Page 1

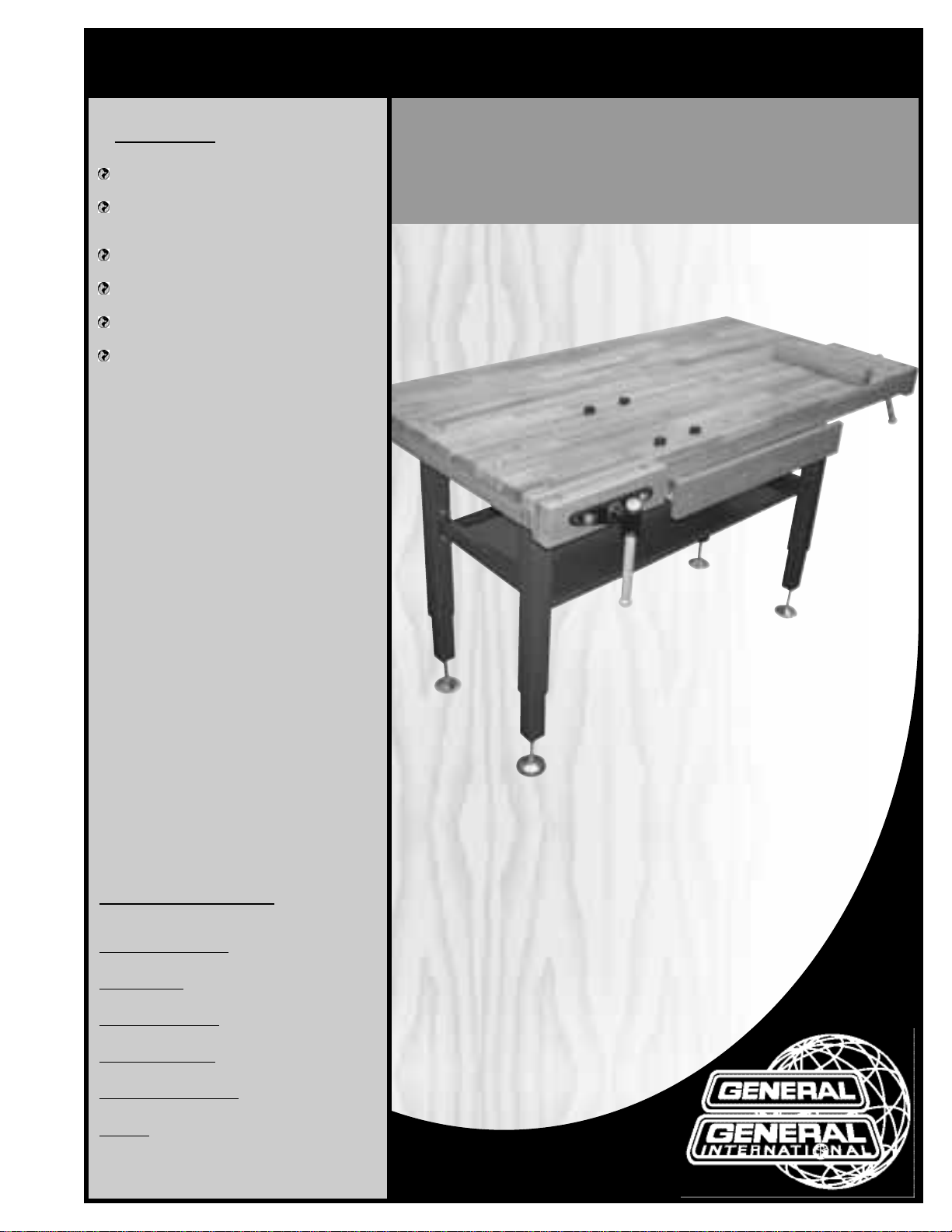

FEATURES

Solid 1”thick table top with 3”apron for

extra support around the edges.

Includes both front and end vises with a

double row of bench dog holes in the

table for each vise.

Large storage drawer on ball bearing

slides.

Sturdy adjustable height (33”- 39”) steel

legs.

Includes four bench dogs and one wooden stopper bar.

Durable lacquer finish on all wooden components.

SPECIFICATIONS

TABLE DIMENSIONS

60”x 30” x 1” (1524 x 762 x 25.4 mm)

DRA

WER SIZE

23 5⁄8”x 12 1⁄2”x 2 3⁄8”(600 x 320 x 60 mm)

VISE DIMENSIONS

13”x 3 1/2” x 2” (330 x 90 x 50 mm)

MAX

VISE TRAVEL

4”(100 mm)

T

ABLE HEIGHT RANGE

33”- 39” (838 - 991 mm)

WEIGHT

147 LBS (67 kg)

SETUP & OPERATION MANUAL

MODEL

#95-060

REVISION 1 - OCTOBER 13/09

© COPYRIGHT GENERAL INTERNATIONAL 10/2009

60” X 30”OAK WORKBENCH

WITH STEEL LEGS

Page 2

THANK YOU

for choosing this General®International model 95-060 60” x 30”

Oak Workbench With Steel Legs. This workbench has been carefully tested and inspected

before shipment and if properly used and maintained, will provide you with years of reliable

service.To ensure optimum performance and trouble-free operation,and to get the most from

your investment, please take the time to read this manual before assembling, installing and

operating the unit.

The manual’s purpose is to familiarize you with the safe operation,basic function,and features

of this workbench as well as the set-up,maintenance and identification of its par ts and components. This manual is not intended as a substitute for formal woodworking instruction, nor to

offer the user instruction in the craft of woodworking. If you are not sure about the safety of

performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources,that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

Disclaimer:

The information and specifications in this

manual pertain to the unit as it was supplied from the

factory at the time of printing. Because we are committed to making constant improvements, General

®

International reserves the right to make changes to

components, parts or features of this unit as deemed

necessary,without prior notice and without obligation to

install any such changes on previously delivered units.

Reasonable care is taken at the factory to ensure that

the specifications and information in this manual corres-

ponds with that of the unit with which it was supplied.

However, special orders and “after factory” modifications may render some or all information in this manual

inapplicable to your unit.Further,as several generations

of this model of workbench and several versions of this

manual may be in circulation, if you own an earlier or

later version of this workbench, this manual may not

depict your unit exactly.If you have any doubts or questions contact your retailer or our support line with the

model number of your unit for clarification.

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

Page 3

GENERAL®& GENERAL®INTERNATIONAL WARRANTY

All component parts of General®, General® International and Excalibur by General

International ® products are carefully inspected during all stages of production and each unit

is thoroughly inspected upon completion of assembly.

Limited Lifetime

Warranty

Because of our commitment to quality and customer satisfaction, General® and General®

International agree to repair or replace any part or component which upon examination,

proves to be defective in either workmanship or material to the original purchaser for the life

of the tool.

However, the Limited Lifetime Warranty does not cover any product used for professional or commercial production purposes nor for industrial or educational applications. Such

cases are covered b y our Standar d 2-year Limited W arranty only.The Limited Lifetime Warranty

is also subject to the “Conditions and Exceptions”as lis ted below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial,

industrial and educational applications are warranted for a period of 2 years (24 months) from

the date of purchase. General® and General® Inter national agree to repair or replace any

part or component which upon examination, proves to be defective in either workmanship or

material to the original purchaser during this 2-year warranty period, subject to the “conditions

and exceptions”as lis ted below.

T

o file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime

Warranty, all defective parts, components or machinery must be returned freight or pos tage

prepaid to General® International, or to a nearby distributor, repair center or other location

designated by General® International. For further details call our service department at 1-888949-1161 or your local distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty,a copy of the original proof

of purchase and a “letter of claim”must be included (a warranty claim form can also be used

and can be obtained,upon request,from General® International or an authorized distributor)

clearly stating the model and serial number of the unit (if applicable) and including an explanation of the complaint or presumed defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not

required but documented proof of purchase i.e. a copy of original sales invoice or receipt

showing the date and location of the purchase as well as the purchase price paid, must be

provided at the time of claim.

Warranty does not include f ailures,breakage or defects deemed after inspection by General®

or General® International to have been directly or indirectly caused by or resulting from;

improper use, or lack of or improper maintenance, misuse or abuse, negligence, accidents,

damage in handling or transport, or nor mal wear and tear of any generally considered consumable parts or components .

Repairs made without the written consent of General® Interna tionallwill void all warranty.

Page 4

Carefully unpack and remove the unit and its components from its shipping container and check for missing or

damaged items as per the list of contents below.

NOTE: Please report any damaged or missing items to your GENERAL® INTERNATIONAL distributor immediately.

UNPACKING

LIST OF CONTENTS QTY

A - TABLE...........................................................................................1

B - STORAGE SHELF..........................................................................1

C - STOPPER BAR ..............................................................................1

D - BENCH DOG (STOPPER) ...........................................................4

E - SCREW ASSEMBLY W/VISE SUPPORT BRACKET.........................2

F - UPPER SUPPORT LEG ..................................................................4

G - LOWER SUPPORT LEG.................................................................4

H - DRAWER SIDE PANEL..................................................................2

I - VISE FACE ...................................................................................2

J - VISE HANDLE ..............................................................................2

K - GLUE TUBE...................................................................................1

L - DRAWER REAR PANEL.................................................................1

M - DRAWER FRONT PANEL ..............................................................1

N - DRAWER BOTTOM PANEL...........................................................1

O - DRAWER MOUNTING BLOCK....................................................2

P - LEVELLING FOOT W/HEX NUTS .................................................4

Q - HEX HEAD BOLT........................................................................16

R - FLAT WASHER............................................................................16

S - DOWEL......................................................................................12

T - HEX HEAD WOOD SCREW .......................................................16

U - ROUND HEAD WOOD SCREW ...................................................6

V - FLAT HEAD WOOD SCREW ........................................................8

W - FLAT HEAD WOOD SCREW......................................................20

A

E

I

D

F

G

L

M

N

B

H

O

12X

16X

6X

8X

20X

S

T

U

V

W

4

ADDITIONAL REQUIREMENTS FOR SET UP

• 12 mm open end wrench

• 13 mm open end wrench or socket wrench

• Phillips Screwdriver

• Straightedge

or

P

16X

Q

16X

R

C

J

K

Page 5

ASSEMBLY INSTRUCTIONS

Note: The parts reference numbers in brackets in the assembly instructions written in this manual refer to the reference number of the item as shown in the parts diagram on page 8 of this manual.

TABLE ASSEMBL

Y

A

B

C

D

E

F

DRAWER ASSEMBL

Y

Assemble the drawer as shown using 8 dowels and 8

30 mm flat head wood screws.

SUPPORT LEG ASSEMBLY

Assemble the 4 support legs as shown using 2 hex head

bolts and washers per legs.

Note: Support legs adjust in height from 33” to 39”. Select

the mounting holes that will best fit your height requirements.

5

8X

8X

2X

1. Disassemble both screw assemblies w/vise support bracket by loosening bolts A with a 12 mm

wrench.Remove and set aside bolts A, flat washers

B and screw assemblies C.

2. From the underside of the table, align the holes on

the vise support bracket D with the holes on the

side edge of the table E and secure using six 13

mm flat head wood screws (8) (supplied).

3. Repeat with the second vise support bracket on

the front edge of the table F.

4. Attach the drawer mounting blocks (35) and (36)

to the table mounting blocks as shown using 4 dowels (4) and 6 round head wood screws (3).

Note: The drawer mounting blocks must be oriented with

the rubber stopper G toward the rear of the table

G

Page 6

ATT

ACH THE SUPPORT LEGS TO T

ABLE

4X

Attach the support legs to the underside of the table as

shown,using 4 hex head wood bolts per leg and tighten with a 13 mm wrench.

Note: The right front leg and left front leg (both with a hole

for the vises’ screw) align with the right side edge and front

edge of the table, respectively as shown in H and I.

Note: Do not fully tighten the bolts yet.

H

I

A

TT

ACH THE STORAGE SHELF TO SUPPORT LEGS

Note: The storage shelf is heavy .Have an assistant hold the

shelf while you secure it to the support legs.

Attach the storage shelf to the support legs as shown,

using 2 hex head bolts and washers per leg and tighten with a 13 mm wrench. With the storage shelf secured to the support legs, fully tighten the bolts that

secure the support legs to the table.

2X

VISE ASSEMBLY

2. From under the table,re-install the flat washers and

bolts previously removed in section “TABLE ASSEMBBLY”, step 1, and tighten with a 12 mm wrench.

J

K

1. Insert the screw assembly (1N) through the mid-

dle hole of a vise face (10N) then thread the screw

in the middle hole of the vise support bracket, on

the right side of the workbench.

Note:

Do not thread the screw all the way in yet.

4. Remove the end cap (13) from both ends of one

vise handle (12) then insert the handle through

handle holder as shown and glue the caps back

on the handle using the supplied glue tube.

5. Repeat steps 1 to 4 with the second screw assembly on the front edge of the workbench.

3. Place a straightedge J on the table and vise face.

Manually adjust the vise face K so it is leveled with

the table top then firlmy tighten the screw (1N) to

secure the vise face in position. With the vise face

leveled with the table top,secure the screw assembly to the vise face with 4 wood screws (8).

6

Page 7

INSTALL THE DRAWER

Fit the drawer between the two slides on the drawer

mounting block and push it all the way in.

VISE & BENCH DOG USAGE EXAMPLES

The supplied vises and bench dogs can be used in a wide variety of situations and configurations where clamping

or securing a workpiece to the bench may be useful. Here are but a few examples of the possible uses for the vises

and bench dogs.You may discover, or already have many others , based on your own specific shop needs.

7

Notes

Page 8

4

5

8

7

14

9

15

17

16

18

19

12

13

5

2N

5

5

6

11

1N

2N

12

13

32

33

5

5

35

36

4

4

DIAGRAM

8

Page 9

9

PARTS LIST

95-060

REF N0. PART N0. DESCRIPTION SPECIFICATION QTY

1N 95060-1N SCREW 2

2N 95060-2N SUPPORT ROD 4

3 95060-3 ROUND HEAD WOOD SCREW 1/4" X 1-1/2" 20

4 95060-4 DOWEL 8X30MM 8

5 95060-5 FLAT HEAD WOOD SCREW M4X30MM 8

6 95060-6 GLUE TUBE 1

7 95060-7 SLIDE RAIL 350X18X7MM 2

8 95060-8 FLAT HEAD WOOD SCREW M4X13MM 6

9 95060-9 TABLE 1

10N 95060-10N VISE FACE 2

11 95060-11 STOPPER BAR 1

12 95060-12 VISE HANDLE 2

13 95060-13 END CAP 2

14 95060-14 BENCH DOG (STOPPER) 4

15 95060-15 DRAWER FRONT PANEL 1

16 95060-16 DRAWER LEFT SIDE PANEL 1

17 95060-17 DRAWER RIGHT SIDE PANEL 1

18 95060-18 DRAWER REAR PANEL 1

19 95060-19 DRAWER BOTTOM PANEL 1

20 95060-20 RIGHT FRONT UPPER SUPPORT LEG 1

21 95060-21 LOWER STAND 4

22 95060-22 LEVELLING FOOT 1/2"X4" 4

23 95060-23 STORAGE SHELF 1

24 95060-24 HEX HEAD WOOD SCREW 5/16"X1" 16

25 95060-25 HEX HEAD BOLT 5/16"X3/4" 16

27N 95060-27N VISE SUPPORT BRACKET 2

30 95060-30 FLAT WASHER 4

31 95060-31 CAP NUT 4

32 95060-32 FLAT WASHER 4

33 95060-33 HEX BOLT 4

34 95060-34 REAR UPPER SUPPORT LEG 2

35 95060-35 DRAWER RIGHT MOUNTING BLOCK 1

36 95060-36 DRAWER LEFT MOUNTING BLOCK 1

37 95060-37 LEFT FRONT UPPER SUPPORT LEG 1

38 95060-38 FLAT WASHER 16

Page 10

IMPORTANT

When ordering replacement parts, always give the model number, serial number of the machine and

part number. Also a brief description of each item and quantity desired.

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / Fax: (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

MODEL 95-060

Loading...

Loading...