Page 1

USER INSTRUCTIONS

Valtek Mark 14

Control Valves

FCD VLENIM0115-00 – 06/06

Installation

Operation

Maintenance

Experience In Motion

Page 2

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

2

Page 3

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

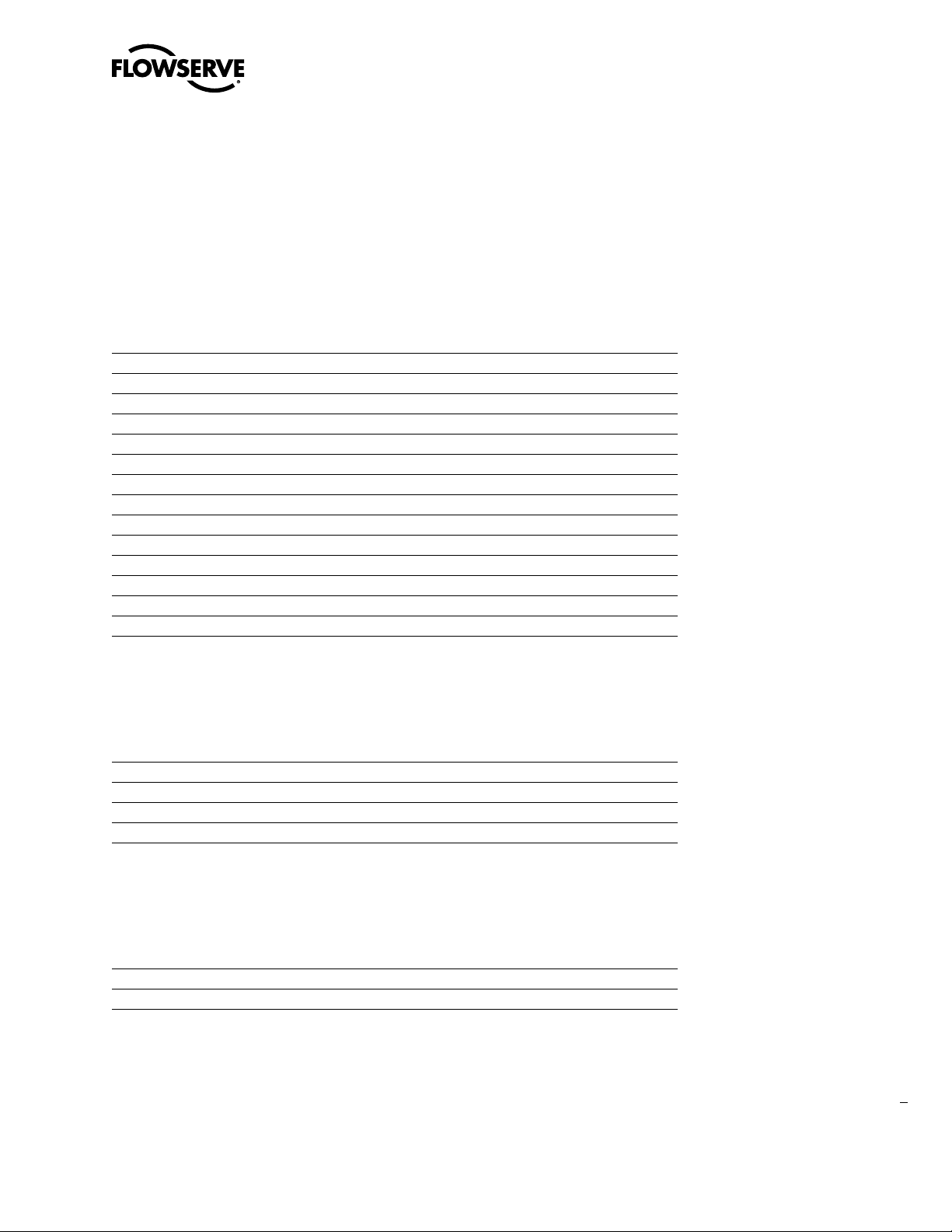

Contents

1 General Information 4

1.1 Using

1.2 Applicability

1.3 Terms Concerning Safety

1.4 Protective Clothing

1.5 Qualified Personnel

1.6 Spare Parts

1.7 Service / Repair

1.8 Storage

2 Unpacking

3 Installation

4 Quick-check

5 Valve Maintenance

6 Disassembly and Inspection

7 Reassembly and Installation

4

4

4

4

5

5

5

5

5

6

6

7

8

9

Figures

Figure 1 – Bonnet and Seat Retaining Rings 8

Figure 2 – Pressure Seal Assembly 11

Figure 3 – Bonnet Bolting 12

Figure 4 – Exploded View 13

Figure 5 – Cross Section

14

Tables

Table 1 – Severe Service Trim Bolt Torque Values 10

Table 2 – Seat and Bonnet Torque Values 1

Table 3 – Plug Adjustment 1

1

3

3

flowserve.com

Page 4

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

1 General Information

1.1 Using

The following instructions are designed to assist in unpacking, installing and performing

maintenance as required on Flowserve products. Product users and maintenance personnel

should thoroughly review this bulletin prior to unpacking, installing, operating, or performing

any maintenance. In most cases, Flowserve valves, actuators and accessories are designed for

specific applications (e.g. with regard to medium, pressure, and temperature). For this reason,

they should not be used in other applications without first contacting the manufacturer. The

product Installation, Operation, and Maintenance Instructions provides important additional

safety information.

1.2 Applicability

The following instructions are applicable to the maintenance and installation of Flowserve

Valtek Mark 14 control valves. These instructions cannot claim to cover all details of all

possible product variations, nor can they provide information for every possible example of

installation, operation or maintenance. This means that the instructions normally include only

the directions to be followed by qualified personal using the product for is defined purpose. If

there are any uncertainties in this respect, particularly in the event of missing product-related

information, clarification must be obtained via the appropriate Flowserve sales office. All

Flowserve User Manuals are available at www.flowserve.com.

1.3 Terms Concerning Safety

1.3.1 The safety terms DANGER, WARNING, CAUTION and NOTE are used in these instructions to

highlight particular dangers and/or to provide additional information on aspects that may not

be readily apparent.

DANGER: Indicates that death, severe personal injury and/or substantial property damage will

b

occur if proper precautions are not taken.

WARNING: Indicates that death, severe personal injury and/or substantial property damage can

c

occur if proper precautions are not taken.

CAUTION: Indicates that minor personal injury and/or property damage can occur if proper

a

precautions are not taken.

NOTE: Indicates and provides additional technical information, which may not be obvious, even to

qualified personnel.

1.3.2 Compliance with other notes, which may not be particularly emphasized, with regard to trans

port, assembly, operation and maintenance and with regard to technical documentation (e.g.

in the operating instructions, product documentation, or on the product itself) is essential, in

order to avoid faults, which can directly or indirectly cause severe personal injury or property

damage.

-

4

Page 5

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

1.4 Protective Clothing

Flowserve products are often used in problematic applications (e.g. under extremely high

pressures with dangerous, toxic or corrosive mediums). When performing service, inspection

or repair operations always ensure that the valve and actuator are depressurized and that the

valve has been cleaned and is free from harmful substances. In such cases, pay particular

attention to personal protection (e.g. protective clothing, gloves, glasses etc.).

1.5 Qualified Personnel

Qualified personnel are people who, on account of their training, experience and instruction

and their knowledge of relevant standards, specifications, accident prevention regulations and

operating conditions, have been authorized by those responsible for the safety of the plant to

perform the necessary work and who can recognize and avoid possible dangers.

1.6 Spare Parts

Use only Flowserve original spare parts. Flowserve cannot accept responsibility for any

damages that occur from using spare parts or fastening materials from other manufactures. If

Flowserve products (especially sealing materials) have been on store for long periods of time

check them for corrosion or deterioration before putting them into use.

1.7 Service / Repair

To avoid possible injury to personnel or damage to products, safety terms must be strictly

adhered to. Modifying this product, substituting non-factory parts, or using maintenance

procedures other than those outlined in these Installation, Operation, and Maintenance

Instructions could drastically affect performance, be hazardous to personnel and equipment,

and may void existing warranties. Between the actuator and the valve there are moving parts.

To avoid injury, Flowserve provides pinch-point-protection in the form of cover plates, especially where side-mounted positioners are fitted. If these plates are removed for inspection,

service or repair special attention is required. After completing work the cover plates must be

refitted. Apart from the operating instructions and the obligatory accident prevention directives valid in the country of use, all recognized regulations for safety and good engineering

practices must be followed.

WARNING: Before products are returned to Flowserve for repair or service, Flowserve must be

c

provided with a certificate that confirms that the product has been decontaminated and is clean.

Flowserve will not accept deliveries if a certificate has not been provided (a form can be obtained

from Flowserve).

1.8 Storage

In most cases, Flowserve products are manufactured from stainless steel. Products not

manufactured from stainless steel are provided with an epoxy resin coating. This means that

Flowserve products are well protected from corrosion. Nevertheless, Flowserve products must

be stored adequately in a clean, dry environment. Plastic caps are fitted to protect the flange

faces and prevent the ingress of foreign materials. These caps should not be removed until the

valve is actually mounted into the system.

5

flowserve.com

Page 6

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

2 Unpacking

2.1 While unpacking the valve, check the packing list against the materials received. Lists

describing the valve and accessories are included in each shipping container.

2.2 When lifting the valve from shipping container, use straps through the yoke legs, or the lifting

lugs attached to the yoke bolting. Take care to position lifting straps to avoid damage to the

tubing and mounted accessories.

WARNING: When lifting a valve be aware that the center of gravity may be above the lifting point.

c

Therefore, support must be given to prevent the valve from rotating. Failure to do so can cause

serious injury to personnel and damage to the valve and nearby equipment.

2.3 Contact your shipper immediately if there is shipping damage.

2.4 Should any problem arise, call your Flowserve representative.

3 Installation

DANGER: Before installation check the order number, serial number, and/or the tag number to

b

ensure that the valve and actuator being installed are correct for the intended application.

CAUTION: Do not insulate extensions that are provided for hot or cold services.

a

CAUTION: On valves equipped with air filters, the air filter must point down to perform properly.

a

NOTE: In some rare cases, the air supply must be limited to less than 150 psi (10.3 bar). This is

indicated on a sticker found near the upper air port on the actuator cylinder. An air regulator should

be installed to ensure the supply pressure does not exceed the line pressure indicated on the sticker.

3.1 Pipelines must be correctly aligned to ensure that the valve is not fitted under tension.

3.2 Fire protection must be provided by the user.

3.3 Before installing the valve, clean the line of dirt, welding chips, scale and other foreign

material.

3.4 Whenever possible, the valve should be installed in an upright position. Vertical installation

permits easier valve maintenance.

3.5 Be sure to provide proper overhead clearance for the actuator to allow for disassembly of

the plug from the valve body. Refer to the appropriate actuator User Instructions for proper

clearances. Actuator User Instructions are available at www.flowserve.com.

3.6 Double-check flow direction to be sure the valve is installed correctly. Flow direction is

indicated by the arrow attached to the body.

3.7 If welding the valve into the line, use extreme care to avoid excess heat buildup in the valve.

3.8 Connect the air supply and instrument signal lines. Throttling control valves are equipped with

a valve positioner. Refer to the appropriate positioner bulletin for connections, maximum air

supplies, and maintenance instructions.

6

Page 7

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

4 Quick-check

Prior to start-up, check the control valve by following these steps:

4.1 Stroke the valve and observe the plug position indicator on the stem clamp compared to the

stroke indicator plate. The plug should change position in a smooth, linear fashion.

NOTE: Due to excessive friction, graphite packing can cause the plug stem to move in a jerky fashion.

4.2 Check for full stroke by making appropriate instrument signal changes.

4.3 Check all air connections for leaks.

4.4 Check packing box bolting for the correct adjustment. Refer to the packing installation manual

for specific details on maintaining the style of packing supplied.

CAUTION: Do not overtighten packing. This can cause excessive packing wear and high stem

a

friction that may impede plug movement.

4.5 Make sure the valve fails in the correct direction in case of air failure. This is done by turning

off the air supply and observing the failure direction.

4.6 After a temperature excursion has occurred, bonnet flange bolting should be re-torqued to

ensure bonnet seals do not leak.

5 Valve Maintenance

At least once every six months, check for proper operation by following the preventative maintenance steps outlined below. These steps can be performed while the valve is in-line and, in some

cases, without interrupting service. If an internal problem is suspected, refer to Section 6, Valve

Disassembly and Inspection.

5.1 Look for signs of gasket leakage through the end flanges and bonnet. Re-torque flange and

bonnet bolting (if required).

5.2 Examine the valve for damage caused by corrosive fumes or process drippings.

5.3 Clean valve and repaint areas of severe oxidation.

5.4 Check packing box bolting for proper tightness. Refer to the packing installation manual for

specific details on maintaining the style of packing supplied.

CAUTION: Do not overtighten packing. This can cause excessive packing wear and high stem

a

friction that may impede stem movement.

5.5 If possible, stroke the valve and check for smooth, full-stroke operation. Unsteady stem move

ment could indicate an internal valve problem.

-

NOTE: Due to excessive friction, graphite packing can cause the plug stem to move in a jerky fashion.

WARNING: Keep hands, hair and clothing away from all moving parts when operating the valve.

c

Failure to do so can cause serious injury.

5.6 Make sure positioner linkage and stem clamp are securely fastened. If the stem clamp is

loose, check plug thread engagement (refer to the “Reassembly and Installation” section for

the correct procedure on aligning the plug with the seat). Tighten stem clamp nut.

7

flowserve.com

Page 8

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

Remove First

Install Last

Remove First

Install Last

5.7 Ensure all accessories, brackets and bolting are securely fastened.

5.8 If possible, remove air supply and observe actuator for correct fail-safe action.

5.9 Check rubber actuator bellows for splits, cuts or wear.

5.10 Spray a soap solution around the actuator cylinder retaining ring and actuator stem guide to

check for air leaks through the O-rings.

5.11 Clean any dirt and other foreign material from the plug stem.

5.12 If an air filter is supplied, check and replace cartridge if necessary.

6 Disassembly and Inspection

To disassemble Mark 14 control valves refer to Figure 4 and 5 and proceed as follows:

WARNING: Depressurize line to atmospheric pressure and drain all fluids before working on the

c

valve. Failure to do so can cause serious injury.

6.1 Remove the air supply from the actuator. Remove the split stem clamp and yoke bolts. Then

remove the actuator from the body sub-assembly by lifting the actuator straight up.

CAUTION: Heavy actuators will require a hoist. Lift the actuator with the yoke legs using a lifting

a

strap and a hoist. Care should be taken to lift the actuator straight off the body to avoid damage.

WARNING: When lifting actuators, be aware that the center of gravity may be above the lifting

c

point. Support must be given to prevent the actuator from rotating. Failure to do so can cause

serious injury to personnel and damage to the actuator and nearby equipment.

6.2 Remove the gland flange bolting and the gland flange from the bonnet.

6.3 Loosen the bonnet flange socket head bolting and remove the bolts and the disk springs

underneath them.

6.4 Remove the bonnet flange.

6.5 If the bonnet has not dropped down to the body/bonnet shelf, push or tap the bonnet with a

rubber mallet until it drops down enough to allow removal of the segmented bonnet retaining

ring.

6.6 Remove the four pieces of the bonnet retaining ring, smaller pieces first. If needed, place a

¼" rod or punch tool through the holes in the body and knock the retaining ring segments in

towards the bonnet. Refer to Figure 1 to determine the order of removal.

Figure 1 – Bonnet and Seat Retaining Rings

8

Page 9

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

6.7 Place lifting rings in both gland flange bolt holes in the bonnet and slowly pull the bonnet,

retaining ring segments, bonnet seal spacer and the bonnet pressure-seal out of the body.

WARNING:

c

could damage the plug and cause damage to the other equipment as well as injury to personnel.

If the plug begins to lift as the bonnet is removed, tap the top of the plug stem with a rubber

mallet to keep the plug in place. Do not remove the plug with the bonnet.

NOTE: The pressure seal may expand as it passes by the retaining ring groove and prevent the

bonnet from coming out. In this event, lower the bonnet back down into the body and remove the

pressure seal independently.

6.8 To replace packing or change the packing box configuration, push out packing, spacer and

6.9 Remove the pilot plug assembly from the valve by lifting on the plug stem threads. For

6.10 With a long extension on a socket head ratchet, remove the seat retaining ring bolts. Remove

6.11 Place two threaded lifting rings in the seat ring lifting holes. Carefully lift the seat ring

NOTE: The pressure seal may expand as it passes by the retaining ring groove and prevent the seat

ring from coming out. In this event lower the seat ring back down into the body and remove the

pressure seal independently.

It is possible for the plug to lift out with the bonnet. If the plug were then to fall free, it

guides with a dowel slightly larger than the plug stem from underneath the bonnet.

instructions on working with pilot operated plug assemblies please refer to Pilot Operated

Trim IOM (Document number VLENIM0064). To obtain a PDF of this IOM, visit

www.flowserve.com

the four seat retaining ring segments. Two of the retaining rings are locked into position by the

other two rings. See Figure 1 to determine which rings must be removed first.

assembly, disk spring retainer, disk spring, seat seal retainer and the seat seal out of the body.

6.12 If the seat ring seating surfaces need re-machining, both surfaces on the plug and seat ring

must be reworked. The seat angle on the plug is 36 degrees and the seat ring is 33 degrees

with respect to the centerline. Lapping is not necessary

6.13 If the seat surface is to be refinished the seat may be left attached to the severe service trim as

long as steps are taken to cover the openings of the trim to prevent metal chip ingress.

6.14 If removal of the severe service stack is required, grind the tack welds off of the socket head

bolts and remove each bolt from the seat ring.

6.15 The lower MegaStream plate is not intended to be removed. If it needs to be removed, the

retaining ring would have to be carefully machined out of the body and the threads in the body

would have to be re-tapped.

NOTE: Carefully inspect the primary plug lower skirt guiding surface and severe service trim bore

for signs of galling and scoring. Superficial scoring can be removed with a light application of emery

cloth. If more serious scoring exists, contact your local Valtek control valve representative.

NOTE: Damaged pilot springs should be replaced.

9

flowserve.com

Page 10

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

7 Reassembly and Installation

7.1 Before re-assembly, carefully inspect the body pressure seal sealing surfaces. These are the

cylindrical surfaces just beneath the and seat retaining ring grooves. If these surfaces are

damaged, they must be reworked to provide a 32 Ra surface finish. Also ensure that the body

shelf that supports the seat ring is free from damage and is clean.

7.2 If the MegaStream plate has been removed from the body, place the plate in the end of the

body with the boss facing the body gallery. Thread in the plate retainer tightly against the plate

and heavily peen the threads to prevent the retainer from unscrewing during service.

7.3 If the seat assembly has been disassembled, index the severe service trim into the seat ring.

7.3.1 Liberally apply thread locking compound (Loctite Blue or equivalent) on the threads of

the seat assembly bolts and thread them into the seat ring. Using Table 1, tighten the

bolts to the values according to the bolt material.

Table 1 – Severe Service Trim Bolt Torque Values

Bolt Size

inches ft-lb N m ft-lb N m ft-lb N m

3

⁄8 24 32.5 19 25.8 15 20.3

7

⁄16 39 52.9 31 42.0 23 31.2

1

⁄2 60 81.3 48 65.1 36 48.8

9

⁄16 87 118 70 94.9 52 70.5

5

⁄8 121 164 97 132 72 97.6

3

⁄4 216 293 173 235 129 175

All values are +/- 10%

Inconel A193 B7/B16 A193 B8

Bolt Material

10

7.3.2 Check the alignment of the seat ring and stack by inserting the plug into the seat

assembly and moving it back and forth, checking for sticking or binding.

7.3.3 Tack-weld each socket head bolt with a compatible weld material. Weld near the OD of

the severe service trim to facilitate the ease of removing the weld later.

7.4 Lower the entire seat assembly into the body with threaded lifting rings in the seat ring.

NOTE: It is critical that the severe service stack centers and indexes over and around the boss located

on the MegaStream plate.

7.5 Carefully install the pressure seal into the body and around the seat ring. Mark 14 pressure

seals have three metal anti-extrusion rings on the seal corners. The side of the seal with two

metal rings must face up when installed. See Figure 2 to determine the correct installation

position.

Page 11

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

Centerline

Disc

Spring

Retainer

Disc

Spring

Pressure

Seal

Retainer

Pressure

Seal

Centerline

Disc

Spring

Retainer

Disc

Spring

Pressure

Seal

Retainer

Pressure

Seal

Figure 2 – Pressure Seal Assembly

7.6 Refer to Figure 2 and assemble the pressure seal as follows:

7.6.1 Place the seat ring pressure seal retainer over the pressure seal with the axial leg

pointed down toward the pressure seal.

7.6.2 The disk spring is a Bellville washer style spring. Place the large disk spring in next

so that the OD makes contact with the pressure seal retainer.

7.6.3 Place the disk spring retainer in next so that its stepped surface is facing up.

7.7 Refer to Figure 1 and place the four segments of the seat retaining ring in the body groove.

Make sure that the side marked “TOP” is facing towards the top of the valve.

7.8 Apply thread locking compound (Locktite Blue or equivalent) to the thread of the socket head

bolts used to compress the seat ring pressure seal. Tighten the bolts down in an alternating

star pattern in several increments until the minimum torque value shown in Table 2 is

achieved.

Table 2 – Seat and Bonnet Torque Values

Bolt Size

inches ft-lb N m ft-lb N m

3

⁄8 18 24.4 13 17.6

7

⁄16 29 39.3 22 29.8

1

⁄2 44 59.7 33 44.7

9

⁄16 64 86.8 48 65.1

5

⁄8 88 119 66 89.5

3

⁄4 158 214 118 160

7

⁄8 257 348 192 260

All values are +/- 10%

A193 B7/B16 A193 B8

Bolt Material

7.9 Place the pilot operated plug assembly through the seat ring until in comes to rest on the seat.

For instructions on working with pilot operated plug assemblies please refer to Pilot Operated

Trim IOM; Document number VLENIM0064. To obtain a PDF of this IOM, visit

www.flowserve.com

NOTE: The plug should insert smoothly into the seat ring. If binding or sticking occurs, remove the

plug immediately and check for damage and misalignment.

11

flowserve.com

Page 12

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

Bonnet Flange Bolting

Disc Springs

Bonnet Flange

Body

Bonnet

Segmented Retaining Ring

Pressure Seal Retainer

Pressure Seal

Bonnet Flange Bolting

Disc Springs

Bonnet Flange

Body

Bonnet

Segmented Retaining Ring

Pressure Seal Retainer

Pressure Seal

7.10 Replace the packing, guides and spacers into the bonnet. The appropriate User Instructions

have detailed instructions for each packing style.

7.11 Place the bonnet into the body, sliding it over the plug stem until it comes to rest on the body

bonnet shelf.

7.12 Refer to Figure 2 and place the bonnet pressure seal into the body and around the bonnet in

the same manner as the seat seal.

7.13 Place the bonnet pressure seal retainer over the bonnet pressure seal.

7.14 Refer to Figure 1 and place the four segmented bonnet retaining rings into their groove with

the side marked “TOP” facing towards the top of the valve.

7.15 Place the bonnet flange into the body until it rests on the body bonnet flange shelf. Align the

flange bolt holes approximately with the bonnet threaded bolt holes.

7.16 Apply thread lubricant compound (Loctite Blue or equivalent) to the bonnet bolts, place

two disk springs in parallel (nested, see Figure 3) under each bolt. Tighten the bolts in an

alternating star pattern in several increments until the minimum torque value shown in Table 2

is achieved.

12

Figure 3 – Bonnet Bolting

NOTE: For best long term bonnet sealing, the bolting should be re-tightened after system pressure is

applied to the body.

7.17 Place the actuator on the body and bolt it to the body tightly. Using air, stroke the actuator to

the bottom of its stroke and hold it there.

7.18 Install the split stem clamp and bolting. Stroke the plug open. Turn the plug stem out of the

actuator stem threads an additional amount according to Table 3. This will ensure that the

piston in the actuator does not hit the yoke before the pilot plug makes contact with its seat.

CAUTION: If binding or sticking is observed, discontinue stroking the valve and reassemble using

a

the above steps. Failure to do so could cause serious valve damage.

Table 3 – Plug Adjustment

Valve Stroke Turn the plug out an additional:

in. mm in. mm

3 or less 76 or less 0.19 5

4 102 0.25 6

6 152 0.38 10

8 203 0.50 13

Page 13

Figure 4 – Exploded View

93, 94, 95

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

Item No. Description

1 Body Assembly

201

71

249

106, 107

86

87

88

88

83

40

117

109

135

80

108

114

70

62

63

58

52

51

53

50

23

22

61

60

59

55

10

10 Seat Ring

20 Severe Service Trim

22 Seat Ring Segmented Ring

23 Socket Head Bolt

30 Seat Ring Bolts

50 Primary Plug Head

51 Pilot Plug Head Assembly

52 Pilot Operated Plug Cap

53 Pilot Operated Plug Spring

55 Seat Ring Pressure Seal

58 Bonnet Pressure Seal

59 Seat Ring Pressure Seal Retainer

60 Disk Spring

61 Disk Spring Retainer

62 Bonnet Segmented Ring

63 Bonnet Pressure Seal Retainer

70 Bonnet Flange

71 Lifting Lug

80 Gland Flange

83 Stem Guide

86 Stem Guide Retainer

87 Stem Guide Liner

88 Packing Set

93, 94, 95 Packing Spacers

106, 107 Actuator Mounting Studs, Nuts

109, 117 Gland Flange Studs, Nuts

114 Belleville Washers

135 Live Loading Kit

201 Actuator Assembly

249 Split Stem Clamp

20

30

1

13

flowserve.com

Page 14

Figure 5 – Cross Section

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

14

Page 15

Valtek Mark 14 Control Valves FCD VLENIM0115-00 – 06/06

flowserve.com

15

Page 16

FCD VLENIM0115-00 Printed in USA.

To find your local Flowserve representative:

For more information about Flowserve Corporation, visit

www.flowserve.com or call USA 1 800 225 6989

United States

Flowserve Corp.

Flow Control

Valtek Control Products

1350 N. Mt. Springs Parkway

Springville, UT 84663 USA

Telephone: 1 801 489 8611

Fax: 1 801 489 3719

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected, this Flowserve product is designed to perform its intended

function safely during its useful life. However, the purchaser or user of Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide

variety of industrial service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specific data and warnings for all possible applications. The

purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection, installation, operation, and maintenance of Flowserve products. The purchaser/user

should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve

products in connection with the specific application.

While the information and specifications contained in this literature are believed to be accurate, they are supplied for informative purposes only and should not be considered certified or as

a guarantee of satisfactory results by reliance thereon. Nothing contained herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this

product. Because Flowserve is continually improving and upgrading its product design, the specifications, dimensions and information contained herein are subject to change without notice.

Should any question arise concerning these provisions, the purchaser/user should contact Flowserve Corporation at any one of its worldwide operations or offices.

© 2006 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

flowserve.com

Loading...

Loading...