Page 1

600 SERIES STEAM STERILIZERS

INSTALLATION MANUAL

61301607027 REV A US

Page 2

INSTALLATION MANUAL

61301607027 REV A US

12/21/07

Getinge®, Biosign®, and EZ-VU® are registered trademarks.

Copyright ©2007 Getinge USA, Inc.

PUBLICATION HISTORY

Revision Date Reason

A

For quality service on the equipment and information on our Performance

Assurance Plan, contact:

Getinge USA, Inc.

1777 East Henrietta Road

Rochester, NY 14623-3133

Phone: 1-800-950-9912

www.getingeproducts.com

NOTE

This manual contains proprietary information of Getinge USA, Inc. It shall

not be reproduced in whole or in part without the written permission of

Getinge USA, Inc.

This manual is intended for qualified technicians with specialized training. If

you require additional help, contact the company service representative.

WARNING

POSSIBILITY OF INJURY: Misuse of equipment or bypassing its safety

features may result in personal injury.

12/2007 Initial Release

CAUTION

POSSIBILITY OF EQUIPMENT DAMAGE: Misuse of equipment may result

in equipment damage.

The 600 Series Steam Sterilizer is designed to steam sterilize hospital and

laboratory goods and solutions. This equipment is NOT intended for use

other than expressly stated.

ii INS 61301607027 Rev A US

Page 3

SECTION 1 PREFACE

600 Series Steam Sterilizers

TABLE OF CONTENTS

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–1

Summary of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–2

Environmental Impact Assessment. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–2

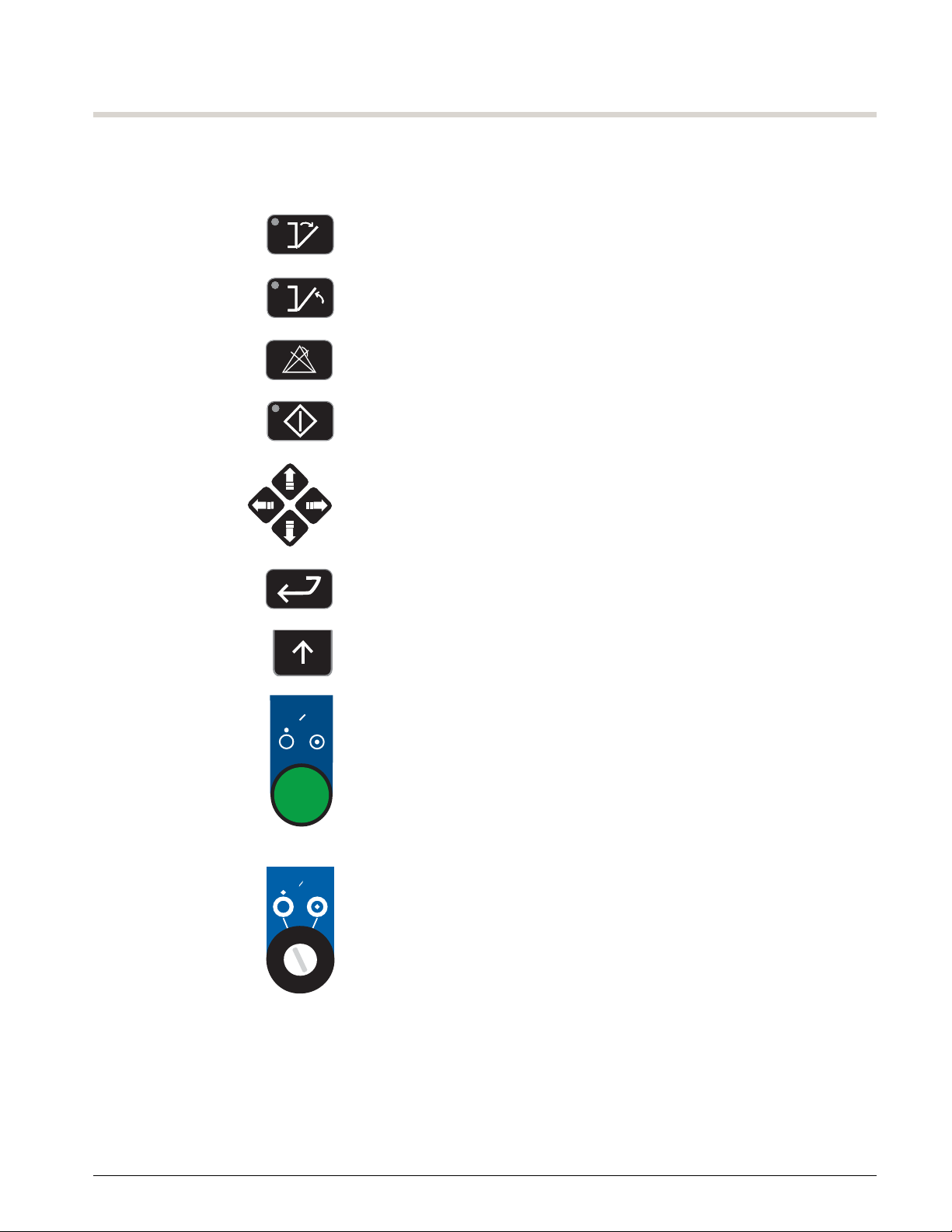

Description of Symbols on the Equipment . . . . . . . . . . . . . . . . . . . . . . .1–3

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–3

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–4

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

Symbols Used in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–5

SECTION 2 SAFETY

SECTION 3 PACKAGING

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

Plan the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

Install the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1–6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–3

Door Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–3

Door Obstruction Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–3

Isolating Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–4

Product Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2–5

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–1

Uncrating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–2

Unpacking the Sterilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–2

Removing the Sterilizer Front Panels . . . . . . . . . . . . . . . . . . . . . . . .3–4

Removing the Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3–5

SECTION 4 INSTALLATION INSTRUCTIONS

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4–1

INS 61301607027 Rev A US iii

Page 4

Table of Contents

Utility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Tools and Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Positioning and Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Positioning the Sterilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Leveling the Sterilizer Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–9

Leveling the Sterilizer Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–13

Installing the Kick Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–17

Re-attaching the Front Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–18

Utility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–19

Connecting the Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

Sterilizer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

Booster Pump (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

Steam Boiler (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

Connecting the Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

Electrical Supply Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 4–22

Connecting the Customer Supply. . . . . . . . . . . . . . . . . . . . . . . . . 4–23

Steam Boiler (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–25

Booster Pump (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–25

Anchoring the Sterilizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–26

Installing the Hold-Down Brackets . . . . . . . . . . . . . . . . . . . . . . . . 4–26

Installing the Seismic Anchoring Brackets . . . . . . . . . . . . . . . . . . 4–28

Installing the Interior Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–31

Installing the Rack and Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . 4–31

Installing the Loading Car Track . . . . . . . . . . . . . . . . . . . . . . . . . . 4–32

SECTION 5 OPTIONAL EQUIPMENT

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Steam Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Boiler Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Connecting the Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Connecting the Electrical Power. . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Checking the Heater Circuit Connections . . . . . . . . . . . . . . . . . . . 5–6

Booster Pump Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–9

Typical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–9

Mounting the Booster Pump and Interface Box . . . . . . . . . . . . . . 5–12

Connecting the Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–13

Connecting the Electrical Power. . . . . . . . . . . . . . . . . . . . . . . . . . 5–14

iv INS 61301607027 Rev A US

Page 5

600 Series Steam Sterilizers

Universal Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–16

Connecting the Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–17

Uninterruptible Power Supply (UPS) . . . . . . . . . . . . . . . . . . . . . . . . . . .5–18

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–19

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–19

Connecting the Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . .5–20

Water-Saver System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–22

Water Treatment System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–25

Cabinet Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–26

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–27

Preparing the Side Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–29

Installing the Support Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . .5–30

Hanging the Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5–32

SECTION 6 DRAWINGS

List of Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–1

Installation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6–1

SECTION 7 TECHNICAL DATA

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–1

Sterilizer Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–2

Interior Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–2

Exterior Dimensions (with Cabinet Package) . . . . . . . . . . . . . . . . . .7–2

Steam Supply Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–3

Steam Boiler Feedwater Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7–5

SECTION 8 FUNCTIONAL CHECK

Installation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–1

Inspection by Installers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–1

Final Inspection by Getinge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–1

Validation by Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8–1

INDEX

INS 61301607027 Rev A US v

Page 6

Table of Contents

vi INS 61301607027 Rev A US

Page 7

BEFORE YOU BEGIN

SECTION 1 PREFACE

Before installing the sterilizer, please read all the instructions and become

familiar with the sterilizer’s design, safety features, and operation.

This manual is intended to provide the knowledge to ensure safe sterilizer

installation by qualified technicians with specialized training in the

installation of Getinge 600 Series Sterilizers. If additional help is required,

contact a qualified Getinge service representative.

The following documentation is supplied with the machine:

• User Manual, Part Number 61301607026 (633HC) or 61301607502

(633LS)

• Installation Manual, Part Number 61301607027

• Quick Reference Poster, Part Number 61301607268 (633HC) or

61301607503 (633LS)

The following documentation is available for purchase:

• Technical Manual, Part Number 61301607028

• Parts Catalog, Part Number 61301607029

NOTE

Getinge reserves the right to make changes to specifications and

equipment without prior notice. The information contained within this

manual is current as of the date of issue.

INS 61301607027 Rev A US 1–1

Page 8

Preface

SUMMARY OF CONTENTS

This manual is divided into eight (8) sections as follows:

• Section 1 Preface—includes information regarding the intended

audience, a summary of the manual’s contents, advisories, and

environmental impact.

• Section 2 Safety—includes important precautions and safety features.

• Section 3 Packaging—includes information regarding the uncrating

and positioning of the sterilizer.

• Section 4 Installation Instructions—includes information regarding the

assembly and connection of the sterilizer, as well as plumbing and

electrical information.

• Section 5 Optional Equipment—includes information and drawings for

all available sterilizer options.

• Section 6 Drawings—includes Roughing-In Drawings, and Seismic

Anchorage Calculations.

• Section 7 Technical Data—includes product requirements and

specifications.

• Section 8 Functional Check—includes a checklist to verify the

operational state of the sterilizer after installation.

ENVIRONMENTAL IMPACT ASSESSMENT

The 600 Series Steam Sterilizers consist of stainless steel, copper, and

electronic and electrical components which can be recycled at the end of

the sterilizer lifecycle. The sterilizer also contains plastic and batteries

which can NOT be recycled and should be disposed of in accordance with

local and federal regulations.

1–2 INS 61301607027 Rev A US

Page 9

DESCRIPTION OF SYMBOLS ON THE EQUIPMENT

!

CONTROLS

DISABLE ENABLE

WS-0243

The following symbols and definitions represent the switches, indicators,

and labels found on the unit.

SWITCHES Open Door

Close Door

Clear Alarm

Start

Directional Arrows (for navigating display screens)

600 Series Steam Sterilizers

CONTROLS

OFF ON

WS-0091

Enter

Up Arrow Softkeys (for selecting softkey options (i.e. Save, Cancel, or OK))

CONTROLS OFF/ON

CONTROLS DISABLE/ENABLE

INS 61301607027 Rev A US 1–3

Page 10

Preface

!

HS

Contact Getinge USA Customer Support (800) 950-9912

If water leaks from the front of the sterilizer,

DO NOT open the door (see User Manual)

Steam released from the sterilizer chamber can

cause serious burns

Stand away while opening the door

WARNING — BURN HAZARD

MGA

61301607429 REV A

PROCESSING A TYPE OF LOAD OTHER

THAN DEFINED IN USER

MANUAL COULD BE HAZARDOUS

OBSERVE PRECAUTIONS

FOR HANDLING

SENSITIVE

DEVICES

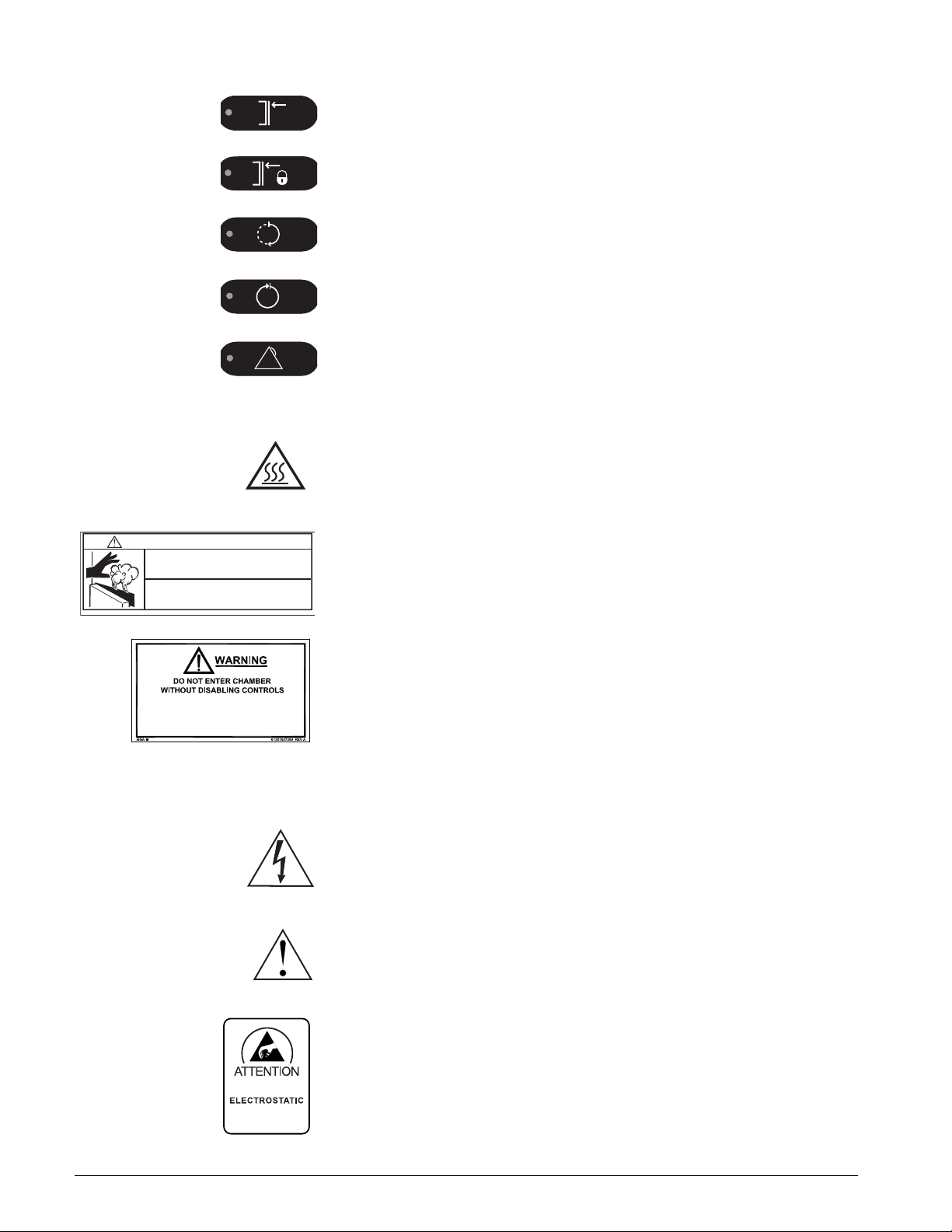

INDICATORS Door(s) Closed

Door(s) Sealed

In Process

Process Complete

Process Failure

LABELS The following labels on the sterilizer alert personnel to possible hazards.

Hot surfaces or heat-emitting area. Avoid contact. Risk of burns.

WARNING—BURN HAZARD: Steam released from the sterilizer chamber

can cause serious burns. Stand away when opening door.

WARNING: Do not enter chamber without disabling controls. Processing a

type of load other than defined in the User Manual could be hazardous.

The following labels on the Control Box and Power Box alert service

personnel to possible hazards.

HIGH VOLTAGE

CAUTION: To reduce the risk of electrical shock, do not remove cover.

Refer servicing to qualified service personnel.

ATTENTION: Refer to accompanying documents for further information.

1–4 INS 61301607027 Rev A US

Electrostatic Sensitive Devices

Page 11

MANUAL CONVENTIONS

600 Series Steam Sterilizers

Before you begin using this manual, it is important to understand the

conventions used. These conventions are established for visual ease of

use.

ITALIC CAPS Display text, such as the ENTER

PASSWORD prompt.

[ALL CAPS] Softkeys on the control panel, such as

[CANCEL] or [OK].

ALL CAPS Switches and indicators on the control panel,

such as ENTER.

> The > symbol leads you through nested

menu items and dialog box options to a final

action. For example: PARAMETERS>enter

password>EDIT.

Italic Upper/Lower Case Cross reference to another manual or guide,

such as: see “Leveling the Sterilizer Door” on

page 4–13.

SYMBOLS USED IN THIS MANUAL

The following symbols with related notes appear in this manual.

WARNING

“Warning” notes alert the user to the possibility of personal injury.

CAUTION

“Caution” notes alert the user to the possibility of damage to the

equipment.

NOTE

“Notes” alert the user to pertinent facts and conditions.

INS 61301607027 Rev A US 1–5

Page 12

Preface

HOW TO USE THIS MANUAL

PLAN THE INSTALLATION Ensure all installation requirements have been met:

1. Review the Installation Drawings (Section 6) and architect’s drawing.

2. Review the Technical Data (Section 7) for steam supply and steam

boiler feedwater quality recommendations.

INSTALL THE EQUIPMENT Install the sterilizer as follows:

1. Unpack the sterilizer.

2. Remove the sterilizer from the skid, then roll the sterilizer to the room

where it will be located.

3. Position and level the sterilizer.

4. Connect the plumbing.

5. Connect the wiring.

6. Install any remaining optional equipment.

7. Anchor the sterilizer.

8. Install the optional cabinet package.

9. Perform the functional check.

1–6 INS 61301607027 Rev A US

Page 13

GENERAL

SECTION 2 SAFETY

The 600 Series Steam Sterilizers are designed to sterilizer and dry (where

applicable) typical healthcare and laboratory goods. The sterilizers will

include pressure pulse gravity steam, pressure vacuum pulsing, and liquids

cycles. These sterilizers are NOT intended for use other than expressly

stated.

The sterilizers are designed with a number of built-in safety devices. To

avoid injury, it is very important that these safety devices are not bypassed

and/or disabled.

CAUTION

DAMAGE TO EQUIPMENT: Follow the instructions in this manual to ensure

the safe and efficient performance of the sterilizer. Failure to comply with

these instructions or to provide specific services could void the warranty.

AUTHORIZED SERVICE REPRESENTATIVE

• Read all instructions thoroughly before installation.

• Installation and service work must be performed by qualified personnel

trained on this sterilizer.

• The sterilizer must be operated by personnel who are knowledgeable

about the sterilizer operation and are trained on its use.

• Personnel must receive regular periodic training on the operation and

maintenance of this equipment in accordance with established

procedures for the workplace.

ELECTRICAL SAFETY

• Switch off the electric power before opening the electrical components.

The components contain the following voltage:

Control Box 24 Vac

Power Box 115 Vac

Boilers 208, 240, 480, or 600 Vac, Three-Phase

• Before welding begins on or close to the sterilizer, all wiring connected

by plugs and sockets must be disconnected from all circuit boards of

the control system.

INS 61301607027 Rev A US 2–1

Page 14

Safety

HOT SURFACES AND PIPES

WARNING

BURN HAZARD: Turn OFF and lock out/tag out the steam and hot water

supplies before servicing the sterilizer. Allow the steam to dissipate and let

the sterilizer cool down before touching any piping or surfaces.

• There are hot surfaces in the service area. Avoid touching any piping

that could contain steam.

• The sterilizer uses hot water and steam which have the potential of

causing burns or serious injuries. Wear personal protective equipment

suitable for hot water and steam.

LOCKOUT

• Always keep the door to the service area locked.

• No personnel should be in the service area while the sterilizer is

running.

• Never bypass the door limit switches of the sterilizer.

• When servicing the unit, the CONTROLS DISABLE/ENABLE switch

should be set to DISABLE. Remove the key and keep it with you.

OTHER CONSIDERATIONS

• Leakage in the system must be repaired without delay.

• The sterilizer must be kept clean to ensure optimum performance.

• Do not hose down the outside of the sterilizer with water.

2–2 INS 61301607027 Rev A US

Page 15

600 Series Steam Sterilizers

WS-0421

Top of Door Light Beam

Door Obstruction Switch

SAFETY FEATURES

WARNING

SHOCK HAZARD: To disconnect all power, turn OFF the sterilizer at the

mains circuit breaker. The On/Off Controls do not remove primary power

from the sterilizer.

NOTE

The maximum sound pressure level of the equipment that the operator is

exposed to does not exceed 85 dBA

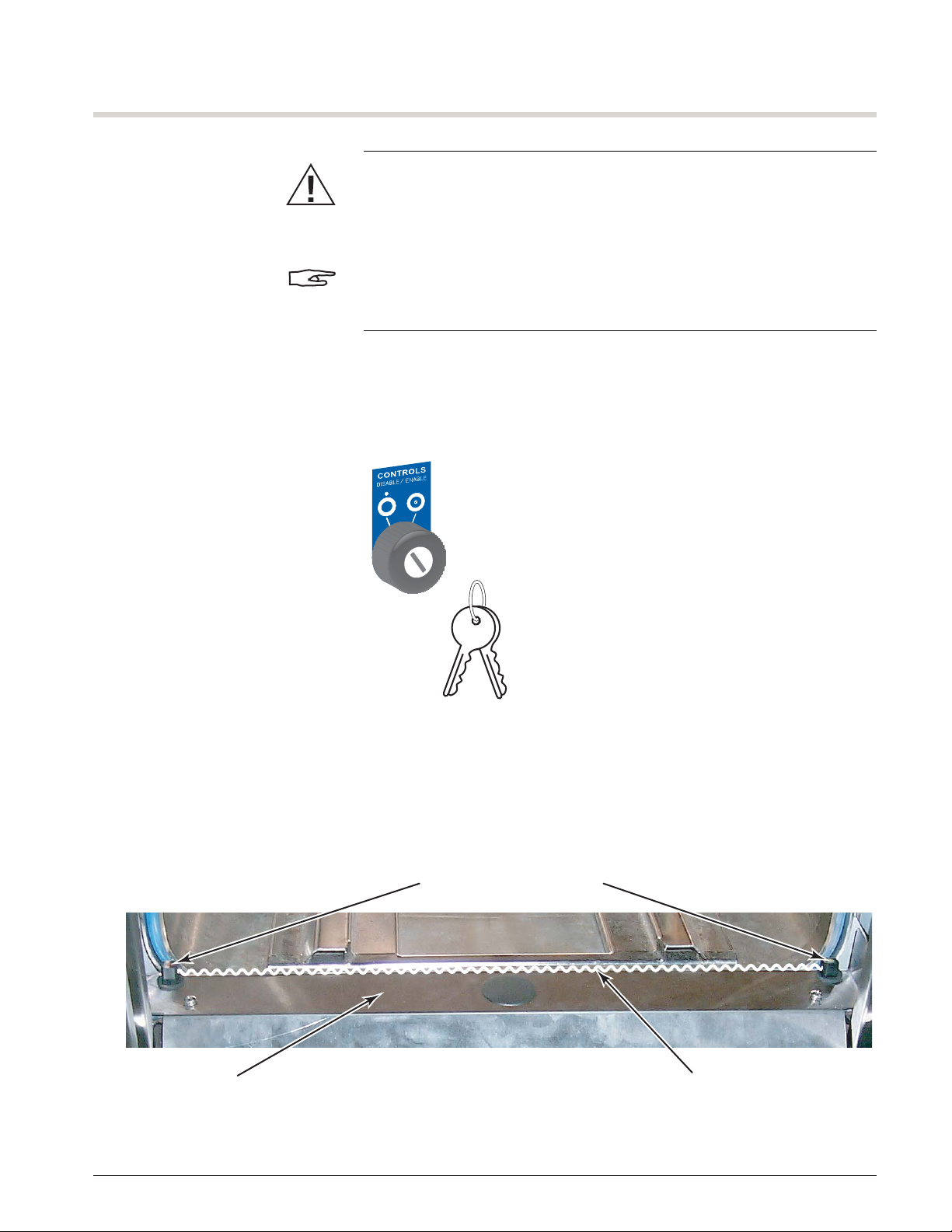

DOOR LOCKOUT The door can be locked in the open position for maintenance when inside

the chamber. Turn the key to DISABLE and remove it. To prevent someone

from closing the door during maintenance, keep the keys with you.

FIGURE 2–1. LOCKING THE DOOR IN THE OPEN POSITION

WS-0420

DOOR OBSTRUCTION SWITCH The sterilizer uses a light beam switch at the top of the door to sense when

an object is in the path of the movement of the door. When the light beam

is broken as the door is closing, the door stops and reverses for two

seconds.

FIGURE 2–2. DOOR OBSTRUCTION SWITCH

INS 61301607027 Rev A US 2–3

Page 16

Safety

A07027-K

Power Box Main Switch

Steam Boiler

(option)

Mains

Disconnect

Breaker

Heater Voltage

(208/240/480/600 Vac

Three-Phase)

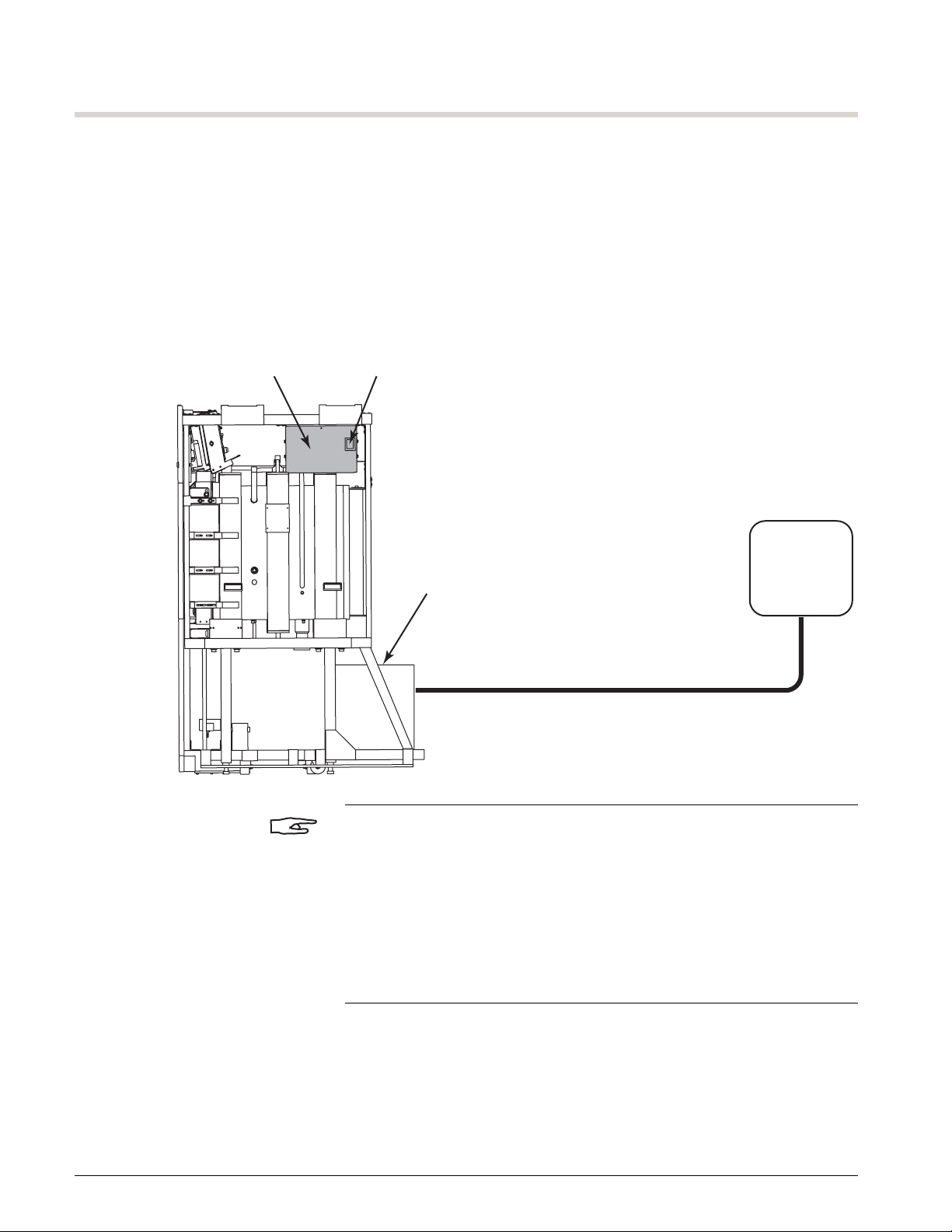

ISOLATING DEVICE

The sterilizer is fitted with a main switch on the power box (located on the

right side of the sterilizer). This switch removes primary power (120 Vac)

from the sterilizer.

Sterilizers with a steam boiler have a three-phase heating circuit that

requires a separate mains disconnect. The power switch on the boiler turns

the boiler control circuits ON and OFF.

FIGURE 2–3. CIRCUIT BREAKER LOCATION

NOTE

The CONTROLS ON/OFF switch turns the sterilizer controls ON and OFF

but does not remove primary power.

The CONTROLS DISABLE/ENABLE switch disables the door motor circuits

to prevent door movement during routine maintenance.

The control voltage for the optional steam boiler is provided by the sterilizer

power box.

2–4 INS 61301607027 Rev A US

Page 17

PRODUCT LIABILITY

600 Series Steam Sterilizers

Modifications made to the sterilizer without the express approval of the

manufacturer, or incorrect use of the unit will invalidate the manufacturer’s

product liability.

INS 61301607027 Rev A US 2–5

Page 18

Safety

2–6 INS 61301607027 Rev A US

Page 19

BEFORE YOU BEGIN

SECTION 3 PACKAGING

The Getinge 600 Series Sterilizers are shipped fully assembled. Only

qualified Getinge service representatives or personnel trained by Getinge

should install the sterilizer.

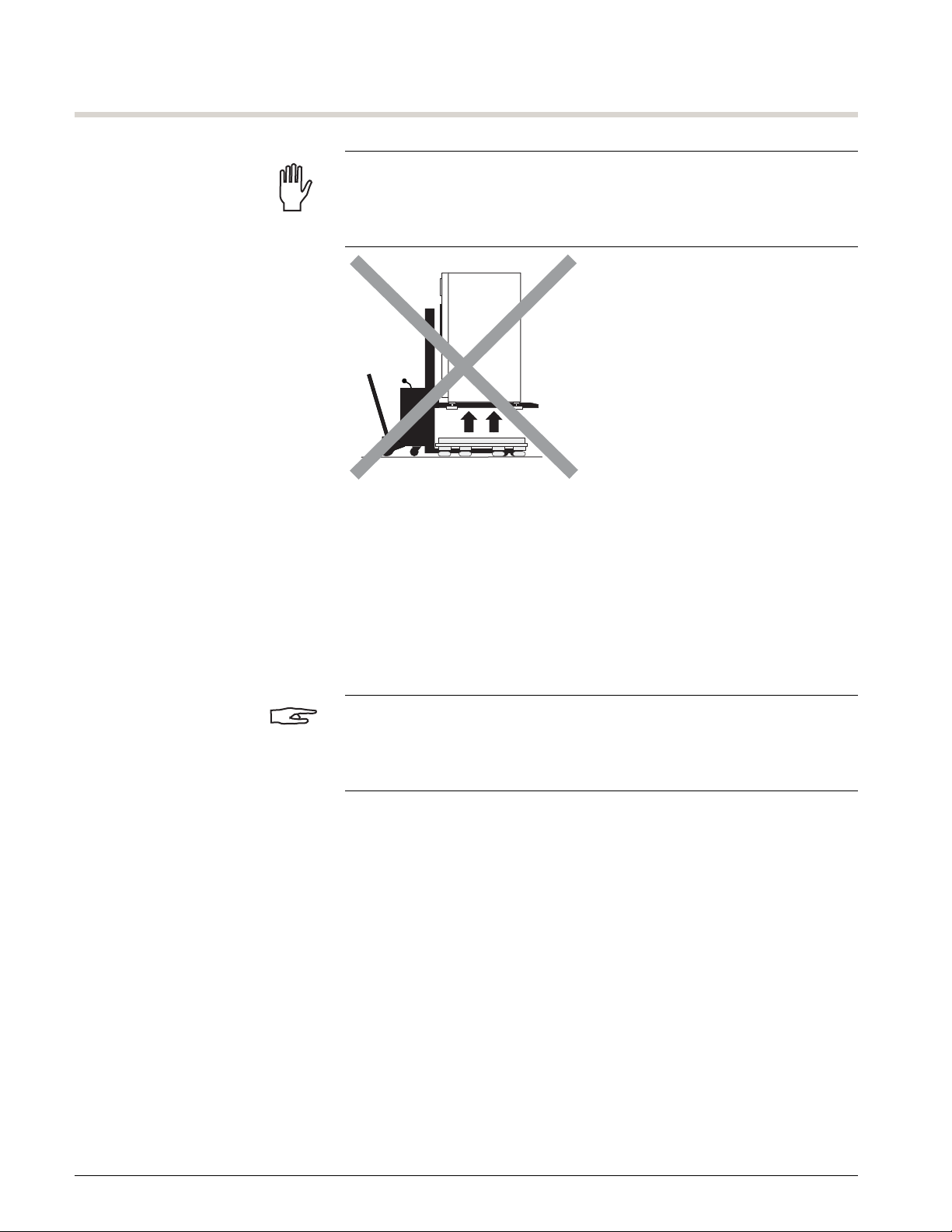

WARNING

POSSIBILITY OF INJURY: The sterilizer is top-heavy and could tip when

you remove it from the shipping base.

Use caution when moving the unit to ensure there is no accidental tipping

causing damage or bodily injury.

SHIPPING WEIGHT

Refer to the following chart for the weight of the crated sterilizers:

Chamber Length 26 in. 39 in. 51 in.

Single Door 1,160 lb

(526 kg)

Double Door N/A 1,508 lb

LIFTING EQUIPMENT

A pallet jack is required to remove the sterilizer from its shipping skid. Once

the skid is removed, the sterilizer can be rolled on its casters to the room

where it will be located.

CLEARANCES

The uncrated sterilizer is 39.5 inches (1003 mm) wide and 73.5 inches (1867

mm) tall. The maximum length of the sterilizer is 65.75 inches (1670 mm).

1,365 lb

(619 kg)

(684 kg)

1,506 lb

(683 kg)

1,649 lb

(748 kg)

INS 61301607027 Rev A US 3–1

Page 20

Packaging

A00294-D

UNCRATING

CAUTION

DAMAGE TO EQUIPMENT: Do not lift or position the sterilizer using the

cross members of the sterilizer frame. Doing so could misalign the door

assembly.

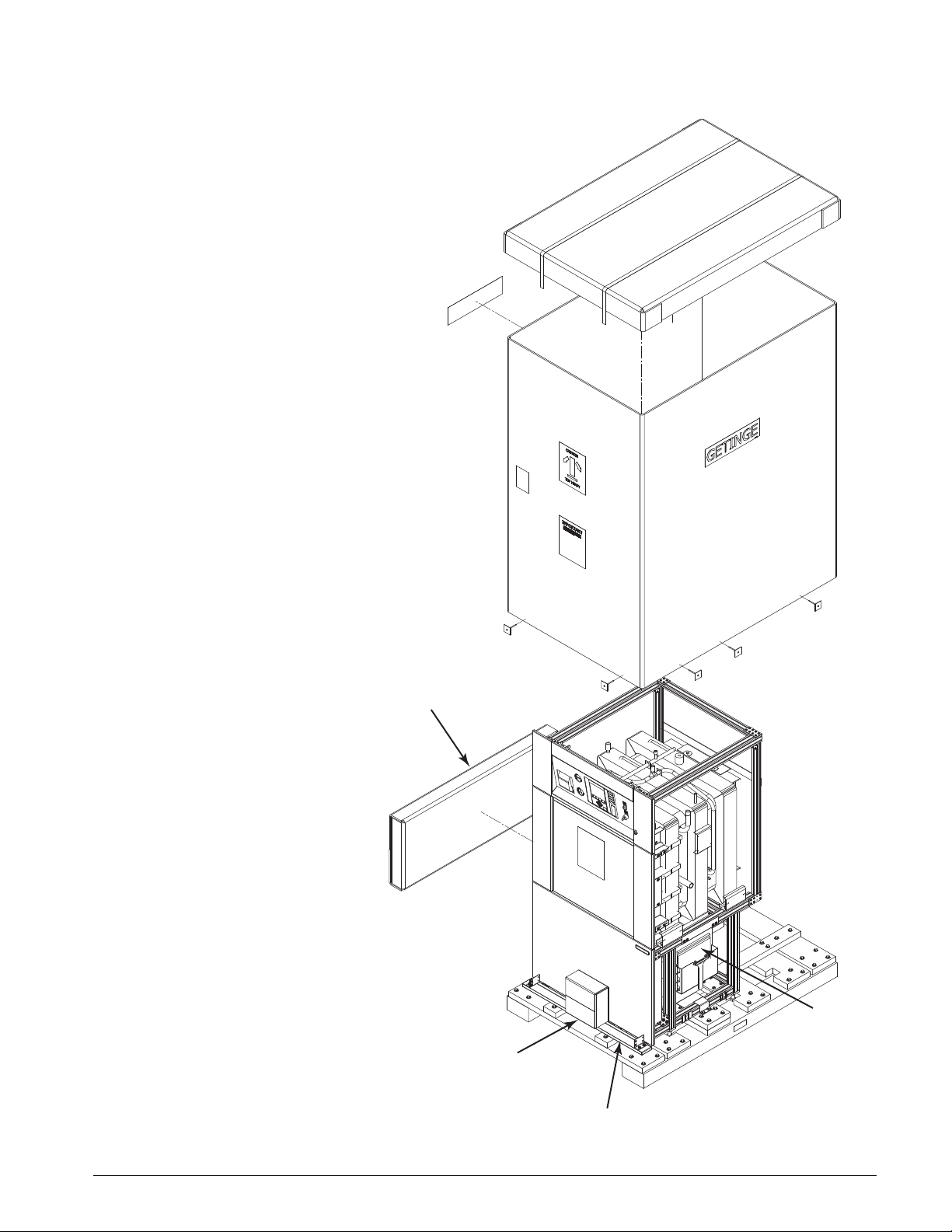

UNPACKING THE STERILIZER To unpack the sterilizer:

1. Move the sterilizer as close to the installation site as possible.

2. Refer to Figure 3–1 on page 3–3. Remove any packaging and shipping

material or tape.

3. Set aside the large carton containing the interior equipment.

NOTE

If a loading car and transfer carriage was purchased, the sterilizer carton will

contain a track for the loading car. The loading car and transfer carriage will

be shipped in a separate carton.

4. Set aside the small carton.

5. Set aside the kick panel.

3–2 INS 61301607027 Rev A US

Page 21

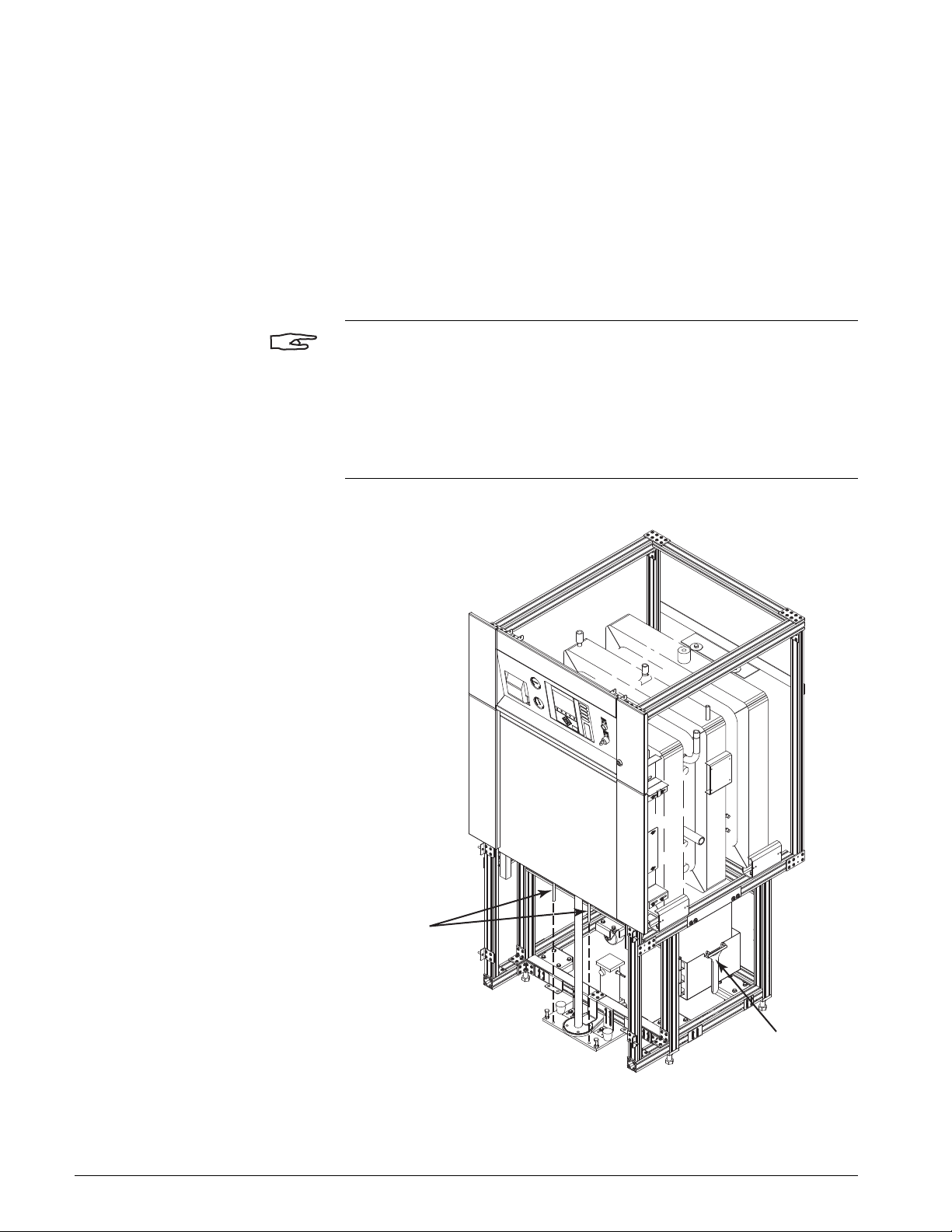

FIGURE 3–1. REMOVING THE PACKAGING

Carton containing

Interior Equipment

Kick Panel

Carton containing

Printer Paper and

Anchor Brackets

A07027-BM

Manuals

600 Series Steam Sterilizers

INS 61301607027 Rev A US 3–3

Page 22

Packaging

Unlock latch

with screwdriver.

Raise and latch

front panel (see detail).

Lift side panels

off frame pins.

Lift bottom panel

off frame pins.

1

2

3

4

A07027-A2

Operator Panel

(in raised position)

Notches

Prop Rod

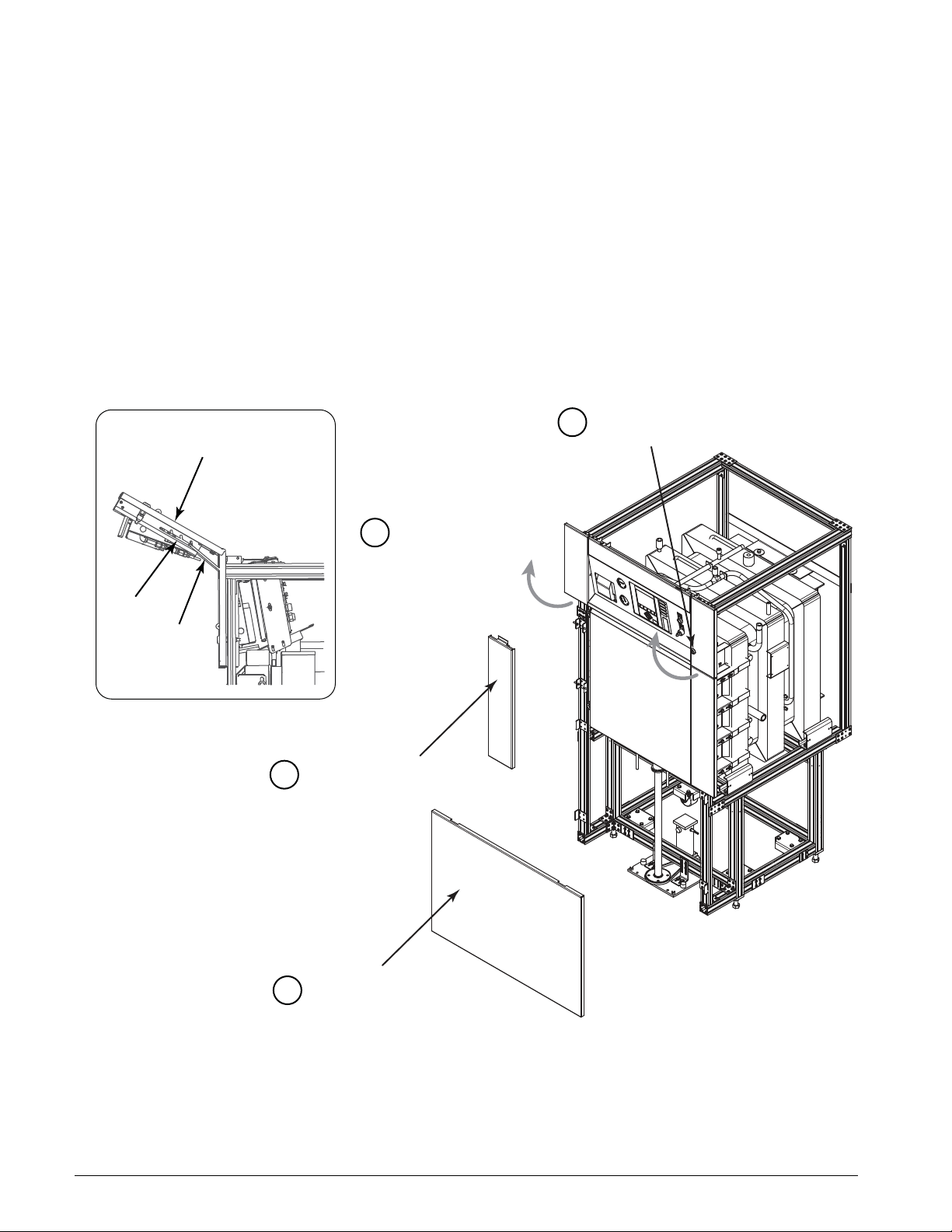

REMOVING THE STERILIZER FRONT PANELS

To remove the front panels:

1. Refer to Figure 3–2. Use a screwdriver to turn the keyhole latch and

unlock the panels.

2. Unlatch the top panel, swing it open, and prop it open with the prop

rods found on the left and right sides of the panel.

3. Lift the left and right side panels off of the frame pins. The pins slide

through the slots on either side of the panels and lift out of the slot in

the lower panel.

4. Lift the bottom panel up off of the frame pins.

FIGURE 3–2. STERILIZER FRONT PANELS

3–4 INS 61301607027 Rev A US

Page 23

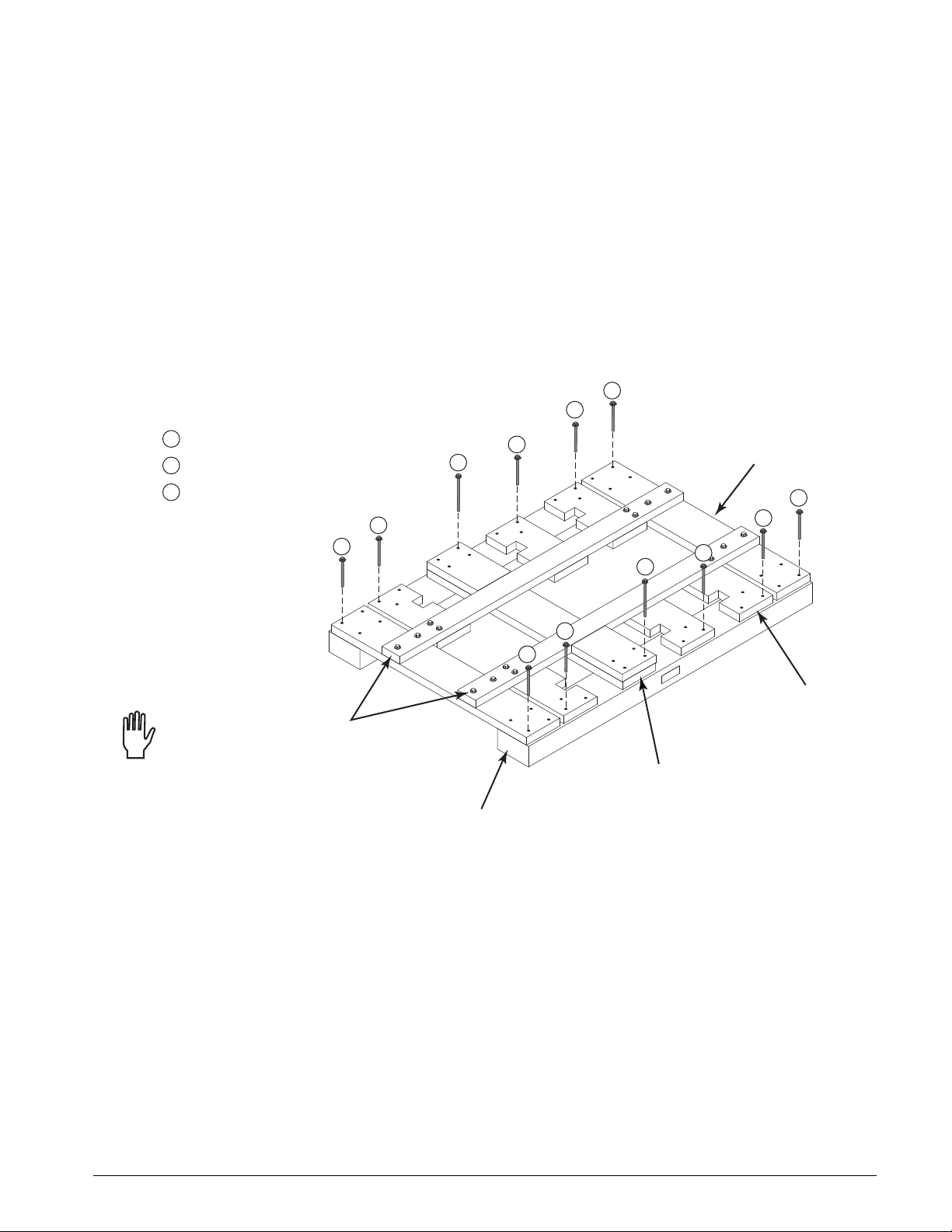

REMOVING THE SKID To remove the sterilizer from its skid:

Outer Beam

Outer

Cross Beam

Leveling Foot

Retaining Block

Center Cross Beam

and Retaining Blocks

A07027-BN

1

1

1

1

2

2

2

2

2

2

3

3

3/8 x 4 in. lag screws

1

1/2 x 4 in. lag screws

2

1/2 x 6 in. lag screws

3

Skid Hardware:

Do not remove hardware

on front to back pieces

1. Refer to Figure 3–3. Remove the hardware from the outer beams:

a. 3/8 x 4 in. lag screws (item 1) that attach the outer cross beams to

the outer beams (16 places).

b. 1/2 x 4 in. lag screws (item 2) that attach the leveling foot retaining

blocks to the outer beams. (18 places on 26 in./39 in. skid, 12

places on 51 in. skid).

c. 1/2 x 6 in. lag screws (item 3) that attach the center cross beam and

retaining blocks to the outer beams (8 places).

FIGURE 3–3. SKID HARDWARE

600 Series Steam Sterilizers

INS 61301607027 Rev A US 3–5

Page 24

Packaging

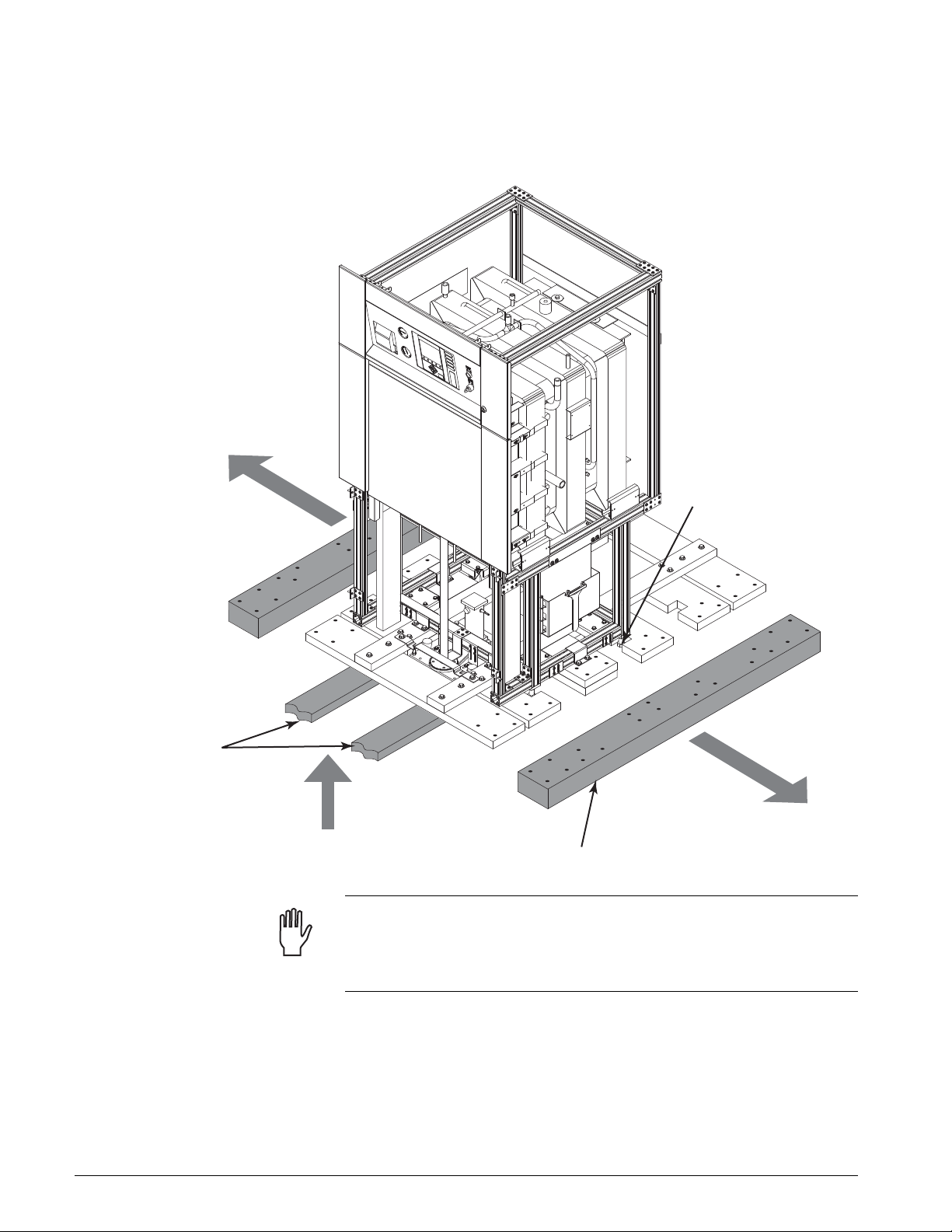

A07027-BH

Outer Beam

Pallet Jack

Forks

Turn down leveling feet

(4 places) while unit is

lifted by pallet jack

2. Using the pallet jack, raise the sterilizer skid until the outer beams can

be removed (see Figure 3–4).

FIGURE 3–4. REMOVING THE OUTER BEAMS

CAUTION

DAMAGE TO EQUIPMENT: Do not extend the leveling bolts more than 5

inches (127 mm). The bolts are 6 inches long (152 mm) and might be

damaged by the weight of the sterilizer if overextended.

3. Once the outer beams have been removed, turn down all four leveling

feet until they extend below the skid.

4. Lower the sterilizer skid until the leveling feet rest on the floor.

5. Remove the pallet jack.

3–6 INS 61301607027 Rev A US

Page 25

600 Series Steam Sterilizers

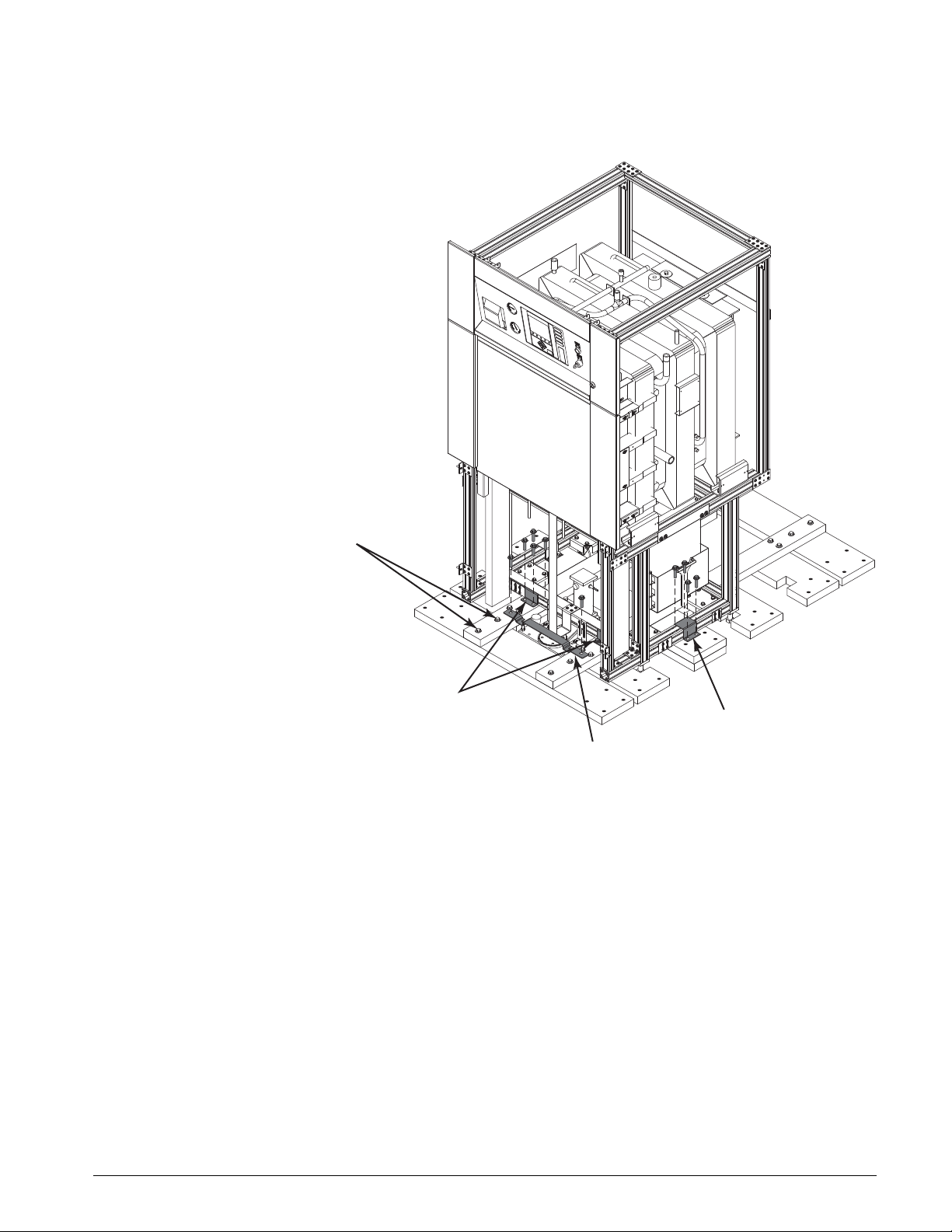

6. Remove the motor mounting plate retaining bracket(s) (see Figure 3–5).

FIGURE 3–5. REMOVING THE RETAINING BRACKETS

Remove all skid hardware

(16 places)

Front/Back

Retaining Brackets

(both ends)

7. Remove the front and back retaining brackets.

8. Remove the side retaining brackets.

9. Remove all the remaining skid hardware.

10. Disassemble and remove the rest of the shipping skid.

Side Retaining

Bracket (both sides)

Motor Plate

Retaining Bracket

A07027-BJ

INS 61301607027 Rev A US 3–7

Page 26

Packaging

A07027-BK

Leveling

Foot

Leveling

Foot

Casters

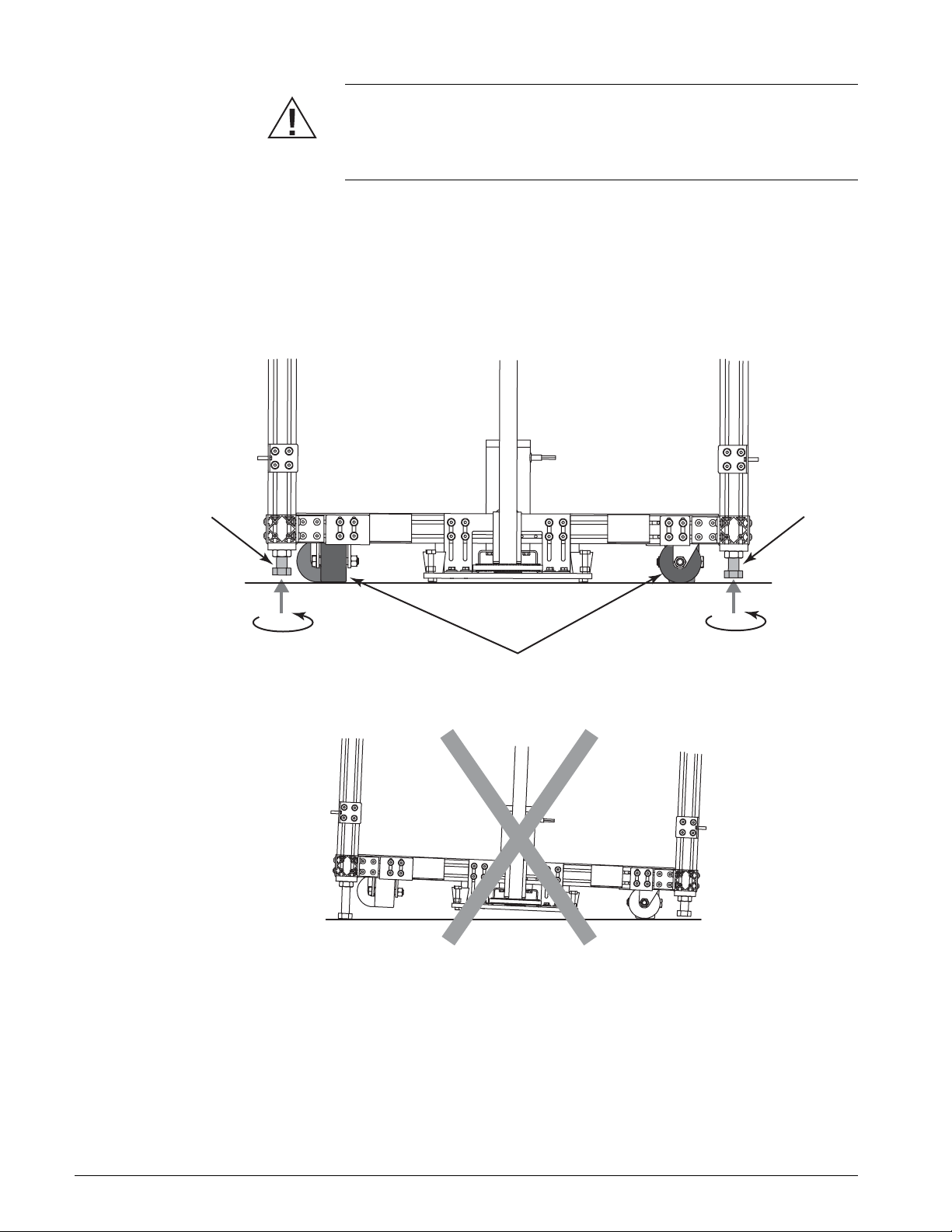

WARNING

POSSIBILITY OF INJURY: When lowering the sterilizer onto the casters,

turn the leveling feet incrementally to keep the unit as even as possible. If

the weight of the sterilizer is not evenly distributed, it may become unstable.

11. Lower the sterilizer onto the casters:

a. Turn each leveling foot one half-turn counterclockwise.

b. Continue to turn the leveling feet incrementally until the sterilizer

rests on the casters.

FIGURE 3–6. LOWERING THE STERILIZER ONTO ITS CASTERS

12. Roll the sterilizer to its final location.

3–8 INS 61301607027 Rev A US

Page 27

SECTION 4 INSTALLATION

INSTRUCTIONS

BEFORE YOU BEGIN

CAUTION

Follow the instructions in this manual to ensure safe and efficient

performance of the equipment. Failure to comply with these instructions or

to provide specific services could void the equipment warranty.

NOTE

Before installing the sterilizer, be sure the location is prepared for water,

electrical power, steam, and waste as outlined on the roughing-in drawing

(Figure 6–1, Sheet 5 on page 6–6).

Review the technical requirements for standard and optional equipment

outlined in this chapter and in Section 5, Optional Equipment.

UTILITY REQUIREMENTS The following utility connections (as specified on the roughing-in drawing)

are required for all sterilizers:

• Manual shutoff valves, pressure gauges, and steam trap (supplied by

customer) for the water and steam supplies at the sterilizer site.

NOTE

Unions must be used for the steam supply, cold water supply, and pressure

relief valve connections to the sterilizer.

• Steam Supply (S). The steam source may be either an integral steam

boiler or a facility steam supply.

• Cold Water Supply (CW). A backflow preventer (supplied by customer)

must be installed as required by local codes.

• 120 Vac Electrical Supply (E). Conveniently accessible fused

disconnect switches (supplied by customer) are required in all electrical

supply lines at the sterilizer site.

• Three-phase Electrical Supply (K). Required if an integral steam boiler

is used. Available boiler voltages are 208, 240, 480, and 600 Vac.

•Drain (D).

• Pressure Relief Valve (SV).

INS 61301607027 Rev A US 4–1

Page 28

Installation Instructions

A

TOOLS AND MATERIALS REQUIRED

The following tools are required to install the sterilizer:

• 2 ft. spirit level

• torpedo level

• try square (or tape measure)

• torque driver set

• spanner wrench (supplied by Getinge—see Figure 4–1)

• 2 in. x 2 in. shims (see note below)

NOTE

Place shims under leveling feet and door motor mounting plate leveling

bolts to prevent damage to soft flooring materials such as linoleum. Single

door units require 8 shims, double door units require 16 shims.

The door alignment pins may be used as a guide when leveling the door.

See “Leveling the Sterilizer Door” on page 4–13.

FIGURE 4–1. INSTALLATION TOOLS

lignment Pins

Spanner Wrench

A07027-BL

4–2 INS 61301607027 Rev A US

Page 29

POSITIONING AND LEVELING

600 Series Steam Sterilizers

CAUTION

Be careful to avoid possible surface damage to the floor when maneuvering

the sterilizer into position.

Permanent positioning is determined by the configuration of the model

being installed. Single door units may be freestanding or recessed into a

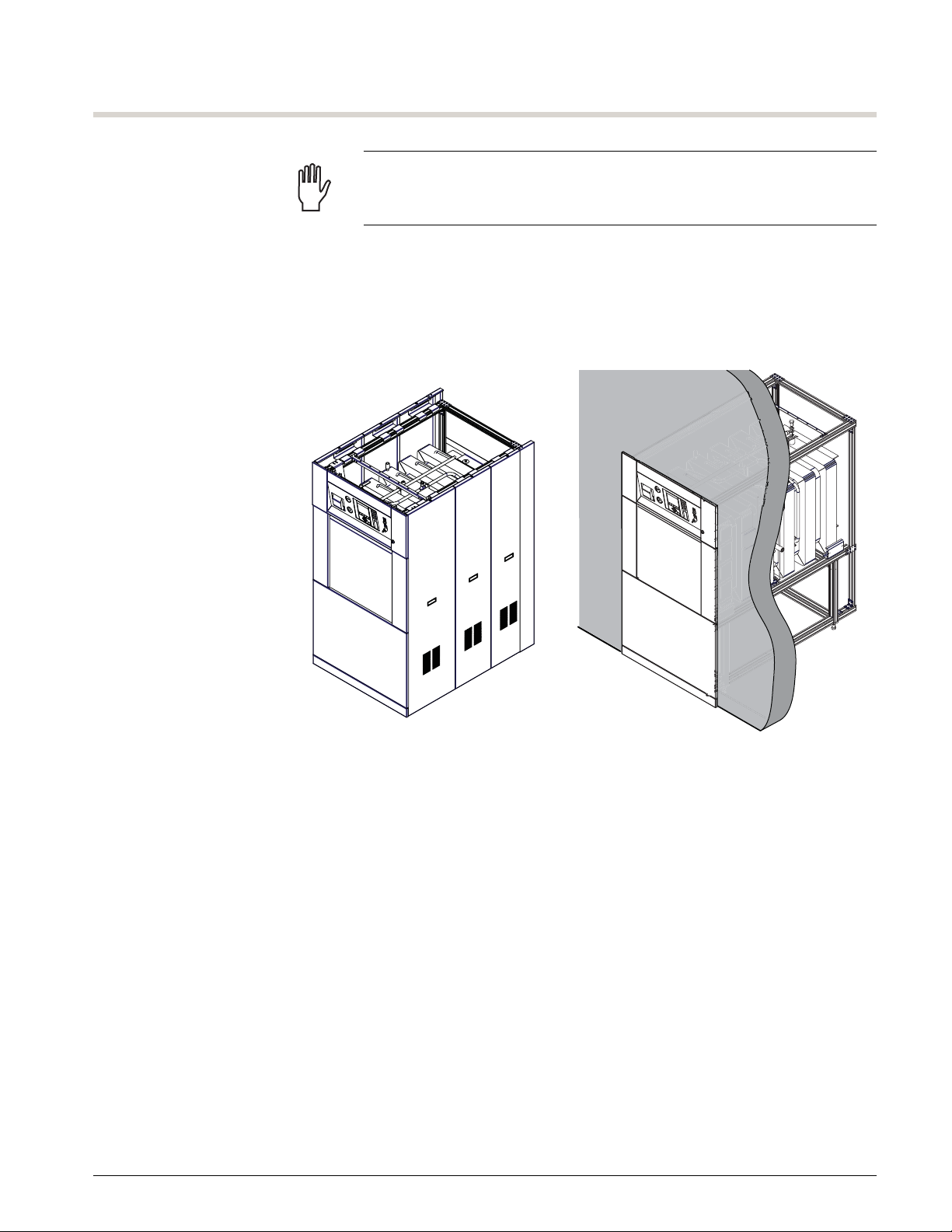

wall (see Figure 4–2).

FIGURE 4–2. SINGLE DOOR INSTALLATION

Freestanding (with Cabinet)

Recessed into Wall

SERVICE

AREA

A07028-B

INS 61301607027 Rev A US 4–3

Page 30

Installation Instructions

Steam Boiler

(option)

A07027-B

Recessed at One End (with Cabinet) Recessed at Both Ends

A07028-C

CONTROL

END

CONTROL

END

REMOTE

END

REMOTE

END

SERVICE

AREA

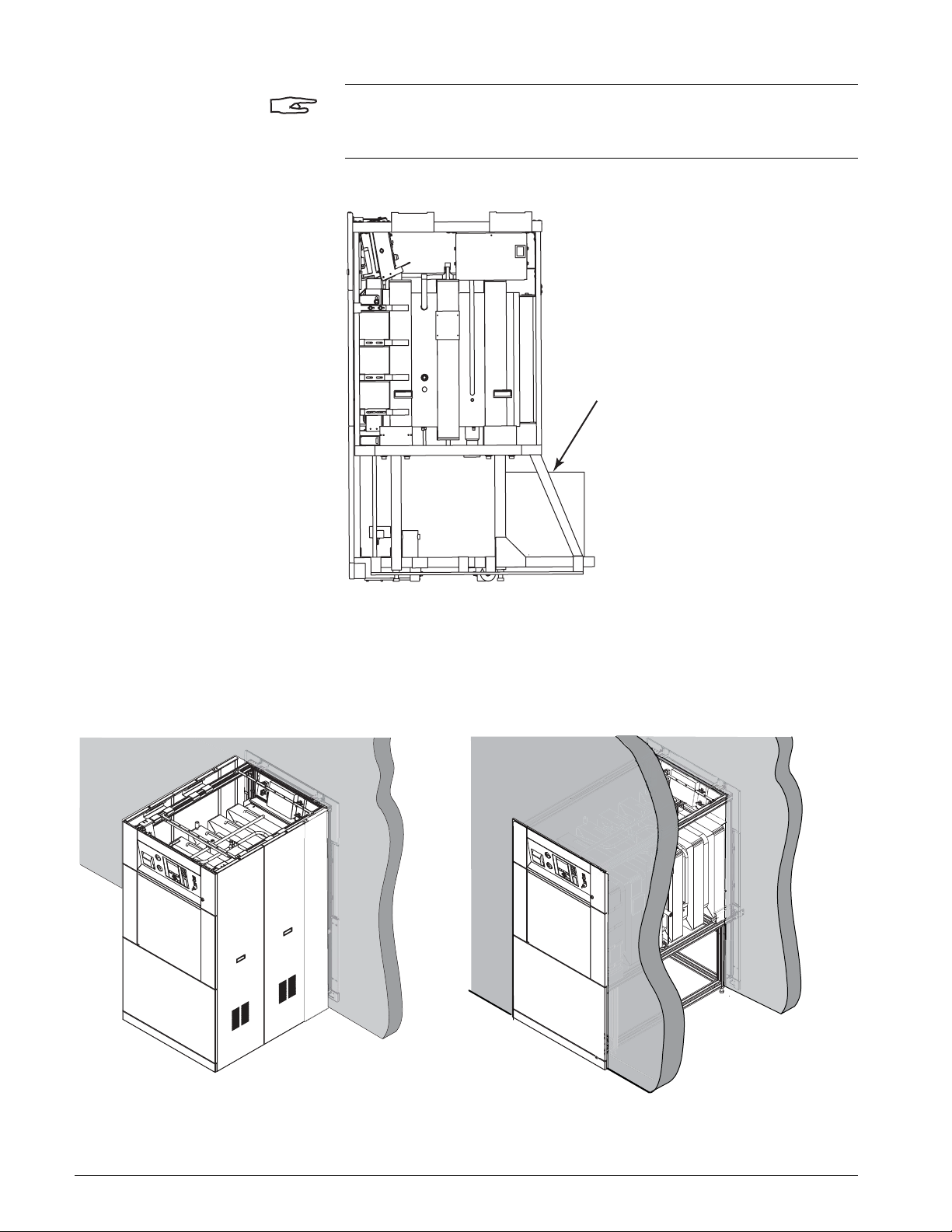

NOTE

26 IN. LENGTH WITH STEAM BOILER: The steam boiler extends beyond

the end of the sterilizer frame (see Figure 4–3).

FIGURE 4–3. 26 IN. LENGTH UNIT WITH STEAM BOILER

Double door units may be recessed into a wall at one end or both ends (see

Figure 4–4). Compliance with the roughing-in drawing specifications is

essential.

FIGURE 4–4. DOUBLE DOOR INSTALLATION

4–4 INS 61301607027 Rev A US

Page 31

POSITIONING THE STERILIZER To position the sterilizer:

A07027-BY

2.25 in. (57 mm)

from nished oor

Foot Block

1. Roll the sterilizer into its final location.

FIGURE 4–5. LEVELING FEET ADJUSTMENT

600 Series Steam Sterilizers

2. Refer to Figure 4–5. From the underside of the sterilizer frame, rotate

the leveling feet in the frame until the bottom of the foot block is

approximately 2.25 inches (57 mm) above the floor (all four corners).

NOTE

This clearance is required for the installation of the kick panel(s) and

optional cabinet panels.

3. IMPORTANT: If seismic anchorage is required by local codes:

a. Position the seismic anchoring brackets on the leveling feet (see

Figure 4–25 on page 4–28).

b. Using the brackets as a template, mark the holes.

c. Raise the leveling feet and roll the sterilizer out of the way.

d. Drill the holes and install the anchoring devices into the floor. See

the seismic anchorage drawing on page 6–10.

e. Roll the sterilizer back into position.

f. Lower the leveling feet.

INS 61301607027 Rev A US 4–5

Page 32

Installation Instructions

NOTE

If a loading car and transfer carriage will be used to load goods in the

sterilizer, the tracks inside the chamber must match the height of the top

plate of the transfer carriage (see Figure 4–6 on page 4–6).

The standard height of the top plate of transfer carriages is 31.50 in. (800

mm) above the floor. Because a transfer carriage may be used with several

sterilizers, adjust the sterilizer height to match the transfer carriage.

FIGURE 4–6. TRANSFER CARRIAGE HEIGHT

Loading

Car

Transfer

Carriage

31.50 in. (800 mm)

Finished Floor

A07026-BR

4–6 INS 61301607027 Rev A US

Page 33

600 Series Steam Sterilizers

A07027-BP

Mounting Plate

Leveling Bolts

(4 places)

Motor Mounting Plate

Support Bracket

Shims

FIGURE 4–7. MOTOR MOUNTING PLATE LEVELING BOLTS

4. Turn down the mounting plate leveling bolts until the plate is supported

by the floor.

5. Loosen the hardware that secures the motor mounting plate support

bracket to the extrusion.

CAUTION

When tightening the mounting plate support bracket hardware, do not

exceed 15 ft-lbs maximum torque. Do not use a powered screwdriver to

tighten the screws.

6. Using a torque driver, tighten the screws on the mounting plate support

bracket to 10 ft-lbs (minimum).

WARNING

POSSIBILITY OF INJURY AND DAMAGE TO THE EQUIPMENT: Be sure the

door motor mounting plate is supported by the floor before removing the

shipping bolts.

7. Remove the shipping bolts as shown in Figure 4–8.

INS 61301607027 Rev A US 4–7

Page 34

Installation Instructions

FIGURE 4–8. REMOVING THE SHIPPING BOLTS

Shipping Bolts

A07027-BT

8. Remove the two stabilizing casters from the front of the sterilizer (26 in.

length units only).

FIGURE 4–9. REMOVING THE STABILIZING CASTERS

Stabilizing

Caster

Caster Bracket

A07027-CL

4–8 INS 61301607027 Rev A US

Page 35

600 Series Steam Sterilizers

LEVELING THE STERILIZER CHAMBER

Once the sterilizer is positioned, check the alignment and leveling of the

chamber. The unit must be level to run properly and align with the loading

carts.

NOTE

If power is available, connect the power to the input terminals inside the

sterilizer Power Box and use the Open Door switch to open the door.

Otherwise, the door must be opened by manually turning the lift screw. Use

a spanner wrench to turn the pulley wheel at the base of the lift screw.

To level the sterilizer chamber:

1. If power is available:

a. Connect 115 Vac to 1TB in Power Box 1A (see “Connecting the

Electrical Power” on page 4–22

).

b. Turn ON the Power Box circuit breaker.

FIGURE 4–10. STERILIZER CONTROL PANEL

CONTROLS

OFF ON

CONTROLS

ON/OFF Switch

CONTROLS

DISABLE EN ABLE

CONTROLS

ENABLE/DISABLE

Switch

Close Door

Switch

Open Door

Switch

A07027-BU

c. Press the CONTROLS ON/OFF switch on the Control Panel.

d. Turn the CONTROLS DISABLE/ENABLE switch to the ENABLE

position.

e. Press the Open Door switch.

INS 61301607027 Rev A US 4–9

Page 36

Installation Instructions

A07026-D

Door Movement

Turn Pulley CCW

If power is not available:

a. Insert the spanner wrench into the holes in the pulley wheel.

NOTE

The spanner wrench is located in a holder on the right side of the sterilizer

frame.

b. Rotate the pulley wheel counterclockwise (CCW) until the door is

low enough to place a level inside the chamber.

FIGURE 4–11. MANUALLY OPENING THE STERILIZER DOOR

4–10 INS 61301607027 Rev A US

Page 37

600 Series Steam Sterilizers

2. Refer to Figure 4–12 on page 4–12. Place the level vertically against the

chamber wall and adjust the feet to level the chamber from side-toside. The minimum distance from the finished floor must be a minimum

of 2.25 inches (57 mm) as shown in Figure 4–5 on page 4–5.

3. Place the level vertically against the door gasket headring and adjust

the feet to level the chamber from front-to-back. The minimum

distance from the finished floor must be a minimum of 2.25 inches (57

mm) as shown in Figure 4–5 on page 4–5.

NOTE

If a loading car and transfer carriage will be used with the sterilizer, be sure

to maintain the proper height adjustment shown in Figure 4–6 on page 4–6.

4. Once the chamber is level, tighten the locknuts on the leveling feet.

5. Raise the sterilizer door by pressing the Close Door switch or turning

the lift screw pulley clockwise.

INS 61301607027 Rev A US 4–11

Page 38

Installation Instructions

FIGURE 4–12. LEVELING THE STERILIZER CHAMBER

Place level vertically

against chamber wall

Place level vertically

against gasket headring

Adjust to level chamber

front-to-back

Adjust to level chamber

side-to-side

A07027-L

4–12 INS 61301607027 Rev A US

Page 39

600 Series Steam Sterilizers

LEVELING THE STERILIZER DOOR

Once the sterilizer is leveled, check the alignment of the door mechanism

to ensure that the door is level and the position of the mounting plate has

not changed.

To level the sterilizer door:

1. Remove the rubber bumpers from the door motor mounting plate. This

will allow a 9 inch torpedo level to be placed on the mounting plate.

2. Adjust the mounting plate leveling bolts until the bottom of the plate is

0.25 in. (6.3 mm) above the finished floor.

FIGURE 4–13. MOUNTING PLATE LEVELING BOLTS

Torpedo Level

0.25 in (6.3 mm)

(bottom of plate to finished floor)

Adjust to level plate

from side to side

Remove bumper to

make space for level

A07027-BE

3. Position a level as shown in Figure 4–13 and check that the mounting

plate is level from side to side.

INS 61301607027 Rev A US 4–13

Page 40

Installation Instructions

A07027-AR

Mounting Plate

Adjustment Bracket

Adjust to level plate

from front to back

DO NOT adjust

mounting bolts

Torpedo Level

FIGURE 4–14. MOUNTING PLATE ADJUSTMENT BRACKETS

4. Position the level as shown in Figure 4–14 and check that the mounting

plate is level from front to back.

5. Adjust the mounting bracket as required to level the plate from front to

back.

4–14 INS 61301607027 Rev A US

Page 41

600 Series Steam Sterilizers

A

A

Dimension A =

5.625 in. (143 mm)

Measure both sides

with try square

Adjust mounting bolts

only if both sides

are not equidistant

A07027-CC

FIGURE 4–15. CHECKING FOR SQUARENESS

6. Refer to Figure 4–15. Using a try square (or tape measure), measure the

distance from the front edge of the mounting plate to the bend in the

mounting bracket. Confirm that this dimension is 5.625 in. (143 mm).

Measure both the left and right sides of the mounting plate.

7. If the measurements on the left and right side of the mounting plate are

equidistant, the mounting plate is square and no adjustment is

required. If not, loosen the bolts that secure the mounting bracket to

the plate and adjust the mounting plate as required.

8. If not already installed, insert the alignment pins into the threaded holes

in the bottom of the door plate.

9. Lower the door.

INS 61301607027 Rev A US 4–15

Page 42

Installation Instructions

Lift Screw

FIGURE 4–16. LIFT SCREW ALIGNMENT

Door cover removed for clarity.

Lift screw must be centered

in the openings in the door plate

Aligned Correctly

Alignment

Pins

Alignment

Holes

Not Aligned

TOP VIEW

(as viewed through opening in door cover)

Door Motor

Mounting Plate

A07027-BG

10. Refer to Figure 4–16. Check that the alignment pins are centered over

the holes in the mounting plate.

11. Remove the plug from the top of the door cover and check that the lift

screw is vertically centered in the openings in the door plate.

12. Readjust the mounting plate as required and check for levelness from

side to side and back to back.

13. Remove the alignment pins and store them on the sides of the holder

for the spanner wrench.

14. Reinstall the rubber door bumpers.

4–16 INS 61301607027 Rev A US

Page 43

INSTALLING THE KICK PANEL To install the kick panel:

T-Nut

Kick Panel

Extrusion

Groove

Corner

Bracket

Back View of Kick Panel

A07027-BV

1. Loosen the screws that secure the T-nuts to the kick panel corner

bracket.

FIGURE 4–17. INSTALLING THE KICK PANEL

600 Series Steam Sterilizers

2. Align the kick panel so that the T-nuts will slide into the lower groove of

the extrusion on each slide.

3. Slide the kick panel over the extrusions until the front of the panel is

flush with the panel above.

4. Tighten the screws that secure the T-nuts to the kick panel corner

bracket.

INS 61301607027 Rev A US 4–17

Page 44

Installation Instructions

RE-ATTACHING THE FRONT PANELS

To re-attach the front panels:

1. Place the bottom panel back onto the unit, aligning the holes in the

panel with the frame pins.

FIGURE 4–18. STERILIZER FRONT PANELS

Unlatch and lower front panel.

3

Lock latch with

4

screwdriver.

Install side panels

2

on frame pins.

Install bottom panel

1

on frame pins.

2. Place the pin at the bottom of one of the side panels into the slot in the

base panel and slide the side pin through the slot on the panel until the

panel is secure. Repeat the process for the other side.

3. Lower the prop rods on the top panel and close the panel.

4. Use a screwdriver to turn the latch to the locked position.

14

A07027-M

4–18 INS 61301607027 Rev A US

Page 45

UTILITY REQUIREMENTS

Hot Water

Shutoff

Steam

Shutoff

Cold Water

Shutoff

Cold Water Supply

Steam Supply

(units without steam boiler)

Hot Water Supply

(units with steam boiler)

Steam Boiler

(option)

Booster Pump

(option)

115 or 230 Vac

Single-Phase

115 Vac

Integral

Transformer

(option)

UPS

(option)

UPS

(option)

Universal

Transformer

(option)

Mains

Disconnect

Circuit

Breaker

230 Vac

Voltages

> 380 Vac

Single-Phase

Power Source

Mains

Disconnect

Circuit

Breaker

Three-Phase

Power Source

Heater Voltage

A07027-BW

Power Box

600 Series Steam Sterilizers

The sterilizer requires steam, cold water and electrical supplies as specified

on the roughing-in drawing. Sterilizers with an integral boiler require a hot

water supply (instead of steam) and three-phase electrical supply as well.

FIGURE 4–19. UTILITY CONNECTIONS

INS 61301607027 Rev A US 4–19

Page 46

Installation Instructions

CONNECTING THE PLUMBING

All service connections must conform with local codes. Refer to the

roughing-in drawing (see Figure 6–1, Sheet 5 on page 6–6) for supply line

pipe sizes and specification requirements for the installation site.

STERILIZER CONNECTIONS Connect the steam and cold water supplies to the sterilizer. The supply line

connections on the sterilizer are tagged for identification.

Getinge recommends installing pressure gauges in the steam and water

supply lines to monitor the incoming pressure. Since some sterilizer

malfunctions may be caused by inadequate steam or water pressure,

pressure gauges in the supply lines are useful in servicing the sterilizer.

Route the sterilizer drain line to the customer-supplied drain point. Getinge

recommends installing a flexible coupling at the drain line connection point.

Connect the outlet of the pressure relief valve to an appropriate discharge

location per local codes.

NOTE

Use unions on the steam, cold water, drain, and pressure relief valve

connections.

The steam supply to the sterilizer is to meet the steam quality specification

on the roughing-in drawing. Install a thermodynamic steam trap or MP-106

Steam Conditioning Package in order to meet the steam requirement for

the sterilizer. See “Steam Supply Quality” on page 7–3 for more information.

BOOSTER PUMP (OPTION) If the sterilizer uses a booster pump, refer to “Booster Pump Package” on

page 5–9 for installation details. The booster pump must be installed before

a cold water supply is connected to the sterilizer.

4–20 INS 61301607027 Rev A US

Page 47

600 Series Steam Sterilizers

WS-0414

CAS-45A STEAM BOILER

(vertical boiler tank)

GTS-30A STEAM BOILER

(horizontal boiler tank)

STEAM BOILER (OPTION) Two models of steam boilers are used with the 600 Series sterilizer:

• GTS-30A on 26 in. length units.

• CAS-45A on 39 in. and 51 in. length units.

If the sterilizer has an integral steam boiler, refer to “Steam Boiler” on

page 5–2 for installation details.

NOTE

The hot water supply is to meet the water quality specification on the

roughing-in drawing. A water treatment system may need to be installed in

order to meet the feedwater requirement for the boiler. See “Steam Boiler

Feedwater Quality” on page 7–5 for more information.

FIGURE 4–20. STEAM BOILER MODELS

INS 61301607027 Rev A US 4–21

Page 48

Installation Instructions

Disconnect switch for

Getinge USA equipment

61301608457 Rev. B

CONNECTING THE ELECTRICAL POWER

It is the customer’s responsibility to complete all electrical connections in

accordance with the National Electrical Code and all applicable local

codes.

CAUTION

Be sure the power box circuit breaker is in the OFF position to ensure that

the power supply will not energize any sterilizer components prior to

performing required adjustments and testing.

ELECTRICAL SUPPLY REQUIREMENTS

A permanently-connected, dedicated electrical supply with a conveniently

accessible disconnect switch (supplied by the customer) is required for

each sterilizer. Where both single-phase and three-phase supplies are

required, two (2) disconnect switches can be used. Disconnect switches

must be located as close to each other and to the sterilizer as possible and

within easy reach of the operator.

NOTE

Refer to roughing-in drawing (Figure 6–1, Sheet 5 on page 6–6) for

recommended breaker/fusing.

All disconnect switches need to be properly labeled as the disconnecting

devices for the specified sterilizer. Affix the Getinge USA label (part number

61301608457) supplied with the sterilizer to each disconnect switch

enclosure and indicate the sterilizer ID on the label.

FIGURE 4–21. GETINGE USA LABEL

4–22 INS 61301607027 Rev A US

NOTE

When the only electrical supply source available to operate the control

system is other than 115 Vac ±10%, 50/60Hz, single-phase, a transformer

is required to provide 115 Vac for connection to the sterilizer control circuit.

See “Connecting the Customer Supply” on page 4–23

Page 49

600 Series Steam Sterilizers

CONNECTING THE CUSTOMER SUPPLY

The primary power connection procedure is dependent on the supply

voltage:

• 115 Vac—power is connected to the Power Box.

See “115 Vac Installation” below.

• 230 Vac—power is connected to the factory-installed Integral

Transformer which steps down the voltage to the 115 Vac required by

the sterilizer. See “230 Vac Installation” on page 4–24.

• 380 Vac and above—power is connected to the Universal Transformer

which steps down the voltage to 115 Vac. The Universal Transformer is

installed and wired by the customer. See “Universal Transformer” on

page 5–16.

NOTE

If the sterilizer has an uninterruptible power supply (UPS), install the UPS

before connecting power to the sterilizer. see “Uninterruptible Power

Supply (UPS)” on page 5–18 for electrical connections.

115 VAC INSTALLATION

Connect the 115 Vac 50/60 Hz single-phase supply circuit to terminals L

(hot), N (neutral), and protective ground on terminal block 1TB inside the

Power Box (see Figure 4–22).

FIGURE 4–22. CONNECTING THE POWER SOURCE (115 VAC)

J5 J4 J3 J2 J1

Power Box 1A

(with Cover Open)

Terminal Block

1TB

Customer Supply

(115 Vac ±10% Single-Phase)

A08205-K

INS 61301607027 Rev A US 4–23

Page 50

Installation Instructions

230 Vac ±10%

Single-Phase Supply

A08205-H

1A

POWER BOX

9A

INTEGRAL

TRANSFORMER

BOX

(W)

(BK)

2

3

1

1TB

(G/Y)

1

2TB

2

3

(BK)

(G/Y)

(W)

(BK)

(W)

(G/Y)

NL

1TB

L1N

3

2

115 Vac

Customer Supply

(230 Vac)

Output to

Power Box 1A

(115 Vac)

LN

1TB

123

5A

2

2TB

1F

1

123

Terminal Block

1TB

Integral

Transformer

Box 9A

230 VAC INSTALLATION

Integral Transformer 9A is a factory-installed option used to step down the

230 Vac customer supply to the 115 Vac required by the sterilizer.

Connect the 230 Vac 50/60 Hz single-phase supply circuit to terminals L

(hot), N (neutral), and protective ground on terminal block 1TB inside the

Integral Transformer Box (see Figure 4–23).

FIGURE 4–23. CONNECTING THE POWER SOURCE (230 VAC)

4–24 INS 61301607027 Rev A US

Page 51

600 Series Steam Sterilizers

STEAM BOILER (OPTION) The steam boiler requires two operating voltages: 115 Vac for the controls

(provided by the sterilizer) and the three-phase voltage for the heater

elements. For instructions on connecting the three-phase supply, see

“Connecting the Electrical Power” on page 5–4.

BOOSTER PUMP (OPTION) The booster pump requires a separate 115 Vac or 230 Vac single-phase

electrical supply to operate the pump motor. The control voltages for these

options are provided by the sterilizer.

For information regarding booster pump installation, see “Connecting the

Electrical Power” on page 5–14.

INS 61301607027 Rev A US 4–25

Page 52

Installation Instructions

ANCHORING THE STERILIZER

The sterilizer is anchored to the floor with two hold-down brackets as

shown in Figure 4–24 on page 4–26.

NOTE

If seismic anchoring is required by local codes, the sterilizer is anchored as

described in “Installing the Seismic Anchoring Brackets” on page 4–28.

INSTALLING THE HOLD-DOWN BRACKETS

To install the hold-down brackets:

1. Remove the brackets and hardware from the small carton that was set

aside during unpacking.

2. Remove the mounting screws from the front of the left front caster.

3. Using the mounting screws provided with the bracket, install the holddown bracket.

4. Drill the mounting holes and insert the necessary anchoring devices to

accept 3/8” diameter lag bolts.

5. Repeat steps 2 thru 4 for the right rear caster. If the rear of the sterilizer

is not accessible, install the hold-down bracket in the alternate location

shown in Figure 4–24 on page 4–26.

4–26 INS 61301607027 Rev A US

Page 53

FIGURE 4–24. HOLD-DOWN BRACKETS

A07027-CE

Hold-Down Bracket

(front left corner)

Hold-Down Bracket

(rear right corner)

Alternate Location

(if rear right corner

is not accessible)

Remove caster

bracket hardware

Anchoring Detail

3/8" dia. Lag Bolt

600 Series Steam Sterilizers

INS 61301607027 Rev A US 4–27

Page 54

Installation Instructions

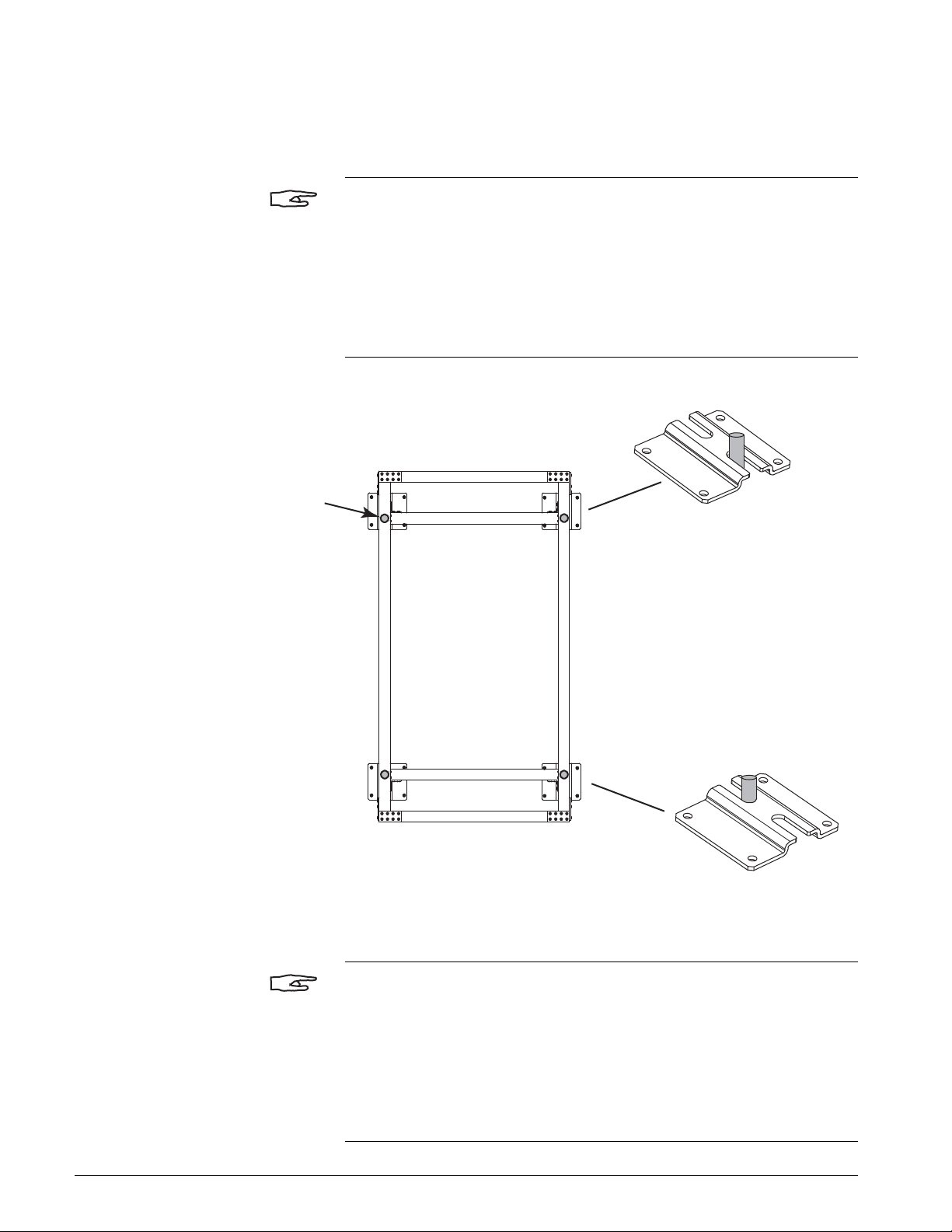

INSTALLING THE SEISMIC ANCHORING BRACKETS

Leveling Bolt

(4 places)

If seismic anchorage is required per local codes, all four leveling feet must

be anchored (see Figure 4–25). Four bolts per corner are required to meet

seismic anchoring codes.

NOTE

The anchoring specifications recommended in this manual (see seismic

anchorage drawing on page 6–10) are in compliance with seismic

anchoring codes set forth by the state of California.

It is recommended that permanent anchoring of the sterilizer to the floor be

done after the unit has been checked out by a qualified Getinge USA

service representative.

FIGURE 4–25. SEISMIC ANCHORING BRACKETS

Front Bracket

Sterilizer Frame

(Top View)

Rear Bracket

A07027-T2

NOTE

The holes cannot be drilled with the sterilizer in place because of

interference with the sterilizer frame. If the holes are not already drilled, it

will be necessary to mark the holes, move the sterilizer out of the way, drill

the holes, then move the sterilizer back to its location.

The casters must be removed to allow the seismic anchorage brackets to

anchored in four places.

4–28 INS 61301607027 Rev A US

Page 55

600 Series Steam Sterilizers

K

To install the seismic anchoring brackets:

1. Remove the casters:

a. Remove the four bolts that secure the caster to the caster bracket.

b. Remove the mounting screws that secure the caster brackets to

the sterilizer frame.

FIGURE 4–26. REMOVING THE CASTERS

Caster Bracket

Hardware

Caster

Bracket

Caster

A07027-C

2. Position the seismic anchoring bracket on the leveling feet as shown in

Figure 4–27.

FIGURE 4–27. SEISMIC ANCHORING BRACKET INSTALLATION

3/8 in Lag Bolt (16 places)

(see seismic anchorage drawing)

Leveling Bolt

Lock Nut

A07027-S

INS 61301607027 Rev A US 4–29

Page 56

Installation Instructions

3. Insert the lag bolts through the bracket and into the anchoring devices

in the floor.

4. Tighten the lock nut against the anchoring bracket.

4–30 INS 61301607027 Rev A US

Page 57

INSTALLING THE INTERIOR EQUIPMENT

600 Series Steam Sterilizers

INSTALLING THE RACK AND SHELVES

The interior equipment package includes a left-hand shelf support, righthand shelf support, and two shelves. One or two additional shelves are

available as an option.

To install the rack and shelves:

1. Align the holes in the uprights of the shelf support with the mounting

studs on the side wall of the chamber.

2. Secure the shelf support to the mounting studs with the hardware

provided.

3. Repeat the procedure for the other shelf support.

NOTE

On 26-inch units, check that the shelf edge facing out has shelf guides.

FIGURE 4–28. INSTALLING A SHELF

Outward Facing Shelf Edge

Shelf Guide

1

3

2

WS-0218-633HC

Stop Tab Shelf GuideShelf Guide

4. Set the shelf on top of the shelf support brackets.

5. Slide the shelf back until the back edge drops down at the end of the

support bracket.

6. Pull the shelf forward until the shelf guide contacts the stop tab on the

shelf support to be sure it is properly installed. Then slide the shelf to

the back of the chamber.

INS 61301607027 Rev A US 4–31

Page 58

Installation Instructions

INSTALLING THE LOADING CAR TRACK

To install the loading car track:

1. Align the holes in the bottom of the track with the mounting studs on

the floor of the chamber.

2. When the track is correctly aligned, with the mounting studs, it will drop

into place.

FIGURE 4–29. ALIGNING THE TRACK WITH THE MOUNTING STUDS

A07027-CF

4–32 INS 61301607027 Rev A US

Page 59

INTRODUCTION

SECTION 5 OPTIONAL EQUIPMENT

This section includes installation instructions for the following options:

• Steam Boiler (GTS-30A or CAS-45A)—see page 5–2.

• Booster Pump Package—see page 5–9.

• Universal Transformer—see page 5–16.

• Uninterruptible Power Supply (UPS)—see page 5–18.

• Water-Saver System (MP-129F)—see page 5–22.

• Water Treatment System—see page 5–25.

• Cabinet Package—see page 5–26.

INS 61301607027 Rev A US 5–1

Page 60

Optional Equipment

STEAM BOILER

SPECIFICATIONS The following utility connections are required for sterilizers with an integral

steam boiler:

• Manual shutoff valve, strainer, and pressure gauge in the hot water

supply line.

• Separate three-phase electrical service for the heating circuit.

For detailed specifications on electrical requirements, hot water (pressure,

flow, and quality), and connection sizes, refer to the roughing-in drawing

(Figure 6–1, Sheet 5 on page 6–6).

BOILER MODELS The steam boiler used varies based on the chamber length of the sterilizer.

Refer to the following table for the proper boiler unit.

TABLE 5–1. AVAILABLE STEAM BOILERS

CHAMBER LENGTH STEAM BOILER

26 in. GTS-30A

39 in. CAS-45A

51 in.

CONNECTING THE PLUMBING The steam boiler is shipped mounted to the sterilizer with the steam output

and drain line connected to the sterilizer. The hot water supply and pressure

relief valve vent are supplied by the customer.

NOTE

Use unions on the hot water supply and pressure relief valve connections.

Recommendation: Pipe the pressure relief valve to a vented manifold

outside the equipment service area per ASME code.

To connect the plumbing to the boiler (see Figure 5–1):

1. Connect the hot water (HW) supply to the water strainer on the boiler.

2. Connect the outlet of the pressure relief valve (SV3) to a vent system.

3. If the boiler is a CAS-45A, connect the blow-down discharge line to a

separator tank (provided by customer).

NOTE

The ES-18/24/30/36/48 Blow-Down Separation Tank (Getinge PN 530957)

is suitable for this application.

5–2 INS 61301607027 Rev A US

Page 61

HW

SV3

Hot Water

Pressure Relief Valve Vent

A07027-P1

See Roughing-In Drawing HS4125

for Utilities Requirements

Pressure Relief

Valve

Water

Strainer

SV3

HW

HW

SV3

Pressure Relief

Valve

Water

Strainer

Blow-Down Separator

(provided by customer)

Drain

Steam

GTS-30A STEAM BOILER

(26" length units)

CAS-45A STEAM BOILER

(39" and 51" length units)

Discharge Piping

½" ID minimum

(supplied by customer)

Manual Drain

Valve

600 Series Steam Sterilizers

FIGURE 5–1. STEAM BOILER PLUMBING CONNECTIONS

INS 61301607027 Rev A US 5–3

Page 62

Optional Equipment

Service Entrance for

Three-Phase Power Supply

K

Electric – 4 wire with Ground

Be sure wires are clean and bright to

ensure good electrical contact.

A07027-CJ

VOLTAGE

208V

240V

480V

600V

CURRENT

83.3 A

72.2 A

36.1 A

28.8 A

POWER

30 KW

30 KW

30 KW

30 KW

WIRE SIZE

(90°C Copper)

3 AWG

4 AWG

8 AWG

10 AWG

CONDUIT

SIZE

1¼"

1"

¾"

¾"

Three-Phase Customer

Supply Connection

(torque to 110 in-lbs)

K

Ground

Connection

ELECTRICAL CABINET

(Cover Removed)

See table below for current

ratings and wire sizes.

CONNECTING THE ELECTRICAL POWER

The steam boiler requires a separate three-phase electrical service for the

heating circuit. The sterilizer provides the 115 Vac required for the boiler

control circuits. Refer to the roughing-in drawing (Figure 6–1 on page 6–2)

for electrical specifications.

To connect the three-phase electrical supply to the steam boiler:

1. Remove the access cover from the steam boiler cabinet.

2. Refer to Figure 5–2 (GTS-30A) or Figure 5–3 on page 5–5 (CAS-45A).

Connect L1, L2, and L3 to the three-phase terminal. Torque the

terminals to 110 in-lbs.

3. Connect the ground wire to the ground terminal. The ground terminal is

located adjacent to the three-phase terminal.

FIGURE 5–2. GTS-30A STEAM BOILER ELECTRICAL CONNECTIONS

5–4 INS 61301607027 Rev A US

Page 63

600 Series Steam Sterilizers

A07027-R

VOLTAGE

208V

240V

480V

600V

125.1 A

108.4 A

54.2 A

43.4 A

POWER

45 KW

45 KW

45 KW

45 KW

WIRE SIZE

(90°C Copper)

2 AWG

3 AWG

8 AWG

8 AWG

CONDUIT

SIZE

1¼"

1¼"

¾"

¾"

CURRENT

K

K

Electric – 4-wire with ground

See table below for current ratings

and wire sizes.

Three-Phase Customer

Supply Connection

(torque to 110 in-lbs.)

Ground

Connection

Wiring to Fuse Box

(208 Vac model only)

Service Entrance for

Three-Phase Power Supply

Be sure wires are clean and bright to

ensure good electrical contact.

NOTE

The 208 Vac version of the CAS-45A has a fuse box mounted on the right

side of the electrical cabinet.The customer three-phase connection is

routed through six 100A fuses before it is connected to the heating element

contactors. For all other voltages, the customer three-phase connection is

routed to the heating element contactors.

FIGURE 5–3. CAS-45A STEAM BOILER ELECTRICAL CONNECTIONS

INS 61301607027 Rev A US 5–5

Page 64

Optional Equipment

CHECKING THE HEATER CIRCUIT CONNECTIONS

CAUTION

IMPORTANT: The element flange bolts, element terminals, contactor

terminals and customer three-phase supply terminals must be tightened to

the specifications shown in Figure 5–4 on page 5–7 (GTS-30A) or

Figure 5–5 on page 5–8 (CAS-45A).

To check the heater circuit connections for tightness:

1. Check the torque of the three-phase supply terminals. Tighten

connections to 110 in-lbs.

2. Check the torque of the contactor terminals. Tighten connections to 45

in-lbs.

3. Check the torque of the heating element terminals. Tighten terminals to

20 in-lbs.

4. Check the torque of the heating element flange bolts. Tighten the bolts

to 22 ft-lbs in the sequence shown in Figure 5–4 and Figure 5–5.

5–6 INS 61301607027 Rev A US

Page 65

600 Series Steam Sterilizers

CB-19

Three-Phase Supply Terminals

To rque to 110 in-lbs

Contactor Terminals

To rque to 45 in-lbs

Element Terminals

To rque to 20 in-lbs

Element Flange Bolts

To rque to 22 ft-lbs

1

2

3

4

5

6

FLANGE BOLT TIGHTENING SEQUENCE

(Heating elements not shown for clarity)

ELECTRICAL CABINET

FIGURE 5–4. GTS-30A BOILER TORQUE SPECIFICATIONS

INS 61301607027 Rev A US 5–7

Page 66

Optional Equipment

Three-Phase Supply Terminals

To rque to 110 in-lbs

Contactor Terminals

To rque to 45 in-lbs

Element Terminals

To rque to 20 in-lbs

Element Flange Bolts

To rque to 22 ft-lbs

A07027-BX

1

2

3

4

5

6

FLANGE BOLT TIGHTENING SEQUENCE

(Heating elements not shown for clarity)

FIGURE 5–5. CAS-45A BOILER TORQUE SPECIFICATIONS

5–8 INS 61301607027 Rev A US

Page 67

600 Series Steam Sterilizers

BOOSTER PUMP PACKAGE

A booster pump package is available for sterilizer installations where the

cold water supply pressure is at least 30 psig dynamic but less than 45 psig

dynamic. When energized, the pump increases the cold water supply

pressure to the sterilizer, providing the necessary pressure required for

normal sterilizer operation (see Figure 6–1, Sheet 5 on page 6–6).

NOTE

The booster pump must be installed before connecting the cold water

supply to the sterilizer.

TYPICAL INSTALLATION The customer must provide a location for installing the pump and junction

box as well as fastening hardware for mounting the pump and junction box.

The following plumbing connections (provided by the customer) are

required:

• a plumbing connection between the discharge orifice of the booster

pump and the water supply inlet orifice (i.e., strainer) of the sterilizer.

This connection must include a pressure gauge.

• a plumbing connection between the suction orifice of the booster

pump and the customer’s water supply (a union is recommended for

this connection).

• a shutoff valve in the water supply line at the sterilizer site.

The following electrical connections (provided by the customer) are

required:

• Electrical supply as indicated on the roughing-in drawing.

• Electrical connection to the booster pump junction box per code

requirements.

Figures 5–6 through 5–12 show a typical installation of the booster pump

package. The actual configuration will depend on the desired location of

the pump and its I/F (interface) box (by customer), as well as the particular

structure of the sterilizer and the sterilizer site.

INS 61301607027 Rev A US 5–9

Page 68

Optional Equipment

Water to Ejector

Solenoid Valve 6SV

(26 in. Length)

Water Supply

Strainer

24 Vac

Cold Water

Cold Water Supply

with Shutoff Valve

(by customer)

Discharge

Suction

115 Vac or 230 Vac

Single-Phase Supply

(by customer)

Pump Motor

Voltage

24 Vac from

Control Box

24 Vac to 6SV

Booster Pump

Junction Box

Booster

Pump

Control Box

A07027-N

This illustration shows a unit with a 26 in. length chamber.

On units with a 39 in. or 51 in. length chamber, the water supply

strainer is located in the upper piping.

Union

(recommended

by Getinge)

FIGURE 5–6. TYPICAL BOOSTER PUMP INSTALLATION

5–10 INS 61301607027 Rev A US

Page 69

600 Series Steam Sterilizers

11A

Booster Pump

Interface Box

Interconnect Cable

(by customer)

115 or 230 Vac

Single-Phase

Electrical

Supply

350069-B

Fused

Disconnect

11A

Booster Pump

Interface Box

8A

Universal

Tran sformer

Interconnect Cable

(by customer)

115 or 230 Vac

Single-Phase

Electrical

Supply

350069-C

FIGURE 5–7. TYPICAL INTERFACE BOX INSTALLATION

NOTE

If the mains voltage is 380/400/415 Vac or 440/460/480 Vac, a universal

transformer will be required to provide 115 Vac or 230Vac for the booster

pump junction box. (See page 5–16.)

FIGURE 5–8. TYPICAL INTERFACE BOX INSTALLATION

(WITH UNIVERSAL TRANSFORMER)

INS 61301607027 Rev A US 5–11

Page 70

Optional Equipment

3.00 in

(76 mm)

4.88 in

(124 mm)

Lag Screws

or Alternate

(by customer)

Booster Pump

Mounting Plate

with 13/32” (10.3 mm)

diameter holes

Mounting Surface

(by customer)

350069-D

MOUNTING THE BOOSTER PUMP AND INTERFACE BOX

To mount the booster pump:

1. Fasten the booster pump to its mounting surface as shown in

Figure 5–9.

FIGURE 5–9. MOUNTING THE BOOSTER PUMP

2. Fasten the interface box to its mounting surface as shown in

Figure 5–10.

FIGURE 5–10. MOUNTING THE INTERFACE BOX

Booster Pump

I/F Box

7/32” (5.56 mm)

diameter holes

Fastener

(by customer)

7.00

(178 mm)

7.00

(178 mm)

Mounting Surface

(by customer)

WS-0333

5–12 INS 61301607027 Rev A US

Page 71

CONNECTING THE PLUMBING Make the following plumbing connections:

WS-0242

Suction Orice

(1¼ NPT)

Discharge Orice

(¾ NPT)

to Cold Water

Inlet on Sterilizer

(¾ NPT)

Pressure Gauge

and Shutoff Valve

(by customer)

CW

CW

Cold Water

See Roughing-In Drawing for

Utilities Requirements

Union

(recommended)

1. Connect the plumbing between the ¾ NPT pump discharge orifice and

the ¾ NPT inlet orifice at the sterilizer water supply strainer.

NOTE

The customer must provide a pressure gauge in the plumbing connection

between the pump discharge orifice and the sterilizer water strainer.

The customer must provide a shutoff valve in the water supply line to the

sterilizer.

2. Connect the plumbing between the 1¼ NPT pump suction orifice and

the water supply line.

NOTE

The pipe size must be 1½ in. OD minimum (the minimum flow rate must be

at least 5.1 gallons/minute).

600 Series Steam Sterilizers

FIGURE 5–11. BOOSTER PUMP PLUMBING CONNECTIONS

INS 61301607027 Rev A US 5–13

Page 72

Optional Equipment

CONNECTING THE ELECTRICAL POWER

To connect the single-phase supply to the booster pump junction box:

1. Connect the booster pump junction box to the booster pump as shown

in Figure 5–12 on page 5–15.

CAUTION

Route the cord so that it does not touch any hot steam lines or sterilizer

surfaces.

2. Connect the cords from the booster pump interface box to the sterilizer

control box.

a. Disconnect the cord from 6JO on the back of the control box (that

goes to solenoid valve 6SV) and connect it to 11A2J on the booster

pump interface box.

b. Using the cord provided (P/N 61311601245), connect 11A1J on the

junction box to 2A6JO on the control box.

3. Connect the electrical supply (provided by the customer) to the booster

pump interface box as follows:

a. Connect Line (L) to 1K relay terminal 1 (L1).

b. Connect Neutral (N) to 1k relay terminal 3 (L2).

c. Connect Protective Earth Ground (G) to the PE Ground screw

inside the box.

4. Install the overload relay inside the interface box and connect the wires

as shown in Figure 5–12 on page 5–15.

5. Set the overload relay current adjustment to match the current

stamped on the rating plate.

5–14 INS 61301607027 Rev A US

Page 73

1B

8A

Universal

Transformer

Water Booster

Pump

To

Water to Ejector

Solenoid Valve

6SV

11A1P4(BK)

11A1P1 (R)

2A6PO

132

4

6JO

11A1K6(W)

11A1K2(BK)

11AGND(G)

6SV(W)

6SV(BK)

2A6PO4 (BK)

2A6PO1 (R)

1P

1KA1

1J

1

4

1K96

2

3

1K96

1KA1

2J

95

1P1

1K4

A2

A1

2P1

1KA2

1K95

5

3

1

1K

1B(BK)

2P4

96

1P4

1B(W)

1K5

1B(G)

4

(W)

(BK)

L2

L1

2

3

1

1TB

(G)

Customer Supply

115 or 230

Vac

Single-Phase

380/400/415 Vac

440/460/480 Vac

Single-Phase

or

Customer

Supply Wires

11A

Pump I/F Box

2A

Control Box

5

3

1

6

4

2

6

4

2

4

3

2

1

2P

Overload

Relay

Customer Supply

(115 or 230 Vac Single-Phase)

Pump Motor

Contactor 1K

to

Booster Pump

1B

From 2A6PO

(Water to Ejector)

Front View of Box

w/o Cover

to

Water to Ejector

Solenoid Valve

6SV

Customer Supply

Current

Adjustment

1J

2J

A08205-G

600 Series Steam Sterilizers

FIGURE 5–12. BOOSTER PUMP ELECTRICAL CONNECTIONS

INS 61301607027 Rev A US 5–15

Page 74

Optional Equipment

UNIVERSAL TRANSFORMER

When the customer power supply is 380 Vac or above, a transformer is

required to step down the voltage to the 115 Vac required by the sterilizer

controls. The customer is to provide:

• mounting of the transformer box.

• a connection from the transformer to the sterilizer power box.

• a connection from the customer supply (mains) to the transformer that

meets local code requirements.

• the required fused disconnects.

CAUTION

If a UPS will be installed, see UPS Installation Instructions (Pub. No.

61301605360) for electrical connections.

FIGURE 5–13. POWER SUPPLY CONNECTIONS

Customer Supply

Universal

Transformer

8A

Output to Power Box

(115 Vac)

380/400/415/440/460/480 Vac

Single Phase Supply

8A

UNIVERSAL

TRANSFORMER

1TB

(G)

L1 L2

312

4

(BK)

(W)

1A

POWER BOX

Wire Transformer Taps

for Customer Supply Voltage

(see Diagram Inside Box)

1TB

2

3

L1N

(W)

(BK)

(G/Y)

115 Vac

A08205-B

5–16 INS 61301607027 Rev A US

Page 75

600 Series Steam Sterilizers

CONNECTING THE TRANSFORMER

To connect the transformer:

1. After the transformer is installed, make the mains power supply

connections (L1 & L2) at the transformer terminal block as shown in

Figure 5–13 on page 5–16.

2. Wire the primary taps of the transformer for the correct voltage (See

chart located on the inside cover of the transformer).

3. Make the electrical connections from the sterilizer power box (1A) to

the transformer (8A) as shown in Figure 5–13 on page 5–16.

INS 61301607027 Rev A US 5–17

Page 76

Optional Equipment

A08214-A

UNINTERRUPTIBLE POWER SUPPLY (UPS)

NOTE

Read the manufacturer’s instruction manual before installing the UPS. After