Page 1

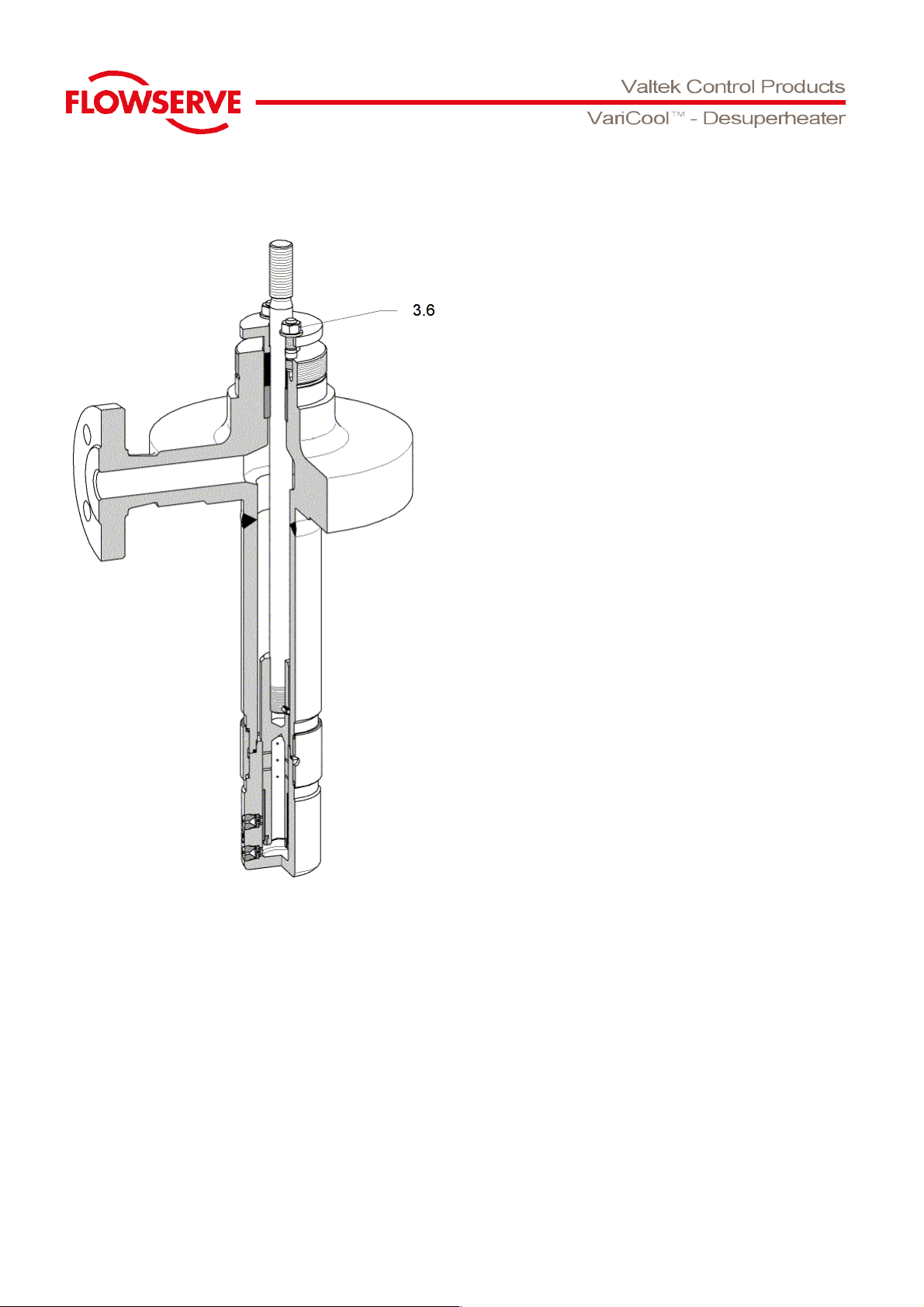

VARICOOL - V901

Injection Nozzle Valve

Fig. 1

Page 2

List of contents

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

2

3

4

5

6

6.1

6.2

6.3

6.4

6.5

6.6

6.7

7

Operating instructions

Installation

Delivery status

Installation recommendation

Physical requirements

System requirements

Preparation for installation in the pipeline

Installation of the SCHMIDT valve

Commissioning

Maintenance

Trouble shooting

Repair

Assembly

Cleaning

Lubrication

Assembly component „Nozzle Body“

Assembly component „Plug“

Assembly component „Packing“

Assembly „VariCool“

Assembly „Finish“

Parts list

3

3

3

3

4

4

5

5

6

6

7 + 8

9

9

9

9

10

11

12

13

14

15

Page 3

Application

Injection control valve for direct steam cooling applications. In combination with a SCHMIDT

multispring or central spring pneumatic actuator, optionally also with an electrical linear or rotary

actuator, can be controlled. Suitable for a wide range of applications due to simple design and

adaptability to different processes.

1 VARICOOL operating instructions

1.1 Installation

The device may only be assembled and put into service by qualified personnel. Qualified

personnel are persons who are familiar with the assembly, commissioning and operation of

this product and have the respective qualifications to perform these activities.

1.2 Delivery status

The SCHMIDT injection nozzle valves are delivered with assembled and calibrated

actuators. They are provided with a protective coating, any shiny parts are greased and the

body openings are provided with blanking plugs. The greatest care must be taken against

knocks or sudden movements during loading and transport, as the lifting appliances must

be attached without pressure on the stem and the position indicator by means of a rope

sling below the actuator mounting flange. Any damage of the corrosion protection during

transport must be remedied immediately. At the construction site, the injection nozzle valves

must be protected against the effects of weather, grime and other damaging influences by

being placed on a firm base in a closed room until required for installation. The blanking

plugs attached for protection of the flange and interior of the control valve may only be

removed at the installation site.

1.3 Installation recommendation

The successful employment of the injection nozzle valve depends directly on a suitable

design of the converting station. As the function of the converting station depends greatly on

the consideration of the physical possibilities, it is recommended to observe the stated

standard values. Deviations may lead to considerable fluctuations in the control loop for

which the nozzle valve manufacturer rejects any liability whatsoever. In borderline cases, an

expensive conversion of the steam converting station should be expected. Even though the

complex physical processes may in individual cases justify a deviation from the standard

values, this requires, however comprehensive system knowledge and the express approval

of the manufacturer.

Page 4

1.4 Physical requirements

• For an optimal operation, the steam speed should be 10 to 100 m/s / 30 to 300 ft/s

6

• To avoid condensate the set temperature should be 5 to 10 °C / 41 to 50 °F

above the saturated steam temperature.

• Max. operating temperature 530 °C / 986 °F

• Recommended cooling media temperature 120 °C / 248 °F

• Cooling media pressure 5 to 10 bar / 76 to 145 psi (see nozzle table) up to

max. 90 bar / 1300 psi above steam pressure.

• We recommend the installation of a strainer into the cooling media pipe

(mesh size 0,1mm / 0.004 inch)

• Minimum steam pipe diameter 150 mm / 6 inch

• Recommended straight pipe after injection nozzle valve: 0,1 x steam speed

min. 4 to 6 m / 13 to 20 ft

• The distance of the temperature sensor should be 0,2 x steam speed or min. 9 m / 30 ft

• The position of the temperature sensor is important for the measuring quality

Pay attention to the mounting instruction of the sensor supplier

1.5 System requirements

• System drawing with design recommendation Experience shows that deviations result in

considerable problems. A stratification of temperature zones is a frequent phenomenon

in large steam piping networks. We recommend the installation of 2 to 3 temperature

sensors with average value calculation.

Page 5

Ensure that the central nozzle and the atomisation cone correspond to the axis of the

piping. The cooling medium must always be injected in the direction of flow of the medium !

1.6 Preparation for installation in the pipeline

The sealing and functional check as well as the quality assurance checks carried out in the

factory ensure the version of the control valve fully corresponds with the version specified in

the supply contract. The model number and data required for operating the valve and drive

are noted on the nameplate. The achievable stroke can be read on the driving starting

pillar/yoke.

Before the installation, the pipelines must be carefully cleaned.

1.7 Installation of the SCHMIDT valve

Checklist:

• Does the name plate agree with the operating data of the system?

Non-agreement can lead to considerable damage of the injection nozzle valves, for

which the manufacturer accepts no liability !

• Is sufficient space available at the installation location for problem-free installation and

removal?

• Have the pipelines been cleaned before the installation?

Carefully remove any foreign bodies !

• Has the control valve been depreserved and cleaned before installation?

• Does the direction arrow attached to the body agree with the direction of flow?

• Do any unallowed voltages occur during installation and operation of the control valve?

Perpendicularity of the flange required !

• Does the spacing of the pipe ends correspond to the overall valve length?

If the aforementioned points are fulfilled, the control valve can be inserted in the pipeline

and screwed together with the connecting material ( seals, screws, nuts - provided by the

builder). Afterwards, the piping of the drive with the plant air in pneumatic actuators or the

wiring of the electrical actuators can be carried out according to the electrical block diagram

located in the removable drive hood or in the drive manufacturer documentation.

Page 6

2 Commissioning

Increase the load on the operational parameters gradually and continuously.

Do not suddenly subject the control valve to full operational pressure and operational

temperature !

After the initial load ( trial run ), while the system is in a pressure-free and cool state:

tighten up the screw connections of the sealing components evenly across the diagonal.

Do not damage the high-quality stem surface !

It is forbidden to work between the pillar / yoke during operation because of the risk

of injury !

3 Maintenance

Maintenance activities

Maintenance interval

Clean the valve spindle with a soft cloth.

Do not damage the high-quality

spindle surface !

Depending on the amount of grime.

The spindle surface must always

retain its metallic shine !

Tighten up the valve spindle seal if any

leakages occur.

Regular check

If any defects or faults occur, contact the manufacturer, his authorized repairers, customer

service or, in special cases, with the express permission of the manufacturer, the operating

company. Any repair activities on the part of third parties invalidate the warranty of the

manufacturer.

Service hotline:

0043 (0) 664 3418616

Page 7

4 Trouble shooting

Defect

No.

Possible cause

Remedy

Spindle does not move

1.1

1.2

1.3

1.4

1.5

1.6

• no aux. energy supply (

pneumatic air or electrical power

) to actuator and accessories (

solenoid valve, filter reducing

station, positioner, limit switch

and special accessories )

• the fitted accessories do not

work

• the pneumatic actuator is

defective

• the electrical actuator is

defective

• excessive tightening of the

stuffing box packing

• Valve trim worn, stuck

• pneumatic actuators: check supply

line for leaks; check pressure (

usually 6 bar )

• electrical actuators: check power

supply (connections, circuit breakers,

voltage)

• see maintenance and operating

instructions of accessories

manufacturer

• contact customer service

departement or contract partner

• see maintenance and operating

instructions of actuator manufacturer

• loosen stuffing box packing nuts until

valve operates properly

Caution: make sure there are no leaks !

• contact customer service

departement or contract partner

Jolting spindle movement

2.1

2.2

2.3

• dirty spindle

• damaged spindle

• actuator not powerful enough

•

clean spindle with suitable cleaning

agent

• contact customer service department

or a contract partner

• compare actuator specs on the

rating plate with operation

specifications of the facility - if

incompatible, contact customer

service department or contract

partner

Spindle travel less than full

stroke

( 0 to 100% stroke )

3.1

3.2

3.3

3.4

3.5

• air supply pressure too low

• pneumatic actuators: bad hand

wheel position (hand wheel

emergency operation)

• electrical actuators: limit switch

misadjusted

• badly adjusted or defective

positioner

• foreign particles in valve seat,

damaged trim

• provide air at the pressure stated on

the rating plate

• take hand wheel to limit position

• readjust limit switch to actuator manu

facturer`s specifications

• readjust positioner to positioner

manu facturer`s specifications

• contact customer services

department or contract partner

Page 8

Defect

No.

Possible cause

Remedy

Excessive valve seat leakage

4.1

4.2

4.3

• damaged sealing edges at

valve seat or plug

• foreign particles in seat area

• plug does not close fully

• contact customer services

department or contract partner

• contact customer services

department or contract partner

• refer to 3.1 to 3.5

Leaking stuffing box system

5.1

5.2

5.3

5.4

• compression force on packing

too low

• worn packing

• dirty spindle

• damaged spindle

• slightly re-tighten stuffing box packing

Caution: make sure the valve spindles

can still move !

• slightly re-tighten stuffing box packing

Caution: make sure the valve spindles

can still move !

• if the packing does not stop leaking,

contact customer service department

or contract partner

• clean spindle with suitable cleaning

agent

• contact customer services

department or contract partner

Leaking top or lid seal

6.1

6.2

• pressing force on seal(s) too

low

• seal(s) defective

• properly re-tighten top or lid nuts

crosswise

• contact customer services

department or contract partner

Leaking housing

7.1

• medium or flow related damage

• contact customer service department

or contract partner

No limit switch signal

8.1

8.2

• power supply to limit switch

interrupted

• limit switch misadjusted

• check power supply

( voltage, circuit

breakers, connections )

• readjust limit switch; operating

distance see limit switch data sheet

Vibrating positioner

9.1

• defective positioner

• see maintenance and operating in

structions of positioner manufacturer

If the problem is not solved by taking the above measures, contact the customer services

department or contract partner.

Page 9

5. Repair

If a fault or defect occurs which, according to the list of measures before, requires the customer

services departement or contract partner to be contacted, the manufacturer`s guarantee shall

be rendered null and void - and the manufacturer released from any responsibility - unless the

customer services department or contract partner is duly notified.

Service hotline Austria:

+43 (0)664 341 8 616

6. Assembly

These procedure assumes that the Injection Nozzle Valve is completely disassembled. If it is

not, start the instructions at the appropriate step.

6.1 Cleaning

Carefully clean all valve parts before beginning assembly!

6.2 Lubrication

Lightly grease all guide pieces

For lubricant to be used, see table 1

LUBRICANT

Klüber Wolfracoat C – Item no.: 089032

Tab.: 1

Lightly grease all screw threads

For lubricant to be used, see table 2

LUBRICANT

Klüber Wolfracoat C – Item no.: 089032

Tab.: 2

Page 10

6.3 Assembly component “Nozzle body”

Fig. 2

• Fixation of the nozzle body (4.4)

• Insert the rotary disk (4.6) and profile

ring (4.7) into the nozzle body (4.4)

and then screw in the nozzle (4.5)

• Place the profile ring (1.2) on the

nozzle body (4.4)

Page 11

6.4 Assembly component “Plug”

Fig. 3

• Fixation of the plug (2.2)

• Screw the stem (2.4) into the plug (2.2)

• Drill both plug (2.2) and stem (2.4)

together

• Press the spring pin (2.3) into the

drilled hole

After pressing in the dowel pin, the plug

and stem must be aligned to one another !

• Insert the fuse carrier (2.14) in the plug

(2.2)

• Put the piston sleeve (2,13) onto the

plug (2.2)

• Screw the lock nut (2.25) onto the plug

(2.2) (for tightening torques, see page

9)

• The lock nut (2.25) must be secured by

welding spots against automatic

loosening !

Page 12

6.5 Assembly component “Packing”

Fig. 4

• Insert the guide sleeve (3.2) in the

body (1.1)

• Insert the packing (3.3) on the guide

bush (3.2)

• Screw the stud bolts (3.5) into the body

(1.1)

• Place the packing box (3.4) on the

packing (3.3)

• Place the disk (3.8) on the packing box

(3.4)

• Screw the hexagonal nuts softly (3.6)

onto the stud bolts (3.5)

Page 13

6.6 Assembly “VariCool”

Fig. 5

• Insert the plug (2.2) in the nozzle body

(4.4)

• Place the LR nut (1.6) onto the nozzle

body (4.4)

• Fixation of the body (1.1)

• Insert the stem (2.4) in the body (1.1)

• Connect the body (1.1) and nozzle

body (4.4) with one another by turning

the LR nut (1.6) (for tightening torques,

see .....)

After assembly, the LR nut (1.6) must be

secured by welding spots against

automatic loosening !

Page 14

6.7 Assembly “Finish”

Fig. 6

• Tighten the hexagonal nuts (3.6) evenly

The stem must move smoothly !

Page 15

7 Parts list

Name

Part

Materials

Spare

parts

Body

1.1

1.4581/1.4571

Profile ring

1.2

Pure graphite

D

LR nut

1.6

1.4922

Plug

2.2

1.4922

K

Spring pin

2.3

A2

K

Stem

2.4

1.4922

K

Piston sleeve

2.13

1.4122 tenifer treatment

K

Protection

against torsion

2.14

1.4122

K

Lock nut

2.25

1.4922

K

Guide bush

3.2

1.4034 hardened

Packing

3.3

Graphite rings

D

Packing box

3.4

1.4571

Stud bolt

3.5

A2-70

Hexagonal nut

3.6

A2-70

Disk

3.8

A2

Nozzle body

4.4

1.4922

Nozzle

4.5

1.4571 tenifer treatment

S

Rotary disk

4.6

1.4571 tenifer treatment

S

Profile ring

4.7

Pure graphite

S

Fig. 7

K plug, stem, piston sleeve

S nozzle-set

D seal-set

Page 16

SAEEIMV901 03.08

Flowserve (Austria) GmbH

Control Valves – Villach Operation

Kasernengasse 6

9500 Villach

Austria

Phone +43 (0) 42 42 / 41 1 81 - 0

Fax +43 (0) 42 42 / 41 1 81 - 50 or 51

E-mail villach_operation@flowserve.com

www.flowserve.com

www.flowserve-villach.com

Loading...

Loading...