Page 1

USER INSTRUCTIONS

R and RX

Centrifugal Rubber Lined Slurry Pump

PCN = 71569242 03-11(E) (incorporating 2162-EID)

Original instructions

Installation

Operation

Maintenance

These instructions must be read prior to installing,

operating, using, and maintaining this equipment.

Page 2

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

CONTENTS

PAGE

1 INTRODUCTION AND SAFETY ............................ 4

1.1 General ............................................................ 4

1.2 CE marking and approvals ............................... 4

1.3 Disclaimer ........................................................ 4

1.4 Copyright .......................................................... 4

1.5 Duty conditions ................................................. 4

1.6 Safety ............................................................... 5

1.7 Safety labels summary ..................................... 9

1.8 Specific machine performance ...................... 10

1 9 Noise level ..................................................... 10

2 TRANSPORT AND STORAGE ........................... 11

2.1 Consignment receipt and unpacking .............. 11

2.2 Handling ......................................................... 11

2.3 Lifting .............................................................. 11

2.4 Storage .......................................................... 11

2.5 Recycling and end of product life ................... 12

3 PUMP DESCRIPTION ......................................... 12

3.1 Configurations ................................................ 12

3.2 Name nomenclature ....................................... 12

3.3 Design of major parts .................................... 12

3.4 Performance and operating limits .................. 13

3.5 Materials Of Construction .............................. 14

3.6 Tables of Engineering Data ........................... 15

4 INSTALLATION .................................................... 19

4.1 Location .......................................................... 19

4.2 Part assemblies .............................................. 19

4.3 Foundation ..................................................... 19

4.4 Baseplate installation ..................................... 19

4.5 Initial alignment .............................................. 20

4.6 Grouting ......................................................... 22

4.7 Piping ............................................................. 22

4.8 Final shaft alignment check ........................... 26

4.9 Electrical connections .................................... 26

4.10 Protection systems ....................................... 27

PAGE

6 MAINTENANCE ................................................... 32

6.1 General ........................................................... 32

6.2 Maintenance schedule .................................... 32

6.3 Spare parts ..................................................... 34

6.4 Recommended spares and consumable items34

6.5 Tools required ................................................. 34

6.6 Fastener torques ............................................ 35

6.7 Renewal clearances ....................................... 35

6.8 Disassembly ................................................... 35

6.9 Examination of parts ..................................... 37

6.10 Assembly ...................................................... 37

6.11 Impeller axial clearance adjustment ............. 44

6.12 Liner Mismatch ............................................. 46

7 FAULTS; CAUSES AND REMEDIES ................... 47

8 PARTS LIST AND DRAWINGS ............................ 49

8.1 Frame 0 – 1.25R090 ....................................... 49

8.2 R Pump - Frames 1&2 .................................... 50

8.3 RX - Frames 1&2 ............................................ 51

8.4 R pump - Frame 3&4 ...................................... 52

8.6 General arrangement drawing ........................ 54

9 CERTIFICATION ................................................... 54

10 OTHER RELEVANT DOCUMENTATION AND

MANUALS ........................................................ 54

10.1 Supplementary User Instruction manuals .... 54

10.2 Change notes ............................................... 54

10.3 Additional sources of information ................. 54

5 COMMISSIONING, START-UP, OPERATION AND

SHUTDOWN .................................................... 27

5.1 Pre-commissioning procedure ....................... 27

5.2 Pump lubricants ............................................. 28

5.3 Direction of rotation ........................................ 29

5.4 Guarding ........................................................ 29

5.5 Priming and auxiliary supplies ....................... 29

5.6 Starting the pump ........................................... 29

5.7 Operating the pump ....................................... 30

5.8 Stopping and shutdown ................................. 31

5.9 Hydraulic, mechanical and electrical duty ...... 31

Page 2 of 54

Page 3

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

INDEX

PAGE

Alignment of shafting (see 4.5, 4.7 and 4.3) ............ 20

CE marking and approvals (1.2) ................................ 3

Clearances (see 6.7, Renewal clearances) ............. 34

Clearance setting (6.11) .......................................... 43

Commissioning and operation (see 5) ..................... 27

Configurations (3.1) ................................................. 12

Direction of rotation (5.3) ......................................... 29

Dismantling (see 6.8, Disassembly) ........................ 35

Duty conditions (1.5) .................................................. 3

Electrical connections (4.8) ..................................... 15

Examination of parts (6.9)........................................ 25

Faults; causes and remedies ................................... 47

General assembly drawings (see 8) ........................ 49

Grouting (4.4) ........................................................... 21

Guarding (5.4) .......................................................... 29

Handling (2.2) ............................................................ 9

Hydraulic, mechanical and electrical duty (5.9) ....... 31

Lifting (2.3) ............................................................... 11

Location (4.1) ........................................................... 21

Lubrication schedule (see 5.2, Pump lubricants) .... 28

Maintenance schedule (6.2) .................................... 32

Piping (4.7) .............................................................. 22

Priming and auxiliary supplies (5.5) ......................... 29

Reassembly (see 6.10, Assembly) .......................... 37

Replacement parts (see 6.3 and 6.4) ...................... 32

Safety, electrical (see 4.9) ....................................... 26

Safety, protection systems (see 1.6) ......................... 5

Sound level (see 1.9, Noise level) ............................. 8

Specific machine performance (1.8) .......................... 8

Starting the pump (5.6) ............................................ 29

Stopping and shutdown (5.8) ................................... 31

Storage (2.4) .............................................................. 9

Supplementary manuals or information sources ..... 54

Tools required (6.5) ................................................. 34

Torques for fasteners (6.6) ...................................... 34

Page 3 of 54

Page 4

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

1 INTRODUCTION AND SAFETY

1.1 General

These instructions must always be kept close

to the product's operating location or directly with

the product.

Flowserve products are designed, developed and

manufactured with state-of-the-art technologies in

modern facilities. The unit is produced with great care

and commitment to continuous quality control, utilizing

sophisticated quality techniques, and safety

requirements.

Flowserve is committed to continuous quality

improvement and being at service for any further

information about the product in its installation and

operation or about its support products, repair and

diagnostic services.

These instructions are intended to facilitate

familiarization with the product and its permitted use.

Operating the product in compliance with these

instructions is important to help ensure reliability in

service and avoid risks. The instructions may not take

into account local regulations; ensure such regulations

are observed by all, including those installing the

product. Always coordinate repair activity with

operations personnel, and follow all plant safety

requirements and applicable safety and health laws

and regulations.

These instructions must be read prior to

installing, operating, using and maintaining the

equipment in any region worldwide. The

equipment must not be put into service until all the

conditions relating to safety noted in the

instructions, have been met. Failure to follow and

apply the present user instructions is considered to

be misuse. Personal injury, product damage, delay

or failure caused by misuse are not covered by the

Flowserve warranty.

1.2 CE marking and approvals

It is a legal requirement that machinery and equipment put

into service within certain regions of the world shall

conform with the applicable CE Marking Directives

covering Machinery and, where applicable, Low Voltage

Equipment, Electromagnetic Compatibility (EMC),

Pressure Equipment Directive (PED) and Equipment for

Potentially Explosive Atmospheres (ATEX).

Where applicable the Directives and any additional

Approvals cover important safety aspects relating to

machinery and equipment and the satisfactory provision

of technical documents and safety instructions. Where

applicable this document incorporates information

relevant to these Directives and Approvals.

To confirm the Approvals applying and if the product is CE

marked, check the serial number plate markings and the

Certification. (See section 9, Certification.)

1.3 Disclaimer

Information in these User Instructions is believed

to be complete and reliable. However, in spite of all

of the efforts of Flowserve Corporation to provide

comprehensive instructions, good engineering and

safety practice should always be used.

Flowserve manufactures products to exacting

International Quality Management System Standards as

certified and audited by external Quality Assurance

organizations. Genuine parts and accessories have been

designed, tested and incorporated into the products to

help ensure their continued product quality and

performance in use. As Flowserve cannot test parts and

accessories sourced from other vendors the incorrect

incorporation of such parts and accessories may

adversely affect the performance and safety features of

the products. The failure to properly select, install or use

authorized Flowserve parts and accessories is considered

to be misuse. Damage or failure caused by misuse is not

covered by the Flowserve warranty. In addition, any

modification of Flowserve products or removal of original

components may impair the safety of these products in

their use.

1.4 Copyright

All rights reserved. No part of these instructions may

be reproduced, stored in a retrieval system or

transmitted in any form or by any means without prior

permission of Flowserve.

1.5 Duty conditions

This product has been selected to meet the

specifications of your purchaser order. The

acknowledgement of these conditions has been sent

separately to the Purchaser. A copy should be kept

with these instructions.

The product must not be operated beyond the

parameters specified for the application. If there is

any doubt as to the suitability of the product for the

application intended, contact Flowserve for advice,

quoting the serial number.

If the conditions of service on your purchase order are

going to be changed (for example liquid pumped,

Page 4 of 54

Page 5

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

temperature or duty) it is requested that the user seeks

the written agreement of Flowserve before start up.

1.6 Safety

1.6.1 Summary of safety markings

These User Instructions contain specific safety markings

where non-observance of an instruction would cause

hazards. The specific safety markings are:

This symbol indicates electrical safety

instructions where non-compliance will involve a high

risk to personal safety or the loss of life.

This symbol indicates safety instructions where

non-compliance would affect personal safety and could

result in loss of life.

This symbol indicates “hazardous and toxic fluid”

safety instructions where non-compliance would affect

personal safety and could result in loss of life.

This symbol indicates safety instructions

where non-compliance will involve some risk to safe

operation and personal safety and would damage the

equipment or property.

This symbol indicates explosive atmosphere

zone marking according to ATEX. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This symbol is used in safety instructions to

remind not to rub non-metallic surfaces with a dry cloth;

ensure the cloth is damp. It is used in safety

instructions where non-compliance in the hazardous

area would cause the risk of an explosion.

This sign is not a safety symbol but indicates an

important instruction in the assembly process.

1.6.2 Personnel qualification and training

All personnel involved in the operation, installation,

inspection and maintenance of the unit must be

qualified to carry out the work involved. If the

personnel in question do not already possess the

necessary knowledge and skill, appropriate training and

instruction must be provided. If required the operator

may commission the manufacturer/supplier to provide

applicable training.

Always coordinate repair activity with operations and

health and safety personnel, and follow all plant safety

requirements and applicable safety and health laws

and regulations.

1.6.3 Safety action

This is a summary of conditions and actions to

prevent injury to personnel and damage to the

environment and to equipment. For products used

in potentially explosive atmospheres section 1.6.4

also applies.

NEVER DO MAINTENANCE WORK

WHEN THE UNIT IS CONNECTED TO POWER

GUARDS MUST NOT BE REMOVED WHILE

THE PUMP IS OPERATIONAL

DRAIN THE PUMP AND ISOLATE PIPEWORK

BEFORE DISMANTLING THE PUMP

The appropriate safety precautions should be taken

where the pumped liquids are hazardous.

FLUORO-ELASTOMERS (When fitted.)

When a pump has experienced temperatures over

250 ºC (482 ºF), partial decomposition of fluoroelastomers (example: Viton) will occur. In this condition

these are extremely dangerous and skin contact must

be avoided.

HANDLING COMPONENTS

Many precision parts have sharp corners and the

wearing of appropriate safety gloves and equipment is

required when handling these components. To lift

heavy pieces above 25 kg (55 lb) use a crane

appropriate for the mass and in accordance with

current local regulations.

APPLYING HEAT TO REMOVE IMPELLER

There may be occasions when the impeller has either

been shrunk fit on to the pump shaft or has become

difficult to remove due to products of corrosion.

If you elect to use heat to remove the impeller, it must

be applied quickly to the impeller boss. TAKE GREAT

CARE!

Before applying heat ensure any residual hazardous

liquid trapped between the impeller and pump shaft is

thoroughly drained out through the impeller keyway to

prevent an explosion or emission of toxic vapour. This

must be carried out with the shaft in the vertical

position. On some pump sizes a cavity exists in the

impeller bore so on occasions a significant volume of

liquid may drain out.

THERMAL SHOCK

Rapid changes in the temperature of the liquid within

the pump can cause thermal shock, which can result in

damage or breakage of components and should be

avoided.

Page 5 of 54

Page 6

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

HOT (and cold) PARTS

If hot or freezing components or auxiliary heating

supplies can present a danger to operators and

persons entering the immediate area action must be

taken to avoid accidental contact. If complete

protection is not possible, the machine access must be

limited to maintenance staff only, with clear visual

warnings and indicators to those entering the

immediate area. Note: bearing housings must not be

insulated and drive motors and bearings may be hot.

If the temperature is greater than 80 ºC (175 ºF) or

below -5 ºC (20 ºF) in a restricted zone, or exceeds

local regulations, action as above shall be taken.

HAZARDOUS LIQUIDS

When the pump is handling hazardous liquids care must

be taken to avoid exposure to the liquid by appropriate

siting of the pump, limiting personnel access and by

operator training. If the liquid is flammable and/or

explosive, strict safety procedures must be applied.

Gland packing must not be used when pumping

hazardous liquids.

PREVENT EXCESSIVE EXTERNAL

PIPE LOAD

Do not use pump as a support for piping. Do not mount

expansion joints, unless allowed by Flowserve in

writing, so that their force, due to internal pressure, acts

on the pump flange.

ENSURE CORRECT LUBRICATION

(See section 5, Commissioning, startup, operation and

shutdown.)

START THE PUMP WITH OUTLET

VALVE PARTLY OPENED

(Unless otherwise instructed at a specific point in the

User Instructions.)

This is recommended to minimize the risk of

overloading and damaging the pump motor at full or

zero flow. Pumps may be started with the valve further

open only on installations where this situation cannot

occur. The pump outlet control valve may need to be

adjusted to comply with the duty following the run-up

process. (See section 5, Commissioning start-up,

operation and shutdown.)

NEVER RUN THE PUMP DRY

INLET VALVES TO BE FULLY OPEN

WHEN PUMP IS RUNNING

Running the pump at zero flow or below the

recommended minimum flow continuously will cause

damage to the pump and mechanical seal.

DO NOT RUN THE PUMP AT

ABNORMALLY HIGH OR LOW FLOW RATES

Operating at a flow rate higher than normal or at a flow

rate with no back pressure on the pump may overload the

motor and cause cavitation. Low flow rates may cause a

reduction in pump/bearing life, overheating of the pump,

instability and cavitation/vibration.

1.6.4 Products used in potentially explosive

atmospheres

Measures are required to:

Avoid excess temperature

Prevent build up of explosive mixtures

Prevent the generation of sparks

Prevent leakages

Maintain the pump to avoid hazard

The following instructions for pumps and pump units when

installed in potentially explosive atmospheres must be

followed to help ensure explosion protection. For ATEX,

both electrical and non-electrical equipment must meet

the requirements of European Directive 94/9/EC. Always

observe the regional legal Ex requirements eg Ex

electrical items outside the EU may be required certified

to other than ATEX eg IECEx, UL.

1.6.4.1 Scope of compliance

Use equipment only in the zone for which it is

appropriate. Always check that the driver, drive coupling

assembly, seal and pump equipment are suitably rated

and/or certified for the classification of the specific

atmosphere in which they are to be installed.

Where Flowserve has supplied only the bare shaft

pump, the Ex rating applies only to the pump. The party

responsible for assembling the ATEX pump set shall

select the coupling, driver and any additional equipment,

with the necessary CE Certificate/ Declaration of

Conformity establishing it is suitable for the area in which

it is to be installed.

The output from a variable frequency drive (VFD) can

cause additional heating affects in the motor and so, for

pumps sets with a VFD, the ATEX Certification for the

motor must state that it is covers the situation where

electrical supply is from the VFD. This particular

requirement still applies even if the VFD is in a safe area.

1.6.4.2 Marking

An example of ATEX equipment marking is shown

below. The actual classification of the pump will be

engraved on the nameplate.

Page 6 of 54

Page 7

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

II 2 GD c IIC 135 ºC (T4)

Equipment Group

I = Mining

II = Non-mining

Category

2 or M2 = high level protection

3 = normal level of protection

Gas and/or dust

G = Gas

D = Dust

c = Constructional safety

(in accordance with EN13463-5)

Gas Group

IIA – Propane (typical)

IIB – Ethylene (typical)

IIC – Hydrogen (typical)

Maximum surface temperature (Temperature Class)

(see section 1.6.4.3.)

1.6.4.3 Avoiding excessive surface temperatures

ENSURE THE EQUIPMENT TEMPERATURE

CLASS IS SUITABLE FOR THE HAZARD ZONE

Pumps have a temperature class as stated in the ATEX

Ex rating on the nameplate. These are based on a

maximum ambient of 40 ºC (104 ºF); refer to Flowserve

for higher ambient temperatures.

The surface temperature on the pump is influenced by

the temperature of the liquid handled. The maximum

permissible liquid temperature depends on the

temperature class and must not exceed the values in

the table that follows.

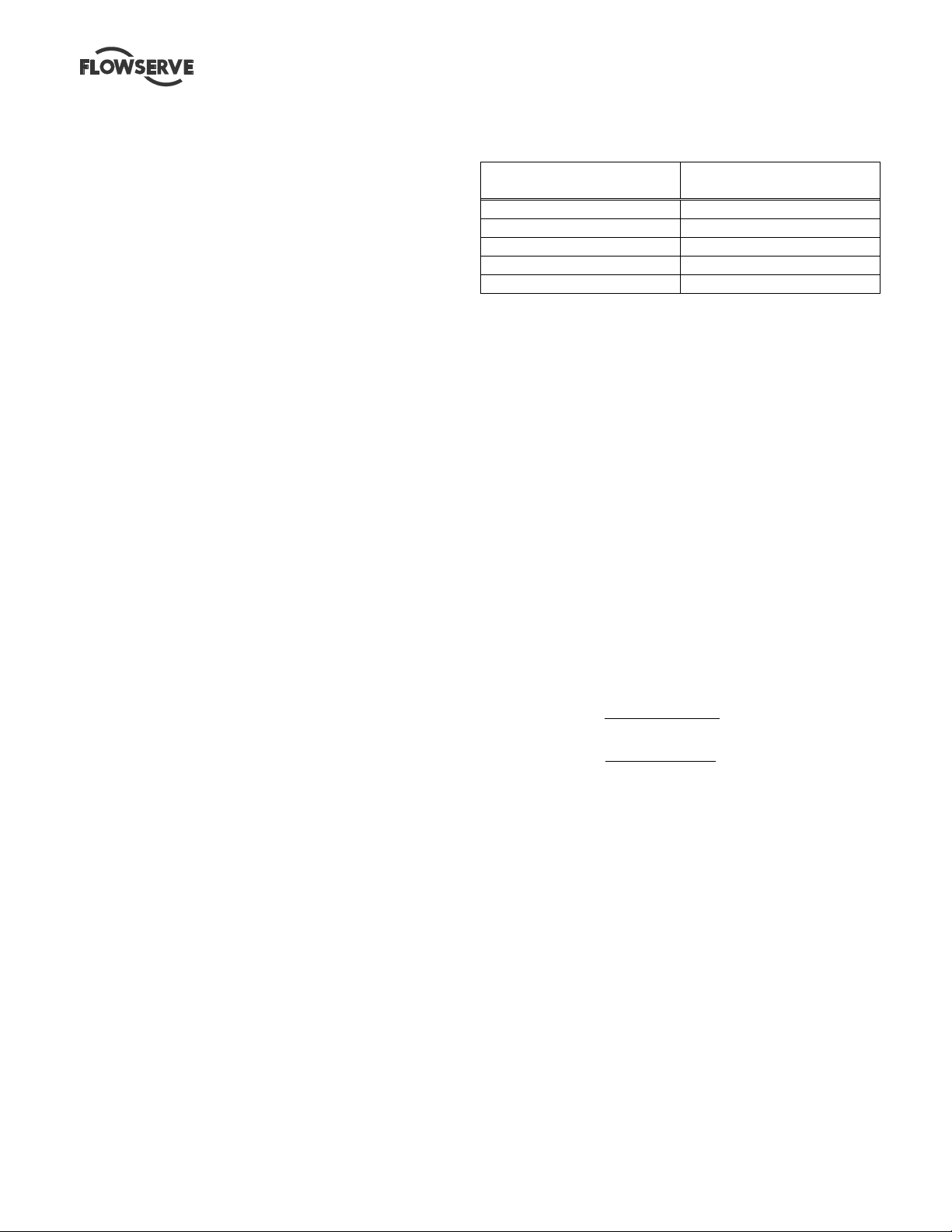

Temperature class

to EN13463-1

T6

T5

T4

T3

T2

T1

* The table only takes the ATEX temperature class into consideration.

Pump design or material, as well as component design or material, may

further limit the maximum working temperature of the liquid.

Maximum surface

temperature permitted

85 °C (185 °F)

100 °C (212 °F)

135 °C (275 °F)

200 °C (392 °F)

300 °C (572 °F)

450 °C (842 °F)

Temperature limit of

liquid handled *

Consult Flowserve

Consult Flowserve

115 °C (239 °F)

180 °C (356 °F)

275 °C (527 °F)

400 °C (752 °F)

The temperature rise at the seals and bearings and due

to the minimum permitted flow rate is taken into

account in the temperatures stated.

The responsibility for compliance with the specified

maximum liquid temperature is with the plant

operator.

Temperature classification “Tx” is used when the liquid

temperature varies and the pump could be installed in

different hazarous atmospheres. In this case the user

is responsible for ensuring that the pump surface

temperature does not exceed that permitted in the

particular hazardous atmosphere.

If an explosive atmosphere exists during the

installation, do not attempt to check the direction of

rotation by starting the pump unfilled. Even a short run

time may give a high temperature resulting from

contact between rotating and stationary components.

Where there is any risk of the pump being run against a

closed valve generating high liquid and casing external

surface temperatures, fit an external surface

temperature protection device.

Avoid mechanical, hydraulic or electrical overload by

using motor overload trips, temperature monitor or a

power monitor and make routine vibration monitoring

checks.

In dirty or dusty environments, make regular checks

and remove dirt from areas around close clearances,

bearing housings and motors.

1.6.4.4 Preventing the build up of explosive

mixtures

ENSURE THE PUMP IS PROPERLY FILLED

AND VENTED AND DOES NOT RUN DRY

Ensure the pump and relevant suction and discharge

pipeline system is totally filled with liquid at all times

during the pump operation, so that an explosive

atmosphere is prevented. In addition it is essential to

make sure that seal chambers, auxiliary shaft seal

systems and any heating and cooling systems are

properly filled.

If the operation of the system cannot avoid this

condition fit an appropriate dry run protection device

(for example liquid detection or a power monitor).

To avoid potential hazards from fugitive emissions of

vapour or gas to atmosphere the surrounding area

must be well ventilated.

1.6.4.5 Preventing sparks

To prevent a potential hazard from mechanical

contact, the coupling guard must be non-sparking.

To avoid the potential hazard from random induced

current generating a spark, the baseplate must be

properly grounded.

Page 7 of 54

Page 8

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

Avoid electrostatic charge: do not rub non-metallic

surfaces with a dry cloth; ensure cloth is damp.

For ATEX application the coupling must be selected to

comply with 94/9/EC. Correct coupling alignment must

be maintained.

Additional requirement for metallic pumps on nonmetallic baseplates

When metallic components are fitted on a non-metallic

baseplate they must be individually earthed.

1.6.4.6 Preventing leakage

The pump must only be used to handle liquids for

which it has been approved to have the correct

corrosion resistance.

Avoid entrapment of liquid in the pump and associated

piping due to closing of suction and discharge valves,

which could cause dangerous excessive pressures to

occur if there is heat input to the liquid. This can occur if

the pump is stationary or running.

Bursting of liquid containing parts due to freezing must

be avoided by draining or protecting the pump and

ancillary systems.

Where there is the potential hazard of a loss of a seal

barrier fluid or external flush, the fluid must be

monitored.

If leakage of liquid to atmosphere can result in a

hazard, install a liquid detection device.

1.6.4.7 Maintenance to avoid the hazard

CORRECT MAINTENANCE IS REQUIRED TO

AVOID POTENTIAL HAZARDS WHICH GIVE A RISK

OF EXPLOSION

The responsibility for compliance with maintenance

instructions is with the plant operator.

To avoid potential explosion hazards during

maintenance, the tools, cleaning and painting materials

used must not give rise to sparking or adversely affect

the ambient conditions. Where there is a risk from

such tools or materials, maintenance must be

conducted in a safe area.

It is recommended that a maintenance plan and

schedule is adopted. (See section 6, Maintenance.)

Page 8 of 54

Page 9

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

1.7 Safety labels summary

1.7.1 Nameplate

For details of nameplate, see the Declaration of Conformity, or separate documentation included with these

User Instructions.

1.7.2 Safety labels

P/N 2113931-001 P/N 2113932-001

MECHANICAL SEAL WARNING ROTATION WARNING

GROUT WARNING LIFTING WARNING

P/N 2113934-001 P/N 9901701-001

LUBRICATION WARNING – QF-440-R01 (2124841)

Oil lubricated units only:

Page 9 of 54

Page 10

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. When the contract requirement specifies

these to be incorporated into User Instructions these

are included here. Where performance data has been

supplied separately to the purchaser these should be

obtained and retained with these User Instructions if

required.

1 9 Noise level

Attention must be given to the exposure of personnel to

the noise, and local legislation will define when

guidance to personnel on noise limitation is required,

and when noise exposure reduction is mandatory. This

is typically 80 to 85 dBA.

The usual approach is to control the exposure time to

the noise or to enclose the machine to reduce emitted

sound. You may have already specified a limiting noise

level when the equipment was ordered, however if no

noise requirements were defined, then attention is

drawn to the following table to give an indication of

equipment noise level so that you can take the

appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipework design and

R and RX Slurry

pump size

Noise Level dBA

(at 1 m (3 ft) reference 20 μPa)

acoustic characteristics of the building, and so the

values given are subject to a 3 dBA tolerance and

cannot be guaranteed.

Similarly the motor noise assumed in the “pump and

motor” noise is that typically expected from standard and

high efficiency motors when on load directly driving the

pump. Note that a motor driven by an inverter may show

an increased noise at some speeds.

If a pump unit only has been purchased for fitting with

your own driver then the “pump only” noise levels in the

table should be combined with the level for the driver

obtained from the supplier. Consult Flowserve or a noise

specialist if assistance is required in combining the values.

It is recommended that where exposure approaches

the prescribed limit, then site noise measurements

should be made.

The values are in sound pressure level L

ft) from the machine, for “free field conditions over a

reflecting plane”.

For estimating sound power level L

add 17 dBA to the sound pressure value.

Pump speed

rpm

Sound Power

Level dBA

at 1 m (3.3

pA

(re 1pW) then

WA

1.25R090 74 2000 88

2.5 R091 75 2250 89

3 R091 75 2250 89

3 R111 77 2000 91

4 R122 80 1780 94

5 R142 80 1600 94

6 R163 81 1350 95

8 R193 82 1180 96

10R234 83 1000 97

12R264 83 880 97

18R416 86 1180 100

Page 10 of 54

Page 11

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

2 TRANSPORT AND STORAGE

2.1 Consignment receipt and unpacking

Immediately after receipt of the equipment it must be

checked against the delivery and shipping documents

for its completeness and that there has been no

damage in transportation. Any shortage and or

damage must be reported immediately to Flowserve

and received in writing within one month of receipt of

the equipment. Later claims cannot be accepted.

Check any crates, boxes and wrappings for any

accessories or spare parts which may be packed

separately with the equipment or attached to side walls

of the box or equipment.

Each product has a unique serial number. Check that

this number corresponds with that advised and always

quote this number in correspondence as well as when

ordering spare parts or further accessories.

2.2 Handling

Boxes, crates, pallets or cartons may be unloaded

using fork lift vehicles or slings dependent on their size

and construction.

The pump should be lifted with suitably sized and

located slings. Do not use the shaft for lifting and take

special care to prevent the pump from rotating in the

slings due to unbalanced weight distribution.

2.3 Lifting

A crane must be used for all pump sets in excess

of 25 kg (55 lb). Fully trained personnel must carry out

lifting, in accordance with local regulations. The driver

and pump weights are recorded on their respective

nameplates or massplates.

Before lifting the driver alone, refer to the

manufacturer’s instructions.

2.4 Storage

2.4.1 Short-Term Storage

When it is necessary to store a pump for a short time

before it can be installed, place it in a dry, cool location.

Protect it thoroughly from moisture and condensation.

Protective flange covers should not be removed until

the pump is being installed.

Wrap the exposed portions of the shaft and coupling to

protect against sand, grit or other foreign matter. Oil

lubricated units should be lubricated (refer to Section

III) to protect the bearings. Grease lubricated units are

lubricated at the factory during assembly. Turn the

rotor over by hand at least once a week to maintain a

protective film on the bearing components.

2.4.2 Long Term Storage

More than precautions are required if long-term storage

in excess of 90 days from factory shipment is

unavoidable.

The internal surfaces of the pump should be sprayed

with a rust preventative such as a water soluble oil or

other suitable alternative. Particular attention should

be given to the impeller, wear plate and stuffing box.

An optional method of protection is to suspend bags of

desiccant material inside casing and completely seal all

openings from the surrounding atmosphere. The

stuffing box should be packed with clean. dry rags.

Use of this method requires that the casing be initially

free of liquid. The desiccant material should be

checked at regular intervals to ensure that it has not

absorbed excessive water vapour. A warning

instruction, advising that the desiccant must be

removed prior to installation should be wired to the

pump.

A rust inhibitor should be added to the lubricating oil of

oil lubricated units to give additional protection without

destroying the lubricating properties of the oil. For

specific recommendations, consult your lubrication

dealer. Grease lubricated units, which can be identified

by the grease fitting at each bearing location, should be

well lubricated prior to placing in storage. Small

amounts of additional grease should be added at

regular intervals during storage. Refer to Section III for

additional information related to grease lubrication.

Storage of pumps in areas of high ambient vibration

should be avoided to prevent bearing damage due to

brinelling. The risk of such damage can be reduced by

frequent rotation of the shaft.

The pump half coupling and key should be removed

from the shaft, coated with rust preventative and

wrapped to prevent metal-to-metal contact. Exposed

surfaces of the pump shaft should be protected with a

rust preventative. All dismantled parts should be

wrapped and tagged according to pump serial number

and a record kept of their location.

Pumps covered with plastic should

not be stored in a cool environment because

resulting condensation can cause rusting.

Page 11 of 54

Page 12

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

2.5 Recycling and end of product life

At the end of the service life of the product or its parts,

the relevant materials and parts should be recycled or

disposed of using an environmentally acceptable

method and in accordance with local regulations. If the

product contains substances that are harmful to the

environment, these should be removed and disposed of

in accordance with current local regulations. This also

includes the liquids and/or gases that may be used in

the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety specifications

must be in accordance with the current local

regulations at all times.

3 PUMP DESCRIPTION

3.1 Configurations

Flowserve "R Slurry" pumps are single stage, end

suction centrifugal pumps specifically designed for

handling abrasive slurries typical of mining and mineral

process. The casing is radially split with the gland side

casing pedestal mounted. The discharge is tangential.

The casings are fitted with removable rubber liners.

The closed impeller with rear pump-out vanes is

capable of passing solids of various sizes. Sealing is

provided at the impeller to shaft fit to prevent corrosion

and thereby facilitate impeller removal. The rigid three

point thrust bearing housing support permits precision

bearing alignment. Since the casing is pedestal

mounted, back pull-out is not a normal feature.

The pump is sealed using non-asbestos packing in the

stuffing box. An optional hydrodynamic seal,

commonly referred to as an expeller is available and

various mechanical seal designs as specified by the

customer may be installed at the factory or retrofitted in

the field.

All pumps are carefully inspected and prepared for

shipment. All exterior machined surfaces are coated

with a rust preventative compound and openings are

provided with covers or plugs. Shaft packing, when

required, is shipped with the pump and should not be

installed until the pump is ready to run. Mechanical

seals, when provided, are factory installed and adjusted

prior to shipment. The axial impeller running clearance

is preset at the factory but should be checked prior to

final alignment in case of tampering.

These User Instructions also cover the RX and RS

configurations, check the nameplate against the

nomenclature.

3.2 Name nomenclature

The pump size will be engraved on the nameplate. The

following example explains how the pump name

identifies the construction features and options.

8R-193

Nominal discharge branch size.

Configuration – see below.

Nominal maximum impeller diameter.

Frame size

R is the basic pump type

X

is added for an expeller

3.3 Design of major parts

3.3.1 Pump casing

The pump casing is a semi-concentric volute type

casing and tangential discharge nozzle and is radially

split. The casing are cast iron and are pedestal

mounted therefore the discharge can be rotated to

meet a number of optional orientations. It is fitted with

replaceable rubber liners. The casing joints are self

sealed by the rubber liners however optional urethane

lined casing may require gaskets at some flange

connections. The casing flanges are also drilled and

tapped

3.3.2 Impeller

The impeller is a closed design as standard but may be

changed to open designs for mud, froth and viscous

applications. The impeller is thread mounted to the

shaft. All impellers are supplied with pump out vanes to

minimise wear and reduce pressure at the stuffing box.

The vanes are curved to optimize efficiency however,

the “S” configuration utilizes straight radial vanes to

reduce blockage. The impeller of the RS pump has

larger front clearances to reduce shear and improve

froth handling capabilities.

3.3.3 Shaft

The large diameter stiff shaft, mounted on bearings,

has a keyed drive end. The shaft extension at the

coupling is extended to cover multi-v-belt drives.

3.3.4 Pump bearings and lubrication

Ball bearings are fitted as standard and may be either

oil or grease lubricated.

Page 12 of 54

Page 13

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

Oil lubrication is only available where the pump shaft is

horizontal. The bearings on frame 6 pumps (18R416)

can not be grease lubricated.

3.3.5 Bearing housing

For oil lubricated bearings, a bulls eye level gauge is

supplied. Constant level oilers can also be fitted. Two

grease nipples enable grease lubricated bearings to be

replenished between major service intervals.

3.3.6 Stuffing box housing

The stuffing box is a loose design and has a spigot

(rabbet) fit with the pump casing. The design enables a

number of sealing options to be fitted as well a wide

range of materials options.

3.3.7 Shaft seal

The mechanical seal(s), attached to the pump shaft,

seals the pumped liquid from the environment. Gland

packing may be fitted as an option. The “X” model is

fitted with an optional dynamic or expeller seal for

certain applications.

3.3.8 Driver

The driver is normally an electric motor. Due to the

hardness of the impeller the norm is to use multi-vbelts. Different drive configurations may be fitted such

as internal combustion engines, turbines, hydraulic

motors etc driving via couplings, belts, gearboxes, drive

shafts etc.

3.3.9 Accessories

Accessories may be fitted when specified by the

customer.

3.4 Performance and operating limits

This product has been selected to meet the

specifications of your purchase order see section 1.5.

The following data is included as additional information

to help with your installation. It is typical, and factors

such as temperature, materials, and seal type may

influence this data. If required, a definitive statement

for your particular application can be obtained from

Flowserve.

3.4.1 Operating limits

3.4.1.1 Temperature

Liner Materials

Maximum Operating

Temperature

Natural Rubber-soft 65ºC (150ºF)

Natural Rubber-Hard 80ºC (176ºF)

Nitrile 93ºC (200ºF)

Neoprene 100ºC (212ºF)

3.4.1.2 Pressure

The maximum working pressure will be 110 PSIG for all

sizes except for the 18R416 which will be 100 PSIG.

Vacuum service should be avoided due to potential of

rubber liner collapse.

3.4.2 Speed torque curves

To bring a centrifugal pump up to rated speed, the

driver must be capable of providing more torque at

each speed than required by the pump. The margin

between the available and required torque affects the

time it takes the unit to reach full speed. If the torque

required by the pump exceeds the torque capability of

the drive at any run-up speed, the unit will not

accelerate to full speed. Normally, this is not a problem

with standard induction or synchronous motors

provided the proper voltage is supplied at the motor.

For pumps started at shut valve conditions, 100 percent

full speed torque can be calculated by using the

formula:

Torque (Nm) = 9545 Shutoff Power (kW)

r/min

Torque (ft.lb) = 5250 Shutoff Power (hp)

r/min

Torque required by the pump at any other speed during

start-up can be determined from the curve above. Note

that the driver manufacturer usually bases 100 percent

torque on the design power of the driver and

consequently the speed-torque curves should be

plotted in torque units (e.g. Nm) instead of percentage

torque to avoid confusion.

Page 13 of 54

Page 14

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

3.5 Materials Of Construction

BASIC

CONSTRUCTION

Natural Rubber

Lined

Neoprene Lined Nitrile Lined

Casing – Suction and Gland Side ASTM A48 CL 35 (Cast iron)

Stuffing Box ASTM A48 CL35 (Cast iron) (2)

Suction Side liner, Gland side Liner Natural Rubber

Impeller Natural Rubber

Neoprene Nitrile

Neoprene Nitrile

Protector Plate HARD STEEL –360 BHN (2) (3)

Impeller Spacer HARD STEEL –360 BHN (2) (3)

Shaft Sleeve ASTM A743 CG3M (1)

Shaft AISI 1045

Gland Halves ASTM A743 CF8M (316)

Pipe Plugs (Stuffing Box) C.I. (2)

Gland Studs And Nuts AISI 316

Liner Studs & Nuts AISI 1018/1020 Steel

PACKING SYNTHETIC FIBRE

SEAL CAGE HALVES ASTM A743 CG8M

GASKETS-CASING SYNTHETIC FIBRE

GASKETS-SLEEVE TEFLON

O-RINGS BUNA-N (120o C MAX.)

MISC. FASTNERS,

PARTS

STEEL

(1) Nickel-Chrome-Boron Coated, except for units with mechanical seals.

(2) For acid kit construction 316 SS (standard) or Alloy C (optional) materials will be supplied.

(3) For severe abrasive applications Stellite 4 is available.

Page 14 of 54

Page 15

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

3.6 Tables of Engineering Data

Table of Engineering Data

3.6.1 (FRAMES 0, 1 & 2 - LIQUID END)

ENGINEERING DATA

PUMP DESIGN TYPE STD STD STD STD STD STD STD STD

SUCTION SIZE mm (in.) 38 (1.5) 64 (2.5) 76 (3) 64 (2.5) 76 (3) 102 (4) 127 (5) 152 (6)

DISCHARGE SIZE mm (in.) 32 (1.25) 64 (2.5) 76 (3) 64 (2.5) 76 (3) 76 (3) 102 (4) 127 (5)

MAX. SPHERE SIZE mm (in.) 10(0.38) 15 (0.6) 23 (0.9) 15 (0.6) 23 (0.9) 31 (1.2) 43 (1.7) 48 (1.9)

VVK²(wet) kg · m² (lb · ft²) 0.12 (2.8) 0.12 (2.8) 0.11 (2.6) 0.12 (2.8) 0.11 (2.6) 0.21 (4.9) 0.44 (11) 0.82 (19)

1 1/4R-090 2 1/2R-393 3R-090 2 1/2R-091 3R-091 3R-111 4R-122 5R-142

PUMP WEIGHT kg (Ibs)

IMPELLER CLEARANCE mm (in.)

O.D. SLEEVE mm (in.)

La STUFFING BOX mm (in.)

DEPTH OF BOX mm (in.)

PACKING SIZE mm (in.)

RECOMMENDED PACKING

ALTERNATIVE PACKING

195 (430) 218 (480) 241 (530) 241 (530) 264 (580) 286 (630) 391 (860) 486 (1 070)

0.38 (0.015)

50.8 (2.0) 76.2 (3.0)

69.85 (2.75) 101.6 (4.0)

71.4 (2.81) 93.5 (3.68)

9.5 (0.375) 12.7 (0.5)

L5 L5

2L3 2L3

0.38 (0.015)

50.8 (2.0)

69.85 (2.75)

71.4 (2.81)

9.5 (0.375)

L5

2L3

0.76 (0.030)

Page 15 of 56 flowserve.com

Page 16

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

Table of Engineering Data

3.6.2 (FRAMES 0, 1 & 2 - FRAME DETAILS)

ENGINEERING DATA

SHAFT AND BEARING DATA

DIA. AT IMP ELL ER

DIA. UNDER SLEEVE

DIA. BETWEEN BEARINGS

DIA. AT COUPLING

LINE BEARING

THRUST BEARING

BEARING SPAN

NOM. IMPELLER

OVERHANG

L10 BEARING LIFE

BEARING SEALS

THRUST BEARING LIP SEAL

LINE BEARING LIP SEAL

1¼ R-090 2½ R-090 3 R-090 3 R-091 3 R-111

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

22.4

(0.88)

25.4

(1.00)

47.8

(1.88)

25.4

(1.00)

2½ R-091

28.58

(1.125)

41.27

(1.625)

63.5

(2.50)

41.27

(1.625)

6307 6311

3307 7309 BUA

mm

(in.)

mm

(in.)

168

(6.61)

(7.09)

193.8

(7.63)

207.8

(8.18)

MINIMUM 3 YEARS

C/R 12458

C/R 9998

C/R 16246

NAT. 473010

C / R 19832

NAT. 472492

4 R-122 5 R-142

34.93

(1.375)

66.68

(2.625)

91.9

(3.62)

63.5

(2.500)

6316

7314 BUA

279.4

(11.00)

204.7180

(8.06)

C/R 24982

NAT. 417449

NAT. 417350

THRUST BEARING O-RING

#240 #250

LINE BEARING O-RING N/A #246

#263

#259

Page 16 of 56 flowserve.com

Page 17

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

3.6.3 (FRAME 3, 4 & 6 - LIQUID END)

Table of Engineering Data

ENGINEERING DATA

SUCTION SIZE

DISCHARGE SIZE

MAX.SPHERE SIZE

WK2 (wet)

PUMP WT.

IMPELLER CLEARANCE

O.D.SLEEVE

I.D.STUFFING BOX

STUFFNG BOX DEPTH

PACKING SIZE

RINGS OF PACKING 5 5 6

kgm

6 R-163 8 R-193

mm 203 254 305 356 508

(in.) (8) (10) (12) (14) (20)

mm 152 203 254 305 457

(in.) (6) (8) (10) (12) (18)

mm 53 71 91 81 50.8

(in.) (2.10) (2.80) (3.60) (3.20) (2.00)

2

1.81 3.62 8.83 12.6 86.79

lbft2

(lbs) (1830) (2220) (3480) (4620) (16000)

mm 1.14 1.5 1.8

(in.) (0.045) (0.06) (0.07)

mm 95.25 120.7 184.1

(in.) (3.75) (4.75) (7.250)

mm 127 152.4 222.3

(in.) (5.00) (6.00) (8.75)

mm 116.3 116.3 165

(in.) (4.58) (4.58) (6.5)

mm 15.9 x 15.9 15.9 x 15.9 19.1 x 19.1

(in.) (0.63 x 0.63) (0.63 x 0.63) (.75 x .75)

(43) (86) (209) (298) (2056)

kg 832 1009 1582 2100 7273

10 R-

234

12 R-

264

18 R-416

RECOMMENDED PACKING L5 L5 L6

ALTERNATIVE PACKING 2L3 2L3 2L4

Page 17 of 56 flowserve.com

Page 18

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

Table of Engineering Data

3.6.4 (FRAMES 3, 4 & 6- FRAME DETAILS)

ENGINEERING DATA

SHAFT AND BEARING DATA

DIA. AT IMPELLER

DIA. UNDER SLEEVE

DIA. BETWEEN BEARINGS

DIA. AT COUPLING

LINE BEARING

THRUST BEARING

BEARING SPAN

NOM. IMPELLER mm

OVERHANG (in.)

L10 BEARING LIFE

BEARING SEALS

THRUST BEARING LIP SEAL

LINE BEARING LIP SEAL

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

mm

(in.)

6 R-163 8 R-193 10 R-234

50.8

(2.00)

(3.88)

82.55 108

(3.25)

91.9

(3.62)

85.72

(3.3 75)

21320

7318 BUA

(4.25)

146.1 184.2

(5.75)

104.78

(4.125)

22226C

QJ322/NU322

279.4

(11.00)

(20.20)

245.4

(9.66)

(13.96)

MINIMUM 3 YEARS

NAT. 417191

C/R 37389

NAT. 417379

NAT. 417511

C/R 42419

NAT. 4 165 56

98.6

513

355

12 R-264

18 R-416

139.7

(5.50)

160

(6.30)

(7.25)

146.05

(5.75)

24034HL

29334 E

23134HL

874

(34.41)

699

(27.50)

C/R 57510

GARL. 53x3275

C/R 63700

GARL. 53x3409

THRUST BEARING O-RING

LINE BEARING O-RING

#276 #269

#267 #269

N/A

N/A

Page 18 of 56 flowserve.com

Page 19

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4, Products used in

potentially explosive atmospheres.

Pump discharge is to stay within the top

vertical or top horizontal discharge position to prevent

the build up of trapped gas. See section, 8.6 General

Arrangement of Pump Discharge Orientation.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Allow sufficient room to facilitate the back pull-out

feature on V-belt driven units.

Refer to the general arrangement drawing for the

pump set.

4.2 Part assemblies

Motors may be supplied loose on M Slurry pumps,

typically on frame sizes 400 and above. It is the

responsibility of the installer to ensure that the motor

is assembled to the pump and lined up as detailed in

section 4.5.2.

4.3 Foundation

The foundation may consist of any

material that will afford permanent, rigid support to the

full area of the pump or driver supporting member. It

should be of sufficient size and mass to absorb

expected strains and shocks that may be encountered

in service. Concrete foundations built on solid ground

are desirable.

The purpose of foundation bolts is to anchor the pump

unit securely to the foundation such that the foundation

and pump assembly become a single structural unit.

High strength steel foundation bolts (SAE Gr. 5 or

equal) of the specified diameter should be located

according to the elevation drawing provided. Each bolt

should be surrounded by a pipe sleeve that is two or

three times the diameter of the bolt. The sleeves should

be securely anchored and designed to allow the bolts to

be moved to conform with the holes in the baseplate.

The bolts should be sufficiently long to allow for wedges

or shims or levelling nuts under the baseplate, and a

washer, heavy hex nut and hex jam nut for retention.

Since baseplate levelling is performed after the

foundation has cured, it is best to use extra long bolts

that can be shortened after the installation is complete.

4.4 Baseplate installation

Position the baseplate and pump next to the foundation

and clean the foundation surface thoroughly. Remove

the rag packing from the pipe sleeves and place

wedges or ships as close to the foundation bolts as

possible. These may be omitted if a jacking nut on the

foundation anchor bolts is preferred for levelling. Initial

levelling should be within 0.75 mm (.030 inches).

Remove the flange covers and check inside the pump

nozzles for cleanliness. Kerosene is recommended as

the best solvent for removing factory applied rust

preventative. Ensure that all traces of rust preventative

are removed from the discharge and suction flange

faces, the exposed shafting and all coupling surfaces.

Flush the pump internals of any rust preventative

applied for long-term storage.

Lift the baseplate assembly, remove the shipping skids

and clean the underside of the baseplate. Position the

baseplate over the foundation and lower the unit over

the foundation bolts and onto the wedges, shims or

jacking nuts.

With the aid of a machinist's level, adjust the wedges,

shims or jacking nuts to level the pump and driver

mounting pads in each direction. Check to ensure that

the suction and discharge flanges are plumb, level, and

at the correct elevation. It is normal practice to set the

mounting pads slightly low in order to permit lowering of

units which may be required to suit future piping or

minor changes. Place washers over the foundation

bolts and install nuts. Tighten finger tight only.

Check the impeller axial clearance and that the rotor

turns freely by hand.

Note: Grout is not poured until an initial alignment

of the pump and driver has been performed.

Page 19 of 56 flowserve.com

Page 20

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

4.5 Initial alignment

4.5.1 Thermal expansion

The pump and motor will normally

have to be aligned at ambient temperature and

should be corrected to allow for thermal expansion at

operating temperature. In pump installations

involving high liquid temperatures, the unit should be

run at the actual operating temperature, shut down

and the alignment checked immediately.

4.5.2 Direct Driven Limits

Ensure pump and driver are isolated

electrically and the half couplings are disconnected.

The alignment MUST be checked.

Although the pump will have been aligned at the

factory it is most likely that this alignment will have

been disturbed during transportation or handling. If

necessary, align the motor to the pump, not the pump

to the motor.

4.5.3 Alignment Methods:

The importance of accurate alignment of pump and

driver shafts cannot be overemphasized.

IMPROPER ALIGNMENT IS THE PRIMARY CAUSE

OF VIBRATION PROBLEMS AND REDUCED

BEARING LIFE.

A flexible coupling is used to compensate for slight

changes in alignment that occur during normal

operation and is not used to correct for installation

errors. Install the pump and driver half couplings in

accordance with the coupling manufacturer's

instructions. Note that the coupling hub faces are not

always mounted flush with the ends of the shafts.

Place the driver on the baseplate such that the

correct spacing is obtained between the two half

couplings. In the case of electric motors, such as

those with sleeve bearings, it may be necessary to

run the motor to establish the rotor magnetic center.

Consult

details.

The purpose of the alignment procedure is to ensure

that the pump and driver shafts are in parallel and

angular alignment under the normal operating

conditions of load and temperature

When the pump coupling and driver are assembled

at the factory, the units are aligned prior to shipment.

However, baseplates can be sprung or distorted

during shipment or installation and the alignment

the manufacturer's instruction manual for

.

must be checked before the unit is put in service.

The coupling spacer must be removed to make this

check.

For pumps and drivers that operate at different

temperatures compensation must be made at the

initial alignment stage (when the units are at the

same temperature) to allow for thermal expansion

during operation. Consult the instruction manual

supplied with the driver for the manufacturer's

recommendations.

Shaft alignment is greatly simplified by the use of a

dial indicator with extension rods and a magnetic

base. Before taking readings, ensure that the pump

and driver mounting bolts are secure, and that the

thrust bearing housing is properly aligned in the

bearing frame or cartridge.

4.5.3.1 Parallel Alignment:

Checking parallel misalignment

Mount the magnetic base on the pump half coupling

hub, either the face or O.D. as shown in the sketch.

Place the dial indicator button on the outside diameter

of the driver half coupling hub.

Page 20 of 56 flowserve.com

Page 21

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

The length of extension rods should be kept at

a minimum to reduce deflection.

Rotate the pump shaft and record the dial reading at the

top, bottom and each side. Correct the parallel

alignment by adding or removing shims under the driver

and/or moving the driver horizontally. Repeat this

procedure until the maximum total indicator reading

(T.I.R.) is within 0.076 mm (0.003 inch.)

4.5.3.2 Angular Alignment:

Mount the magnetic base on the pump half coupling

hub, either the face or O.D. as shown in the sketch.

Move the dial indicator button to indicate on the face of

the driver half coupling hub as close to the outside

diameter as possible. When convenient the indicator

can be placed on the inside face to keep spans short.

Turn both shafts 360 and record the dial readings at

90 intervals. Adjust the shims under the motor as

required and repeat the procedure until the angular

alignment is within 0.0005 mm (T.I.R.) per mm (0.0005

inch per inch) of maximum hub diameter.

When the electric motor has sleeve bearings it is

necessary to ensure that the motor is aligned to run

on its magnetic centreline. A button (screwed into

one of the shaft ends) is normally fitted between the

motor and pump shaft ends to fix the axial position.

If the motor does not run in its

magnetic centre the resultant additional axial force

may overload the pump thrust bearing.

Complete piping as below and see sections

4.7, Final shaft alignment check up to and including

section 5, Commissioning, startup, operation and

shutdown before connecting driver and checking

actual rotation.

4.5.4 V-Belt Drive Units:

Check that both sheaves are free of grease, rust, nicks

or burrs. Install the correct size sheave on the pump

shaft and locate the sheave axially to minimize

overhang. Re-check the impeller axial clearance and

ensure that the pump is properly secured to the

baseplate. Install the driver on the adjustable base

provided and install the driver sheave in line with the

pump sheave. Ensure that the sheaves are tight on the

shafts. With a dial indicator, check the runout on the

periphery and face of each sheave to ensure that each

is running true. Tighten the adjustable base and check

that the driver rotation in the correct direction and that

vibration levels are not unacceptable.

Checking angular misalignment

Repeat the checks on parallel and angular alignment,

ensuring the mounting bolts are secure, until the unit is

properly aligned. Note that correction in one direction

may affect the alignment in another direction. Re-check

the gap between the coupling hubs.

If any difficulty is encountered in achieving the

recommended alignment tolerances, the runout of the

pump and driver shafts and each coupling hub diameter

and face should be checked. Occasionally, due to

practical and unavoidable manufacturing tolerance

build-up associate with the pump, coupling and driver, it

may be necessary to match up the two coupling hubs in

the most advantageous relative angular position in order

to achieve an acceptable alignment.

Do not install the coupling spacer or sleeve until

grouting is complete and cured and the alignment is rechecked.

Checking V-Belt Sheave Alignment

Before starting the driver, refer to the

manufacturer’s instruction manual. The correct rotation

of the pump shaft is marked on the pump casing or

frame.

Page 21 of 56 flowserve.com

Page 22

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

Check that all belts making up one drive set have

matched code numbers. Loosen the adjustable base

and install the belts in their proper grooves. Adjust the

center distance between the sheaves to obtain proper

belt tension. Check the alignment of the pump and

driver sheaves with a taught string or straight edge. For

proper alignment and the sheave faces must be parallel

to each other and in line. Adjustments are made by

slackening the belts and moving the sheaves. Retighten

the drive or driver sheave then recheck. The procedure

may need to be repeated to get alignment as close as

possible..

When the sheaves are aligned that the shafts rotate

freely by hand and install safety guard.

4.6 Grouting

The purpose of grouting is to provide rigid support to the

pump and driver by increasing the structural rigidity of

the baseplate and making it an integral mass with the

foundation.

Clean the roughed foundation surface and build a

wooden form around the baseplate (see Fig. 1). For

initial grouting forms should be placed to isolate shims

and levelling nuts. The foundation surface should be

thoroughly saturated with water before grouting. A

typical mixture for grouting-in a pump base is composed

of one part pure Portland cement and two parts of clean

building sand with sufficient water to provide the proper

consistency. The grout should flow freely but not be so

wet as to cause the sand and cement to separate.

Thoroughly puddle the grout while pouring to eliminate

air pockets and low spots. Pour sufficient grouting to

ensure that the bottom surface of the baseplate is

completely submerged. Do not fill isolated areas

around the shims or levelling nuts. Once the grout has

set sufficiently, remove the wooden forms and finish off

the sides and top as desired. At the same time,

roughen the grout surface inside the baseplate. Cover

with wet burlap and allow the grout to cure for at least

40 hours.

After grouting has cured, shims and levelling nuts

should be removed or backed off. Tighten down

baseplate to the new grout to put bolts in tension and

ensure rigidity of structure. Install jam nuts and cut the

bolts to the desired length. Finish grouting isolated

areas. Fill the baseplate including pump and driver

support pedestals with concrete. Trowel and slope the

surface to give suitable drainage.

4.7 Piping

Protective covers are fitted to the pipe

connections to prevent foreign bodies entering during

transportation and installation. Ensure that these

covers are removed from the pump before

connecting any pipes.

4.7.1 Suction and discharge pipework

In order to minimize friction losses and hydraulic

noise in the pipework it is good practice to choose

pipework that is one or two sizes larger than the

pump suction and discharge. Typically main

pipework velocities should not exceed 2 m/s (6 ft/sec)

suction and 3 m/s (9 ft/sec) on the discharge.

Take into account the available NPSH which must be

higher than the required NPSH of the pump.

Never use the pump as a support for

piping.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. To

minimize these forces and moments that may, if

excessive, cause misalignment, hot bearings, worn

couplings, vibration and the possible failure of the

pump casing, the following points should be strictly

followed:

Prevent excessive external pipe load

Never draw piping into place by applying force to

pump flange connections

Do not mount expansion joints so that their force,

due to internal pressure, acts on the pump flange

The table in 4.7.2 summarizes the maximum forces

and moments allowed on M pump casings. Refer to

Flowserve for other configurations.

Ensure piping and fittings are flushed

before use.

Ensure piping for hazardous liquids is arranged

to allow pump flushing before removal of the pump.

4.7.1.1 Flange Facing

R Pumps are designed so that the connecting pipes

at the suction and discharge can be attached without

gaskets. To ensure correct sealing and rubber pinch,

standard flat face weld neck flanges must be used.

Any arrangements other than that shown will affect

pump internal clearances, cause leakage at the

flanges or result in serious damage to the rubber

parts.

Page 22 of 56 flowserve.com

Page 23

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

4.7.1.4 Spool Installation

Do not use raised face flanges

WELD NECK

-NO RAISED FACE

WELD NECK

-RAISED FACE

The sketch below illustrates that a short spool is

recommended to connect to the flange. The spool

should be moved perpendicular to the flange so that

the rubber sealing lip is not dislodged. If the spool is

slid into the flange from the side the sealing lip may

be pushed out of the recess and/or the rubber nozzle

distorted making it impossible to obtain a seal.

Flat faced flange

EQUIVALENT TO

WELD NECK FLANGE

RECOMMENDED DO NOT USE

SLIP-ON FLANGE

4.7.1.2 Flange Size

It is necessary that the I.D. of the pipe flange match

the I.D. of the properly seated liner nozzle. The

suction flange face must be to the nominal flange

size, ie for a 12” flange the flange ID should be 12”.

This can be a particular problem where thinner

walled piping is used which has larger inside

diameters. Weld neck flanges that match the thinner

pipes will reduce clamping area at pump flange and

could lead to a collapse of the suction nozzle in the

pump.

Flange I.D. to be nominal size.

Liner

Liner support plate

Short Spool Piece

Movement

The spool piece when bolted to the casing will fully

compress the rubber sealing lip into the recess, this

will provide a positive metal to metal fit. When the

spool is used with a properly designed flange the

Metal to Metal Fit

Bolt

Casing

Rubber seal lip extension

Check for uniformity

Recess

compression of the rubber is controlled. The flange

bolts are designed for a maximum engagement of

4.7.1.3 Flange Design

Depicted in the sketch above is the suction of the

pump but information applies to the discharge as

well. The rubber seal lip, which protrudes beyond the

flange face of the metal casing must be completely

compressed at assembly to ensure a seal and retain

1.5X the bolt size. Use of longer bolts in the suction

could distort and damage the liner. Bolts that are too

long in the discharge may bottom out in the blind

flange. Before the bolts are tightened ensure that the

I.D. of the spool is even and uniform with the rubber

bore. Figure 8C shows the alignment and illustrates

the suction flange bolting.

the liner nozzle. At assembly and prior to installing

piping ensure that the lip is properly seated in the

recess of the casing.

Page 23 of 56 flowserve.com

Page 24

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

Once the spool is installed additional suction piping

may be installed. These flange joints will require

gaskets. Figure 8D illustrates the assembly of other

piping, flange facings at other joints then the pump

may be raised of flat.

Suction Piping

Spool piece

Page 24 of 56 flowserve.com

Page 25

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

4.7.2 Maximum forces and moments allowed on M Slurry pump flanges

Flange Size

DN

(in.)

≤50

≤(2)

65

(2-1/2)

80

(3)

100

(4)

125

(5)

150

(6)

200

(8)

250

(10)

300

(12)

350

(14)

400

(16)

450

(18)

500

(20)

550

(24)

Mx My Mz Fx Fy Fz Mx My Mz Fx Fy Fz

460

(340)

710

(520)

950

(700)

1330

(980)

1830

(1340)

2300

(1700)

3530

(2600)

5020

(3700)

6100

(4500)

6370

(4700)

7320

(5400)

8200

(6050)

9080

(6700)

10850

(8000)

230

(170)

350

(260)

470

(350)

680

(500)

940

(690)

1180

(870)

1760

(1300)

2440

(1800)

2980

(2200)

3120

(2300)

3660

(2700)

4200

(3100)

4750

(3500)

5830

(4300)

Maximum forces (F) in N (lbf) and moments (M) in Nm (lbf•ft)

Suction Discharge

350

(260)

540

(400)

720

(530)

1000

(740)

1450

(1070)

1760

(1300)

2580

(1900)

3800

(2800)

4610

(3400)

4750

(3500)

5420

(4000)

6100

(4500)

6780

(5000)

8130

(6000)

890

(200)

1110

(250)

1330

(300)

1780

(400)

2450

(550)

3110

(700)

4890

(1100)

6670

(1500)

8000

(1800)

8900

(2000)

10230

(2300)

11570

(2600)

12900

(2900)

15480

(3480)

Notes:

1) F = External force (tension or compression) M = External

moment, clockwise or counter-clockwise

2) Forces and moments may be applied simultaneously in any

direction

3) Values apply to all materials

4) Higher loads may be applicable, if direction and magnitude of

individual loads are known, but these need written approval from

Flowserve

5) Pumps must be on rigid foundations and baseplates must be

fully grouted

710

(160)

890

(200)

1070

(240)

1420

(320)

1960

(440)

2490

(560)

3780

(850)

5340

(1200)

6670

(1500)

7120

(1600)

8450

(1900)

9650

(2170)

10720

(2410)

13120

(2950)

5808

(130)

760

(170)

890

(200)

1160

(260)

1600

(360)

2050

(460)

3110

(700)

4450

(1000)

5340

(1200)

5780

(1300)

6670

(1500)

7560

(1700)

8450

(1900)

10230

(2300)

460

(340)

710

(520)

950

(700)

1330

(980)

1830

(1340)

2300

(1700)

3530

(2600)

5020

(3700)

6100

(4500)

6370

(4700)

7320

(5400)

8200

(6050)

9080

(6700)

10850

(8000)

230

(170)

350

(260)

470

(350)

680

(500)

940

(690)

1180

(870)

1760

(1300)

2440

(1800)

2980

(2200)

3120

(2300)

3660

(2700)

4200

(3100)

4750

(3500)

5830

(4300)

350

(260)

540

(400)

720

(530)

1000

(740)

1450

(1070)

1780

(1300)

2580

(1900)

3800

(2800)

4610

(3400)

4750

(3500)

5420

(4000)

6100

(4500)

6780

(5000)

8130

(6000)

710

(160)

890

(200)

1070

(240)

1420

(320)

1960

(440)

2490

(560)

3780

(850)

5340

(1200)

6670

(1500)

7120

(1600)

8450

(1900)

9610

(2160)

10760

(2420)

13080

(2940)

580

(130)

760

(170)

890

(200)

1160

(260)

1600

(360)

2050

(460)

3110

(700)

4450

(1000)

5340

(1200)

5780

(1300)

6670

(1500)

7560

(1700)

8450

(1900)

10230

(2300)

(1100)

(1500)

(1800)

(2000)

10230

(2300)

11570

(2600)

12900

(2900)

15660

(3520)

6) Pump/baseplate should not used as pipe anchor. Expansion

joints must be properly tied

7) The pump mounting bolt torques specified must be used to

prevent relative movement between the pump casing and

baseplate. (See section 6.6, Fastener torques.) The bolt

material must have a minimum yield strength of 600 N/mm

(87 000 lb/in.

2

)

890

(200)

1110

(250)

1330

(300)

1780

(400)

2450

(550)

3110

(700)

4890

6670

8000

8900

2

Page 25 of 56 flowserve.com

Page 26

®

R and RX SLURRY Pump USER INSTRUCTIONS ENGLISH 71569242 03-11 (E)

4.7.3 Suction piping

a) The inlet pipe should be one or two sizes larger

than the pump inlet bore and pipe bends should

be as large a radius as possible.

b) Pipework reducers should have a maximum

total angle of divergence of 15 degrees.

c) On suction lift the piping should be inclined up