GTS 8XX/GPA 65

Installation Manual

(Includes the GA 58 Antenna)

190-00587-00 April, 2009 Revision 4TP

© Copyright 2009

Garmin Ltd. or its subsidiaries

All Rights Reserved

Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted,

disseminated, downloaded or stored in any storage medium, for any purpose without the express prior

written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual

and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and

to print one copy of this manual or of any revision hereto, provided that such electronic or printed copy of

this manual or revision must contain the complete text of this copyright notice and provided further that

any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Garmin International, Inc.

1200 E. 151

st

Street

Olathe, KS 66062 USA

Telephone: 913-397-8200

Aviation Dealer Technical Support Line (Toll Free): (888) 606-5482

www.garmin.com

Garmin (Europe) Ltd

Liberty House

Bulls Copse Road

Hounsdown Business Park

Southampton, SO40 9RB, UK

Telephone: +44 (0) 8708501241

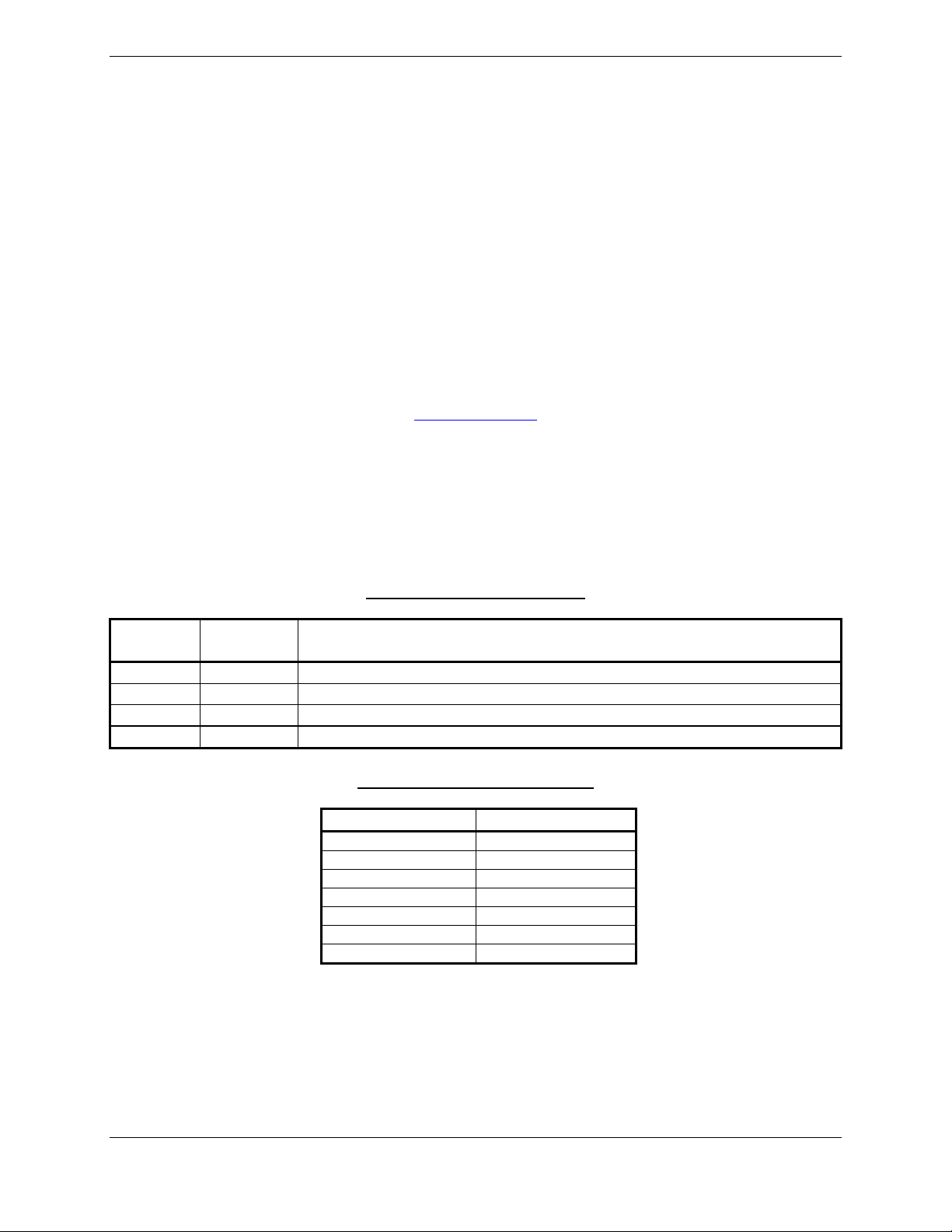

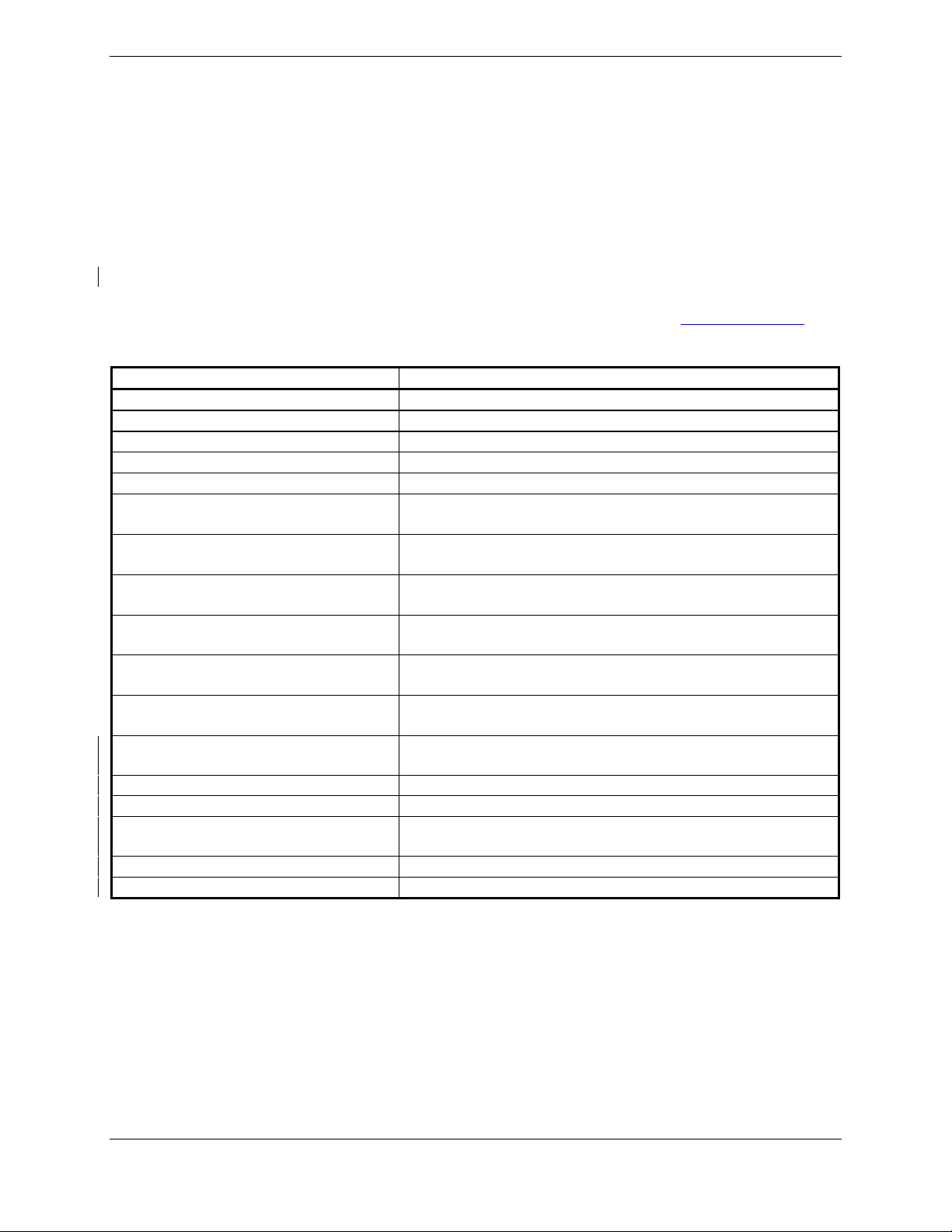

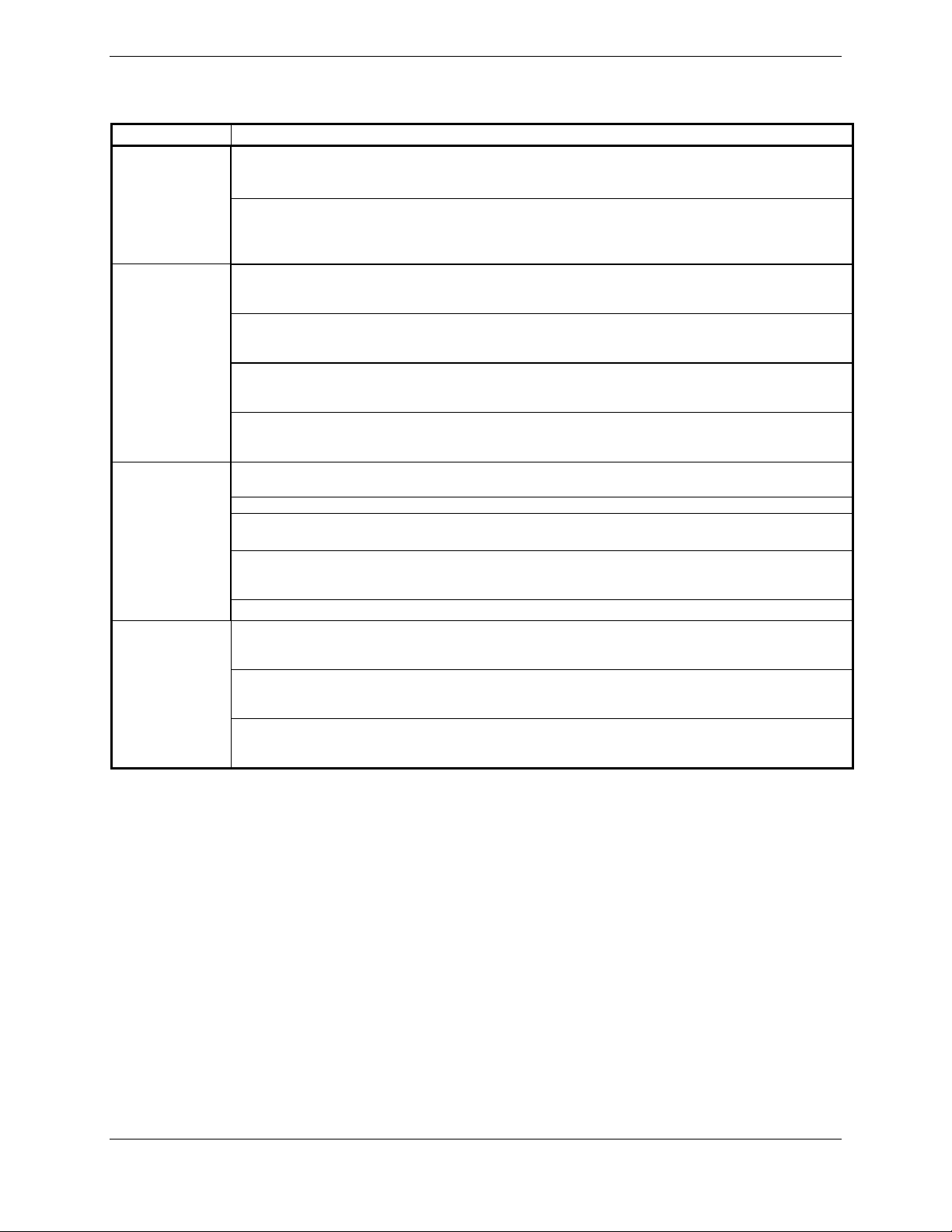

RECORD OF REVISIONS

Revision

1TP 08/06/08 1TP Release

2TP 9/17/08 Updated manual with various engineering changes

3TP 2/18/09 Updated manual with various engineering changes

4TP Updated manual with various engineering changes

Revision

Date

Description

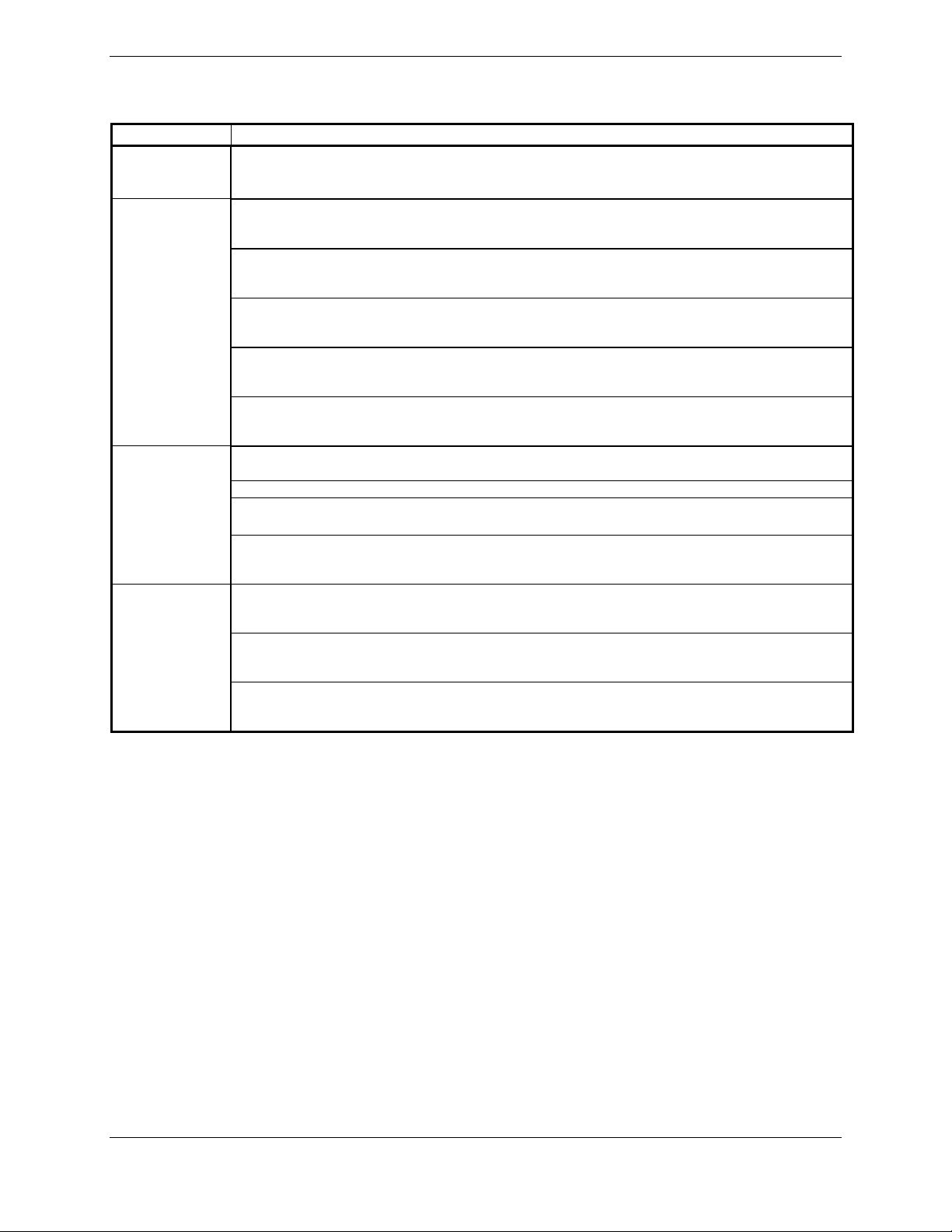

DOCUMENT PAGINATION

Section Page Range

Table of Contents i – vi

Section 1 1-1 – 1-10

Section 2 2-1 – 2-16

Section 3 3-1 – 3-20

Section 4 4-1 – 4-14

Appendix A A-1 – A-14

Appendix B B-1 – B-18

Page A GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

This manual reflects the operation of software version X.XX. Some differences in operation may be

observed when comparing the information in this manual to earlier or later software versions.

INFORMATION SUBJECT TO EXPORT CONTROL LAWS

This document may contain information which is subject to the Export Administration Regulations

(“EAR”) issued by the United States Department of Commerce (15 CFR, Chapter VII Subchapter C) and

which may not be exported, released or disclosed to foreign nationals inside or outside the United States

without first obtaining an export license. The preceding statement is required to be included on any and

all reproductions in whole or in part of this manual.

NOTE

Throughout this document references made to the GTS 8XX shall equally apply to the

GTS 800, 820, and 850 except where specifically noted.

WARNING

This product, its packaging, and its components contain chemicals known to the State of

California to cause cancer, birth defects, or reproductive harm. This Notice is being

provided in accordance with California's Proposition 65. If you have any questions or

would like additional information, please refer to our web site at

www.garmin.com/prop65

.

GTS 8XX/GPA 65 Installation Manual Page i

190-00587-00 Revision 4TP

This page intentionally left blank

Page ii GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

TABLE OF CONTENTS

PARAGRAPH PAGE

1 GENERAL DESCRIPTION..............................................................................................................1-1

1.1 Introduction........................................................................................................................................1-1

1.2 Equipment Description......................................................................................................................1-1

1.3 Interface Summary.............................................................................................................................1-1

1.4 Technical Specifications....................................................................................................................1-2

1.5 Certification.......................................................................................................................................1-4

1.6 Reference Documents........................................................................................................................1-8

1.7 Limited Warranty...............................................................................................................................1-9

2 INSTALLATION OVERVIEW........................................................................................................2-1

2.1 Introduction........................................................................................................................................2-1

2.2 Installation Considerations ................................................................................................................2-3

2.3 Electrical Bonding .............................................................................................................................2-5

2.4 Cabling and Wiring............................................................................................................................2-5

2.5 Cooling Requirements .....................................................................................................................2-15

2.6 Mounting Requirements ..................................................................................................................2-16

3 INSTALLATION PROCEDURE......................................................................................................3-1

3.1 Unpacking Unit..................................................................................................................................3-1

3.2 Wiring Harness Installation...............................................................................................................3-1

3.3 QMA Connector Insertion and Removal...........................................................................................3-3

3.4 Backshell, Pigtail Circular Connector, and Configuration Module Assemblies................................3-5

3.5 Unit Installation .................................................................................................................................3-5

3.6 GA 58 Antenna Installation.............................................................................................................3-19

3.7 GPA 65 PA/LNA Installation..........................................................................................................3-20

3.8 Continued Airworthiness.................................................................................................................3-20

4 SYSTEM INTERCONNECTS..........................................................................................................4-1

4.1 GTS 8XX Pin Function List ..............................................................................................................4-1

4.2 GPA 65 Pin Function List..................................................................................................................4-6

4.3 Power.................................................................................................................................................4-7

4.4 Serial Data .........................................................................................................................................4-9

4.5 Configuration...................................................................................................................................4-12

4.6 Analog/Discrete...............................................................................................................................4-12

4.7 Mutual Suppression Bus..................................................................................................................4-14

APPENDIX A: OUTLINE & INSTALLATION DRAWINGS..............................................................A-1

APPENDIX B: INTERCONNECT EXAMPLE...................................................................................... B-1

GTS 8XX/GPA 65 Installation Manual Page iii

190-00587-00 Revision 4TP

LIST OF ILLUSTRATIONS

FIGURE PAGE

2-1 GTS 800 Installation with Top and Bottom Directional Antennas....................................................2-7

2-2 GTS 800 Installation with Top and Bottom Monopole Antennas.....................................................2-8

2-3 GTS 800 Installation with Top Directional Antennas and no Bottom Antenna................................2-8

2-4 GTS 820/GTS 850 Installation Top and Bottom Directional Antennas............................................2-9

2-5 GTS 820/GTS 850 Installation with Top Directional and Bottom Monopole Antenna..................2-10

2-6 GTS 820/GTS 850 Installation with Top Directional and no Bottom Antenna...............................2-10

2-7 RG-400/RG-142 Coaxial Cable Stripping Dimensions...................................................................2-14

2-8 Ferrule and Crimp Die Positioning..................................................................................................2-14

2-9 Heat Shrink Positioning...................................................................................................................2-15

2-10 GTS 8XX Vertical Installation Rack (Garmin P/N 115-00781-00) ................................................2-16

2-11 GTS 8XX Horizontal Installation Rack (Garmin P/N 115-00784-00)............................................2-16

3-1 Engaging QMA Connectors...............................................................................................................3-3

3-2 Disengaging QMA Connectors..........................................................................................................3-4

3-3 GTS 8XX Install Tool – Normal Tab................................................................................................3-7

3-4 GTS 8XX Install Tool – Configuration Tab (GTS 800)....................................................................3-8

3-5 GTS 8XX Install Tool – Configuration Tab (GTS 820 and GTS 850)..............................................3-9

3-6 GTS 8XX Install Tool – Upload Tab...............................................................................................3-12

3-7 Self Test...........................................................................................................................................3-15

3-8 Ground Test .....................................................................................................................................3-16

A-1 GTS 8XX Vertical Outline Drawing ................................................................................................A-1

A-2 GTS 8XX Vertical Installation Drawing ..........................................................................................A-3

A-3 GTS 8XX Horizontal Outline Drawing............................................................................................A-5

A-4 GTS 8XX Horizontal Installation Drawing......................................................................................A-7

A-5 GPA 65 Outline Drawing .................................................................................................................A-9

A-6 GPA 65 Installation Drawing .........................................................................................................A-11

A-7 GA 58 Antenna Outline Drawing...................................................................................................A-13

B-1 Notes................................................................................................................................................. B-1

B-2 GTS 820/850/GPA 65 Example Interconnect ................................................................................... B-3

B-3 GTS 800 Example Interconnect........................................................................................................ B-5

B-4 GTS 8XX G1000 Example Interconnect ..........................................................................................B-7

B-5 GTS 8XX GNS 4XX/GNS 5XX/GMX 200 Example Interconnect.................................................B-9

B-6 GTS 8XX/GMA/Altimeter Example Interconnect ......................................................................... B-11

B-7 GTS 8XX Dongle Cable (Non-G 1000 Installations Only).............................................................B-13

B-8 GTS 8XX Discrete Interconnects ................................................................................................... B-15

B-9 GTS 8XX Config Module Example Interconnect .......................................................................... B-17

Page iv GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

LIST OF TABLES

TABLE PAGE

2-1 GPA 65 Minimum Wiring Requirements..........................................................................................2-6

2-2 Cable Types and QMA Connectors.................................................................................................2-11

2-3 Recommended Coaxial Length........................................................................................................2-12

2-4 Coaxial Cable Set Length Tolerance ...............................................................................................2-13

3-1 Socket and Pin Contact part Numbers...............................................................................................3-1

3-2 Socket Contact MIL SPEC M39029/5-115 Crimp Tooling...............................................................3-1

3-3 Pin Contact GPN 336-00021-00 MIL SPEC M39029/58-360 Crimp Tooling .................................3-2

3-4 Pin Socket Contacts GPN 336-00022-00 MIL SPEC M39029/63-368 and GPN 336-00023-00 Crimp

Tooling...............................................................................................................................................3-2

3-5 Self Test...........................................................................................................................................3-15

GTS 8XX/GPA 65 Installation Manual Page v

190-00587-00 Revision 4TP

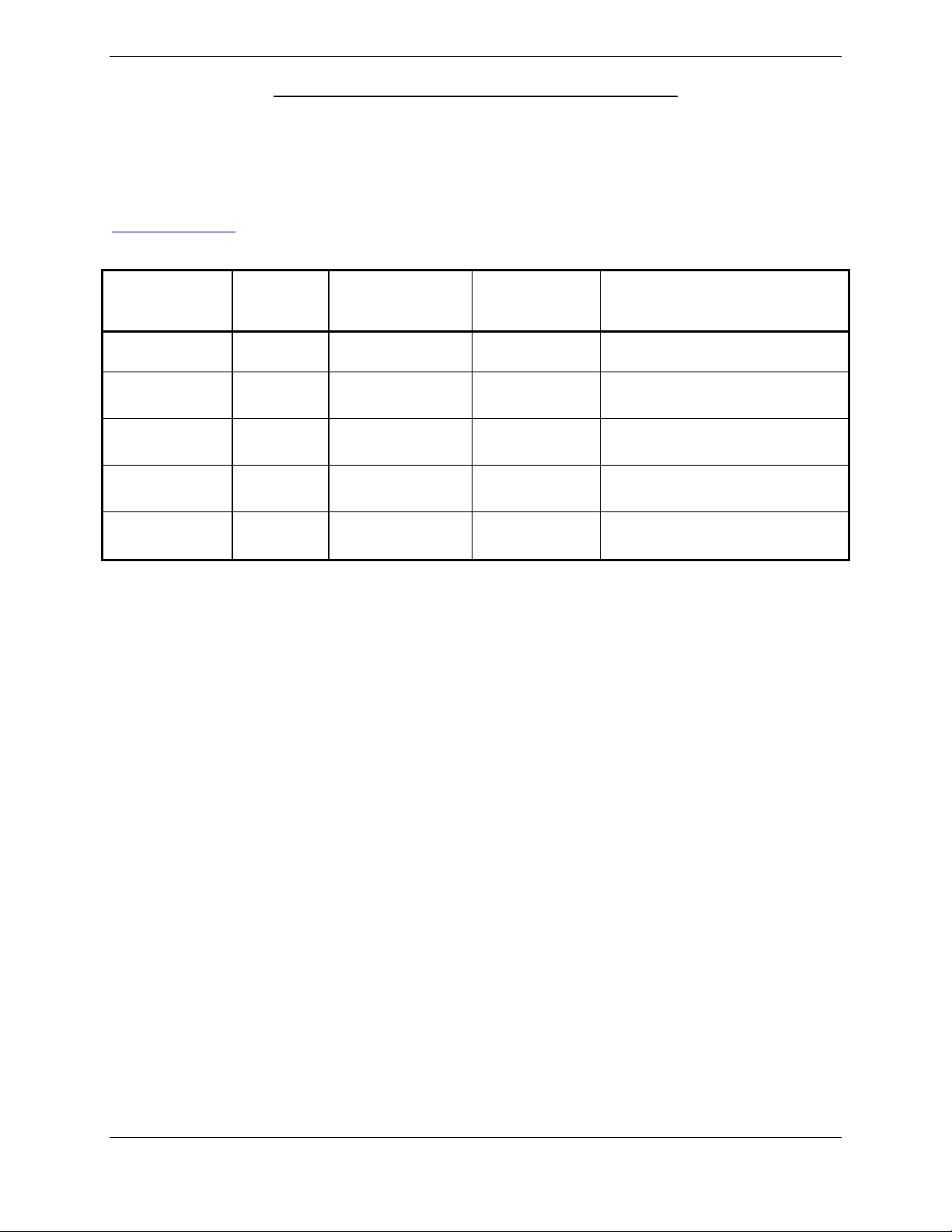

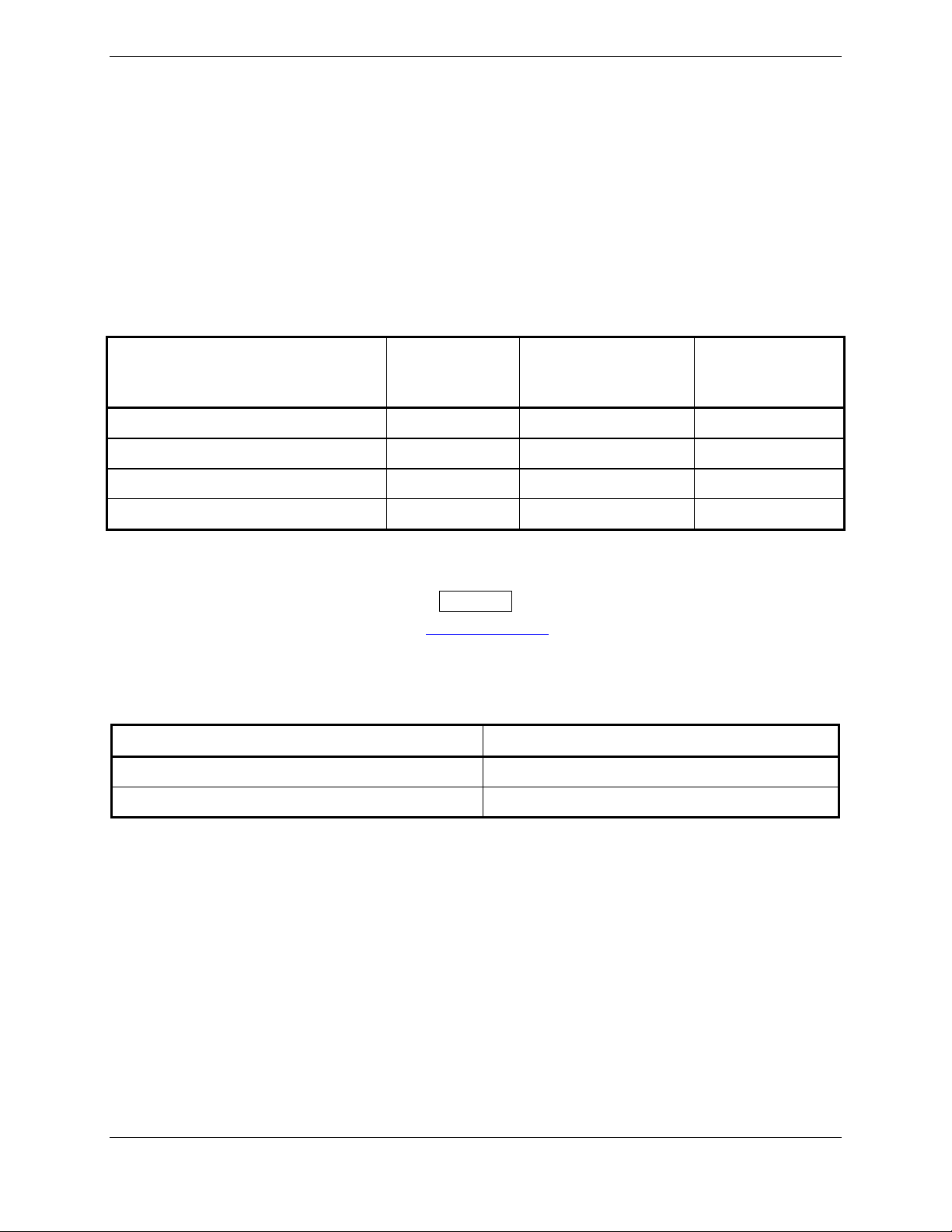

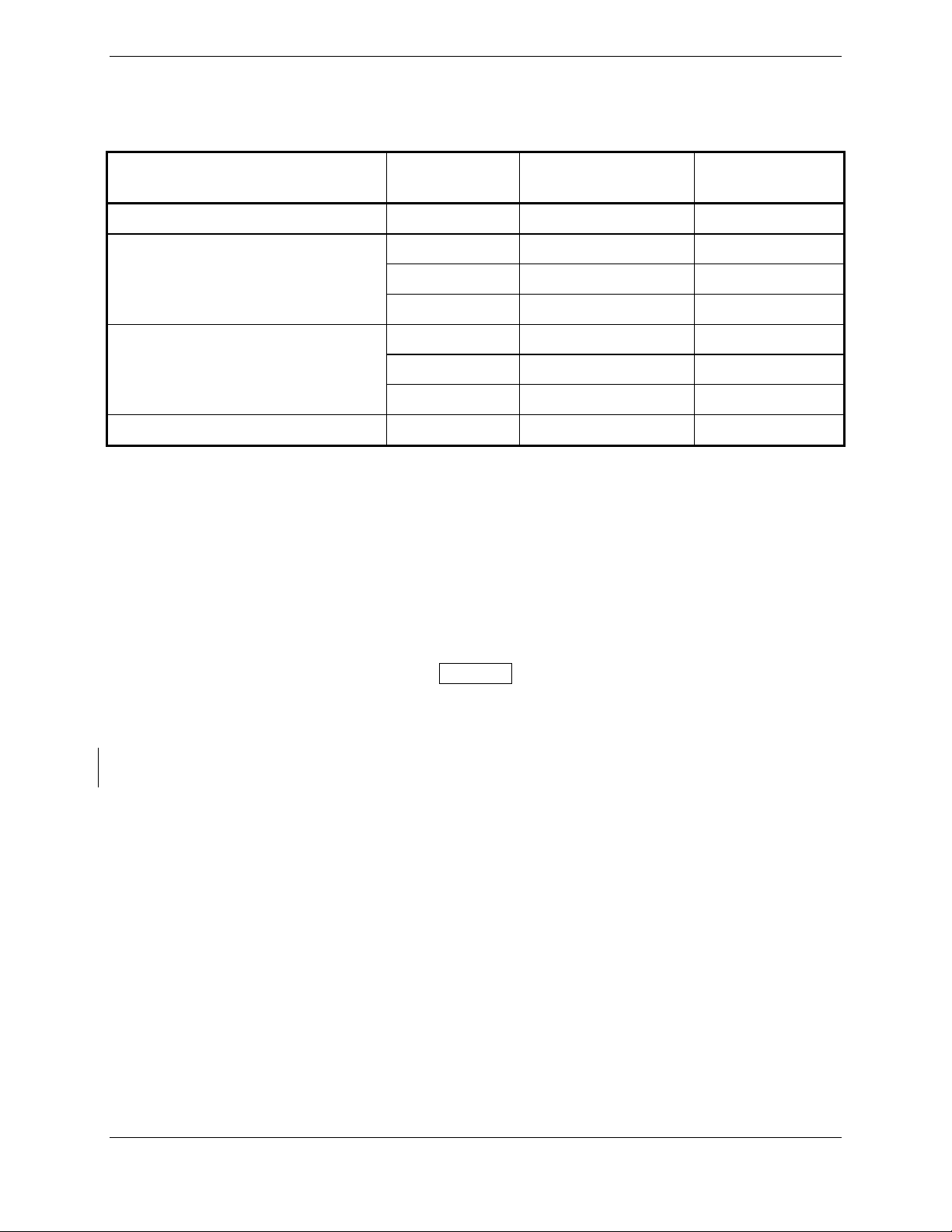

GTS 8XX HARDWARE MOD LEVEL HISTORY

The following table identifies hardware modification (Mod) Levels for the GTS 8XX. Mod Levels are

listed with the associated service bulletin number, service bulletin date, and the purpose of the

modification. The table is current at the time of publication of this manual (see date on front cover) and is

subject to change without notice. Authorized Garmin Sales and Service Centers are encouraged to access

the most up-to-date bulletin and advisory information on the Garmin Dealer Resource web site at

www.garmin.com

APPLICABLE

LRU PART

NUMBER

using their Garmin-provided user name and password.

MOD

LEVEL

SERVICE

BULLETIN

NUMBER

SERVICE

BULLETIN

DATE

PURPOSE OF

MODIFICATION

Page vi GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

(

)

1 GENERAL DESCRIPTION

1.1 Introduction

This manual presents mechanical and electrical installation requirements for installing the

GTS 8XX/GPA 65 Traffic Advisory System (TAS) and Traffic Collision Avoidance System (TCAS I).

1.2 Equipment Description

The GTS 8XX is a microprocessor-based Line Replaceable Unit (LRU) that uses active interrogations of

Mode S (GTS 820 and GTS 850 only) and Mode C transponders to provide Traffic Advisories to the

pilot. The GTS 820 and GTS 850 include a GPA 65 power amplifier/low-noise amplifier (PA/LNA)

module, which allows for up to 40 nm of active surveillance range as well as Mode S interrogation

capability. When installed with a 1090 MHz ADS-B transmit class of equipment the GTS 8XX also

utilizes passive surveillance. Traffic is displayed on an external MFD via ARINC 429 and/or Ethernet

High Speed Data Bus (HSDB). An aural alert is also provided to inform the crew a traffic advisory (TA)

will be displayed.

A top-mounted directional antenna is used to derive bearing of the intruder aircraft, which is displayed

with relative altitude to own aircraft. Top antenna transmitted interrogations are directional, reducing the

number of transponders that receive the interrogation thus reducing potential garble on the 1090 MHz

band. Optional bottom antenna transmit interrogations are omni directional, using a monopole antenna

(recommended for fixed gear installations) or a directional antenna (recommended for retractable gear

installations). A bottom directional antenna installation gives the benefit of intruder bearing visibility for

targets that are shaded from the top directional antenna.

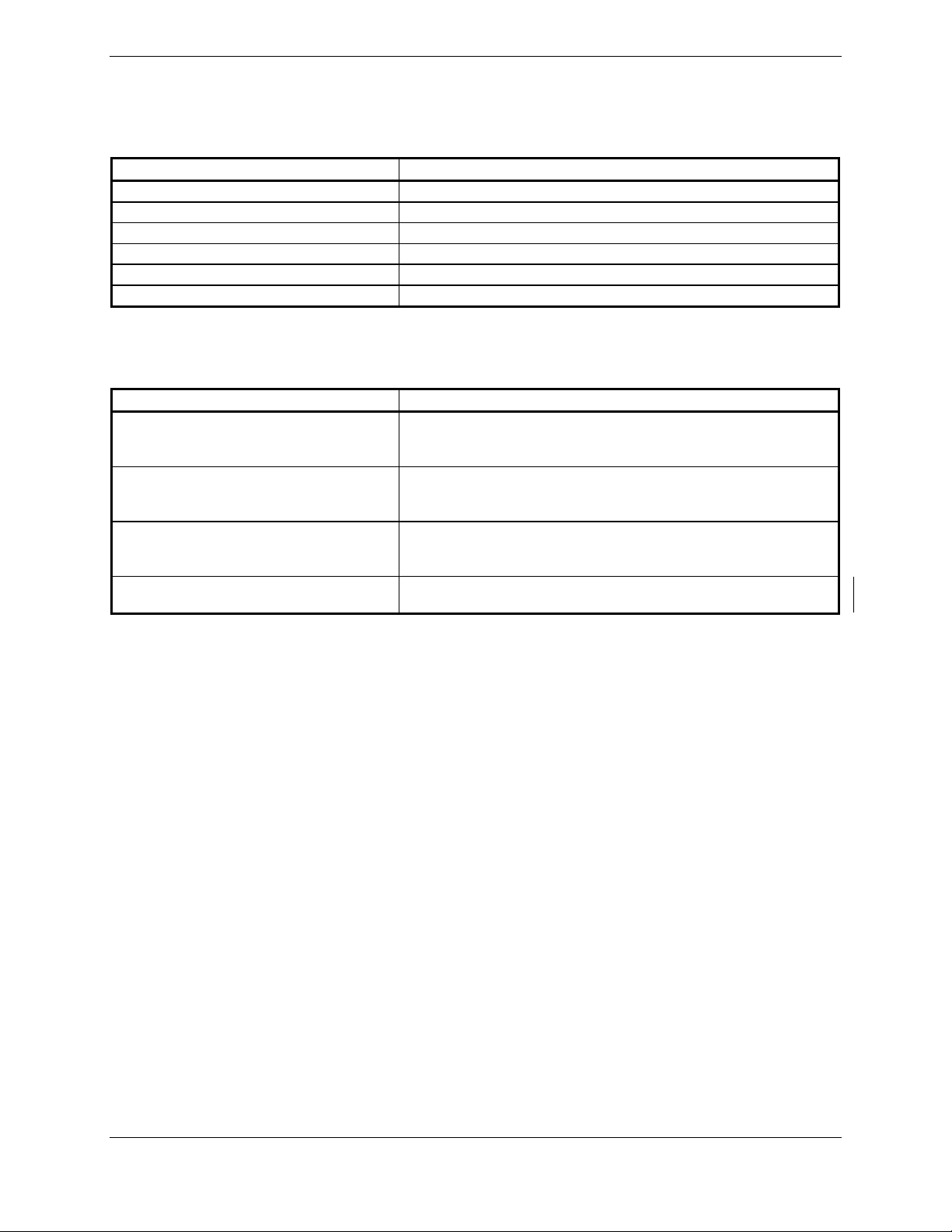

1.2.1 GTS 8XX Model Differences

The following table summarizes the differences between the various GTS 8XX models documented in

this manual.

GTS 800 011-01356-00

GTS 820 011-01446-00

GTS 850 011-01553-00

(TAS)

Traffic Advisory System

X X 40

X X X 200

X X X 200

TCAS I

Receiver

Traffic Collision

1090 ES ADS-B

Avoidance System

GPA 65

PA/LNA

(Watts)

Transmit Power

1.3 Interface Summary

The GTS 8XX is designed as an open architecture system that uses typical ARINC 429, RS-232, and

Ethernet communications interfaces.

GTS 8XX/GPA 65 Installation Manual Page 1-1

190-00587-00 Revision 4TP

1.4 Technical Specifications

1.4.1 Environmental Qualification Form

It is the responsibility of the installing agency to obtain the latest revision of the GTS 8XX/GPA

Environmental Qualification Form. This form is available directly from Garmin under the following part

number:

GTS 8XX Environmental Qualification Form, Garmin part number 005-00323-02

GPA 65 PA/LNA Environmental Qualification Form, Garmin part number 005-00323-22

GA 58 Antenna Environmental Qualification Form, Garmin part number 005-00232-23

To obtain a copy of this form, see the dealer/OEM portion of the Garmin web site (www.garmin.com

).

1.4.2 Physical Characteristics

Characteristics Specifications

GTS 8XX Width 2.81 inches (7.14 cm)

GTS 8XX Height 6.94 inches (17.63 cm)

GTS 8XX Depth w/Connector Kit 14.78 inches (37.54 cm)

GPA 65 Width 4.25 inches (10.80 cm)

GPA 65 Height 1.00 inches (2.54 cm)

GPA 65 Depth Not Including

Connector And Cable

GPA 65 Depth w/Connector And

Cable Fully Extended

GTS 8XX Unit Weight w/out

Connector Kit

GTS 8XX Unit Weight with

Connector Kit/w Vertical Rack

GTS 8XX Unit Weight with

Connector Kit/w Horizontal Rack

GPA 65 PA/LNA Unit Weight with

Pigtail Connector Kit*

GA 58 TAS/TCAS Antenna

w/screws and o-ring

QMA straight connector kit, 4 pcs 0.10 lbs. (0.05 kg)

QMA straight connector kit, 1 pc 0.03 lbs. (0.01 kg)

QMA right angle connector kit,

4 pcs

QMA right angle connector kit, 1 pc 0.05 lbs. (0.02 kg)

QMA termination connector kit 0.07 lbs. (0.03 kg)

*Used with the GTS 820 and 850.

7.96 inches (20.22 cm)

16.83 inches (42.75 cm)

9.0 lbs. (4.08 kg)

10.7 lbs. (4.85 kg)

11.5 lbs. (5.22 kg)

1.9 lbs. (0.86 kg)

0.82 lbs. (0.37 kg)

0.18 lbs. (0.08 kg)

Page 1-2 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

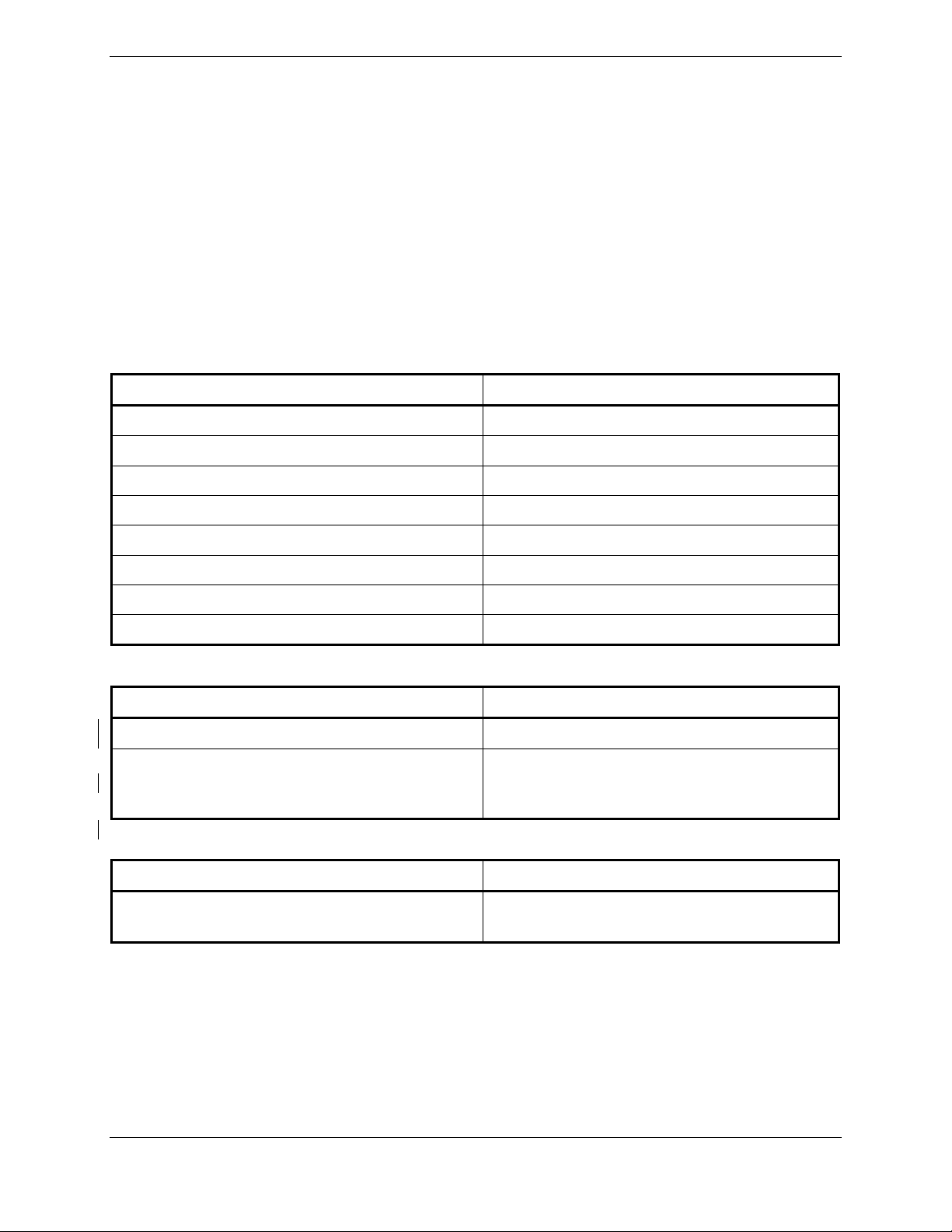

1.4.3 General Specifications

The table below contains general specifications. For detailed environmental specifications, see the

Environmental Qualification Form.

Characteristics Specifications

Operating Temperature Range -55°C to +70°C.

Humidity 95% non-condensing

Altitude Range -1,500 ft to 55,000 ft

Software Compliance RTCA/DO-178B levels B, C, and D

Hardware Compliance RTCA/DO-254 Level C

Environmental Compliance RTCA/DO-160E

1.4.4 Power Requirements

Characteristics Specifications

GTS 8XX Power Requirements 14/28 Vdc. See the Environmental Qualification Form for

details on surge ratings and minimum/maximum operating

voltages.

GTS 800 Power Consumption 1.1 +/- 0.2 A typical 1.5 A max operating @ 28 Vdc

2.2 +/- 0.2 A typical 2.6 A max operating @ 14 Vdc

GTS 820/850 Power Consumption 1.3 +/- 0.2 A typical 1.6 A max operating @ 28 Vdc

2.7 +/- 0.3 A typical 3.2 A max operating @ 14 Vdc

GTS 8XX Boot-up Current Draw 4.0 A @ 28 Vdc for 70 ms

5.6 A @ 14 Vdc for 100 ms

GTS 8XX/GPA 65 Installation Manual Page 1-3

190-00587-00 Revision 4TP

1.5 Certification

The conditions and tests required for TSO approval of this article are minimum performance standards. It

is the responsibility of those installing this article either on or within a specific type or class of aircraft to

determine that the aircraft installation conditions are within the TSO standards. TSO articles must have

separate approval for installation in an aircraft. The article may be installed only if performed under 14

CFR part 43 or the applicable airworthiness requirements.

The following table provides a list of applicable TSO/ETSOs for the GTS 8XX/GPA 65.

1.5.1 TSO/ETSO Compliance

Applicable

LRU

GTS 850

GPA 65

GTS 800

GTS 820

GPA 65

GTS 800

GTS 820

GTS 850

Function TSO/ETSO Category

Traffic Alert and Collision

Avoidance System (TCAS I)

Airborne Equipment

Traffic Advisory System

(TAS) Airborne Equipment

Extended Squitter Automatic

Dependent Surveillance –

Broadcast (ADS-B) and

Traffic Information Service –

Broadcast (TIS-B)

Equipment Operating on the

Radio Frequency of 1090

Megahertz (MHz)

TSO-C118

ETSO-C118

TSO-C147

ETSO-C147

TSO-C166a

Applicable

LRU SW Part

Numbers

006-B0551-()

Class A 006-B0551-()

Class

A0/Type 1

Receiving

Only*

Class

A1/Type 1

Receiving

Only*

006-B0551-() 006-C0081-()**

Applicable

CLD Part

Numbers

006-C0081-()**

006-C0092-()***

006-C0081-()**

006-C0092-()***

* Equipment is Class A0 when installed with a single antenna, Class A1 when installed with diversity

antennas.

**GTS 8XX only

***GPA 65 only

Page 1-4 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

1.5.2 TSO/ETSO Deviations

1.5.2.1 GTS 800

TSO/ETSO Deviation

TSO-C147 1. Garmin was granted a deviation from TSO-C147 section 1.c to use RTCA DO-160E, instead of

RTCA DO-160D as the standard for Environmental Conditions and Test Procedures for Airborne

Equipment.

RTCA DO-197A

RTCA DO-185A

RTCA DO-260A

1. Garmin was granted a deviation from RTCA DO-197A section 2.2.3.2.1 to use the Interrogations

Spectrum requirement of RTCA DO-185A section 2.2.3.3 instead of the requirement of RTCA DO197A section 2.2.3.2.1

3. Garmin was granted a deviation from RTCA DO-197A section 2.2.9.1 to realize the bearing

estimation function using a direction finding antenna augmented by tracked correlated ADS-B data

when such data is available and of sufficient integrity.

4. Garmin was granted a deviation from RTCA DO-197A section 2.2.11 to use the suppression

pulse on the aircraft suppression bus specified by RTCA DO-185A section 2.2.3.12 (70 +/-1 µs from

top antenna and 90 +/-1 µs from bottom antenna) instead of 100 +/-5 µs.

1. Garmin was granted a deviation to use DO-185A as modified by Appendix 1 of TSO-C119B and

‘RWG Recommended Modification 2.0 to TSO-C119B.’

2. Garmin was granted a deviation from RTCA DO-185A section 2.2.3.8.2 Mode S signal definition.

3. Garmin was granted a deviation from RTCA DO-185A section 2.2.4.4.2.2.b to use the Enhanced

Preamble Detection method of RTCA DO-260A Appendix I section I.4.1.

4. Garmin was granted a deviation from RTCA DO-185A section 2.2.4.4.2.2.c to use the Baseline

Multi-sample bit and confidence declaration technique of RTCA DO-260A Appendix I section

I.4.2.3.1.

5. Garmin was granted a deviation from RTCA DO-185A section 2.4.2.1.1.4.

1. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.3.4.7.3.b to use the

Conservative and Brute Force error correction techniques specified by RTCA DO-260A section

2.2.4.4.3.1 instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

2. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.4.2 to use the Conservative

and Brute Force error correction techniques specified by RTCA DO-260A section 2.2.4.4.3.1

instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

3. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.5.b to use the Conservative

and Brute Force error correction techniques specified by RTCA DO-260A section 2.2.4.4.3.1

instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

GTS 8XX/GPA 65 Installation Manual Page 1-5

190-00587-00 Revision 4TP

1.5.2.2 GTS 820

TSO/ETSO Deviation

TSO-C147

RTCA DO-197A

RTCA DO-185A

RTCA DO-260A

1. Garmin was granted a deviation from TSO-C147 section 1.c to use RTCA DO-160E, instead of

RTCA DO-160D as the standard for Environmental Conditions and Test Procedures for Airborne

Equipment.

2. Garmin was granted a deviation from TSO-C147 Appendix 1 section 1.6 to use selective Mode S

interrogations as specified by RTCA DO-185A section 2.2.3.8.1 and 2.2.3.9 following all the

applicable protocols for Mode-S surveillance interrogations in the NAS as stated in DO-1 85A and

DO-181C.

1. Garmin was granted a deviation from RTCA DO-197A section 2.2.3.2.1 to use the Interrogations

Spectrum requirement of RTCA DO-185A section 2.2.3.3 instead of the requirement of RTCA DO197A section 2.2.3.2.1

2. Garmin was granted a deviation from RTCA DO-197A section 2.2.3.5 to use the “Mode C Only

All-Call” format specified by RTCA DO-185A section 2.2.3.8.1 instead of the “Mode C” format for

ATCRBS interrogations.

3. Garmin was granted a deviation from RTCA DO-197A section 2.2.9.1 to realize the bearing

estimation function using a direction finding antenna augmented by tracked correlated ADS-B data

when such data is available and of sufficient integrity.

4. Garmin was granted a deviation from RTCA DO-197A section 2.2.11 to use the suppression

pulse on the aircraft suppression bus specified by RTCA DO-185A section 2.2.3.12 (70 +/-1 µs from

top antenna and 90 +/-1 µs from bottom antenna) instead of 100 +/-5 µs.

1. Garmin was granted a deviation to use DO-185A as modified by Appendix 1 of TSO-C119B and

‘RWG Recommended Modification 2.0 to TSO-C119B.’

2. Garmin was granted a deviation from RTCA DO-185A section 2.2.3.8.2 Mode S signal definition.

3. Garmin was granted a deviation from RTCA DO-185A section 2.2.4.4.2.2.b to use the Enhanced

Preamble Detection method of RTCA DO-260A Appendix I section I.4.1.

4. Garmin was granted a deviation from RTCA DO-185A section 2.2.4.4.2.2.c to use the Baseline

Multi-sample bit and confidence declaration technique of RTCA DO-260A Appendix I section

I.4.2.3.1.

5. Garmin was granted a deviation from RTCA DO-185A section 2.4.2.1.1.4.

1. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.3.4.7.3.b to use the

Conservative and Brute Force error correction techniques specified by RTCA DO-260A section

2.2.4.4.3.1 instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

2. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.4.2 to use the Conservative

and Brute Force error correction techniques specified by RTCA DO-260A section 2.2.4.4.3.1

instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

3. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.5.b to use the Conservative

and Brute Force error correction techniques specified by RTCA DO-260A section 2.2.4.4.3.1

instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

Page 1-6 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

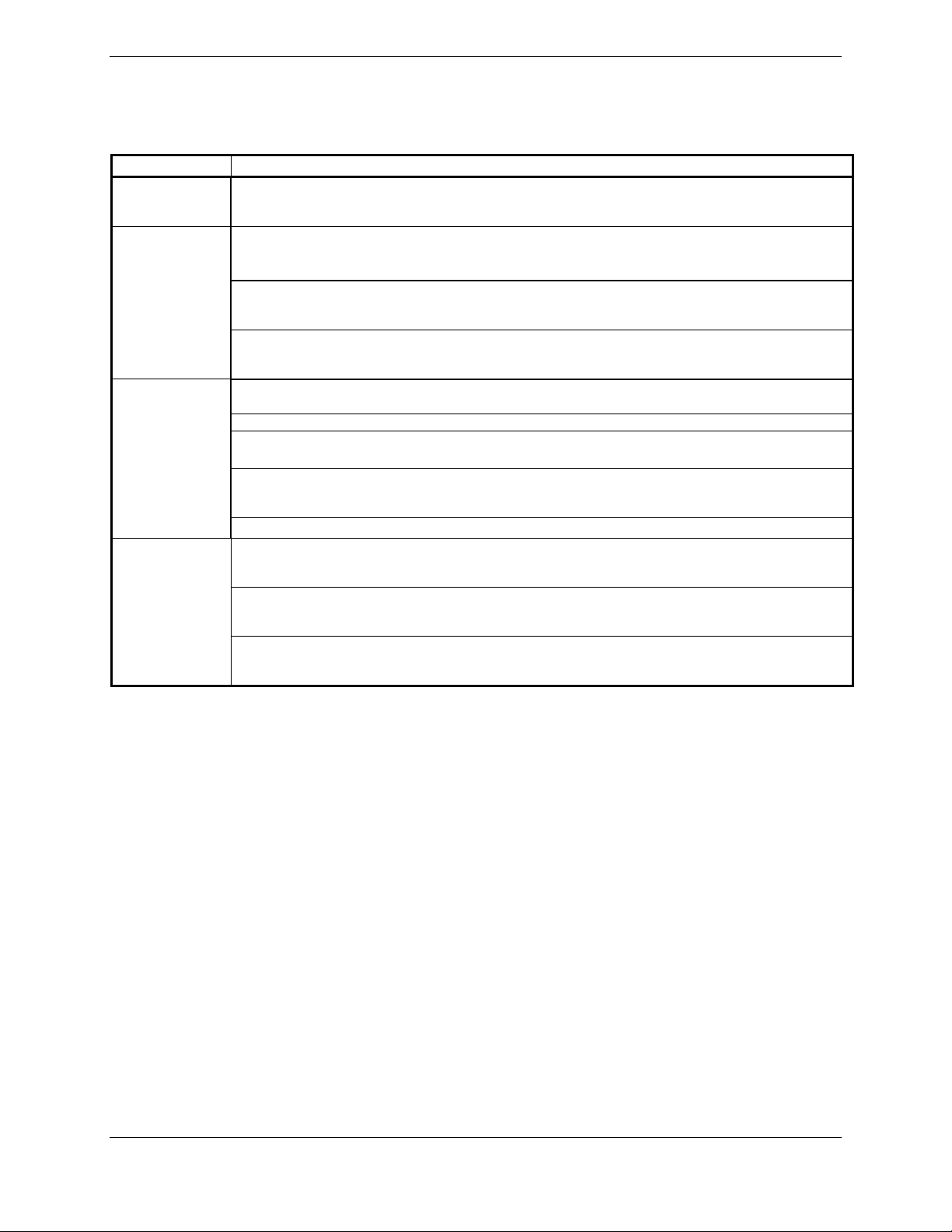

1.5.2.3 GTS 850

TSO/ETSO Deviation

TSO-C118

RTCA DO-197A

RTCA DO-185A

RTCA DO-260A

1. Garmin was granted a deviation from TSO-C118 section a.(2) to use RTCA DO-160E, instead of

RTCA DO-160B as the standard for Environmental Conditions and Test Procedures for Airborne

Equipment.

1. Garmin was granted a deviation from RTCA DO-197A section 2.2.3.2.1 to use the Interrogations

Spectrum requirement of RTCA DO-185A section 2.2.3.3 instead of the requirement of RTCA DO197A section 2.2.3.2.1.

2. Garmin was granted a deviation from RTCA DO-197A section 2.2.3.5 to use the “Mode C Only

All-Call” format specified by RTCA DO-185A section 2.2.3.8.1 instead of the “Mode C” format for

ATCRBS interrogations.

3. Garmin was granted a deviation from RTCA DO-197A section 2.2.6 to use selective Mode S

interrogations following all the applicable protocols for Mode-S surveillance interrogations in the

NAS as stated in DO-185A and DO-181C.

4. Garmin was granted a deviation from RTCA DO-197A section 2.2.9.1 to realize the bearing

estimation function using a direction finding antenna augmented by tracked correlated ADS-B data

when such data is available and of sufficient integrity.

5. Garmin was granted a deviation from RTCA DO-197A section 2.2.11 to use the suppression

pulse on the aircraft suppression bus specified by RTCA DO-185A section 2.2.3.12 (70 +/-1 µs from

top antenna and 90 +/-1 µs from bottom antenna) instead of 100 +/-5 µs.

1. Garmin was granted a deviation to use RTCA DO-185A as modified by Appendix 1 of TSOC119B and ‘RWG Recommended Modification 2.0 to TSO-C119B’.

2. Garmin was granted a deviation from RTCA DO-185A section 2.2.3.8.2 Mode S signal definition.

3. Garmin was granted a deviation from RTCA DO-185A section 2.2.4.4.2.2.b to use the Enhanced

Preamble Detection method of RTCA DO-260A Appendix I section I.4.1.

4. Garmin was granted a deviation from RTCA DO-185A section 2.2.4.4.2.2.c to use the Baseline

Multi-sample bit and confidence declaration technique of RTCA DO-260A Appendix I section

I.4.2.3.1.

1. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.3.4.7.3.b to use the

Conservative and Brute Force error correction techniques specified by RTCA DO-260A section

2.2.4.4.3.1 instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

2. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.4.2 to use the Conservative

and Brute Force error correction techniques specified by RTCA DO-260A section 2.2.4.4.3.1

instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

3. Garmin was granted a deviation from RTCA DO-260A section 2.2.4.5.b to use the Conservative

and Brute Force error correction techniques specified by RTCA DO-260A section 2.2.4.4.3.1

instead of section 2.2.4.4.2.2.d and Appendix A, Section 3 of RTCA DO-185A.

GTS 8XX/GPA 65 Installation Manual Page 1-7

190-00587-00 Revision 4TP

1.6 Reference Documents

The following publications are sources of additional information for installing the GTS 8XX. Before

installing the GTS 8XX, the technician should read all referenced materials along with the manual.

Part Number Document

190-00313-11 Jackscrew Backshell Installation Instructions

190-00303-00 G1000 System Installation Manual

190-00303-04

190-00903-00 G1000 System Maintenace Manual LJ/VLJ

190-00907-00

G1000 Line Maintenance and Configuration

Manual

G1000 System Maintenance Manual Standard

Piston/Turboprop Aircraft

Page 1-8 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

1.7 Limited Warranty

This Garmin product is warranted to be free from defects in materials or workmanship for two years from

the date of purchase. Within this period, Garmin will at its sole option, repair or replace any components

that fail in normal use. Such repairs or replacement will be made at no charge to the customer for parts or

labor, provided that the customer shall be responsible for any transportation cost. This warranty does not

cover failures due to abuse, misuse, accident or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES EXPRESS OR IMPLIED OR STATUTORY, INCLUDING ANY

LIABILITY ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, WHICH MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL GARMIN BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE, OR

INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. Some states do not

allow the exclusion of incidental or consequential damages, so the above limitations may not apply to

you.

Garmin retains the exclusive right to repair or replace the unit or software or offer a full refund of the

purchase price at its sole discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE

REMEDY FOR ANY BREACH OF WARRANTY.

To obtain warranty service, contact your local Garmin Authorized Service Center. For assistance in

locating a Service Center near you, call Garmin Customer Service at one of the numbers shown below.

Products sold through online auctions are not eligible for rebates or other special offers from Garmin.

Online auction confirmations are not accepted for warranty verification. To obtain warranty service, an

original or copy of the sales receipt from the original retailer is required. Garmin will not replace missing

components from any package purchased through an online auction.

Garmin International, Inc. Garmin (Europe) Ltd.

1200 E. 151st Street Liberty House

Olathe, KS 66062, U.S.A. Bulls Copse Road

Phone: 800/800.1020 Hounsdown Business Park

FAX: 913/397.0836 Southampton, SO40 9RB, UK

Telephone: 44 (0) 8708501241

GTS 8XX/GPA 65 Installation Manual Page 1-9

190-00587-00 Revision 4TP

This page intentionally left blank

Page 1-10 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

2 INSTALLATION OVERVIEW

2.1 Introduction

This section provides hardware equipment information for installing the GTS 8XX/GPA 65 and related

hardware. Installation of the GTS 8XX/GPA 65 should follow the aircraft TC or STC requirements.

Cabling is fabricated by the installing agency to fit each particular aircraft. The guidance of FAA

advisory circulars AC 43.13-1B and AC 43.13-2A, where applicable, may be found useful for making

retro-fit installations that comply with FAA regulations.

2.1.1 Unit Configurations

The GTS 8XX and GPA 65 are available under the following part numbers:

Applicable

Item

GTS 800, (011-01356-00) 006-B0551-() 006-C0081-() 010-00519-00

GTS 820, (011-01446-00) 006-B0551-() 006-C0081-() 010-00562-00

GTS 850, (011-01553-00) 006-B0551-() 006-C0081-() 010-00563-00

GPA 65, (011-01347-00) 006-B0551-() 006-C0092-() 010-10721-00

LRU Software

Part Numbers

Applicable Custom

Logic Device

Part Numbers

Garmin P/N

2.1.2 Required Accessories

NOTE

Refer to the Dealer’s Only portion of www.garmin.com for instructions on determining

what accessories are needed.

Each of the following accessories are provided separately from the GTS 8XX and GPA 65 unit and are

required to install the unit.

Installation Racks* Garmin P/N

GTS 8XX Vertical Installation Rack 115-00781-00

GTS 8XX Horizontal Installation Rack 115-00784-00

* Only one is required.

GTS 8XX/GPA 65 Installation Manual Page 2-1

190-00587-00 Revision 4TP

For a GTS 800 installation with a single GA 58 directional antenna, two QMA Connector Kits (4 pieces,

either straight or right angle) are required.

For a GTS 800 installation with dual GA 58 directional antennas, four QMA Connector Kits (4 pieces,

either straight or right angle) kits are required.

For a GTS 800 installation with a single GA 58 directional antenna and a monopole antenna, two QMA

Connector Kits (4 pieces, either straight or right angle) and one QMA Connector Kit (1 piece, either

straight or right angle) are required.

For GTS 820 and 850 installations, add two QMA Connector Kits (4 pieces, either straight or right angle)

for the GPA 65 connections.

One QMA Termination Connector Kit (4 pieces) is required for single antenna installations.

Connector Kits Garmin P/N

QMA Right Angle Connector Kit (4 pieces) 011-01364-00

QMA Straight Connector Kit (4 pieces) 011-01364-01

QMA Right Angle Connector Kit (1 piece) 011-01364-02

QMA Straight Connector Kit (1 piece) 011-01364-03

QMA Termination Connector Kit (4 pieces) 011-01364-04

GTS 8XX Connector Kit 011-01360-00

GPA 65 Circular Connector Kit 011-01365-00

USB-B Pigtail (non-G1000 installations only) 011-01782-00

Antennas Garmin P/N

GA 58 Directional Antenna, (011-01346-00) 010-10720-00*

Monopole Antenna 010-10160-00 or

L-Band Monopole Antenna that meets

TSO-C74c

*010-10720-00 includes mounting screws and o-ring, unless specifically requested to exclude.

Configuration Module Garmin P/N

Configuration Module (non-G1000 installations

only)

011-00979-20

Page 2-2 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

2.2 Installation Considerations

Fabrication of a wiring harness is required. Sound mechanical and electrical methods and practices are

required for installation of the GTS 8XX/GPS 65.

2.2.1 Antenna Considerations

Antenna installations on pressurized cabin aircraft require FAA approved installation design and

engineering substantiation data whenever such antenna installations incorporate alteration (penetration) of

the cabin pressure vessel by connector holes and/or mounting arrangements. For needed engineering

support pertaining to the design and approval of such pressurized aircraft antenna installations, it is

recommended that the installer proceed according to any of the following listed alternatives:

1. Obtain approved antenna installation design data from the aircraft manufacturer.

2. Obtain an FAA approved STC, pertaining to, and valid for the antenna installation.

3. Contact the FAA Aircraft Certification Office in the appropriate Region and request identification

of FAA Designated Engineering Representatives (DERs) who are authorized to prepare and

approve the required antenna installation engineering data.

4. Obtain FAA Advisory Circular AC-183C and identify a DER from the roster of individuals in it.

5. Contact an aviation industry organization such as the Aircraft Electronics Association for

assistance.

For all composite aircraft, antenna installation requires that a ground plane be fabricated on the internal

surface of the aircraft directly under the antenna. The TAS/TCAS antenna pattern is dependent upon a

ground plane under the antenna. The minimum recommended antenna ground plane dimensions are

18” x 18” for composite aircraft.

A fabricated doubler plate assembly supplied by the installing agent or antenna vendor may be required

inside the fuselage to complete the antenna hardware installation.

NOTE

For all GTS 8XX installations, a monopole antenna is recommended if installing an

optional bottom mounted antenna on a fixed-gear aircraft, while retractable-gear aircraft

may use either a monopole or a directional bottom mounted antenna. The target bearing

accuracy may be degraded for bottom directional antenna installations on aircraft with

fixed gear.

GTS 8XX/GPA 65 Installation Manual Page 2-3

190-00587-00 Revision 4TP

2.2.1.1 TAS/TCAS Antenna Location

To achieve proper interrogation and surveillance volumes the following GTS 8XX antenna installation

guidelines should be followed.

The GTS 8XX requires a top-mounted directional antenna. An optional bottom mounted directional or

L-band monopole antenna can be installed in conjunction with the top-mounted directional antenna.

Antenna locations are critical to maintain the surveillance coverage across all azimuth and elevation

angles. Locations shall be chosen so the top mounted and bottom mounted antenna will represent same

range and bearing to an intruder. The mounting location, geometry, and surroundings of the antenna can

affect the system performance. The following guidance provides information to aid the installer in

ensuring that the most optimum location is selected for the installation of the antenna. Because meeting

all of these installations guidelines may not be possible on all aircraft, these guidelines are listed in order

of importance to achieve optimum performance. The installer must use best judgment to balance the

installation guidelines.

Installations must be thoroughly tested to verify that performance degradation as a result of antenna

placement is not an issue for the TAS/TCAS system as well as other systems.

1. As far as physically possible, the top directional antenna shall be mounted at the most forward

location.

2. The TAS/TCAS antenna(s) shall be mounted on the aircraft skin so that the horizontal base is

horizontal to within +/-5° in longitudinal and lateral axes when the aircraft is in level flight.

3. The TAS/TCAS antenna(s) shall be mounted on a flat section of the fuselage to reduce the gap

formed between the base plate and the fuselage when normal mounting torque is applied.

4. It is recommended that all antennas be mounted at least 20 inches away (measured from center to

center) from the TAS/TCAS antenna(s).

5. Ground plane considerations shall include minimization of any discontinuities such as overlapped

un-riveted airframe skins, cowlings, or hatches. It is recommended that all such discontinuities be

at least 18 inches from the nearest edge of the TAS/TCAS antenna.

6. For installations using a bottom mounted antenna, it is recommended that the top and bottom

antennas be located near the same vertical line through the aircraft such that they represent the

same range and bearing to an intruder.

7. The top and bottom mounted TAS/TCAS Antenna shall be as close as possible to the aircraft

centerline.

8. It is recommended that no antenna be mounted in front of the TAS/TCAS antenna(s).

Page 2-4 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

2.3 Electrical Bonding

Electrical equipment, supporting brackets, and racks should be electrically bonded to the aircraft’s main

structure. Refer to SAE ARP 1870 section 5 when surface preparation is required to achieve electrical

bond. The electrical bond should achieve direct current (DC) resistance less than or equal to 2.5

milliohms to local structure to where the equipment is mounted. Compliance should be verified by

inspection using a calibrated milliohm meter. An equivalent OEM procedure may also be substituted.

There may be OEM-specific reasons for electrically isolating equipment or having a higher bond

resistance. These reasons should be rationalized upon installation approval. In general, Garmin

recommends that all GTS 8XX equipment be electrically bonded.

The antenna ground plane and doubler plate must be electrically bonded to the antenna baseplate. The

electrical bond must achieve direct current (DC) resistance less than or equal to 2.5 milliohms.

For composite aircraft, the antenna baseplate must be electrically bonded to the common ground of other

installed equipment for lightning purposes. This can be achieved through the antenna mounting screws.

2.4 Cabling and Wiring

Use #24 AWG or larger diameter wire for all connections unless otherwise specified. The minimum

diameter wire size for all GTS 8XX installation wiring is #24 AWG, except in the case of Aircraft Power

and Aircraft Ground and both shall be a minimum of #18 AWG. Refer to Table 2-1 for GPA 65 wiring

specifications.

A single circuit breaker shall be dedicated to the GTS 8XX unless specifically approved by the

manufacturer on a case by case basis, or allowed by the STC. Do not attempt to combine more than one

unit on the same circuit breaker unless it is specified on an aircraft manufacturer approved drawing, or

STC documentation, for the specific installation requiring a combined configuration.

The current rating for each standard density 37-pin D-sub connector pin is 5 Amps, and the current rating

for each high density 78-pin D-sub connector pin is 2 Amps. A 14 Vdc installation requires a minimum

of two Aircraft Power and two Aircraft Ground wires in the harness. A 28 Vdc installation requires a

minimum of one Aircraft Power and one Aircraft Ground wires in the harness.

It is the responsibility of the installing agency to take into account wire sizing based on the length and

number of wires, current draw of the unit, D-sub connector pin current rating, and the unit’s internal

protection requirements.

NOTE

GTS 8XX/GPA 65 Installation Manual Page 2-5

190-00587-00 Revision 4TP

The maximum wiring length from the GTS 8XX to the GPA 65 is 45 feet.

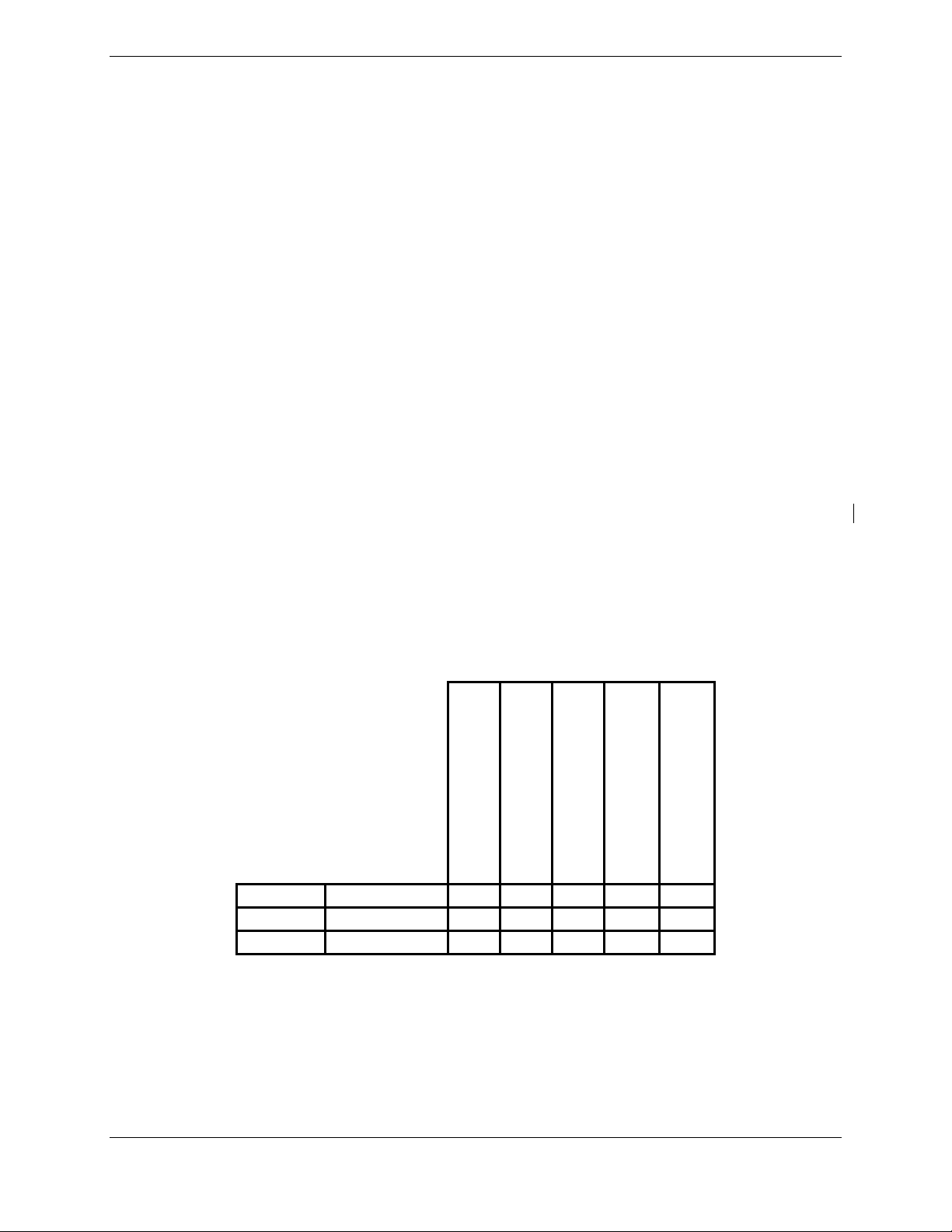

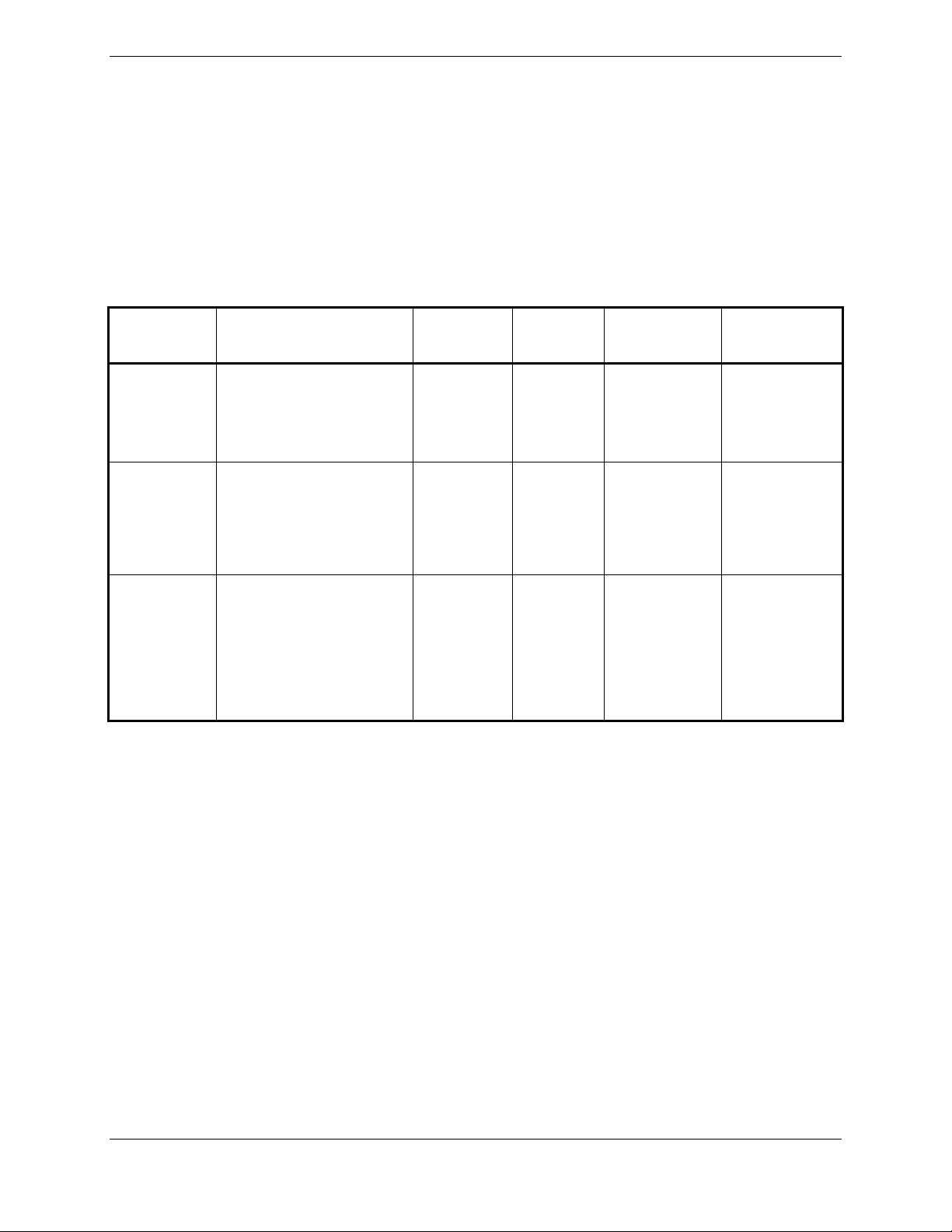

Table 2-1. GPA 65 Minimum Wiring Requirements

Line

Number of

Pins/Wires

Length of Wire

Wire Gauge

Specification

+35V 2 Up To 45' #24 AWG

2 Up To 45' #24 AWG

+6V

1 Up To 30' #22 AWG

1 Up To 20' #24 AWG

2 Up To 45' #24 AWG

-5V

1 Up To 30' #22 AWG

1 Up To 20' #24 AWG

Ground 3 Up To 45' #24 AWG

The contacts used to facilitate the use of #18 AWG wire for Aircraft Power and Aircraft Ground have

expanded-diameter barrels that extend out from the back of the standard D-sub connector body to

accommodate the larger diameter wire. Appropriate heat shrink tubing should be utilized to provide

sufficient insulation from surrounding contacts.

Ensure that routing of the wiring does not come in contact with sources of heat, RF or EMI interference.

Check that there is ample space for the cabling and mating connectors. Avoid sharp bends in cabling and

routing near aircraft control cables.

NOTE

All appliance to antenna cabling shall bundle top channels as a group and bottom

channels as a group to prevent incorrect wiring between top and bottom channels.

A visual inspection shall be performed to verify that all coaxial cables are connected properly, before

attempting to operate the equipment.

Page 2-6 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

2.4.1 Coaxial Cable

The GTS 800 requires two sets of coaxial cable assemblies and the GTS 820/850 requires three sets of

coaxial cable assemblies when a directional GA 58 antenna (or other Garmin approved antenna) is used

for both top and bottom. Each set consists of four coaxial cable assemblies.

Each set of four cables must be assembled using the same type of coaxial cable in order to meet phase and

attenuation matching requirements. In order for the system to operate in compliance with manufacturer

specifications, the coaxial cable assemblies must not exceed the attenuation specifications as stated in this

document. This section explains in further detail the coaxial cable and termination requirements.

2.4.1.1 GTS 800 Installations

NOTE

A monopole antenna is required if installing an optional bottom mounted antenna on all

fixed-gear aircraft. Retractable-gear aircraft can use either a monopole or a directional

bottom mounted antenna.

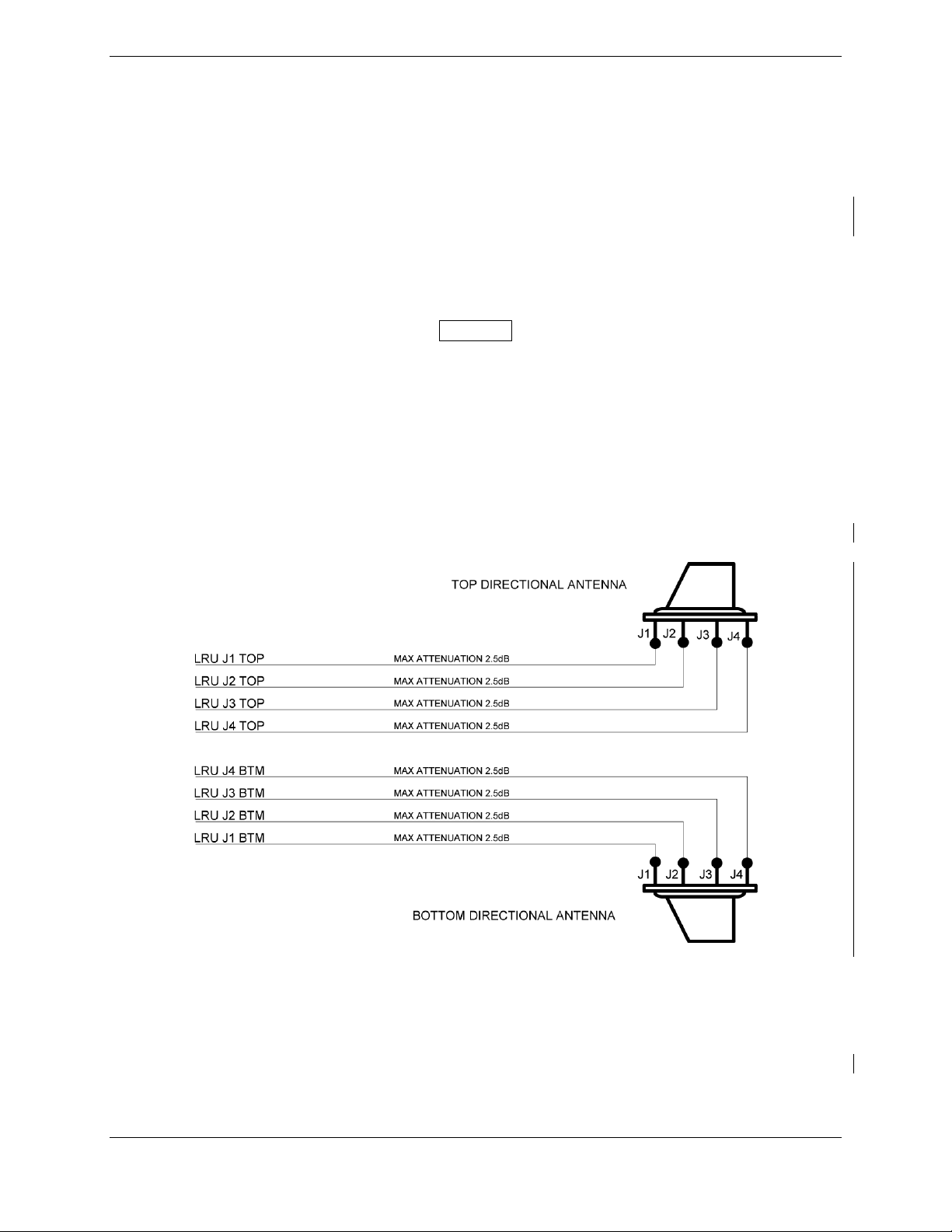

A GTS 800 installation with both top and bottom mounted directional antennas uses one set of coaxial

cables for the four GTS 800 TOP jacks (J1 TOP, J2 TOP, J3 TOP, J4 TOP) that are connected to the

corresponding top antenna jacks J1, J2, J3 and J4. A second set of coaxial cables are used for the four

GTS 800 BTM jacks (J1 BTM, J2 BTM, J3 BTM, J4 BTM) that are connected to the corresponding

bottom antenna jacks J1, J2, J3 and J4. Each cable assembly shall not exceed the maximum attenuation

of 2.5dB at 1090MHz as shown in Figure 2-1.

Figure 2-1. GTS 800 Installation with Top and Bottom Directional Antennas

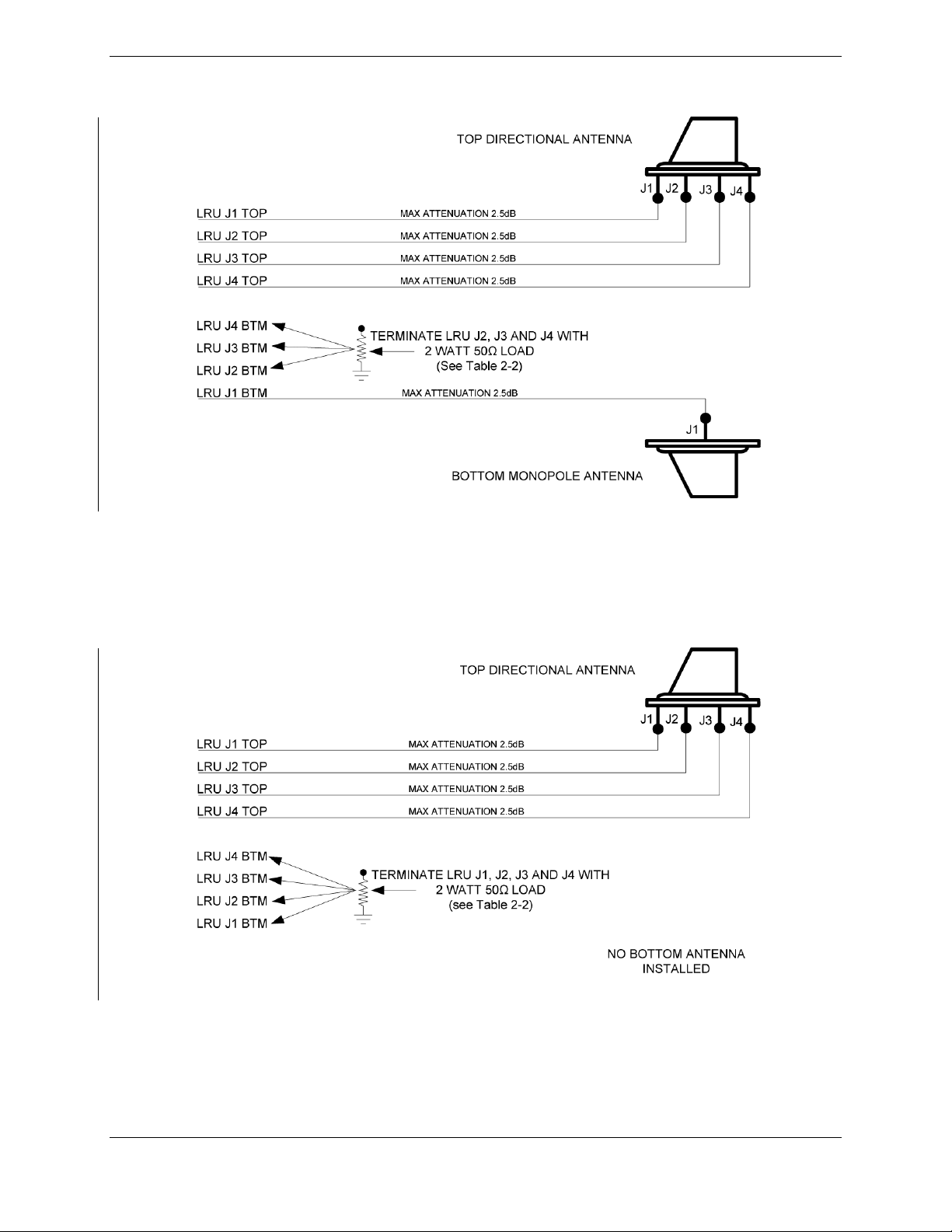

If an optional bottom mount monopole antenna is installed, a single coaxial cable must be used to connect

the GTS 800 bottom jack J1 BTM to the monopole antenna jack. The coaxial cable assembly shall not

exceed the maximum attenuation of 2.5dB at 1090MHz as shown in Figure 2-2 and stated in Table 2-4.

Each of the remaining GTS 800 bottom jacks (J2 BTM, J3 BTM, J4 BTM) are to be terminated using a

QMA 2 watt termination as specified in Table 2-2.

GTS 8XX/GPA 65 Installation Manual Page 2-7

190-00587-00 Revision 4TP

Figure 2-2. GTS 800 Installation with Top and Bottom Monopole Antennas

If no bottom mount antenna is installed, each of the GTS 800 bottom jacks (J1 BTM, J2 BTM, J3 BTM

and J4 BTM) must be terminated with a QMA 2 watt termination as specified in Table 2-2 and shown in

Figure 2-3.

Figure 2-3. GTS 800 Installation with Top Directional Antennas and No Bottom Antenna

Page 2-8 GTS 8XX/GPA 65 Installation Manual

Revision 4TP 190-00587-00

Loading...

Loading...