Page 1

3PDF

Instruction

Manual

ForCar'sandBoat's

3ChannelDigitalProportionalR/CSystem

1M23N02102

Page 2

Thank you for purchasing the Futaba 3PDF.

Prior to operating your 3PDF, please read this manual thoroughly and use

your system in a safe manner.

After reading this manual store it in a safe place.

See the glossary on page (P36) for the definition’s of the special terms used in

this manual.

Application, Export and Reconstruction

1. Use this product in surface models only.

The product described in this manual is subject to regulations of the Ministry of

Radio/Telecommunications and is restricted under Japanese law to such purposes.

2. Exportation Precautions

(a) When this product is exported from Japan, its use is to be approved by the

Radio Law of the country of the destination.

(b) Use of this product with other than models may be restricted by Export and

Trade Control Regulations. An application for export approval must be submitted.

3. Modification, adjustment and replacement of parts.

Futaba is not responsible for unauthorized modification, adjustment and replacement of parts of this product.

THE FOLLOWING STATEMENT APPLIES TO THE

RECEIVER (FOR U.S.A.)

This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions.

(1) This devise may not cause harmful interference, and

(2) This devise must accept any interference received, including interference

that may cause undesired operation.

-No part of this manual may be reproduced in any form without prior permission.

-The contents of this manual are subject to change without prior notice.

-This manual has been carefully written, please write to Futaba if you feel that any corrections or clarifications should be made.

-Futaba is not responsible for the use of this product.

-Futaba is an registered trademark of Futaba Corporation.

Page 3

3PDF

Table of Contens

For your safety as well as

that of others.

Explanation of Symbols 2

Operation Precautions 2

Nicad Battery Handling Precautions

4

Other Precautions 4

Storage and Disposal Precautions

5

Prior to Operation

Features 6

Set Contents 7

Nomenclature / Handling 8

Digital Trim Operating Instructions

11

D/R ATL CH3 LeverOperating In-

structions 11

Display / Key Operation 12

Warning Displays 13

Precautions when turning the power

switches off and on. 13

Assembly

ダ

Receiver and Servo Connections

イ

レ

Assembly Safety Precautions 15

ク

Preparations Prior to Setting Trans-

mitter 16

ト

E.S.C. MC210CB Adjustment 17

モ

14

ー

ド

機

能

Function Map

Function Mode Group 18

System Mode Group 18

Direct Mode Group 19

Description of Functions

Steering Trim 20

Throttle Trim 21

Servo Reverse 22

Steering ATV 23

Throttle ATV 24

Steering D/R 25

Throttle ATL 26

Steering Exponential 27

Throttle Exponential 28

Model Select 29

Model Name 30

Lever Function Select 31

Channel 3 Function Selection 32

CH3 Position Setting 33

Reference

Ratings 34

Optional parts 34

Troubleshooting 35

Glossary 36

When requesting repair 37

For your safety

as well as that

of others.

Prior to

Operation

Assembly

Function

Map

Description

of

Functions

Reference

11

1

11

Page 4

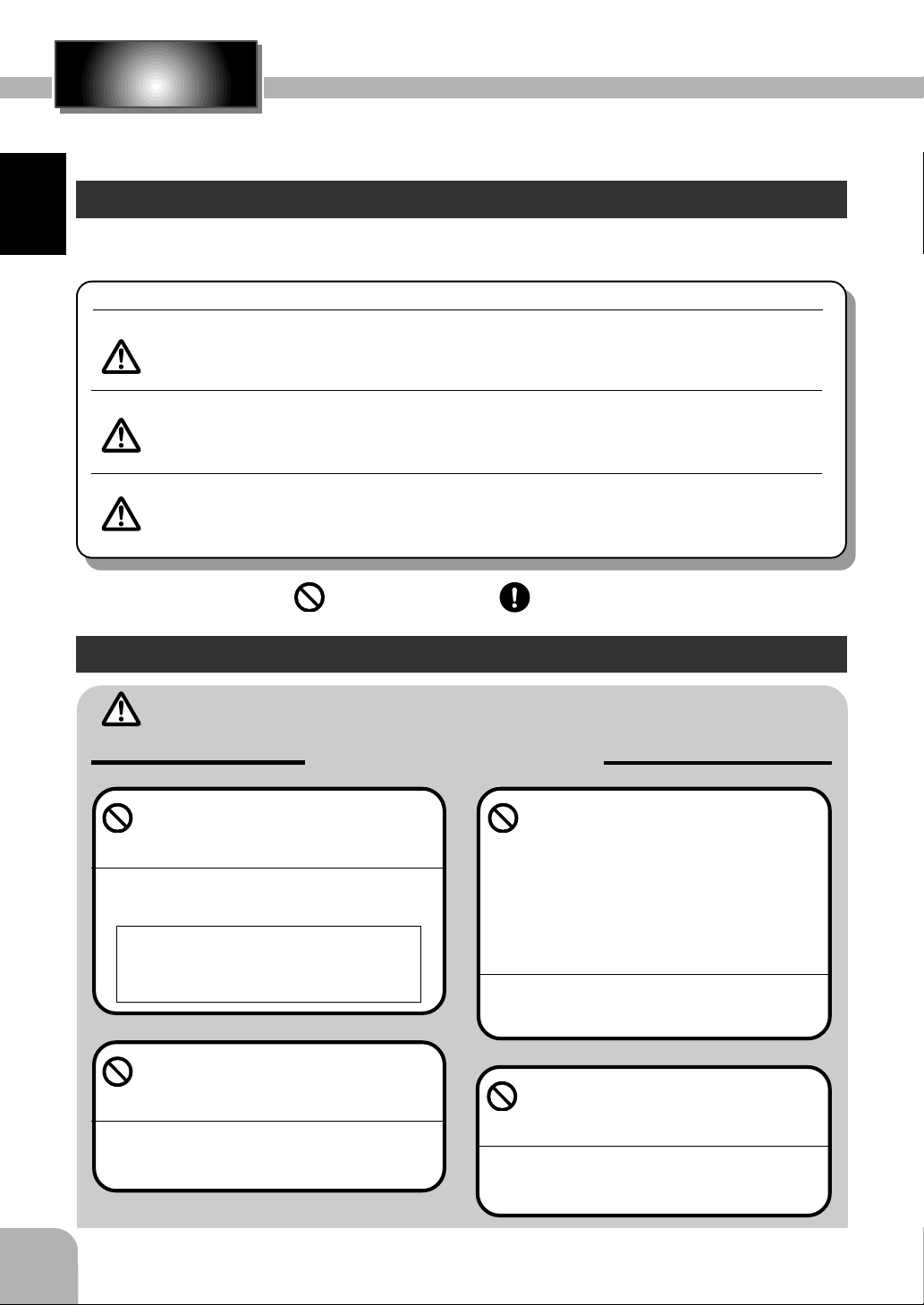

3PDF

For your safety as well as that of others.

Use this product in a safe manner. Please observe the following safety precautions at

all times.

Explanation of Symbols

For your safety as well as that of others.

and must be observed.

Symbols Explanation

DANGER

Warning

Caution

Indicates a procedure which could lead to a dangerous situation and may cause death or serious injury if ignored and

not performed properly.

Indicates procedures which may lead to dangerous situations and could cause death or serious injury as well as superficial injury and physical damage.

Indicates procedures that may not cause serious injury, but

could lead to physical damage.

Symbols: ; Prohibited ; Mandatory

Operation Precautions

Warning

The parts of this manual indicated by the following symbols are extremely important

22

2

22

Prohibited Procedures

Do not operate two or more models

on the same frequency at the same

time.

Operating two or more models at same time on the

same frequency will cause interference and loss of

control of both models.

AM, FM (PPM) and PCM are different methods

of modulation. Nonetheless the same frequency

can not be used at the same point in time, regardless of the signal format.

Do not operate outdoors on rainy

days , run through puddles of water or

when visibility is limited.

Should any type of moisture (water or snow) enter any

compoent of the system, erratic opreation and loss of

control may occur.

Do not operate in the following

places.

-Near other sites where other radio control

activity may occur.

-Near people or roads.

-On any pond when rowboats are present.

-Near high tension power lines or communication broadcasting antennas.

Interference could cause loss of control . Improper installation of your Radio Control System in your model

could result in serious injury.

Do not operate this R/C system when

you are tired, not feeling well or under

the influence of alcohol or drugs.

Your judgment is impaired and could result in a dangerous situation that may cause serious injury to

yourself as well as others.

Page 5

Mandatory Procedures

Tx Rx

Tx: Transmitter

Rx: Receiver

Use genuine Futaba

crystal sets only.

Extend the transmitter antenna to its full

length.

If the transmitter antenna is not

fully extended the operating

range of the radio will be re-

duced.

Extend to

full length

Always perform a operating range

check prior to use.

Problems with the radio control system as well as im-

proper installation in a model could cause loss of con-

trol.

(Simple range test method)

Have a friend hold the model, or clamp it down or

place it where the wheels or prop can not come in

contact with any object. Walk away and check to

see if the servos follow the movement of the controls on the transmitter. Should you notice any abnormal operation, Do not operate the model. Also

check to be sure the model memory matches the

model in use.

Caution

Prohibited Procedures

When changing the frequency, be

sure to always use genuine Futaba

crystal sets (transmitter and receiver)

as specified in this manual. (Changing the frequency crystals in systems

on 75MHz is illegal per FCC regulations)

If other brands of crystals are

used the system may not operate or the operating range

may be reduced.Loss of control will occur .

Item Check

Check the transmitter antenna to be

sure it is not loose.

If the transmitter antenna works loose, or is disconnected while the model is running signal transmission

will be lost. This will cause you to lose control of the

model..

For your safety as well as that of others.

1. Turn on the transmitter power switch.

2. Turn on the receiver or speed control

power switch.

Turning off the power switches

Always be sure the engine is not

running or the motor is stopped.

1. Turn off the receiver or speed control power switch.

2. Then turn off the transmitter power switch.

If the power switches are turned off in the opposite

order the model may unexpectedly run out of control

and cause a very dangerous situation.

Do not touch the engine, motor, speed control or any part of

the model that will generate heat while the model is operating

or immediately after its use.

These parts may be very hot and can cause serious burns.

Mandatory Procedures

Turning on the power switches.

Always check the throttle trigger on the

transmitter to be sure it is at the neutral

position.

Power ON

Power OFF

When making adjustments to

the model do so with the engine not running or the motor

disconnected.

You may unexpectedly lose control and

create a dangerous situation.

FP-R113F

FM

1

2

3

B/C

When operating your model

always display a frequency

flag on your transmitter antenna.

When you change the frequency, also

change the flag to the corresponding channel.

33

3

33

Page 6

Nicad Battery Handling Precautions

Shock

Prohibited

(Only when Nicad batteries are used)

Warning

Mandatory Procedures

For your safety as well as that of others.

Always check to be sure your batteries have been charged prior to operating the model.

Should the battery go dead while the model is operat-

ing loss of control will occur and create a very danger-

ous situation.

When the model is not being used,

always remove or disconnect the

Nicad battery .

Should the battery be left connected this could create

a dangerous situation if someone accidentally turns

on the receiver power switch. Loss of control would

occur.

Caution

Prohibited Items

Do not use commercial AA size Nicad

batteries.

Quick charging may cause the

battery contacts to overheat and

damage the battery holder.

Use

prohibited

Nicad AA size

batteries.

To recharge the transmitter Nicad ,

use the special charger made for this

purpose.

Overcharging could cause the Nicad battery to overheat, leak or explode. This may lead to fire, burns,

loss of sight and many other type's of injuries.

Special

Charger

Do not drop the Nicad battery or expose it to strong shocks or vibrations.

The battery may short circuit and overheat, electrolyte

may leak out and cause burns or chemical damage.

44

4

44

Do not short circuit the Nicad battery

terminals.

Causing a short circuit across the battery terminals

may cause abnormal heating, fire and burns.

Other Precautions

Caution

Prohibited Procedures

Do not expose plastic parts to fuel,

motor spray, waste oil or exhaust.

The fuel, motor spray, waste oil and exhaust will pen-

etrate and damage the plastic.

Mandatory Procedures

Always use only genuine Futaba

transmitters, receivers, servos, FET

amps (electronic speed

controls),Nicad batteries and other

optional accessories.

Futaba will not be responsible for problems caused by

the use of other than Futaba genuine parts. Use the

parts specified in the instruction manual and catalog.

Page 7

Storage and Disposal Precautions

Warning

Prohibited Procedures

Do not leave the radio system or

models within the reach of small children.

A small child may accidentally operate the system,

this could cause a dangerous situation and injuries.

Nicad batteries can be very dangerous when mis-

handled and cause chemical damage.

Do not throw Nicad batteries into a

fire. Do not expose Nicad batteries to

extreme heat. Also do not disassemble or modify a Nicad battery

pack.

Overheating and breakage will cause the electrolyte

to leak from the cells and cause skin burns, loss of

sight as well as other injuries.

<Nicad Battery Electrolyte>

The electrolyte in Nicad batteries is a strong alkali. Should you get even the

smallest amount of the electrolyte in your eyes, DO NOT RUB, wash immediately with water, seek medical attention at once. The electrolyte can cause blindness. If electrolyte comes in contact with your skin or clothes, wash with water

immediately.

Mandatory Procedures

When the system will not be used for

any length of time store the system

with batteries in a discharged state.

Be sure to recharge the batteries prior

to the next time the system is used.

If the batteries are repeatedly recharged in a slightly

discharged state the memory effect of the nicad battery may considerably reduce the capacity . A reduction in operating time will occur even when the batteries are charged for the recommended time.

For your safety as well as that of others.

Caution

Prohibited Procedures

Do not store your R/C system in the

following places.

- Where it is extremely hot or cold.

- Where the system will be exposed to direct

sunlight.

- Where the humidity is high.

-Where vibration is prevalent.

-Where dust is prevalent.

-Where the system would be exposed to

steam and condensation.

Storing your R/C system under adverse conditions

could cause deformation and numerous problems

with opreation.

<Nicad Battery Recycling>

A used Nicad battery is valuable resource. Insulate the battery terminals and

dispose the battery by taking it to a battery recycling center.

Mandatory Procedure

If the system will not be used for a

long period of time remove the batteries from the transmitter and model

and store in a cool dry place.

If the batteries are left in the transmitter electrolyte

may leak and damage the transmitter. This applies to

the model also, remove the batteries from it also to

prevent damage.

55

5

55

Page 8

3PDF

-Multiple Model Memory (3 Models)

A model name can be assigned each memory using six alphabetic,

numeric and symbolic characters. (P30)

Digital Trim Memory will recall all trim settings. As you go from

model to model memory all trim settings will not have to be reset.

Prior to operation

Features

Prior to operation

All program information is displayed on a 8 character 2 line display. The large display is easy to read.

-The third channel can be used to match your

application in specialty models.

-Large LCD Display

The third channel can be used in five operation modes.(P32)

-Digital Trim

Digital trim will allow positive and quick settings to be made.

-Lever Function Selection (P31)

This function applies to D/R, ATL and 3rd channel levers.. Since

they are digital, when you change the model memory these will not

require you to readjust the settings . They will be where they were

the last time that model memory was used.

-New Lightweight and Balanced Design

-Trigger Brake Stop (Mechanical ATL) (P8)

-Body Rest can be used (Option)

66

6

66

-Servo Reverse Function (P22) / Steering

ATV Function (P23) / Steering D/R function

(P25) / Throttle ATV Function (P24) / Throttle

ATL Function (P26)

Page 9

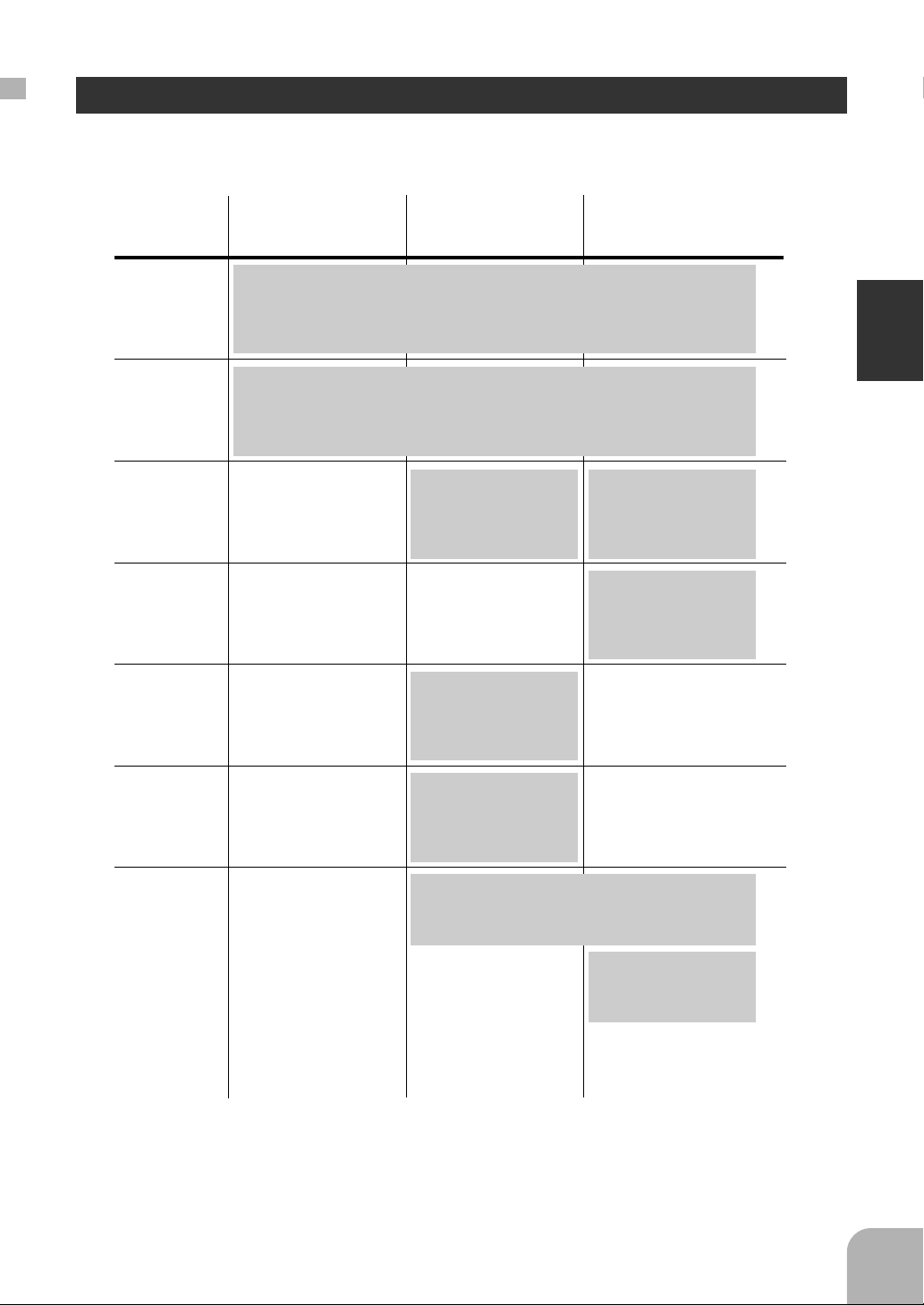

Set Contents

After opening the container, check the contents for the following items. The contents

will vary with the system purchased.

Transmitter

Receiver

Servo

E.S.C.

Switch

Transmitter

/ Receiver

System with

2 servos

T3PDF (x1)

R113F (x1)

S3003 (x2 )

CSW-GS (x1)

or (none)

System with

1 MC210CB

S3003 (x1)

MC210CB (x1)

Prior to operation

Battery

Holder

Miscellaneous

R2-BSS-B (x1)

or (none)

Servo mounting hardware and servo horns

Mini Screwdriver

-Should any item be missing or you are uncertian of the contents of the system, please

contact the dealer where the system was purchased.

77

7

77

Page 10

Transmitter T3PDF (Front)

Throttle Trim

Prior to operation

LCD

Screen

Nomemclature / Handling

Antenna

Steering Trim

Steering Wheel

Channel 3

Lever

Edit Keys

MULTI FUNCTION DISPLAY

Power LED

Power Switch

DOT MATRIX

POWER

CHARGE

Charging Jack

Steering D/R Lever

Throttle ATL Lever

Body Rest

Mounting Hole

* In the figure above the levers are shown in the neutral position.

Charging Jack

This jack is used to charge Nicad bat-

tery when used.

Caution

Never charge a dry cell type (NonNicad) battery.

Charging a non nicad type battery may damage the

transmitter, and could cause the battery electrolyte

to leak and cause additional damage.

DIGITAL PROPORTIONAL RADIO CONTROL SYSTEM

Mechanical ATL

The throttle trigger travel can be adjusted to limit the brake stroke.

-Adjustment Method

When the screw is turned clockwise

the brake stroke will become shorter.

When the screw is turned counter

clockwise the stroke becomes longer

as shown in the figure above.

MODE

RESET

SELECT

Mechanical ATL

Adjustment Hole

Throttle Trigger

Grip Handle

88

8

88

Page 11

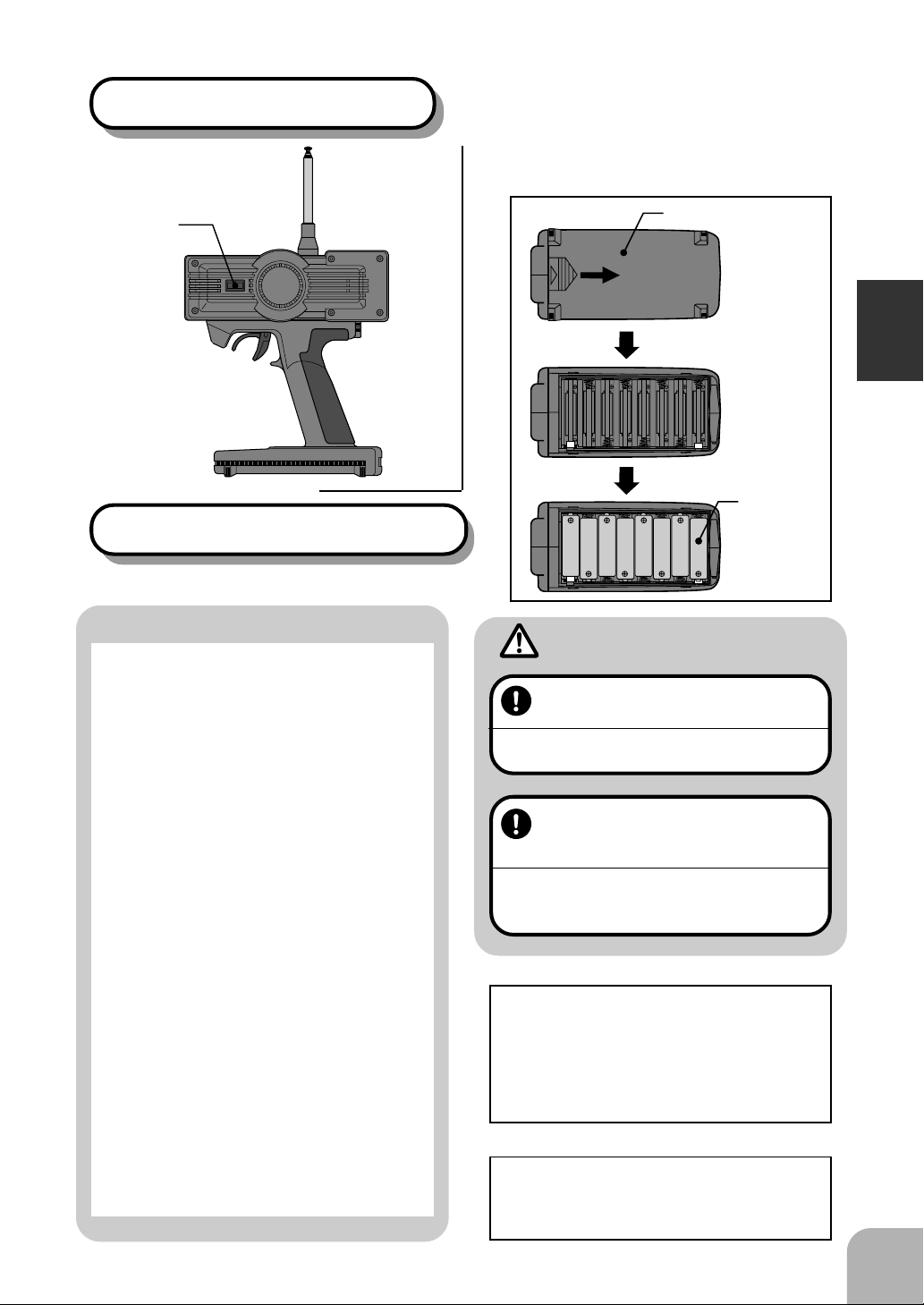

Transmitter T3PDF (Rear)

When the battery alarm sounds

change the batteries, or if Nicads are

used recharge.

(Alarm voltage: approx. 8.7 Volts)

Crystal

Transmitter T3PDF (Bottom)

Handling the batteries (8 AA size batteries)

Battery Replacement

1Open the battery cover by slid-

ing in the direction of the arrow

shown in the figure.

2Remove used batteries.

Battery Cover

Open

Batteries

(8 AA Size

Batteries)

Prior to operation

Caution

Be sure to load the batteries in the

correct polarity order.

If the polarity is reversed the transmitter may be

damaged.

3Load the new AA size batteries.

Pay very close attention to the

polarity markings and reinsert

accordingly.

4Slide the battery cover back

into place.

<Check>

Turn the power switch on and check

voltage displayed on the LCD screen.

With new batteries the voltage dis-

played should be around 12 volts.

If the displayed voltage is low or does

not light all, check the batteries for in-

sufficient contact or incorrect battery

polarity.

When the system will not be used

for any length of time remove the

batteries.

If the batteries do happen to leak, clean the battery

contacts thoroughly. Make sure the contacts are

free of corrosion.

<Battery Disposal>

Some states require special handling

when any type of battery is disposed.

Contact the State Agency responsible

for recycling hazardous waste for procedures in your area.

<Converting to Nicad Batteries>

Purchase Futaba Part Number NT8JY to convert your transmitter to

Nicad use.

99

9

99

Page 12

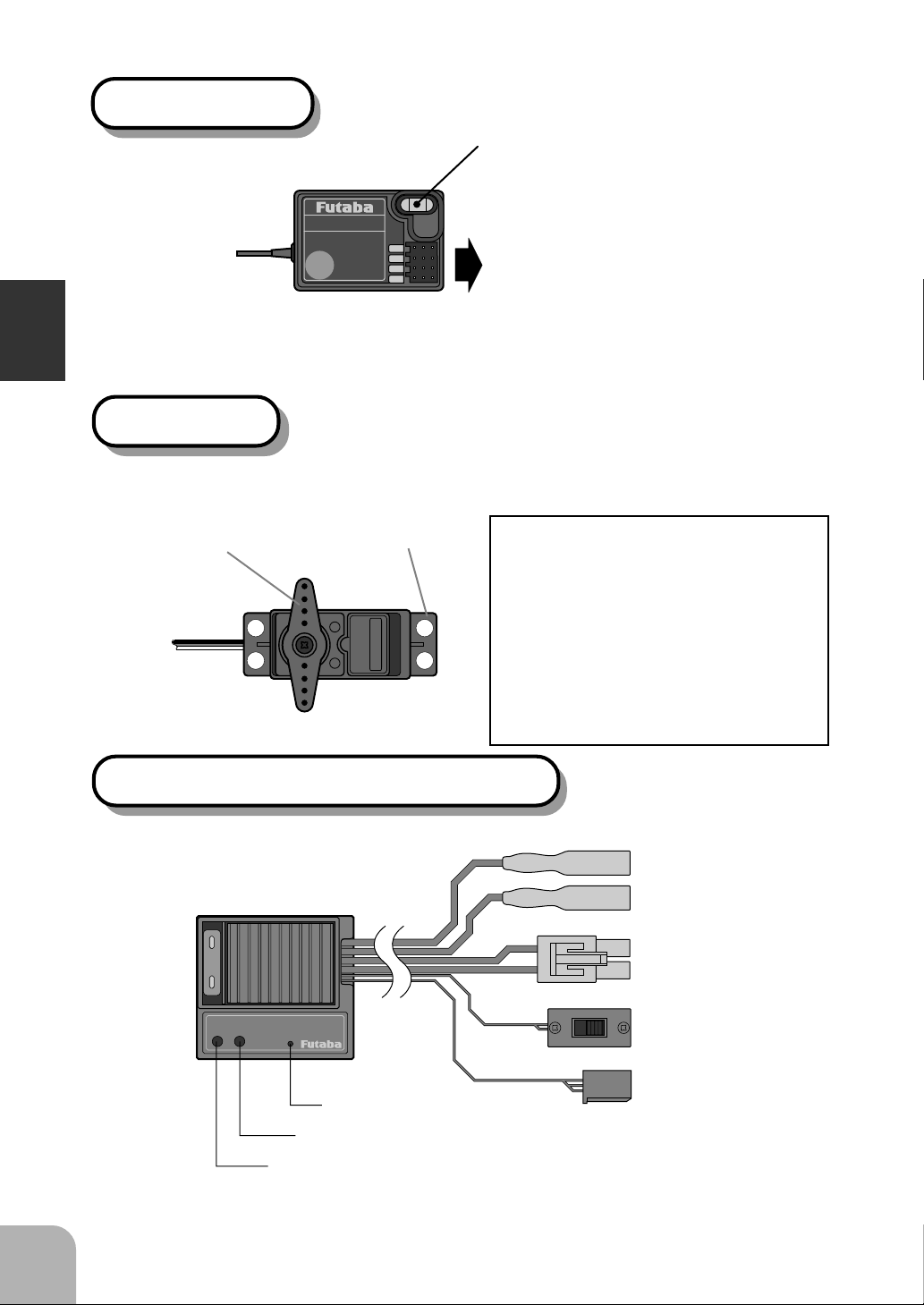

Receiver R113F

Crystal

Antenna

Prior to operation

Servo S3003

Servo Horn

To Receiver

FP-R113F

FM

1

2

3

B/C

Mounting Flange

Output Connector

“1”: Steering Servo (Ch1)

“2”: Throttle Servo (Ch2)

“3”: CH3 Servo (CH3)

Power Connector

<Accessories>

The following accessories are supplied with the system;

-Spare servo horns: Use to match

your application.

-Servo mounting hardware: Rubber

bushing, grommet, wood screws.

(For mounting precautions see

pages 15.)

1010

10

1010

Electronic speed control MC210CB

MC 210CB

Monitor Lamp

Neutral Point Trim

High Point Trim

Connects

to Motor

Connects

to Battery

ON

Power

OFF

switch

Connects

to Receiver

Page 13

Digital Trim Operating Instructions

To operate the digital trim push the trim lever to the left or right.

-A “Tone” will indicate each step.

-When the trim movement reaches its maximum travel the “tone” will change pitch.

-When a trim lever is moved the current trim position will be displayed on the LCD

screen.

Steering Trim

Lever

Throttle Trim

Lever

Prior to operation

D/R ATL CH3 Lever Operating Instructions

Operate the levers by pushing them to the left or right (up or down).

-A “Tone” will indicate each step.

-When a lever reaches its maximum travel the pitch of tone will change.

-When a lever is moved its current position will be displayed on the LCD screen.

ATL Lever D/R Lever

Channel 3

Lever

MODE

SELECT

RESET

1111

11

1111

Page 14

Initial Screen (Normal Screen)

Model Number Display (1~3)

Displays the number currently in use.

Prior to operation

LCD screen contrast adjustment

1Turn on the transmitter power switch , the screen

will show the current settings.

2Adjust the Contrast by pressing the + or - key

while pressing the Select key at the same time.

-The Contrast can be adjusted in 4 steps.

+ key: darker

- key: Lighter

Display / Key Operation

Model name display (only when set)

(6 characters)

Batttery voltage display

Displays the current

transmitter battery

voltage lavel.

Edit Keys

Mode Key

Used to select the function

Select Key

Used to select the channel, etc. at

the function screen.

1212

12

1212

MODE

SELECT

RESET

+ Key / - Key

Used to input data at the function

screen.

Page 15

Warning Displays

Low Battery Warning

When the transmitter battery voltage drops to 8.7 volts or less. A audible alarm will

sound and the message “Low Batt” will appear on the display screen. Replace or

recharge the batteries when you hear this alarm.

LCD Screen: Audible Alarm:

Continuous Tone will sound.

Warning

When the low battery alarm is heard, immediately stop operating the model. Retrieve

the model and turn off the power switches in the proper order (Receiver then Transmitter).

A discharged battery will no longer operate the transmitter and cause loss of control.

Memory Error

Prior to operation

If the data is destroyed for any reason an audible alarm will sound. The message

“MEMORY ERROR” will appear on the display screen as a warning.

LCD Screen:

Audible Alarm:

Continuous Tone will sound.

Warning

When a memory error is generated immediately stop operating the system and request

repair by the Futaba service center.

If you continue to operate the system control may be erratic and cause of control is highly likely.

Precautions when turning the power switches off and on.

If the power switches are turned off within 2 seconds after the data has been changed

by using the edit keys or trim levers. The information may not be retained by the

memory.

1313

13

1313

Page 16

3PDF

Assembly

Receiver and Servo Connections

Connect and install the receiver and servos in accordance with the "Assembly Safety

Precautions" on the next page.

When a E.S.C. is used (MC210CB)

Connect to motor

Connect to battery

Assembly

Gas Powered Model

Connect to

receiver battery

MC 210CB

E.S.C.

(Electronic speed control)

FP-R113F

FM

1

2

3

B/C

Receiver

FP-R113F

FM

Receiver

1

2

3

B/C

(B)

Power Switch

(1CH)

(2CH)

(1CH)

(2CH)

(3CH)

ON

OFF

Power Switch

Steering Servo

Steering Servo

Throttle Servo

Channel 3 Servo

1414

14

1414

Page 17

Assembly Safety Precautions

Warning

Connector Connections

Be sure the receiver, servo and battery connectors are fully and firmly

connected.

If vibration from the model cause a connector to work

loose while the model is in operation. You may lose

control .

Receiver Vibration Damping and

Waterproofing

(Car)

Dampen the vibration to the receiver

by mounting to the chassis or mounting plate with thick double sided tape

in electric powered models. In gas

powered models wrap the receiver in

foam and mount it where the vibration

is the least prevalent.

(Boat)

Dampen the vibration to the receiver

by wrapping it in foam. Waterproof by

placing it in plastic bag or watertight

radio box in model.

If the receiver is subjected to strong vibration or shock

erratic or loss of control may occur. If any moisture

comes in contact the receiver and servos you may

expertise the same result as well as damage to the

system.

Electronic speed control

Install the heat sinks where they will

not come in contact with aluminum,

carbon fiber or other parts that conduct electricity.

If the FET Amp (Electronic speed control) heat sinks

touch other materials that conduct electricity a short

circuit could occur. This could result in loss of control

and damage to the system.

Servo Throw

Operate each servo over its full stroke

and be sure the linkage does not bind

or is loose.

The continuous application of unreasonable force to a

servo may cause damage and excessive battery

drain.

Servo Installation

When you install the servos always

use the rubber grommets provided in

servo hardware bags. Mount the servos so they do not directly come in

contact with the mount.

If the servo case comes in direct contact with the

mount vibration will be directly transmitted to the

servo.

If this condition continues for a long time the servo

may be damaged and control will be lost.

Assembly

Receiver Antenna

Do not cut or bundle the receiver antenna

Do not bundle the receiver antenna

together with the servo lead wires

Keep the receiver antenna at least 1

inch away from the motor and battery

and wires that handle heavy current

loads..

Cutting, bundling or routing the receiver antenna near

any devise that produce noise will reduce the operat-

ing range of the system and result in loss of control.

*Also route the receiver antenna away from metal,

carbon fiber and other parts that conduct electricity. These parts can transmit high frequency noise.

Motor Noise Suppression

Always install capacitors to suppress

noise when electric motors are used.

If capacitors are not properly installed you could experience erratic operation and reduced range as well

as loss of control.

Other Noise Suppression Methods

Be sure there are no metal parts in

your model which under vibration can

come in contact with other metal

parts.

Metal to metal contacts under vibration will omit a high

frequency noise that will effect the receivers performance. You could experience erratic operation and

reduced range as well as loss of control.

1515

15

1515

Page 18

Preparations Prior to Setting Transmitter

Prior to making any setting on the transmitter check the following items.

Assembly

2

Throttle Trim Lever

TRIM.Pos

TH 0

3

Lever A

D/R .Pos

L100R100

1

Steering Trim Lever

TRIM.Pos

ST 0

4

Lever B

ATL .Pos

100

Preparations Prior to Setting Transmitter

1To set the steering trim to neutral, push the channel 1 trim lever to the left

or right. The display will read TRIM.Pos. Hold the lever to the left or right

until you set 0 on the display. This will be the neutral position.

2To set the throttle trim to neutral, push the channel 2 trim lever up or down.

The display will read TRIM.Pos. Hold the lever up or down until you see 0

on the display. This will be the neutral position..

3To set Grip Dial A to maximum, push the upper lever to the left or right. The

display will read GDA. Hold the lever to the right or left. The maximum

setting will be L100 R100.

4To set Grip Dial B to maximum, push the lower lever to the left or right. The

display will read GDB.Pos ATL. Hold the lever to the left or right. The maximum setting will be 100.

1616

16

1616

Page 19

E.S.C. MC210CB Adjustment

*Use the accessory mini screwdriver to make adjust-

ments.

Preparation

1Set the transmitter servo reversing switch to the

normal position.

2Turn the high point trim fully clockwise.

Neutral Adjustment

1Have the throttle trigger at neutral.

2Set the neutral trim to the point where the monitor

lamp goes off.

- The point where the monitor lamp changes from a rapidly flashing light

to off is the neutral point.

High Point Adjustment

1Set the throttle trigger to just a little before full

throttle.

2Set the high point trim to the point where the

monitor lamp is a steady light.

- The point where the monitor lamp changes from a rapidly flashing to a

steady light is full throttle.

MC210CB

Fully Clockwise

MC210CB

Point at which monitor

lamp goes off.

MC210CB

Point where the monitor

lamp is a steady light.

Assembly

Monitor Lamp

NeutralPoint HighPoint

Reverse Forward

SlowFlashingOffRapidlyFlashingSteadyLight

1717

17

1717

Page 20

3PDF

Function Map

When the Mode key is pressed from the initial

screen where the voltage is displayed , this will

call the FUNCTION MODE.

FUNCTION

MODE

Function Mode

Function Map

MDL.SEL

When the MODE key and the SELECT key are

pressed simultaneously at the initial screen.,

this will call the SYSTEM MODE.

P12

1:

10.5V

Initial Screen

Pressed

Simultaneously

SELECT

MODE MODE

MODE

Select key

pressed first

SELECT

SYSTEM

MODE

System Mode

Each different

function screen

can be sequen-

MODE

tially called by

pressing the

MODE key.

P29

MODE

P22

REVERSE

Pressed

Simultaneously

SELECT

MODE

Each different

function screen

can be sequentially called by

pressing the

MODE key.

Model Select

MODE

P23

ST.ATV

Steering ATV

MODE

P27

ST.EXP

Steering Exp

Function Mode

Group

MODE

TH.EXP

Throttle Exp

MODE

TH.ATV

Throttle ATV

MODE

P28

P24

Servo Reverse

MODE

P32

AUX.SEL

Channel 3 Select

Function

MODE

System Mode

Group

MODE

P30

MDL.NAME

Model Name

MODE

P31

GD.SELCT

Dial Function Select

1818

18

1818

Page 21

When a lever is operated from an

arbitrary screen, that screen is displayed for about 5 seconds.

* However, when the system mode

setup screen is displayed, the direct mode screen is not displayed

even if a lever is operated.

P20

TRIM.Pos

ST

Steering Trim

Position

*Initial Setting: Channel 3

P21

TRIM.Pos

TH

Throttle Trim

Position

P25

D/R .Pos

Lever A

Position

*Initial Setting: Steering D/R

Direct Mode

Group

P33

CH3 .Pos

Lever C

Position

P26

ATL .Pos

Lever B

Position

*Initial Setting: Throttle ATL

Function Map

1919

19

1919

Page 22

3PDF

Description of Functions

Steering Trim

The steering neutral position can be adjusted by moving

the steering trim lever to left or right.

Use this function to make your model run in a straight

line.

1At the initial screen where the Model number and

Voltage are displayed the Steering Trim setting

can be viewed by pressing the Trim lever to the

left or right. If the Steering trim is not operated

for 5 seconds the display will return to the initial

screen.

-When the SYSTEM MODE GROUP is displayed the steering trim position will be displayed.

Racers Tip

Adjust the servo horn and linkage so they are parallel. If

you are using a servo saver be sure the Steering trim is as

close to neutral as possible. Check the transmitter steer-

ing trim and be as close to 0 as you can. Also check the

Description of Functions

instruction manual of the model this system is to be in-

stalled in for the correct servo position.

Steering Trim

Lever

2020

20

2020

Servo Saver

90°

Parallel

Trim Operation and Maximum Travel

Trim adjustments will change the servo movement

range. When you make large trim adjustments recheck

your maximum servo travel. (Steering ATV Right side

and Left side)

When Trim Adjustments are Large

When the trim adjustments have caused the neutral to

shift considerably to the left or right you may need to

readjust the linkage.

Direct Servo

Saver Horn

90°

Page 23

Throttle Trim

The Throttle neutral position can be adjusted by moving

the throttle trim lever up or down.

1At the initial screen where the Model number and

voltage are displayed the Throttle Trim setting

can be viewed by pressing the trim lever up or

down. If the Throttle trim is not operated for 5

seconds the display will return to the initial

screen.

-When a System Mode Group screen is displayed the throttle trim position will not be displayed.

Racers Tip

When using a FET Amp (Electronic speed control) set

the screen to 0 and make the neutral adjustments at the

FET Amp. For gas powered models adjust the throttle

linkage as descried in the engine instruction manual.

When 0 is displayed the carburetor should be fully

closed

Carburetor Fully Closed

(Drum Type) (Slide Type)

Trim Operation and Maximum Travel

Trim adjustments can change the servos overall travel. If

large adjustments are made you may need to readjust the

brake side movement. Check the Throttle ATV B side

and the Throttle ATL. The forward may not be effected

but should be checked.

Throttle Trim Lever

Description of Functions

When Trim Adjustments are Large

When the trim adjustment is large enough to cause the

neutral to shift considerably to the forward or brake side

you may need to readjust the linkage.

2121

21

2121

Page 24

Servo Reverse

This function will reverse the rotation direction of the

Steering, Throttle and Channel 3 servos.

If the trim position is not set to 0. The servo will

shift the same amount off neutral on the opposite

side when the servo is reversed.

1Access the SYSTEM MODE by pressing the SE-

LECT and MODE Keys simultaneously

SELECT

MODE

2Access the Servo Reversing Function screen by

pressing the MODE KEY Once.

MODE

1:

10.5V

SELECT

MODE

SYSTEM

MODE

MODE

REVERSE

MODE

AUX.SEL

MODE

System Mode

Group

Initial Screen

Select key

pressed first

MODE

MDL.NAME

MODE

GD.SELCT

3Select the channel you wish to change by press-

ing the SELECT KEY.

ST: Steering

TH: Throttle

Description of Functions

CH3: Channel 3

(Direction Setting)

4Change the rotation direction with the + or - key.

NOR: Forward Direction

REVE: Reverse Direction

Channel 3 Operation

When CH3 (operation function selection) is set to 1P-4P,

the lever direction versus position movement can be

changed.

SELECT

2222

22

2222

Page 25

Steering ATV

Use this function to limit the servo movement to the left

or right. The servo travel to each side can be indepen-

dently adjusted. This feature will compensate for any

difference in right or left turning angles or radius due to

the characteristics of your model.

Warning

Be sure that the steering linkage does not bind or come

in contact with any suspension parts or arms.

If unreasonable force is applied to the servo. The servo may be damaged

could cause loss of control.

(Steering ATV Selection)

1Access the FUNCTION MODE by pressing the

MODE key from the initial screen.

MODE

2Access the Steering ATV Function by pressing

the MODE KY two times.

1:

10.5V

MODE

FUNCTION

MODE

MODE

MDL.SEL

MODE

ST.ATV

MODE

ST.EXP

Function Mode

Group

Initial Screen

MODE

TH.EXP

MODE

TH.ATV

MODE

MODE

(Steering right side adjustments)

3With the steering wheel turned fully to the right

adjust the right side travel by pressing the + or key.

(Steering Left Side Adjustment)

4With the steering wheel turned fully to the left ad-

just the left side travel with the + and - keys.

When you want to adjust both directions simulta-

neously.

When the + key or - key are operated when the steering

wheel is at the neutral position the right side and left side

directions change simultaneously.

Description of Functions

Setting Range: 0~120

(Pressing the + key and - key simultaneously returns the initial

setting 100)

2323

23

2323

Page 26

Throttle ATV

FUNCTION

MODE

1:

10.5V

ST.ATV

TH.ATV

ST.EXP

TH.EXP

MDL.SEL

MODE

MODE

MODE

MODE

MODE

MODE

MODE

Initial Screen

Function Mode

Group

This function is used to adjust the forward and brake side

servo travel. Each direction can be adjusted independent

of each other. Use this feature to set the throttle servo

travel.

Warning

Be sure that your throttle linkage does not apply excessive force to the servo.

If your linkage installation causes an unreasonable amount of force to be ap-

plied to the servo. The servo may be damaged and result in loss of control.

(Throttle ATV Selection)

1Access this function by pressing the MODE KEY

from the initial screen.

MODE

2Access the THROTTLE ATV screen by pressing

the MODE KEY four times.

Description of Functions

(Throttle Forward Side Adjustment)

3Pull the throttle trigger back and adjust the for-

ward side travel by pressing the + or - key. When

a FET Amp (Electronic speed control) is used set

to 100.

(Throttle Brake Side Adjustment)

4First set the ATL lever to the maximum travel po-

sition (100).

5Push the throttle trigger fully forward adjust the

servo travel by pressing the + and - keys.

When an FET Amp (Electronic speed control) is

used set to 100.

MODE

Setting Range: 0~120

(Pressing the + and - keys simultaneously returns setting to initial

value 100)

Setting Range: 0~120

(Pressing the + and - keys simultaneously returns the initial value

100)

2424

24

2424

Page 27

Steering D/R

(Description when D/R lever is assigned to GDA )

This function is used to limit the steering servo travel.

This feature will limit the servo travel equallyin both

directions. If the car tends to understeer (push) when

cornering add servo travel. If the car tends to over-

steer (loose) take servo travel out.

1At the initial screen or a Function Mode Group

screen . The D/R position will be displayed by

pressing the D/R lever to the left or right. If the

lever is not operated for 5 seconds the display

will return to the initial screen.

When a SYSTEM MODE GROUP screen is displayed the D/R position

will not be displayed.

2Adjust the steering servo travel by pressing the

D/R lever to the left or right.

D/R Lever

Setting Range: 0~120

(The maximum travel can also be

limited by the ATV function)

Description of Functions

2525

25

2525

Page 28

Throttle ATL

(Description when ATL is assigned to GDB)

This function is used to adjust the brakes. If you are

getting to much brake in the car set the ATL number

to lower setting. When you need more brakes set the

number to a higher setting.

1At the initial screen or Function Mode Group

screen. The ATL will be displayed by pressing

the ATL lever to the left or right. If the ATL lever is

not operated for 5 seconds the screen will return

to the initial screen.

If a SYSTEM MODE screen is displayed the ATL position will not be

displayed.

ATL Lever

2Adjust the brake side servo travel by moving the

ATL lever to left or right.

Description of Functions

Setting range: 0~ 120

(The maximum setting is the

travel set at the throttle brake

side)

2626

26

2626

Page 29

Steering Exponential

FUNCTION

MODE

1:

10.5V

ST.ATV

TH.ATV

ST.EXP

TH.EXP

MDL.SEL

MODE

MODE

MODE

MODE

MODE

MODE

MODE

Initial Screen

Function Mode

Group

Use this function to change the sensitivity of the steering

servo around neutral. The - side will make the servo less

sensitive around neutral. The + side will make the servo

more sensitive around the neutral.

Racer Tip

When the handling characteristics of a model are un-

known begin at 0%. At 0% the servo movement is linear.

1Access this function by pressing the MODE KEY

from the initial screen.

MODE

(Steering EXP Selection)

2Access the Steering EXP screen by pressing the

MODE KEY three times.

MODE

(EXP Adjustment)

3When you want the servo reaction to be move

sensitive adjust with the + key. When you want

the servo reaction to be less sensitive adjust with

the - key.

Setting Range: -100~0~+100

(Pressing the + and - keys simultaneously will return the setting to

the initial value 0.)

Description of Functions

2727

27

2727

Page 30

Throttle Exponential

FUNCTION

MODE

1:

10.5V

ST.ATV

TH.ATV

ST.EXP

TH.EXP

MDL.SEL

MODE

MODE

MODE

MODE

MODE

MODE

MODE

Initial Screen

Function Mode

Group

This function will allow you to change the sensitivity of

the throttle servo. The + side will make the servo reac-

tion move sensitive while - side will make it less sensi-

tive.

Racers Tip

When track conditions are good experiment with the +

side. When track conditions are not ideal experiment

with the - side.

1Access the function by pressing the MODE KEY

from the initial screen.

MODE

(Throttle EXP Selection)

2Access the Throttle EXP screen by pressing the

MODE KEY five times.

3Pull the throttle trigger fully back. When you want

the servo reaction to be more sensitive adjust

Description of Functions

with the + key. When you want the servo to less

sensitive adjust with the - key.

(Brake Side Adjustment)

4Push the throttle trigger fully forward. When you

want the servo to react quickly adjust with the +

key. When you want the servo to react mildly adjust with the - side.

When E.S.C. (With reverse) is used.

The EXP function will not be dynamically be felt in re-

verse.

MODE

Setting Range: -100~0+100

(Pressing the + and - keys simultaneously returns setting to initial

value 0 )

Setting Range: -100 ~ +100

(Pressing the + and - keys simultaneously returns the setting to

the initial value 0 )

2828

28

2828

Page 31

Model Select

FUNCTION

MODE

1:

10.5V

ST.ATV

TH.ATV

ST.EXP

TH.EXP

MDL.SEL

MODE

MODE

MODE

MODE

MODE

MODE

MODE

Initial Screen

Function Mode

Group

The 3PDF can store the data for 3 different models.

TheMODELSELECTfunctionisusedto accesseachmodel

memory.Usethisfunctionwhenyouchangefrom onemodel

toanother.

1Access this function by pressing the MODE key

from the initial screen.

MODE

(Model Select Function>

2Access the model select screen by pressing the

Mode key two times.

MODE

(Model Number Selection)

3Call the desired model number with the + or -

key.

Description of Functions

2929

29

2929

Page 32

Model Name

Up to 6 characters can be used to assign each model

memory a name. Alphabetic, numeric and symbols can

be used. This will make your model memos easy to tell

apart.

1Access the SYSTEM MODE by pressing the

MODE KEY and SELECT KEY simultaneously

from the initial screen.

SELECT

MODE

(Model Name Selection)

2Access the model name screen by pressing the

MODE key four times.

MODE

(Selection of characters to changed or used)

1:

10.5V

SELECT

MODE

SYSTEM

MODE

MODE

REVERSE

MODE

AUX.SEL

MODE

System Mode

Initial Screen

Select key

pressed first

MODE

MDL.NAME

MODE

GD.SELCT

Group

3Select the character you want by pressing the

SELECT key.

Description of Functions

(Setting New Character)

4Set the new character with the + and - keys

* Pressing the + and - keys simultaneously will

erase all the characters assigned to that model

memory name.

SELECT

Usable Characters

3030

30

3030

Page 33

Lever Function Select

This function will allow you to assign different functions

to the levers. The steering D/R Throttle ATL and Chan-

nel 3 can be assigned to these levers.

1Access the System mode by pressing the Mode

key and Select key simultaneously from the initial screen.

SELECT

MODE

(Lever function select selection)

2Access the lever function select screen by press-

ing the Mode key three times.

MODE

(Selection of Lever to be assigned)

1:

10.5V

SELECT

MODE

SYSTEM

MODE

MODE

REVERSE

MODE

AUX.SEL

MODE

System Mode

Initial Screen

Select key

pressed first

MODE

MDL.NAME

MODE

GD.SELCT

Group

3Select the desired lever by pressing the Select

key.

GDA: Lever A

GDB: Lever B

GDC: Lever C

(Function Selection)

SELECT

4Select the desired function with the + or - key.

D/R: Steering D/R

ATL: Throttle ATL

CH3: Channel 3

Lever A

(Steering D/R)

(Levers setting from factory)

Lever B

(Throttle ATL)

Lever C

(CH3)

Description of Functions

3131

31

3131

Page 34

Channel 3 Function Selection

The channel 3 operation can be selected from the follow-

ing functions.

1P: The third channel will operate like a self return switch. The servo will

move from servo position (P1) when the lever is not operated to servo

position (P2) while the lever is operated. This function is convenient

when a on board engine is used.

2P: Channel 3 operates like a 2-position Lever operation moves the

servo to two positions: servo position (P1) and servo position (P2).

The servo stops at each function.

3P: Channel 3 operates like a 3-position switch. Lever operation moves

the servo to three positions: servo position (p1) servo position (P2)

and servo position (P3). The servo will stop at each position.

4P: lever operation moves the servo to four positions: servo position (P1)

servo position (P2) servo position (P3) and servo position (P4). The

servo stops at each position.

Lin: lever operation moves the servo from the R (right side) to L (left side)

in steps This is convenient when FET Amp MC510CB with current

control Is used.

1Access the System Mode by pressing the Mode

and Select key simultaneously.

SELECT

1:

10.5V

SELECT

MODE

SYSTEM

MODE

MODE

REVERSE

MODE

AUX.SEL

MODE

System Mode

Initial Screen

Select key

pressed first

MODE

MDL.NAME

MODE

GD.SELCT

Group

(Setup Screen Selection)

2Access the channel 3 function by pressing the

Description of Functions

Mode key two times.

(Function Selection)

3Select the desired function with + or - key.

Travel and Servo Position Setting

Set the LIN type maximum travel and the 1P~4P type

servo position at the CH 4 position display screen

Position Movement Direction

When 1P~4P type is selected the direction of the move-

ment by lever operation can be changed with the servo

reversing function

MODE

MODE

3232

32

3232

Page 35

CH3 Position Setting

MODE

RESET

SELECT

CH3 Lever

(Description is with the CH3 lever position in the initial setting)

* Before using this function to select the servo position

to used with each function. Select the CH3 operation

function selection function. (P32).

(When LIN Type is Set)

The maximum travel can be set

When used with MC510CB

-Screen Display + 100~140A

-Screen Display -100~10A

First set to +100 with the CH3 lever and drive the car. If the car is difficult

to drive decrease the displayed value by moving the lever to the - side.

(When 1P~4P Type is set)

the servo operation position for each position can be set

by calling the setup screen for each position by operating

the CH3 lever.

1When the initial screen or a function mode setup

screen is displayed. You can view the CH 3 position by moving the CH 3 lever up or down. If the

lever is not operated for 5 seconds the display

will return to the initial screen.

When a System Mode Group screen is displayed the CH 3

position will not be displayed.

(LIN Type Setting)

2When adjusting the lever up side throw hold the

lever in the top position. If the tone changes adjust the throw with the + or - key.

When setting the lever down side throw hold the

lever in the down position. If the tone changes

adjust the throw with the + or - key.

(1P ~ 4P Type Setting)

To view each position operate the CH 3 lever

and set the servo operation position by pressing

the + or - key.

Setting Range: -100~+100

(Pressing the + and - keys simultaneously will return the value to

the initial value 0 )

Description of Functions

3333

33

3333

Page 36

3PDF

Reference

Ratings

* Specifications and ratings are subject to change without prior notice.

Transmitter: T3PDF

(Wheel Type 3 Channel)

Transmitting Frequency:

27, 29, 40, 41, or 75mhz band.

Modulation: FM (Frequency Modulation)

Power Requirement:

12 Volts (8 AA size batteries) or 9.6 Volt Nicad.

(Optional Nicad Battery) NT-8JY

Current Drain: 230ma Maximum

Frequencies allocated for surface in USA by F.C.C.

27mhz Channels 1-6

75mhz Channels 61-90

Servo S3003

(Standard Servo)

Power Requirement: 4.8 Volts or 6 Volts (Shared

with receiver)

Current Drain: ma (Stopped)

Output Torque: 42.0 oz/in

Operating Speed: 0.22sec./60

Size: 0.77" x 1.59" x 1.41"

Weight: 1.5oz.

Optional Parts

Receiver R113F

(CH 3 FM Receiver)

Receiving frequency:

27, 29, 40, 41, or 75mhz band.

Intermediate Frequency: 455khz

Power Requirement:

4.8 Volts or 6 Volts (Shared with servo)

Current Drain: 16mA

Size: 1.13" x 1.69" x 0.63"

Weight: 0.72 Oz.

FET Amp MC210CB

(FET Amp with Reverse)

Voltage Drop: Approx. 0.52V/20A (Between amp

input and output)

Maximum Current: 20A (Fuse capacity)

Power Requirement: 7.2 ~ 8.4 Volts

Regulator Output: 6V/3A (Maximum)

Size: 1.79" x 1.63" x 1.02"

(Excluding heat sinks and protruding parts)

Weight: 2.55oz

The following parts are sold separately as optional parts. Refer to the Futaba catalog

for more information.

Futaba Crystal Sets:

FM 27MHz Band crystal

Reference

FM 75MHz Band crystal

(FM single conversion sets only)

There are two types of FM crystals. Dual and Single Conversion.

( Use single conversion with this

system.)

Frequency Flag:

Please specify the frequency used

3434

34

3434

Transmitter Nicad Battery:

NT-8JY Nicad battery Pack

Body Rest:

Body Rest for 3PDF

Colored Steering Wheels:

available in Red Blue and Green

Colored Grips:

available in Red Blue and Green

A smaller size grip

Page 37

Troubleshooting

If your system fails to operate or you experience a short range problem or erratic

control. Check the table below for reasons you may be having these problems. After

you followed the suggestions listed and the problem is not corrected return the sys-

tem to our service department for inspection and repair.

(Item Check)

Transmitter

Battery

Dead battery -> Change the batteries. Charge the Nicad

Batteries inserted incorrectly. -> Reload the batteries in accordance

(Symptom)

Voltage display

does not work.

System operates intermittently

operating

range is short

with the polarity markings

Faulty contact -> Check to see if the contacts are bent and not making

good contact

Dirty contacts -> Clean the contacts and check for corrosion.

Antenna

Loose -> Be sure the antenna is screwed in tightly

Not fully extended -> Fully extend the antenna

Crystal

Loose -> Push the crystal in firmly

Wrong Band -> Be sure the transmitter and receiver frequencies match

Wrong type or brand -> Replace with genuine Futaba crystal

System does

not operate

Receiver does

not operate

Servo movement is abnormal.

servo operation is sluggish

System operation is erratic

when the motor is running

Receiver

Battery

Dead battery -> Replace or recharge

Wrong polarity -> Check connections

Antenna

Near other wiring -> Move away from wiring

Was antenna cut -> Request repair

Is the antenna bundled or coiled -> Keep the antenna straight and as

much in the air as possible

Crystal

Loose -> Push in firmly

Wrong brand -> Be sure the frequencies match in transmitter and receiver

Connector connections

Wring incorrect -> Insert all connectors firmly

Loose connections -> Push the connector in firmly

Linkage

Binding or loose -> Adjust the linkage in model

Is movement stiff -> Adjust linkage in model

Reference

Motor (Electric powered)

Noise problems -> Install capacitors on motor

3535

35

3535

Page 38

Glossary

The following defines the symbols and terms used in this instruction manual

Band

Frequency that receiver and transmitter operate on.

Channel

Represents the number of functions the transmitter will control.

Kit

A set of parts manufactured for building a

model.

Modulation method

Two modulation methods are used with R/C

systems: AM (Amplitude Modulation) and FM

(Frequency Modulation). Another method that

encodes and transmits the modulated signals is

called "PCM".

Neutral

The center position. It is the point where the

steering wheel and throttle return to when they

are not being operated

Proportional

Because today's R/C systems control servos in

proportion to the transmitter operation they are

called proportional.

Throttle

Devise that controls the air mixture at the engine intake. When opened a large air mixture is

sucked in and the engine speed increases.

When closed the engine speed decreases.

Throttle Trigger

Devise provided on the transmitter to control

the throttle. It is shaped like the trigger on a gun.

Trim

Devise that fine adjusts the neutral point of

each servo.

Servo Horn

The part that is installed on the output shaft on

the servo to convert to rotating motion of the

servo to transmit the linear to a control rod.,

Servo horns come in various shapes.

Reference

Servo Mount

Advise used to secure the servo in the model.

(Most often supplied in the model kit)

Steering (ST)

System to make the model turn left or right using the front wheels.

Steering Wheel

A devise for controlling the steering from the

transmitter. It is shaped like a wheel.

3636

36

3636

Page 39

Reference

3737

37

3737

Loading...

Loading...