Page 1

Instructions for use

USER MANUAL

Washer disinfector

0410

Washer disinfector

46-2,46-4,46-5

Mfg. no. SEV0440130-

5018610-00

Page 2

Washer disinfector Instruction for use

Contents

Safety regulations ______________________________ 3

Important ___________________________________ 3

Product liability ______________________________ 3

Symbols on the machine _______________________ 4

Isolator switch _______________________________ 4

Attention symbols ____________________________ 4

General _______________________________________ 5

Programmer _________________________________ 6

Door function _______________________________ 6

Drying _____________________________________ 7

Dosing system_______________________________ 7

Operating instructions___________________________ 8

Fault indications ________________________________ 9

A red lamp lights up __________________________ 9

Handling alarm_______________________________ 9

Fault codes _________________________________10

Acknowledgement of fault code _________________1 1

Inspection ____________________________________ 12

Daily ______________________________________12

If necessary _________________________________13

Washing chamber _________________________13

The outside ______________________________ 13

Program printout ______________________________ 14

Printing out a program__________________________ 14

Program _____________________________________ 15

Hospital A0 600 (90 °C - 1 min) ___________________ 16

Hospital A0 600 (90 °C - 1 min) ___________________ 16

Detergent ____________________________________ 17

Getinge detergent for mechanical washing of:_______1 7

Acidic detergents and neutralizing agents _________17

Lubricants and rinse aids_______________________17

Flusher detergents ____________________________ 17

Technical data_________________________________ 18

0410

2

Page 3

Instructions for use

Safety regulations

This machine is designed with a number of built-in safety devices. To avoid injury,

it is very important that these safety devices are not bypassed and thus disabled.

The equipment must be used in accordance with the safety

instructions below.

If in doubt, contact a representative of the reseller without delay.

Important

• Read the instructions thoroughly before use.

• The equipment must only be used by personnel who know about it and are

trained to use it. Personnel must also receive regular training on this equipment.

• Take care when handling the chemical detergent used in the machine. Read

the details on the container or contact the manufacturer:

- if detergent comes into contact with the operator’s eyes or skin or if the

vapours are breathed in, etc.

- about storing the detergent and disposing of empty containers.

• Take care, because the machine uses hot water and possibly steam.

• Installation and service work must be done by personnel trained for this machine.

• Never bypass the door switch of the machine.

• Leakage in the system, due to a worn door seal for example, must be repaired

without delay.

• The electric power is cut off before the machine cabinet is opened. (The

machine cabinet contains electrical components).

• make sure that there is always detergent in the bottles. This is important both

for the operation of the machine and for keeping the washing chamber free

from discolorations.

• The machine must be kept clean if it is to work properly.

• Do not wash down or hose down the machine with water.

Washer disinfector

Product liability

• Modifications to the equipment made without the approval of the

0410

manufacturer, or incorrect use, invalidate the manufacturer’s product liability.

Page 4

Washer disinfector Instruction for use

Symbols on the machine

Warning, see instructions for use.

Warning, hot surface.

Isolating device

The machine must always be fitted with a separate isolating device in the power

supply, mounted in an easily accessible position on the wall.

Attention symbols

Some of the warnings, instructions and advice in this manual are so important that

we use special symbols to draw attention to them. The symbols used are as follows:

This symbol indicates a warning in the text of the manual. The

nature of what the warning relates to is such that it may result in

more or less severe injury and in certain cases mortal danger.

It also highlights warnings to avoid damage to equipment.

0410

4

Page 5

Instructions for use

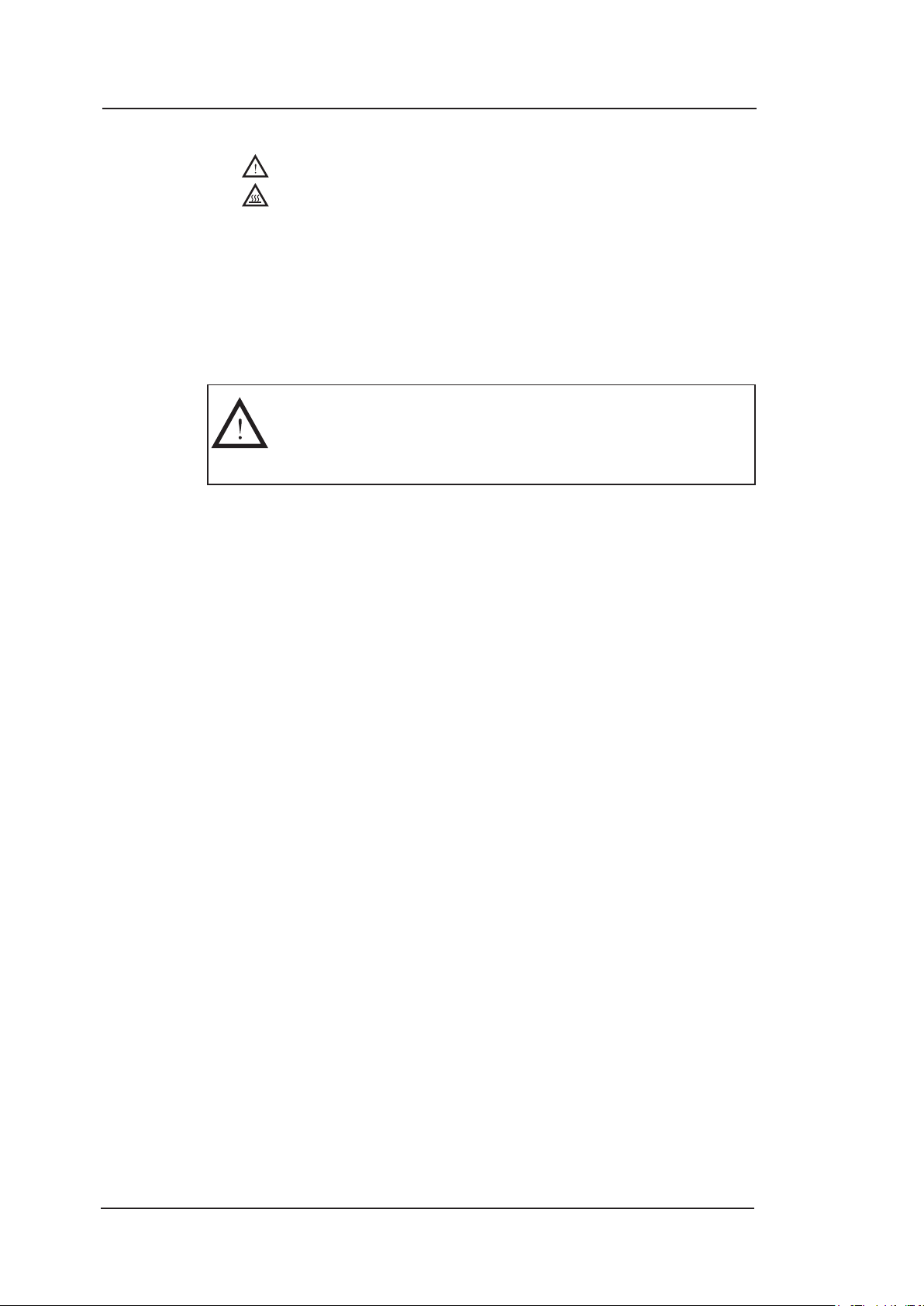

General

Washer disinfector

The Getinge 46-Series are large capacity Washer Disinfectors for cleaning,

disinfection and drying of moisture and temperature stable Surgical Instruments

(rigid and tubular), Hollow ware, Glass ware, Baby bottles, Suction bottles, Wash

bowls, Containers and for 46-4 and 46-5 also Anesthetic accessories.

The machine has spray arms and dockings:

• 46-2 has three spray arms and one docking:

• 46-4 has two spray arms and two dockings:

• 46-5 has two spray arms and three dockings:

The machine can be equipped with several different accessories for different cleaning

requirements. These accessories are presented in a special accessories catalogue.

There are several possible ways of installing and equipping the machine

depending on its field of application:

• 46-2 has electrical heating. 46-4 and 46-5 have electric or steam heating

• 46-2 is fitted with a single door. 46-4 and 46-5 are fitted with a single or double door.

• Connection of distilled or de-ionised water.

• Extra dosing pumps which allow chemical disinfection of heat-sensitive goods.

• With or without built-in drying system.

• Audible signal on process complete, fault code, etc.

The washer-disinfector has been tested and approved to ISO 15883.

.

Control panel

Washing

chamber

Bottom strainer

with handle

Dosing pumps

Hinged door

V1627

Dryer module

Suction pipe

with container

alarm

0410

Detergent container

Page 6

Washer disinfector Instruction for use

Programmer

The machine has an electronic controller which can hold up to 10-15 programs.

Six of these programs can be chosen with the program selection buttons. To

choose other programs, press S. The display now shows SELECT

Press S again, then choose a program with H and J.

The machine comes with a number of standard programs in the programmer (see

the separate program sheet). Contact the manufacturer for customised programs.

Programming may only be done by authorised personnel.

PROGRAM .

Door function

46-2 is fitted with a single door. 46-5 and 46-5 are fitted either with a single door

or with double doors.

Machines with double doors have a system of interlocks to ensure that only one

door can be opened at a time. This means that the clean-side door must be

closed before the dirty-side door can be opened.

When you press V, the door is locked and a yellow lamp (process running) flashes

for about 10 seconds. If you press Vagain during this “cancel time”, the dirty-side

door is unlocked and the door can be opened.

When the program is complete, a green lamp lights up on both sides (if there are

double doors) and the clean-side door is unlocked. When the door has been

opened manually, the green lamp goes out. With double doors, the clean-side

door must be closed before the dirty-side door can be unlocked.

0410

6

Clean side

V398

Dirty side

Page 7

Instructions for use

Dosing system

Washer disinfector

In standard form, the machine has two dosing systems. One is for alkaline

detergent and one is for rinse-aid or acid detergent.

The machine cannot be started until detergent has been added. If the detergent

bottle is empty “ADD DETERGENT” appears on the display.

A third and a fourth dosing system for chemical disinfection of heat-sensitive

goods or instrument milk, for example, can be installed.

Empty container alarm

Drying

Container for

detergent/rinse-aid

If the machine does not have a dryer, we recommend that the goods are dried

in a separate drying cabinet.

0410

Page 8

Washer disinfector Instruction for use

Operating instructions

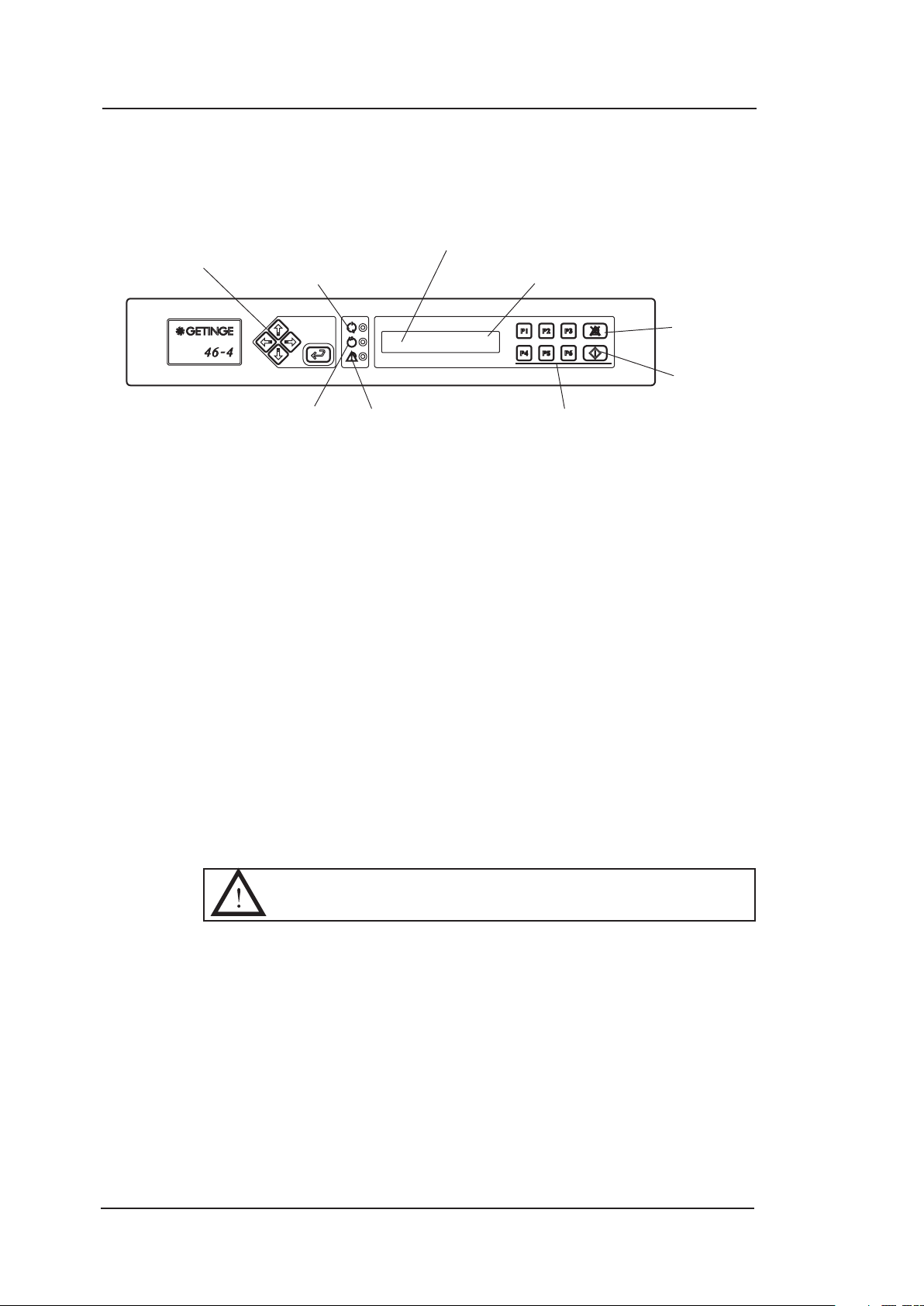

Programming buttons

(see “Service instructions”)

Yellow: Process running

V1624

Green: Process complete

• Load the goods to be washed on to the trolley and run the trolley into the

• Make sure that the washer arms can rotate freely without touching the goods.

• Choose a program in one of the following ways:

• Press V. While the program is running, a yellow lamp at M is lit and the program

• When the program is complete, a green lamp lights up at N and the door is

Program number

P01 OP-SHORT-D

47.0°C

Red: Fault code

Program selection buttons

Before starting: Chosen program

While running: Program phase

(eg “Rinsing”)

Resets alarm

Start wash

program

machine. Examples showing how to load the trolley are shown on the goods

positioning sign.

Close the door.

- by pressing one of the program selection buttons 1 - 6

- by pressing S. The display now shows SELECT CYCLE. Press S again and

choose a program with H and J.

- Press S to confirm .

You can see the machine programs on the separate program sheet.

phase (eg “Rinse”) is shown on the display. Press S to see the current

temperature and press S again for the remaining time.

unlocked (with double doors, the clean-side door).

0410

8

If the goods have not cooled down after a process, be sure to

handle them with care, to avoid burns.

• Empty the machine (and if the machine has double doors, close the clean-side door).

• If the same program is to be used again, there is no need to select the program

again. Simply press V once.

• When you press V, a yellow lamp flashes for 10 seconds. During this time, the

program can be aborted by pressing V again.

Note:

The display switches to rest mode after 30 minutes and returns

automatically when a program is started or selected.

Page 9

Instructions for use

Fault indications

Handling alarm or fault code

Red lamp: Fault code

P01

Add detergent 1

Washer disinfector

V1624

A red lamp lights up

If the red lamp at O lights up, the process has stopped because of a process fault.

If a handling alarm is given, see below for the action to take. For other alarms,

call service personnel.

Handling alarms

Handling alarms appear on the display in plain text. The machine cannot be started

until the fault has been put right. The following handling alarms can be displayed:

Add detergent 1 Empty container alarm 1. If detergent 1 is finished, a handling

Add detergent 2 Empty container alarm 2. If detergent 2 is finished, a handling

Add detergent 3 Empty container alarm 3. If detergent 3 is finished, an

Add detergent 4 Empty container alarm 4. If detergent 4 is finished, an

(Option). operation code is generated. The alarm is reset automatically

Add detergent 1

code is generated. The alarm is reset automatically when

detergent is added.

code is generated. The alarm is reset automatically when

detergent is added.

operation code is generated.(Option). The alarm is reset

automatically when detergent is added.

when detergent is added.

0410

Note:

When the handling alarm “Add detergent 1-4” appears, there is

always enough detergent for one run.

Page 10

Washer disinfector Instruction for use

Fault codes

F01

Fault codes indicate that a serious fault has occurred in the washing process.

The fault must be put right by an authorised service technician.

The following fault codes may occur:

Fault code Description of fault

F0 0 Power failure

F01 Motor cutout has tripped.

F0 2 Water filling takes more than 10 minutes.

F0 3 Draining takes longer than five minutes or there is water remaining

in the washing chamber at the end of the draining phase.

F04 Water leakage in the drying unit.

F05 Dirty-side door does not lock within 10 seconds of program

start or the door is opened while a program is running.

F06 Dirty-side door does not unlock within 10 seconds of the end of

a program.

F09 Dirty-side door does not lock within 10 seconds of program

start or if the door is opened while a program is running.

F10 Dirty-side door does not unlock within 10 seconds of the end of

a program.

F15 Not enough detergent 1 dosed.

F16 Not enough detergent 2 dosed.

F19 Not enough detergent 3 dosed.

F20 Not enough detergent 4 dosed.

F23 High conductivity.

0410

10

F24 Low pressure in drying unit.

F25 High pressure in drying unit.

F2 6 Low pressure from circulation pump.

F2 7 High pressure from circulation pump.

Page 11

Instructions for use

Fault code Description of fault

F2 8 Low temperature in drying unit.

F3 0 Incorrect temperature in washing chamber.

F3 1 Incorrect temperature in washing chamber.

F32 Incorrect temperature in drying unit.

F3 3 Incorrect temperature in washing chamber.

F3 4 Incorrect temperature in washing chamber.

F36 Fault message from independent monitoring system

Acknowledgement of fault code

Acknowledge the fault code by:

• pressing U. The alarm signal stops. The machine is still locked but the current

process has been aborted.

• correct the fault or open the door to gain access to the goods. Pressing U again

drains liquid from the machine and the dirty side door is unlocked.

Washer disinfector

NOTE:

The goods in the machine are not clean. Start a new process.

0410

Page 12

Washer disinfector Instruction for use

Inspection

Centre nut

V317

Coarse strainer

Daily

V1625

Detergent/rinse-aid

Fine strainer

• Check that there are no objects in the bottom of the washing chamber.

• Check that the spray arms can rotate freely. Check that the holes in the spray

arms are not blocked.

If the arms need cleaning, remove them by unscrewing the central nut. The

arms can then be lifted off and washed clean. Check that the arms can rotate

freely when re-installed.

• Remove and clean the strainer in the bottom of the washing chamber.

• If necessary for cleaning, open the strainer with the two nuts.

• Open the detergent door and check that there is detergent/rinse-aid in the

containers.

• Check that the trolley docks properly with the water connections. If the trolley

does not dock properly, adjust the spring.

container

0410

12

Page 13

Instructions for use

Washer disinfector

If necessary

Washing chamber

0410

Keep the washing chamber free of limescale deposits. Remove any remaining

deposits as follows:

• Open the door and dispense 200 ml Lime-Away descaler (sold by Henkel) or

NEODISHER BU (sold by Dr. Weigert) into the wash chamber.

• Close the door and run the descaling program.

NOTE: Do not have any goods in the machine with this program. It is

only for descaling the machine and insert.

Page 14

Washer disinfector Instruction for use

Program printout

An example of a program printout is shown below. In the example the program

P02 OP-D, programmed on program selection button 2 is used in:

PROGRAM:P2 OP-D

DATE:13/04/2004

PROCESS START:13:44:46

MACHINE NAME:46-4

MACHINE NO:1

CYCLE COUNTER:1

PARAMETER

WASH DOS TEMP 35.0C

WASH DOS 1 00:01:00

WASH TEMP. 60.0C

WASH TIME 00:03:00

FINAL R DOS TEMP 80.0C

FINAL R DOS 3 00:00:21

DISINF TIME 00:01:00

DISINF TEMP 90.0C

DRYING TEMP9 0.0C

DRYING TIME 00:18:00

SIGNALS

A107

PROGTIME A107

PH1-START

00:00:00 30.8

PH2-DRAINING 10 s

00:00:00 31.2

PH220-PRE RINSE CW

00:00:10 31.0

TEMP INDEP. CHAMB

PH20-DRAINING 40 s

00:14:18 61.5

PH330-RINSE 1

00:15:29 61.5

PH20-DRAINING 40 s

00:17:39 55.1

PH360-RINSE 2

00:18:46 55.5

PH20-DRAINING 40 s

00:20:55 53.2

PH440-FINAL RINSE

00:22:03 53.5

00:27:53 80.1

DOS.START

00:28:15 81.5

DOS.STOP

00:30:26 90.0

PH450-DISINFECTION

00:30:27 90.1

00:31:26 92.3

PH20-DRAINING 40 s

00:31:28 92.3

PH900-DRYING

00:32:36 91.7

00:51:27 80.8

PH20-DRAINING 40 s

00:02:42 16.2

PH25-WASHING

00:03:51 18.1

00:05:52 35.2

DOS START

00:06:53 39.9

DOS.STOP

00:11:17 60.0

00:12:17 608

00:13:17 61.9

00:14:17 61.5

0410

14

PH1000-ENDING

00:52:43 81.1

SIGNATURE: .........

Page 15

Instructions for use

Program

Machine Program

46-2 with dryer 5016029-13

46-2 with dryer + dist. water conn. 5016029-14

46-4 with dryer 5016030-13

46-4 with dryer + dist. water conn. 5016030-14

46-5 with dryer 5016031-13

46-5 with dryer + dist. water conn. 5016031-14

Washer disinfector

0410

Page 16

Washer disinfector Instruction for use

Hospital A0 600 (90 °C - 1 min)

This program sheet applies to 46-4: 5016030-13, -14

46-5: 5016031-13, -14

Programs Program selection button/ T ype of goods

Program number

INST ./POLY 1 Instruments, circulation goods

INST ./POL Y (ENZ) 2 Instruments, circulation goods

AN/MIS 3 Anaesthesia tubing, mic-instruments

-4-

-5-

-6DRYING P10 * Drying.

DESCALING P11 * Descaling of chamber, inserts, washer arms and washer vanes.

Dose 200 ml Lime-A way descaler (sold by Henkel) or NEODISHER BU (sold

by Dr . W eigert) into the wash chamber. NOTE: Do not have any goods in the

machine with this program. It is only for descaling the machine.

* For choosing this program, see instructions for use.

Hospital A0 600 (90 °C - 1 min)

This program sheet applies to 46-2: 5016029-13, -14

Programs Program selection button/ T ype of goods

Program number

INST ./POLY 1 Instruments, circulation goods

INST ./POL Y (ENZ) 2 Instruments, circulation goods

-4-

-5-

-6DRYING P10 * Drying.

DESCALING P11 * Descaling of chamber, inserts, washer arms and washer vanes.

Dose 200 ml Lime-A way descaler (sold by Henkel) or NEODISHER BU (sold

by Dr. Weigert) into the wash chamber . NOTE: Do not have any goods in the

machine with this program. It is only for descaling the machine.

* For choosing this program, see instructions for use.

es.

0410

16

Page 17

Instructions for use

Detergents

The machine has been tested with Getinge detergents. We recommend that you

use Getinge detergent or detergent from a reputable manufacturer.

Getinge detergent for mechanical washing of:

A - Surgical instruments B - MIS-instruments

C - Anesthesia equipment D - OP-shoes

E - Containers F - Baby-bottles G - Lab glassware

Washer disinfector

Products Alkalinity Surfactants Phosphates Enzymes Suitable for optics Goods to

Getinge Wash Normal Amines + - + + A, B, C, D, E

Getinge Wash Extra Alkaline salts - + - ( +) A, C, D, (E), F

Getinge Wash Intensive Caustic soda + - - - A, C, D, F

Getinge Wash Enzyme - + - + + A, B, C, D, E

Getinge Wash LAB Caustic soda - - - - G

and anodized Alu. be washed

Acidic detergents and neutralizing agents

Products Acids Effects Prewash for Dosage

Getinge Neutralization P Phosphoric Neutralization of alkaline residues, Removal of First rinse after the alkaline

acid, citric removal of mineral residues, e.g. mineral residues wash for neutralization or

acid rust and lime prewash

Getinge Neutralization Citric acids Neutralization of alkaline residues First rinse after the

lab glassware

alkaline wash

Lubricants and rinse aids

Products Ingredients Effects Dosage

Getinge Instrumentmilk Paraffinum perliquidum Lubrication of instruments Final rinse

Getinge Rinse Surfactants Reduction of surface tension Final rinse

emulsifying agents

of water, improved drying

Flusher detergents

Products Alkali Dispersion agents Complexing agents Surfactants

GD Wash + - ++ +

GD Flush - ++ + -

Getinge detergents can be ordered from Getinge resellers.

0410

Page 18

Washer disinfector Instruction for use

Technical data

Weight

Machine 46-2 without dryer 1 5 0 kg

Machine 46-2 with dryer 15 0 kg

Machine 46-4 without dryer 1 5 0 kg

Machine 46-4 with dryer 18 0 kg

Machine 46-5 without dryer 1 5 5 kg

Machine 46-5 with dryer 18 5 kg

Width 650 mm

Depth 690 mm

Height

Machine 46-2 without dryer 1600 m m

Machine 46-2 with dryer 1600 m m

Machine 46-4 without dryer 1600 m m

Machine 46-4 with dryer 1860 m m

Machine 46-5 without dryer 1670 m m

Machine 46-5 with dryer 1930 m m

Chamber size

Machine 46-2, 46-4 H=590mm, W=550mm, D=620mm

Operational volume 201 litres

Total volume 280 litres

0410

Machine 46-5 H=660mm, W=550mm, D=620mm

Operational volume 225 litres

Total volume 305 litres

Environment requirements:

Air humidity max 80% at 31 °C

Room temperature 5 - 40 °C

Water consumption approx 15 litres/phase

Cold water

Connection 15 (1/2") mm

Pressure 100-800 kPa

Flow rate min 20 l/min

Hot water

Temperature 45-60 °C

Connection 15 (1/2") mm

Pressure 100-800 kPa

Flow rate min 20 l/min

Dist./de-ion. water

Connection 20 (3/4") mm

Pressure 50-900 kPa (if the pressure is below

50 kPa a separate feed

pump must be connected)

Flow rate min 20 l/min

Steam

Connection 15 (1/2") mm

Pressure 300-500 kPa

Consumption 0, 5 kg/min at 300 kPa

Waste, water ø 50 m m Capacity 30 l/min

Waste, air ø 63 mm 125-150 m

Humidity 100% 40 sec<

40% after 2 min.

Max outside temperature 5 0 °C

Sound level 60 dB (A)

Electrical connection See Alternative connection

3

/h 35 °C,

18

Page 19

Instructions for use

Washer disinfector

0410

Page 20

Washer disinfector Instruction for use

0410

20

This product is manufactured by:

GETINGE DISINFECTION AB, Ljungadalsgatan 11, Box 1505, 351 15 Växjö, Sweden

Loading...

Loading...