Page 1

OPERATOR MANUAL

61301608206 Rev. C

400LS/500LS

SERIES

STEAM STERILIZERS

Page 2

Page 3

OPERATOR MANUAL

400LS/500LS Series

Steam Sterilizers

Getinge USA, Inc.

1777 East Henrietta Road

Rochester, New York 14623-3133 USA

Phone: (800) 950-9912

Facsimile: (800) 950-2570

Page 4

OPERATOR MANUAL 61301608206

Rev. A (02/2002)

Rev. B (01/2003)

Rev. C (09/2005)

Related Publications:

Manual 400LS/500LS Series

Installation Instructions 61301608205

Supervisor Manuall 61301608207

Service Manual 61301608209

Parts Catalog 61301608210

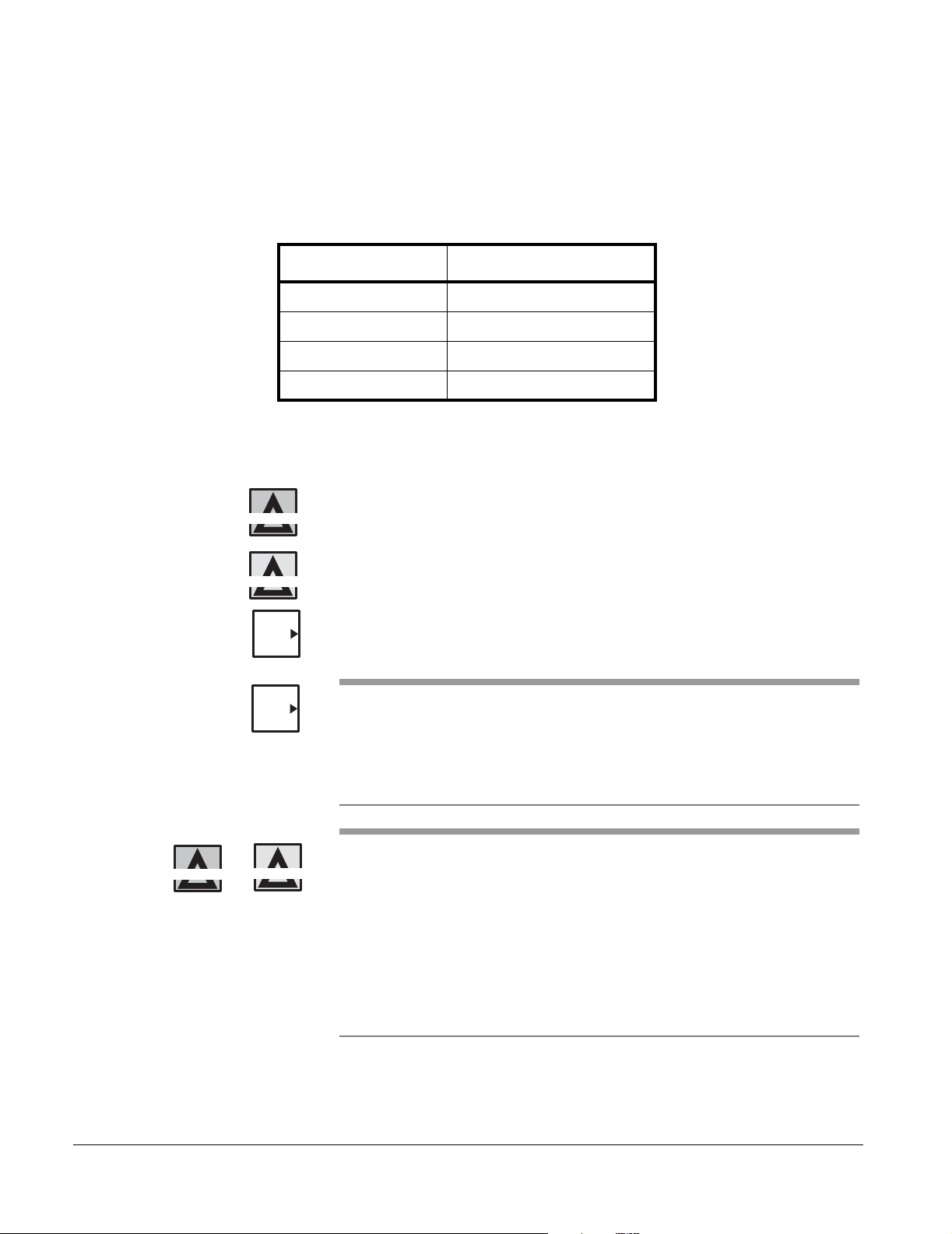

DESCRIPTION OF SYMBOLS & NOTES IN MANUAL

The following symbols with related notes appear in this manual.

“Warning” notes alert the user to the possibility of personal injury.

WARNING

WARNING

CAUTION

NOTE

NOTES

CAUTION

“Caution” notes alert the user to the possibility of damage to the equipment.

“Notes” alert the user to pertinent facts and conditions.

• This manual contains proprietary information of Getinge USA, Inc. It shall

not be reproduced in whole or in part without the written permission of

Getinge USA, Inc.

• This manual is intended for qualified technicians with specialized training.

If you require additional help, contact the company service representative.

• POSSIBILITY OF INJURY: Misuse of equipment or

bypassing its safety features may result in personal injury.

• POSSIBILITY OF EQUIPMENT DAMAGE: Misuse of

equipment may result in equipment damage.

• The 400LS/500LS Series Steam Sterilizers are designed

to steam sterilize laboratory goods and solutions.

This equipment is NOT intended for use other than

expressly stated.

Getinge® is a registered trademark.

Copyright ©2005 by Getinge USA, Inc.

Biosign®, EZ-VU™ Test Pack—registration pending

ii

Page 5

SPECIAL SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . ix

DESCRIPTION OF SYMBOLS ON THE EQUIPMENT . . . . xv

Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

MANUAL CONVENTIONS . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Section 1 Getting Started

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

CONTROLS AND INDICATORS . . . . . . . . . . . . . . . . . . . . 1–2

CYCLE ASSIGNMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

Section 2 Control Panel Navigation

PROCESS SCREENS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Bar Graph Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Details Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

The Plot Graph Screen . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Selecting a Process Screen. . . . . . . . . . . . . . . . . . . . . 2–4

SOFTKEYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

TURNING ON THE CONTROLS . . . . . . . . . . . . . . . . . . . . 2–7

NAVIGATION BASICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Directional Arrows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

ENTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

Select an Item from a List . . . . . . . . . . . . . . . . . . . . . . 2–8

Enter an Alphanumeric Value . . . . . . . . . . . . . . . . . . . 2–9

Communicating With the System. . . . . . . . . . . . . . . . 2–10

Exit from a Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

Table of Contents

Entering Data in Dialog Boxes . . . . . . . . . . . . . . 2–10

Responding to Yes/No Message Boxes . . . . . . . 2–10

iii

Page 6

Section 3 Preparation for Use

DAILY CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

LOAD PREPARATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

TECHNIQUES FOR LOADING . . . . . . . . . . . . . . . . . . . . . 3–4

LOADING ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . 3–9

Section 4 Operating Instructions

SEQUENCE OF OPERATION. . . . . . . . . . . . . . . . . . . . . . 4–1

OPERATING THE STERILIZER . . . . . . . . . . . . . . . . . . . . 4–2

OPENING AND CLOSING THE STERILIZER DOOR. . . 4–15

OPERATING THE PRINTER. . . . . . . . . . . . . . . . . . . . . . 4–19

Operational Readiness . . . . . . . . . . . . . . . . . . . . . . . . 3–1

End of Cycle Routine. . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

Liquid RTD Placement (Option). . . . . . . . . . . . . . . . . . 3–7

Loading Car and Transfer Carriage (533LS only) . . . . 3–9

Rack and Extendable Shelves. . . . . . . . . . . . . . . . . . 3–12

Turning on the Controls. . . . . . . . . . . . . . . . . . . . . . . . 4–2

Previewing/Selecting a Cycle . . . . . . . . . . . . . . . . . . . 4–2

Loading the Sterilizer. . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Editing Cycle Parameters . . . . . . . . . . . . . . . . . . . . . . 4–6

Starting a Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–7

Canceling a Cycle (Manual Abort). . . . . . . . . . . . . . . . 4–9

End of Cycle Routine. . . . . . . . . . . . . . . . . . . . . . . . . 4–10

Unloading the Sterilizer . . . . . . . . . . . . . . . . . . . . . . . 4–12

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–16

Manual Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–16

Power Door (Option) . . . . . . . . . . . . . . . . . . . . . . . . . 4–18

STATUS Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–20

Advancing the Paper. . . . . . . . . . . . . . . . . . . . . . . . . 4–20

Using the Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

Saving Printouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–21

Tearing Off Printer Paper . . . . . . . . . . . . . . . . . . . . . 4–21

Replacing the Printer Paper . . . . . . . . . . . . . . . . . . . 4–21

Removing the Take-up Core . . . . . . . . . . . . . . . . . . . 4–23

Inserting a New Core. . . . . . . . . . . . . . . . . . . . . . . . . 4–23

Inserting a New Roll . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

Loading the Paper. . . . . . . . . . . . . . . . . . . . . . . . . . . 4–23

Storing and Handling Paper Rolls . . . . . . . . . . . . . . . 4–24

Printing a Duplicate Record. . . . . . . . . . . . . . . . . . . . 4–24

iv

Page 7

READING THE CYCLE PRINTOUT. . . . . . . . . . . . . . . . . 4–25

Cycle Start and Parameters. . . . . . . . . . . . . . . . . . . . 4–25

Phases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–25

Validating the Exposure Phase . . . . . . . . . . . . . . . . . 4–26

PERFORMANCE TESTING. . . . . . . . . . . . . . . . . . . . . . . 4–28

Biological Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . 4–28

Vacuum Leak Test. . . . . . . . . . . . . . . . . . . . . . . . . . . 4–29

Section 5 Conditional Instructions

CANCELING A CYCLE (MANUAL ABORT) . . . . . . . . . . . 5–2

Timed Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Untimed Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

ADVANCING A CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

END OF CYCLE ROUTINE . . . . . . . . . . . . . . . . . . . . . . . . 5–9

SHUTTING DOWN THE STERILIZER. . . . . . . . . . . . . . . 5–11

Turning Off Electrical Power . . . . . . . . . . . . . . . . . . . 5–11

Turning Off the Steam and Water Supplies. . . . . . . . 5–12

RECOVERING FROM ELECTRICAL POWER FAILURE 5–13

Power Failure During Standby. . . . . . . . . . . . . . . . . . 5–14

Power Failure During a Cycle . . . . . . . . . . . . . . . . . . 5–14

OPENING THE DOOR MANUALLY. . . . . . . . . . . . . . . . . 5–15

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–16

Remove Pressure from the Gasket . . . . . . . . . . . . . . 5–18

Remove the Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–21

Restore Pressure to the Gasket. . . . . . . . . . . . . . . . . 5–21

CYCLE END . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–26

CYCLE RESULTS . . . . . . . . . . . . . . . . . . . . . . . . 4–26

Section 6 Display Messages

DIAGNOSTIC MESSAGE TYPES. . . . . . . . . . . . . . . . . . . 6–2

Failure Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Fault Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Informational Messages. . . . . . . . . . . . . . . . . . . . . . . . 6–5

Visual Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–6

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–7

DIAGNOSTIC MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . 6–8

v

Page 8

Section 7 Routine Maintenance

MAINTENANCE SCHEDULE . . . . . . . . . . . . . . . . . . . . . . 7–1

DAILY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

WEEKLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

EVERY THREE MONTHS . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

WHEN REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Cleaning the Sediment Screens . . . . . . . . . . . . . . . . . 7–2

Blowing Down the Steam Boiler (option). . . . . . . . . . . 7–3

Cleaning the Exterior Surfaces . . . . . . . . . . . . . . . . . . 7–4

Cleaning theChamber Interior . . . . . . . . . . . . . . . . . . . 7–4

Cleaning the Accessories . . . . . . . . . . . . . . . . . . . . . . 7–4

Cleaning Materials . . . . . . . . . . . . . . . . . . . . . . . . 7–5

Cleaning Agents . . . . . . . . . . . . . . . . . . . . . . . . . . 7–5

Cleaning Methods. . . . . . . . . . . . . . . . . . . . . . . . . 7–5

Checking the Pressure Relief Valves . . . . . . . . . . . . . 7–6

Jacket Pressure Relief Valve . . . . . . . . . . . . . . . . 7–6

Chamber Pressure Relief Valve . . . . . . . . . . . . . . 7–7

Cleaning the Steam and Water Strainers . . . . . . . . . . 7–7

Cleaning the Door Gasket(s). . . . . . . . . . . . . . . . . . . . 7–8

Replacing the Door Gasket(s). . . . . . . . . . . . . . . . . . . 7–9

Replacing the Air Filter . . . . . . . . . . . . . . . . . . . . . . . 7–12

Resetting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . 7–13

Installing/Removing, & Adjusting Shelf Racks. . . . . . 7–15

Installing the Shelves . . . . . . . . . . . . . . . . . . . . . 7–15

Removing the Shelves . . . . . . . . . . . . . . . . . . . . 7–16

Changing the Rack Height . . . . . . . . . . . . . . . . . 7–17

Section 8 Steam Boiler

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . 8–1

WATER QUALITY INFORMATION . . . . . . . . . . . . . . . . . . 8–2

Required Feedwater Quality . . . . . . . . . . . . . . . . . . . . 8–2

Feedwater Quality Recommendations . . . . . . . . . . . . 8–3

Recommended Limits Within a Boiler . . . . . . . . . . . . . 8–3

MANUAL BLOW-DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . 8–4

AUTOMATIC BLOW-DOWN PACKAGE (OPTION) . . . . . 8–7

Setting Up Auto Blow-Down . . . . . . . . . . . . . . . . . . . . 8–8

SERVICE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Section 9 Utilities Control Feature

vi

Page 9

Section 10 Uninterruptible Power Supply

GENERAL DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . 10–1

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–3

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–3

Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–3

Battery Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–4

ROUTINE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 10–5

Cleaning (Weekly) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–5

Testing (Weekly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–5

Replacing Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–5

Section 11 Unidirectional Double Doors

Door Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–1

Section 12 Liquid RTD Package

THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . 12–2

Exposure Timing Based on the Chamber Temperature

(F0 set to zero (disabled)). . . . . . . . . . . . . . . . . . 12–3

Exposure Timing Based on the F0 Value . . . . . . . . . 12–3

Appendix A Consumable Stock and Spare Parts

CONSUMABLE STOCK. . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–2

Appendix B Menu Tree

Glossary

Index

vii

Page 10

viii

Page 11

SPECIAL SAFETY INSTRUCTIONS

THE FOLLOWING SAFETY INSTRUCTIONS APPEAR WITHIN THIS

MANUAL. READ THEM CAREFULLY BEFORE OPERATING THE UNIT.

400LS/500LS Series Steam Sterilizers

WARNING

p. ii POSSIBILITY OF INJURY: Misuse of equipment or bypassing its safety

p. ii POSSIBILITY OF EQUIPMENT DAMAGE: Misuse of equipment may result

p. ii The 400/500 Series Steam Sterilizers are designed to steam sterilize

p. 4-12, 4-15 BURN HAZARD: Before removing a load from the chamber, manually lower

p. 4-6 RISK OF CONTAMINATION: This sterilizer allows the user to modify cycle

“Warning” notes alert the user to the possibility of

personal injury.

features may result in personal injury.

in equipment damage.

laboratory goods and solutions. This equipment is NOT intended for use

other than expressly stated.

the door approximately one inch to allow residual steam to escape. (If the

sterilizer has a power door, unseal the door and wait about a minute for the

steam to vent before opening the door.) Stand back to avoid possible burns

when lowering the door.

settings, which may result in cycle parameters that will not achieve the

desired sterility assurance level (SAL). Users with password access are

responsible for validation of any cycles that use other than the factory set

parameters.

p. 5-15, 5-19 DO NOT attempt to open the sterilizer chamber door unless the CHAMBER

pressure gauge reads zero (0 psig). Hot steam can cause serious injury.

p. 3-2, 3-5, 5-2, 5-6, 5-15 RISK OF CONTAMINATION: Airborne microbial and particulate

contamination is likely to be high in the decontamination area of the sterile

processing department. Wear appropriate personal protective equipment

when preparing items for cleaning.

61301608206 ix

Page 12

WARNING

p. 3-3 CREUTZFELDT-JAKOB DISEASE (CJD) DECONTAMINATION: It is the

“Warning” notes alert the user to the possibility of

personal injury.

responsibility of the laboratory facility to establish internal policies and

procedures relative to processing instruments that have or may have been

exposed to CJD. If instruments exposed to CJD are processed in

accordance with the World Health Organization (WHO) Infection Control

Guidelines for Transmissible Spongiform Encephalopathies (TSE), there

are:

POTENTIAL HAZARDS TO OPERTORS AND REPAIR PERSONNEL:

• Be sure to wear personal protective equipment (PPE) when handling

NaOH liquids.

• Heated NaOH liquids have the potential to injure personnel who handle

the containers.

• Heated NaOH liquids can emit fumes that can be corrosive to eye tissue

and can cause respiratory distress.

• Cleaning residual NaOH from the chamber interior could lead to skin

burns and the production of NaOH aerosol mist.

POTENTIAL DAMAGE TO THE STERILIZER:

• Processing caustic chemicals inside sterilizers is not recommended.

• NaOH is corrosive to copper and brass and has the potential to damage

the chamber and lower piping.

p. 4-5, 4-12, 4-14, 5-2, 5-6 BURN HAZARD: The door and chamber area could be HOT enough to

cause burns. Wear personal protective equipment (PPE) when loading the

chamber.

p. 5-15, 5-17 HOT SURFACES: The pipes on the outside of the chamber may be hot!

Avoid touching the pipes when opening and closing the bleed ball valves.

p. 4-14, 4-16, 4-17 BURN/PINCH HAZARD: KEEP HANDS AND FINGERS AWAY FROM A

MOVING DOOR.

If your hands or fingers are accidentally caught in the door:

POWER DOOR—PRESS THE FOOTSWITCH, OR THE DOOR CONTROL

SWITCH TO REVERSE THE DOOR DIRECTION—or, manually open the

door.

p. 8-4 BURN HAZARD: The drain valve is HOT. Wear personal protective gloves.

p. 5-15 BURN HAZARD: To avoid injury, DO NOT turn the manual valves with the

chamber door open.

p. 3-14, 7-17 HOT SURFACES: The rack and shelves may be hot enough to cause burns.

Wear protective gloves when extending the shelves out of the chamber.

p. 5-22 BURN HAZARD: To avoid injury DO NOT turn ON the manual valve labeled

STEAM TO DOOR(S) with the chamber door open.

x

Page 13

400LS/500LS Series Steam Sterilizers

WARNING

p. 3-14 POSSIBILITY OF INJURY: Observe the following loading

p. 3-1 HOT SURFACES: The chamber and the gasket area could be HOT. Turn

p. 4-12, 4-14, 5-15 BURN HAZARD: Before removing the load, manually lower the door

p. 4-12 HOT SURFACES: The loading car or rack and shelves may be hot enough

p. 4-5, 4-12, 4-15 POSSIBILITY OF INJURY: Do not operate the door while loading or

“Warning” notes alert the user to the possibility of

personal injury.

recommendations:

• The rack can support a maximum load of 100 lbs. An individual shelf can

hold up to 100 lbs., evenly distributed.

• Do not place more than 20 lbs. on the end of an extended shelf.

• Liquid loads (hot or cold) should never be placed on an extended shelf.

Do not extend a shelf with liquid loads (hot or cold).

OFF the controls and make sure the sterilizer is cool before cleaning the

gasket or removing the sediment screen for cleaning.

approximately one inch to allow residual steam to escape. Stand back to

avoid possible burns when lowering the door

to cause burns. Wear protective gloves and eyewear when removing the

load from the chamber.

unloading the sterilizer.

p. 4-12 RISK OF CONTAMINATION: After removing wrapped goods from the

chamber, inspect for residual moisture (wet packs). Moisture on or within a

package can potentially create a pathway for migration of microorganisms

from the outside to the inside of a sterilized package.

p. 3-2, 4-11, 5-10, 5-16, 6-3, 6-17 POSSIBILITY OF INJURY: If a WATER IN DRAIN message displays, DO

NOT open the chamber door manually. Hot water in the chamber may spill

out if the door is opened. Wait until the message clears before attempting to

open the door.

p. 3-2, 3-7, 4-5, 4-7, 4-10, 4-13,

4-15, 5-2, 5-6, 5-9, 5-13, 5-16

p. 3-11 HOT SURFACES: The loading car may be hot enough to cause burns. Wear

p. 6-8 RISK OF CONTAMINATION: If the cycle is advanced or aborted, it must be

p. 3-5 BURN HAZARD: The liquid RTD may be HOT. Wear protective gloves and

POSSIBILITY OF INJURY: Only use vented or open containers to process

liquids in this sterilizer. Use of sealed, unvented containers to process

liquids can result in severe personal injury due to container breakage.

Getinge USA does NOT recommend or endorse use of such containers

protective gloves and eyewear when loading and unloading the chamber.

considered incomplete and the load must be repackaged and reprocessed.

glasses when placing the liquid RTD in the load or removing it from the

load.3–8

61301608206 xi

Page 14

WARNING

p. 3-8, 10-2 POSSIBILITY OF INJURY: Always keep the liquid RTD in the storage

p. 6-18, 6-5 RISK OF CONTAMINATION: If the cycle is cancelled, advanced or aborted,

p. 4-7 Before pressing START, verify that the appropriate cycle is selected for the

p. 5-16, 5-22 If a condition exists OTHER THAN an electrical outage, call Getinge USA

p. 4-12 POSSIBILITY OF INJURY: After completion of a liquids cycle, carefully

p. 4-5, 4-12 POSSIBILITY OF INJURY: Wear protective eyewear and gloves when

“Warning” notes alert the user to the possibility of

personal injury.

pocket (see Figure 3–1) when not in use. If the probe is improperly stored,

the controls may prematurely determine that the cycle is complete. If the

flasks are removed before the cycle is complete, they may burst or crack.

it must be considered incomplete and the load must be reprocessed

(unwrapped goods or liquids) or repacked and reprocessed (wrapped

goods).

load being processed.

service before operating the sterilizer. Failure to do so may result in

personal injury.

remove the container taking care not to agitate the liquid. If the load is

agitated when removed from the chamber, the container may burst or crack.

handling liquids in containers.

p. 8-9 POSSIBILITY OF INJURY: Steam boiler maintenance should be performed

by qualified personnel only.

p. 4-7 POSSIBILITY OF INJURY: If the wrong cycle is selected for a liquid load,

the containers may burst or crack during processing.

p. 4-7 RISK OF CONTAMINATION: If the wrong cycle is selected, the desired

sterility assurance level (SAL) may not be reached.

p. 1-3, 3-2, 3-9, 4-6, 4-7, 4-9,

4-10, 4-12, 5-2, 5-9, 5-13, 5-15,

6-2, 6-8,

p. 4-7, 4-10, 4-12, 4-15, 5-9, 5-13,

5-15, 6-8

p. 4-7, 4-10, 4-12, 4-14, 5-9,

5-13, 5-15, 6-8

p. 5-6 RISK OF CONTAMINATION: If the cycle advance feature is used, the cycle

RISK OF CONTAMINATION: If the cycle is cancelled or aborted, it must be

considered incomplete and the load must be repackaged and reprocessed.

RISK OF CONTAMINATION: If the Process Failure indicator is flashing, the

cycle must be considered incomplete and the load must be repackaged and

reprocessed.

RISK OF CONTAMINATION: If the sterilizer canceled the cycle due to a

power interruption, the load must be repackaged and reprocessed.

must be considered incomplete and the load must be repackaged and

reprocessed.

xii

Page 15

400LS/500LS Series Steam Sterilizers

p. 5-15, 5-17 View the CHAMBER and JACKET pressure gauge while the steam bleeds

from the chamber. Wait until the pressure is at zero (0 psig) before operating

the STEAM TO DOOR(S) and VACUUM TO DOOR(S) valves.

p. 5-15, 5-16 Retracting the door gasket manually should be performed by qualified

service maintenance personnel only. This procedure requires access to the

service side of the equipment.

p. 6-18 POSSIBILITY OF INJURY: Manual mode is intended for use by service

technicians to check the function of individual outputs. Attempting to operate

the sterilizer when any output is set for manual operation may result in

possibly dangerous conditions.

p. 7-2 HOT SURFACE: The chamber and sediment drain screens may be hot.

Allow it to cool before attempting to remove it for cleaning.

p. 7-4 HOT SURFACE: Make sure the sterilizer chamber is cool before attempting

to clean the interior surfaces.

p. 7-6 BURN HAZARD: (1) Keep away from outlet (discharge) end of the safety

valve when operating the pressure release handle. (2) The handle on the

pressure release valve may be hot. Wear protective gloves when operating

the valve.

p. 7-7 BURN HAZARD WHEN CLEANING THE STEAM STRAINER: All steam

lines are hot! Prevent burns by avoiding contact with the lines until the lines

are cool.

p. 7-8, 7-9, 7-15 HOT SURFACE: If the sterilizer is ON, the chamber headring which houses

the gasket, could be hot. Allow the headring to cool before replacing the

door gasket.

p. 5-15 RISK OF NON-STERILE DEVICE: The following procedure is NOT intended

for unidirectional double door units. On unidirectional double door units,

attempting to open the door manually may compromise the integrity of the

biological seal. The door should be unsealed only by authorized personnel

following standard operating procedures at the sterilizer site.

p. 3-9 POSSIBILITY OF INJURY: The loading car can hold a maximum load of 200

lbs. with a maximum of 100 lbs. evenly distributed on each shelf. To avoid

injury or equipment damage, do not exceed these weight limits

61301608206 xiii

Page 16

xiv

Page 17

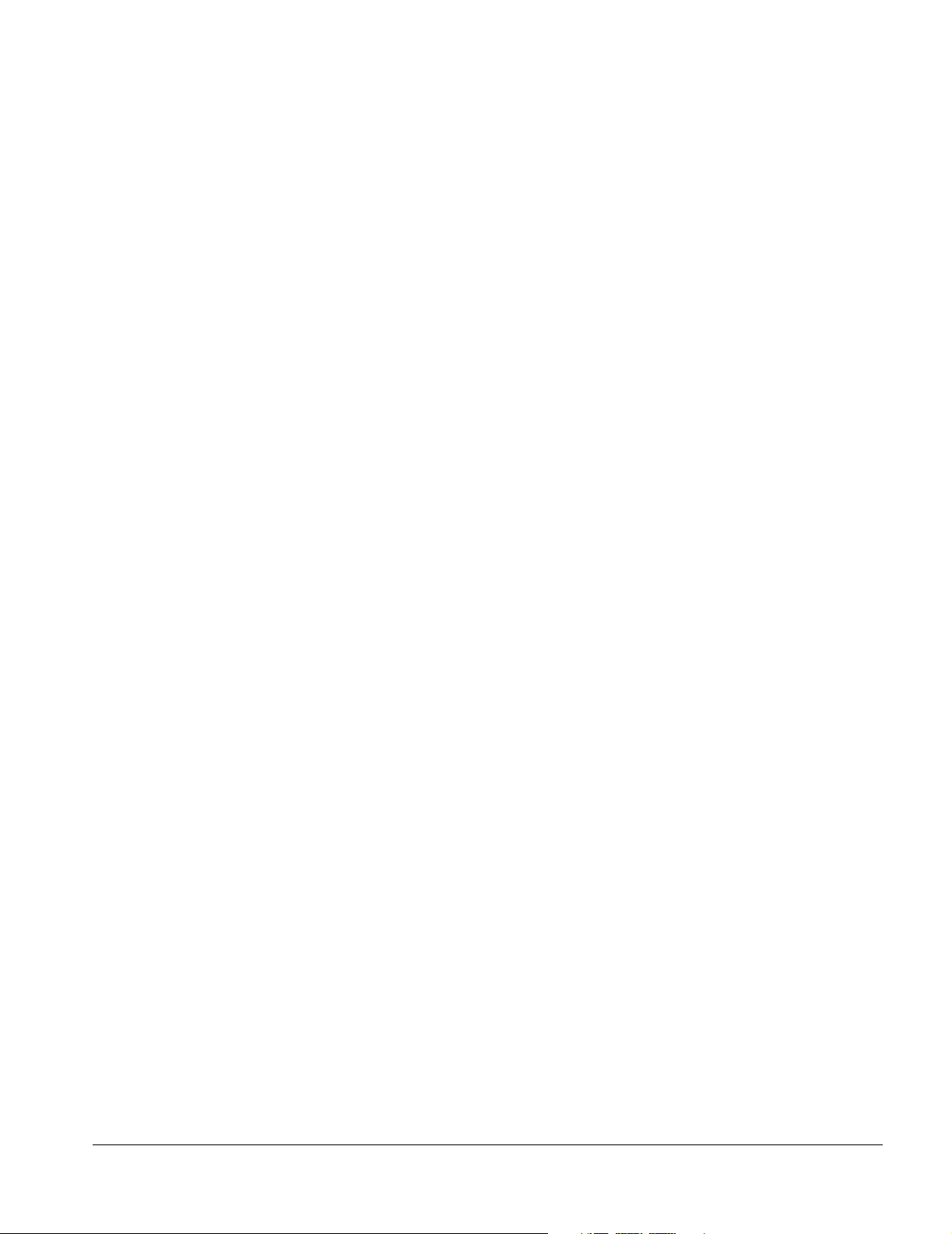

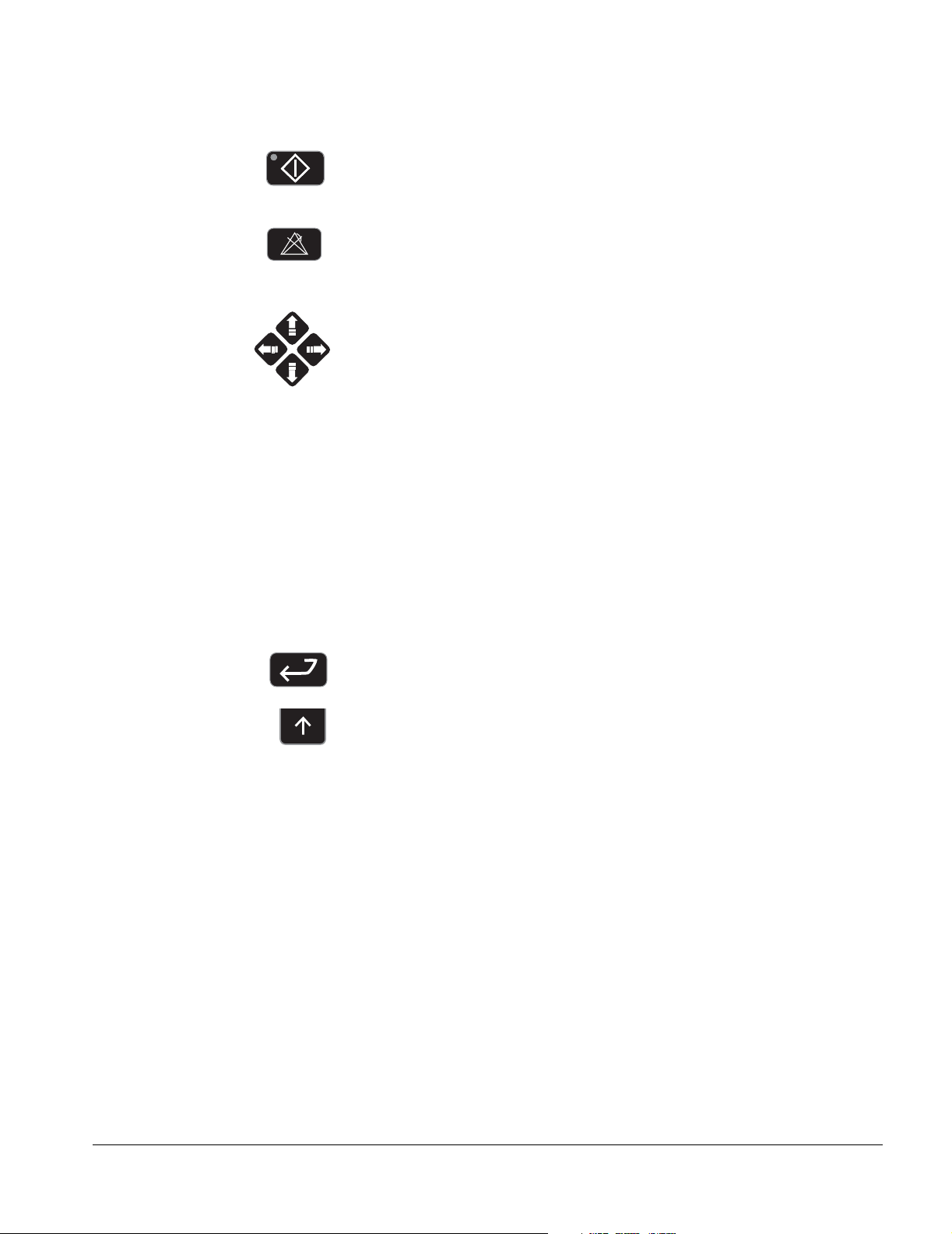

DESCRIPTION OF SYMBOLS ON THE EQUIPMENT

Switches

Open Door

Close Door

Clear Alarm

!

Start

Directional Arrows (for navigating display screens)

400LS/500LS Series Steam Sterilizers

Indicators

Enter

Up Arrows (for selecting softkey options (i.e. Save, Cancel, OK, and so

forth)

Door(s) Closed

Door(s) Sealed

In Process

Process Complete

Process Failure

!

61301608206 xv

Page 18

Labels The following labels on the sterilizer alerts personnel to possible hazards.

BURN HAZARD: Hot surfaces or heat-emitting area. Avoid contact. Risk of

burns.

HS

Burn Hazard

WARNING — BURN HAZARD

Steam released from the sterilizer chamber can

cause serious burns

Stand away while opening the door

If water leaks from the front of the sterilizer,

DO NOT open the door (

Contact Getinge USA Customer Support (800)950-9912

MGA

Load Processing Warning

WARNING

Processing a type

of load other

than defined in

Operator's Manual

could be hazardous.

61301609118 Rev. A

WS-0011

see Operator Manual)

61301602908 REV A

The following labels on the Control Box and Power Box alert service

personnel to possible hazards.

HIGH VOLTAGE

CAUTION: To reduce the risk of electrical shock, do not remove cover. Refer

servicing to qualified service personnel.

ATTENTION: Refer to accompanying documents for further information.

Electrostatic Sensitive Devices

OBSERVE PRECAUTIONS

FOR HANDLING

SENSITIVE

DEVICES

xvi

Page 19

MANUAL CONVENTIONS

400LS/500LS Series Steam Sterilizers

Before you begin using this manual, it is important to understand the

conventions used. These conventions are established for visual ease of use.

ITALIC CAPS Display text, such as the ENTER PASSWORD

prompt.

[ALL CAPS] Softkeys on the control panel, such as [MORE] or

[OK].

ALL CAPS Switches and indicators on the control panel, such

as ENTER.

> The > symbol leads you through nested menu

items and dialog box options to a final action. For

example: SYSTEM MENU>enter

password>CONFIGURATION>EDIT CYCLES.

Italic Upper/Lower Case Cross reference to another section, manual, or

guide; such as: see 400/500 Series Steam

Sterilizers Service Manual.

PARAMETER SETTINGS

ACCESS REQUIRED

Parameter Setting Access Required is an alert

that a password with appropriate access rights is

necessary to proceed.

61301608206 xvii

Page 20

xviii

Page 21

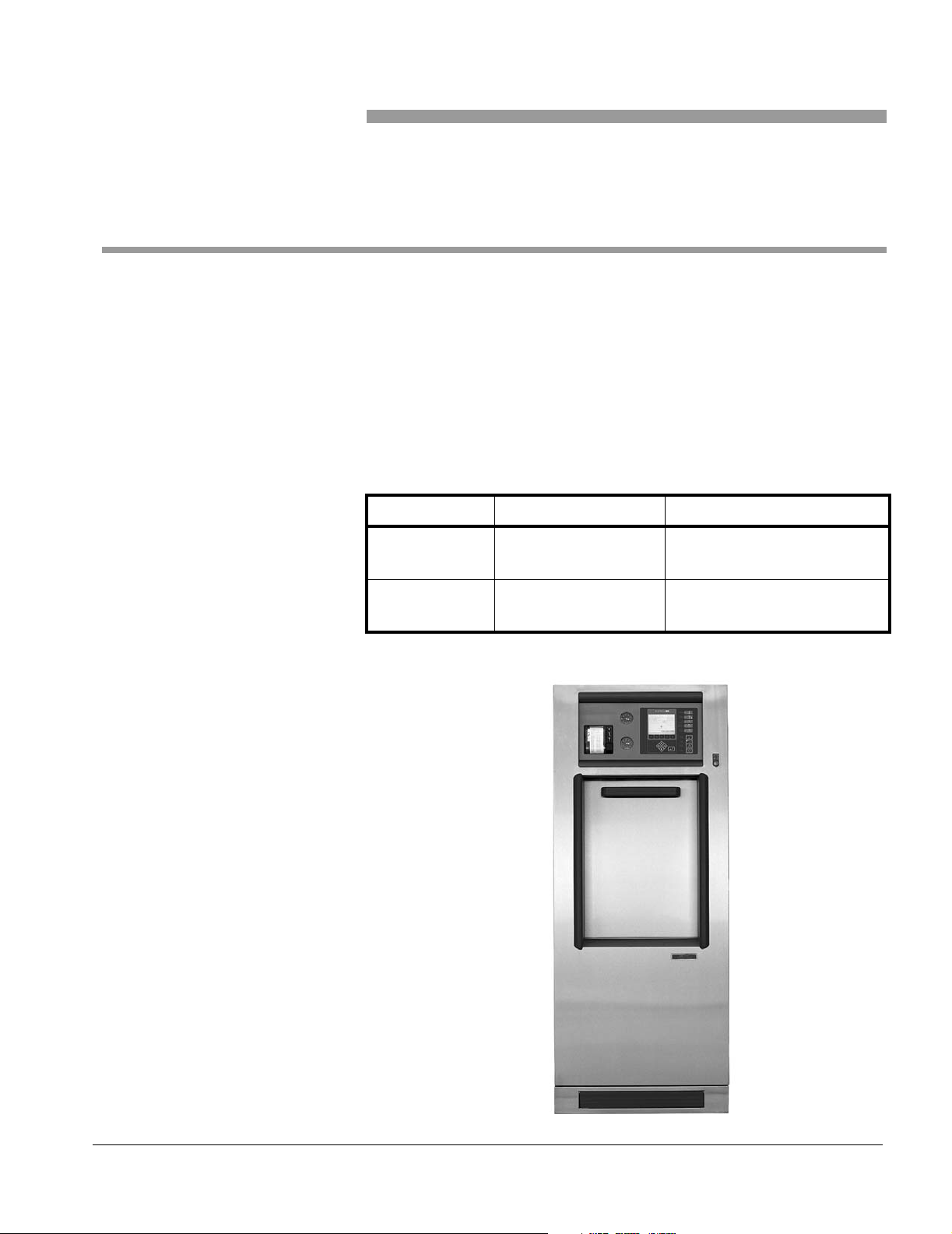

MODELS

Section 1 Getting Started

The 400LS/500LS Series Steam Sterilizers are designed to steam-sterilize

laboratory goods and solutions. Typical applications include:

•utensils

•glassware

• porous goods

• non-porous hard goods

• non-flammable/non-volatile liquids in self-venting or open containers

Models and cycle types are listed in Table 1–1.

Table 1–1. 400LS/500LS Series Steam Sterilizers

MODEL STERILIZER TYPE CYCLE TYPES AVAILABLE

422LS

522LS

433LS

533LS

Figure 1–1. 400LS/500LS SERIES STEAM STERILIZER

Gravity Gravity, Liquids

Vacuum Prevacuum, Gravity, Liquids,

Vacuum Leak Test

61301608206 1–1

Page 22

Getting Started

S

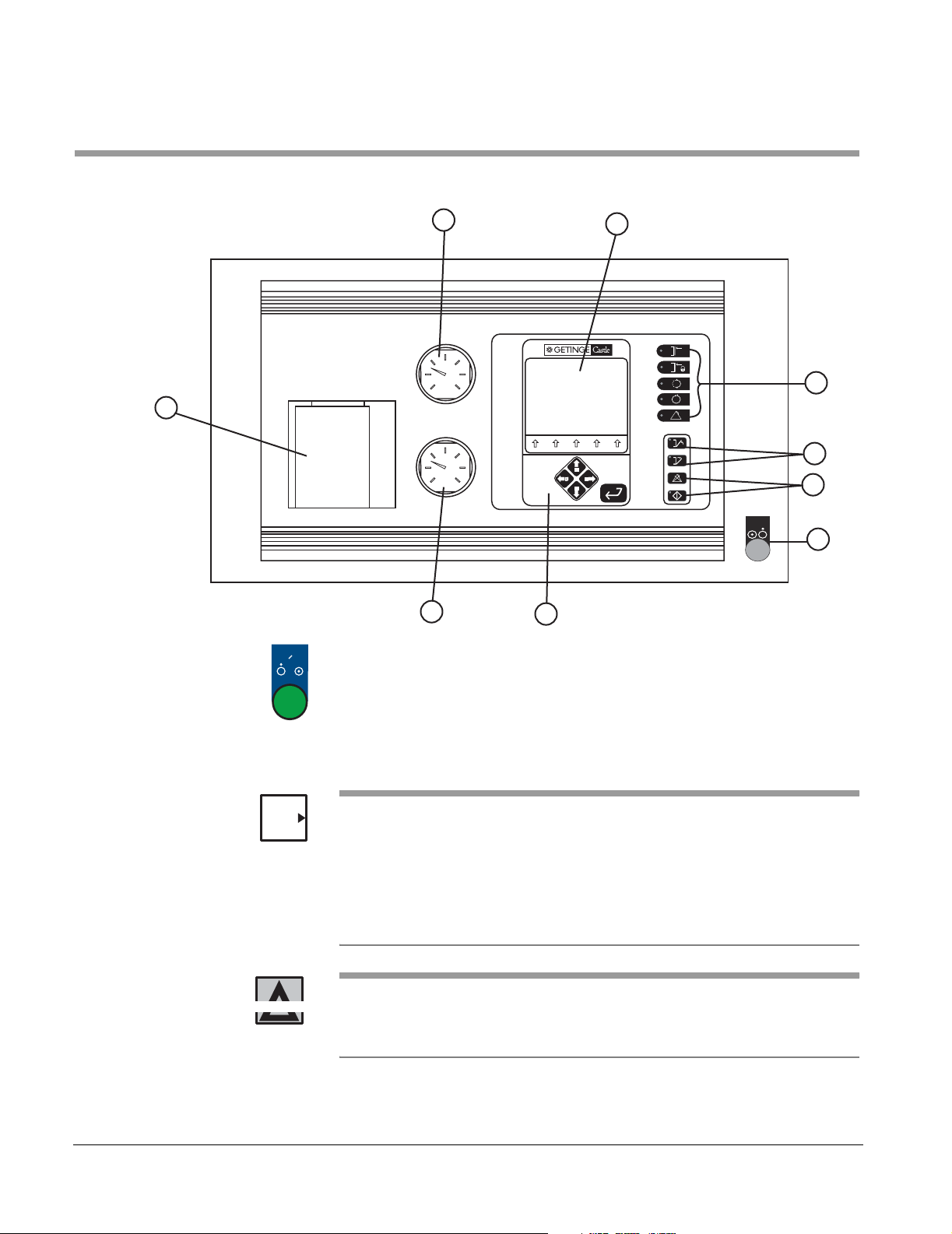

CONTROLS AND INDICATORS

Figure 1–2. STERILIZER FRONT PANEL

8

6

5

7

!

4

!

CONTROLS

ON / / OFF

2

1

WS-0047

CONTROLS

OFF ON

9

1. CONTROLS OFF/ON — This green push button turns the

3

sterilizer controls OFF and ON.

WS-0091

NOTES

WARNING

• Sterilizer controls are ON when the push button is pressed in

and illuminated.

• Sterilizer controls are OFF when the push button is released

and the button is not illuminated.

• If the CONTROLS OFF/ON button is illuminated and the backlit display is

blank, press any button (Up Arrow, Enter, and so forth) on the control

panel to turn ON the display back-light.

• If the CONTROLS OFF/ON button is pressed during a cycle, the cycle will

abort. This is not the recommended method to manually abort a cycle. To

manually abort a cycle, see "Canceling a Cycle (Manual Abort)" on page

5-2.

RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be repackaged and reprocessed.

1–2

Page 23

400LS/500LS Series Steam Sterilizers

2. Cycle Switches:

• START — Begins the selected processing cycle.

• CLEAR/ALARM — Clears display messages and

!

silences any alarm. See "Display Messages" on

page 6-1.

3. Programming Switches:

• UP/DOWN/LEFT/RIGHT arrow keys—Used to:

1)select a cycle

(see "Previewing/Selecting a Cycle" on page 4-2).

2)enter a password

(see Enter a Password in the 400LS/500LS Series

Steam Sterilizers Supervisor Manual).

3)change adjustable cycle parameters

(see Edit Cycle Parameters in the 400LS/500LS

Series Steam Sterilizers Supervisor Manual).

4)navigate the menus

(see Menu Options in the 400LS/500LS Series

Steam Sterilizers Supervisor Manual).

• ENTER—Enables/stores selections in memory.

• UP ARROW softkeys—Usage varies depending on the

cycle and/or cycle phase. The softkey labels appear

above one of the five (5) arrow softkeys.

See Softkeys on page 2-6.

61301608206 1–3

Page 24

Getting Started

4. DOOR CONTROL Switches:

•CLOSE DOOR

Manual Door units—Press the switch to seal the door;

however, the door seals automatically at the beginning

of the cycle.

Power Door units—Press the switch to close the door

or use the foot switch. Press the switch a second time

to seal the door.

• OPEN DOOR

Manual Door units—Press the switch to unseal the

door.

Power Door units—Press the switch to unseal the door.

Press the switch a second time to open the door or use

the foot switch.

Unidirectional Double Door units—unseals the unload

end (Remote End (RE)) door.

See "Opening and Closing the Sterilizer Door" on

page 4-15.

5. STATUS Indicators:

• DOOR(S) CLOSED—Indicates the door is closed, but

not sealed (or both doors are closed, but not sealed on

a double door unit).

• DOOR(S) SEALED—Indicates the door is sealed (or

both doors are sealed on a double door unit).

• IN PROCESS—Indicates a cycle is in progress.

• PROCESS COMPLETE—Green light indicates a cycle

is complete.

Flashing red light indicates an aborted cycle.

!

• PROCESS FAILURE—Flashing red light indicates that

the controls automatically aborted a cycle due to a

process failure, equipment malfunction, or failure while

in STANDBY.

1–4

Page 25

400LS/500LS Series Steam Sterilizers

e

g

j

6. Display Window—The interface between the operator and

the sterilizer

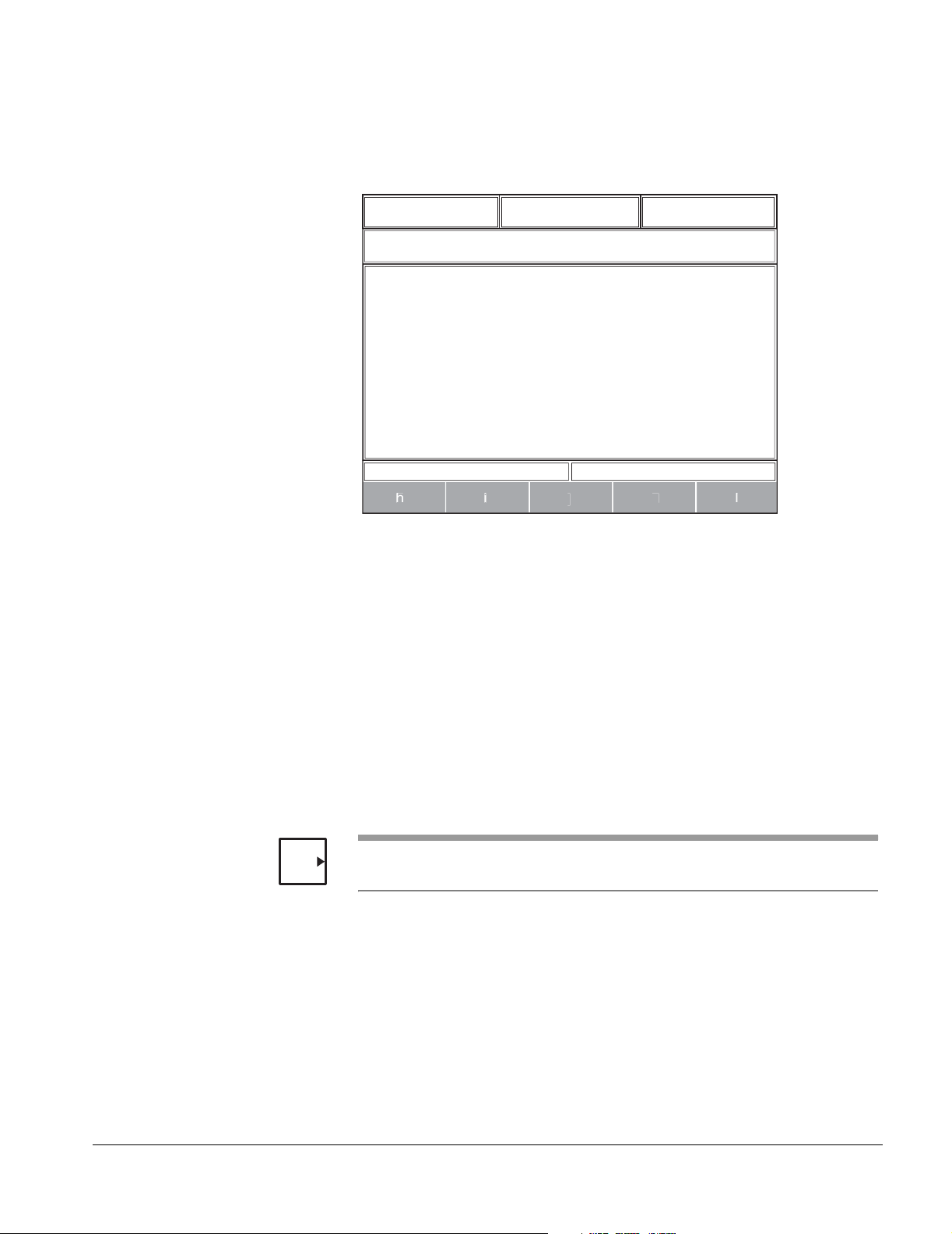

Figure 1–3. DISPLAY WINDOW

a bc

d

NOTE

WS-0104

The Display Window includes:

a. Exposure Time

b. Exposure Temperature

c. Drying Time (not used for Liquid cycles)

d. Cycle information including:

• Cycle selected—Gravity, Liquids and Prevacuum.

• Phase name—Heat up, Exposure, Drying, Exhaust and Cycle

Complete to name a few.

• Time in the cycle—the cycle timer begins when the cycle

starts and continues to increase until the cycle is complete.

When the phase is STANDBY, the cycle timer does not increase.

• Time in current phase—the in-phase timer begins when each

phase starts and resets at the end of each phase.

• CYCLE COMPLETE—Green background

• PROCESS FAILURE—Flashing red background

61301608206 1–5

Page 26

Getting Started

e. Process Screen includes:

• A user selectable process screen:

• Bar graph (See Figure 2–1 on page 2-2)

• Details (See Figure 2–2 on page 2-3)

• Plot graph (See Figure 2–3 on page 2-4)

•Dialog boxes

• Password window

NOTE

If all the items in the list do not fit on one screen, a black bar appears to the

right of the list. Use the UP/DOWN arrows to view any additional items.

f. Critical alarms

• Failure conditions

• Fault conditions

g. Non-critical information and system messages

• Informational messages

h. through l. — Five (5) softkey labels that display

different function names depending on the current

screen and/or cycle phase.

See "Softkeys" on page 2-6.

7. Printer — Provides a record of the cycle.

(see "Operating the Printer" on page 4-19).

8. Jacket Pressure Gauge — Indicates the current jacket

pressure.

9. Chamber Pressure Gauge — Indicates the current

chamber pressure.

1–6

Page 27

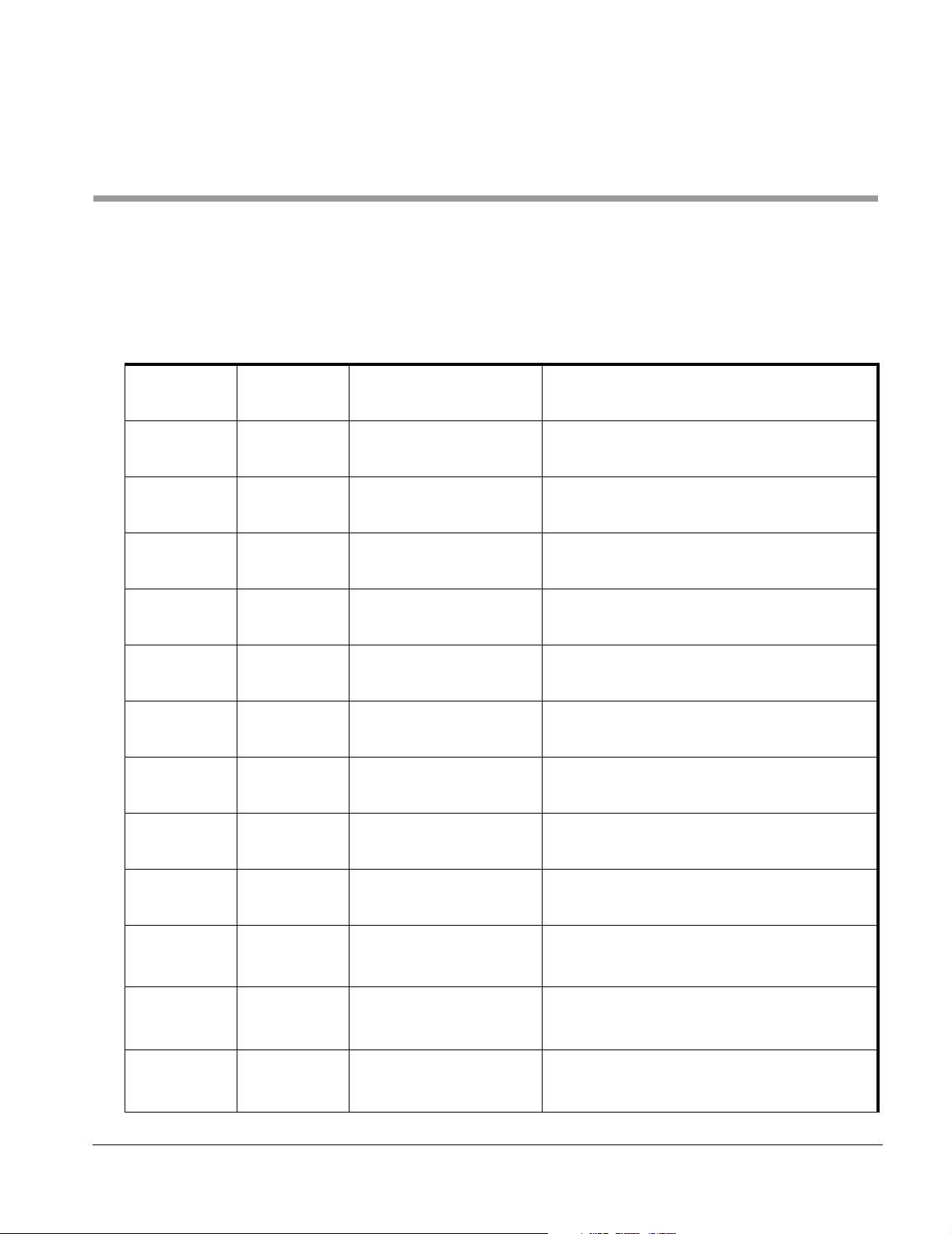

COPY THESE 2 PAGES AND SAVE FOR REFERENCE

CYCLE ASSIGNMENTS

The sterilizer comes from the factory with up to 18 pre-assigned cycles as

shown in the 400LS/500LS Series Steam Sterilizers Supervisor Manual.

The cycle number and name can be changed by a qualified person with

configuration access privileges. When changes are made to the cycle

assignments write your setup in the form below.

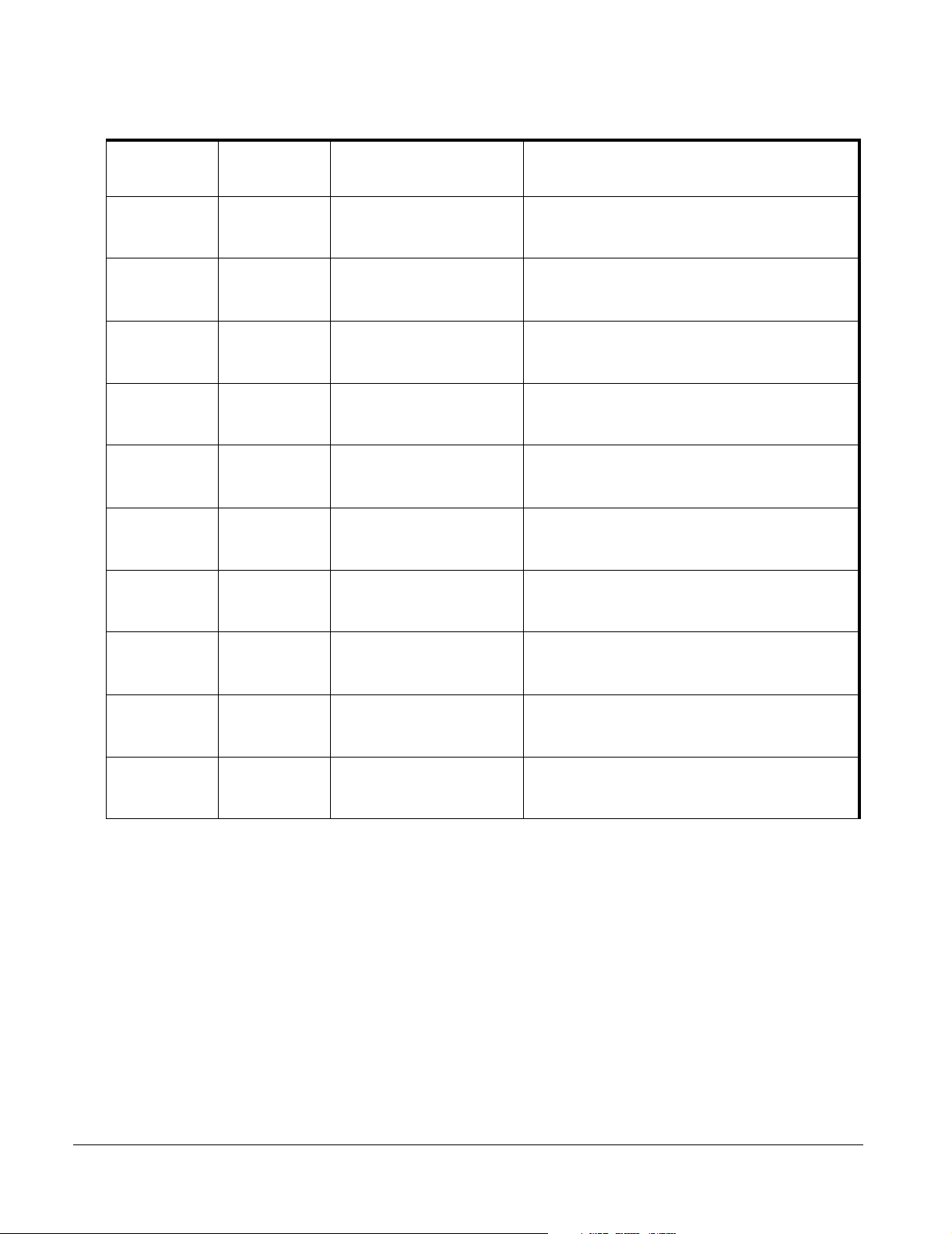

Table 1–2. Cycle Assignments

400LS/500LS Series Steam Sterilizers

Cycle No. Cycle Type

Cycle Name

(8 Characters Max.)

Comments

61301608206 1–7

Page 28

Getting Started

Table 1–2. Cycle Assignments

Cycle No. Cycle Type

Cycle Name

(8 Characters Max.)

Comments

Cycle type abbreviations:

• vac – Prevacuum(Models 433LS/533LS only)

• grv – Gravity

• liq – Liquids

• lkt – Vacuum Leak test (Models 433LS/533LS only)

DATE: ___________________

1–8

Page 29

Section 2 Control Panel Navigation

The 400LS/500LS Series Steam Sterilizers have an easy to use interface.

This section covers:

• Three process screens—see page 2-2

• Softkey label assignments —see page 2-6

• Turning on the backlit display and the sterilizer controls—see page 2-7

• Basic navigation of the software—see page 2-8

For a description of the controls and indicators located on the control panel,

see Controls and Indicators page 1-2.

61301608206 2–1

Page 30

Control Panel Navigation

E

C

P

C

A

PROCESS SCREENS

The user has the option of selecting one of three process screens:

• A screen with an enlarged timer (Bar Graph).

• A list of real-time process critical values, including, but not limited to,

chamber temperature, chamber pressure, jacket temperature,

atmosphere PSIA, chamber PSIA, Exposure temperature maximum,

exposure temperature minimum (Details).

• A screen with a graphical display (Plot Graph).

A password is not required to select a process screen.

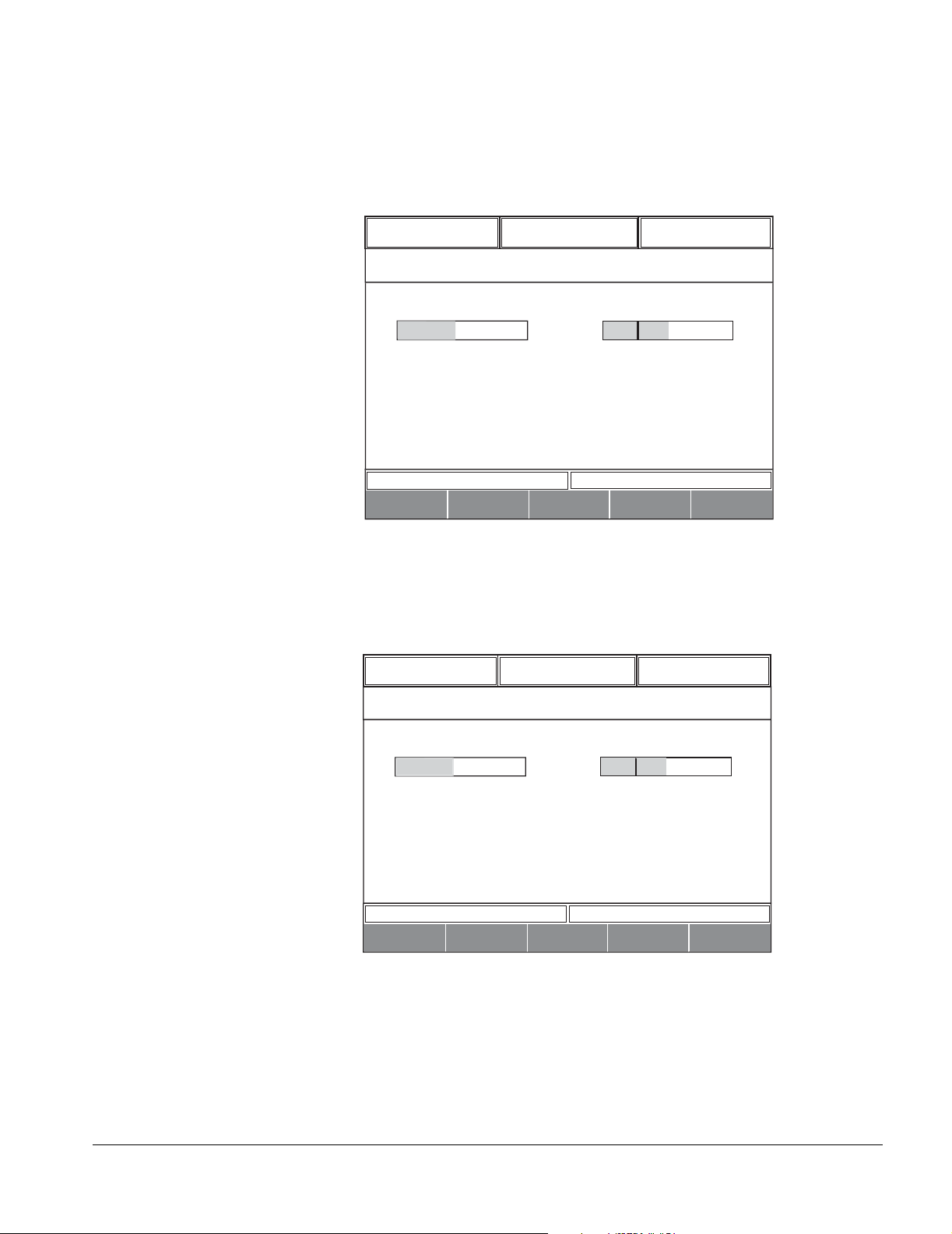

Bar Graph Screen The Bar Graph screen displays the chamber temperature and pressure as a

bar graph and also shows a digital time representing the time remaining in

the cycle.

Figure 2–1. BAR GRAPH SCREEN

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

HAMBER TEM

37.3 C

SETUP

SELECT

CYCLE

121.1 C

Exposure Temp

0

REMAINING TIM

PARA -

METER

00:30:00

Drying Time

HAMBER PSI

14.68 PSI

Time in Cycle

00:00:00

00:24:15

Time in Current

Phase

Estimated Total

Time Remaining

in the Cycle

UNSEAL

WS-0014

2–2

Page 31

400LS/500LS Series Steam Sterilizers

P

p

C

G

p

A

C

A

x

C

C

UNSEAL

S

CT

CYCLE

Details Screen The Details screen displays a list of real-time process critical values,

including: chamber temperature, chamber pressure, jacket temperature,

atmosphere PSIA, chamber PSIA, exposure temperature maximum,

exposure temperature minimum, steam table differential, overall

temperature time, machine counter, daily counter, leak test start, leak test

differential, and software version.

NOTE

If all the items in the list do not fit on one screen, a black bar appears to the

right of the list. Use the UP/DOWN arrows to view any additional items.

Figure 2–2. DETAILS SCREEN

00:30:00

Exposure Time

P10 grv GRAVITY 1

02 CYCL COMPLETE

Chamber Tem

hamb Press/PSI

Jacket Tem

Atmosphere PSI

hamber PSI

Exp. Temp Ma

Exp. Temp Min 121.4

SETU

ELE

121.1 C

Exposure Temp

61.2

0.00 PSI

122.3 C

14.37 PSI

14.35 PSI

121.7 C

00:30:00

Drying Time

01:36:36

00:04:34

WS-0012

61301608206 2–3

Page 32

Control Panel Navigation

1

02 CYCL CO

E

UNSEAL

SETUP

01:36:36

00:03:42

p

C

A

8

35

e

0

0

C

C

SI

S

CT

CYCLE

E

C

P

C

A

The Plot Graph Screen The Plot Graph screen displays the chamber temperature and pressure as a

trend curve using a graphic display.

Figure 2–3. PLOT GRAPH SCREEN

00:30:00

Exposure Time

121.1 C

Exposure Temp

00:30:00

Drying Time

P10 grv GRAVITY

MPLET

14.

1.2

P

1:4

Tim

WS-0013 700H

ChamberTem

hamber PSI

ELE

Selecting a Process Screen The Bar Graph screen displays when the sterilizer control panel is turned

on. See Turning ON the Controls on page 2-7.

Figure 2–4. BAR GRAPH SCREEN

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

HAMBER TEM

37.3 C

SETUP

SELECT

CYCLE

121.1 C

Exposure Temp

REMAINING TIM

1. Press [SETUP].

The SETUP menu appears.

0

PARA -

METER

00:30:00

Drying Time

HAMBER PSI

14.68 PSI

00:00:00

00:24:15

UNSEAL

WS-0014

2–4

Page 33

400LS/500LS Series Steam Sterilizers

2. Use the UP/DOWN ARROWS to select the process

screen:

• Bar Graph

• Details

• Plot Graph

3. Press ENTER.

The process screen selected appears.

61301608206 2–5

Page 34

Control Panel Navigation

SOFTKEYS

Navigation of the software interface is controlled using the softkeys ( )

that appear at the bottom of each screen. The softkey labels, located

directly above the softkeys, change depending on the current main window

and/or the cycle phase. The following illustration shows the labels assigned

to each softkey.

NOTE

Access levels assigned determine the screens that are viewed.

Table 2–1. Softkey Assignments

Softkey Labels Screen or Procedure

SETUP SELECT

CYCLE

SETUP PARA-

SETUP PARA-

ABORT PHS

ADV

SETUP PARA-

CANCEL SETUP Menu

CANCEL OK SELECT CYCLE Screen

CANCEL MORE

CANCEL HOME OK EDIT PARAMETERS screen

CANCEL +/- CYCLE PARAMETER dialog box

CANCEL EDIT OK VIEW PARAMETERS screen

CANCEL CAPS

CANCEL DELETE OK ENTER PASSWORD screen

CANCEL HOME OK

CANCEL HOME System Menu Options

CANCEL HOME BRIGHT

PARA-

METER

METER

METER

METER

PARAMS

DELETE OK ADD USER, ACCESS AREAS or

LOCK

YES NO Confirmation message box

DEC

BRIGHT

INC

UNSEAL Startup or Default screen

UNSEAL Default Screen CYCLE COMPLETE

MORE Default Screen IN-CYCLE

EXIT Default Screen IN-CYCLE (Timed

Phase) (After MORE is pressed)

ABORT Default Screen IN-CYCLE (Untimed

Phase)

OK

or

SAVE

or

SAVE

OK ABOUT Screen

EDIT PARAMETERS screen

[MORE PARAMS]

MACHINE NAME screen

ALARM CLOCK, LANGUAGE DATE

UNITS, or PANEL SETUP screens

(If preference is enabled)

Softkeys

2–6

Page 35

TURNING ON THE CONTROLS

To turn on the backlit display and the controls:

400LS/500LS Series Steam Sterilizers

CONTROLS

OFF ON

WS-0091

NOTES

Press the CONTROLS OFF/ON button.

• The switch illuminates and remains inward.

• The backlit display illuminates.

• The controls turn on.

• If the power is accidentally interrupted by pressing CONTROLS ON/OFF,

turn the controls back ON. The cycle is not cancelled if the controls are

turned ON within 2 seconds.

• If primary power is interrupted (e.g., a circuit breaker trips), the cycle is

not cancelled if power is restored within 59 seconds.

61301608206 2–7

Page 36

Control Panel Navigation

NAVIGATION BASICS

Directional Arrows Each of the Directional Arrows has a specific function:

• Up Arrow ( ↑ )

• scrolls up a list on the process screen

• when the cursor is activated (blinking cursor), increases the

digit or value shown in reverse video

• Right Arrow (→)

• moves the cursor on the current screen or window right to

highlight a field

• Down Arrow ( ↓)

• scrolls down a list on the current screen or window.

• when the cursor is activated (blinking cursor), decreases the

digit or value shown in reverse video

• Left Arrow (←)

• moves the cursor on the current screen or window left to

highlight a field

ENTER Use the ENTER key to:

• Accept numbers and letters when entering passwords, machine names,

or changing a parameter setting.

• Select an item from a list (such as: a cycle from the list of available

cycles, a menu option, or a parameter).

Select an Item from a List Selecting an item from a list is very simple; the UP/DOWN arrow keys are

used to select the item and the ENTER key stores the selection in memory.

For more detailed instructions, see Previewing/Selecting a Cycle

on page 4-2.

2–8

Page 37

400LS/500LS Series Steam Sterilizers

J

\

CE

/

Enter an Alphanumeric Value

When an alphanumeric value needs to be entered, a screen similar to

Figure 2–5 displays.

Figure 2–5. KEYBOARD SCREEN

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

ENTER PASSWORD

PASSWORD:

CANCEL

121.1 C

Exposure Temp

PA

DELETE

00:30:00

Drying Time

00:00:00

00:24:15

OK

WS-0017

When the keyboard screen appears, the blinking cursor is positioned at the

location of the first character of the string and the first key on the keyboard is

highlighted. The UP/DOWN/LEFT/RIGHT arrows are used to navigate to

the appropriate character; ENTER is used to select the character. The

selected character or # sign appears in the position of the blinking cursor

and the blinking cursor moves to the right of the character. Press [OK] when

the password is entered.

Softkeys:

• [CANCEL]—returns to the previous screen without accepting the

alphanumeric value.

• [DELETE]—deletes the character to the left of the cursor.

• [OK]—accepts the alphanumeric value and, in the case of the password

displays the next screen if a valid password is entered.

For more detailed instructions, see:

• Enter a Password in the 400LS/500LS Series Steam Sterilizers

Supervisor Manual.

• Set Up an Operator Password in the 400LS/500LS Series Steam

Sterilizers Supervisor Manual.

• Change an Operator Password in the 400LS/500LS Series Steam

Sterilizers Supervisor Manual.

• Edit the Cycle Number and Name in the 400LS/500LS Series Steam

Sterilizers Supervisor Manual.

• Assign the Sterilizer Name in the 400LS/500LS Series Steam Sterilizers

Supervisor Manual.

61301608206 2–9

Page 38

Control Panel Navigation

E

P

A

c

Atomosphere PSIA

PSI

e

)

ss

Communicating With the System

Entering Data in Dialog Boxes

When a dialog box appears over the process screen, it is in read mode.

When ENTER is pressed, the screen goes into edit mode allowing

parameters to be selected and modified. Once in edit mode:

• LEFT/RIGHT arrows are used to select the parameter to be changed.

• UP/DOWN arrows are used to enter the new value.

• ENTER accepts the changes made and returns the screen to save mode.

• [SAVE] records the new values into memory and returns the screen to

read mode.

Figure 2–6. DATA VALUE ENTRY SCREEN

00:30:00

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

HAMBER TEM

Ja

Lo

Fo

37.3 C

121.1 C

Exposure Temp

Exposure Tim

00:01:00 - 06:00:00

:30:0 hh:mm:

00:30:00

Drying Time

HAMBER PSI

14.68 PSI

00:00:00

00:24:15

.03

0

Chamber PSIA 12.03 PSI

CANCEL

REMAINING TIM

ws-0212

For more detailed instructions, see Edit Cycle Parameters in the 400LS/

500LS Series Steam Sterilizers Supervisor Manual.

Responding to Yes/No Message Boxes

Yes/No message boxes appear over process screens and are used to

confirm changes made by the user (i.e., Confirm Save/Cancel). The user

responds to the message box by pressing either the [YES] or [NO] softkey at

the bottom of the process screen.

For more detailed instructions, see Setup the Display Panel in the 400LS/

500LS Series Steam Sterilizers Supervisor Manual.

2–10

Page 39

400LS/500LS Series Steam Sterilizers

Exit from a Screen There are three commands used to exit from a screen:

• [CANCEL]—return to the previous screen without saving

changes

• [HOME]—return to the Main window and logs out the current

user.

• [OK]— return to the previous screen.

In the case of the Password Screen, pressing [OK] displays

the screen that corresponds to the function selected (when a

valid password is entered).

NOTES

• If both [OK] and [CANCEL] softkeys display:

a. Press [OK] to return to the previous screen.

b. When in edit mode (cursor blinking), press [CANCEL] to return to

the previous screen without saving any changes.

When not in edit mode, press [CANCEL] to return to the previous

screen

• If both [OK] and [CANCEL] (or [SAVE] and [CANCEL]) softkeys display,

the CONFIRM CANCEL? YES OR NO prompt appears when [CANCEL]

is pressed.

• The CONFIRM CANCEL? prompt can be turned off by changing the

CONFIRM SAVE/CANCEL setting on the PANEL SETUP Screen.

(See "Set up the Display Panel" in the 400LS/500LS Series Steam

Sterilizers Supervisor Manual)

61301608206 2–11

Page 40

Control Panel Navigation

2–12

Page 41

DAILY CHECKLIST

Section 3 Preparation for Use

HS

WARNING

NOTE

HOT SURFACES: The chamber and the gasket area could be

HOT. Turn OFF the controls and make sure the sterilizer is cool

before cleaning the gasket or removing the sediment screen for

cleaning.

Before operating the sterilizer each day:

1. Check the printer paper roll and replace it if necessary.

See Replacing the Printer Paper on page 4-21

2. Clean the sediment screens in the chamber drain.

See Cleaning the Sediment Screens on page 7-2

3. If the sterilizer is equipped with a steam boiler:

•allow the steam boiler to warm up for 20 to 30 minutes

before running a cycle.

•blow down the steam boiler as required.

See Manual Blow-Down on page 8-4

Some Getinge USA steam boilers are configured for automatic blow-down.

If your sterilizer has this feature, see "Automatic Blow-Down Package

(Option)" on page 8-7 for setup instructions for the automatic blow-down

option.

Operational Readiness To ensure that the sterilizer is ready for processing without requiring a

warm-up period:

• leave the sterilizer ON during regular periods of

sterilizer inactivity.

• close but do not seal the sterilizer door(s).

After daily operation, press CONTROLS OFF/ON to turn OFF the sterilizer

and allow the chamber time to cool down before cleaning the door gasket

and sediment screen.

61301608206 3–1

Page 42

Preparation for Use

LOAD PREPARATION

WARNING

CAUTION

NOTE

• RISK OF CONTAMINATION: Airborne microbial and

particulate contamination is likely to be high in the

preparation area. Wear appropriate personal protective

equipment when preparing items for cleaning.

• RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be repackaged and reprocessed.

• POSSIBILITY OF INJURY: Only use vented or open

containers to process liquids in this sterilizer. Use of sealed,

unvented containers to process liquids can result in severe

personal injury due to container breakage. Getinge USA

does NOT recommend or endorse use of such containers.

POSSIBILITY OF EQUIPMENT DAMAGE: use of sealed unvented

containers to process liquids can result in permanent damage to

the sterilizer.

RIGID CONTAINER SYSTEM USERS: Contact the Rigid Container System

Manufacturer to determine validated cycle parameters and proper loading of

contents into the containers.

The 400LS/500LS Series Steam Sterilizers are designed to steam-sterilize

laboratory goods and solutions. Typical applications include:

•utensils

•glassware

• porous goods

• non-porous hard goods

• non-flammable/non-volatile liquids in self-venting or open containers

Clean, package, and load items according to established procedures for

your workplace.

3–2

Page 43

400LS/500LS Series Steam Sterilizers

CREUTZFELDT-JAKOB DISEASE (CJD)

DECONTAMINATION

It is the responsibility of the laboratory facility to establish internal policies

and procedures relative to processing instruments that have or may have

been exposed to CJD. If instruments exposed to CJD are processed in

accordance with the World Health Organization (WHO) Infection Control

Guidelines for Transmissible Spongiform Encephalopathies (TSE), there

are:

POTENTIAL HAZARDS TO OPERATORS AND REPAIR PERSONNEL:

• Be sure to wear personal protective equipment (PPE) when

handling NaOH liquids.

• Heated NaOH liquids have the potential to injure personnel

who handle the containers.

• Heated NaOH liquids can emit fumes that can be corrosive to

eye tissue and can cause respiratory distress.

• Cleaning residual NaOH from the chamber interior could lead

to skin burns and the production of NaOH aerosol mist.

POTENTIAL DAMAGE TO THE STERILIZER:

• Processing caustic chemicals inside sterilizers is not

recommended.

• NaOH is corrosive to copper and brass and has the potential

to damage the chamber and lower piping.

Table 3–1. Load Chart

CYCLE TYPE TYPICAL LOAD

Gravity (grv)

Prevacuum (vac) Porous goods and hard goods

Liquids (liq)

Vacuum Leak Test (lkt) Empty chamber

• Hard goods, such as utensils and glassware

• Porous goods

• Goods that may be damaged if subjected to a

vacuum.

• Liquids in open or vented sealed containers

only

• Use flasks of Type 1 borosilicate (i.e. Pyrex

glass) only

61301608206 3–3

Page 44

Preparation for Use

TECHNIQUES FOR LOADING

POSSIBILITY OF INJURY: Only use vented or open containers

WARNING

CAUTION

to process liquids in this sterilizer. Use of sealed, unvented

containers to process liquids can result in severe personal

injury due to container breakage. Getinge USA does NOT

recommend or endorse use of such containers.

POSSIBILITY OF EQUIPMENT DAMAGE: use of sealed unvented

containers to process liquids can result in permanent damage to

the sterilizer.

The following recommendations apply both to the loading car and transfer

carriage (see page 3-9) and to the rack and extendable shelves (see page

3-12):

• All packages must be positioned in the chamber to allow free circulation

and penetration of steam, enhance air elimination, and prevent

entrapment of air or water.

• Do not overload the loading car or shelves. When placing items on the

car or shelves, be sure there is enough space for free circulation of steam

around each pack and each item. This also ensures adequate air

elimination, steam penetration, and drainage of condensate, which are all

needed to attain product sterility.

• Items capable of holding water, such as basins and trays, should be

oriented in the same direction and arranged so that any condensate

drains out. Wicking material such as absorbent towels should be used to

absorb condensate.

• Large or heavy metal items should be placed on the lowest shelf to

enable the condensate to drain out without wetting other items in the

load.

• When using non-woven wrap, ensure there are no low spots that might

hold condensation.

• When processing liquids in open containers, fill the containers to only

75% of capacity (e.g., 750 mL for a 1 liter container). This will limit the

liquid loss to < 6% of the volume.

• Heat penetration of liquid solutions is affected by both liquid volume and

container geometry. To ensure effective sterilization processing, liquid

loads should be of a uniform volume and container size.

3–4

Page 45

End of Cycle Routine

WARNINGS

NOTES

400LS/500LS Series Steam Sterilizers

• RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be reprocessed or repacked and reprocessed.

• RISK OF CONTAMINATION: Airborne microbial and

particulate contamination is likely to be high in the

preparation area. Wear appropriate personal protective

equipment when preparing items for cleaning.

• For detailed information regarding failure and fault conditions and

informational messages, refer to Diagnostic Message Types on page 6-2.

• For information regarding troubleshooting, refer to page 6-7.

The status of the completed load should be verified before removing the

load from the sterilizer. The following table outlines what to look for to

determine if a cycle completed successfully or aborted

61301608206 3–5

Page 46

Preparation for Use

.

Table 3–2. Cycle Result Determination

Successful Cycle Aborted Cycle

• CYCLE COMPLETE is printed on the printout below the

• CYCLE ABORTED is printed on the printout.

CYCLE RESULTS.

SAMPLE PRINTOUT--COMPLETED CYCLE SAMPLE PRINTOUT--ABORTED CYCLE

SIGNATURE:................

PROCESS END

14:35:41

CYCLE RESULTS

Exp. Temp Max 121.8C

Exp. Temp Min 121.5C

Overall Time at Temp 00:32:34

DAILY COUNTER 2

01:36:36 14.37 102.9

CYCL COMPLETE

01:36:04 14.31 106.8

CE UNSEALING

01:36:04 14.31 106.9

CYCLE COMPLETE

• CYCLE COMPLETE appears against a green background* in the cycle information portion of the Display

window (Figure 1–3, Area d).

• PROCESS COMPLETE status indicator is green indicating a successfully completed cycle.

(NOTE: The message/phase clears/changes when the sterilizer door opens.)

• STANDBY appears against a flashing red background* in

• The failure message appears against a flashing red back-

• Pulsing alarm tone is activated.

• PROCESS COMPLETE status indicator is flashing red

• PROCESS FAILURE status indicator is flashing red.

• The sterilizer’s control system remains in STANDBY.

• The alarm silences when CLEAR ALARM is pressed.

• The message clears when the cause of the failure is cor-

SIGNATURE:................

CYCLE ABORTED

00:03:11 14.26 88.8

AIR-IN

00:03:00 14.24 89.1

00:02:10 14.22 100.3

DRYING

00:02:00 18.69 107.8

00:01:26 37.23 126.9

ABORT -HIGH TEMP

00:01.26 37.23 126.9

CYCLE ABORTED

the cycle information portion of the Display window. (Figure 1–3, Area d)

ground* in the critical alarms portion of the Display window. (Figure 1–3, Area f).

indicating an aborted cycle.

rected and CLEAR ALARM is pressed.

• The door automatically unseals, remains closed, and

ready to open.

(NOTE: Doors on unidirectional units do NOT automatically

unseal; check the cycle printout to confirm results.)

*panel version 3.07 or later

3–6

• The door remains sealed.

(NOTE: The door remains sealed until the failure condition is

acknowledged.)

POSSIBILITY OF INJURY: If a

WATER IN DRAIN message

WARNING

displays, DO NOT open the

chamber door manually. Hot water

in the chamber may spill out if the door is

opened. Wait until the message clears before

attempting to open the door.

Page 47

Liquid RTD Placement (Option)

400LS/500LS Series Steam Sterilizers

WARNING

WARNINGS

BURN HAZARD: The liquid RTD may be HOT. Wear protective

gloves and glasses when placing the liquid RTD in the load or

removing it from the load.

Place the liquid RTD (load probe) into the center of the largest container

with the greatest volume of liquid and locate it in the coolest part of the

chamber (usually near the chamber drain). If the container is sealed, a selfventing automatic sealing stopper with an opening for the load probe is

required.

• POSSIBILITY OF INJURY: Only use vented or open

containers to process liquids in this sterilizer. Use of sealed,

unvented containers to process liquids can result in severe

personal injury due to container breakage. Getinge USA does

NOT recommend or endorse use of such containers.

• POSSIBILITY OF INJURY: Always keep the liquid RTD in the

storage holster (see Figure 3–1) when not in use. If the probe

is improperly stored, the controls may prematurely determine

that the cycle is complete. If the flasks are removed before

the cycle is complete, they may burst or crack.

POSSIBILITY OF EQUIPMENT DAMAGE: Use of sealed, unvented

CAUTION

Self-Venting

Automatic

Sealing Stopper

(bottom drain baffle

removed for clarity)

containers to process liquids can be result in permanent damage

to the sterilizer.

Figure 3–1. LIQUID RTD PLACEMENT

Drain

Storage Holster

Liquid RTD

(Load Probe)

WS-0226

61301608206 3–7

Page 48

Preparation for Use

NOTE

For more information about the load probe, see Liquid RTD Package on

page 12-1.

3–8

Page 49

LOADING ACCESSORIES

400LS/500LS Series Steam Sterilizers

CAUTION

Loading Car and Transfer Carriage (533LS only)

WARNING

Do not place items on the floor of the chamber. Always use the loading car

or shelf provided.

POSSIBILITY OF INJURY: The loading car can hold a

maximum load of 200 lbs. with a maximum of 100 lbs. evenly

distributed on each shelf. To avoid injury or equipment

damage, do not exceed these weight limits.

Figure 3–2. LOADING CAR AND TRANSFER CARRIAGE (533LS only)

Sterilizer

Chamber

Loading Car

(Door Open)

Track

Assembly

NOTES

Transfer

Carriage

Units equipped for racks and shelves

will not accept a loading car

and transfer carriage.

WS-0054

NOTE:

• Loading cars and transfer carriages are not available for 400LS Series

Steam Sterilizers.

• On power door units, be careful when aligning the transfer carriage with

the sterilizer chamber. Bumping the door control footswitch may

accidentally activate the door motor.

61301608206 3–9

Page 50

Preparation for Use

To transfer the loading car to the chamber:

1. Align the car and carriage directly in front of the open

chamber. Make sure the carriage’s locking rod handle is in

the down position (see Figure 3–3).

2. Move the transfer carriage forward until the carriage

contacts the sterilizer door and the notches in the transfer

carriage align with the chamber rails.

3. Turn the locking rod handle approximately 90° to the “Lock

to Sterilizer” position.

4. Push the loading car onto the track assembly located in the

chamber.

5. Turn the locking rod handle back to the "Unlock and

Transport" position, then pull the carriage away from the

sterilizer.

Figure 3–3. TRANSFER CARRIAGE OPERATION

Sterilizer

Chamber

Notch

Carriage Locking

Plate

Chamber

Rail

Loading

Car

Lock to

Sterilizer

LOCKING ROD HANDLE DETAIL

Locking Rod

Handle

Unlock and

Transport

Transfer

Carriage

Transfer

Carriage

Loading Car Frame

Carriage

Lock

Loading Car Frame

WS-0095

3–10

Page 51

400LS/500LS Series Steam Sterilizers

HS

WARNING

HOT SURFACES: The loading car may be hot enough to

cause burns. Wear protective gloves and eyewear when

loading and unloading the chamber.

To remove the loading car from the chamber:

1. Follow steps 1 through 3 on page 3-10 for positioning and

securing the transfer carriage in front of the open chamber.

2. Pull the loading car out of the chamber until the car’s axle

makes contact with the rod support rear block on the

carriage.

3. Turn the locking rod handle back to the “Unlock and

Transport” position.

4. Pull the carriage away from the sterilizer.

61301608206 3–11

Page 52

Preparation for Use

Rack and Extendable Shelves The rack and extendable shelves are constructed of 300 series stainless

steel. The shelves are removable to facilitate cleaning.

The rack can hold up to four shelves. Two shelves are supplied; additional

shelves may be purchased as an option.

WARNINGS

HS

shelf-caution1

20 lbs.

MAX

DO NOT EXCEED 20 POUNDS

ON EXTENDED SHELVES

• HOT SURFACES: The rack and shelves may be hot enough

to cause burns. Wear protective gloves when loading and

unloading the chamber.

• POSSIBILITY OF INJURY: Observe the following loading

recommendations:

-The rack can support a maximum load of 100 lbs. An

individual shelf can hold up to 100 lbs., evenly distributed.

-Do not place more than 20 lbs. on the end of an extended

shelf.

-Liquid loads (hot or cold) should never be placed on an

extended shelf.

-Do not extend a shelf with liquid loads (hot or cold).

Figure 3–4. RACK AND EXTENDABLE SHELVES

Rack

(100 lb. Total Load

All Shelves)

Extendable

Shelves

DO NOT EXTEND SHELVES

CONTAINING BOTTLES

NOTE

• Routine cleaning (see page 7-4) prolongs the useful life of the shelves, as

chlorides from the steam or spillage from liquid loads may otherwise

corrode 300 series stainless steel.

• For information on positioning shelves and racks, see "Installing/

Removing, & Adjusting Shelf Racks" on page 7-15.

CAUTION

Do not place items on the floor of the chamber. Always use the loading car

or shelf.

3–12

Page 53

SEQUENCE OF OPERATION

Section 4 Operating Instructions

This section covers the sequence a user may follow when sterilizing a load:

• Turning on the Controls—see page 4-2

• Previewing/Selecting a Cycle—see page 4-2.

• Loading the Sterilizer—see page 4-5.

• Editing Cycle Parameters—see page 4-6.

• Starting a Cycle—see page 4-7.

• Canceling a Cycle (Manual Abort)—see page 4-9.

• End of Cycle Routine—see page 4-10

• Unloading the Sterilizer—see page 4-12.

This section also covers:

• Opening and Closing the Sterilizer Door—see page 4-15.

• Operating the Printer—see page 4-19.

• Reading the Cycle Printout—see page 4-25.

• Performance Testing—see page 4-28.

61301608206 4–1

Page 54

Operating Instructions

E

P

A

OPERATING THE STERILIZER

Turning on the Controls For information regarding controls, see Turning ON the Controls on page 2-

7.

Previewing/Selecting a Cycle When making a cycle selection, pressing ENTER displays the exposure

time and temperature, drying time, and the cycle name for the selected

cycle at the top of the Main Display window (see Figure 4–1). This feature

permits preview of several different cycle settings before final selection.

After previewing the cycle, press OK to select the cycle.

NOTES

• The information that appears in the main display window depends on the

type of display chosen as the default (Details, Plot Graph, or Bar Graph).

• Press CANCEL at any time to return to the main display window without

selecting a cycle.

Figure 4–1. MAIN DISPLAY WINDOW (Bar Graph)

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

HAMBER TEM

37.3 C

121.1 C

Exposure Temp

00:30:00

Drying Time

HAMBER PSI

14.68 PSI

00:00:00

00:24:15

0

REMAINING TIM

SETUP

SELECT

CYCLE

PARA-

METER

UNSEAL

WS-0014-B

4–2

Page 55

400LS/500LS Series Steam Sterilizers

E

P

A

E

P

A

To select a cycle:

1. From the main display window, press [SELECT CYCLE].

The SELECT CYCLE screen appears.

Figure 4–2. SELECT CYCLE SCREEN

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

SELECT CYCLE

P01

P02

P03

P04

P05

P06

P07

CANCEL

HAMBER TEM

vac PREVAC1

vac PREVAC1

37.3 C

vac PREVAC1

vac PREVAC1

vac PREVAC1

vac PREVAC1

grv GRAVITY1

121.1 C

Exposure Temp

0

REMAINING TIM

00:30:00

Drying Time

HAMBER PSI

14.68 PSI

ws-0156 400_500LS

00:00:00

00:24:15

OK

2. Use the UP/DOWN arrows to scroll the list of cycles.

The black bar at the right side of the screen indicates more

cycles exist than will fit on one (1) screen. Continued

scrolling refreshes the screen and displays any additional

cycles.

Stop scrolling when the desired cycle is highlighted.

Press ENTER to view

the parameters for the

highlighted cycle.

Use the UP/DOWN arrows

to highlight a cycle

Press CANCEL at any time

to return to the Main Display

screen without selecting a cycle.

3. Press ENTER to preview the cycle parameters.

The cycle name and cycle parameters appear at the top of

the display window.

Figure 4–3. SELECTING A CYCLE

00:30:00

Exposure Time

P10 grv GRAVITY1

01 STANDBY

SELECT CYCLE

P01

P02

P03

P04

P05

P06

P07

CANCEL

HAMBER TEM

vac PREVAC1

vac PREVAC1

37.3 C

vac PREVAC1

vac PREVAC1

vac PREVAC1

vac PREVAC1

grv GRAVITY1

121.1 C

Exposure Temp

0

REMAINING TIM

00:30:00

Drying Time

HAMBER PSI

14.68 PSI

00:00:00

00:24:15

OK

-

1

Press [OK}

to confirm the

selected cycle

61301608206 4–3

Page 56

Operating Instructions

4. Verify the cycle parameters are correct for the load.

• If correct, press [OK] to confirm the cycle.

• If not correct, repeat steps 2 and 3 until the correct cycle

is selected.

NOTE

NOTE

Press CANCEL at any time to return to the main display window without

selecting a cycle.

The main display window displays.

If a cycle is highlighted without pressing [ENTER], pressing

[OK] will confirm the last cycle entered instead of the cycle

currently highlighted.

4–4

Page 57

Loading the Sterilizer

WARNINGS

CAUTION

400LS/500LS Series Steam Sterilizers

• BURN HAZARD: The door and chamber area could be HOT

enough to cause burns. Wear personal protective equipment

(PPE) when loading the chamber.

• POSSIBILITY OF INJURY: Do not operate the door while

loading or unloading the sterilizer.

• POSSIBILITY OF INJURY: Wear protective eyewear, and

gloves when handling liquids in containers.

• POSSIBILITY OF INJURY: Only use vented or open

containers to process liquids in this sterilizer. Use of sealed,

unvented containers to process liquids can result in severe

personal injury due to container breakage. Getinge USA

does NOT recommend or endorse use of such containers.

POSSIBILITY OF EQUIPMENT DAMAGE: Use of sealed, unvented

containers to process liquids can be result in permanent damage to the

sterilizer.

NOTE

To load the sterilizer:

1. Open the door (if necessary). See Opening and Closing

the Sterilizer Door on page 4-15.

2. Place the load into the chamber.

See Loading Car and Transfer Carriage (533HC only) on

page 3-9 or Rack and Extendable Shelves on page 3-12.

Always place the load on a shelf or rack. Do not place the load on the floor

of the chamber.

3. Close the door. See Opening and Closing the Sterilizer

Door on page 4-15.

61301608206 4–5

Page 58

Operating Instructions

Editing Cycle Parameters

• RISK OF CONTAMINATION: This sterilizer allows the user to

modify cycle settings, which may result in cycle parameters

that will not achieve the desired sterility assurance level

(SAL). Users with password access are responsible for

validation of any cycles that use other than the factory set

parameters.

• RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be repackaged and reprocessed.

After the load is placed within the sterilizer chamber, edit the cycle

parameters as necessary. A password is required to edit cycle parameters.

NOTE

For information regarding editing a cycle parameter, see Edit Cycle

Parameters in the 400LS/500LS Series Steam Sterilizers Supervisor

Manual.

4–6

Page 59

Starting a Cycle

400LS/500LS Series Steam Sterilizers

WARNINGS

• Before pressing START, verify that the appropriate cycle is

selected for the load being processed.

• POSSIBILITY OF INJURY: If the wrong cycle is selected for a

liquid load, the containers may burst or crack during

processing.

• RISK OF CONTAMINATION: If the wrong cycle is selected,

the desired sterility assurance level (SAL) may not be

reached.

• RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be reprocessed (unwrapped goods or liquids) or repacked

and reprocessed (wrapped goods).

• RISK OF CONTAMINATION: If the Process Failure indicator

is flashing, the cycle must be considered incomplete and the

load must be repackaged and reprocessed.

• RISK OF CONTAMINATION: If the sterilizer canceled the

cycle due to a power interruption, the load must be

repackaged and reprocessed.

• POSSIBILITY OF INJURY: Only use vented or open

containers to process liquids in this sterilizer. Use of sealed,

unvented containers to process liquids can result in severe

personal injury due to container breakage. Getinge USA

does NOT recommend or endorse use of such containers.

POSSIBILITY OF EQUIPMENT DAMAGE: Use of sealed, unvented

CAUTION

NOTE

containers to process liquids can be result in permanent damage to the

sterilizer.

If the control panel shows UTILITY SHUTDOWN, see Bypassing Utility

Shutdown Mode on page B-53.

61301608206 4–7

Page 60

Operating Instructions

To begin the sterilization cycle:

1. Press START.

a. The door(s) automatically seal (if not previously

sealed) and the DOOR(S) SEALED LED illuminates.

b. During the cycle, the IN PROCESS LED illuminates

and the chamber temperature and the elapsed time in

each phase display on the display screen.

c. At the end of the cycle, the PROCESS COMPLETE

LED illuminates and the buzzer sounds (the buzzer

silences automatically).

If the LED appears green, the cycle is complete.

If the LED appears flashing red, the cycle was aborted.

If a process failure occurs, the PROCESS FAILURE LED

!

flashes, an alarm sounds, the process stops, and a

diagnostic message appears on the printout.

NOTE

!

The failure message appears against a flashing red background* in the

critical alarms portion of the Display window. (Figure 1–3, Area f).

• Press CLEAR ALARM to clear the message (if the alarm

has corrected) and silence the alarm.

• Refer to Diagnostic Messages on page 6-8 for corrective

action.

4–8

Page 61

Canceling a Cycle (Manual Abort)

400LS/500LS Series Steam Sterilizers

WARNING

NOTE

RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be repackaged and reprocessed.

A cycle can be cancelled during any phase. However, the softkeys at the

bottom of the display screen show different labels depending on the phase

of the cycle. If the cycle is in a timed phase (i.e. exposure), [MORE]

displays. If the cycle is in an untimed phase (i.e. heat-up), [ABORT]

displays.

See Canceling a Cycle (Manual Abort) on page 5-2.

If the CONTROLS OFF/ON button is pressed during a cycle, the cycle will

abort (after a 2 second timer expires). Therefore, this is not the

recommended method to manually abort a cycle. Use the [ABORT] softkey

instead

61301608206 4–9

Page 62

Operating Instructions

End of Cycle Routine

WARNING

CAUTION

• RISK OF CONTAMINATION: If the cycle is cancelled or

aborted, it must be considered incomplete and the load must

be repackaged and reprocessed.

• RISK OF CONTAMINATION: If the Process Failure indicator

is flashing, the cycle must be considered incomplete and the

load must be repackaged and reprocessed.

• RISK OF CONTAMINATION: If the sterilizer canceled the

cycle due to a power interruption, the load must be

repackaged and reprocessed.

• POSSIBILITY OF INJURY: Only use vented or open

containers to process liquids in this sterilizer. Use of sealed,

unvented containers to process liquids can result in severe

personal injury due to container breakage. Getinge USA