

The screen closes and returns to default process screen.

Page 40 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 41

System menu (2.1.6)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

ENTER PASSWORD

PASSWORD:

CANCEL DELETE OK

A

K

U

!

.

2

B

L

V

”

:

3

C

M

W

#

+

4

D

N

X

%

SPACE

5

E

O

Y

&

6

F

P

Z

(

7

G

Q

Å

)

8

H

R

Ä

\

-

9

I

S

Ö

,

/

0

J

T

Ü

;

=

000719

1

4

3

2

1

1. OK

2. DELETE

3. CANCEL

4. PASSWORD

DELETE removes the last character in the string. Entering the correct password and pushing OK moves

to SYSTEM MENU (2.1.6).

Page 41 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 42

TIME REMAINING

DISCHARGE PRESS

0.000 BAR

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

000720

PLOTGRAPH

BAR GRAPH

ABOUT

DETAILS

SYSTEM MENU

TIME SETTINGS

CALIBRATION

DOCUMENTATION

CONFIGURATION

SYSTEM SETUP

PASSWORD

1

2

1. CANCEL

2. TIME SETTINGS

CANCEL returns to the menu screen (2.1). The system menu is a series of pop-up list boxes. If more

selections are available than are visible then a scroll bar should indicate this.

Page 42 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 43

Time settings (2.1.6.1)

TIME REMAINING

0.000 BAR

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

000721

PLOTGRAPH

BARGRAPH

ABOUT

DETALS

SYSTEM MENU

TIME SETTING

CALIBRATION

DOCUMENTATION

CONFIGURATION

SYSTEM SETUP

PASSWORD

CALENDAR

ALARM CLOCK

DISCHARGE PRESS

3

1

2

1. SYSTEM MENU

2. TIME SETTINGS

3. CALENDAR

Page 43 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 44

Calendar (2.1.6.1.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL HOME OK

002629

CALENDAR

TIME 11:36:34 HH:MM:SS

DATE 2013/12/17 YYYY/MM/DD

4

2 1

3

1. OK

2. CANCEL

3. DATE

4. TIME

Select the value to be changed using the button arrows and confirm with ENTER. When a value is

selected, the screen will be displayed in SAVE mode. Modify the time and date using the arrow buttons.

Confirm with the SAVE button when the time and date are correct. When the values are confirmed, the

Time settings screen reappears (2.1.6.1).

Page 44 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 45

Alarm clock (2.1.6.1.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

OK

ALARM CLOCK

(HH:M) MTOTFLS

000722

1

3

2

1. WEEKDAYS

2. A SYMBOL DISPLAYS HERE IF THERE IS AN ACTIVE ALARM

3. TIME

When there is an alarm clock in the system, the time appears in the field under (HH:MM) and the

weekdays when the alarm clock is active are MTWTFSS. If the alarm is active on Mondays, a 1 is

displayed under the M, if the alarm is inactive, a 0 is displayed.

Page 45 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 46

Calibration (2.1.6.2)

TIME REMAINING

DISCHARGE PRESS

0.000 BAR

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

000723

PLOTGRAPH

BAR GRAPH

ABOUT

DETAILS

SYSTEM MENU

TIME SETTINGS

CALIBRATION

DOCUMENTATION

CONFIGURATION

SYSTEM SETUP

PASSWORD

MANUAL

AUTOMATIC

DOSE MONITOR

3

2

1

1. HOME

2. CANCEL

3. MANUAL

Page 46 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 47

Manual calibration (2.1.6.2.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

OK

MANUAL CALIBRATION

SENSOR GAIN OFFSET VALUE

00 CHAMBER TEMP 1,000 0,0 49,1

01 DRYER TEMP 1,000 0,0 128,0

02 DRAIN TEMP 1,000 0,0 9,999

03 BOOSTER TEMP 1,000 0,0 1,205

05 DISCHARGE PRESS 1,000 0,0 43,1

06 CONDUCTIVITY FR 1,000 0,0 9,999

000724

1

1. VALUE

The "Value" field cannot be edited. It displays the current sensor value.

The PRINT button is displayed in standby mode and prints a list of all specified sensors.

Page 47 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 48

Automatic calibration (2.1.6.2.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

AUTOMATIC CALIBRATION

SENSOR CALIBRATE

00 CHAMBER TEMP YES

01 DRYER TEMP NO

02 DRAIN TEMP NO

03 BOOSTER TEMP NO

05 DISCHARGE PRESS NO

06 CONDUCTIVITY FR NO

000725

2

1

1. CALIBRATE YES/NO

2. CANCEL

Default value is NO. When any sensor is set to YES and this is confirmed with ENTER, the NEXT button

appears in the bottom right corner. NEXT opens the AUTOMATIC CALIBRATION HIGH/LOW (2.1.8.2.2.2)

screen.

If a sensor is set to YES, the other sensors change color and cannot be selected.

Page 48 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 49

Automatic calibration setting low (2.1.6.2.2.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

LOW

SAVE

SCROLL

UP

SCROLL

DOWN

+/-

AUTOMATIC CALIBRATION

SENSOR GAIN OFFSET VALUE

00 CHAMBER TEMP 1,000 0,0 49,1

LOW REF 0.0 HIGH REF 0.0

000726

1

1. LOW SAVE

The LOW SAVE button is used to confirm low reference value and to open screen (2.1.6.2.2.2).

Page 49 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 50

Automatic calibration setting Hi (2.1.6.2.2.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HIGH

SAVE

SCROLL

UP

SCROLL

DOWN

+/-

AUTOMATIC CALIBRATION

SENSOR GAIN OFFSET VALUE

00 CHAMBER TEMP 1,000 0,0 49,1

LOW REF 0.0 HIGH REF 0.0

000727

2

1

3

1. HIGH REF

2. HIGH SAVE

3. CANCEL

CANCEL opens the Select automatic sensor calibration (2.1.6.2.2).

Use the HIGH SAVE button to confirm the reference HIGH and open the screen where a calibration

protocol can be printed (2.1.6.2.2.3).

The values for increasing and compensation as recalculated.

Page 50 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 51

Automatic calibration setting print calibration protocol (2.1.6.2.2.3)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

YES

NO

AUTOMATIC CALIBRATION

PRINT CALIBRATION PROTOCOL?

000728

2

1

1. NO

2. YES

NO opens the CALIBRATION menu (2.1.8.2)

YES prints calibration protocol using the logged in name as signature and opens CALIBRATION (2.1.8.2).

Page 51 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 52

Dose monitor calibration (2.1.6.2.3)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL CALIB

001814

DOSE MONITOR SELECTION

DOSE MONITOR

DET PUMP 1

DET PUMP 2

DET PUMP 3

DET PUMP 4

3

4

1

2

1. CALIB

2. DET PUMP 1

3. DOSE MONITOR

4. DOSE MONITOR SELECTION

The CALIB button is used to confirm the selected dosage monitor and to enter the DOSE MONITOR

CALIBRATION menu (2.1.8.2.3.2).

Page 52 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 53

Dose monitor calibration - measured volume (2.1.8.2.3.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL SET MAN

001812

DOSE MONITOR CALIBRATION

DET PUMP 1

DESIRED VOLUME:

MEASURED VOLUME:

ml

DOSE MONITOR TYPE UNIT FACTOR

0.154PC

0.0

0.0

3

2

4

1

1. FACTOR

2. MAN

3. SET

4. MEASURED VOLUME

Press MAN for manual calibration and enter factor. Press SET to confirm the desired volume and select

the MEASURED VOLUME field. The dose pump will then start. Use the MAN button to select the

FACTOR field.

Page 53 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 54

Dose monitor calibration - desired volume (2.1.8.2.3.3)

DOSE MONITOR CALIBRATION

DOSE MONITOR TYPE UNIT FACTOR

DET PUMP 1 PC ml 0.130

DESIRED VOLUME: 200.0

MEASURED VOLUME: 180.0

49.1 C

CHAMBER TEMP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

1.202

DISCHARGE PRESS

128.1 C

DRYER TEMP

CANCEL CALC

001813

1

1. CALC

Use the CALC button to confirm the measured volume and to return to the menu to select the dose

monitor (2.1.6.2.3). Recalculate the factor.

Page 54 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 55

Calibrating the dose monitor - factor (2.1.8.2.3.4)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL SET MAN

001811

DOSE MONITOR CALIBRATION

DET PUMP 1

DESIRED VOLUME:

MEASURED VOLUME:

ml

DOSE MONITOR TYPE UNIT FACTOR

0.154PC

0.0

0.0

1

2

1. SET

2. DOSE MONITOR

Use the SET button to confirm the factor and to return to the menu to select the dose monitor (2.1.6.2.3.)

Documentation (2.1.6.3)

TIME REMAINING

DISCHARGE PRESS

0.000 BAR

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

000729

PLOTGRAPH

BAR GRAPH

ABOUT

DETAILS

SYSTEM MENU

TIME SETTINGS

CALIBRATION

DOCUMENTATION

CONFIGURATION

SYSTEM SETUP

PASSWORD

PRINT CYCLE SETUP

PRINTER

PRINT LOGG VALUES

Page 55 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 56

Select program to print (2.1.6.3.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

PRINT

PRINT

ALL

OK

PRINTOUT CYCLE SETUP

P01 HC SHORT

000730

2

1

3

4

1. PRINT ALL

2. PRINT

3. PO1 HC SHORT

4. PRINTOUT CYCLE SETUP

PRINT prints the highlighted program.

PRINT ALL prints all programs.

Page 56 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 57

Printer (2.1.6.3.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

OK

PRINTER

1

01:00

00:03

MODE

SLOW LOG INTERVAL:

FAST LOG INTERVAL:

000731

1

2

3

1. FAST LOG INTERVAL

2. SLOW LOG INTERVAL

3. MODE

MODE is a numerical toggle field with the values 1, 2, 3, 4, 5.

LONG and SHORT LOG INTERVAL can be set with values between 00:00-59:59.

Page 57 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 58

Log values for printer (2.1.6.3.3)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

DELETE

NEXT

LIST

OK

PRINT LOG VALUES

DEFINITION LIST

1

CHAMBER TEMP

INDEPENDENT TEMP

DISCHARGE PRESS

DRYER TEMP

1

2

3

4

5

6

000732

3

2

4

5 1

1. LIST NO 1 OF 3

2. OK

3. DELETE

4. NEXT LIST

5. DEFINITION LIST

NEXT LIST selects next definition list (3 lists available). If the last list is selected then it cycles back to the

first list.

Press the ENTER key to open Printer log value type selection screen (2.1.6.3.3.1).

Press DELETE to clear the selected field and set the screen in SAVE mode.

Page 58 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 59

Printer log value type selection (2.1.6.3.3.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

PRINT LOG VALUES

DEFINITION LIST

2

ANALOG INPUT

ANALOG OUTPUT

FO CALCULATION

TP CONVERTER

FUNCTION CALCULATION

COMPARATOR

A1

A0

FO

TP

FC

CP

000733

1

1. PRINT LOG VALUES

The ENTER button opens the Printer log value item selection (2.1.8.3.3.1.1) screen.

Page 59 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 60

Printer log value item selection (2.1.6.3.3.1.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

PRINT LOG VALUES

DEFINITION LIST

2

CHAMBER TEMP

DRYER TEMP

DRAIN TEMP

BOOSTER TEMP

DISCHARGE PRESS

CONDUCTIVITY FR

AI00

AI01

AI02

AI03

AI05

AI06

000734

1

2

1. SELECTED FIELD

2. PRINT LOG VALUES

ENTER opens the PRINTER LOG VALUE (2.1.8.3.3.3) screen in save mode and inserts the new value in

the selected field.

Page 60 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 61

Configuration (2.1.6.4)

TIME REMAINING

DISCHARGE PRESS

0.000 BAR

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL

HOME

000735

PLOTGRAPH

BARGRAPH

ABOT

DETAILS

SYSTEM MENU

TIME SETTINGS

CALIBRATION

DOCUMENTATION

CONFIGURATION

SYSTEM SETUP

PASSWORD

EDIT CYCLES

MACHINE NAME

LANGUAGE DATE UNITS

PANEL SETUP

EXTENDED PARAMETERS

3

1

2

1. SYSTEM MENU

2. CONFIGURATION

3. EDIT CYCLES

Page 61 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 62

Edit cycles (2.1.6.4.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL HOME OK

000736

EDIT CYCLES

1 HC SHORT

3

2

1

1. OK

2. HC SHORT

3. EDIT CYCLES

When the cycle number is highlighted, ENTER will allow the number to be edited using the up/down

cursor keys to increase/decrease the number. If two or more numbers are equal when SAVE is pushed, a

message "TWO OR MORE SEQ. NUMBERS EQUAL" will be displayed for three seconds and then return

to save mode.

When cycle name is selected, ENTER will move to the menu below (2.1.6.4.1.1).

Page 62 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 63

Enter name (2.1.6.4.1.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

ENTER NAME

NAME:

CANCEL DELETE

CAPS

LOCK

OK

A

K

U

!

.

2

B

L

V

”

:

3

C

M

W

#

+

4

D

N

X

%

SPACE

5

E

O

Y

&

F

P

Z

(

7

G

Q

Å

)

8

H

R

Ä

\

-

9

I

S

Ö

,

/

0

J

T

Ü

;

=

000737

1 6

2

1

3

4

1. OK

2. CANCEL

3. NAME

4. ENTER NAME

CANCEL reverts to previous screen (2.1.8.4.1) in SAVE mode.

OK closes screen and reverts to (2.1.8.4.1) in SAVE mode, and fill in the NAME field.

Page 63 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 64

Machine name (2.1.6.4.2)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL HOME OK

000738

MACHINE NAME

NAME 9128

1

2

1. NAME

2. OK

Pressing the ENTER button in the NAME field moves you to (2.1.6.4.2.1).

Page 64 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 65

Machine name entry (2.1.6.4.2.1)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

ENTER NAME

NAME:

CANCEL DELETE

CAPS

LOCK

OK

A

K

U

!

.

2

B

L

V

”

:

3

C

M

W

#

+

4

D

N

X

%

SPACE

5

E

O

Y

&

F

P

Z

(

7

G

Q

Å

)

8

H

R

Ä

\

-

9

I

S

Ö

,

/

0

J

T

Ü

;

=

000739

1 6

3

2

1

4

1. OK

2. DELETE

3. CAPS LOCK

4. CANCEL

CANCEL opens the previous screen (2.1.8.4.2) in the Read mode.

SHIFT LOCK activates the caps lock.

DELETE removes the last character in the string.

OK closes the screen and opens (2.1.8.4.2) in Save mode, and insert the field NAME.

Page 65 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 66

Language and date units (2.1.6.4.3)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL HOME OK

000740

LANGUAGE DATE UNITS

LANGUAGE

DATE FORMAT

PRESSURE UNITS

TEMP UNITS

ENGLISH

YY/MM/DD

BAR

C

2

3

4

1

1. TEMP UNITS

2. PRESSURE UNITS

3. DATE FORMAT

4. LANGUAGE

All fields are toggle fields.

LANGUAGE field value: Choose language by scrolling with the arrows keys.

DATE FORMAT field values DD/MM/YY, MM/DD/YY, YY/MM/DD

PRESSURE UNITS field values BAR, PSI, kPa

TEMPERATURE UNITS field values C, F

Page 66 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 67

Panel setup (2.1.6.4.4)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL SAVE

000741

PANEL SETUP

DEFAULT MENU:

PARAMETER EDIT:

SCREEN SAVER:

CONFIRM SAVE/CANCEL:

DETAILS

FULL

20 (MIN)

NO

6

3

4

5

2

1

1. SAVE

2. CANCEL

3. CONFIRM SAVE/CANCEL

4. SCREEN SAVER

5. PARAMETER EDIT

6. DEFAULT MENU

SCREENSAVER numeric field.

All other fields are on/off fields.

Default values:

START MENU:DEATAILS (DETAILS, PLOT GRAPH, BAR GRAPH)

EDIT PARAMETER: FAST (FAST, FULL)

SCREENSAVER: 10 MIN (00-99 MIN)

CONFIRM SAVE/CANCEL: YES (YES, NO)

Screensaver = Background lighting off, delayed timer only active during startup if the keyboard is not

activated

Page 67 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 68

Edit parameters (2.1.6.4.5)

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL HOME OK

247000

EDIT PARAMETERS

P: DRY TIME 00:06:00

2

1

1. OK

2. EDIT PARAMETERS

49,1 C

WASH1 TEMP SP

P1 HC SHORT 00:12:24

01 STANDBY 00:02:22

A34 I/O FAULT

00:03:00

WASH1 TIME

128,1 C

DRYER TEMP

CANCEL HOME OK

347000

EDIT PARAMETERS

P: DRY TIME 00:06:00

DRY TIME

00:06:00 hh:mm:ss

( 00:01:00 - 00:30:00)

2

1

1. OK

2. EDIT PARAMETERS

Press ENTER to open the Editing menu for the selected field.

ENTER saves the value, closes the screen and reverts to (2.1.6.4.5) SAVE mode.

Page 68 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 69

OP-Panel selectable parameters

PRE RINSE STANDARD

VALUE (type)

PF00 P RINSE SELECTOR: value 0.1

Pre rinse selector (Main parameter for selecting or deselecting the whole

pre rinse.)

0 (P)

CT00 P RINSE FILL TYPE: value 1, 2, 3, 4, 5 (CW, HW, CW+HW, booster,

HCW)

Switch for selecting rinse water type (parameter for selecting type of water

to be used in the pre-rinse.

1=Cold water, 2=Hot water, 3=Mixed cold and hot water, 4=Filling from

booster tank, 5= High quality water.)

1 (P)

LI00 P RINSE TEMP SP-value 0-90°C

Set pre-rinse temperature.

0°C (P)

TI00 P RINSE TIME: value 0-60 min

Pre rinse time at selected pre rinse temperature.

1 min (P)

PF16 P RINSE GUARANTEE: value 0.1

Switch for guarantee for pre-rinse temperature. (0=pre-rinse time starts

directly whatever temperature achieved, 1=pre-rinse time starts when set

pre-rinse temperature reached)

1 (P)

Page 69 of 166

<Doc_TEC><Doc_6001341502><Rel.A><Lang_en>

Page 70

WASH 1 STANDARD

VALUE (type)

PF01 WASH1 SELECTOR: value 0.1

Wash 1 selector (Main parameter for selecting or deselecting the whole

wash 1.)

1 (P)

CT01 WASH1 FILLTYPE: value 1, 2, 3, 4, 5 (CW, HW, CW+HW, booster, HCW)

Switch for water type for Wash 1 (parameter for selecting water type to be

used in wash 1

1=cold water, 2=hot water, 3=mixture of cold and hot water, 4=filling from

booster tank, 5=high quality water).

3 (P)