Page 1

GETINGE 9100-SERIES

INSTALLATION MANUAL

6001341302

Page 2

Page 3

Contents

PREFACE...................................................................................................................... 4

SAFETY PRECAUTIONS................................................................................................ 5

Important................................................................................................................ 5

Isolator switch......................................................................................................... 5

In an emergency..................................................................................................... 6

Make sure assembly and installation work is carried out by..................................... 6

When the work is complete, check that................................................................... 6

Product liability........................................................................................................ 6

Attention symbols................................................................................................... 6

INSTALLATION REQUIREMENTS.................................................................................. 7

General Description................................................................................................. 7

Model Identification................................................................................................. 7

Utilities and Specifications....................................................................................... 7

Installation Advisory................................................................................................. 7

Washer-disinfector options...................................................................................... 7

Tools and Materials Required................................................................................ 10

INSTALLATION............................................................................................................ 11

Unpacking............................................................................................................ 12

Assembly.............................................................................................................. 16

Venting system..................................................................................................... 52

Electrical connection............................................................................................. 52

Adjusting the limit switch....................................................................................... 54

Washer-disinfector options.................................................................................... 58

Installation drawings.............................................................................................. 65

TECHNICAL DATA....................................................................................................... 81

DOSAGE...................................................................................................................... 85

Hose material on delivery...................................................................................... 85

Available hose materials from Getinge sales companies........................................ 85

Recommendations when Getinge Disinfection AB's detergent is used.................. 85

General recommendations for non-Getinge AB detergents................................... 86

Flow monitoring.................................................................................................... 86

Starting up............................................................................................................ 86

WATER QUALITY......................................................................................................... 87

HANDLING OF WORN-OUT PRODUCTS.................................................................... 88

ADDRESSES............................................................................................................... 89

Page 3 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 4

PREFACE

This manual is intended for users of products from Getinge Disinfection AB.

The user manual describes the design and operation of the machine and the maintenance for which the

user is responsible. The installation manual describes the machine's installation. The technical manual

describes necessary information for operators and maintenance personnel. The information in the manual

must be complied with to ensure safe and error-free operation.

Read the manual before use.

Users must read through the manual before using the machine for the first time, as well as familiarizing

themselves with the operation of the machine and its safety instructions. Operators and maintenance

personnel must have completed training through Getinge Academy.

The information in this manual describes the machine as dispatched from Getinge Disinfection AB. There

may be differences due to customization for customers or countries.

The machine is accompanied by the following documentation:

• User manual

• Installation manual

• Declaration of conformity

The following documentation is supplied on CD:

• User manual

• Installation manual

• Electrical diagrams

• Program sheets

The following documentation shall be provided by the sales company to the end-user on request:

• Technical manual

• Spare parts list

Getinge Disinfection AB reserves the right to change the specification and design without prior notice.

The information in this manual was up-to-date on the date that the manual was issued.

© Copyright

The content of this manual must not be copied, in

whole or in part, without written consent from

Getinge Disinfection AB.

Page 4 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 5

SAFETY PRECAUTIONS

This machine has a number of built-in safety devices.

To avoid injury, it is highly important not to bypass these safety devices.

If the equipment is used in a manner not specified by the manufacturer this can impair the safety

equipment on the machine.

Operators and maintenance personnel must undergo safety training for the machine. All personnel who

handle chemicals for washing and disinfection must understand the washing process, possible health

hazards and ways of detecting leaks of toxic chemicals.

Operators and maintenance personnel must undergo regular training in the operation and maintenance of

the equipment. There must be a documented list of personnel who have been trained to use the

machine. Trained personal must be tested to verify the training program.

Important

• Take care when handling the chemical agents used in the machine. Read the instructions on

the pack or contact the manufacturer before using the machine for instructions about:

o

if the agent comes into contact with the operator’s eyes or skin or if the vapors are

breathed in, etc.

o

for storage of packs and sorting of empty packs

o

use personal safety equipment such as safety goggles, protective gloves, etc.

• The machine must be connected in accordance with the instructions given in the installation

manual.

• The machine may only be used by adults.

• Installation and servicing may only be done by personnel trained for this machine.

• Never bypass door safety switches.

• Leaks in the system caused by worn seals in the door, for example, must be repaired

immediately.

• Before any welding is done, all cables connected to the control system via connectors and

sockets must be disconnected.

• Before doing any servicing or maintenance work on the machine, isolate it from the electric

power supply and drain all tanks.

• Do not wash down or hose down the machine with water.

• Take care when using corrosive substances.

• Observe safety measures for steam and hot water.

• The machine must not be operated with cladding plates, roof and plinths removed. Doing this

puts at risk the safety and functioning of the machine.

• The electrical cabinet may only be opened by authorized and trained personnel.

• Spare parts may only be obtained from Getinge sales companies.

Isolator switch

The machine must be preceded by a lockable switch for the electric power supply. The switch must be

easily accessible on a wall close to the machine. The installation must conform to and be marked in

accordance with local regulations.

Page 5 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 6

In an emergency

• Press the emergency stop.

• Switch off the main power switch.

• Close shutoff valves in the water and any steam supply lines.

Make sure assembly and installation work is carried out by

To avoid the risk of back injury, this equipment should be assembled and installed

by at least two people.

• by qualified personnel.

• in accordance with current local regulations and rules.

When the work is complete, check that

• all parts have been installed according to the installation manual.

• all screws have been properly tightened

• there are no sharp edges on any parts that may come into contact with people

• all hoses, pipes and connections are intact and free from defects

• all the functions of the machine are working properly. Adjust if necessary.

• make sure that no electrical wires or hoses are touching any hot surfaces

• check electrical connections both inside the electrical cabinet and to elements

Carry out an Installation Qualification, an Operating Qualification, and a Performance Qualification

according to ISO 15883 before putting the machine into service.

Incorrect use may result in damage to objects and personal injury.

Product liability

Any modification or incorrect use of the equipment without the approval of Getinge Disinfection AB

negates Getinge Disinfection AB’s product liability.

This product was manufactured by:

GETINGE DISINFECTION AB

Ljungadalsgatan 11, Box 1505

SE-351 15 Växjö, Sweden

Attention symbols

There are warnings, instructions, and advice in this manual that require extra attention. The symbols and

designs used are:

Risk of injuries or machine damage.

Page 6 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 7

INSTALLATION REQUIREMENTS

General Description

Washer-disinfectors in Getinge's 9100-Series are large capacity, floor loading jet spray washers for

mechanical washing, intermediate level (A0 value = 600 as standard) thermal disinfection and drying of

moisture and temperature stable hospital carts, sterilization containers, material handling carts, stands

and utensils.

The washer can be installed in a shallow pit or installed at level floor level. When installed in a pit, the floor

of the washer’s chamber is level with the room floor, which allows the direct loading and unloading of

carts. When the washer is installed at floor level, the floor of the chamber is higher than the room floor.

Ramps are then provided as standard equipment to facilitate loading and unloading.

The washer has a number of side spray nozzles arranged on spray arms (on either side of the chamber).

Available as an accessory is a docking mechanism in the floor, for docking wash carts with spray arms.

Detergent and rinse aid solutions are dispensed automatically as a standard feature.

The washer is fitted with one or two doors. Two doors create an airlock function between the soiled and

clean sides of the machine. The doors are horizontal sliding doors. The washer-disinfector is available in

four different sizes: the models 9120, 9125, 9128 and 9122.

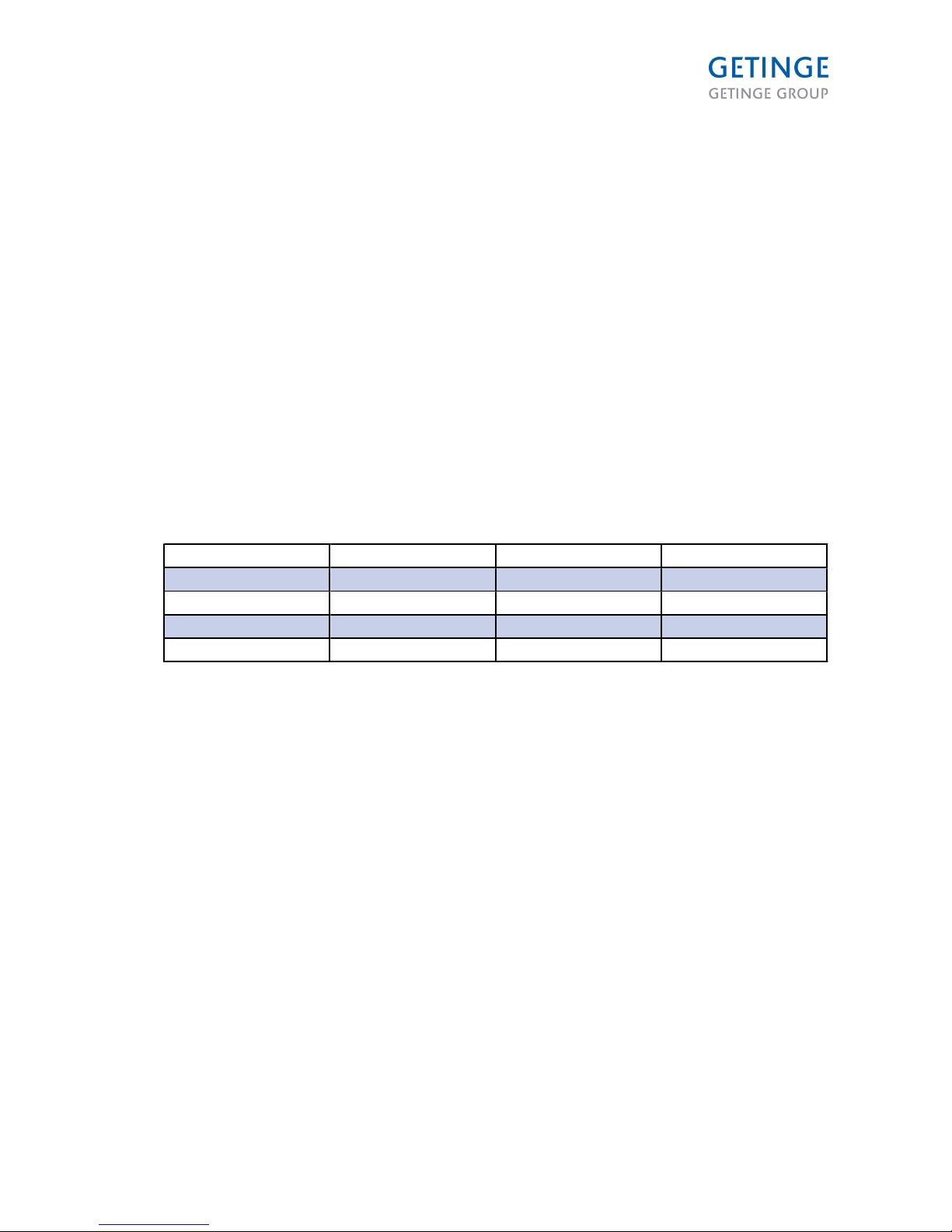

Wash chamber interior dimensions

Model

Door Width Door High Load Length

9120 960 (38”) 2000 (80”) 2000 (80”)

9125 960 (38”) 2000 (80”) 2500 (98”)

9128 960 (38”) 2000 (80”) 2850 (112”)

9122 1170 (46”) 2200 (86”) 2200 (86”)

Model Identification

The rating plate for washer-disinfectors in the 9100-Series is affixed to the electrical cabinet. Make a note

of the model type and serial number (S/N) from the rating plate.

TYP:_______________________________________________________________________

SERIENUMMER:____________________________________________________________

Always include the model type and serial number when communicating with Getinge Disinfection AB.

Utilities and Specifications

Utility requirements and specifications are included on the appropriate rough-in drawings (pit mounted or

floor mounted version).

Installation Advisory

Washer-disinfectors are assembled at the factory, tested and then disassembled for shipment. Extensive

on-site reassembly is required. The installation instructions in the Installation Manual are intended as the

primary reference for accomplishing this reassembly. Every effort has been to make this information as

accurate as possible.

Washer-disinfector options

The 9100-Series washer-disinfectors may be equipped with the following options.

Page 7 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 8

Size

There are four different models of washer-disinfectors in the 9100 series; see the section Wash chamber

interior dimensions, Page 7. The washer comes in modules; see the section Unpacking, Page 12 .

Dimension and weight of the largest modules

9120 9125 9128 9122

Main module

unit

Dimensions

(mm)

(inches)

1350 × 2440 ×

1203

53 × 96 × 47

1350 × 2440 ×

1203

53 × 96 × 47

1350 × 2440 ×

1203

53 × 96 × 47

1560 × 2640 ×

1203

61 × 104 × 47

Weight (kg)

(lb)

250

551

250

551

250

551

280

617

Chamber

extension

module

Dimensions

(mm)

(inches)

1315 × 2445 × 415

52 × 96 × 16

1315 × 2445 ×

665

52 × 96 × 26

1315 × 2445 ×

840

52 × 96 × 33

1315 × 2445 ×

515

52 × 96 × 20

Weight (kg)

(lb)

105

232

150

331

177

390

138

304

Glass Door Dimensions

(mm)

(inches)

1095 × 2100 × 35

43 × 83 × 1.5

1095 × 2100 ×

35

43 × 83 × 1.5

1095 × 2100 ×

35

43 × 83 × 1.5

1095 × 2100 ×

35

43 × 83 × 1.5

Weight (kg)

(lb)

100

220

100

220

100

220

130

287

Floor Mount or Pit Mount

For a floor-mounted washer-disinfector, ramps are required to access the washer-disinfector. The inner

floor of a pit-mounted washer-disinfector is at the same level as the area's floor.

Right Side or Left Side Service Area

Provide access to components such as plumbing, valves, pumps, tanks, electrical cabinet, etc. The

location of service area on your washer can be located left or right hand.

One or two doors

One door for loading/unloading on the same side, or two doors - one for loading on soiled side and one

for unloading on clean side.

Horizontal or inclined sliding door

As standard, the door opens horizontally, straight to the side. An inclined sliding door is required if the

unit is mounted in a pit with a width of 1900-2400 mm. The sliding doors open toward the service area.

Steam or electric heating

The heating elements for water, drying and the booster tank are heated with the building's steam or

electricity.

Connection for treated water

Connection for treated water in addition to hot and cold water, which are standard.

Page 8 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 9

Dosing pumps for detergent

The washer-disinfector comes as standard with two dosing pumps for detergent for process chemicals,

but a third and fourth can also be installed. This allows the chemical disinfection of e.g. heat-sensitive

objects. All dosing pumps for detergents have flow-regulation.

Water-saving tanks

One or two water-saving tanks can be installed in the service area.

Docking for wash cart

A docking mechanism in the floor to dock wash carts equipped with spray arms.

Booster tank

A docking mechanism in the floor to dock wash carts equipped with spray arms.

Automatic spray system for valve rack

The spray system to be used with special carts equipped with this type of spray system.

Waste cooling

Cooling system to adjust the temperature of the waste water that comes from the machine.

Neutralization system for waste water

Neutralization system for adjusting the pH value for the waste water that comes from the machine.

Comes in two versions, time control or pH monitoring.

Conductivity control, final rinse

Conductivity control for the final rinse.

Conductivity control, dosage

Conductivity control for dosage of detergent

Wash cart incline

The Chamber floor can be tilted in the washing phase so that the water on the items can drip off and the

items can dry faster.

Printer, option 1

Thermal printer that provides a printout of activities in the washer-disinfector during the process at a

preset time.

Printer, option 2

Laser printer

Flow sensor with kalrez seal

Flow sensor with kalrez seal for highly concentrated detergent.

Front panels for service area

Cover plates to conceal the service area. The cover plates have a door for easy access to the space.

Page 9 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 10

Installation kit

• Manometer, stop valve and filter for water and steam connection.

• Air bleeding kit with drainage hose.

Instrument wash

Instrument wash is a program for the washer-disinfector that cleans, disinfects and dries soiled, heavy

surgical instruments. To use this program, you need a wash cart that is suitable for these type of objects.

Ramp

Washers-disinfectors that are floor-mounted come with a split or whole ramp.

NetCom

Netcom connection

Tools and Materials Required

The following lists the specific tools and materials required at the installation site. Items marked with an

asterisk* are supplied by Getinge Desinfection AB.

• Common hand tools

• Lever

• *Silicone

• *Stainless Steel Nuts, Bolts and Washers

• Dolly

• Ladder

Page 10 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 11

INSTALLATION

The washer-disinfector is shipped in separate modules. Only personnel from Getinge Desinfection AB or

personnel trained by Getinge Desinfection AB may assemble the modules and install the machine.

Before installation, the installation area must be prepared with connections for water, electricity, steam

and waste water as per the information in Installation drawings, Page 65, TECHNICAL DATA, Page

81 and Electrical connection, Page 52.

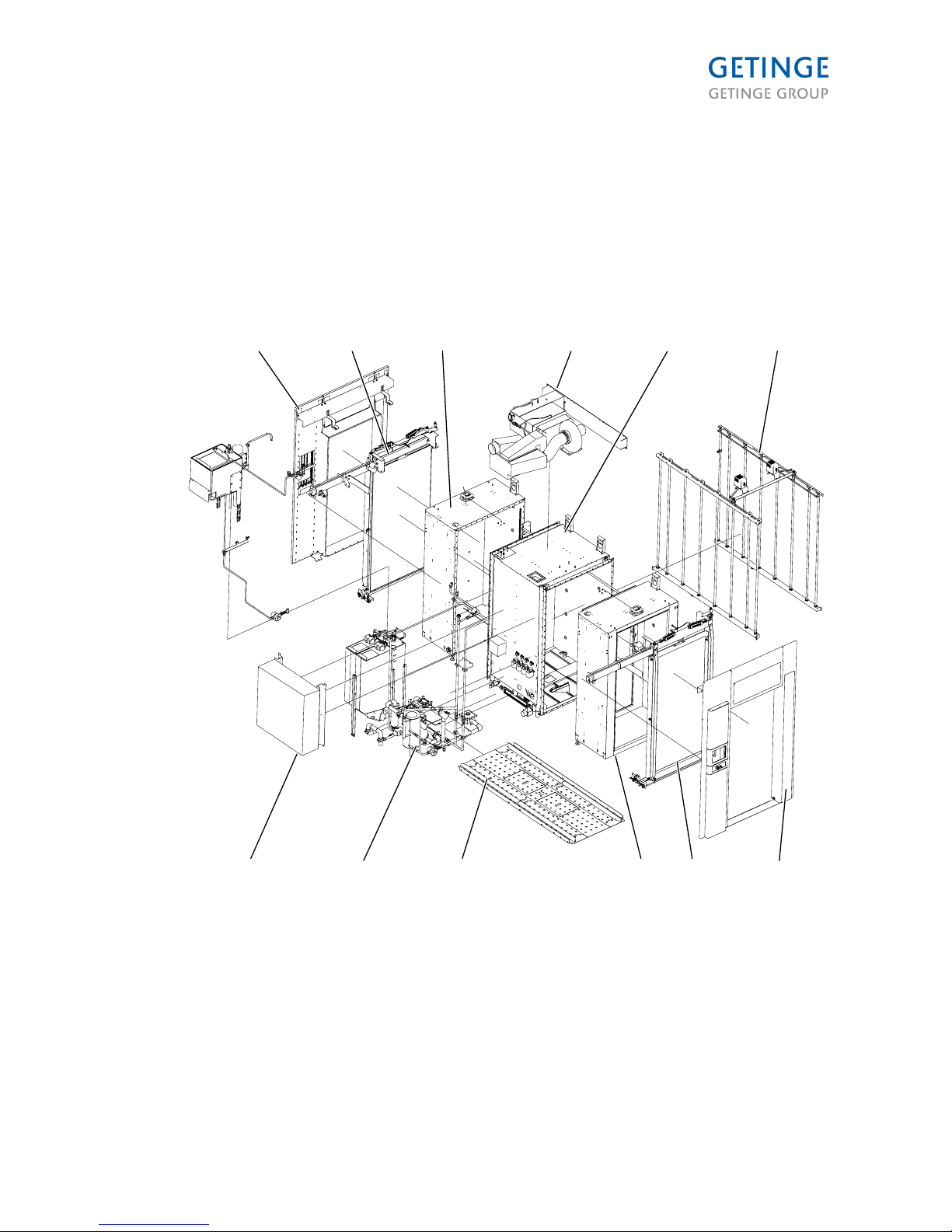

An example showing how the machine is delivered in modules.

001726

1

7 8 9 3 2 1

2 3 4 5 6

1. Panel package module (load end, unload

end)

2. Glass Door Module

3. Chamber Extension Module

4. Dryer module

5. Core Module

6. Side spraying module

7. Electrical cabinet module

8. Heater, pump & piping module

9. Chamber Floor Module

Page 11 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 12

Unpacking

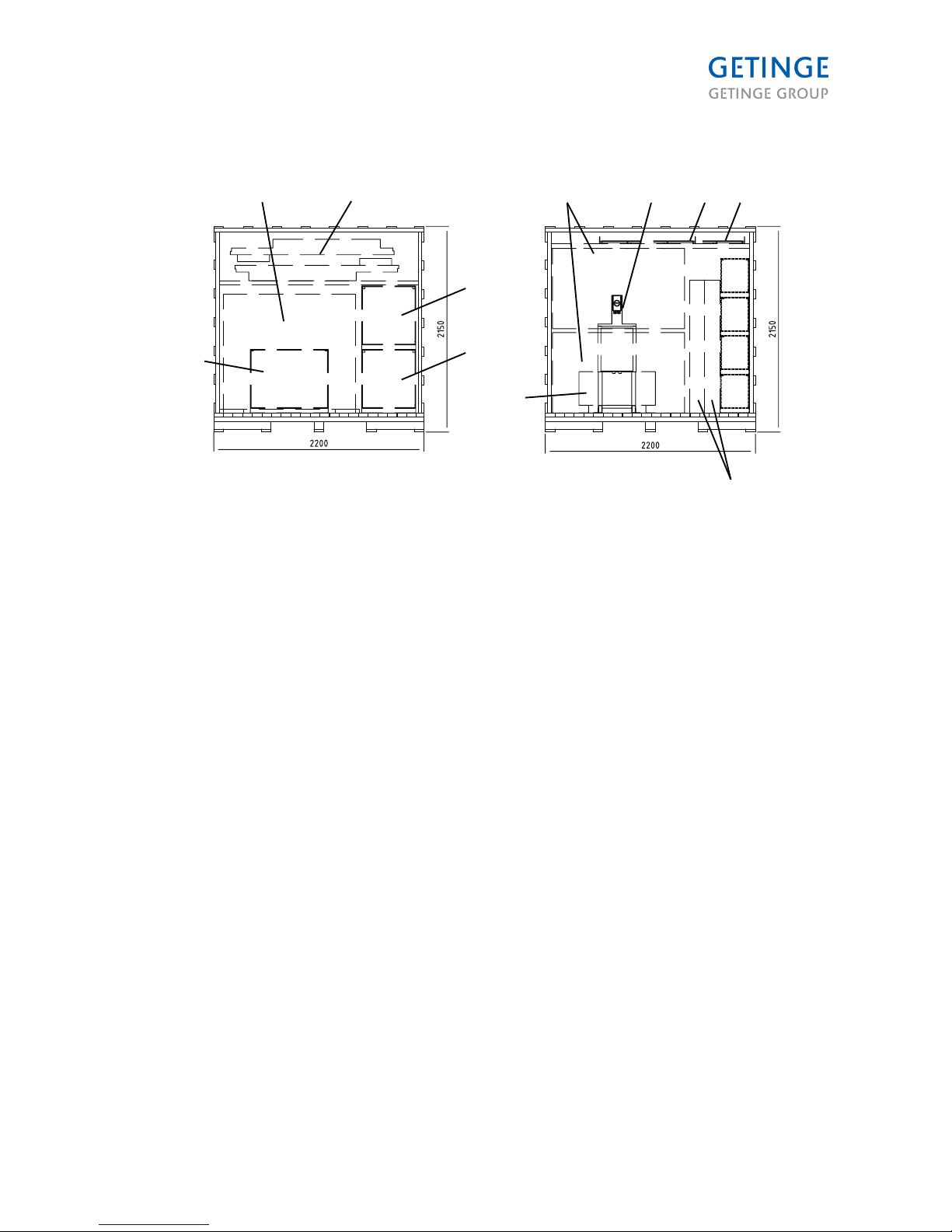

Packaging 9122

R

T

S

S

8

9

104 5

7

11

1

2

3

001728

6

1. Core Module

2. Dryer module

3. Heater, pump & piping module

4. Waste water, saving and booster tank

5. Chamber Floor Module

6. Module with front panel for service door

(option)

7. Glass doors

8. Chamber Extension Module

9. Electrical cabinet

10. Panel package module (load end, unload

end)

11. Transformer, complete

Packaging L=2850 Packaging L=3020

Core Module Chamber Extension Module

Dryer module Transformer, complete

Heater, pump & piping module Electrical cabinet

Glass doors Door rails 2 pcs (S)

Waste water, water-saving tank and booster tank Beams and pipes (R)

Chamber Floor Module Panel package module (load end, unload end)

Door locking lower (T)

Page 12 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 13

Packaging 9120

4

1

2

3

8

9

5

7

10 11

T

R

S

S

6

001730

1. Core Module

2. Dryer module

3. Heater, pump & piping module

4. Waste water, saving and booster tank

5. Chamber Floor Module

6. Module with front panel for service door

(option)

7. Glass doors

8. Chamber Extension Module

9. Electrical cabinet

10. Panel package module (load end, unload

end)

11. Transformer, complete

Packaging L=2850 Packaging L=2850

Core Module Chamber Extension Module

Dryer module Transformer, complete

Heater, pump & piping module Electrical cabinet

Glass doors Panel package module (load end, unload end)

Waste water, water-saving tank and booster tank

Chamber Floor Module

Door locking lower (T)

Door rails 2 pcs (S)

Beams and pipes (R)

Page 13 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 14

Packaging 9125

3

1

2

6

7

11

8 9 10

T

R

S

S

54

001731

1. Core Module

2. Waste water, saving and booster tank

3. Chamber Floor Module

4. Glass doors

5. Module with front panel for service door

(option)

6. Chamber Extension Module

7. Electrical cabinet

8. Transformer, complete

9. Panel package module (load end, unload

end)

10. Dryer module

11. Heater, pump & piping module

Packaging L=2850 Packaging L=2850

Core Module Chamber Extension Module

Glass doors Dryer module

Waste water, water-saving tank and booster tank Heater, pump & piping module

Chamber Floor Module Transformer, complete

Door locking lower (T) Electrical cabinet

Door rails 2 pcs (S) Panel package module (load end, unload end)

Beams and pipes (R)

Page 14 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 15

Packaging 9128

R

S

S

T

2 3 7 8 9 10

1

4

5

6

11

001732

1. Waste water, saving and booster tank

2. Core Module

3. Panel package module (load end, unload

end)

4. Dryer module

5. Heater, pump & piping module

6. Electrical cabinet

7. Chamber Extension Module

8. Transformer, complete

9. Chamber Floor Module

10. Module with front panel for service door

(option)

11. Glass doors

Packaging L=2850 Packaging L=3020

Core Module Chamber Extension Module

Waste water, water-saving tank and booster tank Glass doors

Dryer module Transformer, complete

Heater, pump & piping module Electrical cabinet

Panel package module (load end, unload end) Chamber Floor Module

Door locking lower (T)

Door rails 2 pcs (S)

Beams and pipes (R)

Page 15 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 16

Assembly

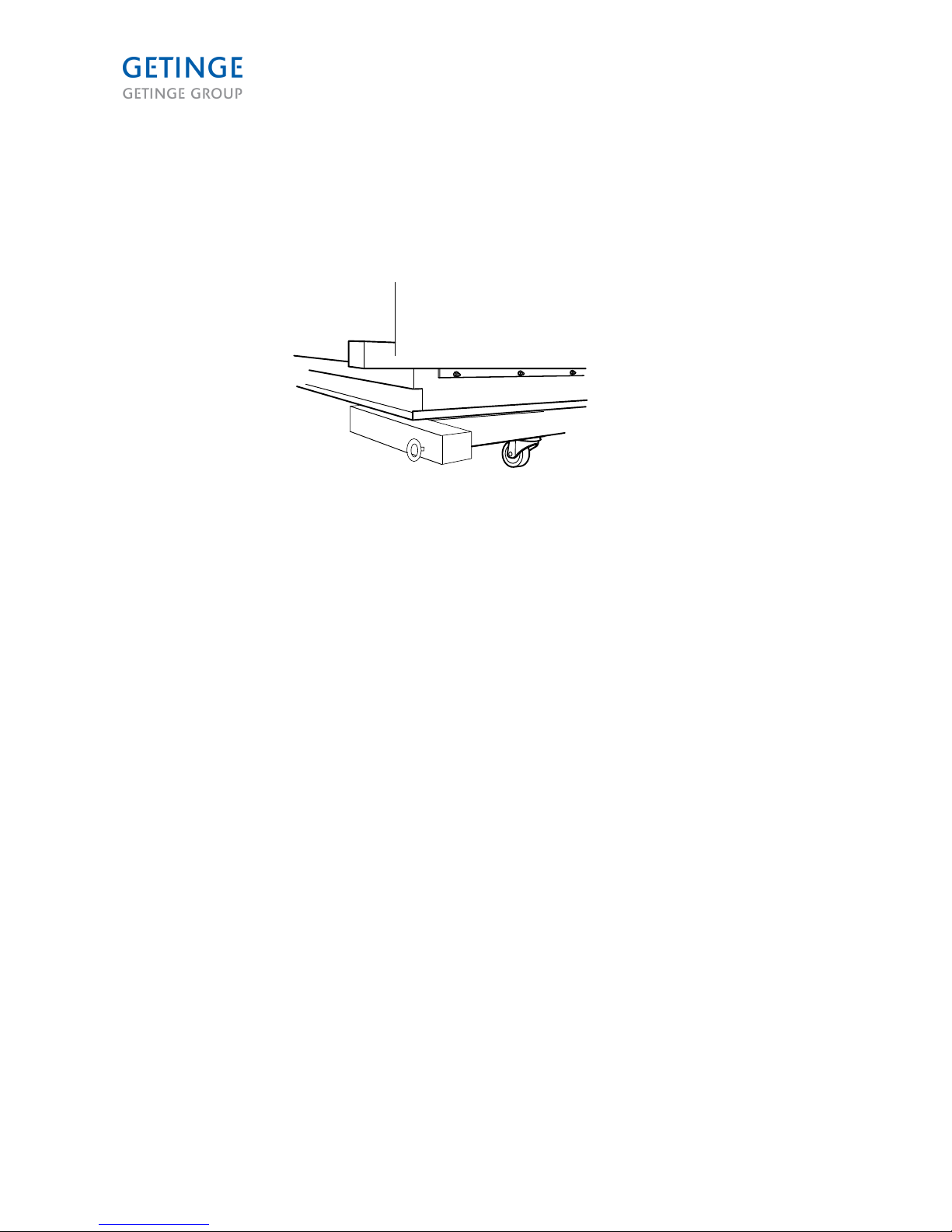

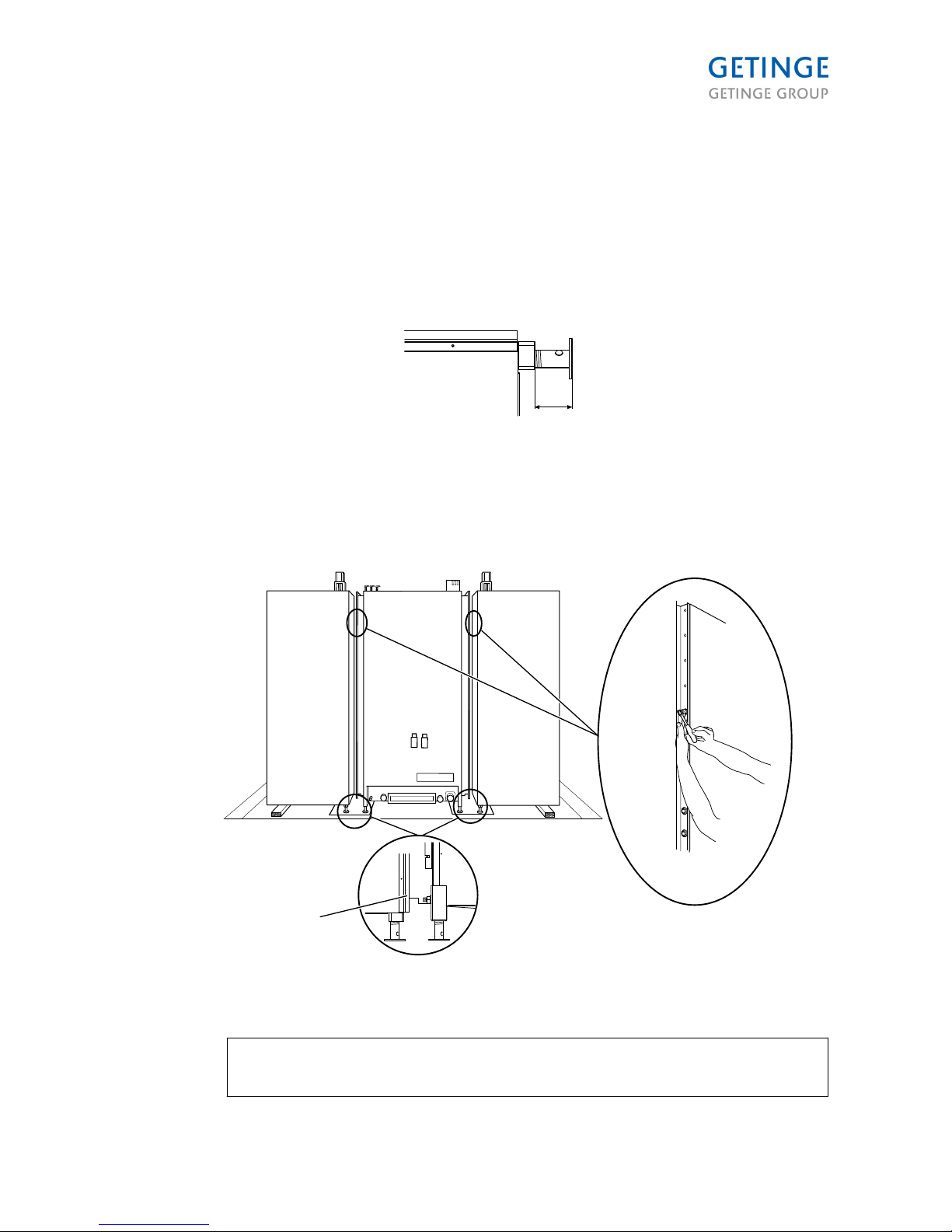

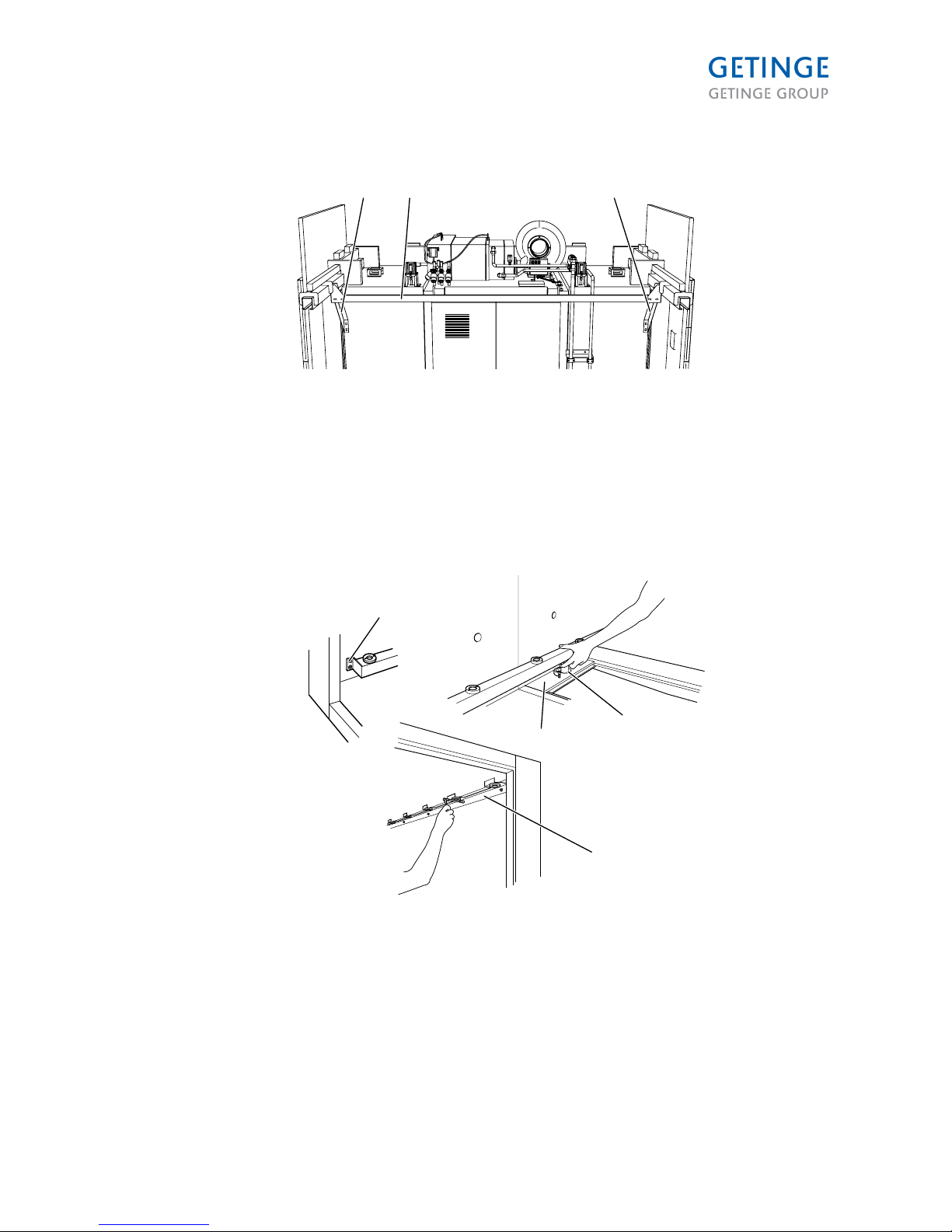

Installation begins with assembly of the main modules. This module is affixed to four corner supports.

Four wheels could be mounted on the supports to facilitate transportation to the pit. There are two eye

bolts that can be screwed into the corner supports. These can be used as lifting aids.

• Move the main module and the chamber extension modules to the installation space.

000523

• Measure up exactly where the module will be located. Place four pieces of metal sheeting in the

pit for the module's legs. (The sheeting makes it easier to move the module later on.)

Page 16 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 17

• Adjust the adjustable feet, so the module is level with the floor of the room. If the washerdisinfector is to be installed in a pit, it is a good idea to measure the depth of the pit before

adjusting the feet. If the pit's depth is 150 mm, the adjustable feet must be lengthened approx.

50 mm, as illustrated below. This means that the extended length of the feet must be 100 mm

less than the depth of the pit.

50 mm

000634

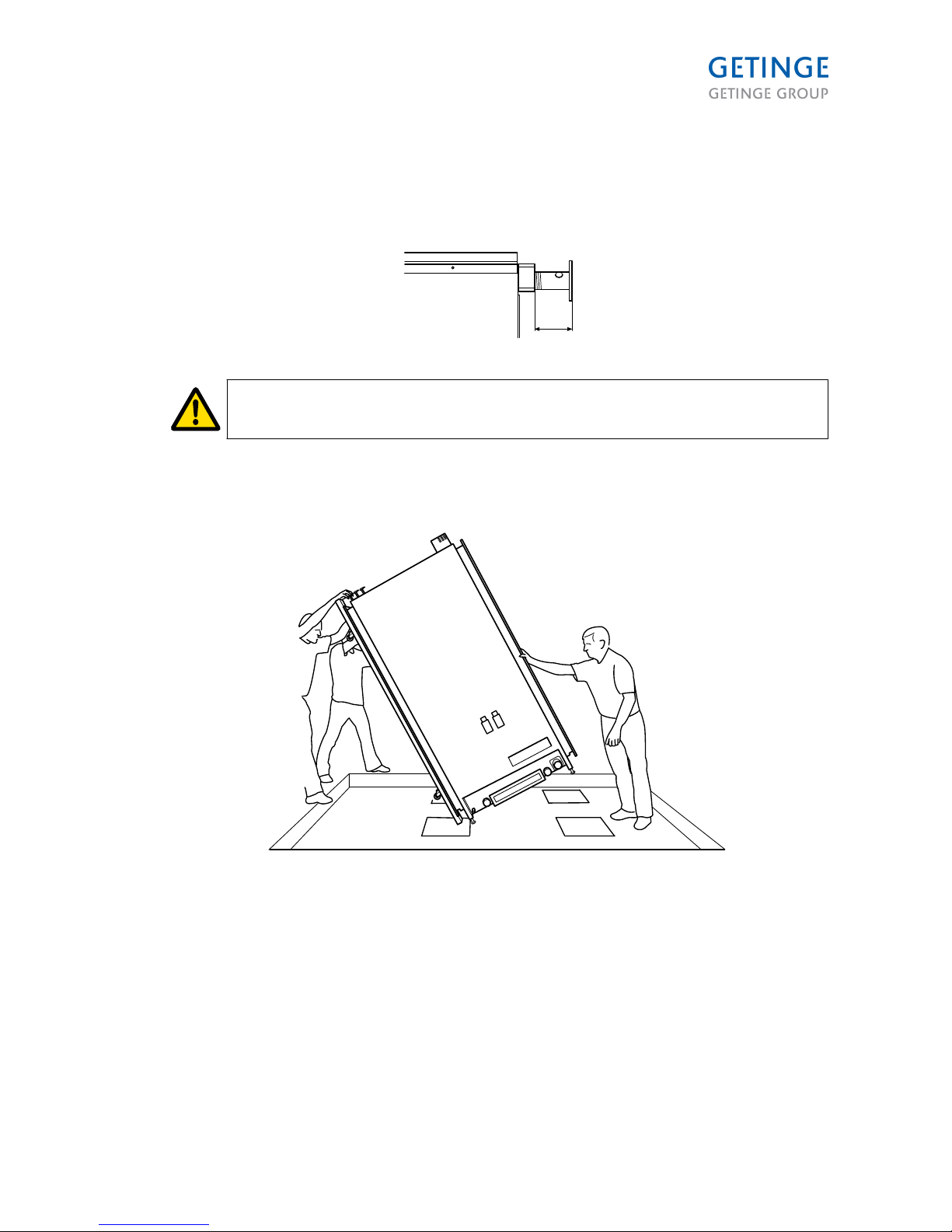

Three people are required for this step. Two to lift the module and one to hold the

rear of the module.

• Lower the lower end of the module into the pit, stand it on the front pair of wheels and push it

towards the middle of the pit. Lift the module into a vertical position and check that the

module's legs are on the pieces of plating.

000524

Page 17 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 18

• Remove the packing frame.

• Clean the surface where the sealing strip is to be placed.

• Place the sealing strips on the two ends of the main module.

• Apply silicone in the lower corners of both ends of the module. Apply the silicone from the

corner and about 20 cm up along the edge where the strip will be placed. Also apply silicone

from the corner and about 20 cm in towards the middle of the main module, along the edge

where the strip will be located.

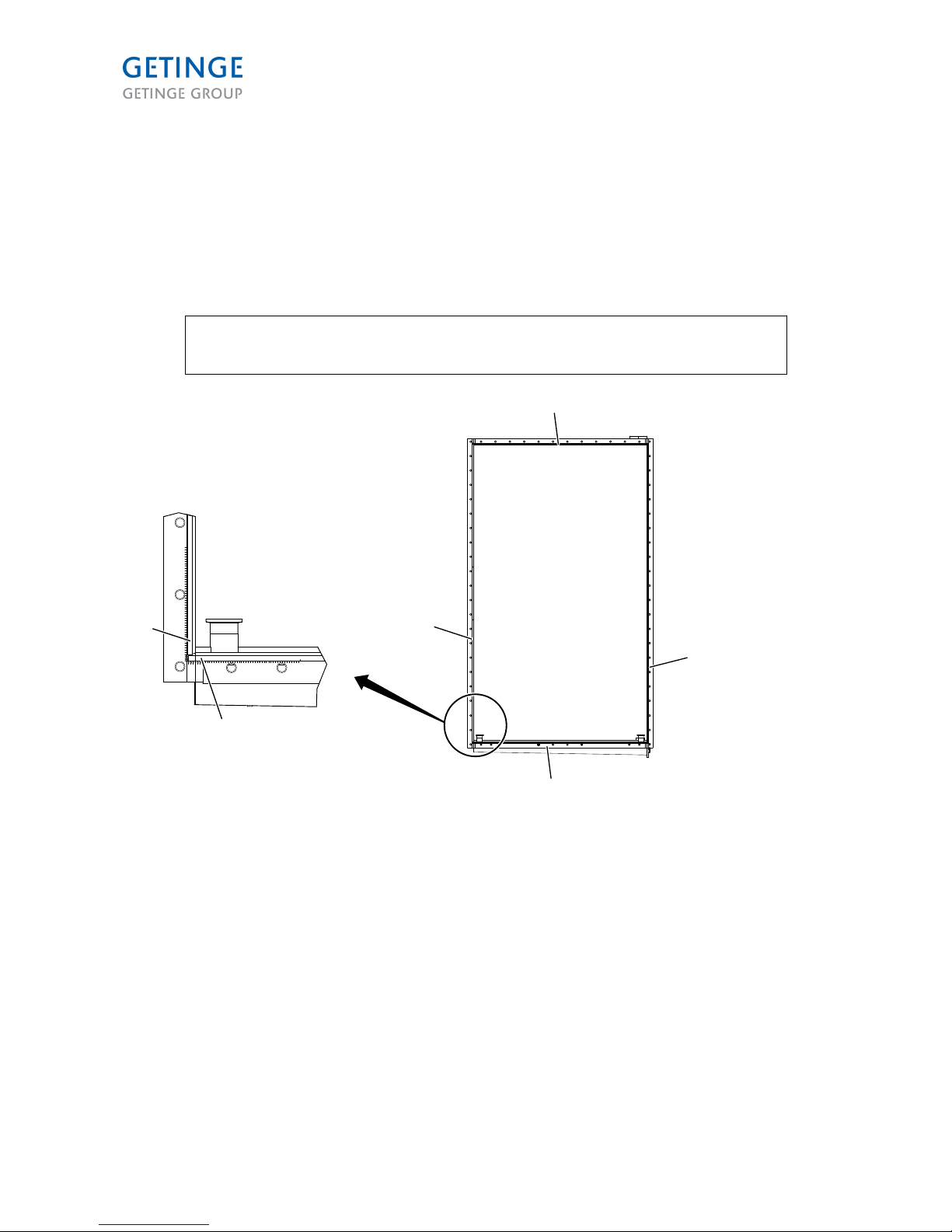

Note: It is very important that the sealing strip follows the edge of the seal plate.

Be sure not to take any short cuts in the corners.

000633

1

1

1

1

1

1

1. Sealing strip

Page 18 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 19

• Repeat the following steps (1-4) for modules with a chamber extension.

1. Get one of the modules with chamber extension and adjust the feet so that the module is level

with the main module. If the washer-disinfector is to be installed in a pit, it is a good idea to

measure the depth of the pit before adjusting the feet. If the pit's depth is 150 mm, the

adjustable feet must be lengthened approx. 50 mm, as illustrated below. This means that the

extended length of the feet must be 100 mm less than the depth of the pit.

50 mm

000634

2. Move the extension module against the main module and insert (do not pull out yet) the top

screw on both sides, to attach the module with chamber extension to the main module.

3. Insert the two guide pins on the floor edge of the chamber extension module into the

corresponding holes in the main module, and move the module for chamber extension towards

the main module.

000635

1

1. Locating pins

Note: Use the silicone seal 732 that comes with the machine. Let the silicone

harden for 12 hours before using the machine.

Page 19 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 20

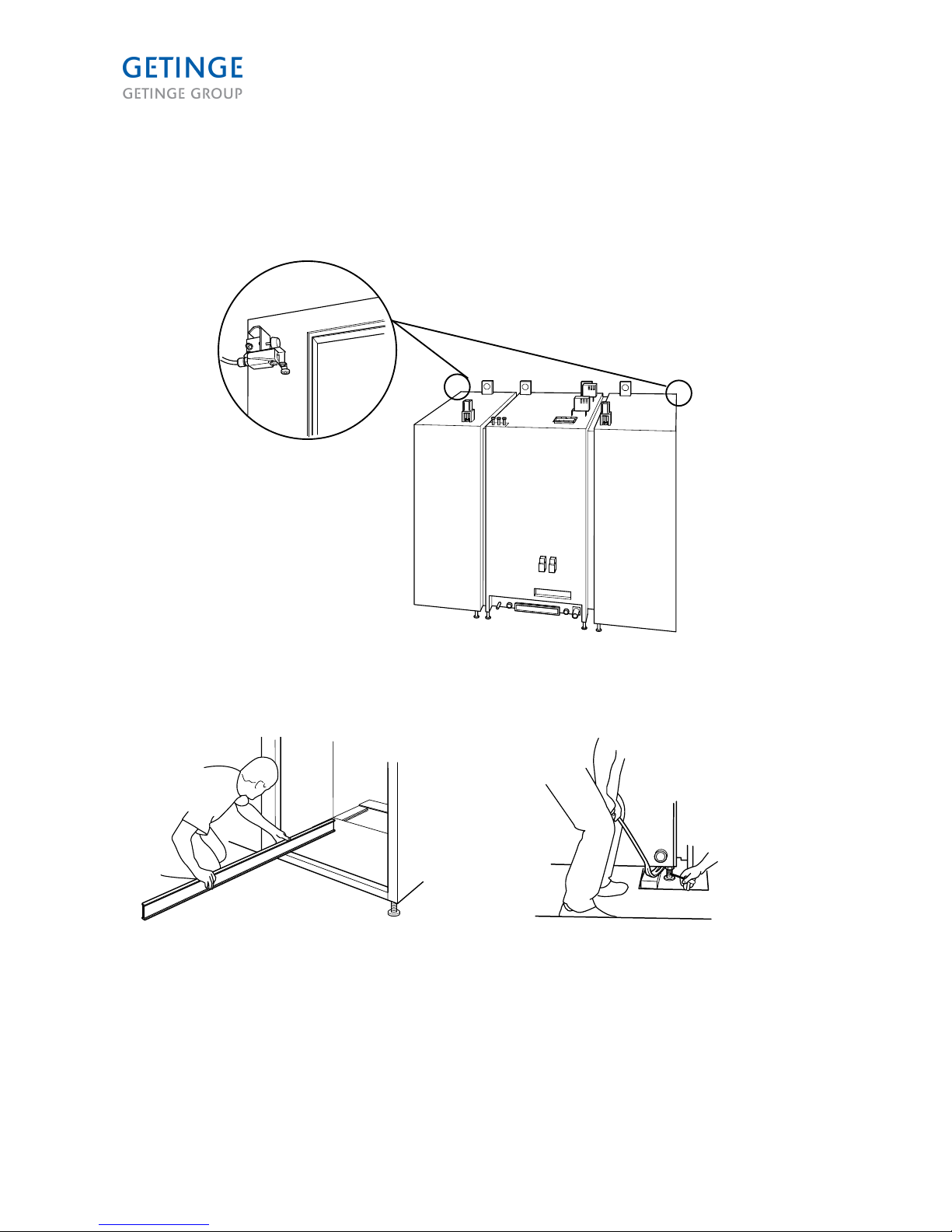

4. Screw the chamber extension module to the main module. Check that the seal is sitting

correctly before screwing on the chamber extension modules. Fill the gap between the modules

on the inner side of the chamber with silicone, the entire lower part and about 20 cm up the

walls.

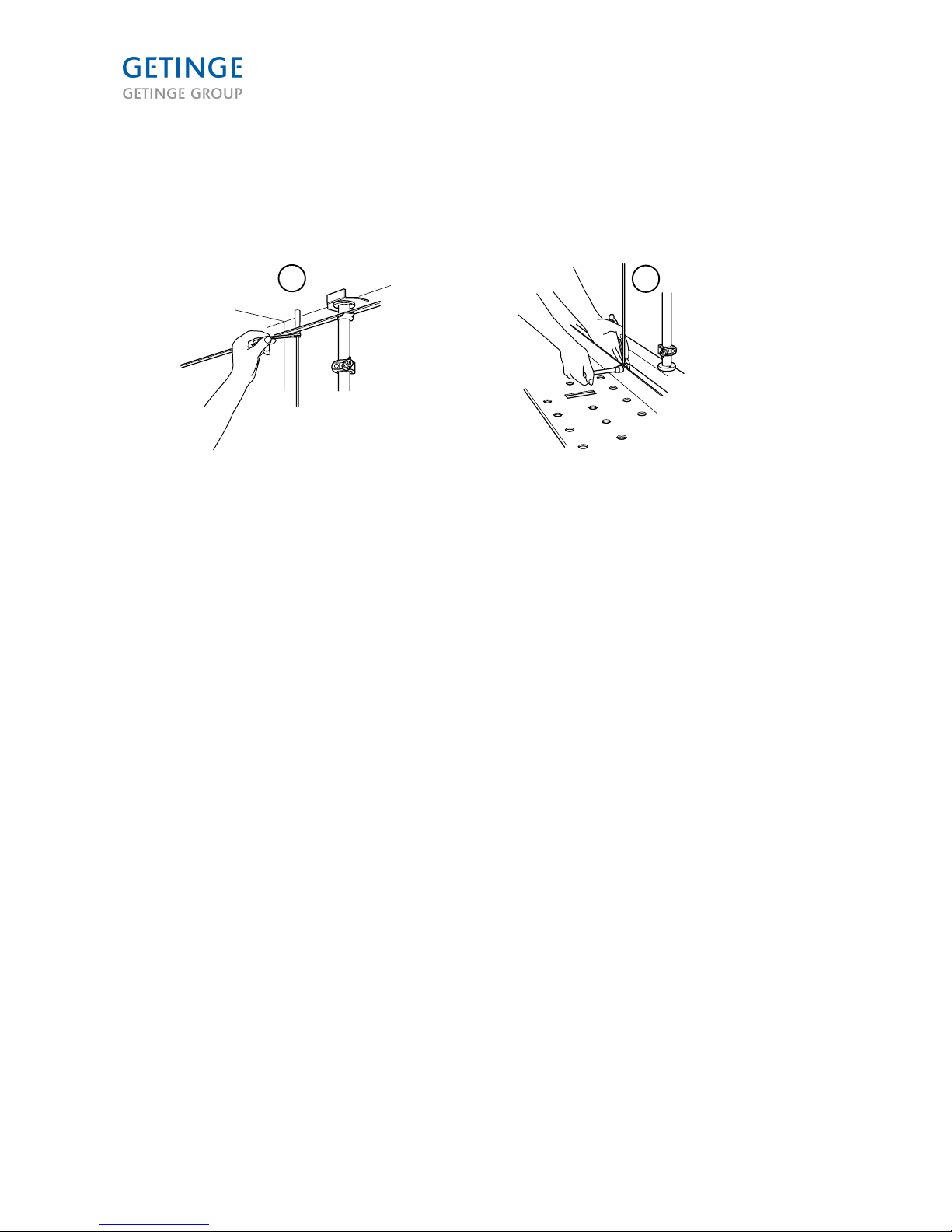

• Fit the limit switch for closed door to each chamber extension module.

000525

• Adjust the chamber floor in relation to the floor level (tolerance 0 to +2 mm). The chamber floor

must be level with or slightly above the building's floor level. Use a straight-edge ruler and a

level. Check and adjust using the four machine feet and a crowbar.

000521

Page 20 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 21

• Position the machine correctly. Use a lever to adjust the position of the machine.

000534

• Check that the floor of the chamber is level with the floor if installing the washer-disinfector in a

pit. Adjust the chamber floor as needed, according to the instructions in previous steps.

• Lift up and fit the two door rails on the roof.

• Install the distribution canal.

1 1

000637

1. Door rail

Page 21 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 22

• Install the Dryer module.

• Position the filter and air duct.

1

000638

1. Air duct

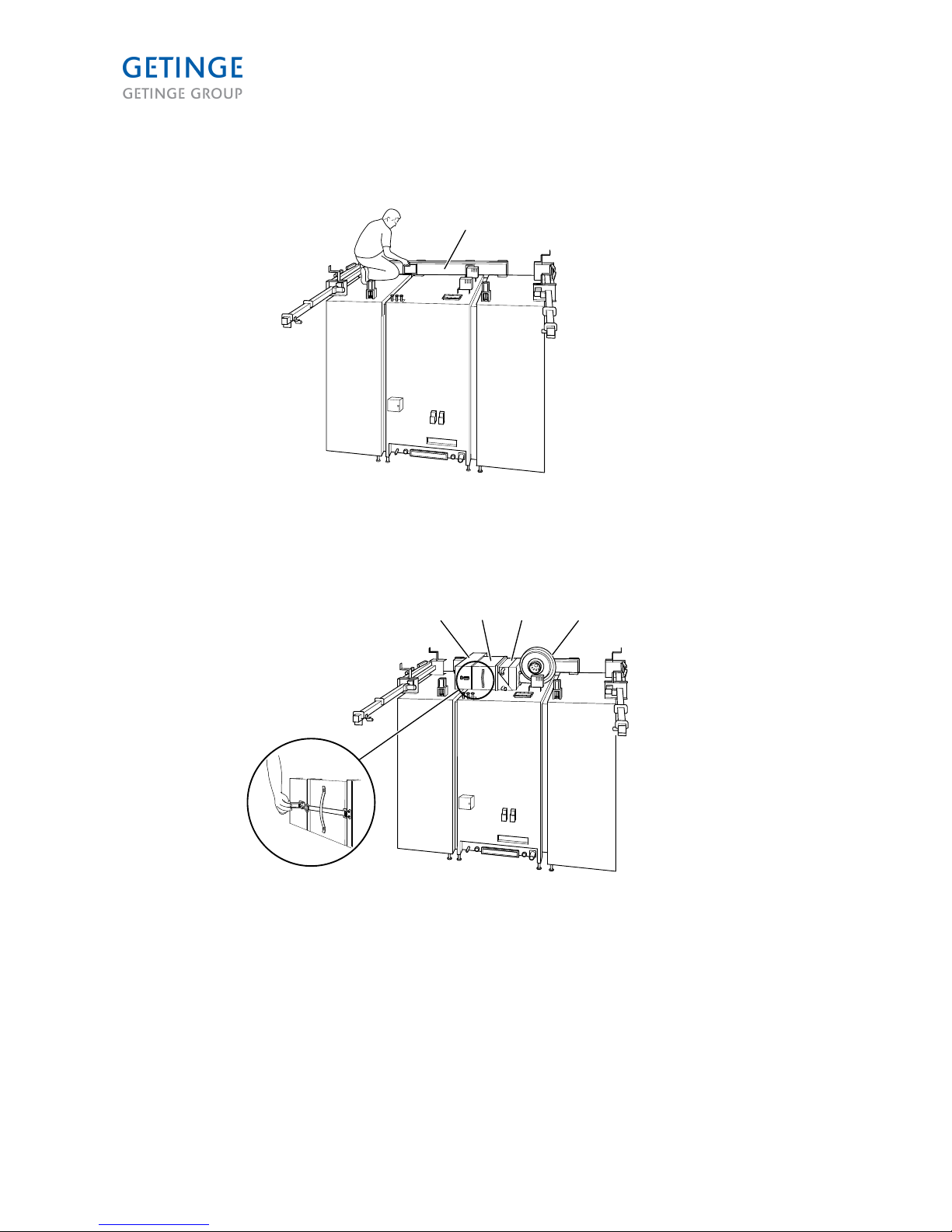

• Install the fan.

• Attach the filter and the air duct to the heating element with tension straps.

1 2 3 4

001734

1. Air duct

2. Filter

3. Heating element

4. Fan

Page 22 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 23

• Install the two brackets and the support beam between them.

1 2

001753

1

1. Brackets

2. Support beam

• Install two distribution pipes inside the chamber. Attach the pipes with a tri-clamp to the water

connection on the underside and with two screws at each end. Start by connecting the

distribution pipe to the water connection on the service side of the machine. Then tighten the

screws.

4

1

2

3

000640

1. Screw

2. End cover

3. Tri-clamp

4. Upper bracket

Page 23 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 24

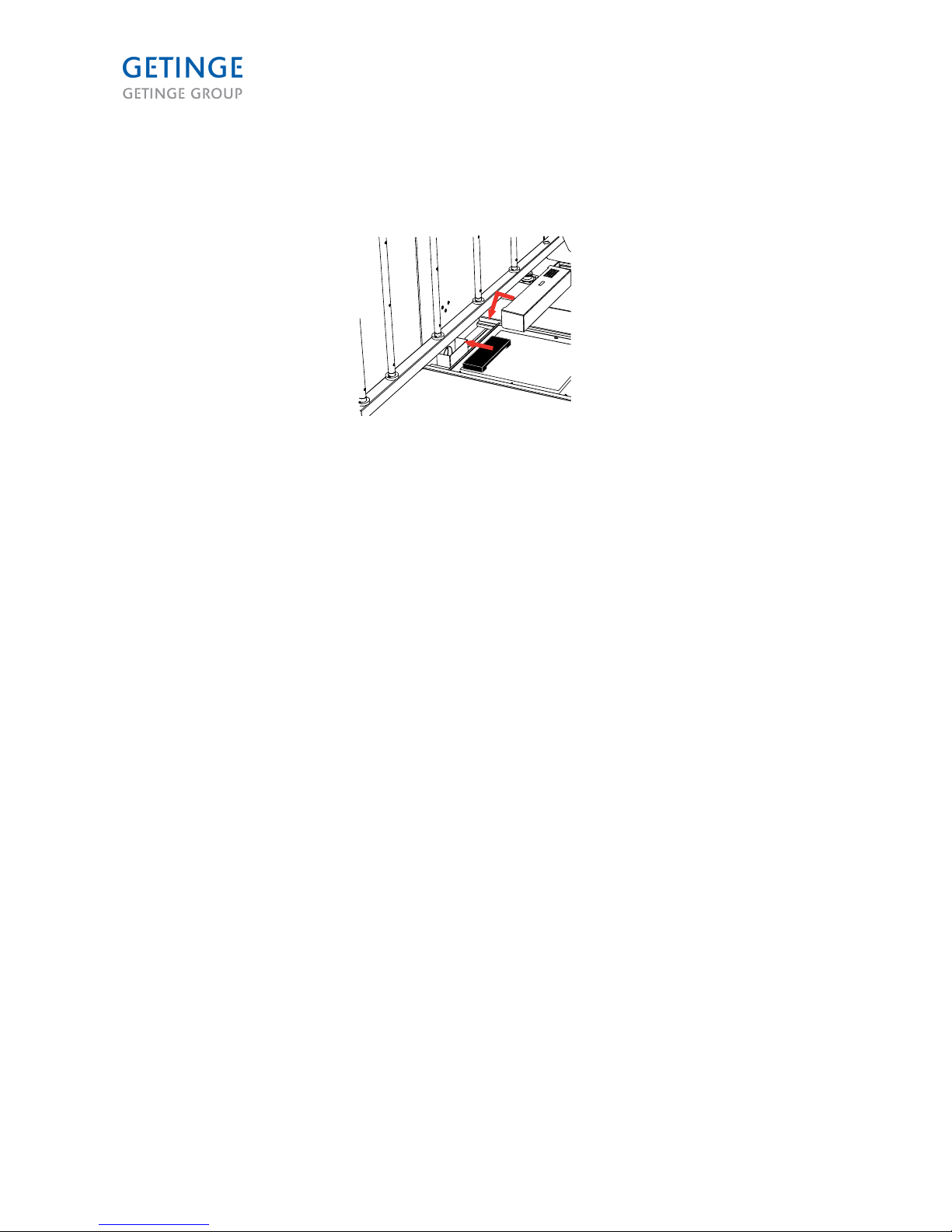

• Fit the blower protection cover (the black cover) over the overflow box. Install metal cover over

the box. Push the slotted metal flap downwards (90° angle) to keep the blow protector in the

proper position. Make sure that the black casing can move freely between the trap and the

edge of the casing.

000520

Page 24 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 25

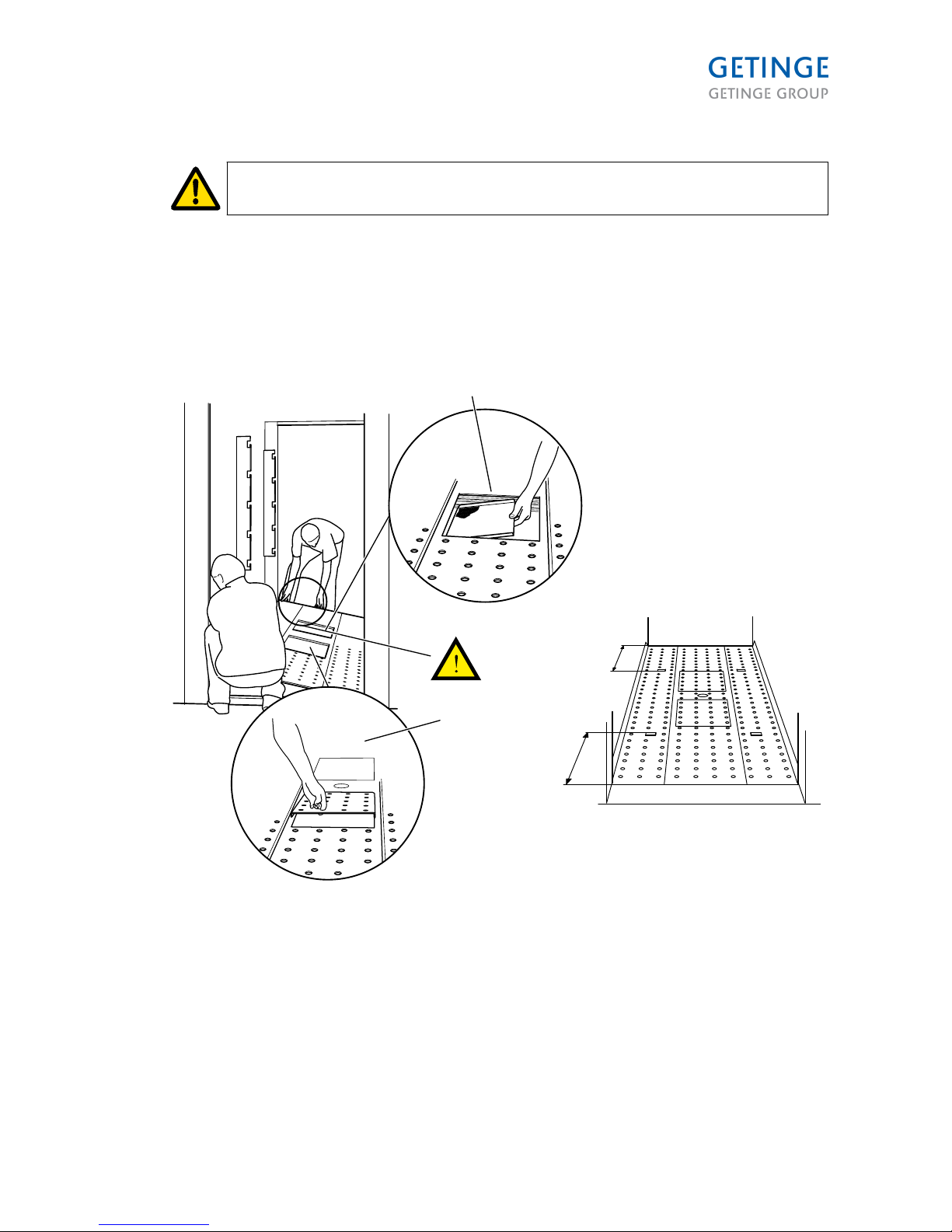

Risk of crushing when the chamber floor is lowered.

• Install the Chamber floor module. Be careful to place the module in the right direction. The

loading side on the chamber floor is farther from the marks for the wash cart. Check by

measuring or calculating the number of holes before the marks.

• Place four coarse strainers in the two holes on the floor plate and place the service panel over

the two holes. (For 9122 there are also two 105 mm spacers to be placed closest to the

chamber walls.)

B

A

C

001736

2

1

1. Coarse strainer 2 x 4 pce

2. Two service panels

A. Loading side

B. Short

C. Long

Page 25 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 26

• Place the sealing for the pump module in its groove (A).

• Install the pump module with seven screws (B).

001735

B

A

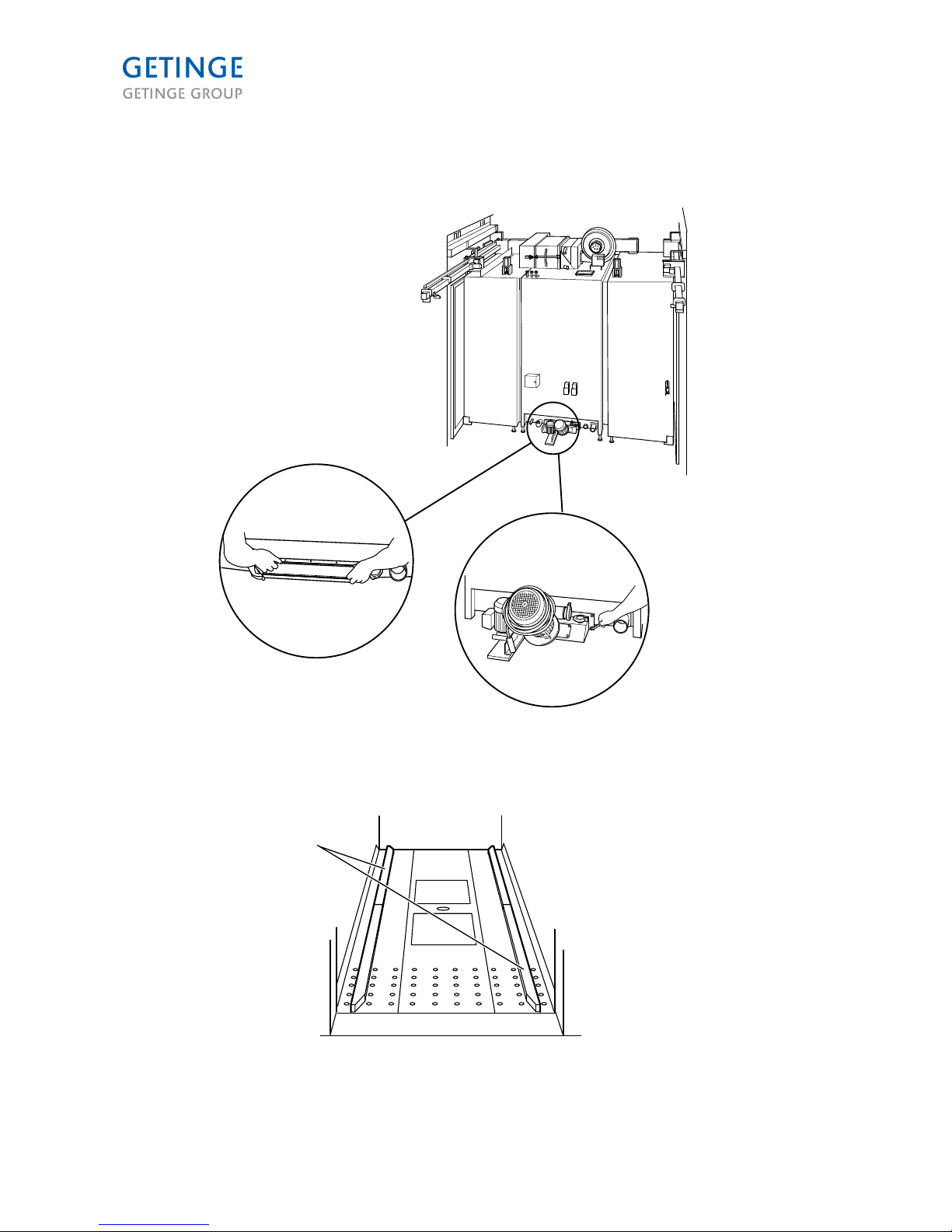

• Install the profiles for guiding the goods trolley in the machine (adjustable). Place them so that

the cart docking aligns exactly with the floor docking. (Normally they are placed in the second

line of holes from the wall)

1

001737

1. Profiles

Page 26 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 27

• Fit the two upper fittings for the nozzle pipes, (one on either side of the chamber).

• Place the springs in the holes of the distribution pipes and place a teflon washer at the top of

the spring.

000516

• Install the nozzle pipes on both sides. Press them down towards the springs and pass them

through the holes in the upper bracket.

Note: The left arms should point towards the wall. See illustration below.

• Attach the two link arms to run in the reciprocal direction. The holes in the link arms are not

centered. Make sure that the edge closest to the hole is placed against the wall.

1

2

3

000643

1. Nozzles

2. Link arms

3. The edge nearest the hole must be facing the wall.

Page 27 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 28

• Install the two long, narrow lifting rods with threads and nuts at the top edge and the eyelet at

the bottom edge (to tilt the chamber).

Screw into the sleeve at the top and tighten the

locknut (A).

Screw the eyelet to the floor plate (B).

A

000532

B

Page 28 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 29

• Position the six guard rails in the holders on the wall of the chamber.

000543

Page 29 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 30

• Fit the door seals. Hold the outside of each seal part to prevent the sealing strip bladder from

returning to the normal position because of vacuum.

001738

Page 30 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 31

• Line up the doors with their mountings in the door rails. Fit screws and nuts. Move the door

sideways to the middle of the door rail. Push the door upwards to insert the brackets into the

rail against the force of the spring, and lower the door into the pit. (If this method does not work

because there is too little space in the pit, lower the door into the pit first and then insert from

below, so the door can be attached to the brackets.)

000530

• The wire should be treaded as shown in the illustration below.

000531

Page 31 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 32

• Install the thresholds with three screws on each side.

• Place two plastic slider blocks on the moving part of the threshold.

1

000644

1. Plastic sliding blocks

• Place the electrical cabinet with the door facing down.

1

2

3

000636

• Fit two temporary supports with four screws and four nuts.

1. Electrical cabinet

2. Temporary supports for installing the electrical

cabinet

3. Wood beams

Page 32 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 33

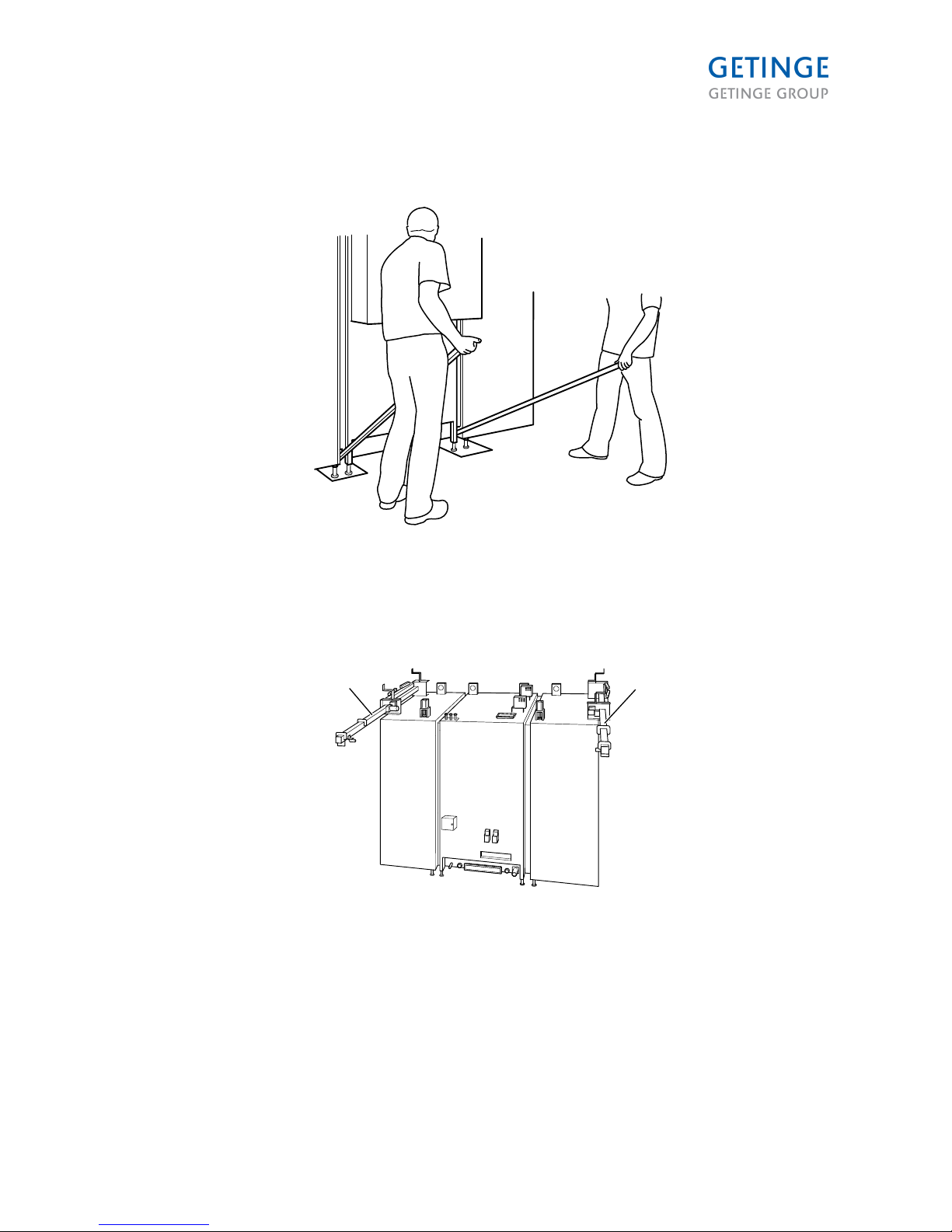

• Stand the cabinet up with the help of the temporary supports. Place some wooden blocks

against the legs of the machine to get the right point of rotation.

001733

Note: Make sure that the lifting eyes are correctly tightened.

• Hang the cabinet from the top edge of the machine in the main module.

• Remove the temporary supports and secure the electrical cabinet with four screws.

000536

Page 33 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 34

• Place the lower plastic guide in the hole.

• Insert the first of the two upper plastic guides on to the rod and place the rod in the upper

bracket.

• Insert the rod into the lower plastic guide.

• Position the lower locking plate of the upper bracket and tighten the plastic guide from below.

• Place the second upper plastic guide on the rod from above and the locking plate from below.

Tighten the plastic guide.

000645

1

2

1. Upper plastic guides

2. Lower plastic guides

Page 34 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 35

• Fit outer plates with panel (nine screws at the bottom edge and four screws at the top edge).

• Install and adjust the black round piece of Delrin so that the threshold plate can be moved

easily but is held back by the back edge.

• Adjust the height as needed in the manner described earlier.

2

1

3

000648

1. Screws at the top edge

2. Screws at the bottom edge

3. Delrin block

• Apply silicone to the joint between the threshold and the extension module. Clean the surface

before applying the silicone.

002927

Page 35 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 36

• Install pipe bends (90°) with a tri-clamp.

001739

• Attach the link arms from the piston rod to the rod and attach the door closure emergency

release spring (two on each side of the machine).

000646

1

1. Link arm

Page 36 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 37

• Install the support beams for the “door sealing shafts”.

1

2

000647

1. Support leg beam

2. Screws

Page 37 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 38

• Pull the safety line inside the chamber through the hole in the chamber wall.

000527

• Install the bracket with the safety line switch on the outside. Connect the hook from the wire

end to the bottle screw. Next connect the bottle screw to the safety wire's switch.

• Secure the end of the wire to the eyelet inside the chamber using a pin.

4

1

2

3

000649

1. Bracket

2. Safety line breaker

3. Bottle screw

4. Eyelet in chamber

• Adjust with bottle screw, so the arrow aligns with the line at the position indicator.

1

001740

1. Position indicator

Page 38 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 39

• Install all the cable ducts (18) and the cable tray.

001741

K209

K206

K104

K208

K207

K107

K205

K106

K105

K109

K212

K110

K213

K108

K101

K201

K211

K102

K103

K202

K204

K203

K210

Model 9120

Marking on drawing Quantity Length (mm) Installed/Not installed

K 205/106 1 Not installed

K 206/210 2 2000 Not installed

K105 1 440 Not installed

K 208/213/108/110/209 5 1000 All installed except K 209

K 204 1 750 Installed

K 203 1 590 Installed

K 103 1 690 Installed

K 107.2/109.2 2 500 Not installed

K 207/212 4 590 Not installed

K 107.1/109.1 2 660 Not installed

Page 39 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 40

Model 9120

Marking on drawing Quantity Length (mm) Installed/Not installed

K 211 1 270 Not installed

K 104 1 330 Not installed

K 102 1 400 Installed

K 202 1 600 Installed

K 101/201 2 1000 Not installed

Model 9122

Marking on drawing Quantity Length (mm) Installed/Not installed

K 205/106 1 Not installed

K 206/210 2 2000 Not installed

K 105 1 650 Not installed

K 208/213/209 3 1000 All installed except K 209

K 108/110 2 1300 Installed

K 204 1 750 Installed

K 103/203 2 800 Installed

K 107/109/207/212 4 1300 Not installed

K 211 1 270 Not installed

K 104 1 330 Not installed

K 102 1 440 Installed

K 202 1 600 Installed

K 101/201 2 1000 Not installed

Model 9125

Marking on drawing Quantity Length (mm) Installed/Not installed

K 205/106 1 Not installed

K 206/210 2 2000 Not installed

K105 1 440 Not installed

K 208/213/108/110/209 5 1000 All installed except K 209

K 204 1 750 Installed

K 203 1 590 Installed

K 103 1 690 Installed

K 107/109/207/212 4 1000 Not installed

K 102/211 2 400 K102 Not installed, K211

Installed

K 104 1 470 Not installed

K 202 1 600 Installed

K 101/201 2 1000 Not installed

Page 40 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 41

Model 9128

Marking on drawing Quantity Length (mm) Installed/Not installed

K 205/106 1 Not installed

K 206/210 2 2000 Not installed

K105 1 440 Not installed

K 208/213/108/110/209 5 1000 All installed except K 209

K 204 1 750 Installed

K 203 1 590 Installed

K 103 1 690 Installed

K 107/109/207/212 4 1000 Not installed

K 102 1 400 Not installed

K 104 1 650 Not installed

K 202/211 2 600 K 202 Installed, K211 Not

installed

K 101/201 2 1000 Not installed

• The electrical cables are connected and coiled at the various loads. Draw the cables in the

cable ducts as shown in the illustrations below and connect them in the electrical cabinet.

• The cables for 230/400 V must be placed in the cable duct/tray with the number K1xx (cable

ducts for 24 V cables have number K2xx) as shown in the illustration on the previous page. All

cables for 230/400 V must be connected to the electrical cabinet via cable duct K102 at the

cabinet entrance on the left side. If the object is on the right side of the electrical cabinet, the

cables must be drawn over the machine in the cable tray marked K106 above the chamber.

Place remaining cable in the cable tray on top of the machine marked K106.

A

001742

A. 230 V/400 V cables

Page 41 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 42

• The cables for 24 V must be placed in a cable duct/tray with the munber number K2xx as

shown in the illustration on the previous page. All cables for 24 V must be connected to the

electrical cabinet via cable duct K202 at the entrance to the cabinet on the right side. If the

object to which the cable is to be drawn is on the left side of the cabinet, the cables must be

drawn over the machine via cable tray marked K205 above the chamber. Place excess cable in

the cable tray on the top of the machine marked K205.

A

1

1

001743

1. Cable split

A 24 V Cables

Page 42 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 43

• Connect the cable from the door modules, soiled side (SS) and clean side (CS, option) to the

cable splits. Connect from the SS door equipment to cable split X215 with cables 251...

Connect from the CS door equipment to cable split X220 with cables 261...

000540

-X257 (C.S)

-X267 (S.S)

-X256 (C.S)

-X266 (S.S)

-X255 (C.S)

-X265 (S.S)

-X252 (C.S)

-X262 (S.S)

-X251 (C.S)

-X261 (S.S)

-X220 (C.S)

-X215 (S.S)

Jack

Cable label Destination

1 -X251

-X261

Door SS Unlock 1 Switch S02.1

Door CS Unlock 1 Switch S06.1

2 -X252

-X262

Door SS Unlock 2 Switch S02.2

Door CS Unlock 2 Switch S06.2

3 Not used.

4 Not used.

5 -X255

-X265

Door SS Threshold Switch S11

Door CS Threshold Switch S12

6 -X256

-X266

Door SS Locked 1 Switch S01.1

Door CS Locked 1 Switch S05.1

7 -X257

-X267

Door SS Locked 1 Switch S01.2

Door CS Locked 1 Switch S05.2

8 Not used.

Page 43 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 44

• Install the two chamber temperature sensors for the chamber in the chamber wall.

000528

• Install the transmitter for differential pressure and the temperature sensor on the dryer unit.

2

1

001744

1. Temperature sensor

2. Transmitter for differential pressure

Page 44 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 45

• The air hoses are secured and coiled at the various loads. Draw the air hoses and attach them

as shown in the illustration below and connect them to the respective air valve.

001745

PORT B PORT A

Y31 DOOR LOCK (CS) 530 Y21 DOOR LOCK (SS) 527

RESERVE Y22 FILL FROM BOOSTER TANK 535

Y18 NEUTRALIZATION 534 Y17 LOW LEVEL - DRAINAGE 533

Y30 THRESHOLD (CS) FRONT INTAKE 526 Y30 THRESHOLD (CS) 525

Y20 THRESHOLD (SS) FRONT INTAKE 524 Y20 THRESHOLD (SS) 523

Y09 SPLIT WATER CIRCUIT 518 Y09 SPLIT WATER CIRCUIT 517

Y19 WASH CART INCLINE 514 Y04 FILTER DRAINAGE 513

Y14 FROM WASTE WATER TANK 2 512 Y13 TO WASTE WATER TANK 2 511

Y12 FROM WASTE WATER TANK 1 510 Y11 TO WASTE WATER TANK 1 509

Y10 AVRFS 508 Y10 DRAINAGE TANK 507

Y06 STEAM, CHAMBER 506 Y05 STEAM, DRYER UNIT 505

Y07 STEAM, BOOSTER TANK 504 Y03 HQ WATER 503

Y02 HOT WATER 502 Y01 COLD WATER 501

Page 45 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 46

• Install the heater module with a “tri-clamp”.

1

CW HW DW

001746

1. Heater module

• Install the filter pipe module with a tri-clamp.

1

001747

1. Strainer pipe module

Page 46 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 47

• Install the waste water tank with two screws. Secure the hose on the drainage pump with hose

clamps.

1. Tanks

2. Hose to drain pump

• Install the waste water pipe between tank and drain. Install the hose between the filter pipe and

the drain.

1 2

001749

1. Drain pipes

2. Hose

Page 47 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 48

• Install the vent pipe.

001750

1

1. Vent pipe

Page 48 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 49

• Install the lower part of the steam pipe in the chamber wall and to the pipe at the heater

module.

1

001751

1. Lower part of steam pipe

Page 49 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 50

• Install the upper steam pipe unit between the pipe in the lower steam pipe section and the

heating element. Attach the module on the chamber wall.

• Connect the air hoses to the two valves on the steam pipe unit.

• Install the steam pipes on top of the chamber.

1

001752

2 4

3

3

1. Steam pipe

2. Heating element

3. Valve

4. Upper steam pipe unit

Page 50 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 51

• Install the heat exchanger and let the outer end rest on the support beam. Attach the hose

using hose clamps. Do not forget the drainage hose.

1 2

001754

1. Heat exchanger

2. Hose

The water can leak from the spillway during a process or if a problem arises.

• Run the draining hoses from the thresholds to the gully.

002882

Page 51 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 52

• Place the casing that covers the cables on the respective cable ducts.

• Fit the cover panels on the clean and soiled sides.

557100

0

1

1

1. Cover panel

Venting system

The venting system shall have an air gap of at least 50 mm direct after the exhaust. See drawing no.

5018514 for more information.

50 mm

1

001756

1. Not supplied by Getinge

Electrical connection

The electrical installation may only be performed by an authorized electrician.

The power supply cable is connected to the incoming connection terminals and the protective earth

connects to the ”PE” connection terminal.

Page 52 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 53

Installation category

The electrical installation should be made in accordance with CAT II

Main switch

Om maskinen värms upp med ånga utan transformator måste maskinen förses med en separat, låsbar

brytarenhet i elförsörjningen. Huvudbrytaren ska sitta lättillgänglig på en vägg nära maskinen.

Installationen måste utföras och märkas enligt lokala bestämmelser. (Eluppvärmda maskiner har en

matningsbrytare och maskiner med transformator en huvudbrytare.)

Power supply cable transformer

Transformatorn ska anslutas till elskåpet av behörig elektriker. Kontrollera att anslutningsalternativen i

transformatorn är korrekt inställda för den aktuella installationen. Påsarna med kiselgel ska tas bort från

elskåpet och transformatorn innan maskinen används.

Power supply cable steam heated

Ingående kopplingsstyrkablar med en diameter på mellan AWG 18- 1/0. Matningskabeln måste

dimensioneras enligt lokala bestämmer men får inte vara mindre än AWG 12.

Power supply cable electrically heated

Ingående kopplingsstyrkablar med en diameter på mellan AWG 6- 1/0. Matningskabeln måste

dimensioneras enligt lokala bestämmer men får inte vara mindre än AWG 1/0.

Eluppvärmda maskiner måste skyddas med en säkring med egenskaperna 100 A kurva C.

EL

Rekommenderad

servicefrånkoppling

Primär transformator

Full belastningsström

Sekundär transformator Full

belastningsström (maskin)

Ånguppvärmning

200 V 50/60 Hz 3+PE 20 A kurva C 15,5 A 7,3 A

208 V 50/60 Hz 3+PE 20 A kurva C 15,2 A 7,3 A

220 V 50/60 Hz 3+PE 20 A kurva C 14,7 A 7,3 A

230 V 50/60 Hz 3+PE 20 A kurva C 14,3 A 7,3 A

240 V 50/60 Hz 3+PE 20 A kurva C 14,0 A 7,3 A

380 V 50/60 Hz 3+PE 16 A kurva C 8,5 A 7,3 A

400 V 50/60 Hz 3N+PE 16 A kurva C - (Ingen transformator) 7,3 A

415 V 50/60 Hz 3N+PE 16 A kurva C 7,1 A 7,3 A

480 V 50/60 Hz 3+PE 10 A kurva C 6,9 A 7,3 A

600 V 50/60 Hz 3+PE 10 A kurva C 5,0 A 7,3 A

Eluppvärmning

400 V 50/60 Hz 3N+PE 100 A kurva C - (Ingen transformator) 90 A

Page 53 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 54

Adjusting the limit switch

Adjusting the pressure stabilizer

The pressure stabilizer is placed on the electrical cabinet and adjusted by pulling up the control knob and

then turning it. Adjust the stabilizer so the barometer displays 0.5 MPa of pressure.

001762

Open door

Manually open the door enough so the entire door is outside the door opening. Adjust the mechanical

end stop so it is against the door when the door is open all the way. The mechanical end stop consists of

an adjustable angle bracket and an adjustable rubber stopper.

001757

The switch's mounting is adjustable in two directions, which is used to adjust the switch's point of

impact. When adjusting for an open door, make sure that the point of impact for activated/non-activated

switches is distinct and that the breakpoint is not in the switch's outer area.

Page 54 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 55

Closed door

Close the door manually so the door is symmetrical to the door opening. The mechanical end stop

consists of an adjustable angle plate that is adjusted according to the door.

With the door in a closed position, adjust the limit switch so it is activated by the door. The switch's

mounting allows for horizontal adjustment. When adjusting for an open door, make sure that the point of

impact for activated/non-activated switches is distinct and that the breakpoint is not in the switch's outer

area.

S04

001758

Adjusting the restrictor check valve

For smooth operation when opening and closing doors and when locking the threshold lock, use

restrictor check valves. Maneuver the doors manually by having a person hold down the button

to

open or the button to close while another person adjusts by turning the knob on the flow limiter.

001763

Page 55 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 56

Crush protection, door

The switch for the door's crush protection is adjustable horizontally. Adjust the sensor's position so it is

as close to the crush protection plate as possible, without being activated.

15°

15°

001759

The sensor's joint can be adjusted as needed to achieve the right position.

Check that the point of impact for activated/non-activated switches is distinct and that the breakpoint is

not in the switch's outer area.

Threshold cylinder switch

The cylinder for threshold control is fitted with a sensor that indicates when the cylinder is fully extended.

2

1

001760

1. Sensor D1/D0

2. Sensitivity point

Activate manual mode for the digital output that controls the threshold cylinder

Test digital output

(2.1.6.8.2.4)

. Move the cylinder to its outer position. Move the sensor along the cylinder until it is

becomes activated, which is indicated by the sensor's built-in LED. Mark the position with a line on the

cylinder at the same level as the sensor's sensitivity point, which is marked on the sensor. Then continue

to move the sensor until it becomes non-activated, and mark this position on the cylinder. Place the

sensor so that its sensitivity point is centered between both marks.

Verify that the adjustment is correct by moving the threshold forward and backward. Adjust the restrictor

check valves to achieve a gentle and fluid motion.

Page 56 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 57

Door locking switch

Two cylinders are used for door locking. The cylinders are fitted with two sensors, which indicate when

the door is locked or unlocked.

2

1

001761

1. Sensitivity point

2. Sensor D1/D0

Activate manual mode for the digital output that controls door locking

Test digital output (2.1.6.8.2.4)

.

Place the cylinder in its retracted position and move the sensor outward from the center until the sensor

is activated. Any activation is indicated by a built-in LED. Mark the position on the cylinder at the sensor's

sensitivity point. Continue to move the sensor until the sensor again becomes non-activated, and mark

the position. Position and fasten the sensor so the sensitivity point is centered between the marks.

Place the cylinder in its fully extended position and repeat the marking step and adjustment of the sensor

for the unlocked position. Make the same adjustment with the other cylinder.

Page 57 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 58

Washer-disinfector options

One or two saving tanks

1 2

001764

1. Saving tank 1

2. Saving tank 2

Page 58 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 59

Docking for items cart

1

001765

1. Cart docking

Page 59 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 60

Waste cooling

1

001766

1. Waste cooling

Booster tank

1

001767

1. Booster tank

Page 60 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 61

Neutralization system for waste water (pH sensor)

1

001768

1. pH sensor

Page 61 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 62

Neutralization system for waste water (only time control)

1

001769

1. Neutralization system for waste water

Connection for treated water

1

001771

1. High-quality water valve

Page 62 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 63

3rd and 4th dosage pump

1 2

001773

1. 3rd dosage pump

2. 4th dosage pump

Page 63 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 64

Drying filter

2

1

001774

1. HEPA-filter

2. Heat exchanger

Page 64 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 65

Installation drawings

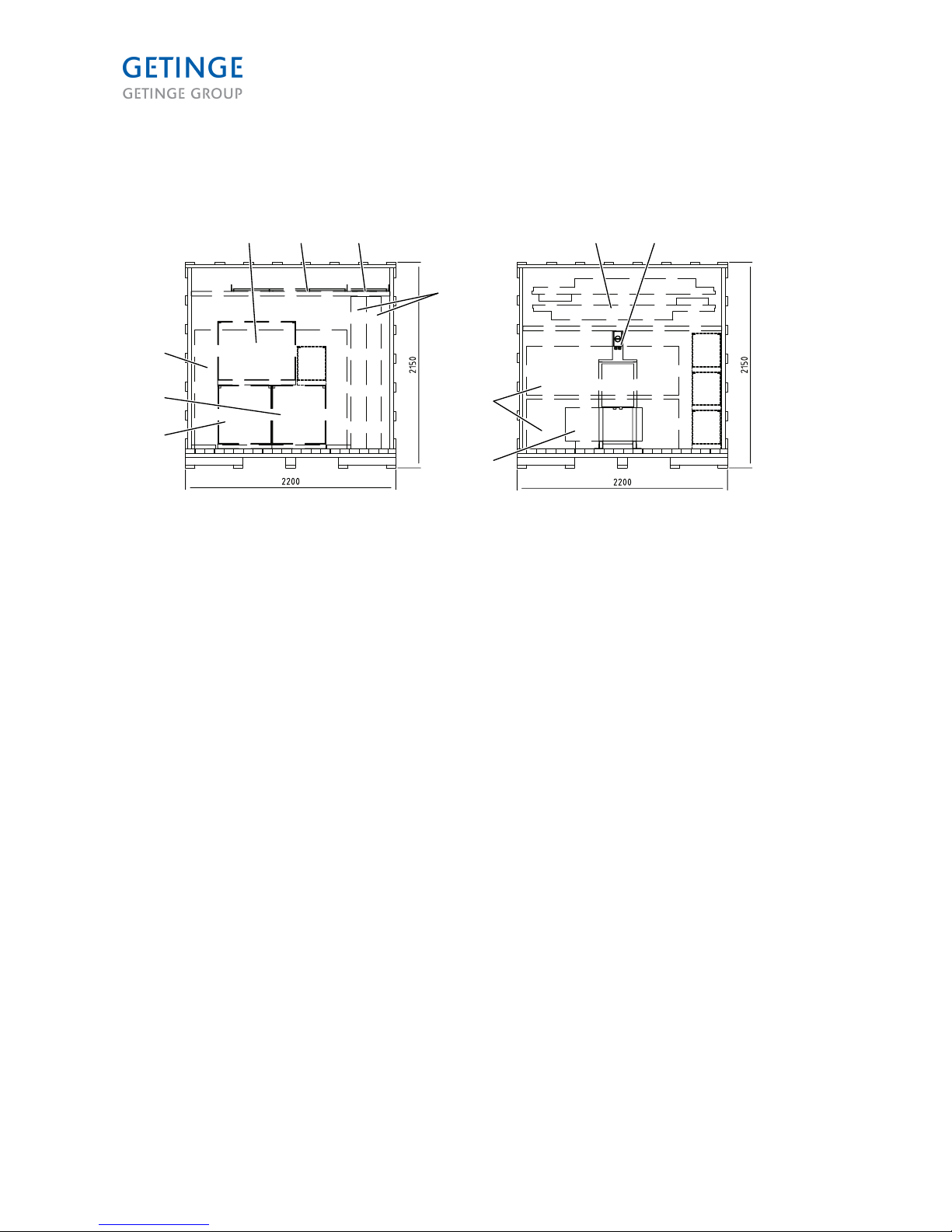

9120, 9125, 9128 two doors, pit installation

577100

Page 65 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 66

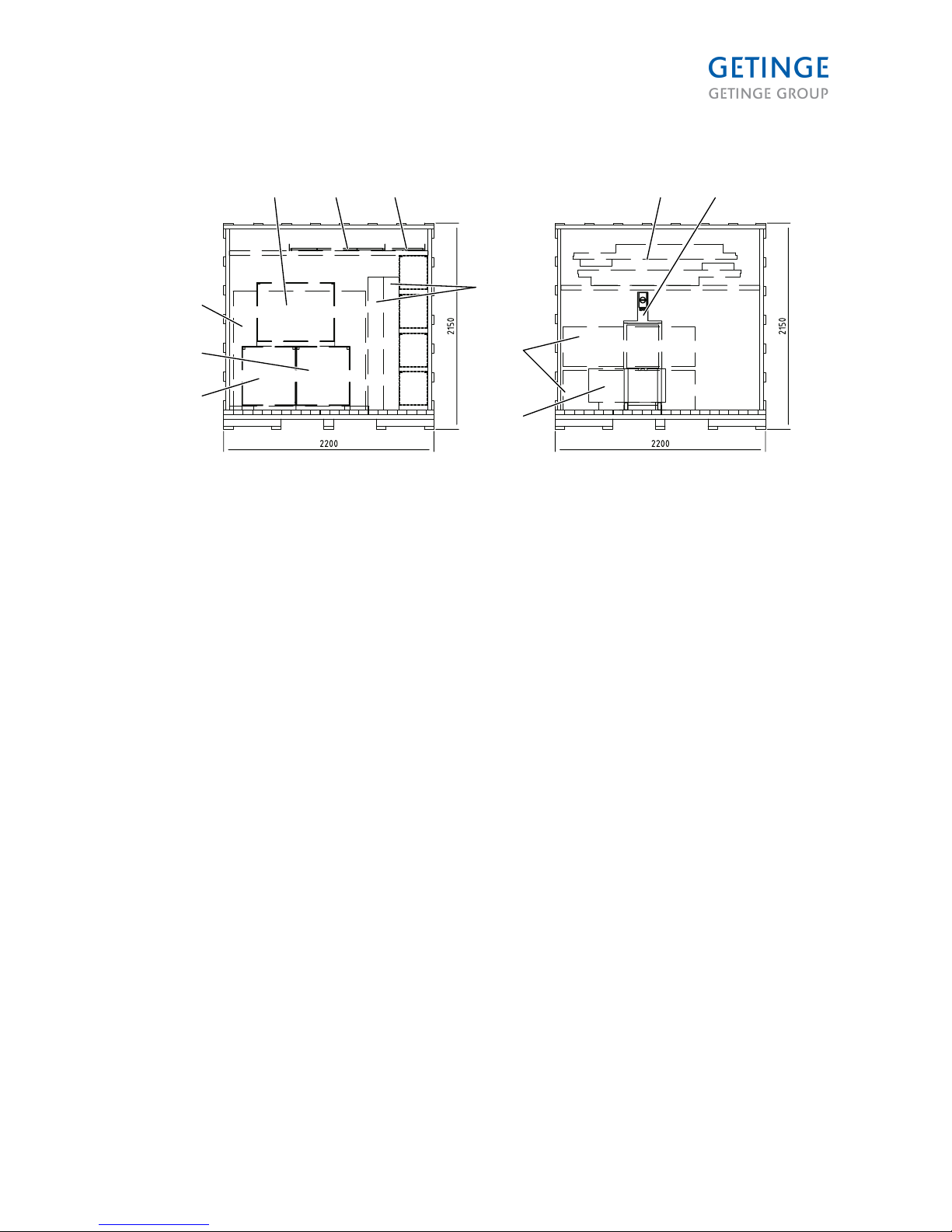

9120, 9125, 9128 one door, left, pit installation

677100

Page 66 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 67

9120, 9125, 9128 one door, right, pit installation

777100

Page 67 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 68

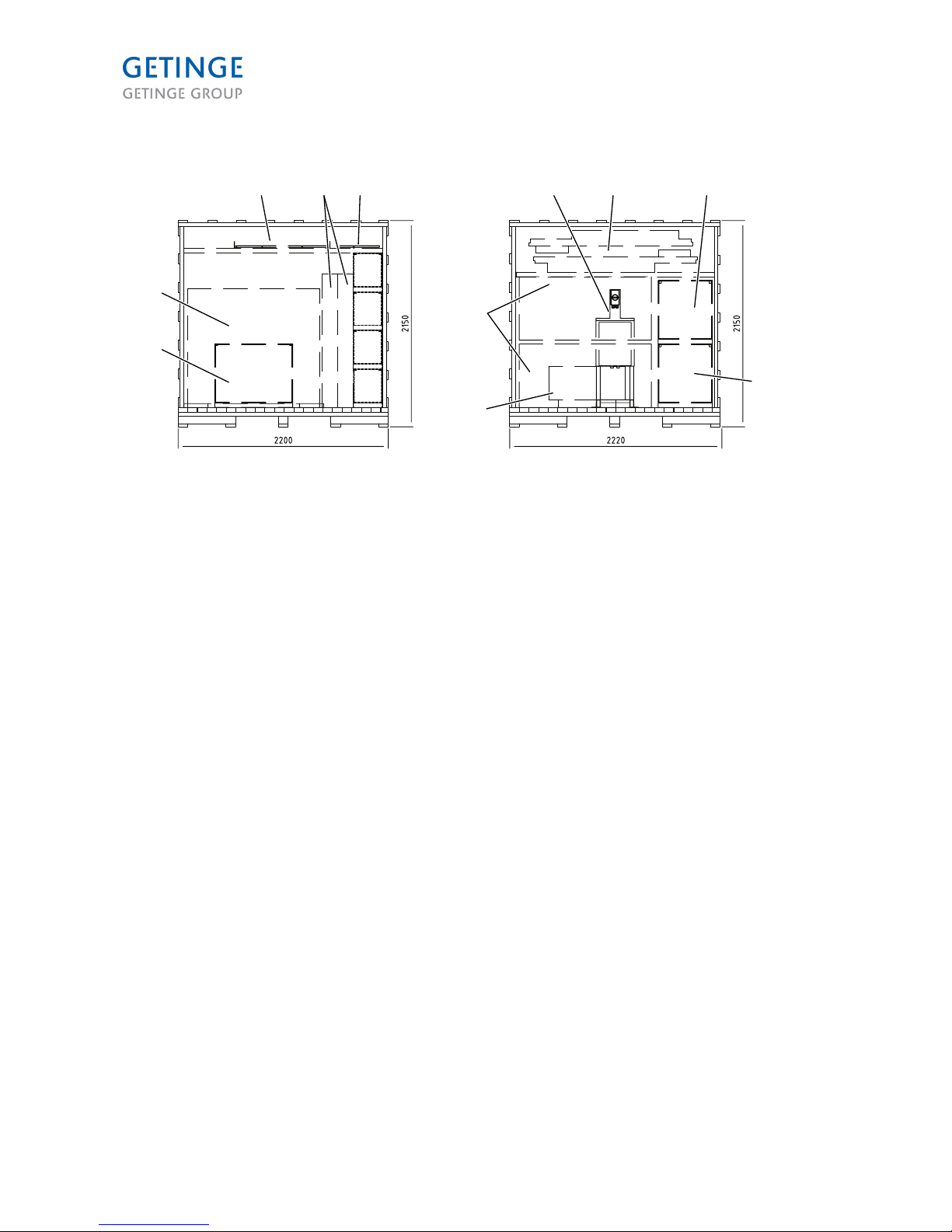

9120, 9125, 9128 pit installation

001778

Page 68 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 69

9120, 9125, 9128 two doors, pit installation

977100

Page 69 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 70

9120, 9125, 9128 one door, left, floor installation

0

87100

Page 70 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 71

9120, 9125, 9128 one door, right, floor installation

001781

Page 71 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 72

9120, 9125, 9128, front panels service

FRONT, Floor "RH"

FRONT, Pit "RH"

FRONT, "LH" LOAD

A

A

LOAD END (LH)

LOAD END

(RH)

LOAD END (LH)

* Loading ramp,

(floor mounted)

* Loading ramp,

(floor mounted)

2803 [9'-2

3

8

"] - Unit height

2650 [8'-8

3

8

"] - Unit height

3000 [9'-10

1

8

"] - Rec. Height (ceiling)

2670 [8'-9

1

8

"] - Rec. Wall opening

2820 [9'-3"] - Rec. Wall opening

3150 [10'-4"] - Rec. Height (ceiling)

2810 [9'-2

5

8

"] - Rec. Wall opening

2784 [9'-1

5

8

"] - Barrier Trim panels

100 [0'-3

7

8

"]

970 [3'-2

1

4

"]

1270 [4'-2"]

- Rec. Service access

1218 [3'-11

7

8

"]

Electrical

Fallback

1225 [4'-

1

4

"]1225 [4'-

1

4

"]

L1 - Unit Length

13 [0'-

1

2

"]

200 [0'-7

7

8

"]

Rec. dist.

to wall

100 [0'-3

7

8

"]

BARRIER TRIM PANELS

"Hinged door"

Not included in machine

152 [0'-6"]

9120 9125 9128 9027L12500 3000 3350 3150

[L1]

8'-2 3/8" 9'-10 1/8" 10'-11 7/8"

10'- 4"

120 [0'-4

3

4

"]MAX

Rec. wall thickness

002939

Page 72 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 73

9122 double doors, pit installation

Page 73 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 74

9122 one door, left, pit installation

001783

Page 74 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 75

9122 one door, right, pit installation

Page 75 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 76

9122 pit installation

Page 76 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 77

9122 double doors, floor installation

Page 77 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 78

9122 one door, left, floor installation

001787

Page 78 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 79

9122 one door, right, floor installation

001788

Page 79 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 80

9122, front panels service

A

A

LOAD END

(LH)

LOAD END

(RH)

* Loading ramp,

(floor mounted)

* Loading ramp,

(floor mounted)

LOAD END

(LH)

FRONT, "LH" LOAD

3003 [9'-10

1

4

"] - Unit height

2850 [9'-4

1

4

"] - Unit height

3200 [10'-6"] - Rec. height (ceiling)

FRONT, Floor "RH"

FRONT, Pit "RH"

2700 [8'-10

1

4

"] - Unit length

2991 [9'-9

3

4

"] - Barrier Trim panels

1225 [4'-

1

4

"] 1225 [4'-

1

4

"]

73 [0'-2

7

8

"]

3020 [9'-10

7

8

"] - Rec. Wall opening

152 [0'-6"]

2870 [9'-5"] - Rec. wall opening

3020 [9'-10

7

8

"] - Rec. wall opening

3350 [10'-11

7

8

"] - Rec. height (ceiling)

200 [0'-7

7

8

"]

Rec. dist.

to wall

Barrier Trim

31 [0'-1

1

4

"]

15 [0'-

5

8

"]

127 [0'-5"] 940 [3'-1"]

(Hook door)

BARRIER TRIM PANELS;

"Hooked door" (US-model)

Not included in machine

1270 [4'-2"]

- Rec. Service access

330 [1'-1"]

1217 [3'-11

7

8

"]

Electrical

Fallback

120 [0'-4

3

4

"]MAX

Rec. wall thicknes

2994 [9'-9

7

8

"] - Barrier Trim panels

100 [0'-3

7

8

"]

970 [3'-2

1

4

"]

BARRIER TRIM PANELS;

"Hinged door"

Not included in machine

Other measurement, see "hooked door"

002940

Page 80 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 81

TECHNICAL DATA

UTILITY REQUIREMENTS

Utility Connection Pressure,

rec.

measuremen

t

Recommended

9100

Comments

CW = Cold water

See notes 1, 2 and 3

Tri-clamp ø25

pipe ø18xi

2-8 bar > 100 l/min Alt. connection thread 3/4”

Temp. 5-20°C (see Water

Quality chapter)

HW = Hot water

See notes 1, 2 and 3

Tri-clamp ø25

pipe ø18xi

2-8 bar > 100 l/min Alternative connection

thread 3/4" Temp. 45-60°C

(see chapter water quality)

HQW = High Quality

Water (option)

Tri-clamp ø25

pipe ø18xi

2-8 bar > 100 l/min Alt. connection thread 3/4”

Temp. 5-90°C (see Water

Quality chapter)

CA = compressed

air

1/4” thread 5-8 bar 10 l/min Air free from oil and water

G = gully Not Applicable Not Applicable > 200 l/min

Temp. max. 93°C

D = process

drainage (dict)

ø50 Not Applicable > 200 l/min

Temp. max. 93°C

ø80 floor drain Temp. max

60°C with drainage cooling

S = steam 1” thread 2-4 bar 300-400 kg/h Dynamic steam pressure

C = condensate 3/4” thread Not Applicable Connection point at floor

level may not exceed 0.3

bar

EX = exhaust

See note 5

ø160 Not Applicable Normal vol. >800

m3/h Forced

ventilation during

drying 1200-2000

m³/h

Connection to building

ventilation system with air

gap

E = Electrical See Electrical connection

chapter or CD Electrical

diagrams

ENVIRONMENTAL REQUIREMENTS

Temperature service area 5–30°C (41–86°F)

Relative humidity Max 80% at 31°C

Main supply voltage fluctuations Not to exceed ±10% of nominal voltage

Max. altitude above sea level for operation Standard if <1000 m above sea level.

Special if >1000 m above sea level

Diff pressure elimination in glass doors

Page 81 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 82

OPERATING REQUIREMENTS

Surface temp clean and soiled sides <50°C

Humidity level Humidity dropping to less than 40% after approx 5

min drying

Noise level, see note 14 Approx 65 db (A) Inbuilt machine

Radiant heat loss Clean side 2.25 kW

Soiled side 0.90 kW

Service area 5-10 kW

Power consumption Steam heated Max 5.2 KW

Electrically heated max. 65 kW

Air exhaust during drying 800 m³/h

Page 82 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 83

weights and dimensions

Outer Dimensions

9120 Width: 2650 mm Height: 2800 mm Depth: 2500 mm

9125 Width: 2650 mm Height: 2800 mm Depth: 3000 mm

9128 Width: 2650 mm Height: 2800 mm Depth: 3350 mm

9122 (LS) Width: 2860 mm Height: 3000 mm Depth: 2700 mm

Effective Chamber dimensions

9120 Width: 960 mm Height: 2000 mm Depth: 2000 mm

9125 Width: 960 mm Height: 2000 mm Depth: 2500 mm

9128 Width: 960 mm Height: 2000 mm Depth: 2850 mm

9122 Width: 1170 mm Height: 2200 mm Depth: 2200 mm

Minimum clearance (the area required to install the unit)

9120 Width: 3200 mm Height*: 3150 mm Depth**: 2500 mm

9125 Width: 3200 mm Height*: 3150 mm Depth**: 3000 mm

9128 Width: 3200 mm Height*: 3150 mm Depth**: 3350 mm

9122 Width: 3400 mm Height*: 3350 mm Depth**: 2700 mm

Chamber

9120 Width: 1350 mm Height*: 2440 mm Depth**: 1200 mm

9125 Width: 1350 mm Height*: 2440 mm Depth**: 1200 mm

9128 Width: 1350 mm Height*: 2440 mm Depth**: 1200 mm

9122 Width: 1560 mm Height*: 2640 mm Depth**: 1200 mm

Weight 9120: 250 kg 9122: 280 kg 9125: 250 kg 9128: 250 kg

End section

9120 Width: 1315 mm Height*: 2445 mm Depth**: 415 mm

9125 Width: 1315 mm Height*: 2445 mm Depth**: 665 mm

9128 Width: 1315 mm Height*: 2445 mm Depth**: 840 mm

9122 Width: 1525 mm Height*: 2645 mm Depth**: 515 mm

Weight 9120: 105 kg 9122: 138 kg 9125: 150 kg 9128: 177 kg

Glass Door

9120 Width: 1095 mm Height*: 2100 mm Depth**: 35 mm

9125 Width: 1095 mm Height*: 2100 mm Depth**: 35 mm

9128 Width: 1095 mm Height*: 2100 mm Depth**: 35 mm

9122 Width: 1305 mm Height*: 2300 mm Depth**: 35 mm

Weight 9120: 110 kg 9122: 130 kg 9125: 100 kg 9128: 100 kg

Total Weight

9120: 1400 kg 9122: 1650 kg 9125: 1500 kg 9128: 1600 kg

Page 83 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 84

Notes:

1. It is the customer's responsibility to insure by use of pressure regulators or other means that

maximum specified pressures are not exceeded.

2. It is the customer's responsibility to eliminate water or steam hammer conditions should they

occur in the service pipes.

3. It is the customer's responsibility to ensure that water supplies are properly protected against

internal cross connection according to local building and pipe regulations.

4. It is the customer's responsibility to provide a properly sized and located drainage system in

accordance with the relevant national regulations in the area. Consider what other equipment is

connected to drain to eliminate slow drainage or backup. If conditions dictate that the washerdisinfector will dump water directly into the pit, the pit should be watertight.

5. It is the customer's responsibility to provide a service area with a ventilation system according

to the following specifications:

Alt.1) A system with a constant draught of 1200-1200 m³/h.

Alt 2) A system with a basic draught of 500-800 m³/h and a controlled forced draught during

drying (1200-2000 m3/h). (When forced draught ventilation is required, it is signal-activated.)

The system should be a well-functioning, corrosion proof & watertight ventilation system. Direct

the ventilation back towards the washer-disinfector.

6. It is the customer's responsibility to complete all electrical connections using properly sized

wiring in accordance with national regulations.

7. It is the customer's responsibility to provide a fused switch in all electrical supply lines to the

washer-disinfector area.

8. The noise level value applies when the washer-disinfector and service area are built in.

Measured 1 meter in front of the washer and 1.5 m above floor level.

*) The measurement refers to a floorstanding unit. Deduct 150 mm for units installed in a pit

**) Measurements refer to double door installation. Deduct 200 mm for a door.

Page 84 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 85

DOSAGE

Hose material on delivery

The machines come with the following hose material:

Transport hoses Pump hose

503645300, Tygon 503611700, Norprene

Depending on the agent used, the hose in the dosing pump may be replaced to achieve more favorable

operation. The hoses in the hose pumps are exposed both to chemical wear and mechanical wear. It is

therefore important that the correct hose material is selected with regard to the chosen detergent to

achieve safe operation and satisfactory service life. The hoses in the hose pumps are wear parts with an

anticipated service life of one year.

Available hose materials from Getinge sales companies

Article number

Pump hose Design

503611700 Norprene Black with white text

503611701 Tygon Transparent, clear

503611702 Tygon Transparent, yellow

503611703 Silicone Transparent, matt

503611704 Fluran Black

Note: Calibration must always be done after a pump hose replacement. See

"Technical Manual."

Recommendations when Getinge Disinfection AB's detergent is

used

The following hose materials are tested for the following detergents:

Detergent

Recommended pump hose

GETINGE CLEAN HEAVY SOIL DETERGENT

503611600, Norprene

GETINGE CLEAN UNIVERSAL DETERGENT

503611600, Norprene

GETINGE CLEAN ENZYMATIC DETERGENT

503611600, Norprene

GETINGE MIS DETERGENT

503611600, Norprene

GETINGE CLEAN NEUTRALIZER

503611603, Silicon

GETINGE CLEAN NEUTRALIZER PLUS

503611600, Norprene

GETINGE CLEAN RINSE AID

503611603, Silicon

GETINGE CLEAN INSTRUMENT LUBRICANT

503611602, Tygon

Page 85 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 86

General recommendations for non-Getinge AB detergents

Type Recommended pump hose

Alkaline detergents 503611700, Norprene

Acidic detergents (dishwasher detergent, fabric

softener, neutral)

503611703, Silicone

Enzymes 503611700, Norprene

Lubricants 503611702, Tygon

Variations may occur as the chemical composition of different detergents on the market can vary

considerably. For example, Silicone 503611703 is recommended for acidic agents based on citric acid,

while Fluran 503611704 is recommended for acidic agents based on phosphoric acid. Contact the

current detergent supplier if uncertain about which hose to select.

Flow monitoring

Getinge Disinfection AB's washer-disinfectors are type-tested using Getinge Disinfection AB's own

process chemical range, Getinge Clean. The washer-disinfector, including the dosing equipment, is

adapted and tested with these agents. If process chemicals with a higher viscosity than 10 cSt are used,

there is a risk that monitoring is not working to satisfaction.

The user has sole responsibility for drawing up a hands-on routine to ensure that the dosing system

works.

Starting up

The operation of detergent dosing is checked in the factory using water. When starting up, calibration

with the agent in question must be carried out for the machine to work properly. See the section

Dose

monitor calibration (2.1.6.2.3)

Page 86 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 87

WATER QUALITY

It is the customer’s responsibility to supply the washer-disinfector with water of

the right quality.

The quality of the water used in all stages of cleaning is important for good cleaning results. The water

used in each step should be compatible with:

• The material that the washer-disinfector is made of.

• The chemicals used in the process.

• Process requirements for the various stages of the process

The main factors for good water quality are:

Hardness High hardness will cause limescale deposits in the washer-disinfector,

leading to poor cleaning results.

Ionic contaminants A high concentration of ionic contaminants may cause corrosion and

pitting on stainless steel.

Heavy metals such as iron, manganese or copper cause instruments to

tarnish.

Microbial contaminants Items to be washed are treated for microorganisms and their residual

products, which may cause fever-like symptoms if they get into the human

body. Use water that does not increase the biological load.

Sanitary chemicals High concentrations of, and high exposure to, sanitary chemicals may

cause corrosion and pitting on stainless steel.

Getinge Disinfection AB recommends that water used in the pre-rinsing, washing and final rinsing phases

should be of drinking quality in accordance with the guidelines. Recommended water quality is drinking

water with max. 5°dH. Detailed information about acceptable water quality can be found in “Guidelines

for Drinking Water Quality, 3rd Edition” published by WHO.

Follow local standards if they are stricter that Getinge Disinfection AB's recommendations. Especially

when treated water is used for the final washing/disinfection phase. A typical specification for treated

water is:

pH

5.5 to 8

Conductivity <30 µs.cm-1

TDS <40 mg/l

Maximum hardness <50 mg/l

Chlorine <10 mg/l

Heavy metals <10 mg/l

Phosphates <0.2 mg/l as P2O5

Silicates <0.2 mg/l as SiO2

Endotoxins <0.25 EU/ml

Total number of micro-organisms <100 per 100 ml

Additional advice should also be obtained from the manufacturers of chemical and medical equipment.

Page 87 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 88

HANDLING OF WORN-OUT PRODUCTS

This product and its accessories comply with the requirements in the WEEE directive (Waste Electrical &

Electronic Equipment) 2002/96/EC. Worn-out products must be disposed of at recycling stations in

accordance with local regulations. If required, contact your reseller for more information.

Note: The product may be contaminated and has to be disinfected before

recycling.

000052

Page 88 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 89

ADDRESSES

Australia

Getinge Australia PTY Ltd

PO Box 50

Bulimba QLD 4171

Austrailia

Cust Support: 1300 155 500

Phone: +61 7 3399 3311

Fax: +61 7 3395 6712

E-mail:

info@getinge.com.au

Belgium

Getinge NV

Vosveld 4 B-2

B-2110 Wijnegem

Belgium

Phone: +32-33 542 865

E-mail:

info@getinge.be

Canada

Getinge Canada Ltd

6685, Millcreek drive

Unit 3-5

Mississauga, Ontario L5N5M5

Canada

Phone: +1-905-629-8777

E-mail:

customercare@getinge.ca

China

Getinge (Suzhou) Co.Ltd

No.158, Fang Zhou Road,

Suzhou Industrial Park

215 021 Suzhou

Jiangsu Province P.R. China

Phone: +86-51 262 838 966

E-mail:

info@getinge.com.cn

China

Getinge Shanghai Trading Co.Ltd.

No.3, Lane 128, Lin Hong Road

Changing District

200335 Shanghai China

Phone: +86-21 6197 3999

E-mail:

info@getinge.com.cn

Denmark

Getinge Danmark A/S

Industriparken 44 B

DK-2750 Ballerup

Denmark

Phone: +45 45 93 27 27

Fax: +45 45 93 41 20

E-mail:

getinge.denmark@getinge.com

Finland

Getinge Finland AB

Niittykatu 8

FI-02200 Espoo

Finland

Phone: +35-89 6824 120

E-mail:

getinge.finland@getinge.com

France

Getinge France SAS

BP 49, avenue du Canada

ZA de Courtaboeuf

Les Ulis, FR-91942

France

Phone: +33-1 64 86 89 00

E-mail:

getinge.france@getinge.fr

Germany

Getinge Vertrieb & Service GmbH

Kehler Strasse 31

764 37 RASTATT

Gemany

Phone: +49-7222 932 306

Fax: +49-7222 932 597

E-mail:

info.inco-de@getinge.com

Italy

Getinge S.p.A

via Poggio Verde, 34

00148 Roma

Italy

Phone: +39-06 656 631

E-mail:

info@getinge-it

Japan

Getinge Japan K.K.

3-9-2 Tatsumi,

Koto-ku, Tokyo

135-0053 JAPAN

Phone: +81-3-6758-2280

Netherlands

Getinge b.v.

Biezenwei 21

4004 MB Tiel

The Netherlands

Phone: +31 (0)344-809900

Fax: +31 (0)344-640885

E-mail:

info@getinge.nl

Page 89 of 92

<Doc_INS><Doc_6001341302><Rel.A><Lang_en>

Page 90

Norway

Getinge Norge A/S

Strandveien 13

1366 Lysaker

Norway

Phone: +47-23 03 52 00

E-mail:

info@getinge.no

Poland

Getinge Poland sp. z o. o.

ul. Osmańska 14,

PL-02-823 Warszawa

Polen

Phone: +48-22 882 06 26

E-mail:

office@getinge.pl

Singapore

Getinge International Far East Pte.

Ltd

20 Bendemeer Road,

#06-02, Cyberhub Building

Singapore, SG-339914

Phone: +65-6396 7298

E-mail:

info.sg@getinge.com

Spain

Getinge Iberica SL

C/ marie Curie, 5

Edificio Alfa, Planta 6a

28521 Rivas Vaciamadrid

Spain

Phone: +34-916 78 26 26

E-mail:

administracion@getinge.es

Sweden

Getinge Sverige AB

P O Box 69

SE-310 44 Getinge

Sweden

Phone: +46 10 335 30 00

E-mail:

info@getinge.com

Switzerland

Getinge ALFA AG

Weidenweg 17

4310 Rheinfelden

Switzerland

www.getingealfa.ch

Phone: +41-61 836 15 15

E-mail:

info@alfo.ag

United Kingdom

Getinge UK Ltd

Orchard Way Calladine Park

Sutton-In-Ashfield

Notts NG 17 1JU

United Kingdom

Phone: +44-1623510033

E-mail:

sales@getinge.co.uk

USA

Getinge USA Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133

USA

Phone: +1-800-475-9040

E-mail: