GE Weldstar Brochure

GE

Inspection Technologies

Weldstar

Hybrid AUT Girth Weld Inspection

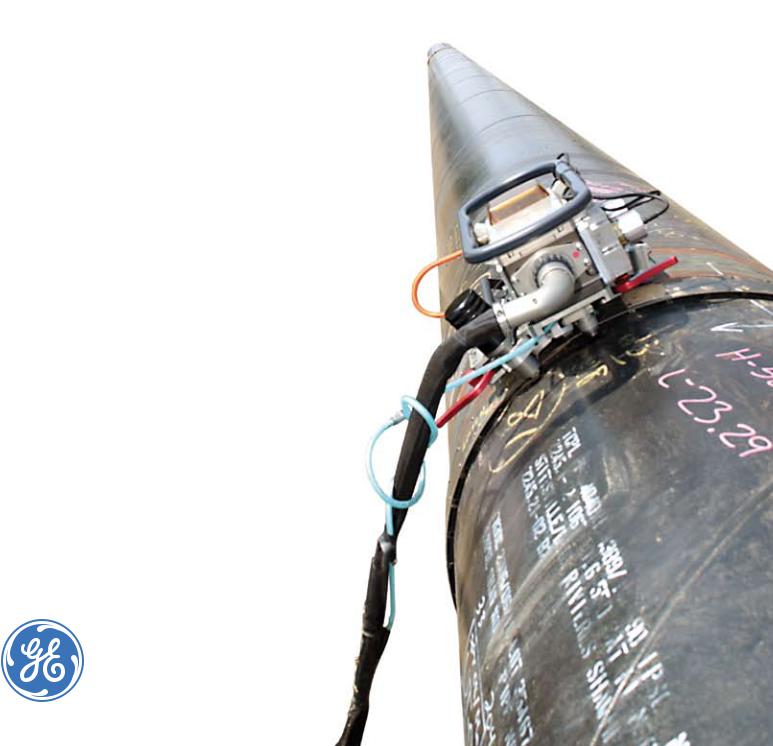

Weldstar is the latest in pipeline girthweld inspection system from GE Inspection Technologies. It features a combination of conventional and Phased Array ultrasonics and thus offers an inspection solution not

compromised by a single ultrasonic technique. Together with its unique modular design, this high-performance system is extremely versatile and reliable.

Inspection integrity, unrivaled versatility.

The latest generation pipeline girth weld inspection system from GE Inspection Technologies is an automated ultrasonic testing solution that provides all functionality required for the job, from set-up to data archiving. Combining conventional and Phased Array ultrasonics, this advanced inspection tool provides the benefits of both techniques without compromise. Weldstar’s unique modular design with the ultrasonic electronics located on the scanner head, and the simple umbilical that can be changed quickly, provides numerous benefits in applications versatility, performance and reliability.

Inspection Integrity where Rapid Defect Detection is Critical

Hybrid ultrasonic flexibility

Weldstar’s remote scanner head contains all its ultrasonic hardware in four field-replaceable modules. The scanner head can be configured with four 8-channel conventional modules for a total of 32 conventional ultrasonic channels. Or, two of the modules can be exchanged for two 64-channel Phased Array modules providing a hybrid system containing 16 conventional and 128 Phased Array channels.

With its ability to fire 32 virtual elements from each 64-element Phased Array module and its unique connector design, Weldstar can fire a pair of 64-element Phased Array transducers or two pairs of 32-element Phased Array transducers. Weldstar’s tremendous flexibility allows the operator to configure the optimum inspection solution for virtually any pipeline girth weld application.

Highly versatile scanner design

The Weldstar scanner delivers the ultimate in versatility with the ability to adjust for pipe diameters as small as 200 mm (8 in) up to virtually flat surfaces. The Weldstar scanner is the only scanner adjustable to fit a variety of current pipe weld bands and can

be configured to allow minimum coating cutback of less than 150 mm (6 in).

Resistant to electromagnetic interference

Typical AUT systems are highly susceptible to electromagnetic interference preventing inspections from taking place while welding equipment is active. Great care is taken in the Weldstar’s design to minimize the impact of this noise allowing greater inspection productivity and test integrity.

Availability = reliability + serviceability

With a quick-change umbilical coupled to the scanner on a connector swivel, Weldstar minimizes costly downtime associated with umbilical failures. Modular electronics housed in the machined remote scanner head provide plug and play serviceability. To ensure robustness, the Weldstar design has been validated through severe shock, vibration, environmental and thermal loading. Weldstar has been tested to operate in ambient temperatures from -50C to +60C. Weldstar is supported by GE Inspection Technologies global service and training network.

Loading...

Loading...