Page 1

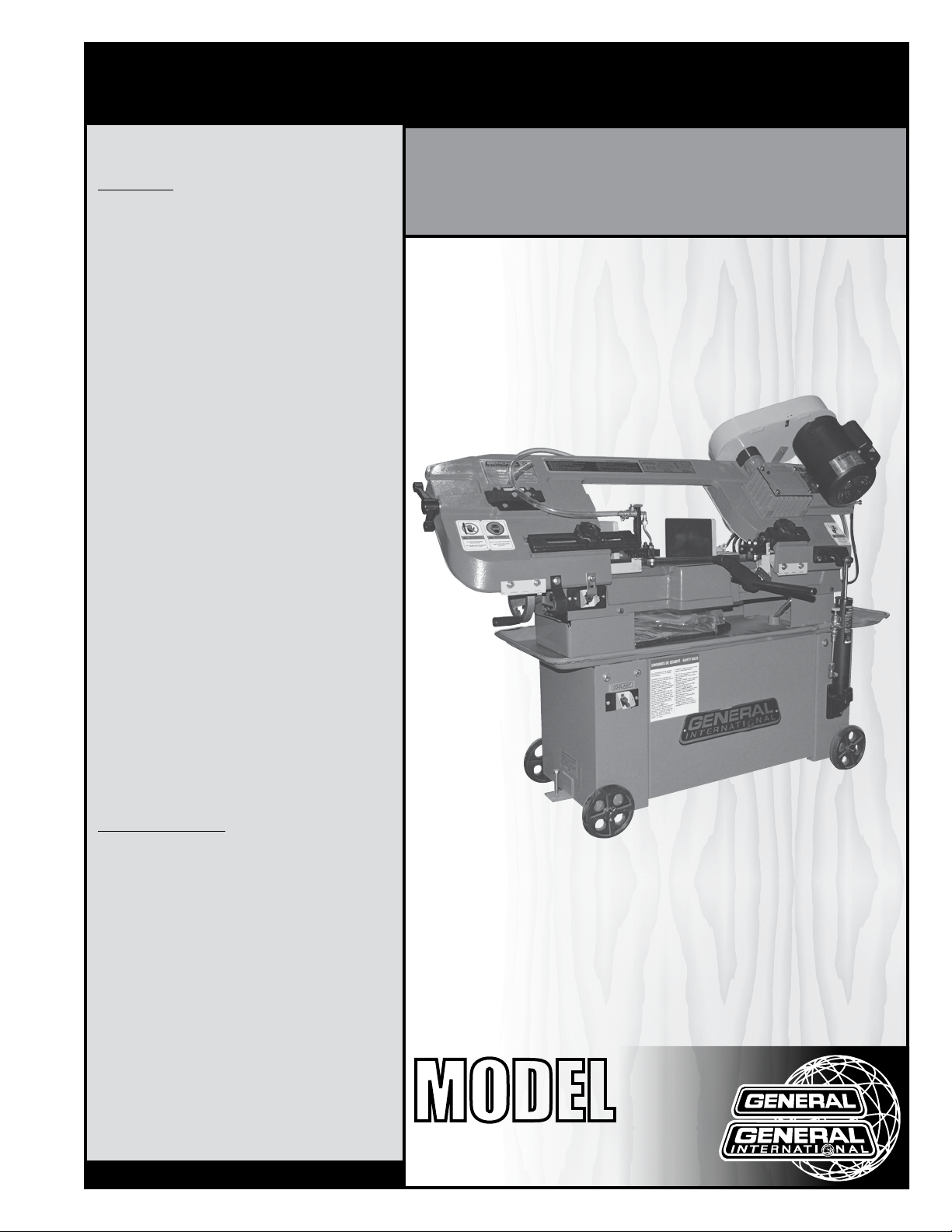

SETUP & OPERATION MANUAL

FEATURES

Horizontal or vertical cutting.

Automatic shut-off.

Chip brush and safety guard included.

Adjustable blade tension and guide bearings.

Adjustable hydraulic down feed control.

Coolant system with built-in tank and pump.

4-speed design.

7” X 10” METAL CUTTING BANDSAW

SPECIFICATIONS

• Cutting capacity at 90º (Rectangular)

7” x 10 7/8” (180 x 275 mm)

• Cutting capacity at 90º (Round)

7” (179 mm)

• Cutting capacity at 45º (Rectangular)

4” x 7” (102 x 178 mm)

• Cutting capacity at 45º (Round)

4” (102 mm)

• Blade size

3/4” x 0.035” x 93” (19 x 0.9 x 2360 mm)

• Blade speeds (4)

86, 132, 178 & 260 fpm (26, 40, 54 & 79 mpm)

• Overall dimensions (L x W x H)

49 1/4” x 27 1/8” x 40 3/4” (1250 x 690 x 1035 mm)

• Motor (pre-wired 120 V)

1 HP, 120/240 V, 1 Ph, 9/4.5 A

• Weight

330 lbs (150 kg)

Version #1_Revision #1 - September 2014

© Copyright General International

MODEL

#

90-730

Page 2

GENERAL® INTERNATIONAL

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Telephone (514) 326-1161 • Fax (514) 326-5555 • www.general.ca

THANK YOU

for choosing this General® International model 90-730 7” x

10” Metal Cutting Bandsaw. This bandsaw has been carefully tested and inspected before

shipment and if properly used and maintained, will provide you with years of reliable service.

For your safety, as well as to ensure optimum performance and trouble-free operation, and to

get the most from your investment, please take the time to read this manual before assembling,

installing and operating the unit.

The manual’s purpose is to familiarize you with the safe operation, basic function, and

features of this bandsaw as well as the set-up, maintenance and identification of its parts and

components. This manual is not intended as a substitute for formal metalworking instruction,

nor to offer the user instruction in the craft of metalworking. If you are not sure about the safety

of performing a certain operation or procedure, do not proceed until you can confirm, from

knowledgeable and qualified sources, that it is safe to do so.

Once you’ve read through these instructions, keep this manual handy for future reference.

DISCLAIMER: The information and specifications

in this manual pertain to the unit as it was supplied

from the factory at the time of printing. Because we

are committed to making constant improvements,

General® International reserves the right to make

changes to components, parts or features of this unit

as deemed necessary, without prior notice and without

obligation to install any such changes on previously

delivered units. Reasonable care is taken at the factory

to ensure that the specifications and information in this

manual corresponds with that of the unit with which it

was supplied. However, special orders and “after factory”

modifications may render some or all information in

this manual inapplicable to your machine. Further,

as several generations of this model of Metal Cutting

Bandsaw and several versions of this manual may be

in circulation, if you own an earlier or later version of

this unit, this manual may not depict your unit exactly. If

you have any doubts or questions contact your retailer

or our support line with the model and serial number of

your unit for clarification.

Page 3

GENERAL® INTERNATIONAL WARRANTY

All component parts of General® International and Excalibur by General International® products

are carefully inspected during all stages of production and each unit is thoroughly inspected upon

completion of assembly.

Limited Lifetime Warranty

Because of our commitment to quality and customer satisfaction, General® International agrees to

repair or replace any part or component which upon examination, proves to be defective in either

workmanship or material to the original purchaser for the life of the tool. However, the Limited Lifetime

Warranty does not cover any product used for professional or commercial production purposes nor

for industrial or educational applications. Such cases are covered by our Standard 2-year Limited

Warranty only. The Limited Lifetime Warranty is also subject to the “Conditions and Exceptions” as listed

below.

Standard 2-Year Limited Warranty

All products not covered by our lifetime warranty including products used in commercial, industrial

and educational applications are warranted for a period of 2 years (24 months) from the date of

purchase. General® International agrees to repair or replace any part or component which upon

examination, proves to be defective in either workmanship or material to the original purchaser during

this 2-year warranty period, subject to the “conditions and exceptions” as listed below.

To file a Claim

To file a claim under our Standard 2-year Limited Warranty or under our Limited Lifetime Warranty,

all defective parts, components or machinery must be returned freight or postage prepaid to

General® International, or to a nearby distributor, repair center or other location designated by

General® International. For further details call our service department at 1-888-949-1161 or your local

distributor for assistance when filing your claim.

Along with the return of the product being claimed for warranty, a copy of the original proof of purchase

and a “letter of claim” must be included (a warranty claim form can also be used and can be obtained,

upon request, from General® International or an authorized distributor) clearly stating the model and

serial number of the unit (if applicable) and including an explanation of the complaint or presumed

defect in material or workmanship.

CONDITIONS AND EXCEPTIONS:

This coverage is extended to the original purchaser only. Prior warranty registration is not required but

documented proof of purchase i.e. a copy of original sales invoice or receipt showing the date and

location of the purchase as well as the purchase price paid, must be provided at the time of claim.

Warranty does not include failures, breakage or defects deemed after inspection by

General® International to have been directly or indirectly caused by or resulting from; improper use,

or lack of or improper maintenance, misuse or abuse, negligence, accidents, damage in handling or

transport, or normal wear and tear of any generally considered consumable parts or components.

Repairs made without the written consent of General® International will void all warranty.

Page 4

TABLE OF CONTENTS

Rules for safe operation ..................................................................................................... 5

Electrical requirements ...................................................................................................... 6

Identification of main parts and components .................................................................. 7

Unpacking .......................................................................................................................... 8

Basic functions ................................................................................................................... 8

Placement within the shop ................................................................................................ 9

Assembly instructions ................................................................................................... 9-11

Installing the wheels ........................................................................................................................................... 9

Installing the pulley cover ................................................................................................................................10

Installing the work stop .................................................................................................................................... 10

Installing the table for vertical cutting ............................................................................................................ 10

Install the coolant/recovery tray filter ............................................................................................................ 11

Basic adjustments and controls ................................................................................. 11-18

Connecting to a power source .......................................................................................................................11

Main On/Off switch ........................................................................................................................................... 11

Removing/installing a blade .......................................................................................................................... 12

Adjusting blade tension ................................................................................................................................... 13

Adjusting blade tracking ................................................................................................................................. 13

Squaring the blade to the work table ............................................................................................................ 14

Squaring the vise to the table/using the vise ................................................................................................ 14

Adjusting the blade guides ............................................................................................................................. 15

Adjusting the thrust bearings ........................................................................................................................... 16

Adjusting the blade guards ............................................................................................................................. 16

Changing speeds ............................................................................................................................................. 16

Speed selection chart ...................................................................................................................................... 17

Cutting feed rate ............................................................................................................................................... 17

Using the coolant pump .................................................................................................................................. 17

Immobilizing the machine .............................................................................................................................. 18

Operating Instructions ................................................................................................ 18-19

Checklist before starting .................................................................................................................................. 18

Operations step-by-step ................................................................................................................................... 18

Maintenance ............................................................................................................... 19-20

Cleaning ............................................................................................................................................................ 19

Lubrication ......................................................................................................................................................... 19

Changing the belt & aligning the pulleys ..................................................................................................... 20

Trouble shooting ..........................................................................................................................................21-22

Parts list & diagram .................................................................................................... 23-29

Contact information ........................................................................................................ 30

Page 5

RULES FOR SAFE OPERATION

To help ensure safe operation, please take a moment to learn the machine’s applications and limitations,

as well as potential hazards. General

harmless for any injury that may result from the improper use of it’s equipment.

1. Do not operate the bandsaw when tired, distracted

or under the effects of drugs, alcohol or any medI cation that impairs reflexes or alertness.

2. The work area should be well lit, clean and free

of debris.

3. Keep children and visitors at a safe distance when

the bandsaw is in operation; do not permit them to

operate the bandsaw.

4. Childproof and tamper proof your shop and all ma chinery with locks, master electrical switches and

switch keys, to prevent unauthorized or unsupervised

use.

5. STAY ALERT! Give your work your undivided attention.

Even a momentary distraction can lead to serious

injury.

6. Fine particulate dust is a carcinogen that can be

hazardous to health. Work in a well-ventilated area.

Wear face, eye, ear, respiratory and body protec tion devices.

7. Do not wear loose clothing, gloves, bracelets,

necklaces or other jewelry while the bandsaw is in

operation.

8. Be sure that adjusting wrenches, tools, drinks and

other clutter are removed from the machine and/or

the table surface before operating.

9. Keep hands well away from the blade and all

moving parts. Use a brush, not hands, to clear away

chips and dust.

10. Adjust and position the blade guides before starting

to cut.

11. Adjust blade tension and tracking before starting to

cut.

12. Blade teeth must point down toward the table.

13. Be sure that the blade has gained full operating

speed before starting to cut.

14. Always use a clean, properly sharpened blade.

Dirty or dull blades are unsafe and can lead to

accidents.

®

International disclaims any real or implied warranty and hold itself

15. Use suitable workpiece support if the workpiece

does not have a flat surface.

16. Make sure the workpiece is securely held in place

in the vise.

17. Do not work on long stock without adequate sup port on the out feed end of the table.

18. Do not push or force stock into the blade. The band saw will perform better and more safely when work ing at the rate for which it was designed.

19. Avoid working from awkward or off balance posi tions. Do not overreach and keep both feet on floor.

20. Keep guards in place and in working order. If a

guard must be removed for maintenance or clean ing be sure it is properly re-attached before using

the saw again.

21. Never leave the machine unattended while it is run- ning or with the power on.

22. Use of parts and accessories NOT recommended

by General

malfunction or risk of injury.

23. Never stand on machinery. Serious injury could re sult if the tool is tipped over or if the cutting tool is

unintentionally contacted.

24. Always disconnect the saw from the power

source before servicing or changing accessories

such as blades, or before performing any mainte nance or cleaning, or if the machine will be left

unattended.

25. Make sure that the switch is in the “OFF” position

before plugging in the power cord.

26. Make sure the machine is properly grounded. If

equipped with a 3-prong plug it should be used with

a three-pole receptacle. Never remove the third

prong.

27. Do not use this bandsaw for other than

its intended use. If used for other purposes,

General® International disclaims any real or im plied warranty and holds itself harmless for any in jury, which may result from that use.

®

International may result in equipment

5

Page 6

ELECTRICAL REQUIREMENTS

BEFORE CONNECTING THE MACHINE TO THE POWER SOURCE, VERIFY THAT THE VOLTAGE OF YOUR POWER

SUPPLY CORRESPONDS WITH THE VOLTAGE SPECIFIED ON THE MOTOR I.D. NAMEPLATE. A POWER SOURCE

WITH GREATER VOLTAGE THAN NEEDED CAN RESULT IN SERIOUS INJURY TO THE USER AS WELL AS DAMAGE

TO THE MACHINE. IF IN DOUBT, CONTACT A QUALIFIED ELECTRICIAN BEFORE CONNECTING TO THE POWER

SOURCE.

THIS TOOL IS FOR INDOOR USE ONLY. DO NOT EXPOSE TO RAIN OR USE IN WET OR DAMP LOCATIONS.

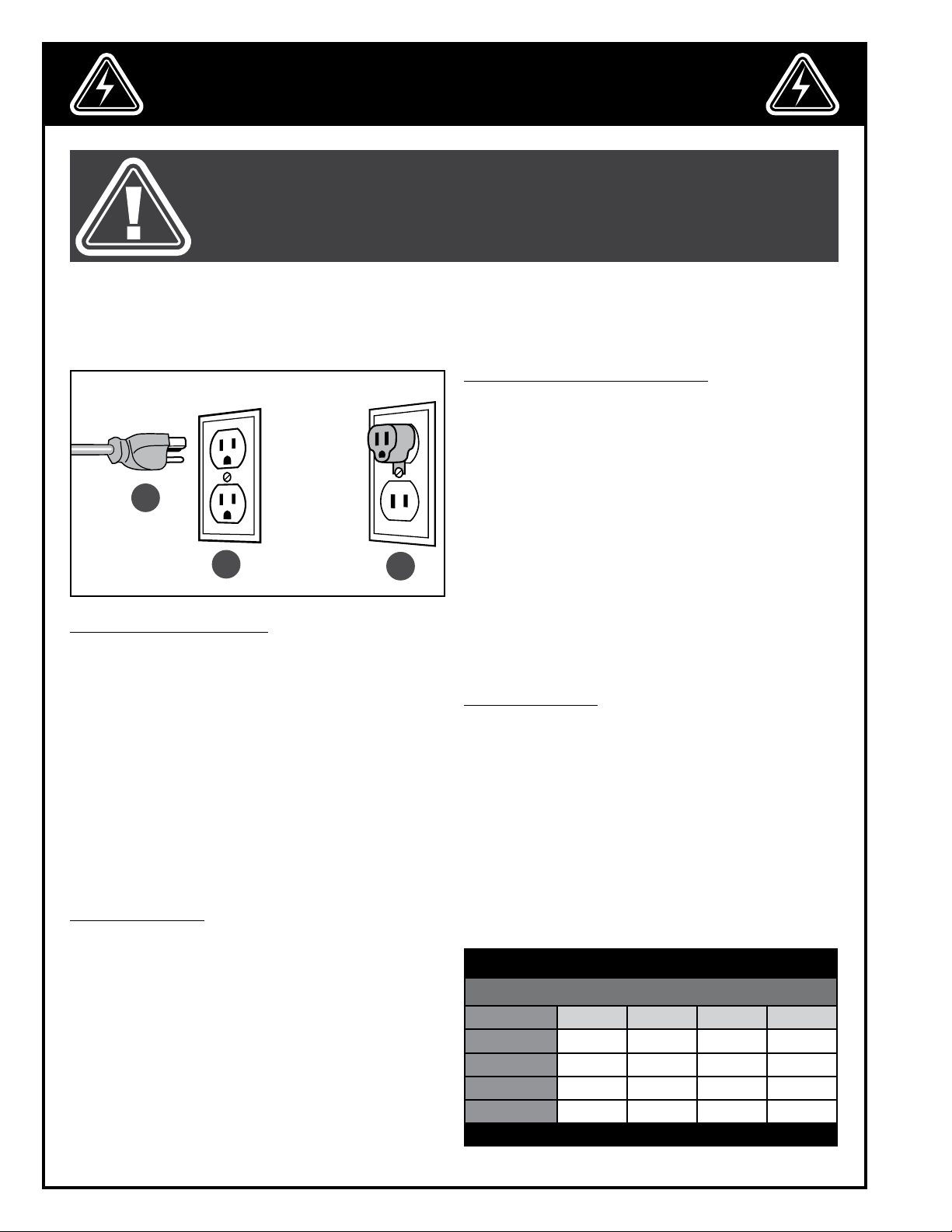

A

B

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short circuit,

grounding reduces the risk of electric shock. The motor

of this machine is wired for 120 V single phase operation and is equipped with a 3-conductor cord and a

3-prong grounding plug A to fit a grounded type receptacle B. Do not remove the 3rd prong (grounding pin)

to make it fit into an old 2-hole wall socket or extension

cord. If an adaptor plug is used C, it must be attached

to the metal screw of the receptacle.

Note: The use of an adaptor plug is illegal in some

areas. Check your local codes. If you have any doubts

or if the supplied plug does not correspond to your

electrical outlet, consult a qualified electrician before

proceeding.

CIRCUIT CAPACITY

Make sure that the wires in your circuit are capable of

handling the amperage draw from your machine, as

well as any other machines that could be operating on

the same circuit. If you are unsure, consult a qualified

electrician. If the circuit breaker trips or the fuse blows

regularly, your machine may be operating on a circuit

that is close to its amperage draw capacity. However,

if an unusual amperage draw does not exist and a

power failure still occurs, contact a qualified technician

or our service department.

C

CONVERTING THE MOTOR TO 240V

Note: When converting motor voltage on a machine that

is equipped with a magnetic switch, the switch contactor

must also be changed out for one made for the appropriate voltage, as well as the thermal relay/circuit breaker

and “power in” indicator light (if applicable). Failure to

make these necessary modifications to the switch will lead

to malfunction and permanent switch failure.

Should you need to convert your machine’s motor

from 120 V to 240 V power, contact a qualified electrician. Unless you are a qualified electrician, we do

not recommend attempting this conversion on your

own. If you choose to do so, you may risk serious personal injury, damage to the motor and voiding the

warranty of your machine. We suggest you ask your

local General International distributor to recommend

qualified electricians in your area (or perhaps one of

their own technicians) who can make this conversion

properly and safely.

EXTENSION CORDS

If you find it necessary to use an extension cord with

your machine, use only 3-wire extension cords that have

3-prong grounding plug and a matching 3-pole receptacle that accepts the tool’s plug. Repair or replace a

damaged extension cord or plug immediately.Make

sure the cord rating is suitable for the amperage listed

on the motor I.D. plate. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. The accompanying chart shows the correct

size extension cord to be used based on cord length

and motor I.D. plate amp rating. If in doubt, use the next

heavier gauge. The smaller the number, the heavier the

gauge.

TABLE - MINIMUM GAUGE FOR CORD

EXTENSION CORD LENGTH

AMPERES 50 feet 100 feet 200 feet 300 feet

< 5

6 to 10

10 to 12

12 to 16

*NR = Not Recommended

18 16 16 14

18 16 14 12

16 16 14 12

14 12 *NR *NR

6

Page 7

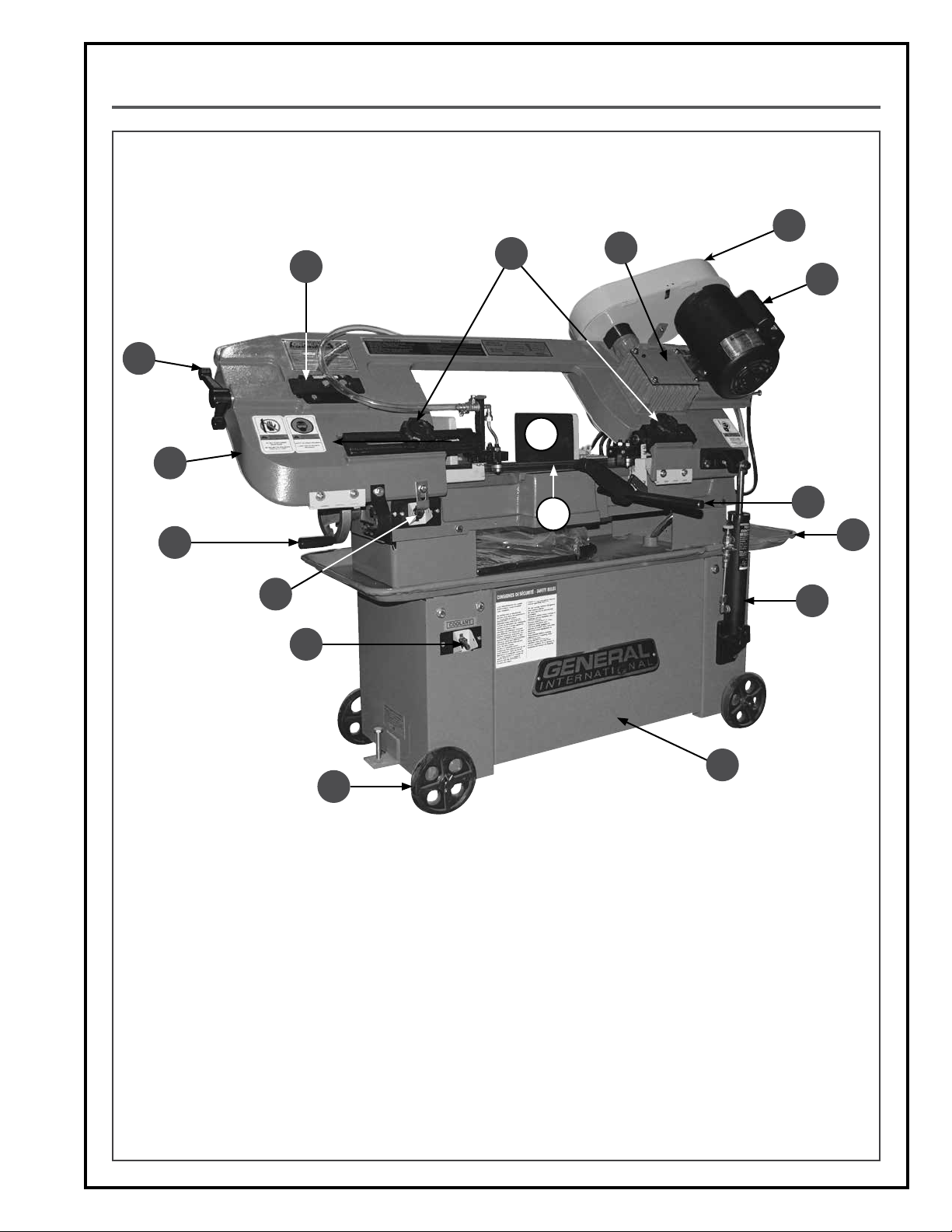

IDENTIFICATION OF MAIN PARTS AND COMPONENTS

Q

I

J

A

P

O

C

B

D

E

F

G

A. BLADE TENSIONING HANDLE

B. BLADE ARM

C. VISE

D. VISE ADJUSTMENT HANDWHEEL

E. MAIN ON/OFF SWITCH

F. COOLANT PUMP SWITCH

G. WHEELS (4)

H. BLADE

I. GEAR BOX

H

K

L

N

M

J. MOTOR

K. WORKPIECE STOP

L. COOLANT RECOVERY TRAY

M. STAND

N. FEED RATE CONTROL CYLINDER

O. BLADE GUARDS (2)

P. BLADE TENSION INDICATOR

Q. PULLEY COVER

7

Page 8

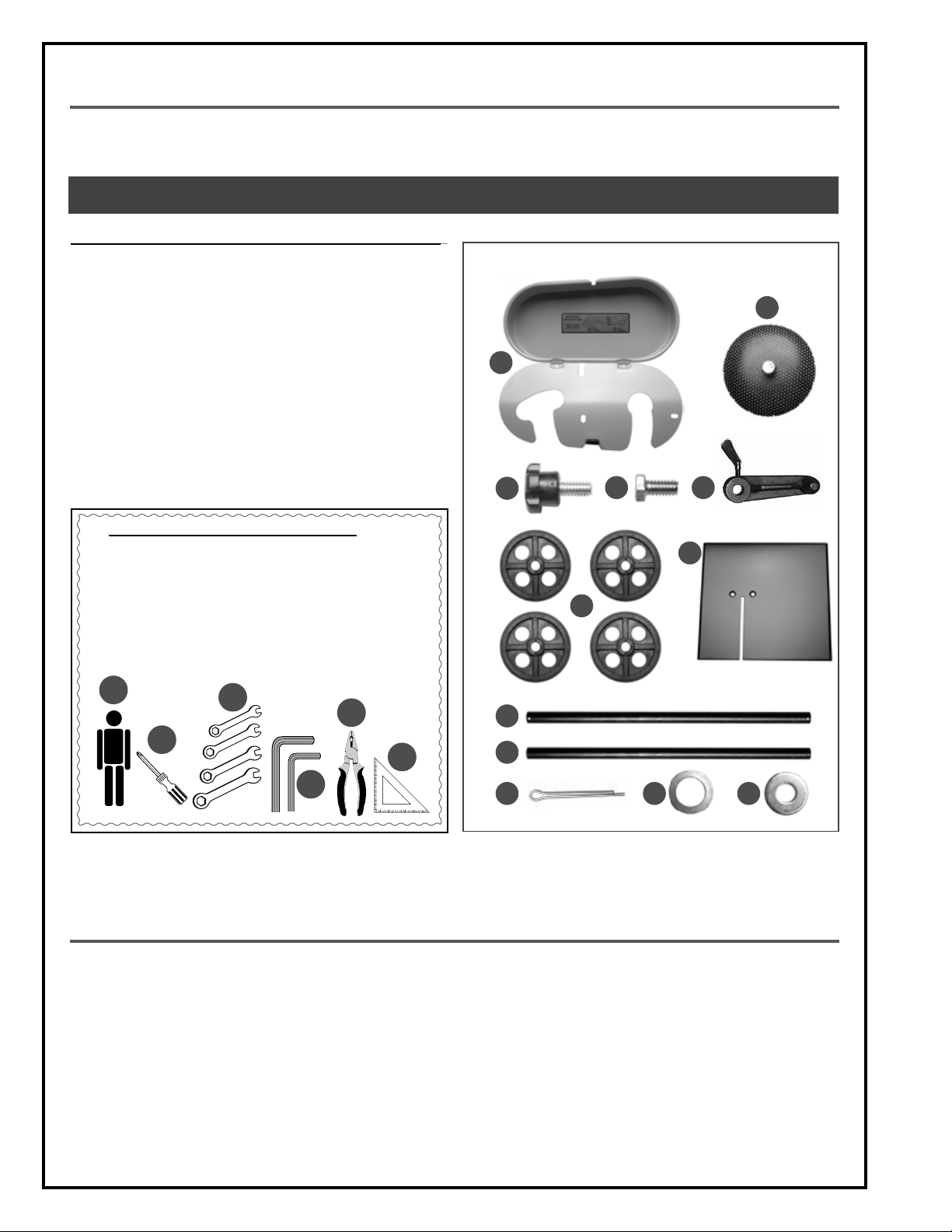

UNPACKING

Carefully unpack and remove the unit and its components from its shipping container and check for missing or

damaged items as per the list of contents below.

NOTE: PLEASE REPORT ANY DAMAGED OR MISSING ITEMS TO YOUR GENERAL® INTERNATIONAL DISTRIBUTOR IMMEDIATELY.

LIST OF CONTENTS QTY

A. PULLEY COVER ......................................................................... 1

B. COOLANT FILTER ...................................................................... 1

C. LOCK KNOB ............................................................................. 1

D. HEX HEAD BOLT ....................................................................... 2

E. WORKPIECE STOP .................................................................... 1

F. VERTICAL CUTTING TABLE ....................................................... 1

G. WHEEL ...................................................................................... 4

H. WHEEL AXLE ............................................................................. 2

I. STOP SHAFT .............................................................................. 1

J. COTTER PIN ............................................................................. 4

K. FLAT WHEEL WASHER ................................................................ 4

L. PULLEY COVER WASHER .......................................................... 2

ADDITIONAL REQUIREMENTS FOR SET UP

A. EXTRA PERSON FOR HELP WITH LIFTING

B. PHILLIPS SCREWDRIVER

C. 10, 12,14 & 20 MM WRENCHES

D. 4 & 6 MM ALLEN KEYS

E. PLIERS

F. SQUARE

A

C

E

B

F

A

C

H

I

D E

F

G

B

D

J

LK

BASIC FUNCTIONS

This 7” x 10” horizontal metal cutting band saw is designed for both vertical and horizontal cutting in metalworking

and machine shops for cutting various types of bar stock, channel stock, piping, and thin-walled tubing.

With four blade speeds to accommodate a wide range of cutting needs, the unit features an automatic hydraulically controlled down feed with auto shutoff at the end of the cutting cycle.

The coolant system with built-in pump is designed to supply a continuous flow of liquid coolant to the cutting area

to prevent overheating of both the blade and the workpiece, providing cleaner cuts and prolonging blade life.

8

Page 9

PLACEMENT WITHIN THE SHOP / SAFETY ZONE

THIS METAL CUTTING BANDSAW MODEL 90-730 IS HEAVY. DO NOT OVER-EXERT. A HOIST OR FORKLIFT WITH STRAPS

SHOULD BE USED TO LIFT THIS MACHINE. TO LIMIT THE RISK OF SERIOUS INJURY OR DAMAGE TO THE MACHINE,

ANY EQUIPMENT USED TO LIFT THIS MACHINE SHOULD HAVE A RATED CAPACITY IN EXCESS OF 330 LBS (150 KG).

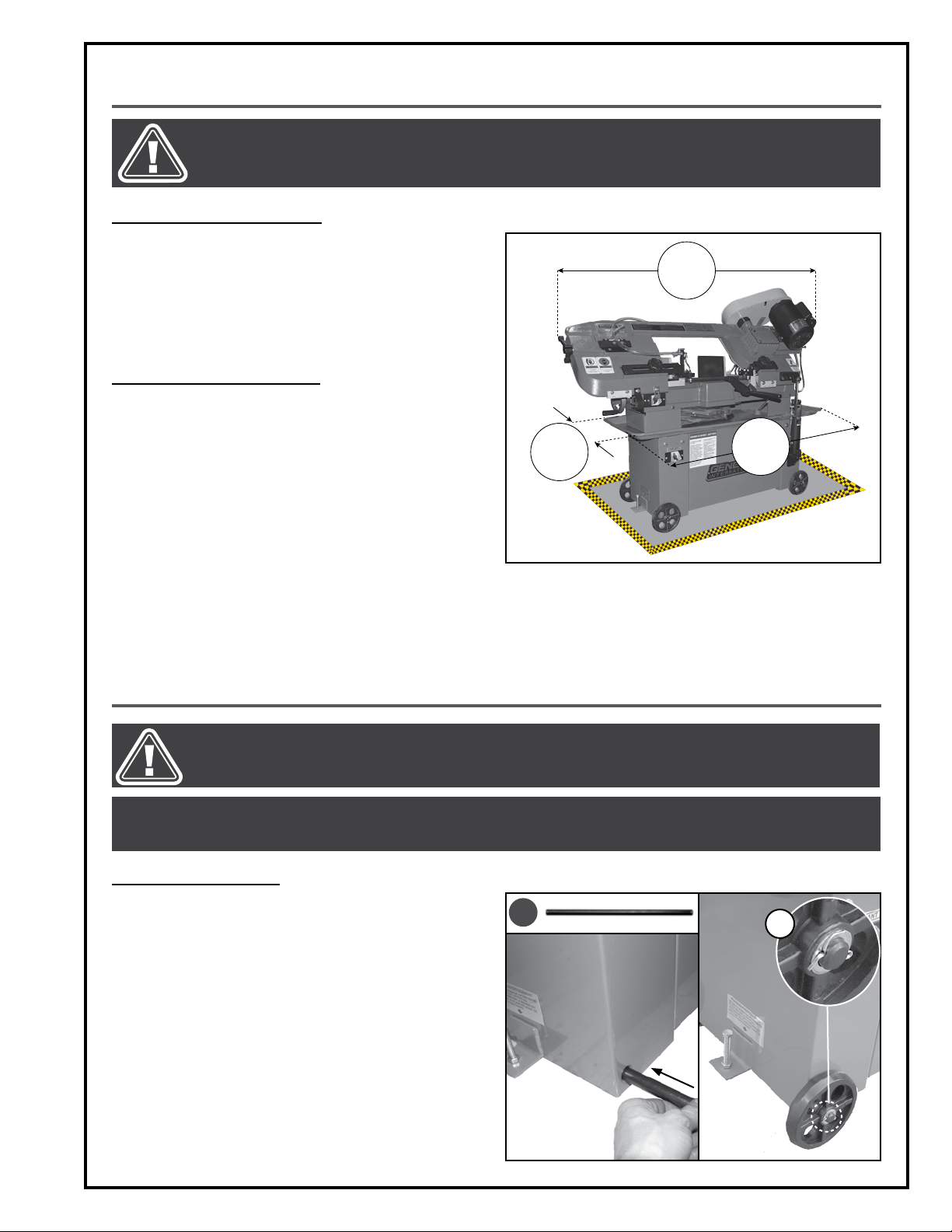

PLACEMENT WITHIN THE SHOP

This machine should be installed and operated only on

a solid, flat and stable floor that is able to support the

weight of the machine (330 lbs - 150 kg) and the operator. Using the dimensions shown as a guideline, plan for

placement within your shop that will allow the operator

to work unencumbered and unobstructed by foot traffic (either passing shop visitors or other shop workers) or

other tools or machinery.

ESTABLISHING A SAFETY ZONE

For shops with frequent visitors or multiple operators,

it is advisable to establish a safety zone around shop

machinery. A clearly defined “no-go” zone on the floor

around each machine can help avoid accidents that

could cause injury to either the operator or the shop

visitor.

It is advisable to take a few moments to either paint

(using non-slip paint) or using tape, define on the floor

the limits or perimeter of each machines safety zone.

Take steps to ensure that all operators and shop visitors

are aware that these areas are off limits whenever a

machine is running for everyone but the individual operating the unit.

16"

50"

40"

ASSEMBLY INSTRUCTIONS

BEFORE ASSEMBLING, MAKE SURE THAT THE SWITCH IS IN THE “OFF” POSITION AND THAT THE POWER CORD IS

UNPLUGGED. DO NOT PLUG IN OR TURN ON THE MACHINE UNTIL YOU HAVE COMPLETED THE ASSEMBLY AND

INSTALLATION STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

TIP: TO INSTALL THE WHEELS, YOU WILL NEED TO LIFT THE MACHINE. DUE TO THE WEIGHT OF THE MACHINE, ADEQUATE LIFTING

EQUIPMENT SUCH AS A JACK, HOIST, OR FORKLIFT WITH STRAPS IS REQUIRED. ANY EQUIPMENT USED TO LIFT THE MACHINE MUST

HAVE A MINIMUM WEIGHT CAPACITY OF 330 LBS (150 KG).

INSTALLING THE WHEELS

1. At one end of the machine, install an axle A as

shown.

Note: The ends of the axle should protrude beyond

the sides of the machine.

2. Lift the machine and install the wheels on the ends

of the axle.

3. Slide a flat washer onto the axle and against each

wheel and then insert a cotter pin (provided)

through the holes on each end of axle as shown B.

4. Fold down the prongs of the cotter pin as shown.

5. Repeat the previous steps with the other axle and

wheels.

A

B

9

Page 10

BEFORE ASSEMBLING, MAKE SURE THAT THE SWITCH IS IN THE “OFF” POSITION AND THAT THE POWER CORD IS

UNPLUGGED. DO NOT PLUG IN OR TURN ON THE MACHINE UNTIL YOU HAVE COMPLETED THE ASSEMBLY AND

INSTALLATION STEPS DESCRIBED IN THIS SECTION OF THE MANUAL.

INSTALLING THE PULLEY COVER

A B

1. Slide the pulley cover behind the pulleys A and line

up its mounting holes with the corresponding holes

on the machine B.

INSTALLING THE WORKPIECE STOP

F

C

2. Attach the cover to the machine using a flat washer

and bolt C with a 10 mm wrench. Then screw the

lock knob in place D to keep the cover door closed

during operations.

G

H

D

E

1. Using a 12 mm wrench loosen bolt E without re-

moving it, then slide the stop bar all the way into its

mounting hole F and re-tighten the bolt to secure

the bar in place.

INSTALLING THE TABLE FOR VERTICAL CUTTING

I

1. To lock the blade arm in the UP position shut off the

hydraulic downfeed control valve I and lift the arm

into the vertical position.

2. Slide the workpiece stop onto the bar as shown G

and tighten the thumbscrew H to secure it in place.

K

J

2. Remove the screws on either side of the blade J.

Guide the table slot around the blade and line up

the holes in the table with the holes in the bracket

K. Secure the table to the bracket using the screws

removed in step 1.

10

Page 11

ON

ON

OFF

INSTALL THE COOLANT SYSTEM/RECOVERY TRAY FILTER

The coolant system with built-in pump is designed to

supply a continuous flow of liquid coolant to the cutting area to prevent overheating of both the blade and

the workpiece, providing cleaner cuts and prolonging

blade life.

1. Fit the steel mesh filter A over the coolant recovery

tank drain B.

A

Note: To prolong the life of the pump and prevent

blockages in the coolant system, remove and clean

the filter regularly using a compressed air blow gun

to remove metal chips and other debris.

BASIC ADJUSTMENTS & CONTROLS

TO REDUCE THE RISK OF SHOCK OR FIRE DO NOT OPERATE THE UNIT WITH A DAMAGED POWER CORD OR PLUG. REPLACE DAMAGED CORD OR PLUG IMMEDIATELY. TO AVOID UNEXPECTED OR UNINTENTIONAL START-UP, MAKE SURE

THE POWER SWITCH IS IN THE OFF POSITION BEFORE CONNECTING TO A POWER SOURCE.

B

CONNECTING TO A POWER SOURCE

Once the assembly steps have been completed, plug

the power cord into an appropriate outlet.

Refer back to the section entitled “Electrical Require

ments” and make sure all requirements and grounding

instructions are followed.

When operations have been completed, unplug the

saw from the power source.

MAIN ON/OFF POWER SWITCH

This machine is equipped with an ON/OFF toggle style

power switch A.

To start the machine flip the switch up 1.

To stop the machine during the cut push the switch

down 2.

End the end of the cut the steel tab B bolted to the head

of the saw is designed to make contact with and turn

off the switch automatically.

If necessary the height of the tab can be adjusted loosing bolt C with a 12 mm wrench and sliding the tab up

or down along its elongated slot. Once the tab is adjusted to be able to turn off the machine, retighten bolt

C to secure the tab in place.

SWITCH OFF

-

OFF

ON

1

TO AVOID UNEXPECTED OR UNINTENTIONAL

START-UP, MAKE SURE THAT THE POWER SWITCH

IS IN THE OFF POSITION BEFORE CONNECTING

TO A POWER SOURCE.

2

C

B

A

11

Page 12

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

INSTALLING A BLADE

There are a variety of different types of bandsaw blades on the market to suit various cutting applications. Your

results may vary based on usage, experience and personal preference. Ask your local tool dealer for suggestions

for bandsaw blades in 0.035” (0,9 mm) thickness and 3/4” (19 mm) width x 93” (2360 mm) length.

Note: Generally speaking, because one wheel height is somewhat adjustable (to allow for blade tensioning), a blade length variation of plus or minus 1/2” from the “ideal blade length” can be accommodated.

A

B

1. Lift the arm into the vertical position. Loosen the lock

knob A and then push the guard down as shown.

Remove the two lock knobs B and open the blade

cover.

3. Remove the metal brush with a Phillips screwdriver

as shown.

WHEEL SHOULDER

SHOULDER

BLADE

2. Loosen the blade by turning the tensioning handle

counterclockwise.

THE SAW BLADES ARE SHARP, HANDLE THEM CAREFULLY AND MAKE SURE YOU HAVE PROTECTIVE

GLOVES IF NECESSARY TO AVOID INJURY.

4. Carefully remove the blade from the wheels.

C

BLADE

BLADE

5. Install a new blade with the teeth towards you. To ten-

sion the blade, hold the blade against the shoulder

of the wheels as shown, and then turn the tension

handle.

Note: See section “Adusting blade tension”.

12

WHEEL SHOULDER

BLADE

6. Re-install the metal brush positioning it along its

elongated mounting holes C, and close the blade

cover.

Page 13

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

ADJUSTING BLADE TENSION

A properly tensioned blade is critical to obtaining maximum performance from any bandsaw. A properly tensioned blade will last longer and be much less likely to break prematurely.

If the blade tension is too loose you will notice that the blade will have a tendency to drift or slip off-line when

cutting and you will have more difficulty controlling your cuts. A blade that is tensioned too tightly will break prematurely.

The following information can be used as a guideline or starting point to assist you in determining ideal blade tension.This bandsaw is equipped with a blade tension scale, which can be used as a reference for the ideal tension

with various blade widths.

To adjust the blade tension

1. Lower the arm into the horizontal posi-

tion.

2. Turn the handle A clockwise to ten-

sion the blade or counterclockwise to

loosen. The white mark B shoud be centered in the shaded zone C of the tension indicator.

3. Make a test cut on a sample piece and

if needed, re-adjust the blade tension.

Note: To check the blade tension, apply

gentle finger pressure on the blade side

facing you. The blade should not move

more than 0.004”.

C

A

B

A

ADJUSTING BLADE TRACKING

The upper wheel is aligned at the factory, but it may eventually be necessary to re-adjust the alignment after a

long period of use or after maintenance. This potential misalignment can be corrected by adjusting the tilt of the

upper wheel.

F

D

E

1. Shut off the hydraulic downfeed control valve and

lift the arm into the vertical position. Loosen lock

knob D and slide the blade guard down as shown.

Remove the two lock knobs E and open the blade

cover.

2. Loosen the two bolts F with a 14 mm wrench.

13

Page 14

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

ADJUSTING BLADE TRACKING (CONTINUED)

3. Loosen the blade by turning the handwheel coun-

terclockwise.

SQUARING THE BLADE TO THE WORK TABLE

E

BLADE

BLADE

SHOULDER

A

BLADE

B

BLADE

4. Adjust the wheel tilt by turning the screw A with a 4

mm Allen key, so that the blade stays against the

shoulder of the pulley. Tighten two bolts B, close the

blade cover and tension the blade.

C

D

SQUARE

WORK TABLE

1. Lower the arm into the horizontal position and then

place a square against the vise face and against

the blade as shown E. If the blade is not square to

the table go to the step 2.

SQUARE

WORK TABLE

2. Loosen screw C with a 6 mm Allen key and make

sure that the blade is parallel with the square by

turning the blade support D. Retighten screw C

once finished adjusting. Repeat with the second

support on the other side.

SQUARING THE VISE TO THE BLADE/USING THE VISE

The vise can accommodate workpieces up to 7“ wide. Adjust the angle of cut or square the vise to the table as follows:

F

VISE JAW

VISE JAW

SQ

U

B

A

BL

L

RE

AD

A

DE

E

SQ

U

A

B

L

RE

A

D

E

1. Lower the arm into the horizontal position and place

a square against one of the jaws and the blade as

shown.

14

Note: The blade must be perfectly squared to the

vise F. If the blade is not squared, go to the next step.

Page 15

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORM-

0,001"

0,001"

ING ANY MAINTENANCE OR ADJUSTMENTS.

SQUARING THE VISE TO THE BLADE/USING THE VISE (CONTINUED)

2. To adjust the left jaw, loosen bolts A and B using a

20 mm wrench.

3. Position the jaw to the desired angle, or squared to

the blade, and then tighten bolts A and B.

4. Repeat the previous steps with the right jaw using

the bolts C and D.

Note: Use the vise handwheel to open or close the

vise.

A

A

B

D

C

ADJUSTING THE BLADE GUIDES

The guide bearings K keep the blade from moving from side to side during the cutting and must be adjusted

close to the blade (but not touching the blade) in order to ensure accurate cuts. The space between each guide

bearing and the blade must not exceed 0.001”. If less space is left, the blade will get stuck or jammed between the

bearings. Too much friction will cause blade to overheat and break.

Note: Before adjusting the blade guides, make sure the blade is tensioned and tracking properly. Re-adjust

the blade guides after each blade tension or tracking adjustment.

LEFT SIDE

RIGHT SIDE

H

E

G

1. Loosen lock knobs E & F and push the two blade

guards G & H in the direction of the arrows. Shut off

the hydraulic downfeed control, and then lift the

arm into the vertical position.

F

K

J

I

2. Loosen nut I using a 14 mm opend wrench.

3. Turn the eccentric shaft J with pliers until the blade

and bearing are about 0.001” apart as shown K.

4. To lock the bearing position, retighten nut I while

holding shaft J with pliers. Repeat steps 2 to 4 for the

other bearing, and then for the second assembly

located on the other side of the saw arm.

5. Make a test cut and re-adjust the blade guides if

needed.

15

Page 16

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

ADJUSTING THE THRUST BEARINGS

The thrust bearing keeps the blade from moving back and out of position when the saw arm pushes against the

workpiece. The thrust bearing must be very close to the back of the blade A to prevent damage to the blade during cutting. To adjust it, proceed as follows:

A

1. Shut off the hydraulic downfeed control valve and

lift the arm into the vertical position. Loosen screw B

on bracket C.

ADJUSTING THE BLADE GUARDS

The blade guards should be adjusted based the dimensions of the workpiece.

To prevent the blade (which is flexible and which would

not otherwise be supported) from slipping out of position during cutting, and to reduce risks of injuries, a

minimum amount of blade should be exposed.

For a straight cut and to reduce the risk of twisting, loosen lock knobs I & J and position the blade guards G &

H as close as possible to the workpiece, then retighten

the lock knobs.

D

E

1/32”

B

C

2. Push bracket C as shown D until the thrust bearing

touches the back of the blade A. Repeat for the

other thrust bearing.

Note: The blade guides must remain at least 1/32”

behind the blade teeth to prevent damage to the

blade as shown E

LEFT SIDE

I

G

RIGHT SIDE

H

J

CHANGING SPEEDS

1. Lower the arm into the horizontal position and loos-

en the jam nut and bolt K with a 12 mm wrench.

2. Loosen the jam nuts L and bolts M with a 12 mm

wrench until the base of the motor can move.

3. Open the pulley cover and change the speed (refer to the chart in the manual or the sticker inside

the pulley cover).

Note: if there is not enough slack to move the belt,

loosen tension bolts M as needed.

4. Retighten bolts M alternating until the belt tension

is properly adjusted, then secure the motor in position by tightening jam nuts L and jam nut and bolt

K. Close the pulley cover.

16

K

L

M

TIP: CHECK TENSION BY PUSHING THE BELT WITH YOUR FINGER. THE BELT SHOULD NOT MOVE MORE THAN 1/2”.

Page 17

AA

B

C

D

AA

B

C

D

POULIE DE L’ARBRE

POULIE DU MOTEUR

SPINDLE PULLEY

MOTOR PULLEY

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORM-

ON

ING ANY MAINTENANCE OR ADJUSTMENTS.

SPEED SELECTION CHART

BELT SPEED (fpm)

BLADE SPEEDS

CUTTING FEED RATE/ SAW ARM TENSION

A hydraulic cylinder allows adjustments to the downfeed speed of the arm to control cutting speed.

Note: The valve must to be open in order to adjust the cutting feed rate.

A

VALVE OPENED

VALVE CLOSED

- Turn the knob A clockwise to increase the cutting

- Turn the knob A counterclockwise to reduce the

Note: Forcing the blade into the workpiece increases

the risk of blade breakage and can affect the quality

of the cut (burrs, chips, etc.).

USING THE COOLANT PUMP

The switch D allows you to turn on or turn off the pump

of the coolant system. You can also stop the flow of the

liquid coolant by closing the tap E.

Make sure that the level of liquid coolant in the tank

located under the work table is between 3 liters (minimum) and 5 liters (maximum).

Don’t start the pump during vertical cuts.

Note: To reduce the risk of blade breakage and obtain cleaner cuts, it is recommended to turn on the

pump systematically when using the machine, excep for the vertical cuts.

A

B

C

D

feed rate.

cutting feed rate.

260

178

132

86

B C

A tension spring helps lift the arm into the the vertical

position and slows down its descent. If too little tension

makes it difficult to raise the arm, proceed as follow:

1. Loosen the jam nut B and tighten bolt C a few turns.

2. Repeat as needed until desired tension is achieved

and then retighten the jam nut B.

Note: for less tension, loosen bolt C.

ON

OFF

TAP OPENED

D

TAP CLOSED

E

17

Page 18

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

IMMOBILIZING THE MACHINE

Machine vibration during operation may cause the

machine to move, particularly when installed on uneven surfaces.

The bolt-down tab and anchor bolt A can be used to

help keep the machine immobilized by either lowering the bolt against the floor to act as another point of

contact with the floor, or for permanent installations, by

drilling into the floor and bolting the machine in place.

A

OPERATING INSTRUCTIONS

CHECKLIST BEFORE STARTING

VERIFY ALL CHECK POINTS BEFORE STARTING. FAILURE TO COMPLY CAN RESULT IN SERIOUS INJURIES.

1. Make sure you and any assistants are wearing safe and appropriate workshop attire.

2. To reduce the risk of damage to the machine, as well as potential for personal injury, after initial set-up as well

as before each use, make sure that everything is securely installed and that all fasteners and moving parts on

this machine are locked in place before starting the machine.

3. Make sure to have on safety glasses as well as hearing or/and respiratory protection at all times when using the

machine.

4. Check the level of coolant in the tank and fill it as necessary. The level should be between 3 liters (minimum)

and 5 liters (maximum).

5. Use only recommended parts and accessories. The use of parts or accessories NOT recommended by

GENERAL® INTERNATIONAL may result in a risk of injury or damage to the machine.

6.

Be sure that adjusting wrenches, tools, drinks and other clutter are removed from the machine and/or the

table surface before operating.

OPERATIONS STEP-BY-STEP

NEVER USE THE SAW WITHOUT ALL GUARDS AND COVERS IN PLACE BEFORE STARTING THE SAW. BE SURE THAT THE

BLADE IS NOT ALREADY IN CONTACT WITH THE WORKPIECE.

For horizontal cuts

1. Raise the saw arm by the handle and lock it in position by shutting off the hydraulic downfeed control valve.

2. Trace the cutting line on your workpiece with a pencil and clamp the material firmly in the vise to ensure a

straight cut through the material. Make sure the workpiece is properly secured in the vise. Refer to the chart

below for proper stock placement in the vise.

Note: Use the work stop to make repeat cuts to the same length.

3. Adjust the blade guards as close as possible to the workpiece.

4. Start the machine.

5. Allow the blade to come to full speed, then begin the cut by opening the hydraulic downfeed control valve

and letting the head down slowly onto the workpiece. Re-adjust the cutting feed rate if needed.

Note: Do not drop or force the head onto the workpiece.

6. Wait for the automatic shutdown of the saw before carefully removing the workpiece from the vise.

BURN DANGER: DO NOT USE BARE HANDS TO TOUCH THE WORKPIECE AT THE CUT LOCATION UNTIL IT HAS COOLED.

18

Page 19

OPERATIONS STEP-BY-STEP (CONTINUED)

NEVER USE THE SAW WITHOUT ALL GUARDS AND COVERS IN PLACE. BEFORE STARTING THE SAW BE SURE THAT THE

BLADE IS NOT ALREADY IN CONTACT WITH THE WORKPIECE.

For vertical cuts

1. Shut off the hydraulic downfeed control valve and lift the arm into the vertical position.

2. Make sure that the vertical table is securely installed so that it will adequately support the workpiece.

3. Adjust the blade guards as close as possible to the workpiece to minimize side-to-side blade movement.

4. Start the machine.

Note: Don’t turn on the coolant pump.

5. Slowly feed the workpiece into the blade by hand. Keep your fingers away from the blade and always hold

the workpiece securely against the table.

6. Stop the machine once finished.

MAINTENANCE

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

CLEANING

Cleaning the bandsaw is relatively easy. After using your bandsaw, sweep up and discard any excess metal and

chips and debris. For optimum performance from your machine, follow this maintenance schedule and refer to

any specific instructions given in this section.

Daily:

• Check for loose mounting bolts

• Check the blade for damage

• Check for worn or damaged electrical wires

• Check for any other unsafe conditions

• Clean the metal blade brush

Monthly:

• Inspect V-belt tension, damage, or wear

• Clean the vise screw with air compressed as shown

and lubricate with an all-purpose oil.

LUBRICATION

1. Periodically clean the filter and the recovery tray. Fill the tank with coolant so that the level of liquid coolant is

between 3 and 5 liters.

2. Machine gears are mounted in an oil-bath. You

don’t need to fill it up, except in case of gear box

leak or overheating.

3. Change the oil once a year by replacing it with a

80W/90 oil as follows:

a. Remove bolts A with a 10 mm wrench and then

remove the gear box cover to drain the gear box.

b. Reinstall the cover and then remove plug B. Fill

the gear box with until it reaches the hole and then

retighten the plug B.

B

A

19

Page 20

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

CHANGING THE BELT & ALIGNING THE PULLEYS

A

D

B

C

TIP: CHECK THE TENSION BY PUSHING GENTLY THE BELT

WITH YOUR FINGER. THE BELT SHOULD NOT MOVE MORE

THAN 1/2”.

1. Lower the arm into the horizontal position and loos-

en the jam nut and bolt A with a 12 mm wrench.

2. Loosen jam nuts B and bolts C with a 12 mm wrench

until the motor base can be moved.

3. Open the pulley cover and change the belt.

Note: if there is not enough slack to move the belt,

loosen tension screws C as needed.

4. Place a straightedge on the two pulleys as shown D

to verify their alignment.

5. If the pulleys are not aligned, loosen the four bolts

E and F located on the motor mounting plate, and

then re-position the motor along the slotted mounting holes so that the pulleys are aligned.

6. With the pulleys aligned, retighten the four bolts E

and F.

7. Retighten the two bolts C alternating one turn at a time until the belt is tensioned properly. Then secure the motor in position by tightening the jam nuts B and the jam nut and bolt A.

8. Close the pulley cover.

E

F

20

NOTES

Page 21

TROUBLE SHOOTING

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS.

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Workpiece loose in vise Tighten the vise

Incorrect feed or speed Adjust feed or speed

Blade teeth space too large Replace the blade

EXCESSIVE BLADE BREAKAGE

MOTOR OVERHEATING

Material to coarse Use a blade of slow speed and

Incorrect blade tension Tension the blade

Teeth in contact with workpiece before saw is turned on

Blade rubs on wheel flange Adjust wheel alignment

Misaligned guide bearing Adjust guide bearing

Blade too thick Use thinner blade

Blade cracking at weld Weld again

Blade tension too high Reduce blade tension

Motor belt tension too high Reduce belt tension

Blade is too coarse for work Use finer blade

Blade is too thin to work Use thicker blade

Improperly aligned gears

Binding blade Reduce feed pressure

Gears need lubrication Check oil level

Feed pressure too high Reduce feed pressure

small teeth spacing

Place the blade in contact with

blade after turning on the machine

Adjust gears so that worm is in center of gear

BAD CUT (CROOKED)

BAD CUT (ROUGH)

Guide bearings not adjusted Adjust guie bearings

Inadequate blade tension Tension the blade

Dull blade Replace the blade

Speed incorrect Adjust speed

Blade guide too far from blade Adjust guide spacing

Blade guide loosens Re-tighten lock knobs

Blade tracks too far from wheel

shoulder

Blade or feed speed too high Reduce blade of speed or feed

Blade is too thick Replace with thinner blade

Blade tension insufficient Tension the blade

Binding blade Reduce feed pressure

Blade tension too high Reduce blade tension

Adjust blade tracking

21

Page 22

TROUBLE SHOOTING

MAKE SURE THE MACHINE HAS BEEN TURNED OFF AND UNPLUGGED FROM THE POWER SOURCE BEFORE PERFORMING ANY MAINTENANCE OR ADJUSTMENTS

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Blade teeth too coarse Use finer tooth blade

Speed too high Reduce speed

Feed pressure to high Reduce feed pressure with cylinder

PREMATURE BLADE DULLING

BLADE IS TWISTING

BROKEN TEETH

Hard spots or scale on material

Hardening of material

Blade twists

Insufficient blade tension Tension the blade

Blade slides Tension the blade

Bending blade Reduce feed pressure

Blade tension too high Reduce blade tension

Blade teeth too coarse Use finer tooth blade

Pressure too high or speed too slow Reduce pressure, increase speed

Vibrating workpiece Clamp the workpiece properly

Excessive chips

Reduce speed, increase feed pressure

Increase feed pressure by tightening the cylinder lock knob

Replace the blade and adjust its

tension

Use thicker tooth blade or brush regularly to remove chips

NOTES

22

Page 23

DIAGRAM

23

Page 24

DIAGRAM

24

Page 25

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PIECE # DESCRIPTION SPECIFICATIONS QTY

90730-01 BOTTOM PAN 1

90730-02 LEG (LEFT) 1

90730-03 LEG (RIGHT) 1

90730-04 SKIRT 1

90730-05 SHELF 1

90730-10 SWITCH BRACKET 1

90730-11 TOGGLE SWITCH 1

90730-12 ELECTRICAL BOX 1

90730-13 HEX HEAD SCREW 5/16X3/4 8

90730-14 WASHER 5/16 8

90730-15 WASHER 5/16 8

90730-16 LOCK WASHER 5/16 8

90730-17 NUT 5/16 8

90730-18 HEX HEAD SCREW 5/16X1/2 6

90730-19 NUT 5/16 6

90730-20 CYLINDER 1

90730-21 CAP SCREW M10X40 1

90730-22 WASHER 3/8 1

90730-23 LOCK WASHER M10 1

90730-24 NUT M10 1

90730-25 HEX HEAD SCREW 3/8X1 2

90730-26 LOCK WASHER 3/8 2

90730-27 SUPPORT ROD 1

90730-28 SET SCREW 1/4X3/8 1

90730-29 BOTTOM SUPPORT 1

90730-33 WASHER 5/8 4

90730-34 WHEEL 5” 4

90730-35 WHEEL SHAFT 2

90730-36 CUTTER PIN 4

90730-37 TOGGLE SWITCH 1

90730-38 ELECTRIC CORD ASSEMBLY 1

90730-39 TABLE 1

90730-40 HEX HEAD SCREW 5/16X1 5

90730-41 WASHER 5/16 5

90730-42 LOCK WASHER 5/16 5

90730-43 NUT 5/16 5

90730-44 FILTER 1

90730-45 ROUND HEAD SCREW 3/16X3/8 2

90730-46 ELECTRIC BOX ASSEMBLY 1

90730-47 HANDLE WHEEL 1

90730-48 SET SCREW 5/16X3/8 1

90730-49 KEY 5X20 1

90730-50 LEAD SCREW 1

90730-51 NUT SEAT 1

90730-52 ACME NUT 1

90730-53 BUTTON 1

90730-54 RETAINER 1

90730-55 LOCK WASHER M5 1

90730-56 ROUND HEAD SCREW M5X8 1

90730-57 HEX HEAD SCREW 5/16X5/8 2

25

Page 26

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PIECE # DESCRIPTION SPECIFICATIONS QTY

90730-58 LOCK WASHER 5/16 2

90730-58-1 WASHER 5/16 2

90730-59 SUPPORT PLATE 1

90730-60 STOP SCREW 1

90730-61 NUT 5/16 2

90730-62 HEX HEAD SCREW 3/8X1 1

90730-63 NUT 3/8 1

90730-64 90° POSITION SUPPORT 1

90730-65 NUT 3/8 2

90730-66 LOCK WASHER 3/8 2

90730-67 LIMIT SWITCH 1

90730-68 LIMIT SWITCH SEAT 1

90730-69 ROUND HEAD SCREW 5/32X1 2

90730-70 HEX HEAD SCREW 3/8X1 1/2 2

90730-71 HEX HEAD SCREW 5/16X3/4 1

90730-72 THUMB SCREW 1

90730-73 STOP BLOCK 1

90730-74 WORK STOP ROD 1

90730-75N FIBER HEX. NUT 1/2 2

90730-76 WASHER 1/2 2

90730-77 BEARING BUSHING (FRONT) 1

90730-78 RUBBER COVER 1

90730-79 WASHER 5/32 2

90730-80N SUPPORT SHAFT 22MM 1

90730-80-1 BUSHING 1

90730-81 PIVOT ARM 1

90730-84 PLATE 1

90730-85 LOCK WASHER 3/8 2

90730-86 HEX HEAD SCREW 3/8X1 1/2 2

90730-87 SPRING 1

90730-88 ADJUSTABLE SPRING ROD 1

90730-89 SPRING BRACKET 1

90730-90 HEX HEAD SCREW 5/16X1 1

90730-91 NUT 318 2

90730-92 LOCK WASHER 5/16 1

90730-92-1 WASHER 5/16 1

90730-93 NUT 5/16 1

90730-94 FRONT VISE 1

90730-95 REAR VISE 1

90730-96 VISE THRUST SHAFT 1

90730-96-1 LOCK WASHER 3/8 2

90730-96-2 WASHER 3/8 1

90730-97 HEX HEAD SCREW 3/8X1 1/2 1

90730-98 HEX HEAD SCREW 1/2X1 1/2 1

90730-98-1 LOCK WASHER 1/2 2

90730-98-2 WASHER 1/2 1

90730-99 HEX HEAD SCREW 1/2X1 1/4 1

90730-100 SCALE 1

90730-101 CAP SCREW 3/8X1 3/4 1

90730-101-1 NUT 3/8 1

26

Page 27

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PIECE # DESCRIPTION SPECIFICATIONS QTY

90730-102 HOSE 1” 1

90730-103 PUMP 1

90730-104 HEX HEAD SCREW 1/4X1/2 4

90730-105 STRAIN RELIEF 1

90730-107 COOLANT TANK 1

90730-108 HOSE FITTING 1

90730-109 HOSE CLAMP 13MM 1

90730-110 HOSE 5/16 1

90730-111 SAW ARM 1

90730-112N SELF TAPPING SCREW 6X20 4

90730-113 VENT PLUG 1

90730-114N GEAR BOX COVER 1

90730-115N GEAR BOX GASKET 1

90730-116 WORM GEAR 1

90730-117 KEY 6X20 1

90730-118 BEARING 6005 3

90730-119 HEX HEAD SCREW 3/8X1 1

90730-119-1 LOCK WASHER 3/8 1

90730-119-2 WASHER 3/8X35X4 1

90730-120 OIL SEAL 25. 47. 7 1

90730-121N GEAR BOX 1

90730-122 LOCK WASHER 5/16 4

90730-123 HEX HEAD SCREW 5/16X1 1/4 4

90730-123-1 SET SCREW 1/4X3/8 2

90730-124 BLADE WHEEL {REAR) 1

90730-125 BEARING BUSHING 1

90730-126 CAP SCREW 3/16X5/8 3

90730-127 BLADE 1

90730-128 BLADE BACK COVER 1

90730-129 WHEEL COVER 1

90730-130 PLUM SCREW 2

90730-130-1 WASHER 1/4 2

90730-131 ADJUSTABLE GUIDE KNOB 2

90730-132 ADJUSTABLE BRACKET (REAR) 1

90730-133 BEARING 608 ZZ 2

90730-134 ADJUSTABLE BLADE SEAT {REAR) 1

90730-135 BEARING PIN 2

90730-136 ECCENTRIC SHAFT ASSEMBLY 2

90730-136-1 CENTER SHAFT ASSEMBLY 2

90730-137 NUT 3/8X24UNF 4

90730-137-1 LOCK WASHER 3/8 4

90730-138 WASHER 5/16 2

90730-139 LOCK WASHER 5/16 2

90730-140 CAP SCREW 5/16X1 1/8 1

90730-141 HEAD SCREW 1/4X1/2 2

90730-142 VERTICAL CUTTING PLATE (SMALL) 1

90730-143 ADJUSTABLE BLADE SEAT (FRONT) 1

90730-144 HEX HEAD SCREW 3/8X1 1/4 2

90730-145 TOP SUPPORT 1

90730-146 LOCK WASHER 3/8 2

27

Page 28

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PIECE # DESCRIPTION SPECIFICATIONS QTY

90730-147 NUT 3/8 2

90730-148 ROUND HEAD SCREW 1/4X1/2 2

90730-149 WASHER 1/4 2

90730-150 BRUSH HOLDER 1

90730-151 HEX HEAD SCREW 5/16X2 1/2 2

90730-152 NUT 5/16 2

90730-153 BRUSH 1

90730-154 HEX HEAD SCREW 5/16X5/8 3

90730-154-1 LOCK WASHER 5/16 3

90730-156 NOZZLE 1

90730-157 SET SCREW 1/4X3/8 1

90730-158 NOZZLE SUPPORT 1

90730-159 VALVE 1

90730-160 ROUND HEAD SCREW 3/16X3/8 2

90730-161 CAP SCREW 5/16X1 1/8 1

90730-161-1 LOCK WASHER 5/16 1

90730-163 ADJUSTABLE BRACKET (FRONT) 1

90730-164 BLADE GUARD 1

90730-164-1 ROUND HEAD SCREW 3/16X1/4 2

90730-165 HEX HEAD SCREW 1/4X1/2 4

90730-166 SLIDING GUIDE PLATE 2

90730-167 SET SCREW 5/16X3/4 1

90730-168 HEX HEAD SCREW 5/16X1 1/2 2

90730-169 BLADE TENSION SLIDING BLOCK 1

90730-170 HEX HEAD SCREW 1/4X1/2 1

90730-170-1 LOCK WASHER 1/4 1

90730-170-2 WASHER 1/4 1

90730-171 SLIDING DRAW BLOCK 1

90730-172 BRACKET 1

90730-173 BEARING BUSHING (REAR) 1

90730-174 BEARING 6203 ZZ 2

90730-175 BLADE WHEEL {FRONT) 1

90730-176 WASHER 5/16 1

90730-176-1 LOCK WASHER 5/16 1

90730-177 HEX HEAD SCREW 5/16X3/4 1

90730-178 ROUND HEAD SCREW 1/4X1/2 2

90730-179 WASHER 1/4 2

90730-180 WASHER 3/8 1

90730-181 BLADE ADJUSTMENT HANDLE 1

90730-182 VERTICAL CUTTING PLATE OPTION 1

90730-183 BELT 3V270 1

90730-184 WORM PULLEY 1

90730-185 MOTOR PULLEY 1

90730-186 SET SCREW 5/16X3/8 3

90730-187 HEX HEAD SCREW 1/4X1/2 2

90730-188 WASHER 1/4 2

90730-189 PULLEY COVER 1

90730-190 PLUM SCREW 1

90730-191 KEY 5MM 1

28

Page 29

PARTS LIST

IMPORTANT: When ordering replacement parts, always give the model number, serial number of the

machine and part number. Also a brief description of each item and quantity desired.

PIECE # DESCRIPTION SPECIFICATIONS QTY

90730-192 MOTOR 1

90730-193 HEX HEAD SCREW 5/16X1 4

90730-194 MOTOR MOUNT PLATE 1

90730-195 WASHER 5/16 4

90730-196 LOCK WASHER 5/16 4

90730-197 NUT 5/16 4

90730-198N WORM SHAFT STOPPER 1

90730-198-1 SET SCREW 5/16X1/4 1

90730-199 BEARING 6003 3

90730-200 BLOCK PLATE 1

90730-201 OIL SEAL 17. 35. 7 1

90730-202 BEARING BUSHING 1

90730-203 WORM SHAFT 1

90730-203-1 KEY 5X5X50 1

90730-204 HEX HEAD SCREW 1/4X1/2 2

90730-205 WASHER 1/4 2

90730-206 SUPPORT PLATE 1

90730-207 LIMIT SWITCH RACK 1

90730-208 HEX HEAD SCREW 1/4X1/2 1

90730-209 NUT 1/4 1

90730-210 WASHER 1/4 1

90730-211 LOCK WASHER 1/4 1

90730-212 HEX HEAD SCREW 1/4X1/2 1

90730-213 NUT 5/16 1

90730-214 HEX HEAD SCREW 5/16X1 1/4 1

90730-217 RETENTION RING R47 2

NOTES

29

Page 30

8360 Champ-d’Eau, Montreal (Quebec) Canada H1P 1Y3

Tel.: (514) 326-1161

Fax: (514) 326-5565 - Parts & Service / (514) 326-5555 - Order Desk

orderdesk@general.ca

www.general.ca

Follow us:

Loading...

Loading...