Page 1

URB 1

Installation Instructions 810375-03

Operating Terminal and Display Unit URB 1

1

Page 2

Contents

Page

Important Notes

Usage for the intended purpose ......................................................................................8

Safety note ......................................................................................................................8

Explanatory Notes

Scope of supply ..............................................................................................................8

System description ......................................................................................................8, 9

Function .......................................................................................................................... 9

Technical data ............................................................................................................... 10

Installation

URB 1 ...........................................................................................................................10

Example of installation ................................................................................................ 79

Wiring

Wiring diagram ........................................................................................................ 4, 12

Basic Settings

CAN bus ...................................................................................................................... 13

Node ID for GESTRA bus-based devices URB 1 ....................................................... 13

Factory set default values ............................................................................................ 13

Adjusting display brightness ................................................................................. 14, 15

Changing factory set node ID of URB 1 / adjusting & changing node ID of URB 1 . 16– 18

Possibilities to display bus devices ............................................................................. 18

Setting / changing node IDs of bus-based equipment.......................................... 19– 22

Visual display / parameterisation of bus-based equipment ................................. 23–28

0 %/100 % calibration for capacitance level monitoring system .......................... 29–31

Calibrating feedback potentiometer of an external control valve ......................... 32– 35

Establishing switchpoints and proportional coefficient X

Adjusting sensitivity of response ........................................................................... 40, 41

Setting relay delay times .......................................................................................42– 44

Adjusting conductivity controller ........................................................................... 45– 57

Adjusting LIN (linear) temperature compensation ................................................ 58– 60

Adjusting NORM (standard curve) temperature compensation ........................... 61–65

Enabling AUTO temperature compensation ............................................................ 66, 67

Disabling temperature compensation ................................................................... 68, 69

.................................... 36–39

P

2

Page 3

Contents

Page

Operation

Manual operation via external control valve ............................................................... 70

Stand-by operation with the steam boiler disconnected............................................. 71

System Malfunctions

Systematic malfunction analysis for troubleshooting .................................................. 72

Fault finding list ...................................................................................................... 73, 74

Annex

Establishing / changing node ID ................................................................................. 75

Factory set node IDs .............................................................................................. 75, 76

Table: standard curves ................................................................................................ 77

Declaration of conformity............................................................................................. 78

3

Page 4

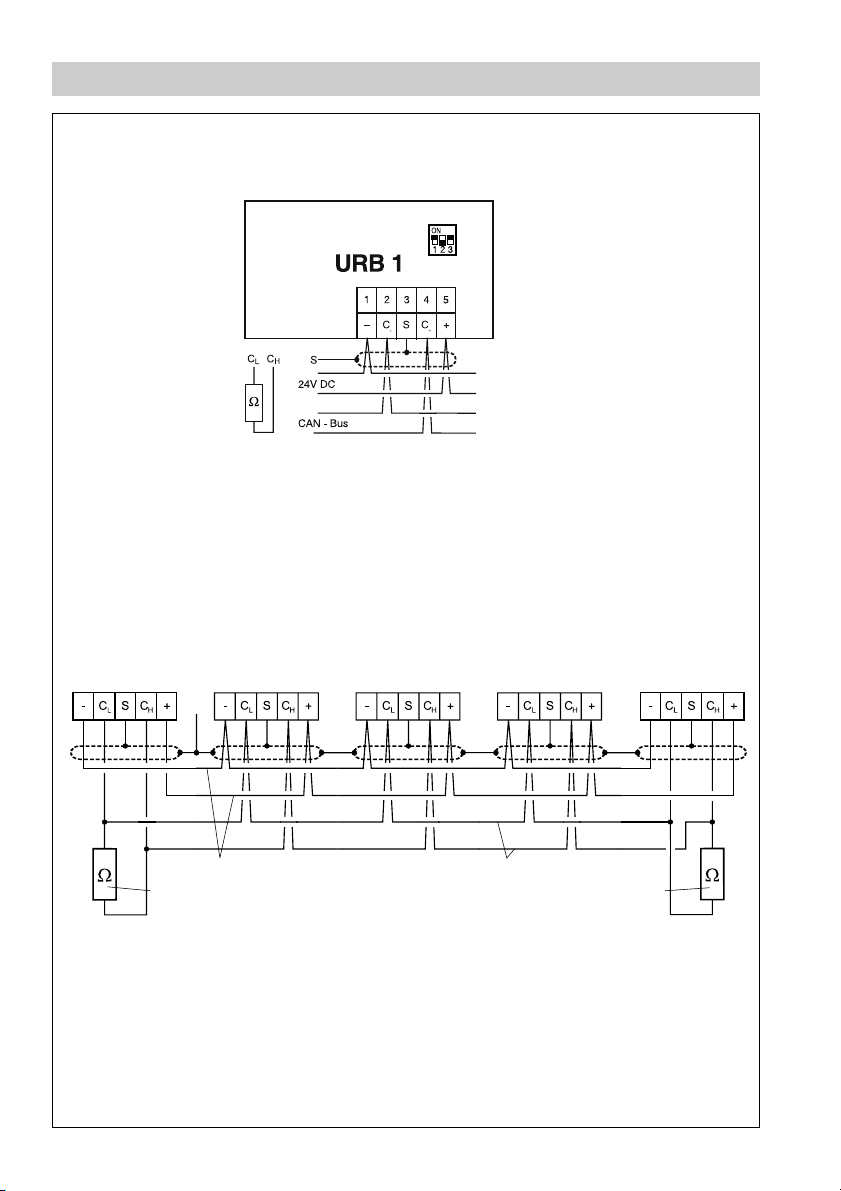

Wiring Diagram

Terminating resistor 120 Ω,

Fig.1

Paired cable

Operating

terminal

URB 1

Level switch

NRS

CEP*)

Voltage supply CAN data line

Terminating resistor

120 Ω

*) CEP = central earthable point

Fig. 2

4

Conductivity

controller

LRR 1-40

Conductivity

electrode

LRG 16-40

Terminating resistor

120 Ω

Electrode

NRG .. .

Page 5

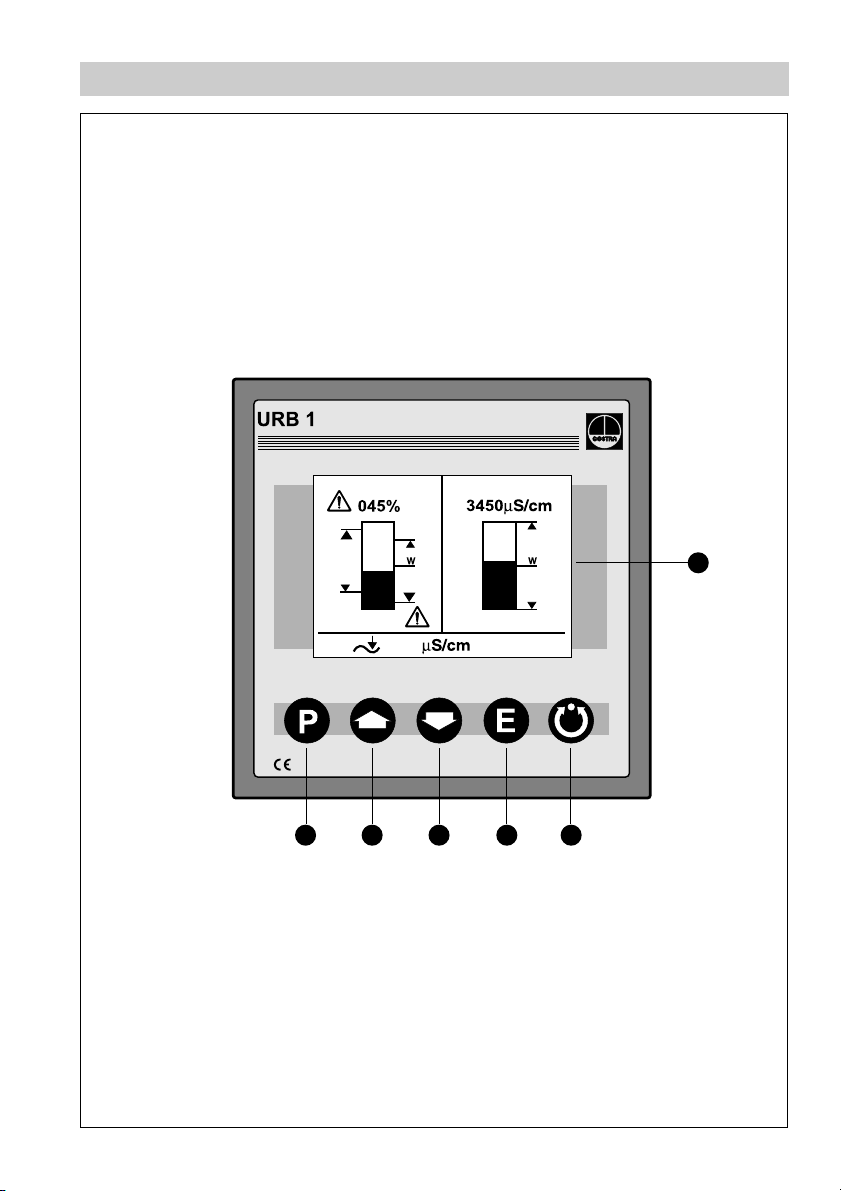

Functional Elements

6

Fig. 3

1 2 3 4

5

5

Page 6

Functional Elements

7

B

Fig. 4

6

A

A

Page 7

Key

Program button for switching between operating mode and parameterisation mode

1

Increase button

2

3

Decrease button

4

Enter button

5

Manual / automatic button

6

Illuminated LCD display, resolution 128 x 64 pixels

Code switch for baud rate setting

7

A

Fixing screws for panel mounting

Five-pole connector

B

7

Page 8

Important Notes

Usage for the intended purpose

Use operating terminal & display unit URB 1 only in conjunction with GESTRA

Spector bus systems (CANopen).

Safety Note

Use operating terminal and display unit URB 1 only for operating and viewing

GESTRA CAN bus systems.

The equipment must only be installed by qualified staff.

Qualified staff are those persons who – through adequate training in electrical

engineering, the use and application of safety equipment in accordance with

regulations concerning electrical safety systems, and first aid & accident prevention –

have achieved a recognised level of competence appropriate to the installation and

commissioning of this device.

Explanatory Notes

Scope of supply

URB 1

1 Operating terminal and display unit URB 1 (in plastic case)

2 Fixing screws for panel mounting

1 Installation manual

System description

The URB 1 is a user-friendly operating terminal and display unit for GESTRA CAN

bus systems using the CANopen protocol. The equipment makes retrieving and

processing standard functions of associated system components very easy.

In addition, the URB 1 simplifies the parameterisation procedure: The switchpoints,

proportional band and response sensitivity can be adjusted by means of the keypad

regardless of the actual level. The energizing and de-energizing times of the relays

can be set individually for their respective switchpoints.

The following tables specifiy the GESTRA systems that can be displayed by the

URB 1.

8

Page 9

Explanatory Notes – continued –

System description – continued –

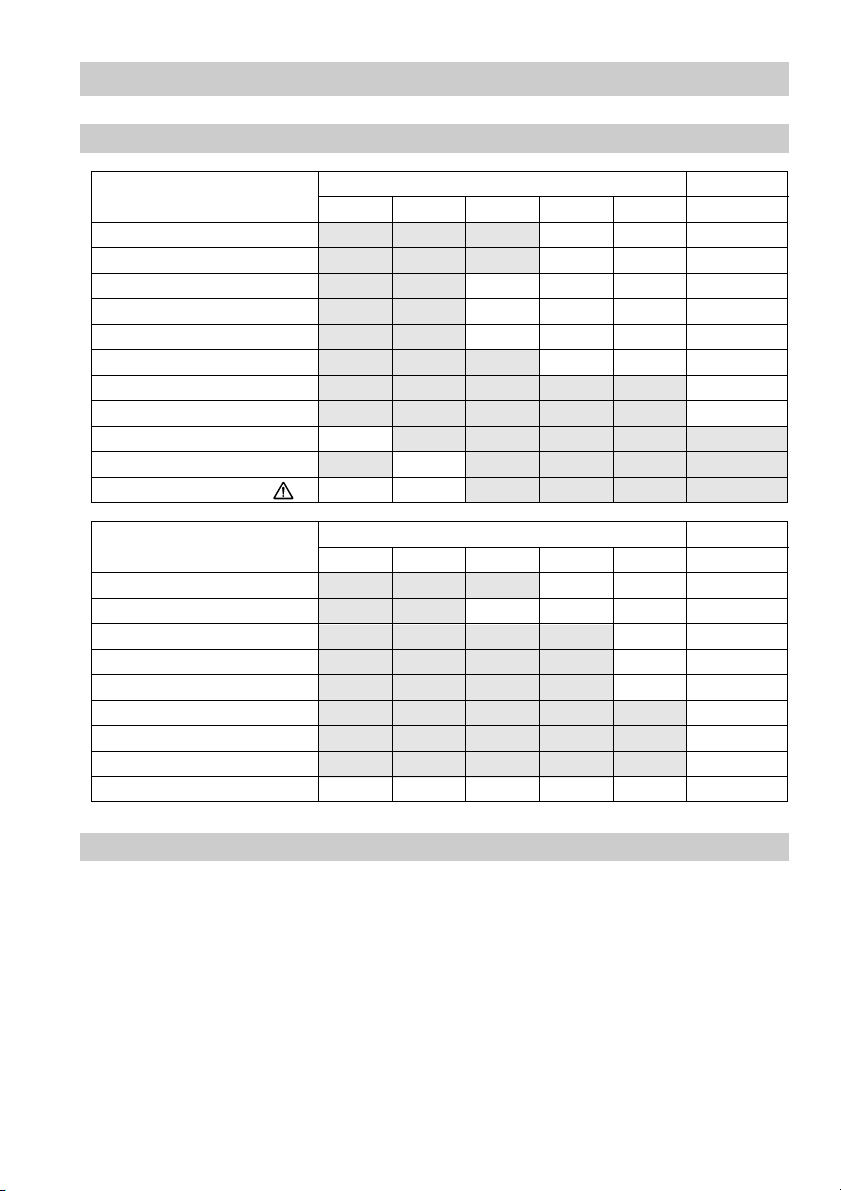

Standard display information

Actual value (bar chart) ●● ●

Actual value (numerical value) ●● ●

Switchpoint (symbol) ●●● ●

High level alarm (electrode HW) ●●● ●

Low level alarm (electrode LW) ●●● ●

Manual/automatic operation ●● ●

Stand-by mode ●

Unit [µS/cm] or [ppm] ●

Low level limit ●

High level limit ●

Alarm (warning triangle) ●●

Further display information

Actual value (continuous) ●● ●

Switchpoints ●●● ●

Setpoint ●●

Deviation ●●

Valve position ●●

Intermittent blowdown ●

Intermittent blowdown interval ●

Purging pulse 24 h ●

Current CAN bus addresses ●●●●● ●

NRS 1-40 NRS 1-41 NRS 1-42

NRS 1-40 NRS 1-41 NRS 1-42

Level Conductivity

NRS 2-40 NRR 2-40

Level Conductivity

NRS 2-40 NRR 2-40

LRR 1-40

LRR 1-40

Function

The URB 1 communicates with other GESTRA system components via a designated

CAN bus using the CANopen protocol to DIN ISO 11898.

The URB 1 can also be used to operate and display further system components

during operation.

■ Capacitance level switch type NRS 2-40 CANopen

■ Level controller type NRR 2-40 CANopen

■ Conductivity level switch type NRS 1-42 CANopen

■ Low-level alarm to TRD 604/EN type NRS 1-40 CANopen

■

High-level alarm to TRD 604/EN type NRS 1-41 CANopen

■

Conductivity controller and limiter to TRD 604/EN type NRS 1-41 CANopen

9

Page 10

Explanatory Notes – continued –

Technical data

Type approval no.

TÜV · 98-399 (level)

TÜV · WÜL · 02-007 (conductivity)

Input

Power supply: 18 V – 36 V DC

Interface for CAN bus using CANopen protocol to DIN ISO 11898

Output

Interface for CAN bus using CANopen protocol to DIN ISO 11898

Indicators and adjustors

1 illuminated display, resolution: 128 x 64 pixels

5 push buttons

1 three-pole code switch for baud rate setting

Supply voltage

18 V – 36 V DC

Protection

Front panel: IP 54 to DIN EN 60529

Back: IP 00 to DIN EN 60529

Admissible ambient temperature

0°C – 55 °C

Case material

Front face: Aluminium with polyester membrane

Casing: Noryl GFN 2 SE 1, glass-fibre reinforced

Weight

Approx. 0.3 kg

Installation

URB 1

Panel mounting

1. Provide panel cut-out, dimensions: 92

2. Install URB 1 using the fixing clips supplied with the equipment.

Tool

■ Screwdriver (5.5/100)

10

+0.8

x 92

+0.8

.

Page 11

Wiring

Note that multi-core control cable with conductors linked in pairs, e. g. UNITRONIC

BUS CAN 2 x 2 x .. mm

2

or RE-2YCYV-fl 2 x 2 x .. mm2 .

®

The baud rate (data transfer rate) dictates the cable length between the bus nodes

and the total power consumption of the sensors dictates the conductor size.

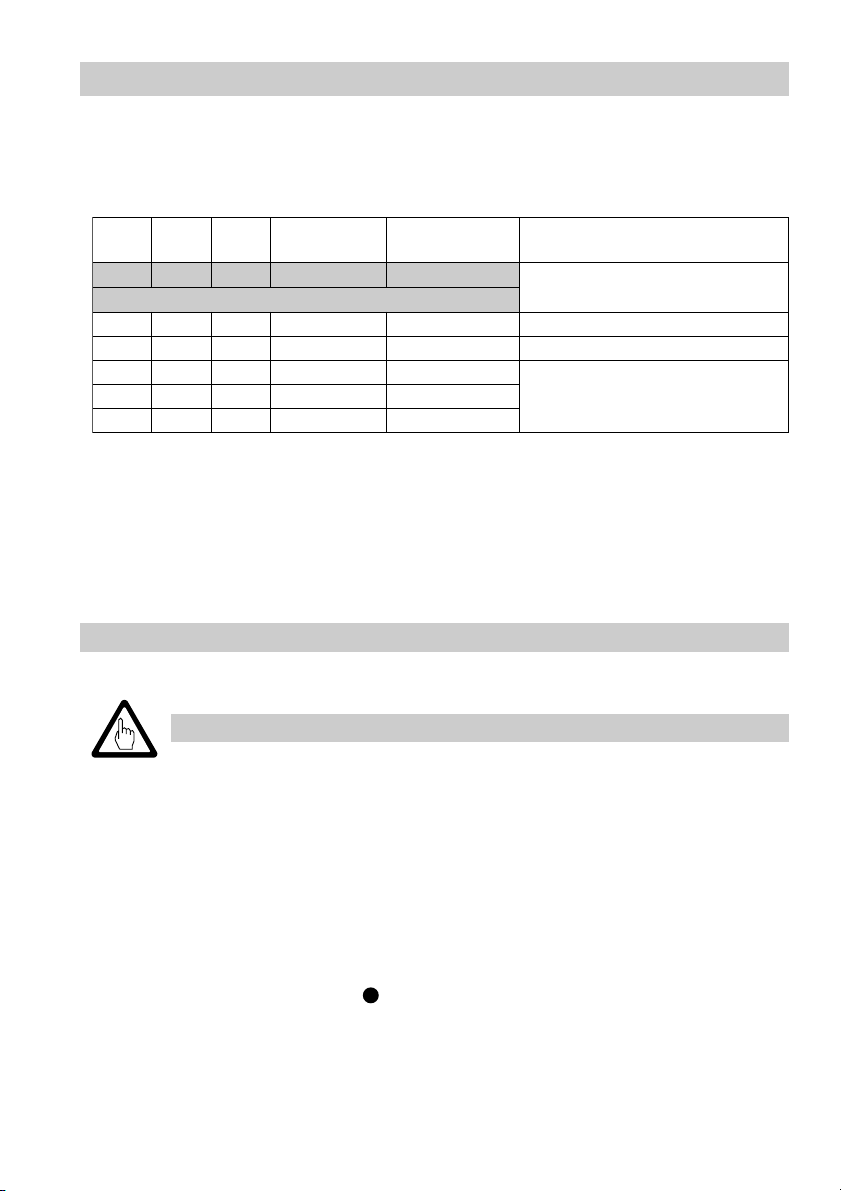

8S9S01SetarduaBhtgnelelbaC

FFO NO FFO s/tiBk052 m521

sgnittesyrotcaF

NONOFFOs/tiBk521m0525,0x2x2

FFOFFONOs/tiBk001m53357,0x2x2

NOFFONOs/tiBk05m005

FFONONOs/tiBk02m0001

NONONOs/tiBk01m0001

sriapforebmuN

2

]

mm[ezisrotcudnocdna

43,0x2x2

notnedneped,tseuqerno

noitarugifnocsub

The baud rate is set via a code switch. Reduce baud rate if cable is longer than

specified in the table above. Make sure that all bus nodes feature the same settings.

To protect the switching contacts fuse circuit with 2.5 A (anti-surge fuse) or according

to TRD regulations (1.0 A for 72 hrs operation).

When a max. cable length of more than 125 m (up to 1000 m) is desired, make

sure to modify the baud rate accordingly. Refer to pages 75 and 76 for more

details.

Wiring diagram

For wiring diagram refer to page 4.

Attention

■ Wire equipment in series. Star-type wiring is not permitted.

■ Interlink screens of control cables such that electrical continuity is

ensured and connect them once to the central earthing point (CEP).

■ If more than one system component is connected to a CAN bus

network provide the first and last equipment with a terminating resistor

of 120 Ω, Fig. 2

■ The CAN bus line must not be interrupted while operating with one or

more system components.

Any interruption will open the control circuit!

If the switching controller has to be replaced be sure to remove first

the terminal strips , Fig. 4

B

Note: Make sure that all system components connected are

operating

UNITRONIC® is a registered trademark of LAPP Kabelwerke GmbH, Stuttgart.

before removing the CAN bus line from the terminal strip!

not

11

Page 12

Wiring – continued –

Note

■

Connect screen only to terminal 3, ensuring electrical continuity and

connect equipment once to the central earthing point (CEP).

■

The loop resistance must be under 10 Ω.

■

The rated voltage is stated on the name plate.

■

Despite correct wiring H.F. interference caused by the installation may

lead to system breakdowns and malfunction messages. If necessary

refer to the fault finding lists of the respective bus equipment.

Tools

■ Screwdriver for slotted screws, size 2.5, completely insulated according to

VDE 0680

12

Page 13

Basic Settings

CAN-Bus

All level and conductivity controllers and associated electrodes are interconnected by

means of a CAN bus using the CANopen protocol. Every item of equipment features

an electronic address (node ID). The four-core bus cable serves as power supply and

data highway for high-speed data exchange.

The CAN address (node ID) can be set between 60 and 123.

The URB 1 is configured at our works and ready for service with other GESTRA

system components without having to set the node ID.

If several systems of the same kind are to communicate in one CAN bus

network, be sure to assign one node ID for each individual system component

(e. g. controller). Refer to page 75 and 76 for more information.

Node ID for GESTRA bus-based device URB 1

Example: Conductivity monitoring and control

Example: Level monitoring and control

Factory set default values

The URB 1 features the following factory default settings:

■ Baud rate: 250 kb/s

■ Node ID: 060 (Do not change this node ID unless required; highest permissible

setting: 123)

13

Page 14

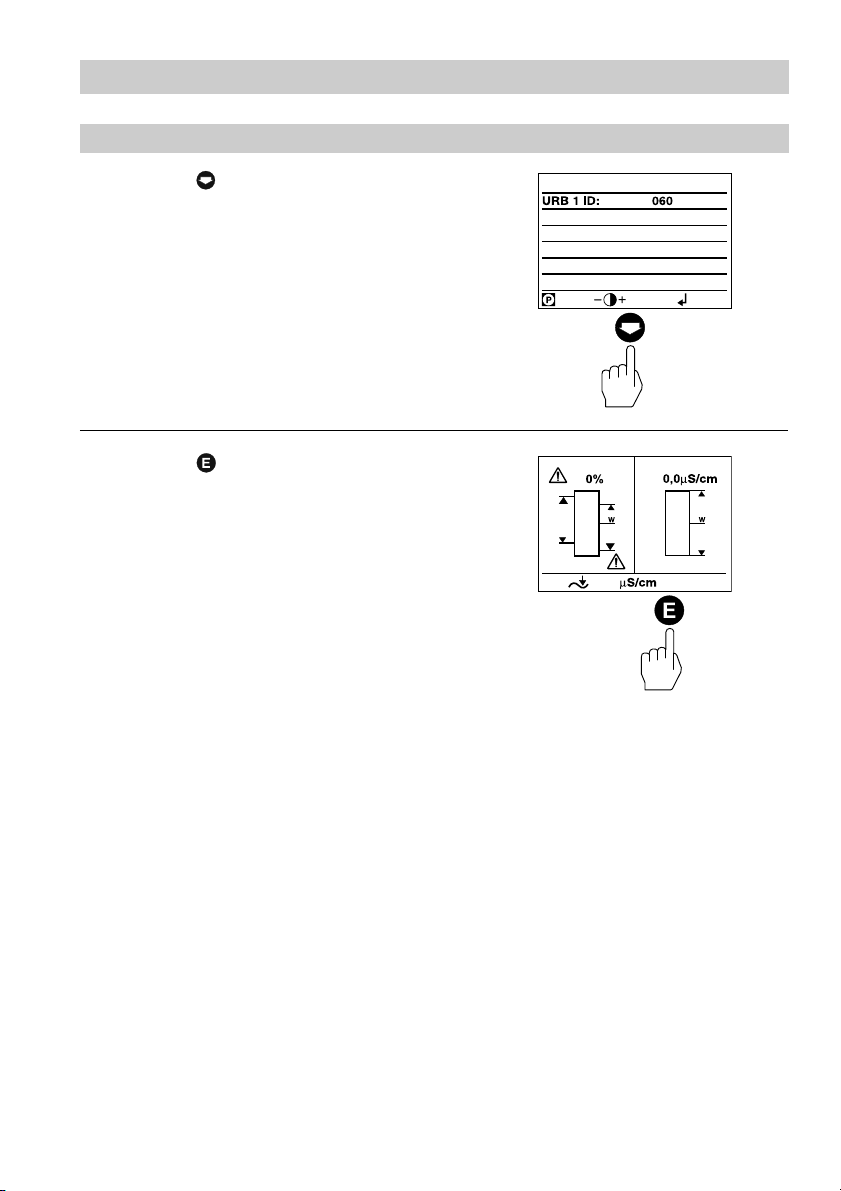

Basic Settings – continued –

Adjusting display brightness

The brightness of the LCD display can be

adjusted as necessary.

Press and hold the button for a few

seconds.

The URB 1 enters the address

parameterisation mode.

Press button several times to reduce

the brightness.

14

several times briefly

several times briefly

Page 15

Basic Settings – continued –

Adjusting display brightness – continued –

Press button several times to

increase the brightness.

Press button briefly to save settings

and return to the main window.

several times briefly

twice briefly

15

Page 16

Basic Settings – continued –

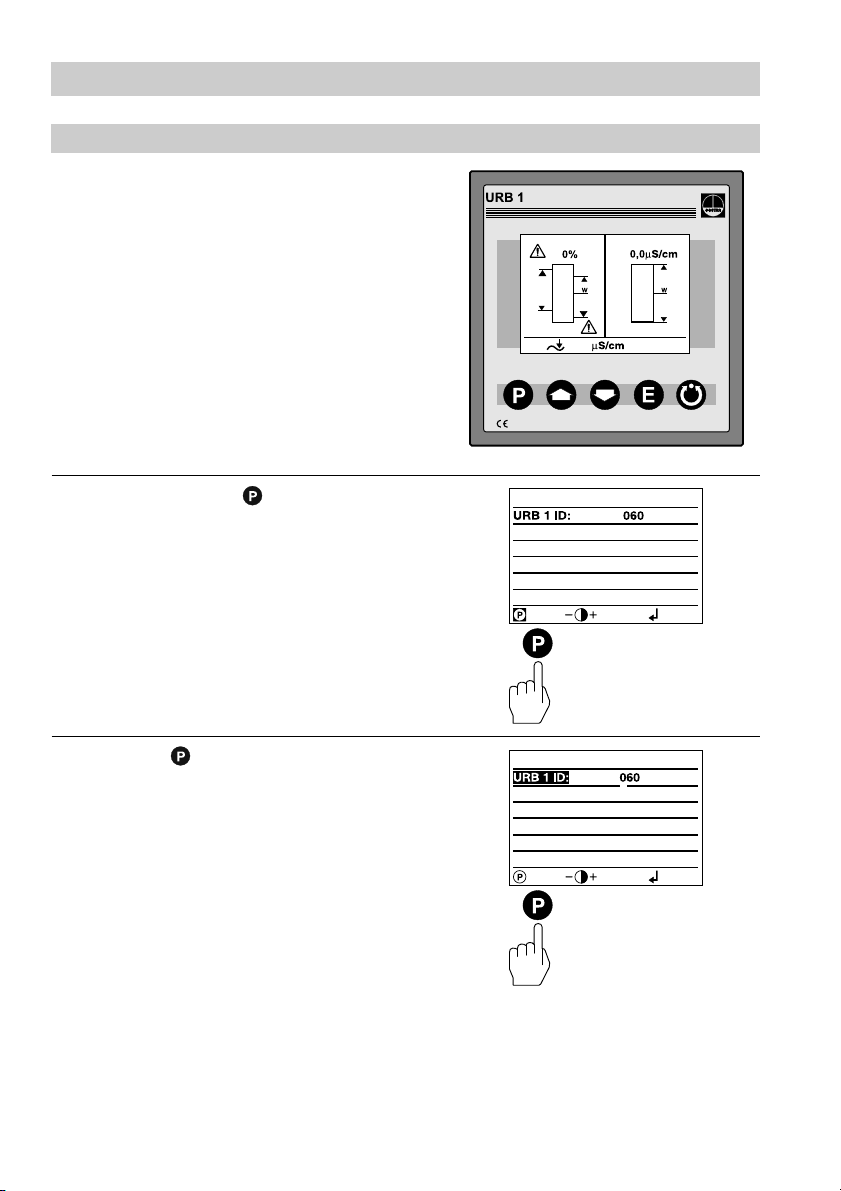

Changing factory set node ID of the URB 1 / Adjusting & changing node ID

The factory set node ID of the URB 1 is

“060”. Node IDs below this value are

reserved for other GESTRA bus

components.

If additional operating terminals type URB 1

are used in a CAN bus system, you have to

set their node IDs to values above “060”.

Note that the newly established node IDs

must not be identical with node IDs of other

bus components.

Press and hold button for a few

seconds to enter the address

parameterisation mode.

Press button briefly to activate the

line selection mode.

16

a few seconds

briefly

Page 17

Basic Settings – continued –

Changing factory set node ID of the URB 1 / Adjusting & changing node ID – continued –

Press button briefly to activate the line

editing mode.

Use button or to increase or

decrease the first digit.

flashing

briefly

Press button briefly to move the

cursor two steps further.

flashing

twice briefly

Press button once briefly to select the

digit “1”.

flashing

once briefly

17

Page 18

Basic Settings – continued –

Changing factory set node ID of the URB 1 / Adjusting & changing node ID – continued –

Press button briefly to activate the line

selection mode.

In our example the node ID was set to

“061”.

briefly

Press button twice briefly to save

settings and return to the main window.

twice briefly

Possibilities to display bus devices

The URB 1 can display only one level monitoring device, one low-level alarm, one

high-level alarm and one conductivity monitoring device per vessel (e. g. steam

boiler or feedwater deaerator).

If the monitoring systems of more than one vessel are to be displayed, provide one

URB 1 per vessel.

18

Page 19

Basic Settings – continued –

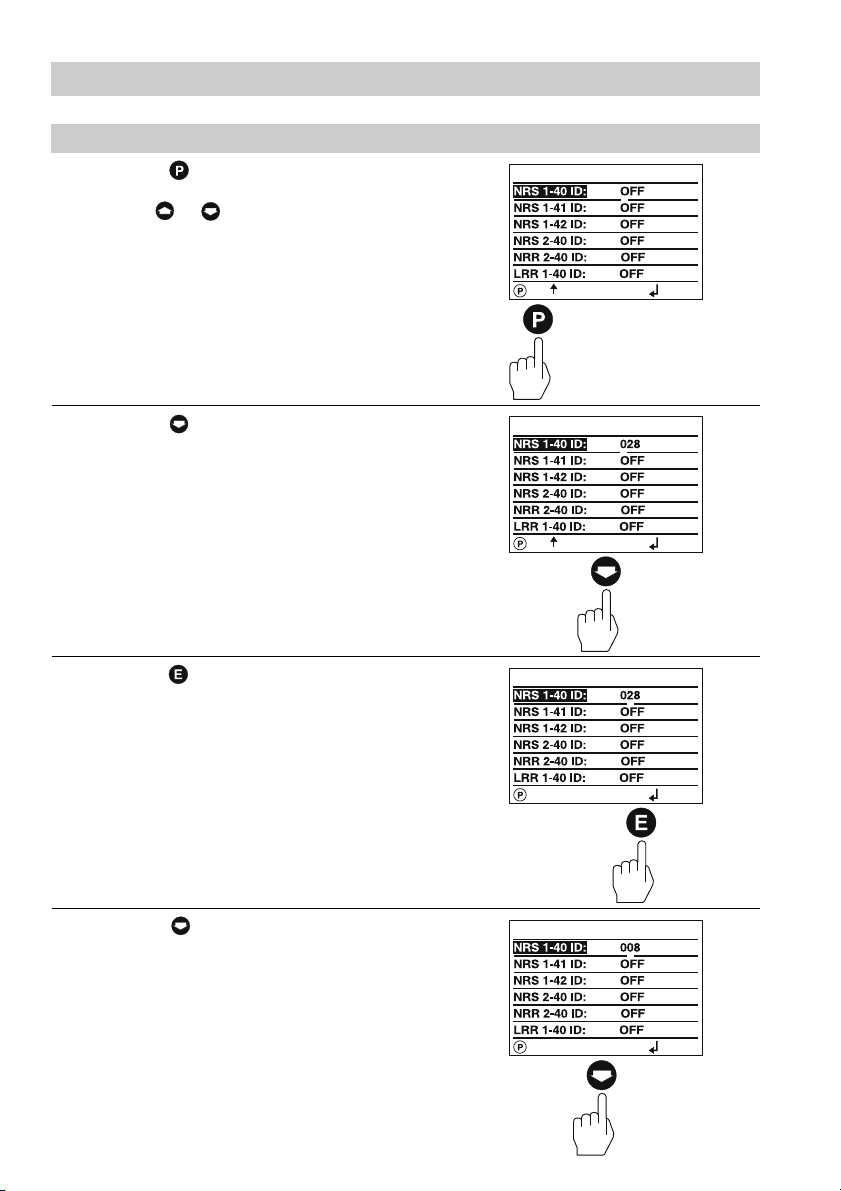

Setting /changing node IDs of bus-based equipment

The standard default node ID setting of all

bus devices that can be displayed is “O

This setting acts as a wild card for all bus

devices which are not displayed with the

URB 1.

For each bus device that shall be displayed

by the URB 1 a node ID has to be

established manually.

We recommend to accept the factory set

node IDs of GESTRA bus devices. For the

relevant node ID setting please refer to the

corresponding installation manual of the

device.

Press button briefly to show the

address list and activate the

parameterisation mode.

FF”.

Press button briefly to activate the line

selection mode.

briefly

briefly

19

Page 20

Basic Settings – continued –

Setting /changing node IDs of bus-based equipment – continued –

Press button briefly to activate the line

editing mode.

Use button or to increase or

decrease the first digit.

flashing

briefly

Press button once briefly to select the

digit “0”.

flashing

once briefly

Press button briefly to move the

cursor one step further.

Press button twice briefly to select

the digit “0”.

20

flashing

briefly

flashing

twice briefly

Page 21

Basic Settings – continued –

Setting /changing node IDs of bus-based equipment – continued –

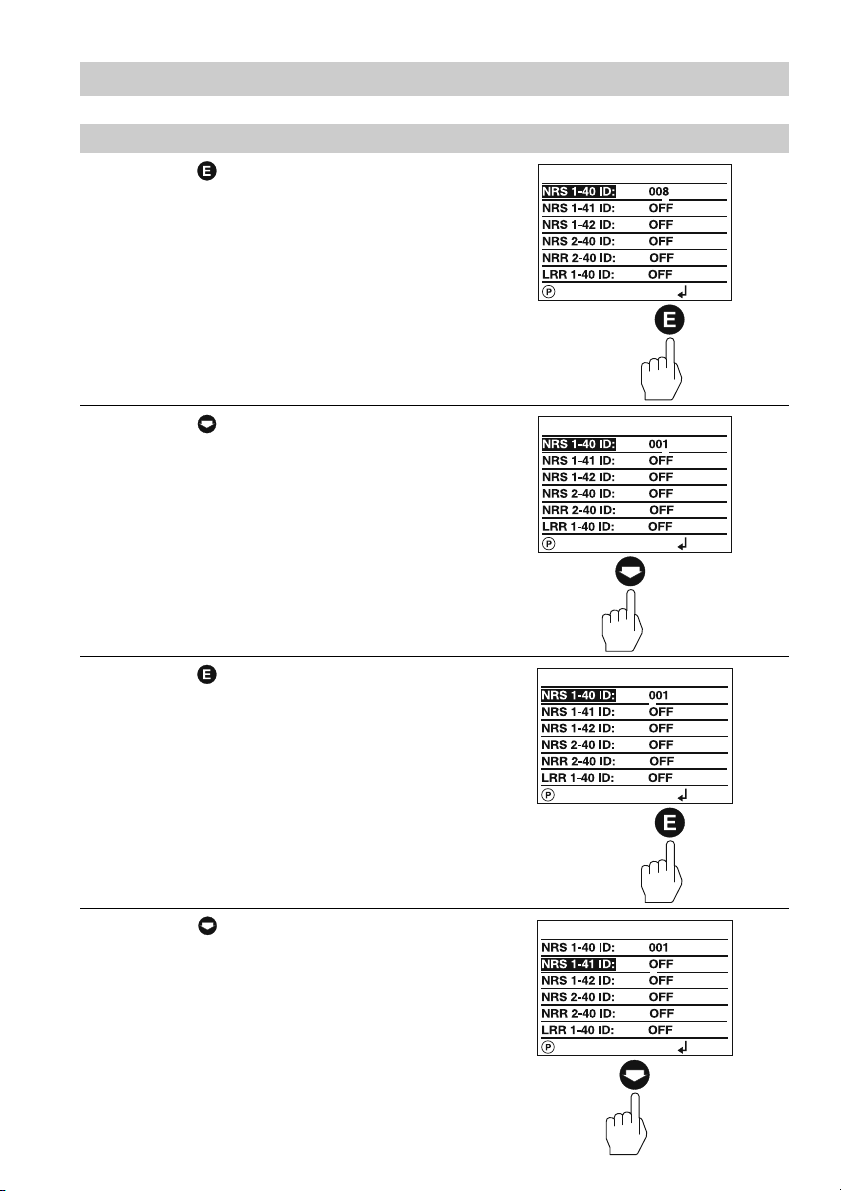

Press button briefly to move the

cursor one step further.

flashing

Press button seven times briefly to

select the digit “1”.

flashing

briefly

7 times briefly

Press button briefly to activate the line

selection mode.

Press button once briefly to move to

the next line.

The node ID of the NRS 1-41 can now

be adjusted.

briefly

once briefly

21

Page 22

Basic Settings – continued –

Setting /changing node IDs of bus-based equipment – continued –

Press button briefly to activate the

parameterisation mode.

In this example the node IDs of all bus

devices have already been adjusted.

If the display of the NRS 1-42 is required

set the node IDs of the NRS 2-40 and

NRR 2-40 to “O

Press button twice briefly to save the

settings and return to the main window.

FF”.

briefly

twice briefly

22

Page 23

Basic Settings – continued –

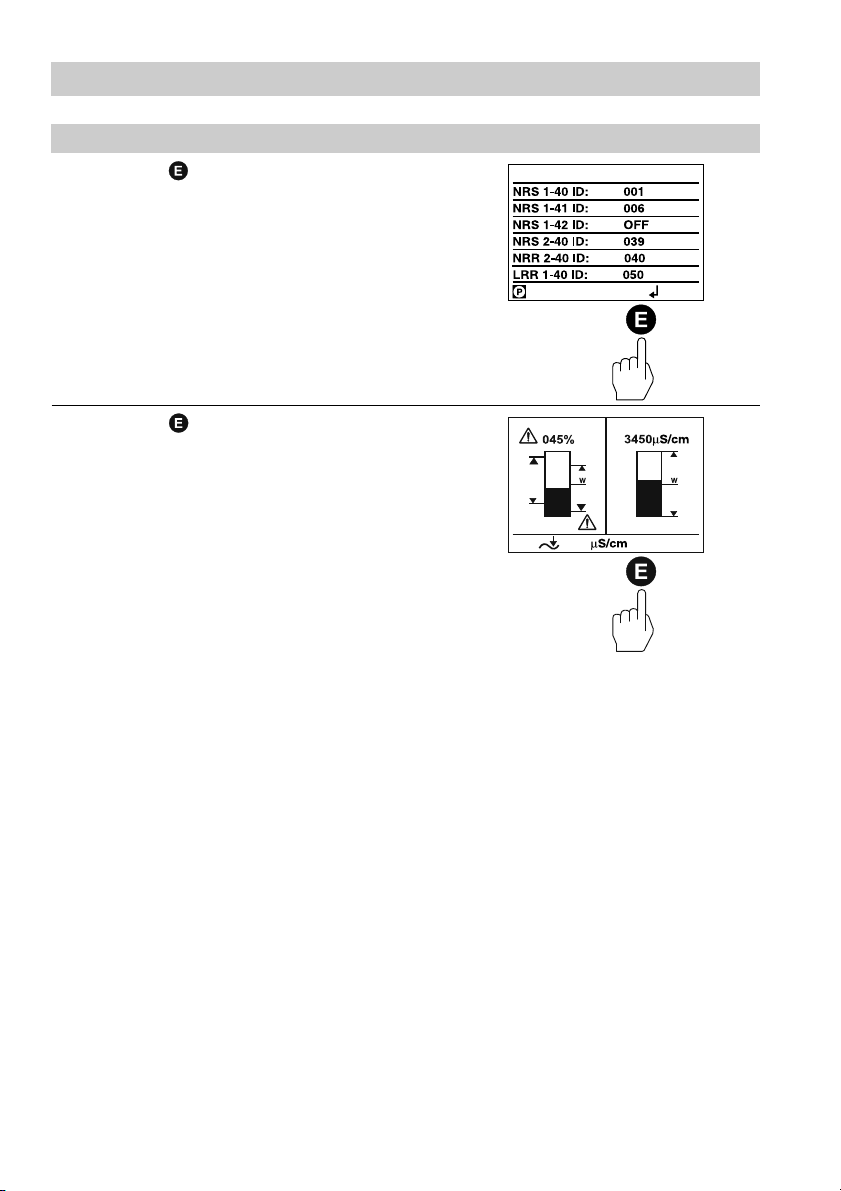

Visual display / Parameterisation of bus devices

The split-screen display window shows which

GESTRA bus devices can be indicated:

■ High-level limiter type NRS 1-41

■ Low-level limiter type NRS 1-40

■ Level switch type NRS 2-40

■ Level controller type NRR 2-40

■ Conductivity controller type LRR 1-40

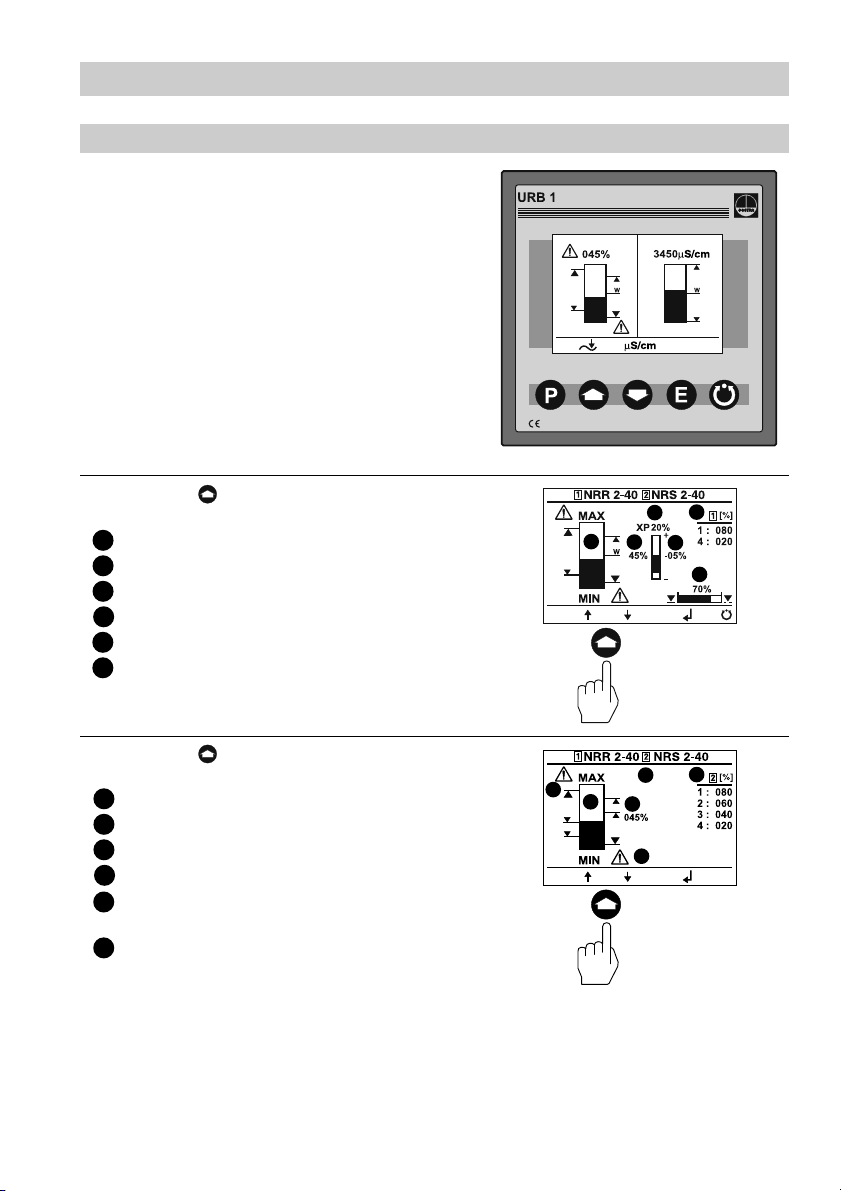

Press button briefly to enter the display

window of the level controller NRR 2-40.

Actual level (graphical representation)

1

Actual level (percentage)

2

3

Setpoint deviation

4

Proportional band X

5

Switchpoints NRR 2-40

6

Valve position

p

Press button briefly to enter the display

window of the level switch NRS 2-40.

1

Actual level (graphical representation)

2

Actual level (percentage)

3

Control unit 2 highlighted

4

Switchpoints for control unit 2

5

Low-level signal

(flashes in the event of an LW alarm)

6

High-level signal

(flashes in the event of an HW alarm)

LW = low water (limiter NRS 1-40)

HW = high water (limiter NRS 1-41

5

4

1

2

3

6

briefly

4

6

3

1

2

5

briefly

23

Page 24

Basic Settings – continued –

Visual display / Parameterisation of bus devices – continued –

Press button briefly to enter the

parameterisation mode for the following

settings:

■ 0 % – 100 % calibration NRG 26-40

■ Switchpoints NRR 2-40

■ Proportional band NRR 2-40

■ Switchpoints NRS 2-40

Press button briefly to enter the

parameterisation mode for the following

settings:

■ Relay energizing delay times

■ Relay de-energizing delay times

briefly

briefly

Press button briefly to enter the error

messages window.

For more information see section

Malfunction, Troubleshooting, Fault

Finding List on pages 72 and 74.

Press button briefly to return to the

main window.

1

Actual conductivity value

2

Actual conductivity

(graphical representation)

24

briefly

1

2

briefly

Page 25

Basic Settings – continued –

Visual display / Parameterisation of bus devices – continued –

Press button briefly to enter the display

window of the conductivity controller LRR 1-40.

Actual conductivity value

1

2

Conductivity setpoint

3

M

AX conductivity value

24 h purging pulse for continuous

4

blowdown valve

5

Operating position of continuous

blowdown valve

Valve position of continous blowdown valve

6

Press button briefly to enter the

parameterisation mode for the following

settings:

■ µS/cm or ppm

■ Indication range of actual value

graphical representation

■ MAX conductivity value

■ Setpoint

■ MIN conductivity value

2

3

4

1

5

6

briefly

briefly

Press button briefly to enter the

parameterisation mode for the following

settings:

■ Proportional band X

■ Controller hysteresis

■ 24 h purging pulse for continuous

p

blowdown valve

■ Operating position of intermittent

blowdown valve

■ Relay contact 4: MIN limit /

Automatic intermittent boiler blowdown

Press button briefly to enter the

parameterisation mode for the following

settings:

■ Linear temperature compensation LIN

■ Automatic temperature compensation AUTO

■ Standard curve temperature compensation

NORM

■ Temperature compensation disabled OFF

briefly

briefly

25

Page 26

Basic Settings – continued –

Visual display / Parameterisation of bus devices – continued –

Press button briefly to enter the error

messages window.

For more information refer to section

Malfunction, Troubleshooting, Fault

Finding List on pages 72 and 74.

Press button briefly to return to the

main window.

briefly

briefly

26

Page 27

Basic Settings – continued –

Visual display / Parameterisation of bus devices – continued –

The split-screen display window shows which

GESTRA bus devices can be indicated:

Level switch type NRS 1-42

This window appears if, as in our example,

only the NRS 1-42 is displayed.

Press button briefly to enter the display

window of the level switch NRS 1-42.

H

IGH LEVEL switchpoint

1

2

Switchpoints

3

L

OW LEVEL switchpoint

1

2

2

3

Press button briefly to select either of the

following two settings:

■ Minimum conductivity of the fluid 0.5 µS/cm

■ Minimum conductivity of the fluid 10 µS/cm

briefly

briefly

27

Page 28

Basic Settings – continued –

Visual display / Parameterisation of bus devices – continued –

Press button briefly to enter the

parameterisation mode for the following

settings:

■ Relay energizing delay times

■ Relay de-energizing delay times

Press button briefly to enter the error

messages window.

For more information please refer to

section Malfunction, Troubleshooting,

Fault Finding List on pages 72 and 74.

briefly

briefly

Press button briefly to return to the

main window.

In this example only the bus device

NRS 1-42 is displayed.

If the node IDs of the bus devices

NRS 2-40 and NRR 2-40 have been

established such that the equipment can

be displayed on the URB 1, the

indication of these devices will take

priority over the NRS 1-42 and the

display window of the NRS 1-42 will be

blanked.

28

briefly

Page 29

Basic Settings – continued –

0 % /100 % calibration for capacitance level monitoring system

The split-screen main window shows

which GESTRA bus devices can be

displayed:

High level limiter NRS 1-41

Low level limiter NRS 1-40

Level switch NRS 2-40

Level controller NRR 2-40

Conductivity controller LRR 1-40

Before commissioning the installation

establish the measuring range of the

capacitance level electrode NRG 26-40 by

calibrating the 0 % and 100 % settings.

Press button three times briefly to enter

the window for calibrating the 0 % and

100 % settings.

Press button twice briefly to enter the

line editing mode.

Lower the water level in the vessel

to 0 %.

3 times briefly

flashing

twice briefly

29

Page 30

Basic Settings – continued –

0 % /100 % calibration for capacitance level monitoring system – continued –

Press button briefly to save the 0 %

level setting.

once briefly

Press button once briefly.

once briefly

Press button once briefly to activate the

line editing mode.

Raise the water level in the vessel to

100 %.

If, for practical reasons, it is not possible to

raise the water level to 100 % please

proceed as follows:

30

flashing

once briefly

Page 31

Basic Settings – continued –

0 % /100 % calibration for capacitance level monitoring system – continued –

Press button five times briefly.

Pressing the button in program mode

will decrement the calibration level in steps

of 10 to a minimum of 50 %.

In our example the calibration level is

50 %.

This calibration method saves time and

prevents the loss of feedwater.

Press button three times briefly to enter

the main window.

flashing

5 times briefly

3 times briefly

31

Page 32

Basic Settings – continued –

Calibrating the feedback potentiometer of an external control valve

The split-screen window shows which

GESTRA bus devices can be displayed:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Before commissioning the installation

calibrate the 0 % (

range of the feedback potentiometer of an

external control valve.

Press button briefly to enter the display

window of the level controller NRR 2-40.

CLOSED) and 100 % (OPEN)

Press button briefly to activate the

manual mode.

Pressing button or in this mode

allows the manual opening or closing of

an external control valve.

32

briefly

briefly

Page 33

Basic Settings – continued –

Calibrating the feedback potentiometer of an external control valve – continued –

Press button three times briefly to

activate the line editing mode for

calibrating the signal of the feedback

potentiometer.

flashing

3 times briefly

Press and hold down button until the

control valve is closed.

flashing

hold down

Press button once briefly to save the

current resistance value of the feedback

potentiometer as 0 % setting (valve

closed).

once briefly

33

Page 34

Basic Settings – continued –

Calibrating the feedback potentiometer of an external control valve – continued –

Press button briefly to select the

calibration of the 100 % setting.

briefly

Press button once briefly to activate the

line editing mode for calibrating the signal

of the feedback potentiometer.

flashing

once briefly

Press and hold down button until the

control valve is open.

34

flashing

hold down

Page 35

Basic Settings – continued –

Calibrating the feedback potentiometer of an external control valve – continued –

Press button three times briefly to save

the current resistance value of the

feedback potentiometer as 100 % setting

(valve

OPEN).

3 times briefly

Press button briefly to deactivate the

manual mode.

briefly

Press button once briefly to return to

the main window.

once briefly

35

Page 36

Basic Settings – continued –

Establishing switchpoints and proportional coefficient X

The split-screen main window shows

which GESTRA bus devices can be

indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity electrode LRR 1-40

Before commissioning the installation

establish proportional band and the M

M

IN switchpoints for the level controller

AX/

NRR 2-40.

For level switch NRS 2-40 you can

establish four switchpoints.

Press button three times briefly to enter

the window where you can establish the

switchpoints and the X

value.

p

p

3 times briefly

Press button once briefly to activate

the line editing mode.

Use button or to scroll back and

forth through the lines

36

once briefly

Page 37

Basic Settings – continued –

Establishing switchpoints and proportional coefficient Xp – continued –

Press button twice briefly to select the

switchpoint 1 (M

NRR 2-40.

Press button once briefly to activate the

line editing mode.

AX switchpoint) of the

twice briefly

flashing

once briefly

Press button once briefly to move to the

next digit in the same line.

flashing

once briefly

37

Page 38

Basic Settings – continued –

Establishing switchpoints and proportional coefficient Xp – continued –

Press button once briefly.

In our example switchpoint 1

(M

AX switchpoint) shall be established at

70 %.

flashing

once briefly

Press button once briefly.

The last digit in the line is selected and

remains “0” for our example switchpoint

M

AX 70 %.

flashing

once briefly

Press button once briefly to deactivate

the line editing mode.

Press button to go to the next line.

38

once briefly

Page 39

Basic Settings – continued –

Establishing switchpoints and proportional coefficient Xp – continued –

Press button once briefly.

Switchpoint 2 marks the upper limit of the

proportional band for the level controller

NRR 2-40.

The difference between switchpoint 2 and

switchpoint 3 gives the proportional band

X

. The example setting corresponds to

p

proportional band of 20 % (060 - 040).

Note that the proportional band must be

greater than “0”.

Press button once briefly.

Switchpoint 3 marks the lower limit of the

proportional band for the level controller

NRR 2-40.

The proportional coefficient and the M

switchpoint of the NRR 2-40 as well as

the switchpoints of the NRS 2-40 can be

adjusted as described above.

IN

once briefly

once briefly

Press button twice briefly to return to

the main window.

twice briefly

39

Page 40

Basic Settings – continued –

Adjusting sensitivity of response

The split-screen window shows which

GESTRA bus devices can be indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 1-42

■ Conductivity controller LRR 1-40

Before commissioning the installation

adjust the response sensitivity of the NRS

1-42.

The response sensitivities of the highlevel and low-level limiters are factory

set and cannot be changed.

Press button twice briefly to select

either of the following two response

sensitivities:

■ 0.5 µS/cm

■ 10 µS/cm

Press button twice briefly to activate

the line editing mode.

Use buttons and to toggle between

the two settings.

40

twice briefly

flashing

twice briefly

Page 41

Basic Settings – continued –

Adjusting sensitivity of response – continued –

Press button briefly.

In our example the response sensitivity

0.5 µS/cm has been selected.

Press button three times briefly to save

the setting and return to the main window.

flashing

briefly

3 times briefly

41

Page 42

Basic Settings – continued –

Setting relay delay times

The split-screen window shows which

GESTRA bus devices can be indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Before commissioning the installation set

the relay delay times for the individual

switchpoints.

Note that the relay delay times of the

low-level and high-level limiters are

factory set and

the URB 1.

Press button four times briefly to enter

the window for setting the relay delay times

of the switchpoints.

The symbol stands for relay energizing

delay.

The symbol stands for relay deenergizing delay.

A number, for instance “001” corresponds

to a delay time of 100

“030” corresponds to 3 sec and the max.

value “255” corresponds to 25.5 sec.

cannot be changed with

m

sec. The value

4 times briefly

Press button once briefly to activate

the line editing mode.

Use button or to scroll back and

forth through the lines.

42

once briefly

Page 43

Basic Settings – continued –

Setting relay delay times – continued –

Press button once briefly to activate the

line editing mode.

Press button once briefly.

Press button to move to the next digit in

the same line.

flashing

once briefly

flashing

once briefly

Press button once briefly.

In our example the digit “2” has been

selected.

flashing

once briefly

43

Page 44

Basic Settings – continued –

Setting relay delay times – continued –

Press button twice briefly to deactivate

the line editing mode.

In our example the relay delay time for the

M

AX switchpoint of the NRR 2-40 is 2 sec.

Press button once briefly.

Switchpoint 2 and switchpoint 3 of the

NRR 2-40 mark the upper and lower limit

of the proportional band. The relay

energizing and de-energizing delays

cannot be adjusted and feature the

number “000”.

The relay delay times of all other

switchpoints can be adjusted as described

above.

twice briefly

once briefly

Press button twice briefly to save the

settings and return to the main window.

44

twice briefly

Page 45

Basic Settings – continued –

Adjusting conductivity controller

The split-screen main window shows

which GESTRA bus devices can be

indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Press button twice briefly to enter the

parameterisation mode for the following

settings:

■ µS/cm or ppm

■ Indicating range of actual value graphics

■ Max. conductivity

■ Setpoint

■ Min. conductivity

Press button twice briefly to activate

the line editing mode.

Use button or to scroll back and

forth through the lines.

twice briefly

flashing

twice briefly

45

Page 46

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to select the

desired unit of measurement (here: ppm).

Press button once briefly to deactivate

the line editing mode.

All conductivity values metered will now be

indicated in [ppm].

flashing

once briefly

once briefly

Press button once briefly.

In this line you can calibrate the graphical

representation (bar chart) of the

conductivity value shown in the main

window. This setting will also calibrate the

actual value output (4 - 20 mA).

First ascertain the conductivity measuring

range used in your installation

(e. g. 0.5 µS/cm up to 20 µS/cm).

Press button once briefly to activate the line

editing mode.

You can choose between the following ranges:

■ 0.5 to 20 µS/cm ■ 0.5 to 1000 µS/cm

■ 0.5 to 100 µS/cm ■ 0.5 to 2000 µS/cm

■ 0.5 to 200 µS/cm ■ 0.5 to 6000 µS/cm

■ 0.5 to 500 µS/cm ■ 0.5 to 12000 µS/cm

46

once briefly

flashing

once briefly

Page 47

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button seven times briefly to

select the range 0.5 to 20 µS/cm.

Press button once briefly to deactivate

the line editing mode.

flashing

7 times briefly

once briefly

Press button once briefly to enter the

line where the conductivity setpoint of the

LRR 1-40 can be adjusted.

Press button once briefly to activate the line

editing mode.

once briefly

flashing

once briefly

47

Page 48

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to move the

cursor one step further.

Press button twice briefly to select the

digit “3”.

flashing

once briefly

flashing

twice briefly

Press button five times briefly.

In our example a conductivity setpoint of

3000 µS/cm has been adjusted.

Press button once briefly to enter the line where

the M

IN conductivity limit of the LRR 1-40 can be

adjusted.

The M

IN switchpoint of the LRR 1-40 can be

adjusted in the same way as the conductivity

setpoint.

48

5 times briefly

once briefly

Page 49

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to enter the

line where the M

LRR 1-40 can be adjusted.

The M

AX switchpoint of the LRR 1-40 can

be adjusted in the same way as the

conductivity setpoint.

Press button once briefly to deactivate

the line editing mode.

AX conductivity limit of the

once briefly

once briefly

Press button once briefly to enter the

parameterisation window for the following

settings:

■ Proportional band X

■ Control hysteresis

■ 24 h purging pulse for continuous

p

blowdown valve

■ Operating position of intermittent

blowdown valve

■ Relay contact 4 / automatic intermittent

boiler blowdown

Press button twice briefly to activate the line

editing mode.

In this line you can set the proportional band X

X

= 0: Two-position (on-off) control

p

X

> 0: Modulating control

p

once briefly

.

p

flashing

twice briefly

49

Page 50

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to move the

cursor one step further.

Press button twice briefly to select the

digit “2”.

flashing

once briefly

flashing

twice briefly

Press button twice briefly.

In our example the proportional band X

p

was set to 20 %.

Press button once briefly to enter the line where

the control hysteresis of the LRR 1-40 can be

adjusted.

The hysteresis can be adjusted within a range of

0 % – 25 %.

The control hysteresis of the LRR 1-40 can be

adjusted the same way as the proportional

band X

If X

.

p

> 0 this function is deactivated.

p

50

twice briefly

once briefly

Page 51

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to enter the

line where the 24 h purging pulse for the

continuous blowdown valve can be

adjusted.

Use buttons and to enable or,

respectively, disable the 24 h purging

pulse.

Press button once briefly to enter the

line where the operating position of the

continuous blowdown valve can be

changed.

once briefly

once briefly

Press button once briefly to enter the window

where the operating position and the feedback

potentiometer of the continuous blowdown valve

can be adjusted.

If X

> 0 the operating position setting

p

is deactivated.

The window shows also the reference values

(in %) as indicated by the scale of the GESTRA

continuous blowdown valve BAE (000 = 0 %, 035

= 35 %) and the current position of the continuous

blowdown valve (in %).

Press button twice briefly to activate the line

editing mode.

Use button or to change the values of the

digits. Press to go to the next digit.

The value 008 corresponds to an opening

position of 8 %. (Max. opening position 25 %)

once briefly

flashing

twice briefly

51

Page 52

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly.

The value 008 = 8

now selected.

Press button once briefly.

In this line you can establish the 0

value of the feedback potentiometer of the

continuous blowdown valve.

% operating position is

%

once briefly

once briefly

Press button once briefly to activate the

line editing mode.

Press and hold down button until the continuous

blowdown valve is closed.

52

flashing

once briefly

flashing

hold down

Page 53

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly.

The current resistance value of the

feedback potentiometer is saved as

0% position (valve CLOSED).

Press button once briefly to activate the

100% adjustment position.

once briefly

once briefly

Press button once briefly to activate the

line editing mode.

Press and hold down button until the

continuous blowdown valve is completely open.

flashing

blinkt

flashing

blinkt

flashing

once briefly

hold down

53

Page 54

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly.

The current resistance value of the

feedback potentiometer is now saved as

100% position (valve OPEN).

Press button three times briefly.

once briefly

3 times briefly

Press button once to activate the line

selection mode.

Press button four times briefly.

In this line you can decide whether you want

to use relay contact 4 (LRR 1-40) for MIN

alarm or for automatic intermittent boiler

blowdown.

The relay contact 4 of the LRR 1-40 is located

across terminals „28“, „29“ and „30“.

Please observe the wiring diagram of the

LRR 1-40.

54

once briefly

4 times briefly

Page 55

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to activate the line

editing mode.

Press button once briefly to activate relay

contact 4 for establishing MIN alarm.

The relay contact 4 of the LRR 1-40 is

located across terminals „28“, „29“ und „30“.

Please observe the wiring diagram of the

LRR 1-40.

flashing

once briefly

flashing

once briefly

Press button once briefly to activate the

automatic intermittent blowdown function.

Press button once briefly to enter the

window where the following parameters

can be set:

■ Frequency of the intermittent blowdown

(in hours)

■ Duration of the intermittent blowdown

(in seconds)

flashing

once briefly

once briefly

55

Page 56

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly to activate the line

selection mode.

The frequency of the intermittent blowdown can

be adjusted in the line editing mode in the same

way as the proportional band X

.

p

once briefly

56

Page 57

Basic Settings – continued –

Adjusting conductivity controller – continued –

Press button once briefly.

The duration of the intermittent

blowdown can be adjusted in the line

editing mode in the same way as the

proportional band X

In our example the blowdown frequency

was set to 1 hour and the blowdown

duration to 1 second.

Press button twice briefly to accept the

configuration.

.

p

once briefly

twice briefly

Press button once briefly to return to

the main window.

once briefly

57

Page 58

Basic Settings – continued –

Adjusting LIN (linear) temperature compensation

The split-screen main window shows

which GESTRA bus devices can be

indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Press button four times briefly to enter the

window where the following parameters can

be set:

■ Linear temperature compensation [% / °C]

■ Recording a temperature curve

■ Cell constant C of the conductivity

electrode

The factory set default setting is “TK:LIN”.

Press button once briefly to activate

the line editing mode.

58

4 times briefly

once briefly

Page 59

Basic Settings – continued –

Adjusting LIN (linear) temperature compensation – continued –

Press button once briefly to enter the line

where the linear temperature compensation

[% /°C] can be adjusted.

The factory set gradient 2.1 [%/ °C] is

normally used for steam boilers operating

with constant pressure.

When the boiler is at full working pressure

compare the indicated value with the reading

of a calibrated conductivity meter – the two

values must tally.

Press button once briefly to activate the

line editing mode.

If the reading of the calibrated conductivity

meter does not tally the value indicated by

the URB 1 the compensation gradient has

to be changed until the two values agree.

Example: With a gradient of 1.9 %/ °C the

two readings tally.

flashing

once briefly

once briefly

Press button once briefly to select the

digit “1”.

Press button once briefly to move

the cursor one step further.

flashing

once briefly

flashing

once briefly

59

Page 60

Basic Settings – continued –

Adjusting LIN (linear) temperature compensation – continued –

Press button twice briefly to select the

digit “9”.

flashing

Press button once briefly to accept the

configuration.

In our example a gradient of 1.9 %/ °C was

adjusted.

twice briefly

once briefly

Press button twice briefly to return to

the main window.

60

twice briefly

Page 61

Basic Settings – continued –

Adjusting NORM (standard curve) temperature compensation

The split-screen main window shows

which GESTRA bus devices can be

indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Press button four times briefly.

The NORM (standard curve) temperature compen-

sation is suitable for steam boilers operating with

variable pressures, which means that the steam

boilers do not feature fixed working pressures/

temperatures (e. g. low load 10 bar, peak load 15 bar).

The standard curves of 11 feedwater conditioning

agents with different conductivities compensate the

thermal influences of the measurement within the

rated operating range. In our example we have started

from the factory set “TK:LIN” mode.

4 times briefly

Press button twice briefly to activate the

line editing mode.

flashing

twice briefly

61

Page 62

Basic Settings – continued –

Adjusting NORM (standard curve) temperature compensation – continued –

Press button twice briefly to select the

function NORM.

The function NORM allows the retrieval of

11 different standard curves stored in the

URB 1. The curves are applicable for different

feedwater conditioning agents with different

basic conductivities.

For more information see Annex (page 77).

Press button once briefly to activate the

line editing mode.

In this window the following parameters can

be set:

Standard curve temperature compensation

[% /°C]

Recording/adding a temperature curve

Cell constant of the conductivity electrode

Our example shows the factory setting “00”,

which means that no standard curve has

been selected and activated.

flashing

twice briefly

once briefly

Press button once briefly to enter the

line where you can select a standard curve.

For more information see Annex (page 77).

Press button once briefly to activate the

line editing mode.

62

once briefly

flashing

once briefly

Page 63

Basic Settings – continued –

Adjusting NORM (standard curve) temperature compensation – continued –

Press button once briefly to move the

cursor one step further.

flashing

Press button once briefly to select

the digit “1”.

flashing

once briefly

once briefly

Press button once briefly to accept the

configuration.

The standard curve “01” is now active.

The temperature values of the standard

curve “01” are based on the conditioning

agent caustic soda with a basic conductivity

of 260 µS/cm at 25°C.

For more information see Annex (page 77).

Press button once briefly to enter the line where

you can start recording the temperature/

conductivity curve that is characteristic of your

steam boiler.

The temp./conductivity values recorded by the

system cover the whole room temp. to service

temp. range.

In case of variable pressure operation we

recommend that you also record the AUTO curve.

If the standard curves are not suitable you can then

still use the AUTO curve.

once briefly

once briefly

63

Page 64

Basic Settings – continued –

Adjusting NORM (standard curve) temperature compensation – continued –

Press button once briefly to activate the

line editing mode.

flashing

once briefly

Press button once briefly to select the

function “start”.

flashing

once briefly

Press button once briefly to finish the

configuration.

Raise temp./ pressure until the steam boiler

settles at full working pressure (in case of

variable pressure operation until the highest

operating pressure is reached).

The LRR 1-40 will now record the

temperature/conductivity values and saves

them as AUTO curve in the URB 1.

The number of recorded temp./conductivity

values is indicated in the line “Temp.”.

Press button once briefly.

The recording of the AUTO curve is

finished once the steam boiler has

reached its working pressure.

In our example 15 temp./conductivity

values were recorded. A temperature of

181.7 °C was detected at the measuring

point of the conductivity electrode

LRG 16-40, which corresponds to a boiler

pressure of 10.3 bar.

64

once briefly

flashing

once briefly

Page 65

Basic Settings – continued –

Adjusting NORM (standard curve) temperature compensation – continued –

Press button twice briefly to select

the function “Stop”.

The recording of the temperature/

conductivity values is now finished.

The boiler specific AUTO curve can be

activated on the display “TK:AUTO”.

For more information see page 77.

Press button three times briefly to

return to the main window.

flashing

once briefly

3 times briefly

65

Page 66

Basic Settings – continued –

Enabling AUTO temperature compensation

The split-screen main window shows

which GESTRA bus devices can be

indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Press button four times briefly.

The AUTO curve temperature compensation is

suitable for steam boilers operating with variable

pressures, which means that the steam boilers do

not feature fixed working pressures/temperatures

(e. g. low load 10 bar, peak load 15 bar).

The procedure for recording an AUTO curve is

described on pages 63 to 65.

In our example we have started from the setting

“TK:NORM”.

4 times briefly

Press button twice briefly to activate

the line editing mode.

66

flashing

twice briefly

Page 67

Basic Settings – continued –

Enabling AUTO temperature compensation – continued –

Press button once briefly to select the

function “Auto”.

flashing

Press button once briefly to finish the

configuration.

In our example we have activated an AUTO curve

with 15 temp./conductivity values which has been

recorded and stored in the URB 1.

A new AUTO curve can always be recorded which

will then overwrite the old one.

The procedure of recording an AUTO curve has

been described on pages 63 to 65.

once briefly

once briefly

Press button once briefly to return to

the main window.

once briefly

67

Page 68

Basic Settings – continued –

Disabling temperature compensation

The split-screen main window shows

which GESTRA bus devices can be

indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Press button four times briefly.

Some industrial applications may require

disabling the temperature compensation. Note

that with this mode all conductivity values

displayed by the URB 1 are absolute

readings of the current conductivity.

In our example we start from the factory set

“TK:LIN” mode.

Press button twice briefly to activate

the line editing mode.

68

4 times briefly

flashing

twice briefly

Page 69

Basic Settings – continued –

Disabling temperature compensation – continued –

Press button three times briefly to

select the function “OFF”.

Press button once briefly to save settings and

finish the configuration.

The temperature compensation is now disabled.

flashing

3 times briefly

once briefly

Press button once briefly to return to

the main window.

once briefly

69

Page 70

Operation

Manual operation via external control valve

The split-screen main window shows which

GESTRA bus devices can be indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Press button briefly to enter the display

window of the level controller NRR 2-40.

Press button briefly to activate the

manual mode.

Use buttons and in this mode to

manually open and close an external

control valve.

Press button a second time to disable

the manual mode and to move the control

valve back into the position dictated by the

controller NRR 2-40.

70

briefly

briefly

Page 71

Operation – continued –

Stand-by operation with the steam boiler disconnected

The split-screen main window shows which

GESTRA bus devices can be indicated:

■ High-level limiter NRS 1-41

■ Low-level limiter NRS 1-40

■ Level switch NRS 2-40

■ Level controller NRR 2-40

■ Conductivity controller LRR 1-40

Use an external switch to enable the stand-by

mode of the conductivity control.

After switching off the burner of the steam boiler

you can deactivate the control of the continuous

and intermittent blowdown valves in order to avoid

loss of boiler water (stand-by operation).

After returning to normal operation the continuous

blowdown valve moves into the control position

and an intermittent blowdown pulse is given

(if activated).

Please take the wiring diagram of the

installation manual for the LRR 1-40 into

consideration.

71

Page 72

System Malfunctions

Troubleshooting

The sources of malfunctions occurring in CAN bus systems operating with several busbased stations must be analysed systematically since faulty components or incorrect

settings can give rise to negative interactions with intact bus devices in the CAN bus

system. These unwanted interactions can cause error messages in fully functional bus

devices, which will make fault detection even more difficult.

We recommend the following systematic fault location procedure:

Step 1 (Start)

Detach terminal strips

in all sensing units of

bus devices.

Level electrode

Conductivity

electrode

Pressure sensor

Temperature sensor

Check

Use fault-finding list

to correct fault(s).

Final test: have all

faults been

eliminated?

System

Malfunction

Use fault-finding list

to identify the fault(s).

Cut off power supply

to the equipment.

72

Step 2

Plug in terminal strip

of the sensing unit of

one system, e. g.

NRS ...

and

NRG ... (sensor).

Step 3

Apply mains voltage

to bus devices of the

system e. g.

NRS ...

and

NRG ...

System O.K.

Detach terminal strips

between bus devices

of the sytem e. g.

NRS ...

and

NRG ...

Page 73

System Malfunctions – continued –

Fault Finding List

The data communication in the CAN

bus line is disrupted.

Check that the CAN bus line has been

wired according to the wiring diagram.

Check that the CAN bus line is not

interrupted due to conductor breakage.

Check that the controllers and

electrodes feature the correct node IDs.

The thermal fuse of one of the level

electrodes has been triggered.

Check that the level electrode has been

mounted as specified in the installation

manual.

Check whether external influences

have caused built-up of heat in the

electrode casing.

flashing flashing

5 times briefly

The thermal fuse of the conductivity

electrode has been triggered.

Check that the conductivity electrode

has been mounted as specified in the

installation manual.

Check whether external influences

have caused built-up of heat in the

electrode casing.

The conductivity electrode is

defective.

The temperature sensor of the

conductivity electrode is short circuited

or interrupted.

Replace conductivity electrode

LRG 16-40.

5 times briefly

5 times briefly

73

Page 74

System Malfunctions – continued –

Fault Finding List – continued –

The conductivity electrode is

defective.

The internal connecting cables of the

conductivity electrode are short

circuited or interrupted.

Replace conductivity electrode

LRG 16-40.

The CAN bus communication of a

controller is disrupted.

Check that the controller and the level

or conductivity electrode have been

mounted as specified in the wiring

diagram.

In our example there is a disruption in

the CAN bus communication of the lowwater level electrode 2 type NRG 16-40.

5 times briefly

once briefly

The CAN bus communication of a

controller is disrupted.

Check that the controller and the level

or conductivity electrode have been

mounted as specified in the wiring

diagram.

In our example there is a disruption in

the CAN bus communication of the

switching controller type NRS 1-40.

If faults occur that are not listed

above, please contact our subsidiary

or agency in your country.

74

once briefly

Page 75

Annex

Establishing / changing node ID

If several systems of the same kind are to communicate in one CAN bus network

establish one node ID for each individual system (e. g. controller).

Factory set node IDs

Controller

The individual node IDs must be adjusted manually on the respective devices.

Please observe the relevant installation instructions.

Attention

■ Do not assign the same node ID twice within the CAN bus network.

Electrode

75

Page 76

Annex – continued –

Fig. 5 Rear panel of the URB 1

76

S8

OFF

ON

OFF

ON

OFF

ON

Fig. 6 Default factory setting 250 kBit/s

S9 S0

OFF

ON

ON

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

Baud rate

250 kBit/s

125 kBit/s

100 kBit/s

50 kBit/s

20 kBit/s

10 kBit/s

Cable length

125 m

250 m

335 m

500 m

1000 m

1000 m

Page 77

Annex – continued –

Table: Standard Curves

.oNtnegagninoitidnoCC°52ta]mc/Sm[ytivitcudnoccisaB

1adoscitsuaC062

2adoscitsuaC0801

3adoscitsuaC0045

4adoscitsuaC00011

5etahpsohpmuidosirT091

6etahpsohpmuidosirT0011

7etahpsohpmuidosirT0095

8etahpsohpmuidosirT00211

9etiflusmuidoS089

01444euqilopiD002

11nixoveL591

77

Page 78

Annex – continued –

Declaration of conformity

We hereby declare that the equipment URB 1 conforms to the following European

guidelines:

■ LV directive 73/23/eec version 93/68/eec

■ EMC guideline 89/336/eec version 93/68/eec

which are based on the following harmonised standards:

■ LV standard EN 50178

■ EMC standard EN 50081-2, EN 50082-2

This declaration is no longer valid if modifications are made to the equipment without

consultation with us.

Bremen, 23rd May 2002

GESTRA GmbH

Dipl.-Ing. Stefan Bode

(Academically qualified engineer)

Head of R & D Dept. Electronics

Key

Fixing screw for panel mounting

A

Dipl.-Ing. Lars Bohl

(Academically qualified engineer)

Quality Assurance Manager

78

Page 79

Example of Installation

95

A

63

Fig. 7

95

79

Page 80

GESTRA Gesellschaften · GESTRA Companies · Sociétés GESTRA · Sociedades Gestra · Società GESTRA

Vertretungen weltweit · Agencies all over the world · Représentations dans le monde entier · Representaciones en todo el mundo · Agenzie in tutto il mondo

Great Britain

Flowserve Flow Control (UK) Ltd.

Burrel Road, Haywards Heath

West Sussex RH 16 1TL

Tel. 00 44 14 44 / 31 44 00

Fax 00 44 14 44 / 31 45 57

E-mail: sales@flowserve.com

France

Flowserve Flow Control S. A.S.

10 Avenue du Centaure, BP 8263

F-95801 CERGY PONTOISE CEDEX

Tél. 00.33.1 / 34 4326 60

Fax 00.33.1 / 34 43 26 87

E-mail: contact@gestra.fr

España

GESTRA ESPAÑOLA S.A.

Luis Cabrera, 86-88

E-28002 Madrid

Tel. 00 34 91/ 5 152 032

Fax 003491/4136747; 5152036

E-mail: gestra@gestra.es

Italia

Flowserve S.p. A

Divisione Italgestra

Via Prealpi, 30 – 20032 Cormano (MI)

Tel. 00 39 02 /66 3251

Fax 0039 02 / 66 32 55 60

E-mail: info@italgestra.it

Portugal

Flowserve Portuguesa, Lda.

Av. Dr. Antunes Guimarães, 1159

Porto 4100-082

Tel. 0035122/6198770

Fax 00351 22 / 61075 75

E-mail: gestra@gestra.pt

®

GESTRA GmbH

Postfach 10 54 60, D-28054 Bremen, Münchener Str. 77, D-28215 Bremen

Telefon +49 (0) 421 35 03- 0, Telefax +49 (0) 421 35 03- 393

E-Mail gestra.gmbh@flowserve.com, Internet www.gestra.de

A Unit of Flowserve Corporation

810375-03/304 · © 2002 GESTRA GmbH · Bremen · Printed in Germany

80

Loading...

Loading...