Page 1

Edward Valves

Maintenance Manual for Edward

Equiwedge

™

Gate Valves

V-378 R1

Page 2

2

Flow Control Division

Edward Valves

Table of Contents

Introduction and Scope .........................3

Gate Valve Figure Numbers ...................3

Description of Equiwedge

Gate Valve Types...............................4

Type I..................................................4

Type II..............................................4-5

Type III................................................5

Type IV................................................5

Type V.................................................5

Service Problems ..................................6

Packing Chamber Leak.......................6

Packing Recommendations..................6

Pressure Seal Gasket Leak ..................7

Pressure Seal Leak.............................7

Gate and Seat Leakage......................8

Body or Bonnet Wall Leak ..................8

Lubrication........................................8

Repair Procedures.................................9

Valve Body Repairs.– Body

Bore Gasket Seal Area Repairs.........9

Body Wall Repairs...........................10

Body Guide Repairs.........................10

Seat Repairs....................................10

Gate Repairs ...................................11

Bonnet Repairs ................................11

Backseat.........................................11

Porosity in Bonnet............................12

Stem Repairs...................................12

Field Repair Equipment.....................12

Disassembly Procedure for

Equiwedge Gate Valves....................13

Disassembly Procedure for Bonnet Types,

Area 3

Type I .............................................14

Type II............................................15

Type III ...........................................16

Type IV & V ....................................17

Reassembly Procedures for Equiwedge

Gate Valves ....................................18

Exploded View...................................19

Reassembly Instructions........................20

Handwheel Actuated Valves ..............20

Tapered Roller Bearing

Preload Instructions ........................21

Reassembly Instructions for

Valves with Composite Pressure

Seal Gaskets Only.........................23

Type I Reassembly............................24

Type II Reassembly...........................25

Type III Reassembly ..........................26

Type IV & V Reassembly...................26

Appendix A

Procedure for Removing Manual

& Electric Actuators...................28-29

Appendix B

Valve Tools Available for Rental.........30

Terms and Conditions ..........................31

Contact Information ............................32

TABLES

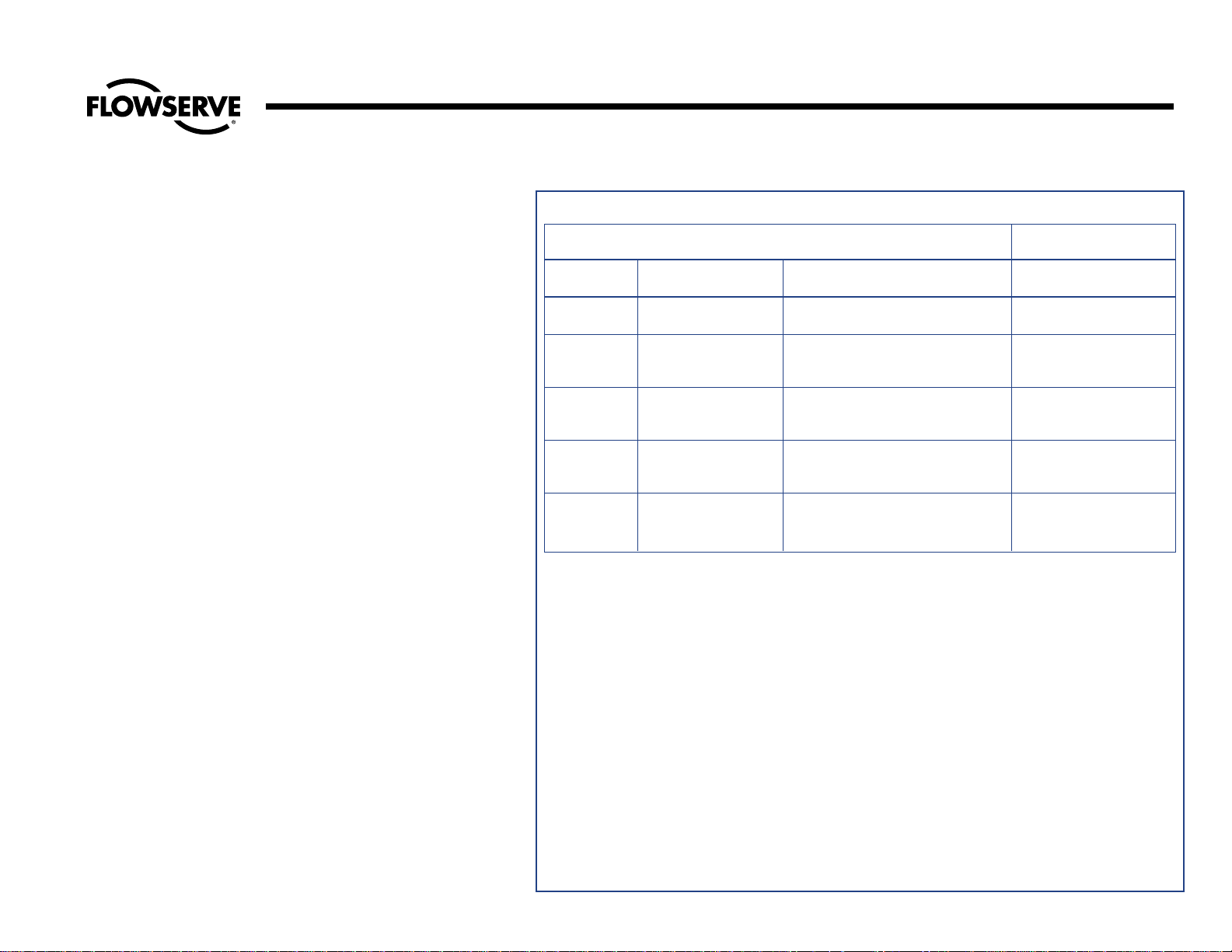

Table 1 Gland Bolt Torques.................7

Table 2 Bonnet/Cover Bolt/

Nut Pull-up Torques.................7

Table 3 Welding Rod

Recommendations ................22

Table 4 Dimensions for

Bearing Preload Washer.......22

Table 5 Bearing Retainer

Preload Torque ....................22

Table 5A ..........................................22

Table 6 Bearing Retainer

Final Torque ........................22

Table 6A ..........................................22

Table 7 Composite Gasket

Bonnet/Cover Bolt/Nut

Pull-Up Torques ....................23

Page 3

3

Flow Control Division

Edward Valves

Introduction and Scope

Introduction

This manual has been prepared to serve as

a guide for maintenance of Edward

Equiwedge gate valves, all of which

feature the pressure seal bonnet joint

construction. Although rigid metallurgical,

non-destructive examination, physical and

visual inspection is standard procedure for

Edward Valves products, it is inevitable

that some valves, after a period of time,

will require repairs. This manual will assist

you in restoring the valve to good working

condition with a minimum of time and

expense.

Scope

Before starting any repairs, it will be

helpful to have some understanding of the

valve’s physical construction. Consequently,

the five basic types of pressure seal construction are discussed and illustrated first.

All Equiwedge gate valves employ one of

these five basic types.

The next major section of this manual

discusses the more common service

problems, and explains the reason for

certain failures. The reason for the problem

should be understood before work is actually started.

Then, the procedure to be followed in making the repair is explained. This section

includes normal valve maintenance as well

as major valve repairs. Field repair equipment available from Edward Valves is

described and illustrated. Valve lubrication

and welding rod recommendations are

also included. These procedures should be

adequate for almost any Equiwedge gate

valve repair or maintenance problem that

may arise.

Following is a section describing the

disassembly procedure for the various

valve components; for example, manual

handwheel, manual geared actuators or

electric actuators, valve yokes, and the five

basic bonnet types. It is very important that

this manual be studied before any

disassembly work is done to avoid needless work and loss of time by selecting the

improper procedures.

The last sections include reassembly instructions and available maintenance equipment and information on the various types

of actuators, both manual and electrical.

Figure No. Class Pressure Seal Type Size

1611-1611Y 600 I & II 21⁄

2 to 28

1711Y Special Class 600 I & II 21⁄2 to 28

1911-1911Y 900 III, IV, & V 21⁄

2 to 28

14311Y Special Class 900 III, IV, & V 21⁄

2 to 28

11511-11511Y 1500 III, IV, & V 21⁄2 to 24

12011Y Special Class 1500 III, IV, & V 21⁄2 to 24

12511-12511Y 2500 III, IV, & V 21⁄2 to 24

14411Y Special Class 2500 III, IV, & V 21⁄2 to 24

Gate Valve Figure Numbers Described in this Manual

Page 4

4

Flow Control Division

Edward Valves

Description of Equiwedge Gate Valve Types

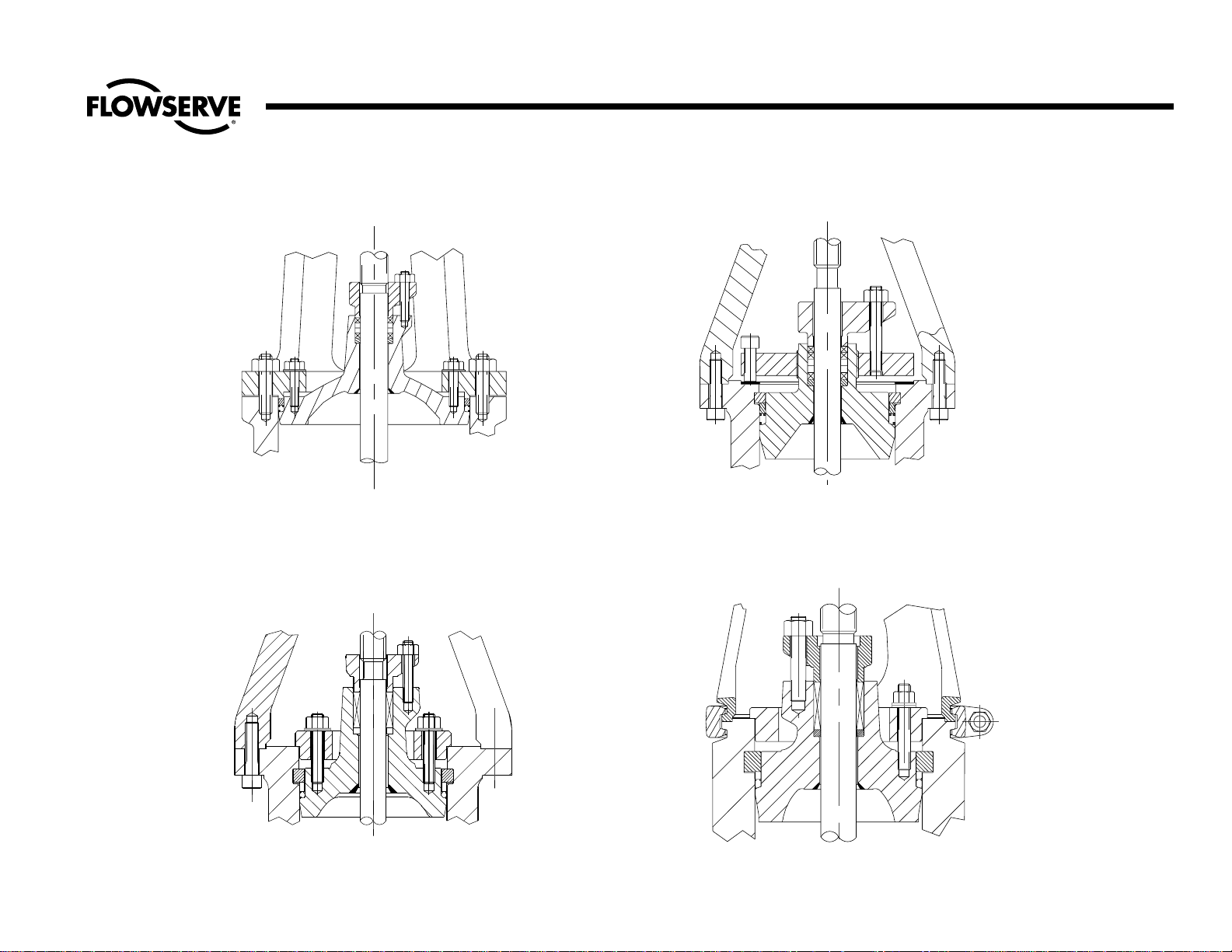

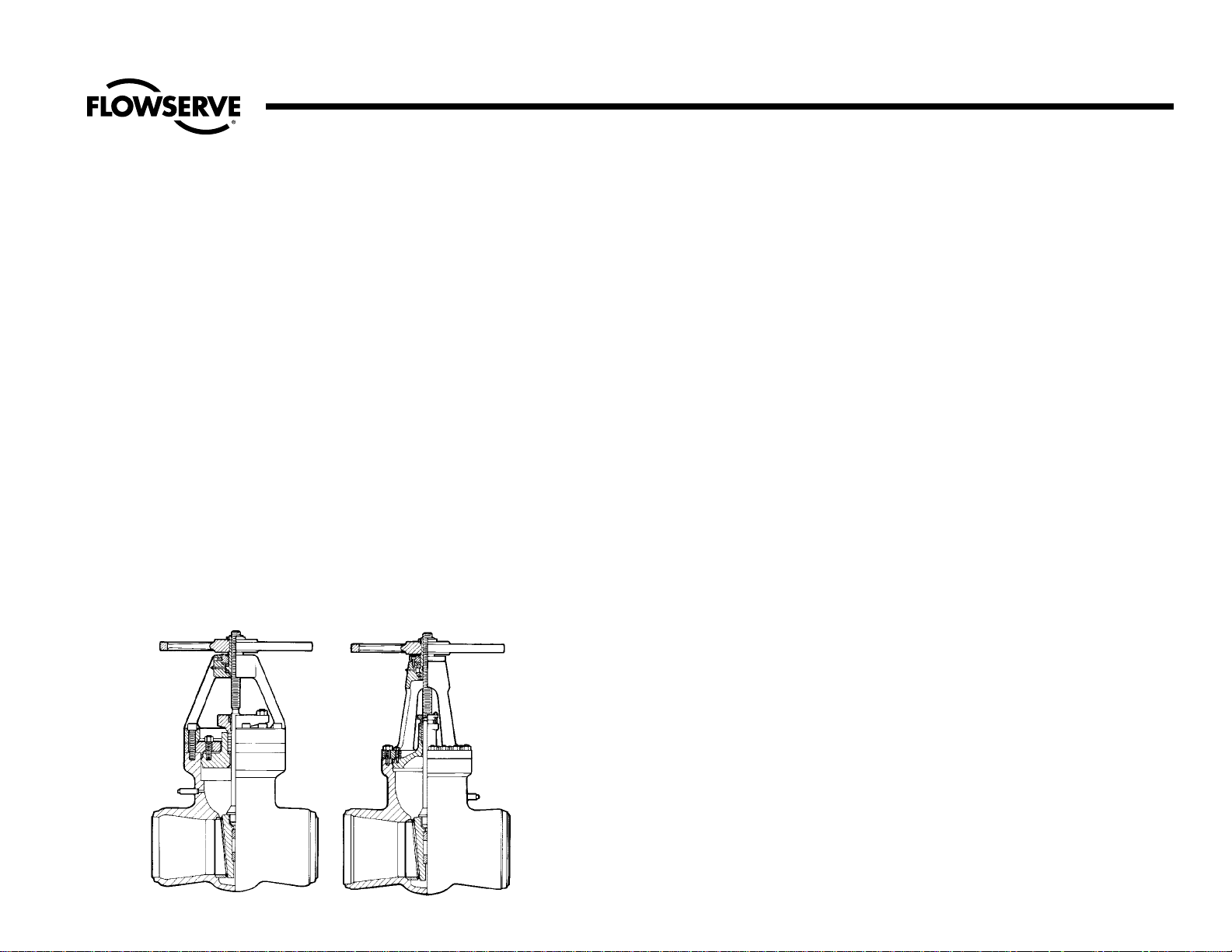

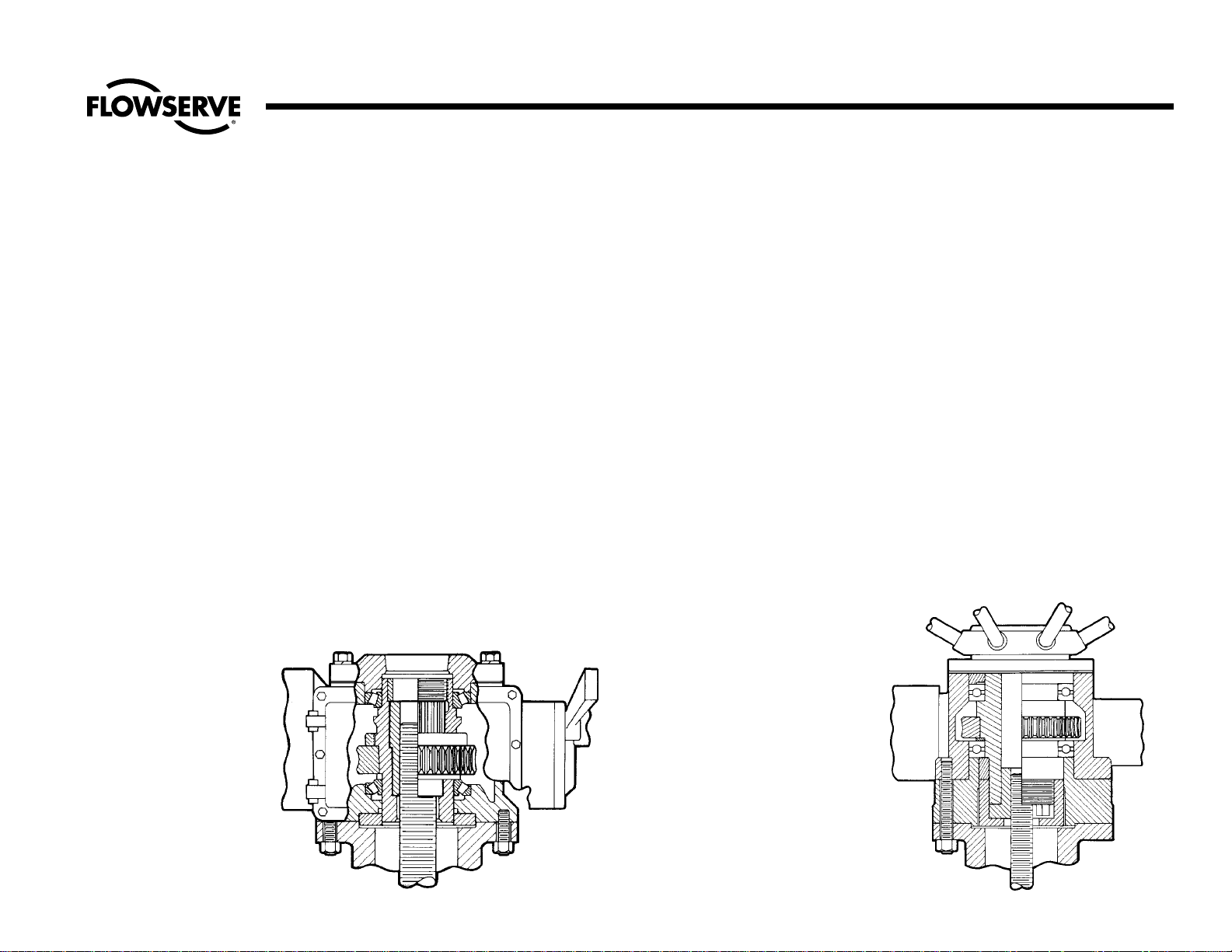

Type I is a flanged yoke design with a

separate gasket retainer ring, both of

which are held to the body by cap

screws. The bonnet retainer is screwed

onto the bonnet and cap screws are

screwed down on top of the body to force

the bonnet into contact with the gasket.

See illustration No. 1.

Type II is a flanged yoke design with or

without a separate bonnet retainer ring,

both of which are held on the body by

cap screws or studs and nuts. The bonnet

is pulled up into contact with the gasket

with studs and hex nuts. See illustrations

Nos. 2A and 2B, pgs. 4 and 5.

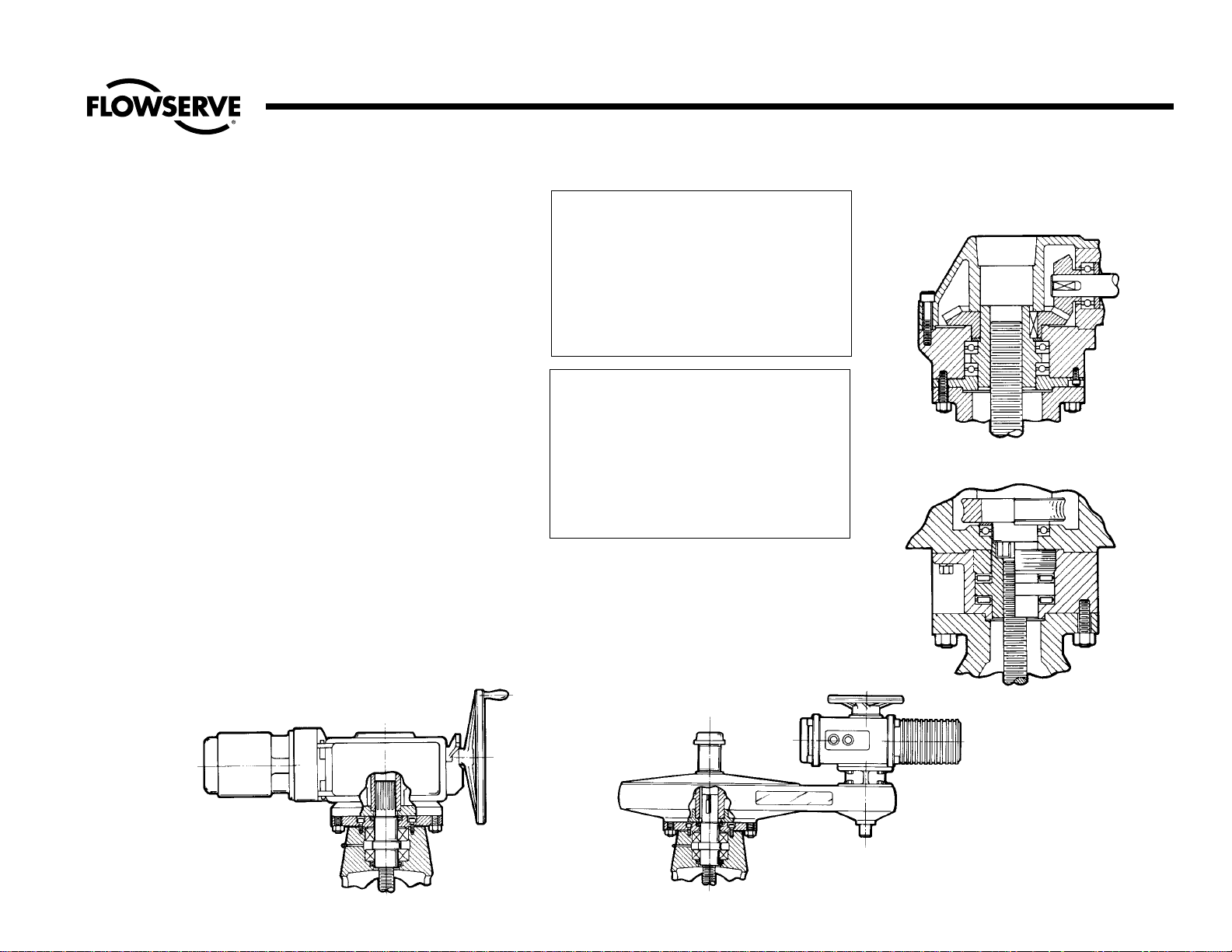

Type III is a wishbone yoke design bolted

to the body. It has a segmental retaining

ring, spacer ring and a screwed on

bonnet retainer equipped with push down

bolts to pull the bonnet up into contact

with the gasket. See illustration No. 3,

pg. 5.

Type IV is a wishbone yoke designed bolted to the body. It has a segmental

retaining ring, spacer ring and separate

bonnet retainer with pull up studs screwed

into the bonnet to contact the gasket. See

illustration No.4, pg. 5.

Type V has a yoke lock ring connection to

the body with a segmented ring, gasket

retainer and a separate bonnet retainer

with studs screwed into the bonnet to pull

up the bonnet against the gasket. See

illustration No. 5, pg. 5.

Illustration No. 1 Illustration No. 2A

Size 2-1/2 & 3 - Figure 1611 and 1611Y Size 4” -Figure 1611 and 1611Y

Size 2-1/2 & 3 - Figure 1711Y Size 4” - Figure 1711Y

Valve Type I Valve Type IIA

Page 5

5

Flow Control Division

Edward Valves

Description of Equiwedge Gate Valve Types (cont.)

Illustration No. 2B

Size 6 - 28 - Figure 1611 and 1611Y

Size 6 - 28 - Figure 1711Y

NOTE: Size 6 and 8 valves are wishbone yoke design with flange.

Valve Type IIB

Illustration No. 4

Size 4 - 8 - Figure 1911-1911Y-14311Y

Size 4 - 8 - Figure 11511-11511Y-12011Y

Size 4 - 8 - Figure 12511-12511Y-14411Y

Valve Type IV

Illustration No. 3

Size 2-1/2 - 3 - Figure 1911-1911Y-14311Y

Size 2-1/2 - 3 - Figure 11511-11511Y-12011Y

Size 2-1/2 - 3 - Figure 12511-12511Y-14411Y

Valve Type III

Illustration No. 5

Size 10 - 28 - Figure 1911-1911Y-14311Y

Size 10 - 24 - Figure 11511-11511Y-12011Y

Size 10 - 24 - Figure 12511-12511Y-14411Y

Valve Type V

Page 6

6

Flow Control Division

Edward Valves

Service Problems

Packing Chamber Leak

Where moisture appears or actual dripping

occurs at the packing chamber around the

stem, gland or gland flange which cannot

be eliminated by re-torquing the gland bolt

the following points should be considered.

1. The packing may have become hard.

Replace the packing.

2. Gland travel has been fully taken up.

Repack with new packing.

3. The wrong packing is being used.

See packing recommendations shown

on this page.

4. A stem should be replaced when it

has become deeply scratched,

burred, or otherwise mutilated from

careless handling, or where the stem

has worn, tapered or has been bent.

5. The gaps in the rings of split packing

have not been staggered around the

stem. They should be inserted in this

manner.

6. The packing gland may be binding

against the packing chamber or stem

and does not compress the packing

properly. Make certain the gland fits

the packing chamber and is tightened down equally on each side.

Packing Recommendations

Edward valves are packed with all-purpose

with packing sets. This is a combination of

packing using braided rings at the top and

bottom in the packing chamber and flexible graphite packing in the center section.

Packing gland should be tightened down

enough to prevent leakage but not enough

to develop excessive operating torque.

When the gland has advanced approximately half way into the packing chamber,

it is recommended that additional packing

rings be added. To obtain best results,

the stem should be thoroughly cleaned.

Replacement packing should be the same

as that originally furnished.

We recommend that replacement packing

be purchased from Edward Valves to

assure packing with the proper density and

corrosion inhibitors is always used.

IMPORTANT:

Long service life from modern graphitic

packing requires that adequate preloads

be applied when repacking.

1. All parts should be clean and not

scored or pitted, especially the stem.

2. The valve internal parts and bonnet

should be assembled prior to

installing the packing.

3. Position split packing rings with the

ends of adjacent rings rotated 90°.

4. Install in the following sequence:

Bottom Ring – Braided Ring

Center Rings – Die formed

expanded graphite

Top Ring – Braided Ring

5. Clean and lubricate the gland eyebolts.

6. Carefully seat each individual packing ring before adding the next ring.

7. Apply the recommended torque to

the gland nuts evenly without cocking

the gland. See Table 1, pg. 7, for

recommended torques.

8. Tighten the nuts to the initial values

shown, then loosen and re-tighten to

the final torque.

9. Stroke the valve, then re-check the

gland nut torques.

Note: The torque values given are for

sealing full rated pressure. For line pressures less than the full CWP rating of the

valve, the final torques may be reduced by

the ratio of P

actual

/CWP down to a mini-

mum of P

actual

= 1500 psig. This will

reduce packing drag and extend packing

life.

Page 7

Flow Control Division

Edward Valves

Service Problems (cont.)

Pressure Seal Gasket Leak

Edward valves have been produced with

two types of pressure seal gasket: Earlier

valves had metal gaskets, while later

designs have composite expanded graphite

gaskets. The valves with composite gaskets

can be identified by a “B” prefix on the figure number. Assembly and disassembly of

the two gasket types are essentially the

same except the composite gasket designs

have belleville spring washers under the

nuts (or capscrews) of the pull-up bolting,

and the tightening torque requirements for

the pull-up bolting are different.

To guard against leakage, the bolts should

he kept tightened at all times.

A torque wrench should be used for tightening the bonnet or cover retainer stud nuts or

capscrews which are used to pre-load the

pressure seal gasket.

All nuts/capscrews should be tightened in

an alternating star pattern to insure even

tightening.

The bolting should be tightened to the

torque values shown in Table 2 while the

valve is under full line pressure.

Pressure Seal Leak

Should the leak fail to stop after tightening,

it must be concluded that there is an imperfect pressure seal, and the valve will have

to be opened for examination.

(Note: Regardless of the cause of failure,

opened pressure-seal bonnets should

always be reassembled with a new gasket.

These are available from stock via Air

Express from Raleigh, North Carolina.)

Such a leak may result from any of the

following causes:

1. Incomplete Seal Between Bonnet and

Gasket. An incomplete seal around

the gasket seating surface of the bonnet (or cover on check valves) may be

caused by corrosion, dirt, chips, or

other foreign matter on the mating surfaces of the sealing angle.

2. Incomplete Seal Between Body I.D.

and Gasket. An incomplete seal in the

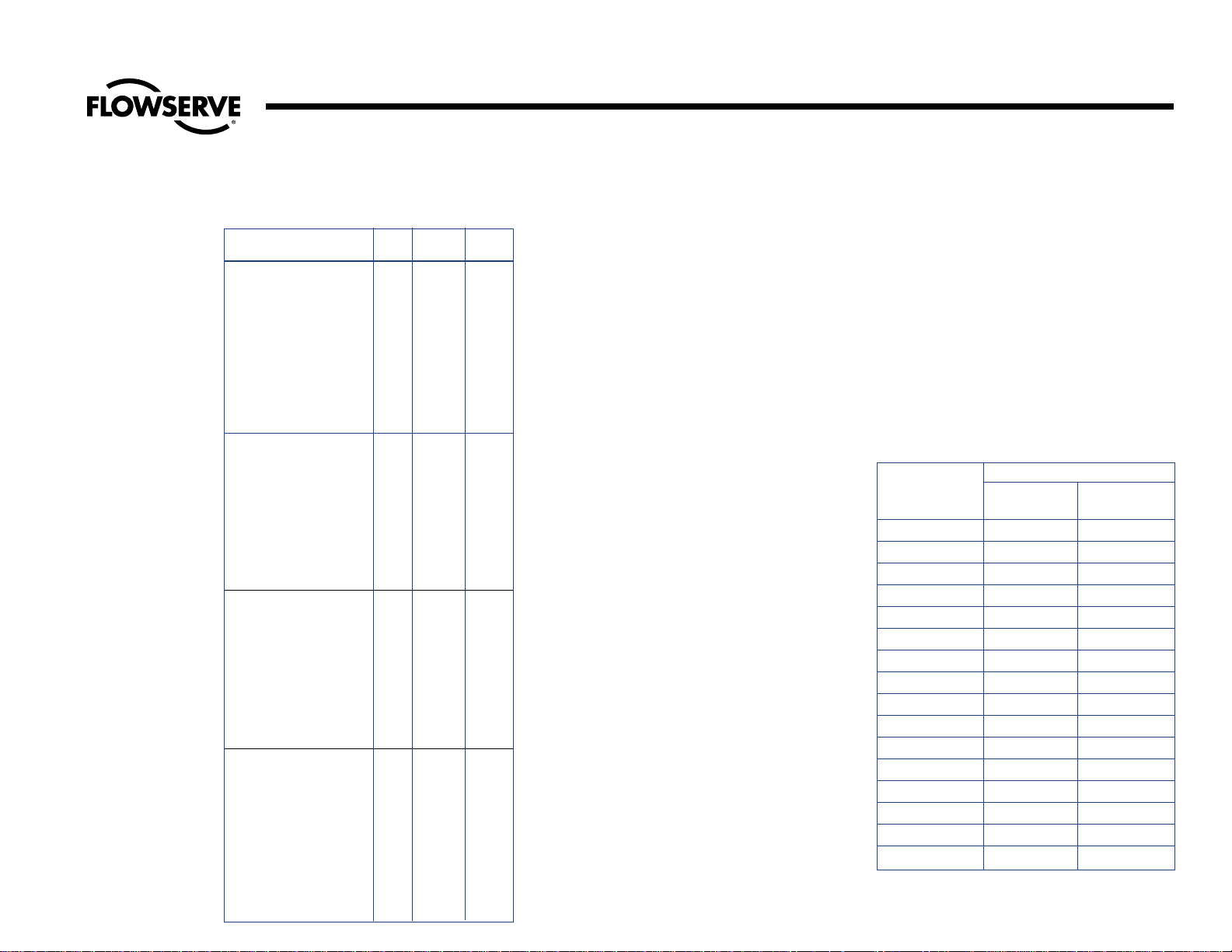

INITIAL FINAL

FIGURE NUMBERS SIZE TORQUE TORQUE

2.5 26 8

326 8

426 8

629 8

844 13

1611, 1611Y, 1711Y 10 67 19

12 72 21

14 76 22

16 95 27

18 121 35

20 127 37

24 156 45

28 221 64

2.5 26 11

326 11

426 11

644 19

864 28

1911, 1911Y, 14311Y 10 72 31

12 107 46

14 151 65

16 159 69

18 167 72

20 208 90

24 193 84

2.5 26 19

326 11

429 21

648 35

890 65

11511, 11511Y, 12011Y 10 151 109

12 223 161

14 242 175

16 343 247

18 353 255

20 378 273

24 268 193

2.5 26 26

326 26

429 29

6 101 101

8 133 133

10 155 155

12511, 12511Y, 14411Y 12 311 311

14 199 199

16 442 442

18 311 311

20 503 503

22 663 663

24 806 806

TABLE 1

GLAND BOLT TORQUES, FT-LBS

CLASS 300 & 600 VALVES

TABLE 2

BONNET/COVER BOLT/NUT PULL-UP

TORQUES

(WITH VALVE UNDER PRESSURE)

REQUIRED TORQUE, FT-LBS

BOLT SIZE METAL COMPOSITE

GASKET GASKET

3/8 18 5

7/16 30 5

1/2 45 7

9/16 68 10

5/8 90 15

3/4 150 25

7/8 240 35

1 370 55

1 1/8 533 80

1 1/4 750 110

1 3/8 1020 150

1 1/2 1200 170

1 5/8 1650 230

1 3/4 2250 320

1 7/8 3000 420

2 3300 460

7

Page 8

8

Flow Control Division

Edward Valves

Service Problems (cont.)

area of the gasket and body I.D. contact

may be caused by surface imperfections

in the body wall in the form of pin holes,

extended cracks, or indentations where

the metal has failed sometime after valve

installation and use. Such imperfections

may be surface indications deeper flaws

in the body casting which may cause a

by-pass around the pressure seal.

Gate and Seat Leakage

A leak existing at the seat and gate of a

properly closed valve might be indicated

by one of the following: a definite pressure

loss in the high pressure side of the valve;

continued flow through an inspection drain

on the low pressure side; or, in hot lines, a

downstream pipe that remains hot beyond

the usual length of time and conductivity

range. First, try opening the valve slightly

to flush any foreign material from the seating surfaces and then fully close the valve.

If this doesn’t stop the leakage, then one or

more of the following may be the cause:

1. Foreign material has been imbedded

into the seating surfaces preventing a

seal.

2. Foreign material has scratched or cut

the seating surface.

3. An obstruction such as a tool or other

foreign material has been lodged across

or between the seats and preventing the

gate from closing.

4. The valve seat has been steam or water

cut by not fully closing the valve during

a previous operation.

If the valve cannot be isolated and

repaired as soon as possible, schedule the

work to be done at the next outage.

Body or Bonnet Wall Leak

This is a leak through the pressure containing parts of the valve. A leak occurring

through the bonnet should be readily

detectable because of the lack of insulation. On the body, because of the heavy

insulation, a small leak may go unnoticed

for a time on a hot line because the piping

evaporates the leakage.

Lubrication

In order to obtain long service life and

maximum reliability, valves require periodic lubrication of the bearings and stem

threads the same as for any machinery

with rotating parts.

All handwheel actuated Equiwedge gate

valves are equipped with low friction bearings, needle bearings in the smaller sizes

and tapered roller bearings in the larger

sizes. These valves have a lube fitting for

convenient relubrication. Both the stem

threads and the bearings can be relubed

through this fitting. In addition, it is advisable to clean the stem first while in the

open position and apply fresh grease to

the threads, then repeat while in the closed

position.

For valves that are operated infrequently,

relubrication at least once a year is recommended. The recommended lubricant for

both bearings and stem threads is Rycon

EP 2, manufactured by the American Oil

Company. This is an extreme pressure,

temperature lubricant of high quality. Use

of other lubricants should be avoided.

For valves that are operated frequently, the

lubricant should be replenished at both the

bearings and stem threads every three

months or at shorter intervals depending

on the severity of the service.

Page 9

9

Flow Control Division

Edward Valves

VALVE BODY REPAIRS

Body Bore Gasket Seal Area Repair

(Valves with metal gasket only)

Class 600 Equiwedge gate valves have

the seal area for the pressure seal just

below the top of the body bore. The seal

surface is inlaid with 18-8 stainless steel

on all valves size 16 and larger.

Class 900 and higher Equiwedge gate

valves have the seal area just below the

gasket retainer groove. The seal surface is

inlaid with 18-8 stainless steel on all valves

in these pressure classes.

The seal area, whether inlaid or not, must

be smooth, round and without any appreciable taper. Upon normal disassembly of

the valve the gasket may leave some vertical score marks when withdrawn.

If the depth of defects are .010” or less,

the seal area can be honed using a

portable Sunnen Hone. This device is

adjustable for different bore sizes and can

be operated by one man using a portable

electric drill of 1/2” to 3/4” capacity.

When the defects are greater than .010”,

welding will be required to cut down the

repair time.

First make visual inspection all around this

area, noting, if possible, where flaws may

occur. Next wash the area with a suitable

solvent, drying with clean rags and, if necessary, polishing with a fine grade of

emery cloth to remove any undesirable

scale or foreign matter which may be been

deposited on the area suspected of having

flaws. Use a dye penetrant test if cracks

are suspected.

Where it is necessary to repair the body

inlay by welding, note the following:

1. Prior to any cutting or welding oper-

ations being performed on the valve,

it is necessary that adequate seat

joint protection be provided and

some means of insurance against

getting chips, weld spatter or other

foreign matter into the pipe line if

the valve is permanently mounted. A

round piece of sheet metal placed in

the bore down to the shoulder above

the guide grooves and taped in

place will protect the guide surfaces

and seats.

2. Chip out the defective area in the

body, being careful to remove the

affected portion to its end, inside the

casting, and to thoroughly clean it

away.

3. With a small hand grinder, grind the

chipped area smooth.

4. Preheat an area large enough

around the imperfection so that during the entire welding operation heat

will be retained at approximately

400 degrees Fahrenheit.

5. Use a stainless steel inlay selected

from either 18-8 stainless steel rod,

Harstain 18-8, Stainweld “K” 18-3,

Stainweld 18-8 or equivalent.

6. Lay the weld in thin, even layers,

peening each layer before proceeding with the next, and being careful

to maintain a temperature above

400 degrees Fahrenheit in the area

being repaired. Peening the bead

actually stretches it and counteracts

its tendency to contract and shrink as

it cools. The last layer of weld must

overlap onto the sound metal to

insure a weld without an undercut at

the edges. The overlapping should

be done along this edge by using a

welding rod of 1/8” maximum diameter. The last layer should bring the

height of the welded area up to

1/16” above the original surface, as

checked with a straight edge along

the body bore.

For this type of weld repair, it is recommended that the last layer be

pounded while still hot with the flat

face of the hammer. Thermal stress

relieving is not recommended.

With a hand grinder, rough grind

the welded surface to within about

.010” of the finished surface. A simple template cut from thin sheet

metal and having the same arc as

the body bore diameter, and straight

edge laid along the body bore can

be used as a guide. A final cut then

can be made, using a fixture similar

to the one shown in Illustration No.

9, pg. 15. Final finishing can be

done with the adjustable Sunnen

hone described on this page.

After removing all the dirt, chips,

slag, spatter, and grinding dust from

the body, the bore should be polished with fine emery cloth and then

thoroughly cleaned before reassembly of the valve.

Repair Procedures

Page 10

10

Flow Control Division

Edward Valves

It is best that a new pressure-seal

gasket be used upon reassembly.

Body Wall Repairs

There are five basic steps in repairing a

casting defect:

1. Cut out to sound metal. Attempting to

weld over the defect will only leave a

notch that may re-introduce the defect.

Cutting may be done by chipping,

grinding or flame gouging. The amount

of metal removed should be held to a

minimum to avoid distortion during subsequent welding.

2. Preheat, using the minimum temperature

specified by the material specification

and/or the design code. Use at least

400F on WC9 or C5 material, 300F

on WC6. Although cast carbon steels

such as WCB or WCC do not require

preheat, it may be advantageous to

remove any moisture or other contaminants from the area to be welded. This

may also identify any leak paths. There

are also disadvantages to preheat,

especially localized preheat, that must

be considered when working in areas

of the casting with finish machined

dimensions. Distortion may result in

more damaging problems than those

concerns created by the original defect.

Lower preheats and the control of interpass temperature are two methods used

to minimize distortion.

3. Welding should be done by qualified

welders, using qualified procedures and

weld material of a chemistry matching

the casting (see Table 3 for welding rod

recommendations). The final weld

TABLE 3 – WELDING ROD RECOMMENDATIONS

MATERIAL TO BE WELDED

WELD ROD

RECOMMENDATIONS

ASME IX

Material ASTM Grade AWS Classification

P-Numbers

P-1 Carbon Steel 1. ASTM A216, Grade WCB AWS 5.1

2. ASTM A105 E7018

P-4 1-1/4% Chromium, 1. ASTM A217, Grade WC6 AWS 5.5

1/2% Molybdenum 2. ASTM A182, Grade F11 E8018-B2

Low Alloy Steel

P-5 2-1/4 Chromium, 1. ASTM A217, Grade WC9 AWS 5.5

1% Molybdenum 2. ASTM A182, Grade F22 E9018-B3

Low-Alloy Steel

P-8 18% Chromium, 1. ASTM A351, Grade CF8M AWS 5.4

8% Nickel 2. ASTM A182, Grade F316 E316

Stainless Steel

P-8 18% Chromium, 1. ASTM A351, Grade CF8C AWS 5.4

8% Nickel 2. ASTM A182, Grade F347 E347

Stainless Steel

Repair Procedures (cont.)

WELDING EDWARD VALVES IN-LINE

When welding a valve in line, the installer

should apply the specific technical rules

imposed by the jurisdictional authority of the

area where the valve is installed, In the

absence of such rules, following are

suggested practices for welding Edward

Valves in line:

1. Welding should be done using procedures

and personnel qualified in accordance

with ASME Section IX. Rules for preheat

and postheat are stated in Chapter V of

ASME B31.1 (Power Piping).

2. The valve should be welded in line, one

end at a time, in a closed position

(approximately a half-turn after the seat in

the body comes in contact with the disk).

This is suggested to preclude warpage

between seating surfaces caused by temperature induced stresses during welding

or subsequent heat treat. It also protects

the seat from weld spatter that might coat

the lapped seat and disk. When postweld

heat treat is required, each weld end

should be heat treated one at a time, to

minimize impact of heat on valve internals.

Do not heat treat an Edward Valve with a

piping attached as a unit in a furnace, as

warpage of parts may occur. After welding, open the valve and flush the line to

clean out all foreign matter.

Page 11

11

Flow Control Division

Edward Valves

should be blended into the contour of

the casting.

4. Stress relieving is generally recommended. Decisions to not stress relieve should

factor in piping code rules. The temperatures must be based on material specification and piping code recommendations. Again, since temperatures are

much higher than those experienced in

welding, there are also disadvantages

that must be considered. Distortion may

result in more damaging problems.

Lower temperature postweld heat treatment is sometimes an option for carbon

steels.

5. The final weld should receive any needed nondestructive testing. This should

include a visual examination and liquid

penetrant or magnetic particle examination. Some major weld repairs could

even mandate radiography to ensure a

sound weld.

Body Guide Repairs

The body guide grooves guide the gate

through about 95% of the valve stroke and

allow only 5% of the valve stroke to thrust

against the seating surfaces. It is important

that the side faces of the groove be smooth

and free of gouges and burrs. A flat file

can be used to remove any burrs and

raised edges.

Seat Repairs

The seats in a gate valve may require

repair when the seating surfaces allow

fluid to pass. This may be due to erosion

of the surfaces caused by not closing the

valve tightly or seating on foreign material.

Verification of such conditions may be

obtained by a seat blueing test or by close

visual examination.

To correct these conditions seat refinishing

will be necessary. A Dexter gate valve

refinishing fixture will speed up repairs.

See Appendix B for a discussion on use of

the Dexter equipment.

Gate Repairs

Gate repairs to the seating surface can be

done on a flat cast iron lapping plate. The

lapping plate should be large enough so

that the seating surface contacts the full

diameter with sufficient additional surface

allowing the gate to be pushed at least

1/3 of its diameter in any direction.

Clover compound “A”, Norton 320 mixed

with olive or sperm oil, or for rough lapping, Carborundum H20 may be used.

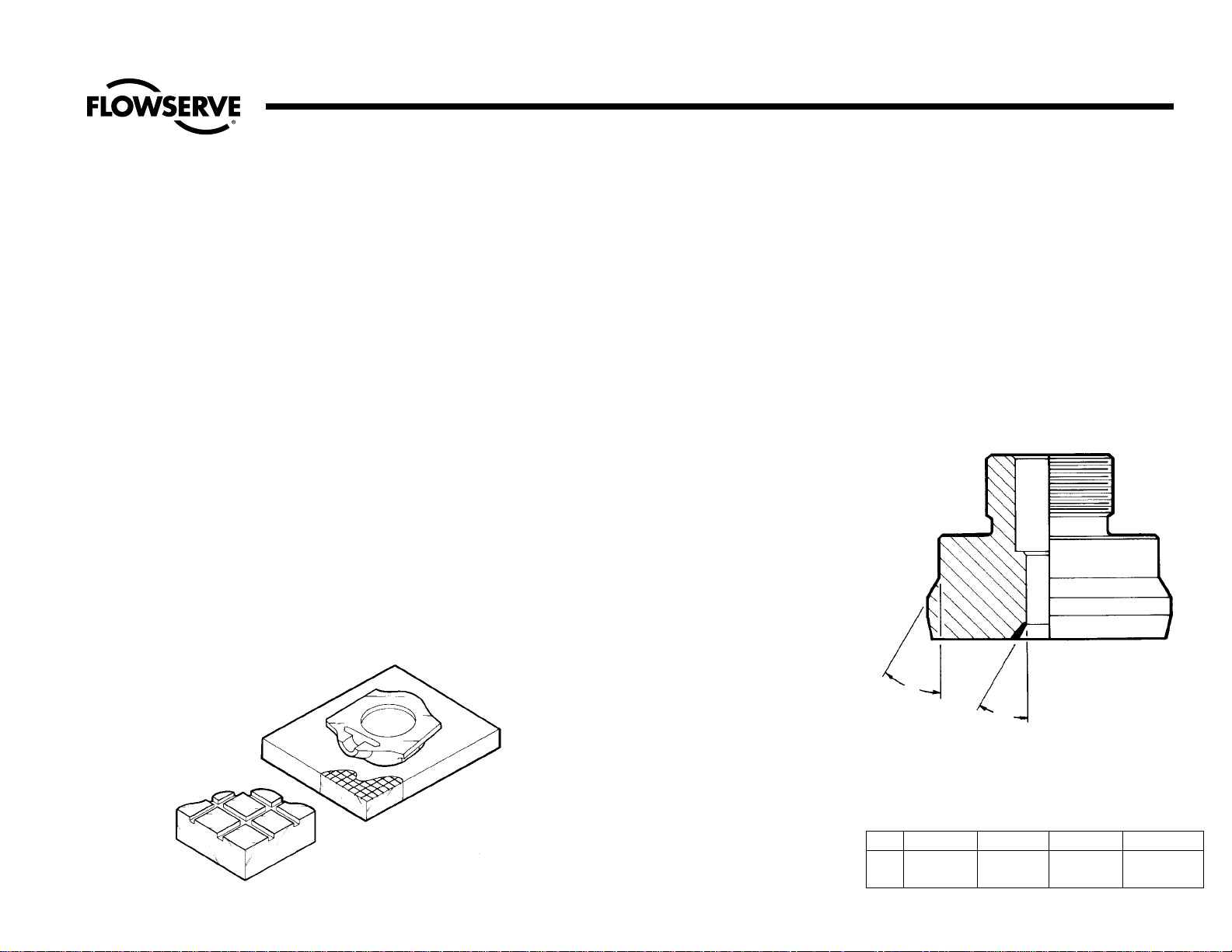

See illustration No. 6A.

Gate guide repairs can be done by rubbing the surface with a square steel block

wrapped with emery cloth.

Bonnet Repairs

The valve bonnet provides several functions

as follows: closure of the pressure vessel, a

packing chamber to seal the stem, a backseat area sealed with the stem so the valve

can be repacked under pressure, and a

sealing arrangement to prevent leakage to

the atmosphere.

Equiwedge gate valves with metal pressure

seal gaskets have a number of different

angles machined on the bonnet to accommodate the pressure seal gasket. These

angles are shown in illustration No. 6B.

Repair Procedures (cont.)

Illustration No. 6A

Valve Gate on

Lapping Plate

A°

±0.25°

30°

Pressure Seal Bonnet Angles

(Valves with metal gasket only)

Illustration No. 6B

Class 600 Class 900 Class 1500 Class 2500

A

25° +0.5° 35° +0.5° 35° +0.5° 45° +0.5°

- 0.0° - 0.0° - 0.0° - 0.0°

Page 12

12

Flow Control Division

Edward Valves

Repair Procedures (cont.)

If the gasket sealing surface of the bonnet

has been damaged by corrosion, erosion

or careless handling, this surface can be

machined in a lathe. Chuck the bonnet,

indicate true the large diameter and the

bottom face before cutting the angle. The

angle should be generated using a high

speed or carbide cutting tool. Remove as

little stock as possible to clean up. The

surface finish should be held to 63 micro

inch (1.6 micrometer) or better.

Backseat

The backseating surface is inlaid with

hardfacing. Any machining on this surface

must be done with carbide tools. The

included angle of the backseat is 60° and

the tolerance on the half angle is ± 0.25°.

The surface finish should be held to 63

micro inch (1.6 micrometer) or better.

Machining of this surface can be done in

the same setup as machining the pressure

seal angle. Once again the angle should

be generated using a carbide cutting tool.

Porosity in Bonnet

In most gate valve sizes and pressure classes, the bonnet is made from a steel casting. Steel castings are subject to various

types of defects such as shrinkage or

porosity. Weld repair any defect in the

bonnet wall the same as a body. If extensive repairs are required, remachining of

the packing chamber, backseat, and pressure seal angle may be required because

of distortion of these surfaces.

Stem Repairs

The basic function of a valve stem is to

actuate the valve open or closed. Because

it penetrates a pressure boundary, it must

provide a diameter for the packing to seal

leakage to the atmosphere and provide a

seal in the fully open or backseated position so that packing may be replaced

under pressure. Stems are made of high

quality martensitic stainless steel or other

stainless alloy and hardened to withstand

the high stresses. Welding is not recommended. Only cosmetic repairs to the

packing diameter and machining of the

backseat should be attempted. The angle

on the backseat of the stem is 28° – 0.50°

+ 0.25°. First contact is made at the top of

the conical surface. Valve stems must be

concentric and free from score marks on

the packing diameter and backseat area to

perform the functions listed above. When

a stem is bent or deeply scored on the

packing diameter, it should be replaced.

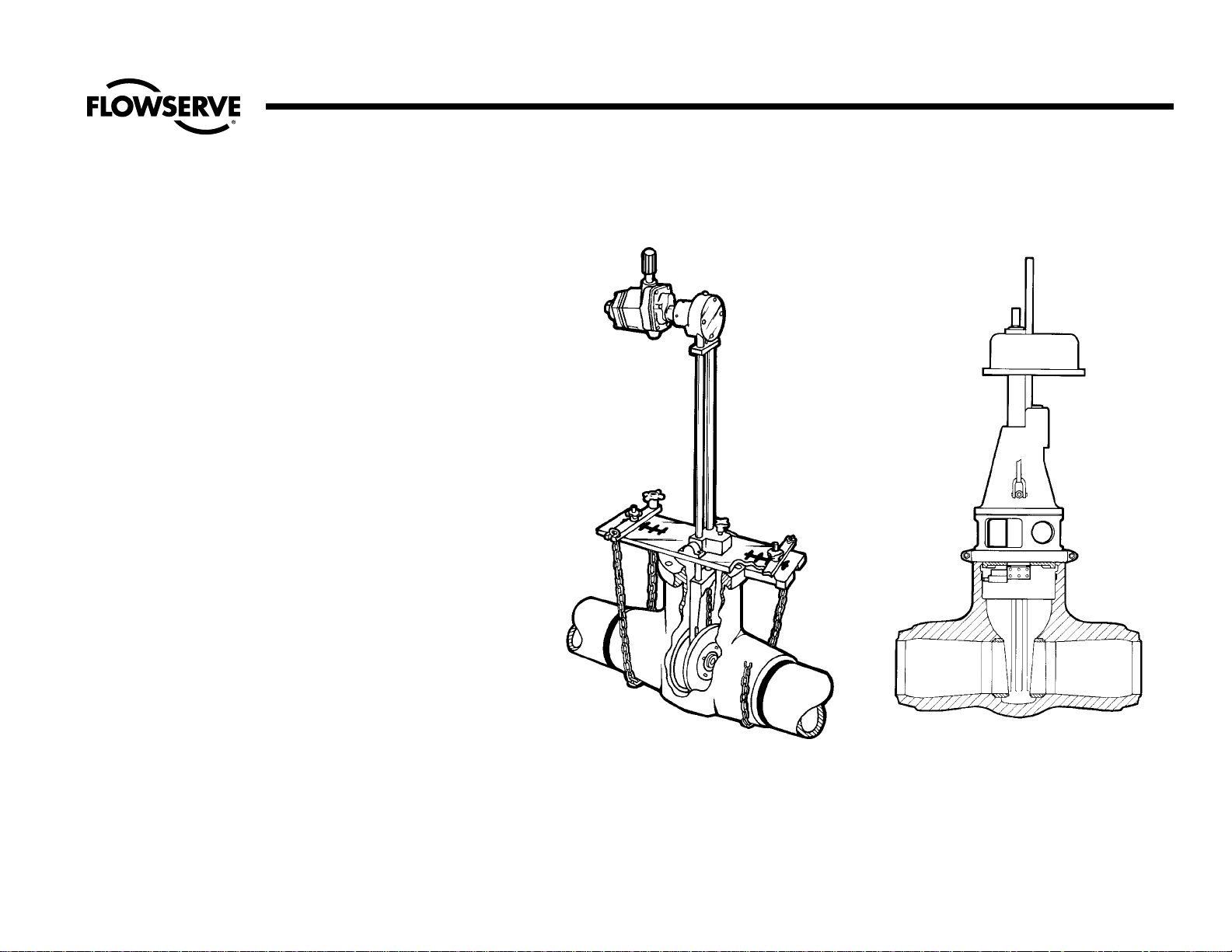

Field Repair Equipment

Available from the Edward Valves plant at

Raleigh, North Carolina are some basic

tools for repairing valves in the field. This

equipment was developed for customer use

on a rental basis. Contact your local

Edward Valves sales representative for

more information. A partial list of this

equipment follows:

1. Four sizes of Dexter seat refinishing

machines complete with refinishing plates

for valve sizes 2-1/2 thru 28.

(See Appendix B, pg. 30)

2. Two sizes of portable boring machines

capable of reboring the pressure seal

area in body on valves size 10 and larger. (See Appendix B, pg. 30)

Page 13

13

Flow Control Division

Edward Valves

Disassembly Procedure for Equiwedge Gate Valves

Introduction

Step-by-step disassembly procedures are

described below for all types of

Equiwedge pressure seal gate valves,

including those with manual and motor

actuators. It is impor tant that the

following instructions be read and understood before any specific disassembly

work is attempted.

First determine the problem area.

Maintenance problems can be divided into

three major areas, and the area involved

will affect the disassembly procedure.

These areas,in general, are:

Area 1 The handwheel, or a manual or

electric motor actuator.

Area 2 The yoke assembly including the

yoke, yoke bushing, and bearings.

Area 3 The valve internals including the

bonnet, body, pressure seal gasket, stem, gate, and seats.

If the problem is in Area 1, usually a manual or electric actuator will be involved

and not a handwheel; see Appendix A,

pg. 29.

If the problem is in Area 2, it will be

necessary to remove the valve actuator

only if the valve is handwheel actuated or

has a torque-only manual or electric

actuator. See procedure on pgs. 28 and

29 and select the proper one.

If the problem is in Area 3, two methods

are available. In method 1 the yoke and

actuator assembly may be removed from

the valve body as a unit. This saves time,

but requires adequate clearance. In

method 2 the actuator and yoke are

removed separately.

If problems are suspected to exist in any

combination of Area 1, 2 or 3, then each

of the respective procedures must be

followed.

CAUTION

AS A GENERAL REMINDER, MAKE SURE ALL THE PRESSURE IS RELIEVED, BOTH UPSTREAM AND DOWNSTREAM AND IN THE

CENTER CAVITY, BEFORE DISASSEMBLY WORK IS STARTED. Exceptions to this rule are noted below.

1. For ser vice In Area 1

If pressure is to be maintained in the valve, backseat to full open position. The actuator, both manual or electrical, torque-only and

torque and thrust types, may be removed. The blowout force on the stem due to pressure in the line will keep the stem on the backseat.

2. For service in Area 2

If pressure is to be maintained in the valve, the yoke may be removed on Types III, IV, and V. The blowout force on the stem due

to pressure in the line will keep the stem on the backseat. UNDER NO CIRCUMSTANCES SHOULD THE YOKE BE REMOVED ON

TYPES I AND II WHILE UNDER PRESSURE.

3. For service In Area 3

Close the valve fully and then open 1/8” (3mm). SERVICE AREA 3 WITHOUT PRESSURE IN LINE.

Page 14

14

Flow Control Division

Edward Valves

Disassembly Procedure of Bonnet Types Area 3

Type I Size

2-1/2 – 3

Class 600,

Figure

Numbers

1611, 1611Y

or 1711Y

Equiwedge

Gate Valves

Illustration No. 7

Valve Type I

Step-by-step disassembly instructions are

described below for each of the five basic

bonnet types. All of the following bonnet

disassembly instructions are arranged in

accordance with the general comments on

pg. 13. Study these pages carefully before

beginning. As disassembly progresses,

place match marks on parts so that the

same orientation can be maintained when

reassembled.

Refer to illustration 7.

1. With the valve in the partially open

position loosen, the gland bolt nuts

and tap the gland (this should relieve

any pressure trapped in the valve).

2. Carefully loosen the yoke hex socket

head cap screws. In case any

trapped pressure remains in valve

after step 1, it will now be relieved.

Remove the yoke cap screws.

3. Loosen the bonnet hex socket head

cap screws.

4. Remove the gland bolt nuts.

5. Rotate the bonnet retainer counter

clockwise on the central bonnet

thread. Close the valve, which when

the gate contacts the seat, will raise

the yoke about 1/2” (13mm). Pry up

the gasket retainer and place three

3/8” (10mm) shims between the

gasket retainer and the body at equal

intervals. Now tighten the bonnet

retainer cap screws in a star pattern

to jack the pressure seal gasket out of

the body. Be careful not to cock the

bonnet. This step may have to be

repeated with thicker shims to finally

break the gasket loose. See the note

below.

6. Once the bonnet is loose, the yoke

can be removed by turning the handwheel to close the valve. When the

threads of the yoke bushing disengage, lift the yoke assembly over the

stem and set on a clean plywood

board or bed of clean rags.

7. The stem, bonnet, and gate assembly

can now be removed, but be careful

to either clamp the gate halves or

hold them securely while withdrawing

parts. See illustration No. 17 pg. 25.

This is necessary because when the

gate halves are disengaged from the

guide grooves in the body, they can

fall off the stem. Place the assembly

on a bed of rags.

Note: These instructions have been

sequenced for a valve in a horizontal

pipeline with the stem in the vertical, up

position. With a different stem orientation,

the steps may have to be slightly modified.

For example, in step 5 if the valves were

in a horizontal pipe with the stem down

when the gasket came free, all the parts

would fall; so at least two of the yoke cap

screws should be engaged into the body

(at least three threads) to prevent this lack

of control. This precaution should also be

observed for other stem orientations.

Page 15

15

Flow Control Division

Edward Valves

See illustrations 8 and 9.

1. With the valve in a partially open

position remove the handwheel. The

handwheel nut is locked in position

with a small nylock set screw. This set

screw must be loosened first before

attempting to remove the handwheel

nut. The handwheel is keyed to the

yoke bushing. Remove the handwheel

nut, handwheel and key and set

aside.

2. Loosen the gland bolt nuts and tap

the gland loose from the packing

chamber. This should relieve any

pressure that may be trapped in the

valve.

3. Carefully loosen the yoke cap screws

or hex nuts. In case any trapped

pressure remains in the valve after

step 2, it will not be relieved.

Remove all yoke cap screws or

hex nuts.

4. Remove the gland bolt nuts.

5. Loosen the bonnet hex nuts about

3/8” (10mm) to 1/2” (13mm).

6. Close the valve, which when the gate

contacts the seat, will raise the yoke.

Place three or four shims 3/8”

(10mm) to 1/2” (13mm) thick equally

spaced between the yoke flange and

the body. Now tighten the bonnet

retainer hex nuts in a star pattern to

jack the gasket out of the body. Be

careful not to cock the bonnet. This

step may have to be repeated with

thicker shims to finally break the gasket loose. See Note this page.

7. Once the bonnet is loose the yoke

can be removed. Remove the bonnet

retainer hex nuts. Sling the yoke

through the windows leaving space

to turn the yokebushing and take up

slack in a chain hoist. With a strap

wrench around the top of the yoke

bushing, close the valve, thereby raising the yoke. Keep a slight tension on

the chain hoist so that the yoke bushing and stem threads are not damaged. Also, the pull point must be in

line with the stem. Raise the yoke in

this manner until the threads are disengaged, then lift away the yoke

assembly. Set the yoke on a clean

plywood board or bed of rags.

8. Valves with stems 1.62” (41.1 mm) to

2” (50.8mm) in diameter are threaded on the top end to accept a 1/2” –

13 eye bolt and those 2” (50.8mm)

in diameter or over to accept a 3/4”

– 10 eye bolt. Screw the eye bolt into

the stem and attach a chain hoist. Lift

the stem, bonnet, and gate out of the

valve but be careful to clamp the

gate halves securely while withdrawing the parts (see illustration No. 17

pg. 25). This is necessary because

when the gate halves are disengaged

from the body guide grooves, the

halves and spacer ring can fall off

the stem. Place the assembly on a

bed of rags.

Note: These instructions have been

sequenced for valve in a horizontal pipeline with the stem in the vertical, up

position. With a different stem orientation,

the steps may have to be slightly modified.

For example, in step 3, if the valve were in

a horizontal pipeline with the stem down,

when the gasket breaks free in step 6, all

the parts would fall; so, at least two of the

yoke cap screws or hex nuts need to be

partially engaged into/onto the body studs

to prevent this. This precaution should also

be observed for other stem orientations.

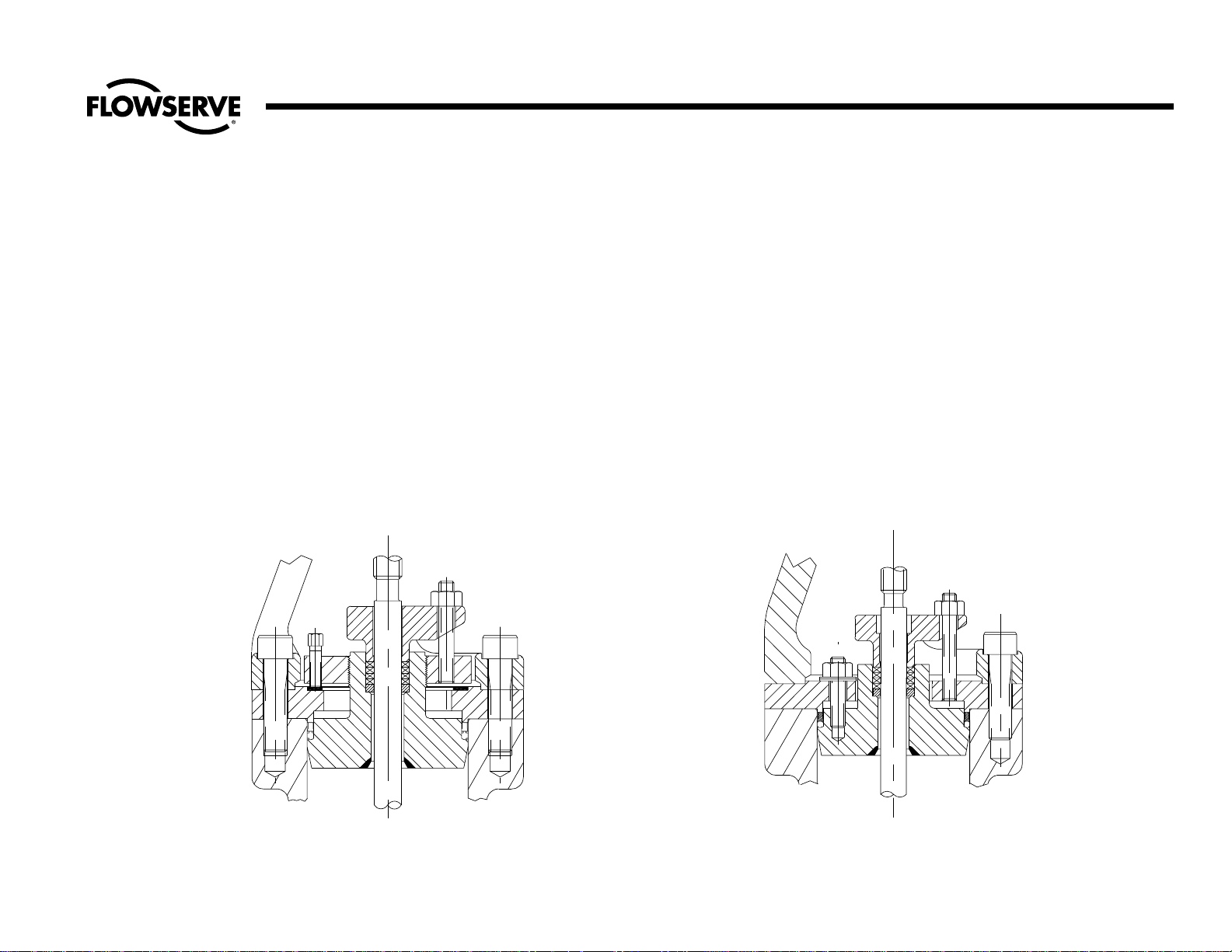

Disassembly Procedure of Bonnet Types Area 3 (cont.)

Valve Type IIA Valve Type IIB

Illustration No. 8

Illustration No. 9

Type II Sizes

4 - 28 Class

600, Figure

Numbers

1611,1611Y

or 1711Y

Equiwedge

Gate Valves

Page 16

16

Flow Control Division

Edward Valves

See illustration No. 10.

1. With the valve in a partially open

position, loosen the gland nuts and

tap the gland to loosen engagement

of the gland barrel with the packing

chamber. This should relieve any

pressure that may be trapped in the

valve.

2. Loosen and remove the hex socket

head cap screws fastening the yoke

to the body. Close the valve and

raise the yoke assembly off the body.

Continue to close the valve until the

stem threads are disengaged from

the yoke bushing. Lift the yoke assembly over the stem and set it on a

clean plywood board or a bed of

rags.

3. Remove the gland nuts and gland

and set the parts aside.

4. Loosen the hex socket head cap

screws on the bonnet retainer.

Unscrew the bonnet retainer from the

bonnet and set aside.

5. Using a brass rod and hammer, drive

the bonnet down into the body far

enough to expose the gasket retainer

segmented rings. Now drive the gasket retainer down to gain clearance

for removal. The gasket retainer ring

is split in three or four pieces; the

shortest must be removed from the

groove first, then the other two or

three.

6. Place the bonnet retainer on top of

the body and lift the stem-bonnet

assembly up through the gasket and

spacer ring. Screw the bonnet retainer onto the bonnet until it is snug

against the body. Tighten the bonnet

retainer hex socket head cap screws

in a star pattern against the body to

jack out the gasket. Be careful not to

cock the bonnet. This step may have

to be repeated by loosening the hex

socket head cap screws and by

screwing the bonnet retainer down

on the bonnet threads to a new position and then tightening the cap

screws against the body until the gasket breaks free. See the note below.

7. The stem, bonnet, and gate assembly

can now be removed but be careful

to either clamp the gate halves

together or hold them securely while

withdrawing parts (see illustration

No. 17, pg. 25). This is necessary

because when the gate halves are

disengaged from the guide grooves

in the body, they can fall off the stem.

Place the assembly on a bed of rags.

Note: These instructions have been

sequenced for a valve in a horizontal

pipeline with the stem in the vertical, up

position. With a different stem orientation the steps will have to be slightly

modified. For example, in step 6, if the

valve were in a horizontal pipeline with

the stem down when the gasket comes

free, all parts would fall; some provision

must be made to support the stem-bonnet assembly when the gasket breaks

loose.

Disassembly Procedure of Bonnet Types Area 3 (cont.)

Type III,

Sizes 2-1/2"- 3",

Classes 900,

1500, 2500

Figure Numbers

1911, 1911Y,

11511, 11511Y,

12511, 12511Y,

12011Y, 14311Y

or 14411Y

Illustration No. 10

Valve Type III

Page 17

17

Flow Control Division

Edward Valves

Disassembly Procedure of Bonnet Types Area 3 (cont.)

See illustrations No. 11 and 12.

1. With the valve in a partially open

position, loosen the gland nuts and

tap the gland to loosen engagement

of the gland barrel with the packing

chamber. This should relieve any

pressure that may be trapped in the

valve.

2. The handwheel nut is locked in

position with a small nylock set

screw. Loosen the set screw then

remove the handwheel nut. The

handwheel is keyed to the yoke

bushing so remove the handwheel

and key and set them aside.

3. Loosen and remove the yoke cap

screws or yoke lock ring bolts. If the

valve is equipped with a yoke lock

ring, it will be necessary to pr y it

off by using a cold chisel, tapping it

into one of the splits to disengage

the clamp rings.

4. Sling the yoke through opposite

windows leaving space to turn the

yoke bushing and take up slack in

the chain hoist. With a strap

wrench around the top of the yoke

bushing, turn the valve to close.

When the gates contact the seats,

the yoke will rise. Continue turning

until the yoke bushing threads are

disengaged from the stem.Carefully

lift the yoke over the stem and set

aside on a plywood board or a

bed of rags.

5. Remove the gland bolts and gland.

Loosen and remove the bonnet

retainer nuts and lift off the bonnet

retainer. Set the parts aside.

6. Place an eyebolt in the threaded

end of the stem.With a chain hoist

mounted in line with the stem and

fastened to the eyebolt, pull the

stem firmly against the backseat.

With clean rags and a vacuum,

clean the top of the valve and

exposed surfaces of the bonnet and

gasket retainer segments.

7. Slack off the chain hoist and with a

brass bar and hammer, and drive

the bonnet down so that the gasket

retainer segments are fully exposed.

8. Using the same tools, drive the gasket retainer segments down to the

bottom of the groove (about 1/16”

[2mm]) in the body.

9. Remove the gasket retainer seg-

ments and set them aside.

10. Place the bonnet retainer back on

the body and with a chain hoist

and lift the stem and bonnet so that

the bonnet contacts the gasket.

Screw nuts onto the bonnet studs

and tighten in a star pattern to jack

out the gasket. Be careful not to

cock the bonnet.

Note: The stem should not be used to

remove the pressure seal gasket.

11. When the bonnet assembly breaks

loose, use a chain hoist to lift the

assembly from the valve body, but

be careful to clamp the gate halves

securely before fully withdrawing

the parts (see illustration No. 17,

pg 25). This is necessary because

when the gate halves are disengaged from the body guide

grooves, the gate halves and spacer ring can fall off the stem. Place

the assembly on a bed of rags.

Note: These instructions have been

sequenced for a valve in a horizontal

pipeline with the stem in the vertical, up

position. With a different stem orientation

the steps will have to be slightly modified.

For example, in step 6, if the valve was in

a horizontal pipeline with the stem down

when the gasket comes free, all the parts

would fall; some provision must be made

to support the stem-bonnet assembly when

the gasket breaks loose.

Type IV & V,

Sizes 4”-24,

Classes 900,

1500, 2500Figure numbers

1911,1911Y,

11511, 11511Y,

12511, 12511Y,

14311Y,

12011Y, or

14411Y

Valve Type V

Valve Type IV

Illustration No. 11 Illustration No. 12

Page 18

18

Flow Control Division

Edward Valves

Introduction

The reassembly procedures in this manual

are not as detailed as the disassembly

procedures since, in most cases, just the

reverse procedure is used. However, stepby-step instructions are provided for each

of the five bonnet types. In addition, the

following general points should be

considered:

1. The most important consideration in

the reassembly of pressure seal

valves is cleanliness. All flaky rust

and dirt should be removed from all

parts with a wire brush and emery

cloth. Oil and grease should be

removed with a suitable solvent to

prevent any foreign material from collecting on the sealing and seating

surfaces.

2. All threaded parts should be relubricated, such as cap screws, nuts,

studs, and bonnet retainer threads,

with a product such as “Never-Seez”.

The stem threads should be washed

with solvent, dried, and a new application of high temperature EP

(extreme pressure) grease applied to

the threads. See pg. 8 for recommen-

dations.

3. An important feature of Equiwedge

gate valves is the two piece gate with

a spacer ring between the two

halves, illustrated in figure 13A. This

spacer can be increased in thickness

to compensate for material removed

from the seats and gates by normal

or extensive refinishing of these surfaces. This is a unique design feature.

For every .005” (.13mm) (total) that

is removed from the seating surfaces,

the gate seats lower in the body

approximately 0.032” (.81mm). This

amount of metal removal will not

require any adjustment to the gate

spacer ring thickness.

But, for example, if 0.050”

(1.27mm) were removed from the

combined seating surfaces, the gate

will seat 0.312” (7.92mm) lower in

the body and this wear can be compensated for by making a new spacer ring. In addition, the guide rails

on each gate half will require grinding by half the amount added to the

spacer ring to restore an adequate

amount of clearance. The gate spacer ring material is stainless steel type

410 heat treated to 26 to 32 RC.

Reassembly Procedures for Equiwedge Gate Valves

Stem-Gate Spacer Ring Assembly

Illustration No. 13A

STEM

GATE HALF

GATE HALF

SPACER RING

Page 19

19

Flow Control Division

Edward Valves

Exploded View

Illustration No. 13B

34

21

20

19

18

17

16

15

14

12

11

13

10

9

8

7

6

5

4

3

2

1

33

32

31

30

29

28

27

26

25

24

23

22

Typical Exploded View of Equiwedge Gate Valve

Part Names for Exploded View of Typical Equiwedge Gate Valves

1. Body

2. Test Nipple

3. Seat Ring

4. Gate

5. Gate Spacer Ring

6. Stem

7. Hex Nut

8. Yoke Lock Ring

9. Stud

10. Bonnet

11. Pressure Seal Gasket

12. Spacer Ring

13. Segmental Retaining Ring

14. Cap Screws

15. Bonnet Retainer Ring

16. Junk Ring

17. Gland Stud

18. Packing

19. Gland

20. Gland Bushing

21. Gland Nuts

22. Yoke

23. Grease Seal

24. Bearing

25. Key

26. Yoke Bushing

27. Bearing

28. Preload Shim Kit

29. Bearing Retainer

30. Grease Seal

31. Cap Screws

32. Handwheel

33. Handwheel Locknut

34. Set Screw

Page 20

Flow Control Division

Edward Valves

Reassembly Instructions

The yoke bushing threads should be

cleaned in the same manner as the other

threaded parts and regreased. The same

lubricant should be used to regrease the

yoke bushing bearings through the lube

fitting. See pg. 8 for lubricant recommen-

dations. Follow these guidelines:

1. Replace the stem packing.

2. Replace the pressure seal gasket with a

new gasket.

3. Observe all match marks assigned during disassembly so that part orientation

is maintained.

4. Reassemble stud nuts and cap screws

using a torque wrench. See Table 2, pg.

7, for recommended torque values.

5. When reassembling the bearings in the

yoke assembly, use the following procedure to obtain the proper clearance or

preload.

Handwheel Actuated Valves

1. Equiwedge gate valves with stems

1-7/8” (47.6mm) diameter and smaller

are equipped with needle bearings. See

illustration No. 14. One bearing set is

placed below the yoke bushing collar

and one set above. All parts are

retained by a screwed-in bearing retainer. This bearing retainer has spanner

wrench holes on the top face for adjustment and is locked in place with a

nylock set screw on the side of the yoke

near the top.

2. The needle bearings should not have a

preload. Rather, a slight amount of

clearance is recommended. Tighten

down the bearing retainer using a spanner wrench until the bearing retainer is

snug, then back it off 15 to 20 degrees.

This is equal to 0.004” to 0.005”

(.10mm to .13mm) clearance.

3. Tighten the set screw and relube through

the lube fitting.

4. On valves with stem diameters 2”

(50.8mm) and greater, the yoke assem-

bly is equipped with tapered roller bearings. One bearing set is placed below

the yoke bushing collar and one set is

placed above this collar. All parts are

retained by a bolted-on bearing

retainer.

5. Tapered roller bearings do require a

preload, See illustration No.15.

Preloading is accomplished by using a

shim kit. If the bearings are not to be

replaced, use all the shims that were in

the original assembly. If the bearings

are to be replaced, a new shim kit

should be used.

Yoke Assembly With Needle Bearings

Illustration No. 14

Yoke Assembly With Taper Roller Bearings

Illustration No. 15

20

Page 21

21

Flow Control Division

Edward Valves

Reassembly instructions (cont.)

Tapered Roller Bearing

Preload Instructions

1. Bearing Assembly - Install the bear-

ings, grease seals and yoke bushing

in the yoke.

2. BEARING PRELOAD WARNING –

FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN BEARING

FAILURE. See illustration No. 16.

a. Use a micrometer to measure the

thickness of the bearing retainer

flange at each measurement hole.

Number each measurement hole

with a grease pencil. Record the

measurements.

b. Mark the bearing retainer flange

and yoke with a grease pencil in

order to know the relative position

of parts and remove the bearing

retainer flange.

c. Use a micrometer to measure the

thickness of the “bearing preload

washer” and record the measurement.

d. Install a “bearing preload washer”

(tool). See Table 4 for dimensions.

Install the bearing retainer flange

(make certain that mating surfaces

are clean) at alignment position

marks and align the bolt holes.

Install 3 or 4 cap screws to secure

the bearing retainer at 90° or

120° intervals. Use a depth

micrometer to level the bearing

retainer flange and take readings

to ensure that the flange remains

level as the torque is increased in

small increments. The preload

torque is indicated in Table 5 for

each applicable cap screw size.

Rotate the yoke bushing after each

increase in torque.

e. Extend a depth micrometer into

each of the holes located in “a”

above until it hits the top of the

yoke. Record the measurements.

Calculate the average dimension

and record.

f. Remove the bearing retainer

flange, cap screws and bearing

preload washer (tool).

g. Add the average dimension

recorded in “a” to the measurement recorded in “c” and record

the result.

h. Subtract the measurement record-

ed in “e”from the average dimension recorded in “g” and record

the result.

i. Shim stock thickness equal to the

result recorded in “h” must be

installed between the top bearing

and the bearing retainer flange.

Illustration No. 16

Bearing Preload Instruction

PRELOAD CAP SCREWS

TORQUE FROM TABLE 5

PRELOAD WASHER

TABLE 4

CAP SCREWS TORQUE

FROM TABLE 5

BEAR RETAINER

FLANGE

YOKE

SHIM STOCK

YOKE BUSHING

3 MEASURING HOLES

Page 22

22

Flow Control Division

Edward Valves

Reassembly Instructions (cont.)

j. Install the bearing retainer flange on

the yoke (make certain that the mating

surfaces are clean), align the position

marks and align the holes in the bearing retainer flange with the holes in

the yoke. Install 3 or 4 cap screws at

900 intervals. Use a depth micrometer

to level the bearing retainer flange

and take readings to ensure that the

flange remains level while the torque

is increased in small increments.

Rotate the yoke bushing after each

increase in torque. Apply a preload

torque indicated on Table 5 to the cap

screws, use a depth micrometer to

take measurements and compare the

measurements with those taken in step

(a) above. If the measurements are the

same as those recorded in step “a”,

then the flange has bottomed on the

yoke. If the measurements are greater

than “a” measurements, then the

flange has not bottomed and the bearing preload procedure should be

repeated. Install the remaining cap

screws and tighten in a star pattern

until the torque indicated in Table 6 is

developed. Be careful to keep the

bearing retainer flange level while

torque is applied to the cap screws.

Table 4—Dimensions For Bearing Preload Washer - in inches (mm)

Valve Stem Diameter

Washer OD Washer ID Washer Thickness

+.005 (±.13) +.010 (±.25) +.001 (±.03)

2.000 (50.80) 5.100 (129.54) 4.56 (115.8) .187 (4.75)

2.125 (53.98) 5.100 (129.54) 4.56 (115.8) .187 (4.75)

2.250 (57.15) 5.687 (144.45) 5.15 (130.8) .187 (4.75)

2.375 (60.32) 6.090 (154.69) 5.38 (136.7) .187 (4.75)

2.500 (63.50) 7.110 (180.59) 6.40 (162.6) .187 (4.75)

2.625 (66.68) 7.075 (179.70) 6.36 (161.5) .187 (4.75)

2.750 (69.85) 6.985 (177.42) 6.30 (160.0) .187 (4.75)

2.875 (73.02) 8.110 (205.99) 7.34 (185.9) .187 (4.75)

3.000 (76.20) 8.985 (228.22) 8.12 (206.2) .187 (4.75)

3.250 (82.55) 9.985 (253.62) 9.00 (228.6) .187 (4.75)

3.500 (88.90) 11.360 (288.54) 10.25 (260.3) .187 (4.75)

3.750 (95.25) 12.485 (317.12) 11.25 (285.8) .187 (4.75)

4.250 (107.95) 12.485 317.12) 11.25 (285.8) .187 (4.75)

Table 5—Bearing Retainer Preload Torque

Cap Screws Threads Per Torque In Ft. Torque No. of Cap

Diameter Inch Pounds In NM Screws

3/4 10 20 27 3 or 4

7/8 9 35 47 3 or 4

1 8 50 68 4

1-1/4 7 135 183 4

Table 5A

Cap Screws

Pitch

Torque No. of Cap

Diameter in NM Screws

16 2 120 3 or 4

20 2.5 240 3 or 4

24 3 400 3 or 4

30 3.5 880 4

Table 6—Bearing Retainer Final Torque

Cap Screws Threads Per Torque in Ft. Torque

Diameter Inch Pounds in NM

3/4 10 165 224

7/8 9 265 360

1 8 405 550

1-1/4 7 895 1215

Table 6A

Cap Screws

Pitch

Torque

Diameter in NM

16 2 120

20 2.5 240

24 3 400

30 3.5 880

Page 23

23

Flow Control Division

Edward Valves

Reassembly Instructions for Valves with Composite Pressure Seal Gaskets Only

It is important to determine that the new

composite pressure seal gasket:, the bonnet and the body sealing area are in satisfactory condition before installation. The

following steps will help ensure superior

performance of the gasket.

1. Carefully inspect the body bore and

bonnet O.D. sealing surfaces.

Remove any raised metal from the

entry chambers and gasket chamber

regions. Repair any gouges in the

sealing region in accordance with

the instructions on pg. 10.

2. Inspect the new composite gasket.

Note: All composite gaskets have

cracks and wrinkles in the flexible

graphite. This is a normal result of

the forming process and will not

affect gasket performance.

3. Be sure the anti-extrusion rings are

tightly bonded to the graphitic gasket, so they will not touch the body

during assembly, If any of the antiextrusion rings are loose, carefully

scrape away all flexible graphite

left on the anti-extrusion ring surface

and re-bond to the graphite surface

using Loctite 454 or other suitable

contact cement. The ends of the

outer rings should touch after bonding. There should be an approximate .020 ± .005 inch gap at the

ends of the inner ring.

4. Place the gasket on the bonnet with

the two anti-extrusion rings facing

up as shown in the illustration. The

gasket should fit snugly around the

bonnet, and the gasket O.D. should

not exceed the O.D. of the bonnet.

This will ensure that the gasket does

not catch on the body and “energize” prematurely.

5. Install the spacer ring on the bonnet

as shown with the wide end toward

the gasket. The valve may now be

reassembled using the assembly

procedures described in the following sections for different types of

bonnets, except that special

torquing procedures are required as

described in the following:

IMPORTANT: The composite pressure

seal must remain dry until fully compacted for proper sealing!

6. Once the bonnet and bonnet retainer holes have been aligned, lightly

lubricate the fasteners with high-temperature anti-seize lubricant.

Assemble the Belleville washers

under the nuts or capscrews.

Assemble remaining parts as

described in previous sections.

7. Preload the bonnet by pulling up

with a well centered crane load or

with come-alongs.

BELLEVILLE

WASHERS

GASKET

RETAINER

SPACER

RING

COMPOSITE

GASKET

TABLE 7

COMPOSITE GASKET BONNET/COVER

BOLT/NUT PULL-UP TORQUES

(FOR INITIAL PULL-UP)

BOLT SIZE REQUIRED TORQUE

FT-LBS

3/8 30

7/16 45

1/2 70

9/16 100

5/8 135

3/4 220

7/8 350

1 540

1-1/8 770

1-1/4 1100

1-3/8 1500

1-1/2 1700

1-5/8 2300

1-3/4 3200

1-7/8 4200

2 4600

Page 24

24

Flow Control Division

Edward Valves

8. Initially compress the pressure seal

gasket making sure that the bonnet

does not cock in the body.

9. While maintaining the pull up load,

torque the bonnet/cover bolts evenly using a varying star pattern, until

the fastener torques reach a value

of 2/3 the torque given in Table 7,

pg. 23.

10. After reaching 2/3 of the torque

value given in Table 7, torque the

bonnet nuts in small torque increments, with no more than 1/6 turn

per tightening round, using a varying star pattern, until the full torque

value given in Table 7 is reached.

11. Re-torque the bolts at the final

torque value several times, until the

gasket no longer compresses. This

step is necessary due to the high

resilience of the graphitic gasket.

12. Complete remaining valve assembly

in accordance with the appropriate

preceding section of this manual.

13. When the valve is next under pressure, either during system hydrostatic test or when put in service, retorque the bolts to the torque values

given in Table 2, pg. 7.

CAUTION

Do not use the torque

values in Table 7 while the

valve is under pressure.

Reassembly Instructions for Valves with Composite Pressure Seal Gaskets Only (cont.)

Reassembly Instructions for Valves with Metal Gaskets Only

Type I Pressure Seal Bonnet

See Illustration No. 7, pg. 14

1. Place one gate half on a clean plywood board. Place the stem T-head

in the recess in the gate.

2. Place the gate spacer ring into the

counterbore in one gate half. Place

the other gate half on top, engaging the spacer ring and stem.

Holding the gate halves together,

lift the stem and lower assembly

into the body, engaging the gate

guide rails with the grooves in the

body. Lower the gate to the seats.

3. Assemble a new pressure seal gasket and the junk ring on the bon-

net. Lift the bonnet assembly over

the stem and lower it into the body.

Be very careful not to mar the pressure seal gasket or other machined

surfaces.

4. Place the gasket retainer plate and

thrust washer on the body and

align cap screw holes on the gasket retainer plate with the body

holes.

5. Place the bonnet retainer plate

over the stem and start threading

onto the bonnet.

6. Place the gland over the stem.

7. Place the yoke over the stem and

engage the stem threads by turning

the yoke bushing counterclockwise.

When the yoke contacts the gasket

retainer plate, align the cap screw

holes and continue to turn the yoke

bushing until the stem contacts the

backseat. This will pull the bonnet

and gasket up against the gasket

retainer and the yoke flange up

against the body.

8. Assemble the yoke flange cap

screws and tighten in a star pattern

using a torque wrench to values as

shown in Table 2, pg. 7.

9. With the bonnet retainer cap

screws flush on the bottom of the

bonnet retainer, screw the bonnet

retainer down until it contacts the

thrust washer. Now back it off

Page 25

25

Flow Control Division

Edward Valves

1/8” (3mm) and align the gland

bolts with the yoke windows.

10. Tighten the bonnet retainer cap

screws using a torque wrench in a

star pattern to the values shown on

Table 2, pg. 7. See step 13 below.

11. Repack the packing chamber following instructions on pg. 6. Place

the gland in position and tighten

the gland nuts.

12. Reassemble the handwheel,(or

actuator) using the reverse of the

instructions for disassembly.

13. After the valve is pressurized,

retighten the bonnet retainer cap

screws using the same torque values in step 10. This is important.

Types IIA & IIB Pressure Seal Bonnet

See Illustration Nos. 8 & 9. pg. 15

1. Place one gate half, seat face

down, on a bed of clean rags or

plywood board. Place the stem Thead into the recess in the gate.

2. Place the gate spacer ring into the

counterbore in one gate half.Place

the other gate half on top, engaging the spacer ring and stem. If

necessary, clamp the gate halves

together on top of the guide rails

using “Kant Twist” type clamps.

Install an eye bolt into the top of

the stem. Stems 1.62” (41.1mm)

and larger in diameter are drilled

and tapped on the top end. See

illustration 17, for clamping

arrangement.

3. Carefully lift the stem-gate assembly using a hoist if necessary to

avoid scratching the stem or gate

surfaces, and lower the assembly

part way into the body with the

guide rails fully engaged with the

guide grooves. Remove the clamps

and lower the assembly until the

gate contacts the seats.

4. Assemble a new pressure seal gasket and the junk ring onto the bonnet. Lift the bonnet over the stem,

using a hoist if necessary, and

lower it into the body. Be very

careful not to mar the pressure seal

gasket or other machined surfaces.

5. Place the bonnet retainer plate on

the body if it is a separate part,

and align the cap screw holes with

the body.Omit this step if the bonnet retainer is integral with the

yoke.

6. Place the gland over the stem.

7. Place the yoke over the stem and

engage the stem threads with the

yoke bushing by turning the yoke

bushing counterclockwise. When

the yoke contacts the bonnet retainer plate or body, align the cap

screw holes and continue to turn

the yoke bushing until the stem

contacts the backseat. This will pull

the bonnet and gasket up against

the gasket retainer and the yoke

flange up against the body. While

this is being accomplished, the

studs in the body and bonnet must

be aligned with the holes in the

yoke(or bonnet retainer plate).

8. Assemble the yoke cap screws or

nuts and tighten in a star pattern

using a torque wrench to the values shown on Table 2, pg. 7.

9. Assemble the nuts on the bonnet

studs and tighten in a star pattern

using a torque wrench to the values shown on Table 2, pg. 7. See

step 12 below.

10. Repack the packing chamber following the instructions on pg. 6.

Place the gland in position over the

studs and tighten the gland nuts.

Reassembly Instructions for Valves with Metal Gaskets Only (cont.)

Clamping For Securing Gate Halves

During Assembly/Disassembly

Illustration No. 17

AJAX

“KANT TWIST” CLAMPS

Page 26

26

Flow Control Division

Edward Valves

11. Reassemble the handwheel, (or

actuator) using the reverse of the

instructions for disassembly.

12. After the valve is pressurized,

retighten the bonnet retainer nuts

using same torque values as in

Step 9. This is important.

Type III Pressure Seal Bonnet

See Illustration No. 10, pg. 16

1. Place one gate half on a clean plywood board. Place the stem T-head

into the recess in the gate.

2. Place the gate spacer ring into the

counterbore in one gate half. Place

the other gate half on top, engaging the spacer ring and stem.

Holding the gate halves together,

lift the stem and lower the assembly into the body engaging the

gate guide rails with the groove in

the body. Lower the gate to the

seats.

3. Assemble a new pressure seal gasket, the spacer ring and junk ring

on the bonnet. Lift the bonnet

assembly over the stem and lower

into the body. Be very careful not

to mar the pressure seal gasket or

other machined surfaces.

4. Assemble the gasket retainer segments into the groove.

5. Place the thrust washer on the

body, and the bonnet retainer

plate on top of the body. Lift the

stem assembly up so that the bonnet penetrates the gasket retainer

segments and engages the threads

of the bonnet retainer and bonnet.

The bonnet retainer cap screw

should be engaged so they are

flush. Lift the stem assembly up and

screw the bonnet retainer down

until it contacts the body. Now

back it off about 1/8” (3mm) and

align the gland bolts for correct orientation.

6. Place the gland over the stem.

7. Place the yoke over the stem and

engage the stem threads by turning

the yoke bushing counterclockwise.

When the yoke contacts the body,

align the cap screw holes and continue to turn the yoke bushing until

the stem contacts the backseat firmly. This will pull the bonnet, gasket,

and spacer ring up against the

bonnet retainer and the yoke up

against the body.

8. Assemble the yoke flange cap

screws and tighten the cap screws

using a torque wrench to the values shown on Table 2, pg. 7. See

step 12 below.

9. Tighten the bonnet retainer cap

screws in a star pattern using a

torque wrench to the values shown

on Table 2, pg. 7.

10. Repack the packing chamber, following the instructions on pg. 6.

Place the gland in position and

tighten the gland nuts.

11. Reassemble the handwheel, (or

actuator) using the reverse of the

instructions for disassembly.

12. After the valve is pressurized,

retighten the bonnet retainer cap

screws, step 8, using the same

torque values. This is important.

Type IV & V Pressure Seal Bonnet

See Illustration Nos. 11 & 12, pg. 17

1. Place one gate half seat face down

on a bed of clean rags or plywood

board. Place the stem T-head into

the recess in the gate.

2. Place the gate spacer ring into the

counterbore in one gate half. Place

the other gate half on top, engaging the spacer ring and stem.

Clamp the gate halves together

near the top of the guide rails.

Place an eyebolt in the top end of

the stem. Stems 1.62” (41.1mm)

and larger are drilled and tapped

on the top end. See illustration No.

17, pg. 25, for clamping arrangement.

3. Carefully lift the stem-gate assembly, using a hoist in the eyebolt if

necessary, so as to avoid scratching the stem or gate surfaces.

Lower the assembly part way into

the body with the gate guide rails

engaged with the body guide

groove. Remove the clamps and

lower the assembly until the gate

contacts the seats.

Reassembly Instructions for Valves with Metal Gaskets Only (cont.)

Page 27

27

Flow Control Division

Edward Valves

Reassembly Instructions for Valves with Metal Gaskets Only (cont.)

4. Assemble a new pressure seal gas-

ket, the spacer ring, junk ring and

gland on the bonnet. Lift the bonnet using a hoist if necessary, and

place it over the stem and lower

into the body. Be very careful not

to mar the pressure seal gasket or

other machined surfaces.

5. Install the gasket retainer ring segments in the body groove. Place

the bonnet retainer over the stem