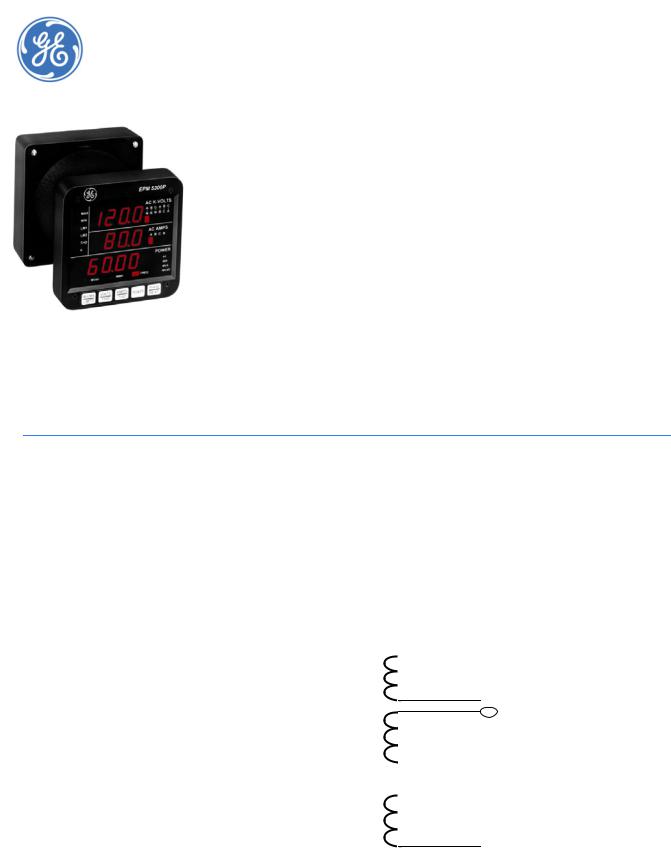

GE EPM 5300, EPM 5350, EPM 5200 User Manual

GE Consumer & Industrial

Multilin

Instruction Manual

Software Revision: 4.5

Manual P/N: 1601-9027-A2

Manual Order Code: GEK-106557B

Copyright © 2007 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEmultilin.com

GE Multilin's Quality Management System is registered to ISO9001:2000

QMI # 005094

*1601-0215-A4*

TABLE OF CONTENTS

Table of Contents

1: AC POWER |

SINGLE PHASE SYSTEM ................................................................................................................. |

1 |

MEASUREMENT |

THREE-PHASE SYSTEM .................................................................................................................. |

3 |

|

CONSUMPTION, DEMAND AND POOR POWER FACTOR ................................................. |

5 |

|

WAVEFORM AND HARMONICS .................................................................................................. |

6 |

2: MECHANICAL |

MECHANICAL INSTALLATION ..................................................................................................... |

1 |

INSTALLATION |

|

|

3: ELECTRICAL |

CONNECTING THE CURRENT CIRCUIT .................................................................................... |

5 |

INSTALLATION |

CT CONNECTION ............................................................................................................................. |

6 |

|

HELPFUL DEBUGGING TOOLS ............................................................................................ |

6 |

|

CONNECTING THE VOLTAGE CIRCUIT .................................................................................... |

7 |

|

SELECTING THE VOLTAGE FUSES ............................................................................................. |

8 |

|

CONNECTION TO THE MAIN POWER SUPPLY ..................................................................... |

9 |

|

ELECTRICAL CONNECTION INSTALLATION ........................................................................... |

10 |

|

LIST OF CONNECTION DIAGRAMS ..................................................................................... |

10 |

|

THE EPM 5300P-S ............................................................................................................................ |

14 |

|

RELAY, PROTECTION AND PULSE OUTPUT ........................................................................... |

16 |

|

EPM 5300P RELAY OVERVIEW ....................................................................................... |

16 |

|

2 RELAYS & 1 KYZ PULSE OUTPUT -NL OPTION ....................................................... |

16 |

|

STANDARD RATE TABLE FOR WATTS* .............................................................................. |

18 |

|

KYZ PULSE OUTPUTS: NL2 OPTION ........................................................................................ |

19 |

4: COMMUNICATION |

RS-232C ............................................................................................................................................... |

21 |

INSTALLATION |

RS-485 .................................................................................................................................................. |

22 |

|

NETWORK OF INSTRUMENTS AND LONG DISTANCE COMMUNICATION .............. |

26 |

|

MODEM CONNECTED TO COMPUTER (ORIGINATE MODEM) ......................................... |

27 |

|

MODEM CONNECTED TO THE DEVICE (REMOTE MODEM) ............................................. |

27 |

5: OVERVIEW |

ACCESSING THE POWER FUNCTIONS ..................................................................................... |

31 |

|

ACCESSING VOLTAGE AND CURRENT PHASES ................................................................... |

32 |

|

ACCESSING %THD FUNCTIONS ................................................................................................. |

33 |

|

VIEWING INDIVIDUAL PHASE INDICATION FOR POWER FUNCTIONS ...................... |

34 |

|

ACCESSING MAX/MIN VALUES ................................................................................................... |

35 |

|

RESETTING VALUES ......................................................................................................................... |

36 |

|

UNPROTECTED RESET ......................................................................................................... |

36 |

|

PROTECTED RESET ............................................................................................................... |

37 |

|

RESETTING HOUR READINGS ..................................................................................................... |

38 |

|

ACCESSING THE LM1/LM2 SET LIMITS ................................................................................... |

39 |

|

VOLTAGE PHASE REVERSAL AND IMBALANCE ................................................................... |

40 |

|

ACCESS MODES ................................................................................................................................ |

41 |

|

PRINT OPERATING DATA ............................................................................................................... |

42 |

|

PRINT PROGRAMMING DATA ...................................................................................................... |

43 |

|

ACCESSING FIRMWARE VERSION/LED TEST ........................................................................ |

44 |

DISTRIBUTED DIGITAL FAULT RECORDER – INSTRUCTION MANUAL |

TOC–I |

TABLE OF CONTENTS |

|

|

6: PROGRAMMING |

GENERAL PROCEDURE .................................................................................................................. |

45 |

OVERVIEW |

SWITCH PACKS ................................................................................................................................. |

46 |

|

PROGRAMMING MODE DATA ENTRY ....................................................................................... |

47 |

|

STANDARD NUMERIC DATA ENTRY .......................................................................................... |

48 |

7: EPM 5200P |

EPM 5200P .......................................................................................................................................... |

49 |

8: ENTERING |

CHECKSUM ERROR—PROTECTIVE SELF-CHECKING ALGORITHMS ............................ |

51 |

PROGRAMMING MODE |

PASSWORD ENTRY .......................................................................................................................... |

52 |

9: PROGRAMMING |

GROUP 0, FUNCTION 0—THE INTEGRATION INTERVAL .................................................. |

54 |

GROUP 0 - GLOBAL |

GROUP 0, FUNCTION 2 — BAUD RATE ................................................................................... |

56 |

METER SETUP |

GROUP 0, FUNCTION 3 — SYSTEM CONFIGURATION ...................................................... |

57 |

|

OPEN DELTA SYSTEM INSTALLATION PROGRAMMING ................................................... |

58 |

|

SWITCHING COMMUNICATION PROTOCOLS, EI-BUS, MODBUS RTU/ASCII, DNP 3.0 59 |

|

|

MODBUS PLUS CAPABILITY ......................................................................................................... |

60 |

|

PRINTING OPTION ............................................................................................................... |

60 |

|

GROUP 0, FUNCTION 3—PROGRAMMING PROCEDURE .................................................. |

61 |

|

RELAY MODE ..................................................................................................................................... |

62 |

|

GROUP 0, FUNCTIONS 4–5—TIME DELAY FOR RELAYS 1 & 2 (OPTION – NL) ........ |

65 |

|

GROUP 0, FUNCTION 6—KYZ PARAMETER SELECTION ................................................... |

67 |

|

HOW TO USE KYZ PULSE VALUE TABLE FOR MULTIPLICATION: ................................. |

69 |

|

HOW TO USE KYZ PULSE VALUE TABLE FOR DIVISION: ............................................... |

70 |

|

GROUP 0, FUNCTION 7—NUMBER OF PHASES ................................................................... |

72 |

10: PROGRAMMING |

GROUP 1, FUNCTION 0 .................................................................................................................. |

74 |

GROUP 1 – VOLTAGE, |

VOLTAGE FULL SCALE: ........................................................................................................ |

74 |

AMP AND WATT SCALE |

GROUP 1, FUNCTION 1 .................................................................................................................. |

77 |

SETTINGS |

GROUP 1, FUNCTION 2 .................................................................................................................. |

79 |

11: PROGRAMMING |

CALIBRATION REQUIREMENTS ................................................................................................... |

84 |

GROUP 2 - METER |

GROUP 2, FUNCTIONS 0–2 .......................................................................................................... |

85 |

CALIBRATION |

|

|

12: GROUPS 4, 5 AND 6— |

TRIP RELAY .......................................................................................................................................... |

90 |

SET LIMITS AND |

TIME DELAYS & RELAY MODE ..................................................................................................... |

91 |

RELAYS |

GROUP 4: FUNCTIONS 0–3—LM1/LM2 SET LIMITS ........................................................... |

92 |

|

GROUP 4: PROGRAMMING FORMAT FOR LIMIT CONDITION ........................................ |

93 |

|

GROUP 5: FUNCTIONS 0–7—LM1/LM2 SET LIMITS ........................................................... |

94 |

|

GROUP 6: LM1/LM2 SET LIMITS: ................................................................................................ |

96 |

|

GROUP 6: THD SET - LIMITS / RELAYS (FOR OPTION -H) .......................................... |

96 |

|

GROUP 6: FUNCTIONS 0–5—LM1/LM2 SET LIMITS AND RELAY TRIGGERS FOR OVER/UN- |

|

|

DER %THD CONDITIONS ..................................................................................... |

97 |

|

LIMITS OR RELAYS PROGRAMMING PROCEDURE .............................................................. |

98 |

TOC–II |

DISTRIBUTED DIGITAL FAULT RECORDER – INSTRUCTION MANUAL |

|

TABLE OF CONTENTS |

|

13: PHASE REVERSAL |

PHASE REVERSAL AND PHASE IMBALANCE ......................................................................... |

101 |

AND PHASE |

TRIP RELAY .......................................................................................................................................... |

102 |

IMBALANCE SET |

GROUP 7, FUNCTION 0—VOLTAGE PHASE REVERSAL DETECTION ........................... |

103 |

LIMITS/RELAYS |

GROUP 7, FUNCTION 1—PERCENTAGE VOLTAGE PHASE IMBALANCE .................... |

105 |

14: EXITING |

EXITING PROGRAMMING MODE ................................................................................................ |

107 |

PROGRAMMING MODE |

|

|

15: PROGRAMMING |

ENTERING THE PROGRAMMING MODE .................................................................................. |

109 |

QUICK REFERENCE |

DATA ENTRY SEQUENCE ............................................................................................................... |

110 |

|

PROGRAMMING GROUPS ............................................................................................................. |

111 |

|

GROUP 0: GLOBAL METER SETUP .................................................................................... |

111 |

|

GROUP 1: FULL SCALE SETUP ........................................................................................... |

112 |

|

GROUP 2: CALIBRATION ..................................................................................................... |

112 |

|

GROUP 3: CALIBRATION RATIOS ....................................................................................... |

113 |

|

GROUP 4: VOLT/CURRENT LIMITS .................................................................................... |

113 |

|

GROUP 5: POWER FUNCTION LIMITS ............................................................................... |

113 |

|

GROUP 6: THD LIMITS ....................................................................................................... |

113 |

|

GROUP 7: IMBALANCE/REVERSAL LIMITS ........................................................................ |

114 |

|

GROUP 8: DC OUTPUT CALIBRATION ............................................................................... |

114 |

16: ETHERNET OPTION |

ETHERNET MODULE ........................................................................................................................ |

118 |

|

ETHERNET OPTION SETUP ........................................................................................................... |

119 |

|

DEFAULT IP ADDRESS ....................................................................................................... |

119 |

|

AUTOIP ................................................................................................................................ |

119 |

|

SETTING THE IP ADDRESS .................................................................................................. |

120 |

|

NETWORK CONFIGURATION .............................................................................................. |

120 |

|

CONFIGURATION PARAMETERS ......................................................................................... |

121 |

DISTRIBUTED DIGITAL FAULT RECORDER – INSTRUCTION MANUAL |

TOC–III |

TABLE OF CONTENTS

TOC–IV |

DISTRIBUTED DIGITAL FAULT RECORDER – INSTRUCTION MANUAL |

GE Consumer & Industrial

Multilin

EPM 5300 Series Meters

Chapter 1: AC Power

Measurement

The economics of electric power distribution networking dictate several configurations of AC power transmission. The number of phases and voltage levels characterize these configurations.

1.1Single Phase System

A single phase system is a basic two-wire system used in low power distribution applications, such as residential communities or offices. Typically, the voltage is 120V AC. For higher power requirements, such as small commercial facilities, the typical power configuration is two lines of 120V AC opposite in phase (see Figure 1.1 B, below).

This system produces 120 volts from line to neutral for lighting and small appliance use. The line-to-line voltage is 240V AC, used for higher loads such as water heaters, electric dryers, ranges and machinery.

A )

S in g le P h a s e 2 W ir e s

B )

S in g le P h a s e 3 W ir e s

L in e

L in e

N e u t r a l

N e u t r a l

L in e 1

N e u t r a l

N e u t r a l

L in e 2

L in e 2

FIGURE 1–1: Single Phase System: (A) Two-Wire, (B) Three-Wire

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

1–1 |

SINGLE PHASE SYSTEM |

CHAPTER 1: AC POWER MEASUREMENT |

The power (W) in a single phase system is:

W = E • I • cosΘ

E = potential, I = current, and cosΘ = phase difference between the potential and the current.

Power in a 120/240V AC system is:

W = (ELine 1 • ILine 1 • cosΘ) + (ELine 2 • ILine 2 • cosΘ)

Phase differential between the potential and the current results from a non-resistive load, either reactive or capacitive.

Reactive power (VAR): The additional power consumed that does not produce any work but must be delivered to the load: .

VAR = E I sinΘ

This is a measure of the inefficiency of the electrical system.

Apparent power (VA): The total power delivered to the load, and the vector sum of real power and reactive power.

Power Factor (PF): The ratio between real power and apparent power:

Reactive

Apparent Power (VA) Power

(VAR)

Real Power (W)

FIGURE 1–2: Relationship between apparent, real and reactive power

Ideal power distribution should have a PF of 1. This condition can be met only if no reactive power loads exist. In real life applications, many loads are inductive loads. Often, corrective capacitors are installed to correct Poor Power Factor (see Section 1.3).

1–2 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 1: AC POWER MEASUREMENT |

THREE-PHASE SYSTEM |

1.2Three-Phase System

A three-phase system delivers higher levels of power for industrial and commercial applications; the three phases correspond to three potential lines. A 120° phase shift exists between the three potential lines.

A typical configuration has either a Delta connection or a Wye connection (see Figure 1.3, below).

In a three-phase system, the voltage levels between the phases and the neutral are uniform and defined by:

E |

an |

= E = E |

cn |

= Eab = Ebc |

= Eac |

|

|

bn |

3 |

3 |

3 |

||

|

|

|

|

|||

A

1) Delta

B

C

A B

2) Wye

N

C

FIGURE 1–3: Three-Phase System: (1) Delta, (2) Wye

Voltages between the phases vary depending on loading factors and the quality of distribution transformers. The three-phase system is distributed in different voltage levels: 208V AC, 480V AC, 2400V AC, 4160V AC, 6900V AC, 13800V AC, and so on.

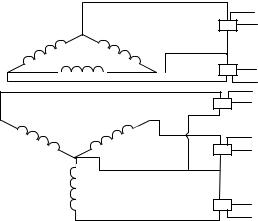

Power measurement in a poly phase system is governed by Blondel's Theorem. Blondel’s Theorem states that in a power distribution network which has N conductors, the number of measurement elements required to determine power is N-1. A typical configuration of poly phase system has either a Delta connection or a Wye connection (see Figure 1.4, below).

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

1–3 |

THREE-PHASE SYSTEM |

CHAPTER 1: AC POWER MEASUREMENT |

|

A |

|

X |

EAB IA |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1) Delta |

|

|

|

P = EAB IA + ECB IC |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|||

C |

|

B |

X |

ECB IC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

X |

EAN IA |

|

|

|

|

|

|

|

A |

|

B |

|

|

|

|

|

|

|

|

|

2) Wye |

|

|

X |

EBN IB |

|

|

|

|

|

|

|

N |

|

P = E |

I + |

E I |

+ |

E |

|

I |

|

||

|

|

|

CN |

C |

|||||||

|

|

|

|

AN |

A |

BN |

B |

|

|

||

|

C |

|

X |

ECN I C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

FIGURE 1–4: Poly Phase System: (1) Delta, (2) Wye

1–4 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 1: AC POWER MEASUREMENT |

CONSUMPTION, DEMAND AND POOR POWER FACTOR |

1.3Consumption, Demand and Poor Power Factor

CONSUMPTION: WH = W × T

W = instantaneous power T = time in hours

The total electric energy usage over a time period is the consumption of WH.

Typically, the unit in which consumption is specified is the kilowatt-hour (KWH): one thousand watts consumed over one hour. Utilities use the WH equation to determine the overall consumption in a billing period.

DEMAND: Average energy consumed over a specified time interval. The utility determines the interval, typically 15 or 30 minutes. The utility measures the maximum demand over a billing period. This measurement exhibits a deviation from average consumption, causing the utility to provide generating capacity to satisfy a high maximum consumption demand. The highest average demand is retained in the metering system until the demand level is reset.

POOR POWER FACTOR: Results in reactive power consumption. Transferring reactive power over a distribution network causes energy loss. To force consumers to correct their Power Factor, utilities monitor reactive power consumption and penalize the user for Poor Power Factor.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

1–5 |

WAVEFORM AND HARMONICS |

CHAPTER 1: AC POWER MEASUREMENT |

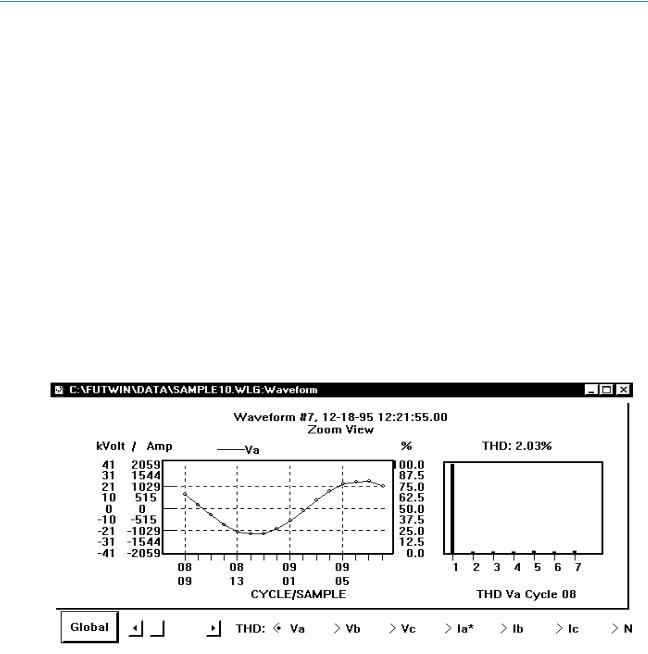

1.4Waveform and Harmonics

Ideal power distribution has sinusoidal waveforms on voltages and currents. In real-life applications, where inverters, computers, and motor controls are used, distorted waveforms are generated. These distortions consist of harmonics of the fundamental frequency.

SINUSOIDAL WAVEFORM:

DISTORTED WAVEFORM:

A • sin (ω t)

A • sin(ω • t) + A1 • sin(ω1 • t) + A2 • sin(ω2 • t) + A3 • sin(ω3 • t) +L

TOTAL HARMONIC DISTORTION (THD):

% of THD = |

RMS of Total Harmonic Distortion Signal |

× 100 |

|

RMS of the Fundamenta l Signal |

|||

|

|

HARMONIC DISTORTION: A destructive force in power distribution systems. It creates safety problems, shortens the life span of distribution transformers, and interferes with the operation of electronic devices. The Futura+ monitors the harmonic distortion to the 31st harmonic. A waveform capture of distorted waveform is also available.

FIGURE 1–5: % THD GRAPH

1–6 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

GE Consumer & Industrial

Multilin

EPM 5300 Series Meters

Chapter 2: Mechanical

Installation

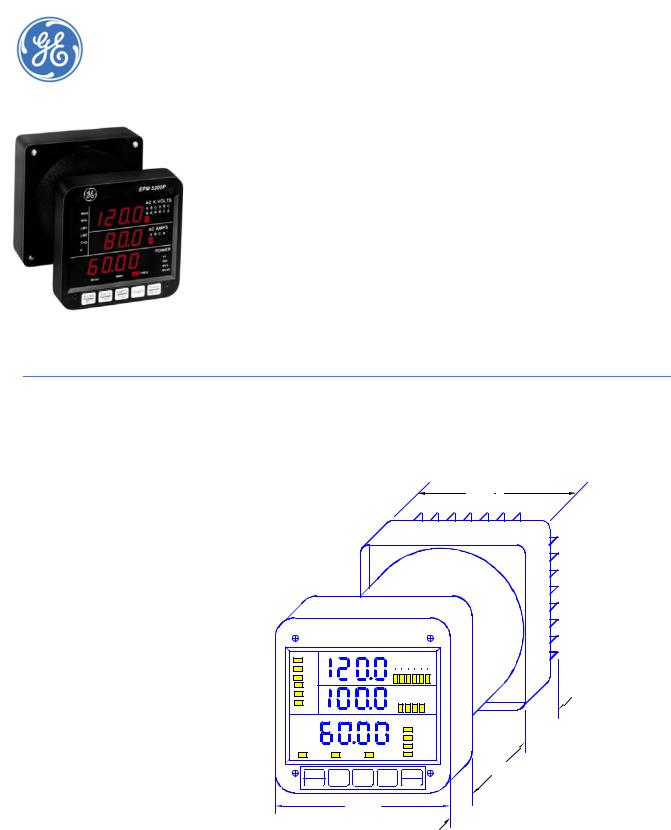

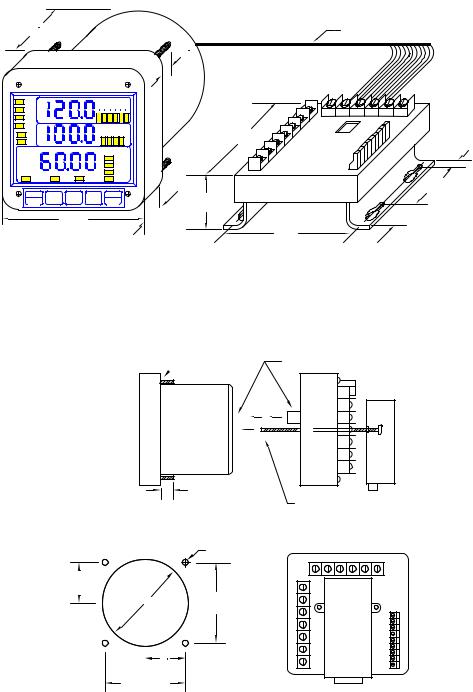

2.1Mechanical Installation

These diagrams display the various possible mechanical installations and Communication

Converter installation. The various models use the same hookup and installation.

|

|

|

|

4.50 |

|

|

|

|

SQ. |

MAX |

|

|

AC VOLTS |

|

MIN |

|

|

A B C A B C |

|

|

|

N N N B C A |

|

|

LM1 |

|

|

|

|

MAX |

|

|

AC AMPS |

|

THD |

|

|

|

|

K |

|

|

A B C N |

|

|

|

|

|

|

|

|

|

POWER |

2.0 |

|

|

|

PF |

|

|

|

|

KW |

|

|

|

|

KVA |

|

KVAH |

KWH |

FREQ |

KVAR |

|

MAX/MIN |

VOLTS |

AMPS |

POWER |

PHASE |

3.0 |

LIMITS |

NEXT |

|

|||

|

|

4.375 |

|

|

0.890 |

|

|

SQ. |

|

|

FIGURE 2–1: Standard installation

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

2–1 |

MECHANICAL INSTALLATION |

CHAPTER 2: MECHANICAL INSTALLATION |

3.50 |

|

|

|

|

3 FOOT CABLE |

|

|

|

|

0.80 |

|

MAX |

|

AC VOLTS |

|

|

|

MIN |

|

A B C A B C |

|

|

|

|

N N N B C A |

|

|

||

LM1 |

|

|

|

|

|

LM2 |

|

|

AC AMPS |

4.50 |

|

THD |

|

|

A B C N |

|

|

K |

|

|

|

SQ. |

|

|

|

|

POWER |

|

|

|

|

|

PF |

|

|

|

|

|

KW |

|

|

|

|

|

KVA |

|

|

KVAH |

KWH |

FREQ |

KVAR |

|

|

MAX/MIN |

|

|

PHASE |

2.425 |

|

LIMITS VOLTS AMPS |

POWER |

NEXT |

|

||

|

4.375 |

|

0.890 |

(4) 8-32 SCREWS |

0.714 |

|

SQ. |

|

|||

|

|

|

5.00 |

|

|

|

|

|

|

|

|

0.336

2.45

FIGURE 2–2: Installation with K-110 option for limited space conditions

SIDE VIEW

(4) 8-32 SCREWS

(4) 8-32 SCREWS

0.80

RECOMMENDED

CUTOUT

0.198 DIA.

1.6875

FIRST PUT (16) PIN CONNECTOR TOGETHER.

(2) 8-32 SCREWS WILL LINE UP WITH 2 PEMS ON THE BACK PLATE.

4.0 DIA. |

3.375 |

|

1.6875

3.375

BACK VIEW

FIGURE 2–3: Standard cutout

2–2 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 2: MECHANICAL INSTALLATION |

|

|

|

|

|

MECHANICAL INSTALLATION |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W Port

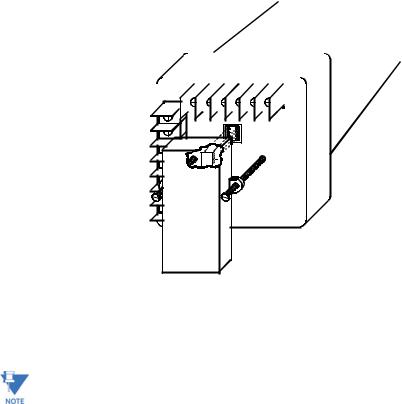

FIGURE 2–4: Optional Communication Converter or DC Output Module Installation

* Recommended wire gauge is 20 AWG for DC Output or RS-485 options. Carefully line up the guide screw and 8 pin port connector to prevent pin breakage.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

2–3 |

MECHANICAL INSTALLATION |

CHAPTER 2: MECHANICAL INSTALLATION |

2–4 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

GE Consumer & Industrial

Multilin

EPM 5300 Series Meters

Chapter 3: Electrical

Installation

3.1Connecting the Current Circuit

Install the wiring for the current at 600V AC insulation as a minimum. The cable connector should be rated for 6 Amps or greater and have a cross-sectional area of 16 AWG minimum.

Mount the current transformers (CTs) as close as possible to the meter for best accuracy. The following table illustrates the maximum recommended distances for various CT sizes, assuming the connection is via 16 AWG cable.

Table 3–1: CT Size and Maximum Distance

|

|

CT Size |

Maximum Distance (CT to Meter) |

|

|

2.5 VA |

10 Feet |

|

|

5.0 VA |

15 Feet |

|

|

7.5 VA |

30 Feet |

|

|

10.0 VA |

40 Feet |

|

|

15.0 VA |

60 Feet |

|

|

30.0 VA |

120 Feet |

|

|

DO NOT leave secondary of the CT open when primary current is flowing. This causes high voltage that will overheat the secondary of the CT. Use a shorting block on the secondary of the CT.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–5 |

CT CONNECTION |

CHAPTER 3: ELECTRICAL INSTALLATION |

3.2CT Connection

If the meter is connected directly to the current (up to 10 Amps max.), maintain the exact connection to avoid incorrect polarity.

When the meter is connected using the CTs, you must maintain the correct CT polarities. CT polarities are dependent upon correct connections of CT leads, and upon the direction the CTs are facing when clamped around conductors. The dot on the CT must face the line side; the corresponding secondary connection must connect to the appropriate input on the meter. Failure to connect CTs properly results in inaccurate power readings. If your meter is not reading power properly, it is more than likely the CT is incorrectly wired.

CTs are shorted if connected to the terminal block model DSP2 or 3 even if it is detached from the meter.

3.2.1Helpful Debugging Tools

Option 1: Isolating a CT Connection Reversal power reading

If your meter does not read the correct watts after installation, it almost always means that the CT’s have been wired in the wrong polarity. To check the polarity of the CT after the monitor has been installed, look at the single phase WATT readings to see that each of the readings are positive (assuming you are consuming power). If one of the WATT readings is negative, that particular phase CT is reversed.

To check the single phase WATT reading, press the Power button twice while the annunciator is positioned to WATTS. Then press the Phase/Next button to cycle through the phases. After connecting the polarity of the CTs, the WATT and VAR readings should be correct.

Option 2: Isolating a CT Connection Reversal using Voltage Readings

ZKW reading. It should be positive.

ZIf negative, reverse the CT wires on terminals 8 and 9.

ZConnect terminal number 6 potential. If KW decreases to about zero, reverse CT wires on terminals 10 and 11.

ZConnect terminal number 7 potential. If KW is one-third of expected reading, reverse CT wires to terminals 12 and 13.

3–6 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 3: ELECTRICAL INSTALLATION |

CONNECTING THE VOLTAGE CIRCUIT |

3.3Connecting the Voltage Circuit

For proper meter operation, the voltage connection must be maintained. The voltage must correspond to the correct terminal.

The cable required to terminate the voltage sense circuit should have an insulation rating greater than 600V AC and a current rating greater than 0.1 A.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–7 |

SELECTING THE VOLTAGE FUSES |

CHAPTER 3: ELECTRICAL INSTALLATION |

3.4Selecting the Voltage Fuses

We strongly recommend using fuses on each of the sense voltages and the control power, although connection diagrams do not show them. Use a 1 Amp fuse on each voltage input.

The meter can handle a maximum voltage of 150V phase to neutral. PTs are required for higher voltages. Suffix -G extends the maximum direct voltage to 300V phase to neutral, 600 volt phase to phase.

3–8 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 3: ELECTRICAL INSTALLATION |

CONNECTION TO THE MAIN POWER SUPPLY |

3.5Connection to the Main Power Supply

The meter requires separate control power to operate. Listed are the five different power supply options and corresponding suffixes.

Table 3–2: Control Power and Current

|

|

|

CONTROL POWER |

OPTION SUFFIX |

CURRENT |

|

|

|

120V AC |

115 A |

0.1 AAC |

|

|

|

240V AC |

230 A |

0.05 AAC |

|

|

|

12V DC |

D4 |

0.10 ADC |

|

|

|

24-48V DC |

D |

0.25-0.5 ADC |

|

|

|

125V AC/DC (universal) |

D2 |

0.10 AAC or DC |

|

|

|

For DC-powered units, polarity should be observed. Connect the negative terminal to L and positive terminal to L1. An earth ground connection to chassis is mandatory for normal operation (terminal three). Do not ground the unit through the negative of the DC supply.

Externally fuse power supply with a slow-blow 3 Amp fuse.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–9 |

ELECTRICAL CONNECTION INSTALLATION |

CHAPTER 3: ELECTRICAL INSTALLATION |

3.6Electrical Connection Installation

Choose the diagram that best suits your application and maintain the CT polarity. Follow the outlined procedure to verify correct connection.

IMPORTANT: For PT connections only, short terminals 3 and 4.

Connect local ground to terminal 3. This protects the unit from spikes and transients.

•The meter and terminal module DSP3 are factory calibrated together; the serial numbers are matched on both. The DSP3 input module and the meter base MUST MATCH!

•Mismatching of the meter and DSP3 input module will cause inaccurate readings because calibration ratios are stored in the meter’s memory, not in the DSP3 input module.

3.6.1List of Connection Diagrams

See phase reversal if a message of CBA appears after installation.

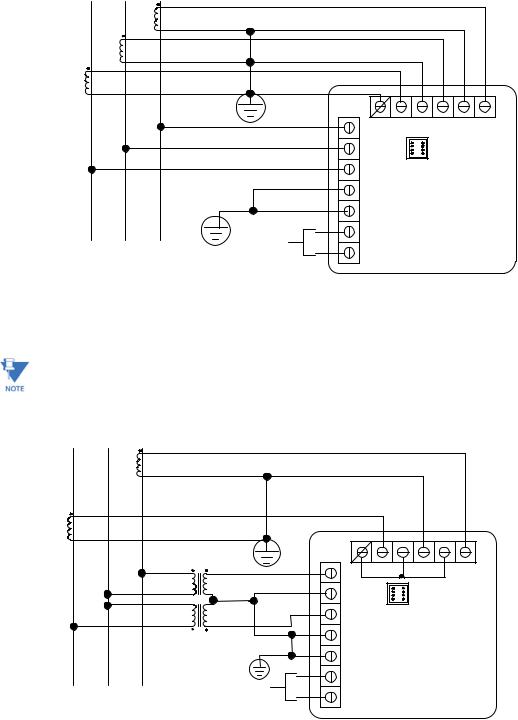

Fig 3-1 |

Three-Phase, Three-Wire System Delta with Direct Voltage and CTs |

|

|

|

Three-Phase, Three-Wire Open Delta with two CTs and two PTs |

Fig 3-2 |

(Open Delta System should only be used if the electrical system is a 3-wire 2 |

PT OPEN DELTA |

|

|

Open Delta can be enabled or disabled in Programming GROUP 0, |

|

FUNCTION 3, Chapter 9, section 9.4) |

|

|

Fig 3-3 |

Three-Phase, Three-Wire Open Delta with three CTs and two PTs |

|

|

Fig 3-4 |

Three-Phase, Four-Wire Wye with Direct Voltage and CTs |

|

|

Fig 3-5 |

Three-Phase, Four-Wire Wye with CTs and PTs |

|

|

VI |

Single Phase with CT and PT Connection |

|

|

VII |

Dual-Phase System |

|

|

VIII |

Three Phase System |

|

|

3–10 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 3: ELECTRICAL INSTALLATION |

ELECTRICAL CONNECTION INSTALLATION |

LINE

A B C

LOAD

BACK VIEW

|

|

7 |

8 |

9 |

10 |

11 |

12 |

13 |

|

|

6 |

|

|

|

|

|

|

|

|

5 |

|

PORT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

CONTROL |

+ |

2 |

L1 |

|

|

|

|

|

|

|

|

|

|

|

|||

POWER

-1 L

FIGURE 3–1: Three Phase, Three-Wire System Delta with Direct Voltage and CTs

Remember to make sure Open Delta bit is programmed in the meters (See Chapter 9).

LINE |

BACK VIEW |

|

A B C |

||

|

LOAD

7 |

8 |

9 |

10 |

11 |

12 |

13 |

6

5 PORT

4

3

+2L1

POWER

-1 L

FIGURE 3–2: Three-Phase, Three-Wire Open Delta with two CTs and two PTs

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–11 |

ELECTRICAL CONNECTION INSTALLATION |

CHAPTER 3: ELECTRICAL INSTALLATION |

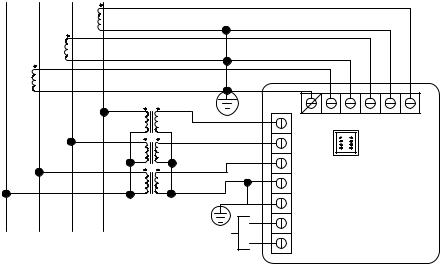

Remember to make sure Open Delta bit is programmed in the meter (see section 9.4).

LINE |

BACK VIEW |

|

A B C |

||

|

LOAD

|

7 8 |

9 |

10 |

11 |

12 |

13 |

|

6 |

|

|

|

|

|

|

5 |

PORT |

|

|

|

|

|

4 |

|

|

|

|

|

|

3 |

|

|

|

|

|

+ |

2 L1 |

|

|

|

|

|

POWER |

1 L |

|

|

|

|

|

- |

|

|

|

|

|

|

FIGURE 3–3: Three-Phase, Three-Wire Open Delta with three CTs and two PTs

Remember to make sure Open Delta bit is programmed in the meter (see Chapter 9).

LINE |

BACK VIEW |

N A B C |

LOAD

|

|

7 |

8 |

9 |

10 |

11 |

12 |

13 |

|

|

6 |

|

|

|

|

|

|

|

|

5 |

|

|

PORT |

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

|

CONTROL |

+ |

2 |

L1 |

|

|

|

|

|

|

|

|

|

|

|

POWER

-1 L

FIGURE 3–4: Three-Phase Four-Wire Wye with Direct Voltage and CTs

3–12 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 3: ELECTRICAL INSTALLATION |

ELECTRICAL CONNECTION INSTALLATION |

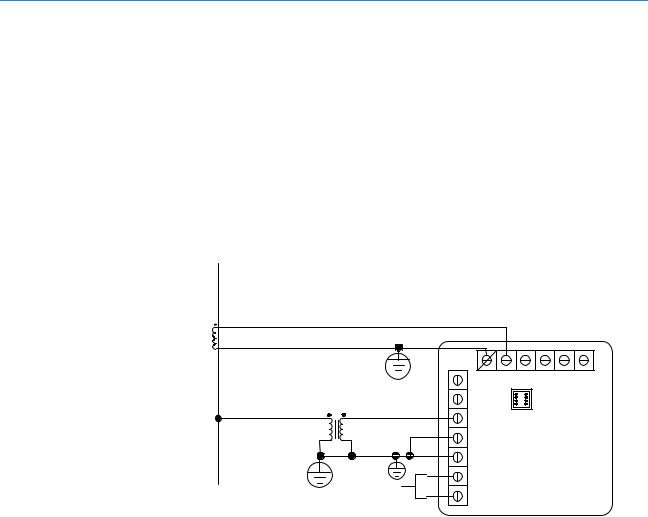

LINE

N A B C |

BACK VIEW |

|

LOAD

7 8 9 10 11 12 13

6

5 PORT

|

4 |

|

3 |

+ |

2L1 |

POWER |

|

-1 L

FIGURE 3–5: Three Phase Four-Wire Wye with CT and PTs

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–13 |

THE EPM 5300P-S |

CHAPTER 3: ELECTRICAL INSTALLATION |

3.7The EPM 5300P-S

The EPM 5300P-S is essentially the 5300P, where through the Programming Mode calculations are changed to reflect either Single Phase or Dual Phase readings.

Single Phase—The connection MUST be identical to Diagram VI.

Dual Phase—The connection MUST be identical to Diagram VII.

Program 1 for Single Phase or 2 for Dual Phase in GROUP 0, FUNCTION 7 to remove Three-

Phase indicators from view.

LINE A

LOAD

BACK VIEW

7 8 9 10 11 12 13

6

5 PORT

4

3

+2 L1

POWER

-1 L

FIGURE 3–6: Single Phase with CT and PT Connection

3–14 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 3: ELECTRICAL INSTALLATION |

THE EPM 5300P-S |

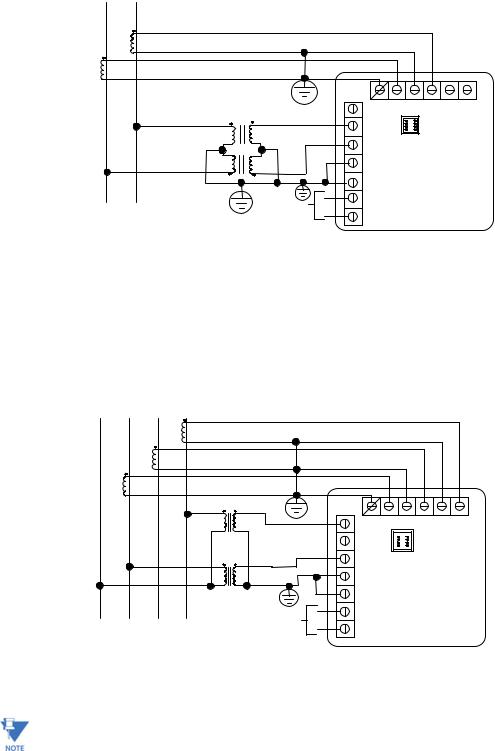

LINE

A B |

BACK VIEW |

|

7 8 9 10 11 12 13

6

5 PORT

4

3

|

+ |

2 L1 |

LOAD |

POWER |

1 L |

- |

FIGURE 3–7: Dual-Phase with CTs and PTs

LINE

N A B C |

BACK VIEW |

|

LOAD

7 8 9 10 11 12 13

6

5 PORT

|

|

4 |

|

|

|

3 |

|

CONTROL |

+ |

2 |

L1 |

|

|||

POWER |

- |

1 L |

|

|

|||

FIGURE 3–8: Three-Phase Four-Wire WYE with 2.5 Element

The 2.5 element option must be custom configured from the factory. You must pre-order this configuration.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–15 |

RELAY, PROTECTION AND PULSE OUTPUT |

CHAPTER 3: ELECTRICAL INSTALLATION |

3.8Relay, Protection and Pulse Output

(This section applies only to the -NL or -NL2 Relay Option.)

3.8.1EPM 5300P Relay Overview

The EPM 5300P offers dry contact relay output capability. The EPM 5200P only offers KYZ pulse outputs and cannot be configured to trip contacts on events.

FAIL-SAFE MODE: The EPM 5300P -NL option gives the user an adjustable tripping bandwidth. The user specifies a range over which functions, such as frequency, phase relation and voltage, are acceptable. The relay releases during times of normal operation, and engages when functions are outside specified normal levels. The relay can be programmed to engage during normal operating conditions, and release outside specified normal range (particularly when power is lost). This is the fail-safe mode.

HYSTERISIS: The EPM 5300P -NL option also includes adjustable hysterisis. In addition to a time delay on activating any contact, the user may specify a lower level to release the relay, rather than releasing after the initial alarm point. This is ideal during load shedding when an alarm activates at a certain level and the user does not want to turn off the alarm until a much lower, safer level.

SETABLE DELAYS: After reaching the alarm point, a change in relay status may be delayed for 255 seconds. The user also has the option of allowing the device to change relay status without any delay. After the alarm condition passes, the relay can be stopped from returning to a normal condition for a programmable time. Each delay time is independent of one another.

AND/OR LOGIC: If several parameters are assigned to one relay, the user can trip the relay if all functions are out of limit (and programming), or if one function is out of limit (or programming). For example, if limits on Voltage, Kilowatts, and Phase Imbalance are programmed and tied to Relay 1, the user can either trip the relay if one function is out of limit, or if all functions are out of limit.

3.8.22 Relays & 1 KYZ Pulse Output -NL OPTION

The EPM 5300P's flexibility accesses a variety of relay options through the Programming Mode (see programming sections). The relay option package consists of three relays: two can be dedicated to alarm or controlled through communication (or both) and one for KYZ pulse output.

If the relays are controlled through communication, there are two different modes:

•Lock ON: Relay will not be affected by any alarm condition.

•Lock OFF: Relay will not be affected by any alarm condition.

If the relays are used for communication and alarm, there are four different modes:

•Lock ON: Relay stays on regardless of any alarm condition.

•Lock OFF: Relay stays off regardless of any alarm condition.

•Free ON: Relay turns on unless other conditions force it off.

•Free OFF: Relay turns off unless other conditions force it on.

3–16 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

CHAPTER 3: ELECTRICAL INSTALLATION |

RELAY, PROTECTION AND PULSE OUTPUT |

Relay connection (see Figure 3.6, below): Form C relays, rated 250V, 5A–2 each.

KYZ relay output (Form C), rated 200V, 100mA–1 each.

20 |

|

|

|

|

N .O . |

A LARM #1 |

21 |

|

|

|

|

N .C . |

|

|

|

|

|

|||

|

|

|

||||

22 |

|

|

|

|

C O M |

|

|

|

|

|

|

||

|

|

|

|

|||

23 |

|

|

|

|

N .O . |

|

|

|

|

|

|

||

|

|

|

|

|||

24 |

|

|

|

|

N .C . |

A LARM #2 |

|

|

|

|

|||

|

|

|

||||

|

|

|

|

|||

25 |

|

|

|

|

C O M |

|

|

|

|

|

|||

26 |

|

|

|

|

K |

|

|

|

|

|

|

||

|

|

|

|

|||

27 |

|

|

|

|

Y |

PULSE |

|

|

|

|

|||

|

|

|

||||

|

|

|

|

|||

28 |

|

|

|

|

Z |

O U TPUT |

|

|

|

|

|||

|

|

|

|

|

|

|

FIGURE 3–9: Close-up of the Relay and KYZ pulse output on the rear panel.

Note: The relays shown in the figure above are in the NOT energized state.

The instrument detects two levels of alarm for the following functions:

•Voltage: AN, BN, CN, AB, BC, CA

•Current: A, B, C, N

•Over and Reverse Power

•Under PF/KVAR Lead or Lag

•Over KVA

•Voltage Imbalance (One level only)

•Over/Under Frequency

•Voltage Phase Reversals (One level only)

•Over/Under %THD (Available only with option –H)

•Over/Under K-Factor

KYZ RELAYS: Provides pulses for energy management systems or any other type of recording device. These pulses represent accumulated watt-hour, negative watt-hour, or VA-hour. Accomplish this assignment through the Programming Mode (see programming sections). The pulse value is determined by the decimal increment of the power function assigned to the pulse. The EPM 5200P can be equipped with KYZ pulse outputs.

Unless otherwise specified, standard KYZ setup represents positive watt hour. See table below for standard rate. The scale factor for wattage (KW or MW) and Full Scale Decimal Point Placement is selectable in Programming Mode GROUP 1, FUNCTION 2. Follow the Decimal Point Placement corresponding to the Change in Level. A multiplication or division factor can be programmed. See Programming GROUP 0, FUNCTION 6 for a different rate.

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

3–17 |

RELAY, PROTECTION AND PULSE OUTPUT CHAPTER 3: ELECTRICAL INSTALLATION

3.8.3 Standard Rate Table for Watts*

|

|

Decimal Point Placement (Kw/mw) |

Change in Level |

|

|

9999.000 |

1.0 Units W-Hour |

|

|

999.900 |

0.1 Units W-Hour |

|

|

99.990 |

0.01 Units W-Hour |

|

|

9.999 |

0.001 Units W-Hour |

|

|

*Units can be Kilowatts or Megawatts.

3–18 |

EPM 5300 SERIES ADVANCED POWER METERS – INSTRUCTION MANUAL |

Loading...

Loading...