Page 1

USER INSTRUCTIONS

Valtek Mark 200

Globe & Angle Control Valve

FCD VLENIM0200-00 – (12/12)

Installation

Operation

Maintenance

Experience In Motion

Page 2

Mark 200 Control Valve FCD VLENIM0200– 12/12

Valtek Mark 200 High Pressure Control Valve

The Mark 200 high pressure globe control valve designed to handle the most extreme severe service applications also offers high competitive fl ow

capacity. The Mark 200’s large galleries include longer stroke lengths which provide fi ner control and result in more stages of severe service protection

in smaller size valves. With a clamped-in (DIN, screwed-in) seat ring, the Mark 200 has been designed for easy maintenance and fl exibility. The seat

retainer/cage (DIN, seat ring) in the Mark 200 can be changed out to provide an exceptional variety of severe service options, including anti-cavitation

and anti-noise.

Further sizing details are available in Performance!, Flowserve’s control valve sizing & selection software program (please contact your local Flowserve

representative for further details). The plug is typically pressure-balanced to allow smaller and more economical actuators. Flow over or under the plug

is available.

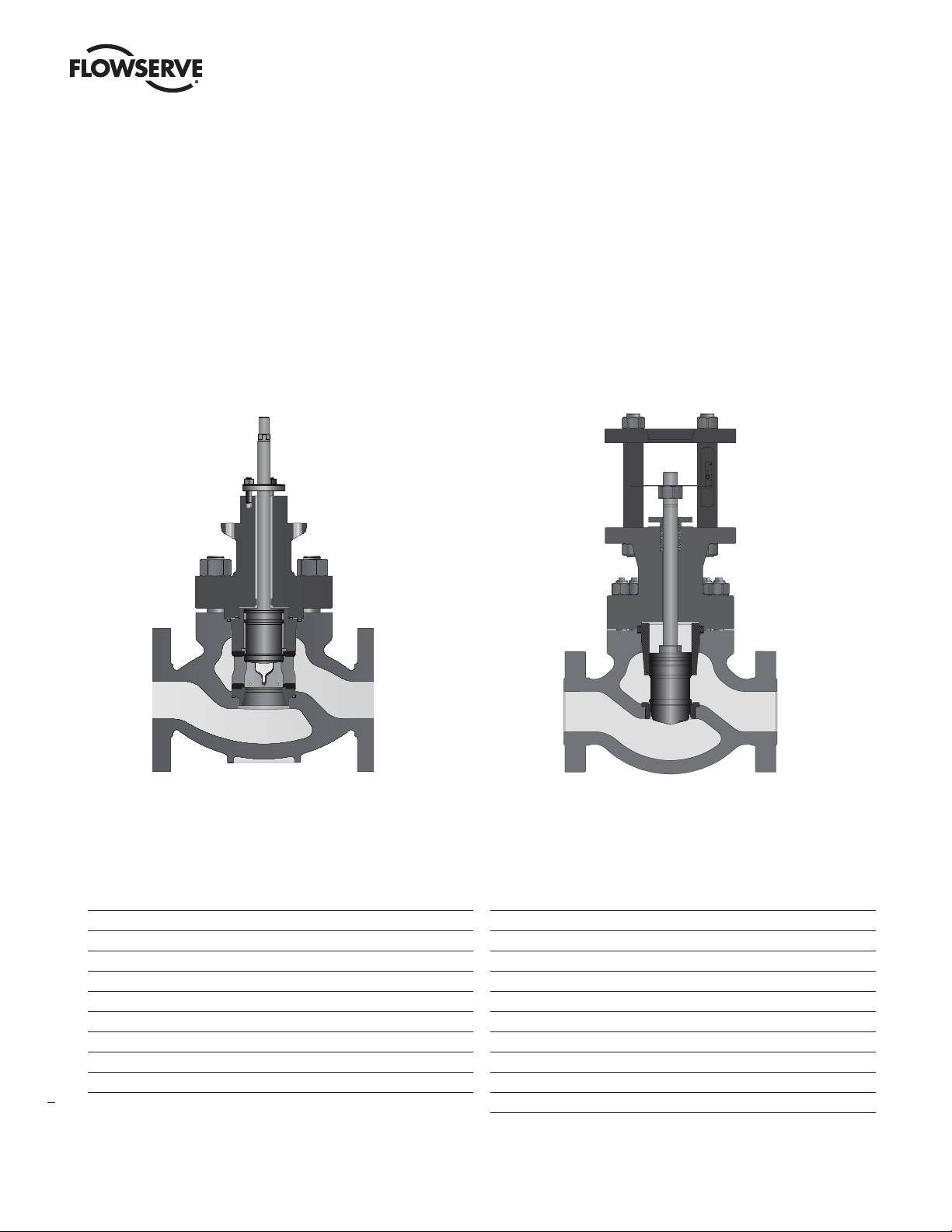

Figure 1: ASME Mark 200 Maximum Capacity Control Valve Figure 2: DIN Mark 200 Maximum Capacity Control Valve

ASME Contents

1 General Information 3

2 Terms Concerning Safety 3

3 ASME Valve Unpacking 4

4 ASME Valve Installation 4

4.1 ASME Valve Quick-check 4

5 ASME Valve Maintenance 5

ASME Valve Disassembly and Reassembly 7

6.1 Disassembling the Body 7

6.2 Reassembling the Body 8

6.3 ASME Valve Troubleshooting Chart 10

2

DIN Contents

1 General Information 3

2 Terms Concerning Safety 3

7 DIN Valve Unpacking 11

8 DIN Valve Installation 11

8.1 DIN Valve Quick-check 12

9 DIN Valve Maintenance 12

DIN Valve Disassembly and Reassembly 14

10.1 Disassembling the Body 14

10.2 Reassembling the Body 15

10.3 Special Tools 16

11 DIN Valve Troubleshooting Chart 17

Page 3

Mark 200 Control Valve FCD VLENIM0200– 12/12

1 General Information

The following instructions are designed to assist in unpacking, installing and

performing maintenance as required on Flowserve Mark 200 control valves.

Product users and maintenance personnel should thoroughly review this

bulletin prior to installing, operating or performing any maintenance on the

valve. Separate Installation, Operation, and Maintenance instructions cover

additional features (such as special trim, actuators, handwheels, packing

and positioners.)

To avoid possible injury to personnel or damage to valve parts, WARNING and

CAUTION notes must be strictly followed. Modifying this product, substituting

non-factory parts or using maintenance procedures other than outlined

could drastically affect performance and be hazardous to personnel

and equipment and may void existing warranties.

WARNING: Standard industry safety practices must be adhered

to when working on this or any other process control product.

Specifically, personal protective and lifting devices must be

used as warranted.

NOTE ON FASTENERS: Selecting the proper fastener material is the

responsibility of the customer. Typically, the supplier does not know what the

valve service conditions or environment may be. Flowserve’s standard body

bolting material is B7/2H. B8 (stainless steel) is optional for applications

more than 800°F / 425°C and with stainless steel or alloy-body valves.

The customer therefore must consider the material’s resistance to stress

corrosion cracking in addition to general corrosion. As with any mechanical

equipment, periodic inspection and maintenance is required. For more

information about fastener materials, contact your Flowserve representative.

2 Terms Concerning Safety

The safety terms DANGER, WARNING, CAUTION and NOTE are used in

these instructions to highlight particular dangers and/or to provide additional

information on aspects that may not be readily apparent.

DANGER: indicates that death, severe personal injury and/or

substantial property damage will occur if proper precautions

are not taken.

WARNING: indicates that death, severe personal injury and/ or

substantial property damage can occur if proper precautions

are not taken.

CAUTION: indicates that minor personal injury and/or property

damage can occur if proper precautions are not taken.

NOTE: indicates and provides additional technical information,

which may not be very obvious even to qualified personnel. Compliance with other, not particularly emphasized notes, with regard to

transport, assembly, operation and maintenance and with regard to

technical documentation (e.g., in the operating instructions, product

documentation or on the product itself) is essential, in order to avoid

faults, which in themselves might directly or indirectly cause severe

personal injury or property damage.

flowserve.com

3

Page 4

Mark 200 Control Valve FCD VLENIM0200– 12/12

3 ASME Valve Unpacking

1. While unpacking the valve, check the packing list against materials

received. Lists describing valve and accessories are in each shipping

container.

2. Take care to position lifting straps to avoid damage to the tubing and

mounted accessories.

WARNING: When lifting a valve using the lifting lugs, be aware

that the center of gravity may be above the lifting point. Therefore,

support must be given to prevent the actuator from rotating. Failure

to do so can cause serious injury to personnel, damage to the valve

or nearby equipment.

3. Contact your shipper immediately if there is shipping damage.

4. Should any problem arise, call your Flowserve representative.

4 ASME Valve Installation

CAUTION: The valve must be installed and commissioned by

qualified staff. Qualified staff is defined as personnel who are

familiar with the installation, commissioning and operation of

this product and possess the relevant qualifications in their

field of activity.

1. Before installing the valve, clean the line of dirt, welding chips, scale or

other foreign material.

2. Whenever possible, the valve should be installed in an upright position.

Vertical installation permits easier valve maintenance. When vertical

installation is not possible contact your Flowserve representative.

CAUTION: Do not insulate extension bonnets that are provided

for hot or cold services.

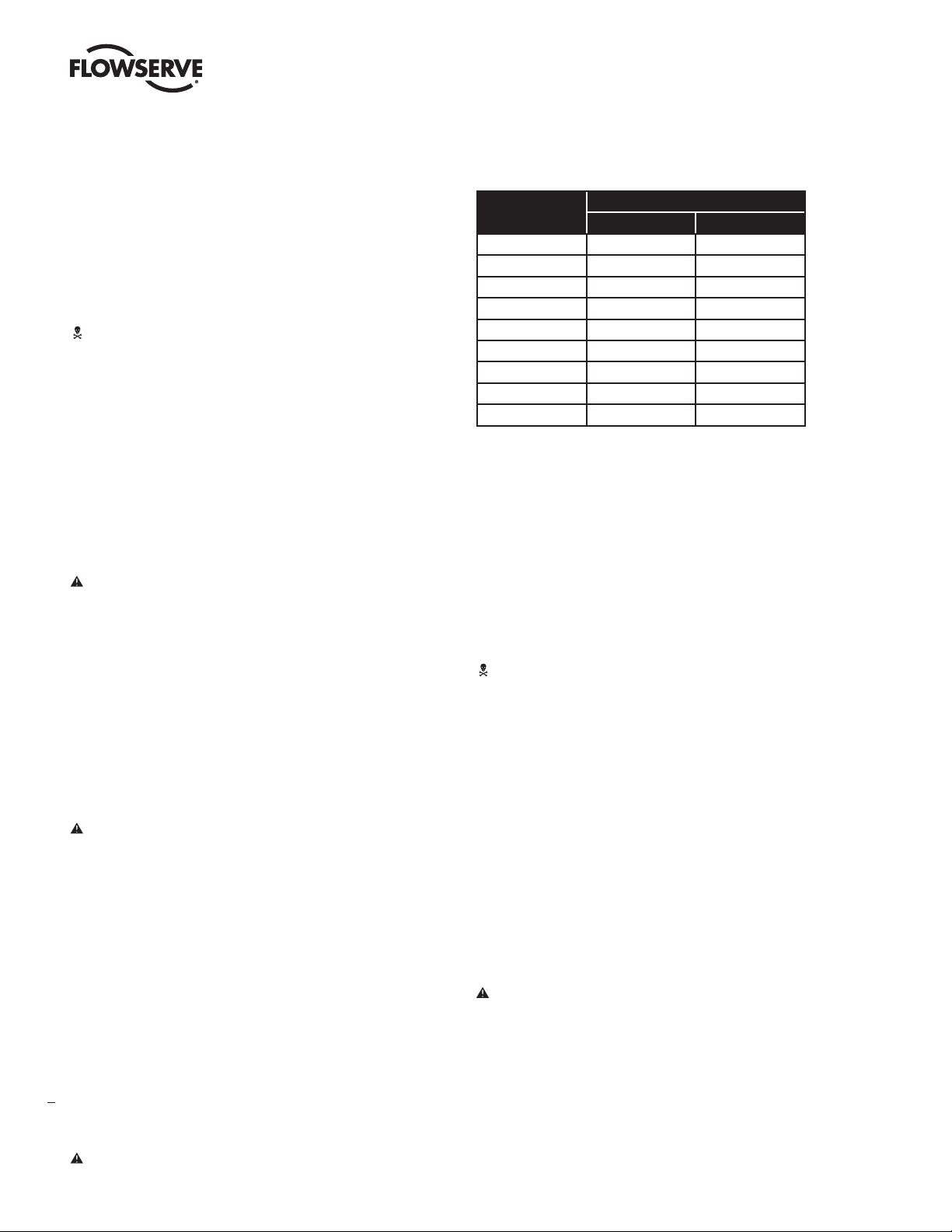

Table 1: ASME Valve Disassembly Clearance

Valve Size

(inches)

2 5 127

3 6 152

4 8 203

6 11 279

8 12 305

10 16 406

12 17 432

14 21 533

16 22 559

NOTE: In some cases, the air supply must be limited to less than 150

psi (10.3 bar). This is indicated on a sticker or type plate found near

the upper air port on the actuator cylinder. An air regulator should

be installed to ensure the supply pressure does not exceed the line

pressure indicated on the sticker.*

Clearance

inches mm

4.1 ASME Valve Quick-check

Prior to start-up, check the control valve by following these steps:

WARNING: Due to the risk of injury, it is prohibited to work

between the yoke/columns while the valve is in operation.

1. Stroke the valve and observe the plug position indicator on the stem

clamp compared to the stroke indicator plate. The plug should change

position in a smooth, linear fashion.

NOTE: Due to excessive friction, graphite packing can cause the plug

stem to move in a jerky fashion.

2. Check for full stroke by making appropriate instrument signal change.

3. Be sure to provide proper overhead clearance for the actuator to allow

for disassembly of the plug from the valve body. Refer to Table 1 for the

necessary clearance needed for valve disassembly.

4. Double-check flow direction to be sure the valve is installed correctly.

Flow direction is indicated by the arrow attached to the body.

5. If welding the valve into the line, use extreme care to avoid excess heat

buildup in the valve.

6. Connect the air supply and instrument signal lines. Throttling control

valves are equipped with a valve positioner. Refer to the appropriate

4

positioner bulletin for connections, maximum air supplies, and

maintenance instructions.*

CAUTION: On valves equipped with air filters, the air filter must

point down to perform properly. *

3. Check all air connections for leaks.*

4. Check packing box bolting for the correct adjustment. Refer to the

packing installation manual for specific details on maintaining the style

of packing supplied.

CAUTION: Do not overtighten packing. This can cause excessive packing wear and high stem friction that may impede

plug movement.

5. Make sure the valve fails in the correct direction in case of air failure.

This is done by turning off the air supply and observing the failure

direction.**

6. After a temperature excursion has occurred, bonnet flange bolting

should be retorqued to ensure bonnet gaskets do not leak. See Table 2.

Page 5

Mark 200 Control Valve FCD VLENIM0200– 12/12

Table 2: Recommended ASME Body Bolt Torque Values

Bolt/Stud Material

Bolt Size

(inches) ft lb N m ft lb N m

1-1⁄8 520 691 380 447

1-¼ 730 990 460 624

1-3⁄8 1000 1356 630 854

1-½ 1320 1790 840 1139

1-5⁄8 1710 2318 1080 1464

1-¾ 2170 2942 1400 1898

1-7⁄8 2700 3660 1700 2305

2 3350 4542 2100 2847

2-¼ 4050 5491 2530 3430

2-½ 4850 6575 3010 4081

2-¾ 5900 8000 4400 5960

3 7273 9860 5913 8015

Carbon Steel Stainless Steel

5 ASME Valve Maintenance

At least once every six months, check for proper operation by following

the preventative maintenance steps outlined below. These steps can be

performed while the valve is in-line and, in some cases, without interrupting

service. If an internal problem is suspected, refer to the “Valve Disassembly

and Reassembly” section.

WARNING: Keep hands, hair and clothing away from all moving

parts when operating the valve. Failure to do so can cause

serious injury.

8. Make sure positioner linkage and stem clamp or coupling pieces are

securely fastened. If the stem clamp or coupling pieces are loose, check

plug thread engagement (refer to the “Reassembling the Body” section

for the correct procedure on aligning the plug with the seat.) Tighten

stem clamp nut or counter nut.

9. Ensure all accessories, brackets and bolting are securely fastened.

10. If possible, remove air supply and observe actuator for correct fail-safe

action.*

11. Check rubber actuator bellows for splits, cuts or wear.*

12. Check tightness of the actuator. Spray a soap solution around the

cylinder actuator retaining ring, adjusting screw and actuator stem

guide to check for air leaks through the O-rings. *

13. Clean any dirt and other foreign material from the plug stem.

14. If an air filter is supplied, check and replace cartridge if necessary.*

* Pneumatic operated control valves

** Pneumatic operated control valves with safety function

1. Look for signs of gasket leakage through the end flanges and bonnet.

Retorque flange and bonnet bolting (if required). See Table 2.

2. Check for fluid leakage to the atmosphere through the body drain plug, if

applicable.

3. Examine the valve for damage caused by corrosive fumes or process

drippings.

4. Clean valve and repaint areas of severe oxidation.

5. Check packing box bolting for proper tightness. Refer to the packing

installation manual for specific details on maintaining the style of

packing supplied.

CAUTION: Do not overtighten packing. This can cause excessive packing wear and high stem friction that may impede

stem movement.

6. If the valve is supplied with a lubricator fitting, check lubricant supply

and add lubricant if necessary. See product documentation or contact

the Flowserve representative.

7. If possible, stroke the valve and check for smooth, full-stroke operation.

Unsteady stem movement could indicate an internal valve problem.

5

NOTE: Due to excessive friction, graphite packing can cause the plug

stem to move in a jerky fashion.

flowserve.com

Page 6

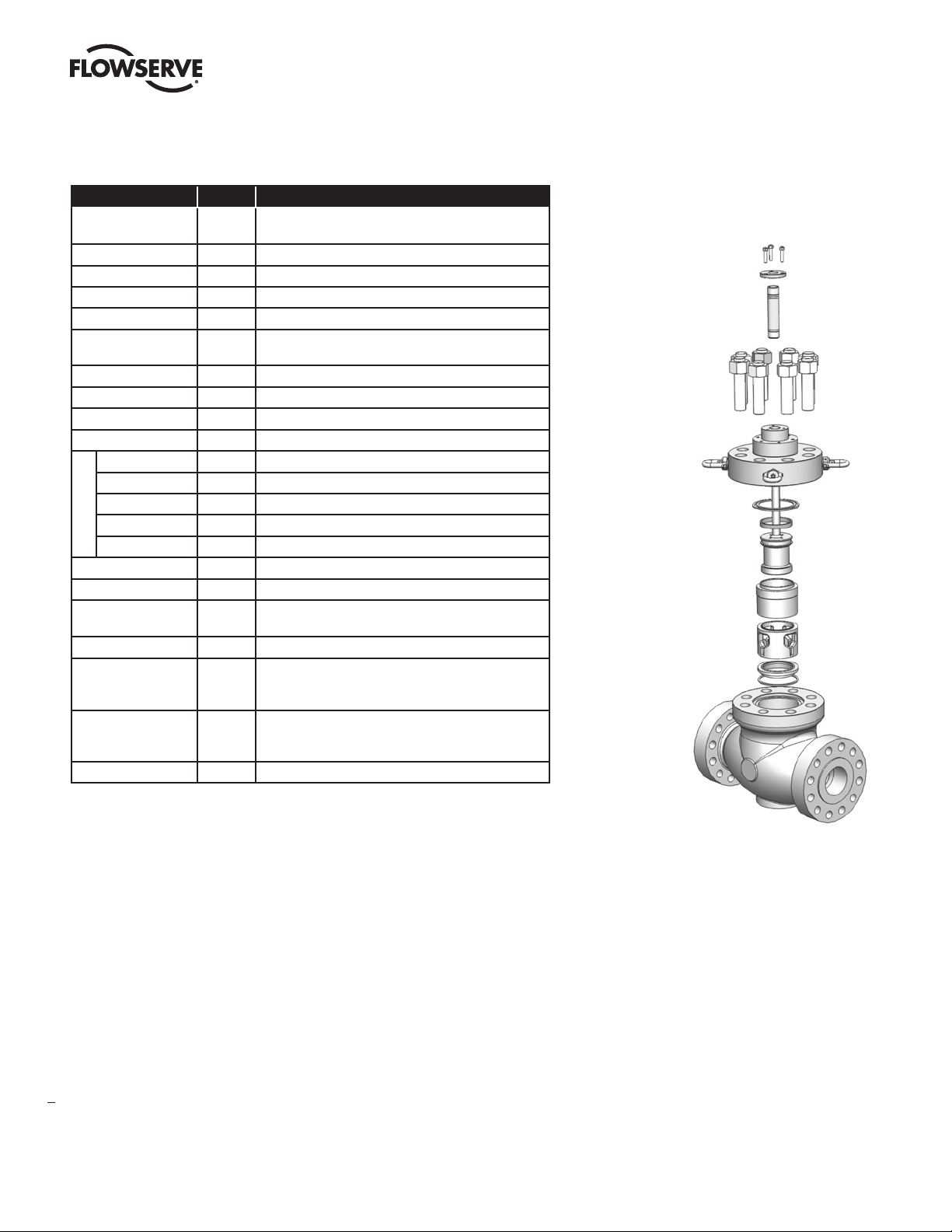

Figure 3 – Exploded Drawing of an ASME Mark 200, pressure balanced with cage

Part Item Available Materials

Body 1

Seat Ring* 20 316 SS, 316 SS / Alloy 6, 410 SS HT, 416 SS HT, 420 SS HT

Plug* 50 316 SS, 316 SS / Alloy 6, 416 SS HT, 420 SS HT, CrMo/Alloy 21

Plug Stem 51 316 SS, 316 SS / Alloy 6, 416 SS HT, 17-4PH SS

Cage 30 316 SS , 416 SS HT, CrMo/Nitrided

Pressure

Balanced Sleeve

Bonnet 40 Carbon Steel, 316 SS, CrMo, Duplex SS

Seat Gasket 55 PTFE, Spiral Graphite

Sleeve Gasket 56 PTFE, Spiral Graphite

Bonnet Gasket 58 PTFE, Spiral Graphite

O-Ring Seal 65 Buna, Viton®, EPDM, Perflouroelastomer

Back-up Ring 66 Carbon-Filled PTFE, PEEK, Vespel

PTFE Seal 65 PTFE, Glass-Loaded PTFE

Seal Types

Metal Multi-Seal 65 Rene 41

Carbon Seal 65 Carbon (Single & Triple)

Gland Flange 80 Carbon Steel

Gland Flange Bolting 109, 117 Carbon Steel

Lower Guide 83

Upper Guide 87 316 SS / GL PTFE

Packing 88

Body Bolting 108

Packing Spacers 93-99 316 SS

Carbon Steel (WCC) , 316 SS (CF8M), CrMo (WC9, C12A),

Duplex SS

316 SS, 410 SS, 410 SS HT, 420 SS HT**, 316 SS / Alloy 6,

31

CrMo/Nitrided

®

, Ryton

®

, Inconel® X-750

1

, Stainless Steel2

1

, Stainless Steel2

316 SS / GL PTFE

1, 2

, 316 SS / Graphite, Bronze C93200,

Alloy 6, Ultimet

1, 2

, 316 SS / Graphite, Bronze C93200

PTFE V-Ring

1, 2

, PTFE / Glass V-Ring, Quick-Set 9001, Braided

PTFE, AFPI, Graphite Rib/Braid, Safeguard, Sureguard, 1303

FEP, Chesterton 5800E, Sureguard XT, TA-Luft Double Graphite

B7-2H Zinc-coated 1, B7-2H Oxide-coated, B7M-2HM (NACE),

B8-8 (304 SS) 2, B8M-8M (NACE), L7-7, L7M-7M (NACE),

B16-7L, L7M-7M Uncoated (NACE)

1,2

®

Mark 200 Control Valve FCD VLENIM0200– 12/12

Gland Flange Bolting 109, 117

Gland Flange 80

Packing, Guides & Spacers

83-88, 93-99

Body Bolting 108

Bonnet 40

Bonnet & Sleeve Gasket

56 & 58

Pressure Balance Seals 65,66

Plug 50

Pressure Balanced Sleeve 31

Seat Ring 20

Seat Gasket 56

Body 1

* The seat ring and plug have hard facing of alloy 6 or other materials on the seating and guiding surfaces

** Internal Sleeve Only

1

Standard for Carbon Steel Body Construction

2

Standard for Stainless Steel Body Construction

6

Page 7

Mark 200 Control Valve FCD VLENIM0200– 12/12

ASME Disassembly and Reassembly

6.1 Disassembling the Body

To disassemble the valve body, refer to Figure 3 or 4 then proceed

as follows:

WARNING: Depressurize line to atmospheric pressure and

drain all fl uids before working on the valve. Failure to do so

can cause serious injury.

1. Fully retract the plug until the stem clamp indicator points to the open

position.

2. Remove the bonnet fl ange bolting and lift the actuator, bonnet and plug

out of the valve body.

WARNING: Danger exists in removing the actuator, bonnet and

plug, especially if PTFE plug seals are used. The sleeve may

stick to the plug and fall during disassembly, causing possible

serious injury and damage to the valve or nearby equipment.

If sleeve is observed sticking to the plug, steps 3–5 should be

consulted.

Figure 4 – ASME Mark 200 Cutaway Drawing

CAUTION: If a rubber bellows is attached to the gland fl ange,

the gland fl ange must be removed prior to removing the

actuator.

CAUTION: Heavy actuators may require a hoist. Lift the actuator

with the yoke legs using a lifting strap and a hoist. Great care

should be taken to lift the actuator and plug straight out of the

body to avoid damage to the plug and seat.

3. If the sleeve is observed sticking to the plug during removal, fully extend

the plug by applying air above the piston, allowing the sleeve to remain

in the body and the bonnet to rise above the body.

4. In the gap between the top of the sleeve and the bottom of the bonnet,

place wooden blocking of equal thickness in at least three places. The

wooden blocks must not extend in far enough that they interfere with

plug movement. The plug must be allowed to stroke up to the bonnet.

5. By applying air below the piston, retract the plug until the plug head is

freed from the sleeve. Once the plug is free from the sleeve, remove the

plug and bonnet assembly from the body.

6. Lift the sleeve out of the valve body using lifting points on the top of the

sleeve.

7. Remove cage, seat ring and gaskets from the valve body.

8. Remove the plug seals from the plug head.

9. Check to see the seating surfaces on both the seat ring and plug are

free of damage to ensure tight shutoff. Make sure the gasket surfaces

on the seat ring, bonnet and body are clean and undamaged. Inspect the

pressure balanced sleeve for scratches or other damage.

11. Turn the actuator off the plug and bonnet without allowing the plug to

rotate within the bonnet. Pull the plug carefully through the packing box.

Inspect the plug stem for damage or scoring.

NOTE: With air-to-close, fail-open valves, it may be necessary to apply

a small amount of air to the top of the actuator to move the plug away

from the bonnet. Otherwise, plug galling may occur.

CAUTION: To avoid scoring guides and plug stem, follow the

above procedure exactly.

12. If the seat surfaces need remachining, both surfaces on plug and seat

ring must be reworked. The seat angle on the plug is 36 degrees and

the seat ring is 33 degrees. Lapping is not necessary if proper assembly

procedures are followed.

CAUTION: If remachining, protect the stem while turning.

Ensure concentricity of the seat surface with the plug stem (or

outside diameter of the seat ring, if machining the seat).

13. To replace packing or change the packing box confi guration, push out

packing, spacer and guides with a dowel slightly larger than the plug

stem from underneath the bonnet.

7

10. Loosen the stem clamp and gland fl ange. Remove the yoke bolts.

fl owserve.com

Page 8

Mark 200 Control Valve FCD VLENIM0200– 12/12

6.2 Reassembling the Body

To reassemble the valve body, refer to Figure 3 or 4 then proceed as follows:

1. Install new bonnet and seat gaskets with the beveled edge up on

fluoropolymer gaskets.

NOTE: All gaskets should be replaced whenever the valve is

disassembled.

2. Relocate the seat ring. Carefully install the cage and then the sleeve

with the indexing feature provided, taking care to ensure they install

with the correct ends up.

3. Replace the plug seals on the plug, referring to Figure 5 and 6, and

observing the following directions:

WARNING: Gloves should be worn to help prevent the hands

from being pinched or burned.

PTFE Seals Heat one seal to 300°F (150°C) and slip it over the plug into the

seal groove. Thermal expansion causes the ring to stretch, thereby making it

relatively easy to slide over the plug head.

Care must be taken to prevent the seal from rolling, rather than sliding over

the plug. The second seal can be installed following the same procedures as

the first. If for any reason the second seal cannot be slipped onto the plug,

cut the seal at approximately a 30° angle (see Figure 6) and place over the

plug. Make certain the cut seal is on the low-pressure side.

Figure 5 – Seal Designs

O-ring Seals

Carbon Single Seal Carbon Triple Seal

Figure 6 – PTFE Seal Cutting Detail

PTFE Seals Metal Multi-Seal

Carbon Seals

Single Seals Each seal must be scored on a face with a sharp knife at

two places, 180 degrees apart. Holding the ring gently in a padded vise,

pull gently on the ring, breaking the ring on the score marks into two equal

pieces. Install the two pieces into the plug seal grooves with the score marks

on the pressure side.

Triple Seals Gently insert one end of seal and wrap the seal into groove.

Install the inside ring first, followed by the two outside rings with joints offset

120 degrees on all three rings (see Figure 5).

CAUTION: Install rings starting with one end and working the

ring carefully into place. Do not spread ring more than necessary. Spreading the ring too much can cause the ring to break.

8

Metal Multi-Seals Install wave spring followed by four seal rings. Stagger

ring openings by at least 90 degrees. Take care not to bend the seal rings as

they are installed.

O-ring with Back-up Rings The O-ring can stretch over plug and into

place. Spread scarf cut back-up rings until they fit on each side of O-ring as

shown in Figure 5.

Page 9

Mark 200 Control Valve FCD VLENIM0200– 12/12

4. Lower the plug into the body and sleeve. Care should be taken with the

plug seals to avoid scoring or galling the sealing surface while fitting

them into the sleeve bore. With metal multi-seals and carbon triple

seals, use a ring compressor on the rings. A suitably sized screw-type

hose clamp will also serve to compress the rings for reassembly.

5. Install sleeve gasket by centering on sleeve.

6. Lower the bonnet onto the plug and body, taking great care to avoid

scoring the plug stem.

7. Once the bonnet is resting squarely in the valve body, finger-tighten the

bonnet flange bolting.

8. Reinstall the packing and guides referring to the appropriate packing

installation manual and reinstalling new packing exactly as shown.

Make sure at least 1⁄8” (3 mm) is left at the top of packing box for the

top guide to enter. Different spacer lengths permit a wide variety of

packing configurations, such as twin seal and vacuum-pressure packing

WARNING: Valves with extended bonnets must not have

lower packing installed. Instead, lower packing rings should

be installed with the upper set. Lower packing installed in

extended bonnets will diminish the integrity of the packing

assembly.

NOTE: Graphite guide liners should be replaced each time the valve

packing is replaced. Do not rebuild the valve without new graphite liners

in the guides.

13. Slowly stroke the plug up and down to check the alignment of the plug

with the sleeve.

CAUTION: If binding or sticking is observed, discontinue

stroking the valve and reassemble using the above steps.

Failure to do so could cause serious valve damage. Contact

your Flowserve representative if binding cannot be resolved.

14. Perform a Quick Check as described in section 4.1.

Figure 7 – Bolt Patterns

Bolts Cross Bolt Tightening Pattern

4 bolts

90° apart

8 bolts

45° apart

9. Replace and tighten the packing gland and bolting. Refer to the packing

installation manual for specific details on maintaining the style of

packing supplied. Make sure gland flange is level after 3 nuts are

tightened.

10. Turn actuator back onto the body assembly, without turning the plug

inside the bonnet. Leave a 3⁄32” to 1⁄8” (2 mm to 3 mm) gap between

the mating surfaces of the bonnet and yoke. Tighten yoke bolting to

close this gap. Firmly tighten the yoke bolting.

11. Using the actuator, seat the plug two or three times to center the seat

ring using pressure on the top of the actuator.

12. Tighten the body bolting, following the bolting sequence outlined in

Figure 7. Use a minimum of four steps to reach the suggested bolt

torque values shown in Table 2. Never exceed more than 30% of the

suggested bolt torque value in a single step.

12 bolts

30° apart

16 bolts

22,5° apart

9

flowserve.com

Page 10

Mark 200 Control Valve FCD VLENIM0200– 12/12

6.3 ASME Valve Troubleshooting Chart

Problem Possible Cause Corrective Action

Stem motion impeded 1. Overtightened packing. 1. Refer to proper maintenance instructions and readjust.

2. Service temperature is beyond operating limits of trim design. 2. Reconfirm service conditions and contact factory.

3. Inadequate air supply. * 3. Check for leaks in air supply or instrument signal system; tighten

4. Malfunctioning positioner. * 4. Refer to positioner maintenance instructions.

Excessive leakage 1. Improperly tightened bonnet flange bolting. 1. Refer to step 11 of “Reassembling the Body” section for

2. Worn or damaged seat ring. 2. Disassemble valve and replace or repair seat ring.

3. Worn or damaged seat or bonnet gasket. 3. Disassemble and replace gaskets.

4. Inadequate actuator thrust. 4. Check for adequate air supply to actuator; if air supply is

5. Incorrectly adjusted plug. 5. Refer to step 9 of “Reassembling the Body” section for correct

6. Improper flow direction. 6. Refer to original specifications or contact factory.

7. Improper handwheel adjustment; handwheel acting as a limit-stop. * 7. Adjust handwheel until plug seats properly.

Inadequate flow 1. Improper plug adjustment, limiting stroke. 1. Refer to step 9 of “Reassembling the Body” section for

2. Malfunctioning positioner. * 2. Refer to positioner maintenance instructions.

3. Service conditions exceed trim design capacity. 3. Verify service conditions and consult factory.

Plug slams 1. Incorrect plug adjustment allowing improper cushion of air between

actuator piston and yoke.*

loose connections and replace leaky lines.

correct tightening procedure.

adequate, reconfirm service conditions and contact factory.

plug adjustment.

correct plug adjustment.

1. Refer to step 9 of “Reassembling the Body” section for

correct plug adjustment.

2. Inadequate air supply. * 2. Check air supply to actuator; repair leaks and remove any

3. Trim sized too large for flow rate. 3. Install reduced trim.

Valve does not fail in

correct position

* Pneumatic operated control valves

1. Incorrect flow direction. 1. Reconfirm direction and, if necessary, correct flow direction

restrictions in supply line.

through valve.

10

Page 11

Mark 200 Control Valve FCD VLENIM0200– 12/12

7 DIN Valve Unpacking

1. Careful loading and transport arrangements are required to avoid

the product suffering impact and jolting movements. Under no

circumstances should lifting gear be attached to the valve stem, travel

indicator or any peripheral units, if applicable. We recommend the use

of a length of rope that is looped around the valve head underneath the

yoke. Promptly touch up any damage to the corrosion protection.

2. Upon arrival on site, store the control valve on a solid base in a closed

room. Until its installation, the valve must be protected from the weather,

dirt or other potentially harmful influences. Under no circumstances

should the valve remain in storage for more than 6 months, as the

impregnation in the stuffing box packing evaporates and leaks may

develop. Do not remove the plugs protecting the flanges and the inside

of the control valve until it has arrived at its place of installation.

3. While unpacking the valve, check the packing list against materials

received. Lists describing valve and accessories are in each shipping

container.

WARNING: When lifting a valve using the rope, be aware that the

center of gravity may be above the lifting point. Therefore, support

must be given to prevent the actuator from rotating. Failure to do

so can cause serious injury to personnel, damage to the valve or

nearby equipment.

4. Contact your shipper immediately if there is shipping damage.

5. Should any problem arise, call your Flowserve representative.

6. The export packaging follows the packaging guidlines according to the

HPE stantards. The nonreturnable package is based on 90% recyclable

materials (cardboard box, wooden pallet etc.).

8 DIN Valve Installation

CAUTION: The valve must be installed and commissioned by

qualified staff. Qualified staff is defined as personnel who are

familiar with the installation, commissioning and operation of

this product and possess the relevant qualifications in their

field of activity.

1. Before installing the valve, clean the line of dirt, welding chips, scale or

other foreign material.

2. Whenever possible, the valve should be installed in an upright position.

Vertical installation permits easier valve maintenance. When vertical

installation is not possible contact your Flowserve representative.

CAUTION: Do not insulate extension bonnets that are provided

for hot or cold services.

3. Be sure to provide proper overhead clearance for the actuator to allow

for disassembly of the plug from the valve body. Refer to Table 3 for the

necessary clearance needed for valve disassembly.

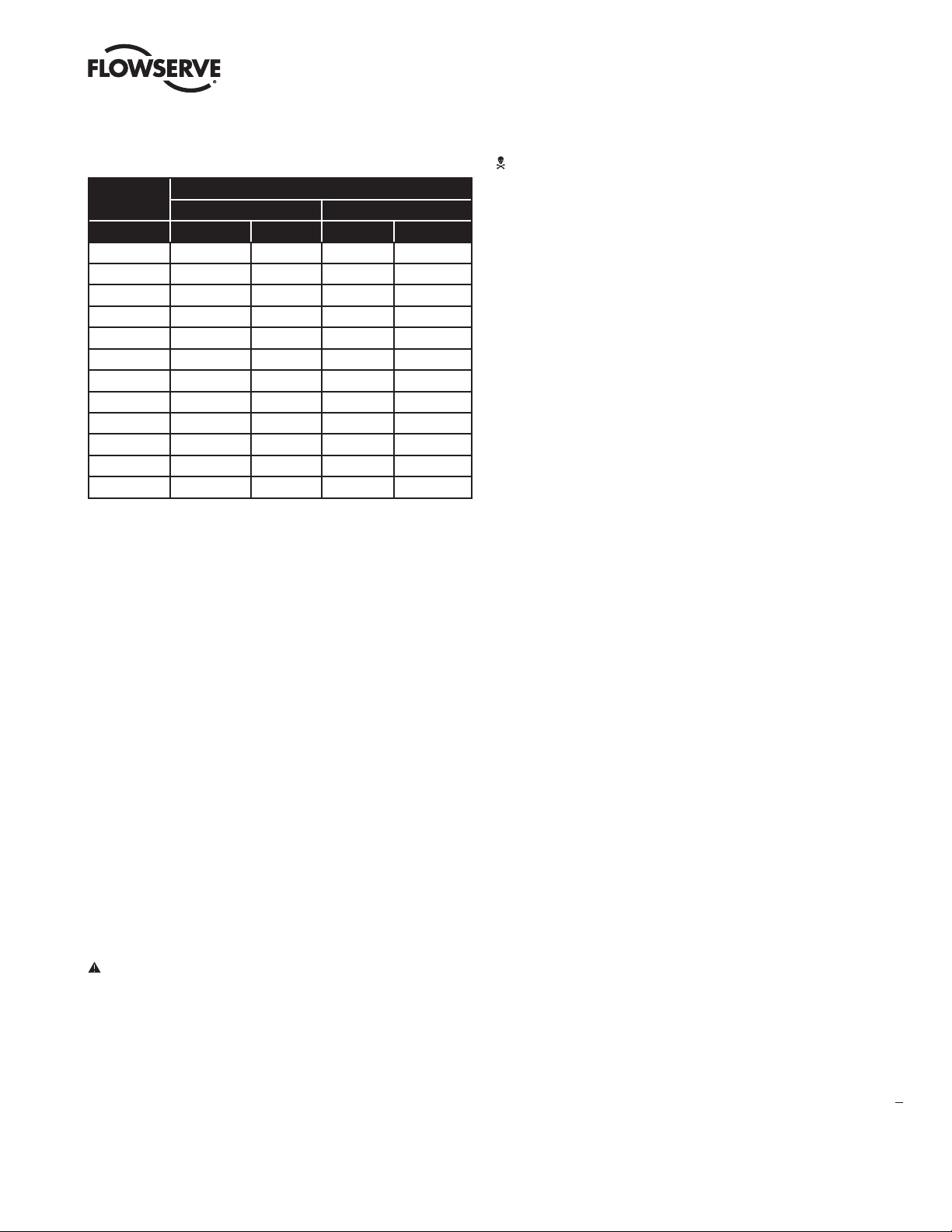

Table 3: DIN Valve Disassembly Clearance

Valve Size

50 7 180

80 7 180

100 7 180

150 7 180

200 7 180

250 7 180

300 7 180

400 7 180

Clearance

inches mm

4. Double-check flow direction to be sure the valve is installed correctly.

Flow direction is indicated by the arrow attached to the body.

5. If welding the valve into the line, use extreme care to avoid excess heat

buildup in the valve.

6. Connect the electric power supply according the wiring diagram (see

removable actuator cover or manufacturer`s actuator documentation).

flowserve.com

11

Page 12

Mark 200 Control Valve FCD VLENIM0200– 12/12

8.1 DIN Valve Quick-check

Prior to start-up, check the control valve by following these steps:

WARNING: Due to the risk of injury, it is prohibited to work

between the yoke/columns while the valve is in operation.

1. Stroke the valve and observe the plug position indicator on the stem

clamp compared to the stroke indicator plate. The plug should change

position in a smooth, linear fashion.

NOTE: Due to excessive friction, graphite packing can cause the plug

stem to move in a jerky fashion.

2. Check for full stroke by making appropriate instrument signal change.

3. Check packing box bolting for the correct adjustment. Refer to the

packing installation manual for specific details on maintaining the style

of packing supplied.

CAUTION: Do not overtighten packing. This can cause

excessive packing wear and high stem friction that may

impede plug movement.

4. After a temperature excursion has occurred, bonnet flange bolting

should be retorqued to ensure bonnet gaskets do not leak. See Table 4.

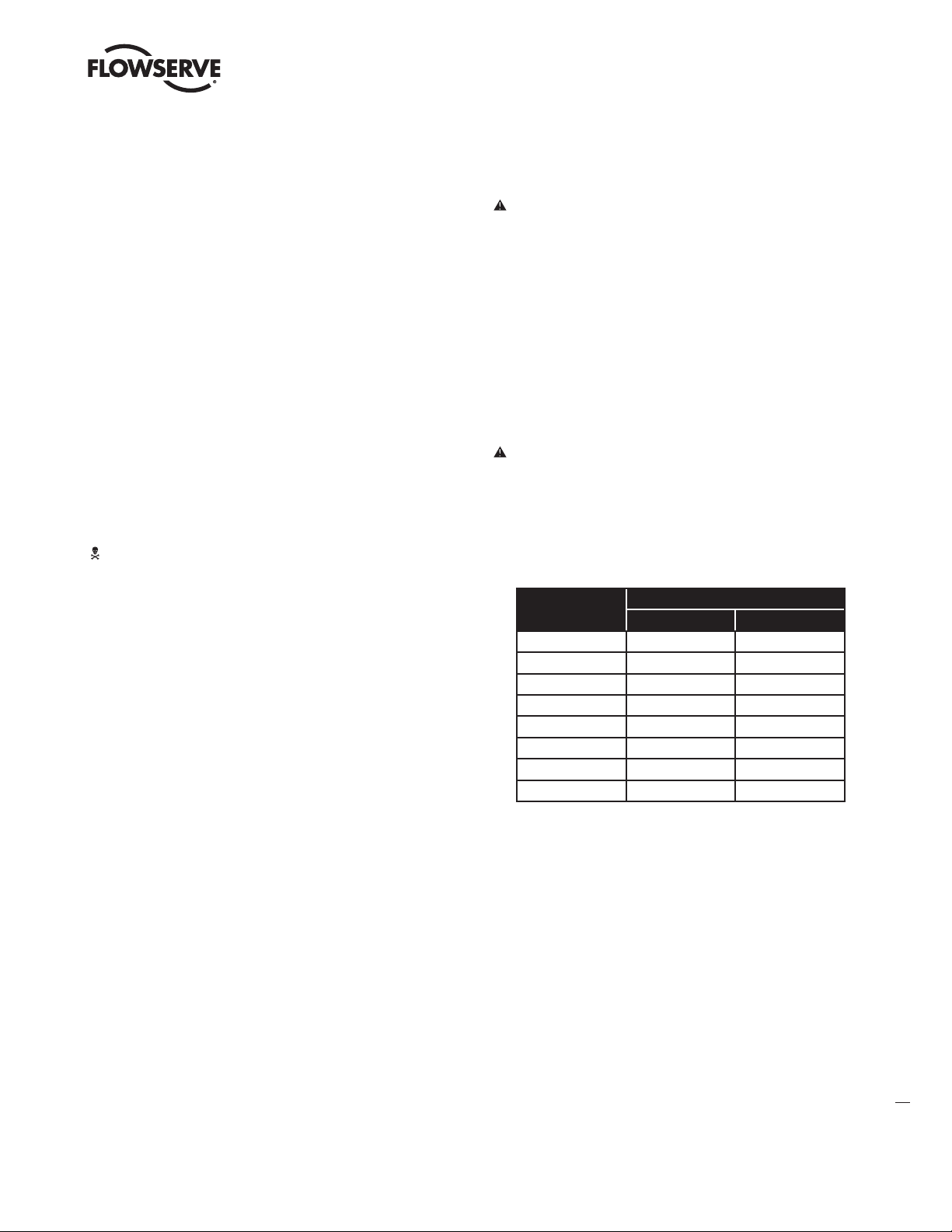

Table 4: Recommended DIN Body Bolt Torque Values

Bolt Size

(mm) ft lb N m ft lb N m ft lb N m

M24 265 360 265 360 300 405

M27 385 525 385 525 410 555

M30 410 555 415 565 480 650

M33 630 860 650 885 740 1000

M39 1220 1650 1220 1650 1250 1700

M42 1400 1900 1400 1900 1550 2100

M52 3250 4400 3250 4400 3250 4400

1.0619, 1.5419 1.7357 1.7379

PN 160 / Body Material

9 DIN Valve Maintenance

At least once every six months, check for proper operation by following

the preventative maintenance steps outlined below. These steps can be

performed while the valve is in-line and, in some cases, without interrupting

service. If an internal problem is suspected, refer to the “Valve Disassembly

and Reassembly” section. If multiple checks in line without claim (record) it

is allowed to extend the maintenance interval by risk of plant operator.

1. Look for signs of gasket leakage through the end flanges and bonnet.

Retorque flange and bonnet bolting (if required). See Table 4.

2. Check for fluid leakage to the atmosphere through the body drain plug, if

applicable.

3. Examine the valve for damage caused by corrosive fumes or process

drippings.

4. Clean valve and repaint areas of severe oxidation.

5. Check packing box bolting for proper tightness. Refer to the packing

installation manual for specific details on maintaining the style of

packing supplied.

CAUTION: Do not overtighten packing. This can cause excessive packing wear and high stem friction that may impede

stem movement.

6. If the valve is supplied with a lubricator fitting, check lubricant supply

and add lubricant if necessary. See product documentation or contact

the Flowserve representative.

7. If possible, stroke the valve and check for smooth, full-stroke operation.

Unsteady stem movement could indicate an internal valve problem.

NOTE: Due to excessive friction, graphite packing can cause the plug

stem to move in a jerky fashion.

WARNING: Keep hands, hair and clothing away from all moving

parts when operating the valve. Failure to do so can cause

serious injury.

Bolt Size

(mm) ft lb N m ft lb N m

M24 265 360 280 (300)* 380 (410)*

M30 427 580 500 680

M39 1150 1570 1220 1660

M45 2060 2800 2060 2800

12

M48 2500 3400 2500 3400

M56 4050 5500 4050 5500

M72 8550 11600 8550 11600

* Nominal Size DN 80 only

PN 250 / Body Material

1.0619, 1.5419, 1.7357 1.7379

8. Make sure positioner linkage and stem clamp or coupling pieces are

securely fastened. If the stem clamp or coupling pieces are loose, check

plug thread engagement (refer to the “Reassembling the Body” section

for the correct procedure on aligning the plug with the seat.) Tighten

stem clamp nut or counter nut.

9. Ensure all accessories, brackets and bolting are securely fastened.

10. Clean any dirt and other foreign material from the plug stem.

Page 13

Mark 200 Control Valve FCD VLENIM0200– 12/12

Figure 8 – Exploded drawing of a DIN Mark 200 with screwed-in seat ring; mounting shown for electric actuator

Part Item Available Materials

Body 1.1 1.0619 1.5419 1.7357 1.7379

Bonnet Gasket 1.2 Pure Graphite on Support Plate from C-276

Stud Bolt 1.3 1.7218 (KG) 1.7709 (GA) 1.4923 (V)

Hex Nut 1.4 1.7218 (KG) 1.7709 (GA) 1.4923 (V)

Extension Sleeve 1.5 1.7218 (KG) 1.7709 (GA) 1.4923 (V)

Screwed Seat 2.1 1.4122 1.4922

Contoured Plug 2.2 1.4122 1.4922

Linear Thrust Unit 12.5

Lock Nut 12.4

Stroke Indicator Disk 5.9

Hex Nut 5.7

Hex Nut 3.6

Gland Flange 3.4

Packing Box 3.3

Bottom Ring 3.2

Bonnet 3.1

Hex Nut 1.4

Extension Sleeve 1.5

Spring Pin 2.3 A2

Stem 2.4 1.4122 1.4922

Profil Ring 2.5 Pure Graphite

Bonnet 3.1 1.0460 1.5415 1.7335 1.7383

Bottom Ring 3.2 1.4922

Packing Box 3.3 Pure Graphite Rings

Gland Flange 3.4 1.4922

Stud Bolt 3.5 1.4923 (V)

Hex Nut 3.6 1.4923 (V)

Yoke Rod 5.1 1.4122

Flange 5.2 1.0460

Hex Nut

Stroke indicator scale 5.4 Aluminium

Hex Bolt 5.5 A2 - 70

Washer 5.6 A2

Hex Nut 5.7 A2 - 50

Stroke indicator Disk 5.9 1.0038

Threaded Ring 5.10 1.0460

Set Screw 5.11 45 H

5.3 A2 - 70

Body Gasket 1.2

Trim 2.2 + 2.4

Screwed Seat 2.1

Seat Gasket 2.5

Stud Bolt 1.3

Body 1.1

13

flowserve.com

Page 14

Mark 200 Control Valve FCD VLENIM0200– 12/12

DIN Disassembly and Reassembly

10.1 Disassembling the Body

To disassemble the valve body, refer to Figure 8 or 9 then proceed

as follows:

WARNING: Depressurize line to atmospheric pressure and

drain all fluids before working on the valve. Failure to do so

can cause serious injury.

1. Fully retract the plug until the stem clamp indicator points to the

open position.

2. Remove the actuator bolting and lift the actuator out of the

linear thrust unit.

CAUTION: Heavy actuators may require a hoist.

3. Unlock the hex nut (5.7) counter clockwise.

4. Unlock the linear thrust unit - lock nut counter clockwise.

5. Unscrew the complete linear thrust unit counter clockwise.

6. Measure the distance from stroke indicator disk (5.9) to the stem

(2.4) top edge. Make a note of the dimension, you will need it for

reassembling.

7. Remove the stroke indicator disk (5.9) and unscrew the hex nut (5.7).

8. Unscrew hex nuts (5.3) and remove the extension sleeves (1.5).

9. Unscrew hex nuts (3.6).

10. Remove gland flange (3.4).

11. Turn the special tool (ring nut, see Table 10.3) on the stem and put in

place slowly.

WARNING: Danger exists in removing the bonnet and plug with

piston ring balancing. The balanced ring may stick to the plug

and fall during disassembly, causing possible serious injury

and damage to the valve or nearby equipment.

Figure 9 – DIN Mark 200 Cutaway Drawing

Table 5: DIN Mark 200 Required Torque for Screwed-in Seat Ring

PN250

Moment [Nm]

Torque [ft lb]

420

310

1290

950

1930

1420

4800

3540

8150

6000

13400

10000

19600

14400

26400

19400

DN

50

80

100

150

200

250

300

400

PN160

Moment [Nm]

Torque [ft lb]

190

140

590

435

880

650

2200

1620

3700

2730

6100

4500

8900

6550

12000

8850

12. Remove flat gasket (1.2).

13. Insert special tool (change seat tool, see Table 10.3) in the body and

remove using a suitable torque wrench (see table 5).

14. Remove screwed seat (2.1) and profile ring (2.5).

14

15. Remove plug - unit (2.2, 2.3, 2.4) from the bonnet.

16. Remove packing (3.3) and bottom ring (3.2) with special tool

(packing driver tool, see Table 10.3).

Page 15

Mark 200 Control Valve FCD VLENIM0200– 12/12

10.2 Reassembling the Body

To reassemble the valve body, refer to Figure 8 or 9 then proceed as follows:

1. Install new profile ring (2.5) and screwed seat (2.1).

NOTE: Clean and inspect all sealing surfaces, threads and remove

damaged parts. Allways use new gaskets whenever the valve is

disassembled.

2. Insert special tool (change seat tool, see Table 10.3) in the body and

turn using a suitable torque wrench (see Table 5).

3. Lower plug unit (2.2, 2.3, 2.4) in the body and put it in the

screwed seat.

NOTE: Check the stem surface for damage. A damaged stem must

be replaced.

4. Install new flat gasket (1.2).

5. Lower the bonnet (3.1) onto the plug unit and body carefully.

NOTE: Take great care to avoid scoring the stem.

6. Fit the extension sleeves (1.5) onto the stud bolts (1.3) and fingertighten

the nuts (1.4).

13. Screw on the linear thrust unit. Lock nut onto the linear thrust

unit clockwise and secure it. Do the same with the hex nut (5.7).

NOTE: The stroke indicator disk should be shown in the open position on

the stroke indicator plate.

14. Replace the multi turn actuator.

15. After replacing the valve in the pipe, perform three full strokes and

check the thigtening torque of the nuts (3.6). Retighten the nuts as

necessary.

16. Log the maintenance interval and the work performed.

Figure 10 – Bolt Patterns

Bolts Cross Bolt Tightening Pattern

8 bolts

45° apart

7. Tighten the nuts (1.4) in four steps (crosswise with 30%, 60%, 100%

and all round 100%) according to the pattern (Figure 10).

NOTE: Check the movement of the plug by lifting (10 mm) between the

steps. If it is hard to move, loosen the nuts and start again.

8. Lower the bottom ring (3.2) and the new packing (3.3).

NOTE: Instal one ring after the other. To do this, use a tamper and push

in each ring individually, carefully and complete. When inserting the

other rings, rotate them each by 180° from their overlapping points.

9. Lubricate the thread and all bearing surfaces (underside of the nuts)

with a suitable, approved lubricant.

10. Place the gland flange (3.4) back on and tighten the nuts (3.6),

alternating evenly in accordance with the instructions from the packing

manufacturer.

NOTE: Tightening unevenly can cause the packing gland follower to jam,

which can result in stem damage.

11. Screw the hex nut (5.7) onto the stem (2.2) and replace the stroke

indicator disk (5.9). Recall the distance between top edge of stem and

replace it.

12 bolts

30° apart

16 bolts

22,5° apart

20 bolts

18° apart

12. Lower the linear thrust unit. Lock nut onto the stroke indicator disk and

screw the complete linear thrust unit onto the stem clockwise.

15

flowserve.com

Page 16

10.3 Special Tools

Special Tools Use

Mark 200 Control Valve FCD VLENIM0200– 12/12

Ring Nut Tool

Recommended tool for disassembling and

reassembing

For part no. see spare parts catalog

Seat Change Tool

Recommended tool for disassembling and

reassembling the screwed in seat

For part no. see spare parts catalog

16

Packing Driver Tool

Recommended tool for disassembling

the packing

For part no. see spare parts catalog

Page 17

Mark 200 Control Valve FCD VLENIM0200– 12/12

11 DIN Valve Troubleshooting Chart

Problem Possible Cause Corrective Action

Stem motion impeded 1. Overtightened packing. 1. Refer to proper maintenance instructions and readjust.

2. Service temperature is beyond operating limits of trim design. 2. Reconfirm service conditions and contact factory.

Excessive leakage 1. Improperly tightened bonnet flange bolting. 1. Refer to step 11 of “Reassembling the Body” section for

2. Worn or damaged seat ring. 2. Disassemble valve and replace or repair seat ring.

3. Worn or damaged seat or bonnet gasket. 3. Disassemble and replace gaskets.

4. Inadequate actuator thrust. 4. Check for adequate multi turn actuator,

5. Incorrectly adjusted plug. 5. Refer to step 9 of “Reassembling the Body” section for correct

6. Improper flow direction. 6. Refer to original specifications or contact factory.

Inadequate flow 1. Improper plug adjustment, limiting stroke. 1. Refer to step 9 of “Reassembling the Body” section for

2. Service conditions exceed trim design capacity. 2. Verify service conditions and consult factory.

Plug slams 1. Trim sized too large for flow rate 1. Install reduced trim.

correct tightening procedure.

reconfirm service conditions and contact factory.

plug adjustment.

correct plug adjustment.

flowserve.com

17

Page 18

Pages available for technician’s notes.

Mark 200 Control Valve FCD VLENIM0200– 12/12

18

Page 19

Pages available for technician’s notes.

Mark 200 Control Valve FCD VLENIM0200– 12/12

flowserve.com

19

Page 20

FCD VLENIM0200-00 Printed in USA. December 2012.

To find your local Flowserve representative

or for more information about Flowserve Corporation, visit

www.flowserve.com.

USA

Flowserve Flow Control Division

1350 N. Mt. Springs Parkway

Springville, UT 84663

USA

Phone: +1 801 489 8611

Fax: +1 801 489 3719

Austria

Flowserve Control Valves Gmbh

Control Valves-Villach Operation

Kasernengasse 6

9500 Villach

Austria

Phone: 43 (0) 4242 41 181 0

Fax: 43 (0) 4242 41181 50

India

Flowserve India Controls Pvt Ltd.

Plot # 4, 1A, Road #8 EPIP

Whitefield

Bangalore, Karnataka, 560066

India

Phone: 91 80 40146200

Fax: 91 80 28410286

China

Flowserve Fluid Motion and

Control (Suzhou)Co., Ltd.

No.35, Baiyu Road,

Suzhou Industrial Park, Suzhou

Jiangsu Province, P.R. 215021

China

Phone: 86 512 6288 8790

Fax: 86 512 6288 8736

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended function

safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The purchaser/user must therefore assume

the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation Operation

Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as a guarantee of

satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because Flowserve

is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice. Should any question arise concerning

these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2012 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Saudi Arabia

Flowserve Abahsain Flow Control

Co., Ltd.

Makkah Road, Phase 4

Plot 10 & 12, 2nd Industrial City

Damman, Kingdom of Saudi Arabia

Phone: +966 3 857 3150 X 243

Fax: +966 3 8574243

Loading...

Loading...